Nonlinear Dyn (2009) 55: 385–393

DOI 10.1007/s11071-008-9371-1

O R I G I N A L PA P E R

Neural networks based self-learning PID control

of electronic throttle

Xiaofang Yuan · Yaonan Wang

Received: 13 April 2008 / Accepted: 9 May 2008 / Published online: 3 June 2008

© Springer Science+Business Media B.V. 2008

Abstract An electronic throttle is a low-power DC

servo drive which positions the throttle plate. Its ap-

plication in modern automotive engines leads to im-

provements in vehicle drivability, fuel economy, and

emissions. In this paper, a neural networks based self-

learning proportional-integral-derivative (PID) con-

troller is presented for electronic throttle. In the pro-

posed self-learning PID controller, the controller pa-

rameters, KP , KI , and KD are treated as neural net-

works weights and they are adjusted using a neural

networks algorithm. The self-learning algorithm is op-

erated iteratively and is developed using the Lyapunov

method. Hence, the convergence of the learning algo-

rithm is guaranteed. The neural networks based self-

learning PID controller for electronic throttle is veri-

fied by computer simulations.

Keywords Nonlinear systems · Nonlinear control ·

Electronic throttle · PID control · Neural networks ·

Self-learning

1 Introduction

Today’s automobile effectively encompasses the spirit

of mechatronic systems with its abundant applica-

X. Yuan () · Y. Wang

College of Electrical and Information Engineering, Hunan

University, Changsha 410082, China

e-mail: yuanxiaofang126@126.com

tion of electronics, sensors, actuators, and micro-

processor-based control systems to provide improved

performance,

fuel economy, emission levels, and

safety. Electronic throttle is a DC motor driven valve

that regulates air inflow into the engine’s combus-

tion system [1]. Electronic throttle can successfully

replace its mechanical counterpart if a control loop

satisfies prescribed requirements: a fast transient re-

sponse without overshoot, positioning within the mea-

surement resolution, and the control action that does

not wear out the components. Vehicles equipped with

electronic throttle control (ETC) systems are gain-

ing popularity in the automotive industry for several

reasons including improved fuel economy, vehicle

drivability, and emissions. As adaptive-cruise-control

and direct-fuel-injection systems become popular, the

market of ETC has become larger [2]. The ETC system

positions the throttle valve according to the reference

opening angle provided by the engine control unit. To-

day’s engine control unit use lookup tables with sev-

eral thousand entries to find the fuel and air combina-

tion which maximizes fuel efficiency and minimizes

emissions while respecting drivers intentions. Hence,

accurate and fast following of the reference opening

angle by the electronic throttle has direct economical

and ecological impacts.

The synthesis of a satisfactory ETC system is diffi-

cult since the plant is burdened with strong nonlinear

effects of friction and limp-home nonlinearity. More-

over, the control strategy should be simple enough

�

386

to be implemented on a typical low-cost automotive

micro-controller system, while it has to be robust for a

range of plant parameters variations. Additionally, the

control strategy should respect physical limitations of

the throttle control input and safety constraints on the

plant variables prescribed by the manufacturer.

Considering everything mentioned before, it is not

a surprise that this challenging control problem has at-

tracted significant attention of the research community

in the last decade [3–9]. There are several ETC con-

trol strategies that differ in the underlying philosophy,

complexity, and the number of sensor signals needed

to determine the desired throttle opening. Several of

the existing control strategies use a linear model of

the plant and derive a proportional-integral-derivative

(PID) controller with feedback compensator [3]. Vari-

able structure control with sliding mode is an effec-

tive method for the control of nonlinear plant with pa-

rameter uncertainty, and it has also been applied in

the ETC system in [4, 5], and [6]. In [4], a discrete-

time sliding mode controller and observer are designed

to realize ETC system by replacing signum functions

with continuous approximations. A sliding model con-

troller coupled with a genetic algorithm (GA) based

variable structure system observer fulfills the demand

for high robustness in nonlinear opening of the throt-

tle in [5]. In [6], a neural networks based sliding mode

controller is described since neural networks has good

learning ability and nonlinear approximation capabil-

ity. In [7], variable structure control technique based

robust control is presented. A time-optimal model pre-

dictive control is proposed in [8] based on the discrete-

time piecewise affine model of the throttle. In [9], re-

current neuro-controller is trained for real time appli-

cation in the electronic throttle and hybrid electric ve-

hicle control.

It is well known that proportional-integral-deriva-

tive (PID) controllers have dominated industrial con-

trol applications for a half of century, although there

has been considerable research interest in the imple-

mentation of advanced controllers. This is due to the

fact that the PID control has a simple structure that

is easily understood by field engineers and is robust

against disturbance and system uncertainty. As most

of the industrial plants demonstrate nonlinearity in the

system dynamics in a wide operating range, different

PID control strategies have been investigated in the

past years.

In this paper, a neural networks based self-learning

PID controller is proposed for the ETC system. The

X. Yuan, Y. Wang

proposed self-learning PID controller is also accept-

able in engineering practice as it can meet the follow-

ing requirements: (1) Fulfill the demand of total non-

linear characteristic in throttle, i.e., stick-slip friction,

nonlinear spring, and gear backlash. (2) Simplicity of

the control strategy is required, so that it can be imple-

mented on a low-cost automotive micro-controller sys-

tem. (3) Robustness of the control system with respect

to variations of plant parameters is required, which can

be caused by production deviations, variations of ex-

ternal conditions. (4) Settling time of the position con-

trol system step response should be less than 0.15 sec-

onds for any operating point and for any reference step

change.

This paper is organized as follows. In Sect. 2, the

nonlinear dynamics of electronic throttle is derived.

In Sect. 3, a self-learning PID controller is presented

and it is implemented using neural networks approach.

At last, several simulations illustrate the performance

of the proposed self-learning PID controller for elec-

tronic throttle.

2 Model of electronic throttle

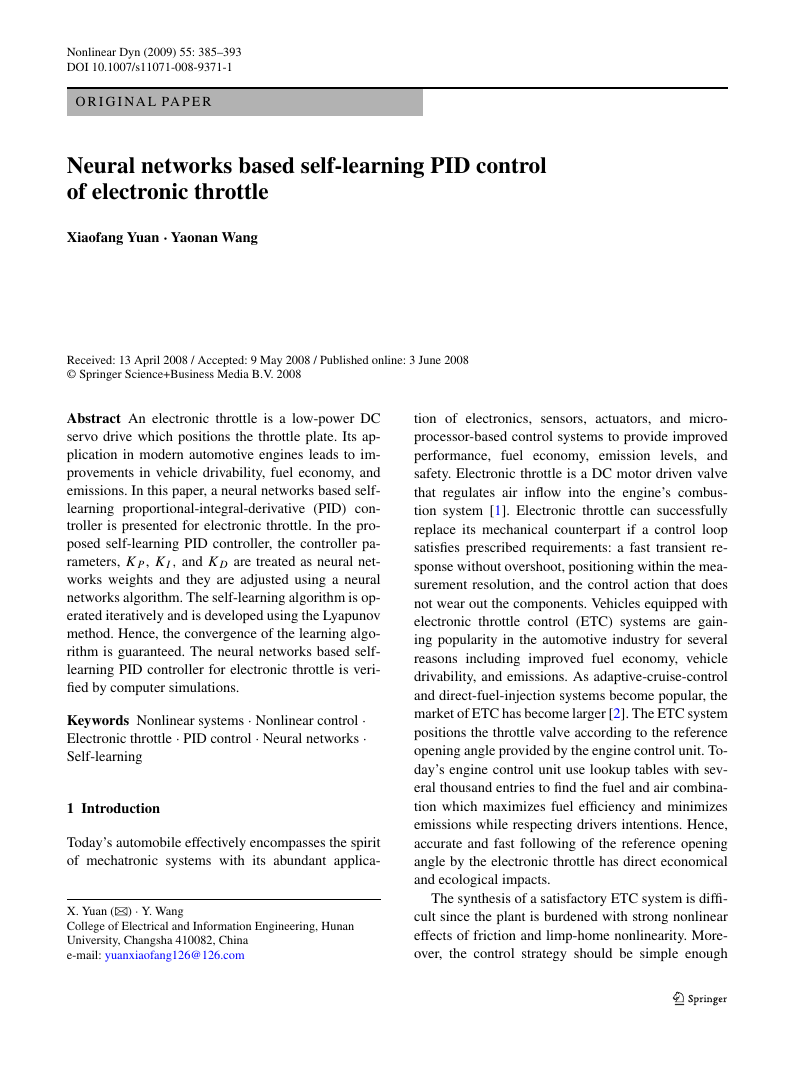

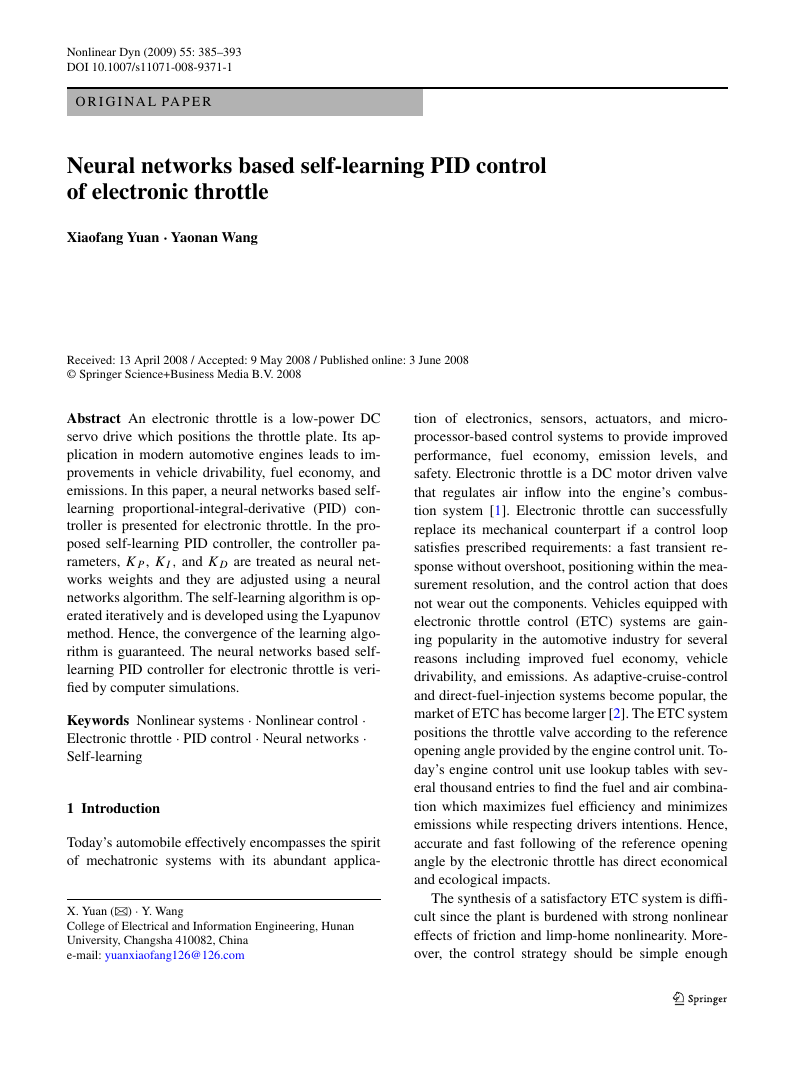

The electronic throttle consists of a DC drive (powered

by the chopper), a gearbox, a valve plate, a dual return

spring, and a position sensor. All throttle components

are assembled in a compact electronic throttle body as

in Fig. 1, which is mounted on the engine air tube. The

control signal is fed to the bipolar chopper, which sup-

plies the DC drive with the appropriate armature volt-

age. The armature current created induces the motor

torque that is transmitted through the gearbox to the

throttle plate. The valve plate movement stops when

the motor torque is counterbalanced by the torque of

the dual return spring, the gearbox friction torque, and

the load torque induced by the air inflow.

The complete electronic throttle plant can be given

by [10]:

˙θ = ω

˙w = − Ks

+ KT

J

J

VBat

Ra + RBat

J

θ − Cs

− K

d

J

ω − Kf

J

sgn(ω)

u

(1)

where θ is the throttle angle; ω is the throttle angular

velocity; J is lumped inertia of throttle plate, reduc-

tion gears and motor rotor; Ks is spring constant; Cs is

torque constant (spring torque at θ = 0); K

d is equiv-

�

Neural networks based self-learning PID control of electronic throttle

387

Fig. 1 The structure of an

electronic throttle

alent viscous friction constant, while Kf is Coulomb

friction constant; KT is motor torque constant; VBat is

no-load voltage; sgn(·) is the signum function; Ra is

armature resistance; RBat is internal resistance of the

source; u is the control signal. In the electronic throt-

tle control system, the throttle angle θ is the control

objective, and u is the control input then:

θ − Cs

− K

d

J

˙θ − Kf

J

sgn(˙θ )

¨θ = − Ks

+ KT

J

J

VBat

Ra + RBat

u

J

we also can present the plant as:

¨θ = f (θ, ˙θ ) + bu + d(t )

y = θ

(2)

(3)

where f is a unknown function, b is a unknown pa-

rameter, but it is assumed to be a constant, d(t ) is

the unknown external disturbance, u ∈ R and y ∈ R

are the input and output of the plant, respectively,

θ = (θ, ˙θ )T ∈ Rn is the state vector of the plant, which

is assumed to be measurable. And it is assumed that

d(t ) have upper bound D, that is, |d(t )| ≤ D.

3 Self-learning PID controller design

3.1 PID control

In control engineering, PID control technique has been

considered as a matured technique in comparing with

other control techniques. In a typical discrete-time PID

controller, its control law can be expressed in the fol-

lowing forms [11, 12]:

u(k) = KP (k)e(k) + KI (k)

ei (k) + KD(k)e(k)

(4)

i

∗

where KP (k), KI (k) and KD(k) are proportional, in-

tegral, and derivative gains, respectively; u(k) is an

overall control force at time k which is a summation

of three components; e(k) is the tracking error defined

as: e(k) = y

(k)− y(k), and e(k) = e(k)− e(k − 1);

∗

(k) is the desired plant output, y(k) is the actual

y

plant output at time k. We also can present the PID

control in the increment forming as:

u(k) = u(k − 1) + u(k)

u(k) = 3

Ki (k) · ei (k)

i=1

(k) − y(k), e2(k) = e1(k) − e1(k −

where e1(k) = y

1), e3(k) = e1(k) − 2e1(k − 1) + e1(k − 2); Ki

(i = 1, 2, 3) are the three parameters for PID control,

if we can select the optimal values of Ki (i = 1, 2, 3),

the PID controller will have good performance. How-

ever, these parameters are not easy to select since the

practical plant is generally nonlinear. In this paper, we

will propose an intelligent PID controller as the para-

meters of PID controller used here can adjust its pa-

rameters in an intelligent way, which is implemented

using neural networks.

(5)

∗

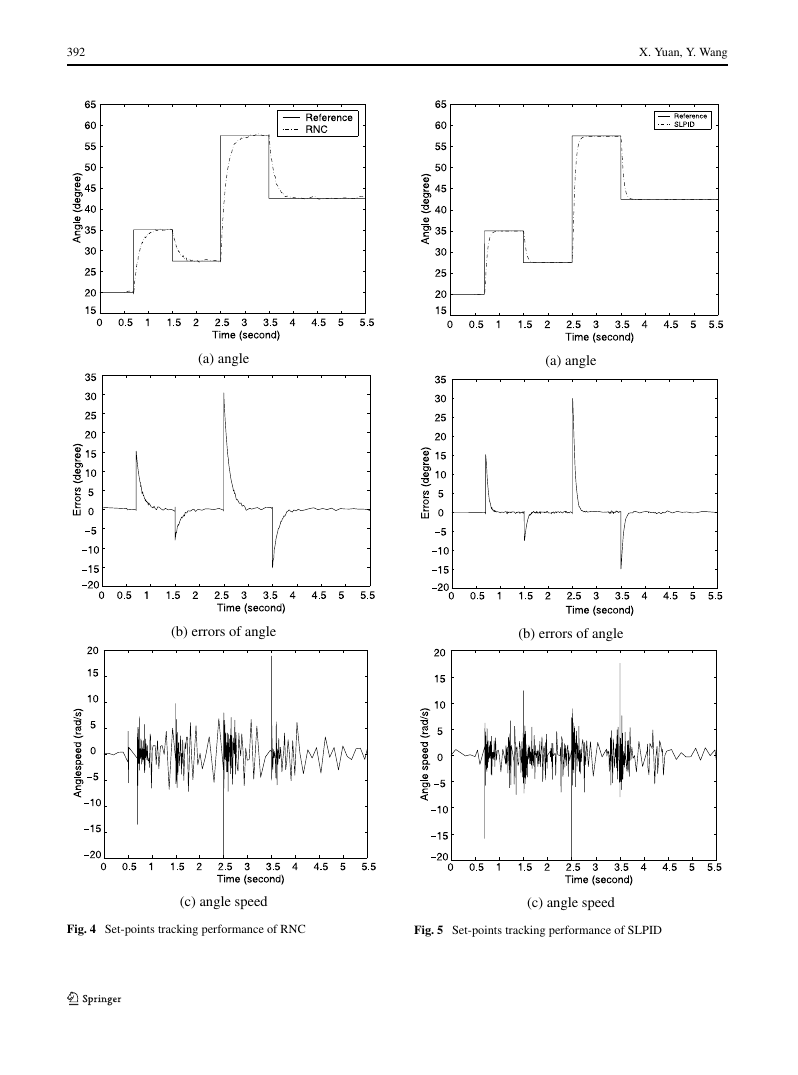

3.2 Structure of self-learning PID control

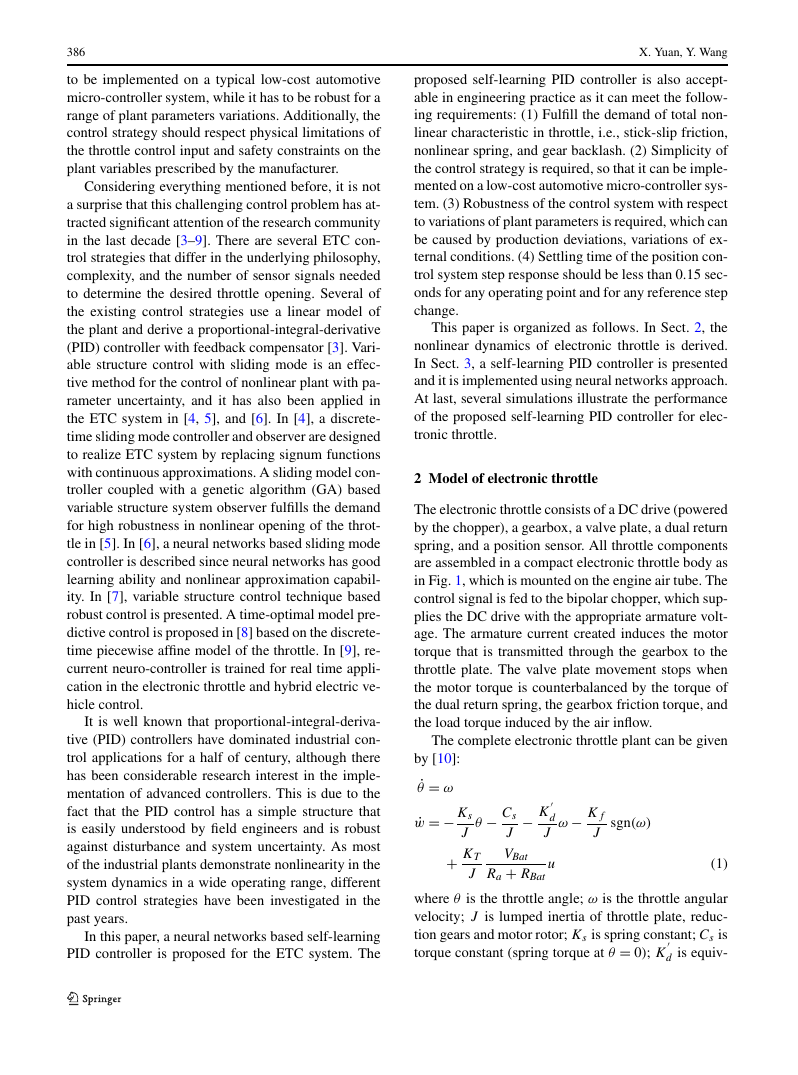

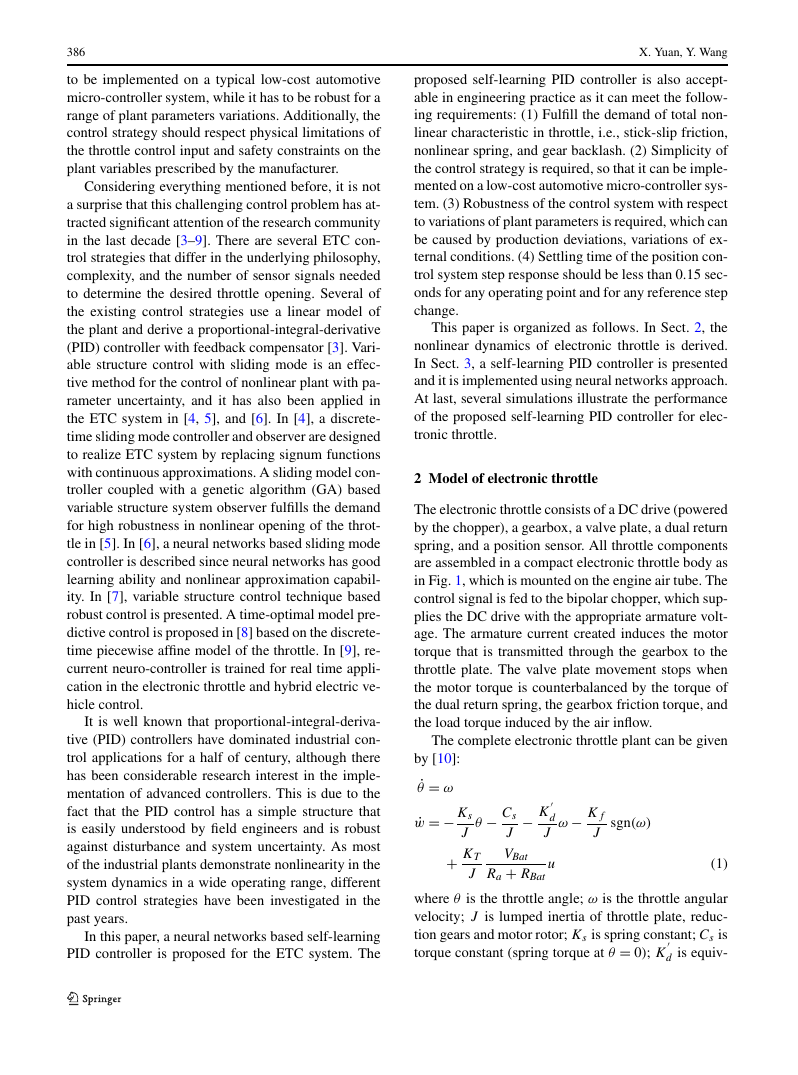

The structure of the proposed self-learning PID con-

troller is illustrated in Fig. 2. There are two neural net-

works; one is a Gaussian potential function networks

(GPFN1), which can identify the nonlinear plant, the

other is another Gaussian potential function networks

(GPFN2), which acts as a PID controller.

GPFN networks may be seen as a three-layer feed-

forward networks, the input layer acts as transmit-

ting input value to the next layer, the second layer is

a hidden-layer, center parameter is included in each

node, the third layer is output layer. Usually, nonlinear

�

388

X. Yuan, Y. Wang

Fig. 2 The structure of self-learning PID controller

plant could be described by nonlinear mapping shown

as follows:

y(k − 1), . . . , y(k − n), u(k), . . . , u(k − d)

y(k) = f

(6)

where n and d are orders of the plant output and con-

trol input. The GPFN1 is used for the construction of

plant model and input layer of GPFN1 is defined as:

y(k−1), . . . , y(k−n), u(k), . . . , u(k−d)

(7)

Xm(k) =

T

then the hidden layer of GPFN1 is

−Xm(k) − am

j (k) = exp

hm

j (k))2

j = 1, 2, . . . , M

2(bm

j (k)2

,

(8)

and the output layer of GPFN1 is obtained as

(9)

W m

j (k)

j (k) · hm

ˆy(k) = M

j=1

j (k) (j = 1, 2, . . . , M) are the networks con-

where W m

necting weights, am

j (k) is the center of the Gaussian

potential function, and bm

j (k) is the width of the

Gaussian potential function, at time k. ˆy(k) in (9) is

the approximation of y(k) in (6), and it constructs the

plant model.

GPFN2 acts as the self-learning PID controller, and

the output of GPFN2 is

u(k) = u(k − 1) + 3

i=1

Ki (k) · Φi (k)

and the hidden layer of GPFN2 is

−X(k) − ai (k)2

Φi (k) = exp

i = 1, 2, 3

i (k)

2b2

,

(10)

(11)

T

and the input layer of GPFN2 is

X1(k), X2(k), X3(k)

X(k) =

(12)

where Ki (k) (i = 1, 2, 3) is the networks connecting

weights, which is corresponding to PID controller pa-

rameters (proportional gains, integral gains, and deriv-

ative gains), X1(k) = e1(k), X2(k) = e2(k), X3(k) =

e3(k), ai (k) is the center of the Gaussian potential

function, and bi (k) is the width of the Gaussian po-

tential function at time k.

3.3 Learning algorithm

In this section, we will present the learning algorithm

for these two GPFN networks. For GPFN1, a cost

function may be defined as

2 = 1

Jm = 1

2

2

y(k) − ˆy(k)

e2

m(k)

(13)

�

Neural networks based self-learning PID control of electronic throttle

389

A gradient descent approach is employed to train

GPFN1 in order to minimize const function Jm.

The gradients of error in (13) with respect to vector

j (k), am

W m

The gradients of error in (20) with respect to vector

Ki (k), ai (k), and bi (k) are given by

· ∂y(k)

(k) − y(k)

= −

∂Jc

∗

y

∂u(k)

∂Ki (k)

= −e(k) · Φi (k) · ∂y(k)

= −

(k) − y(k)

∂u(k)

· ∂y(k)

∗

y

∂u(k)

(14)

∂Jc

∂ai (k)

· ∂u(k)

∂Ki (k)

· ∂u(k)

∂Φi (k)

∂Jm

∂W m

j (k)

∂Jm

j (k)

∂am

∂Jm

j (k)

∂bm

i (k) are given by:

· ∂ ˆy(k)

∂W m

j (k)

y(k) − ˆy(k)

i (k), and bm

= −

= em(k) · hm

j (k)

= −

y(k) − ˆy(k)

= −em(k) · W m

× Xm(k) − am

j (k))2

= −

y(k) − ˆy(k)

= −em(k) · W m

× Xm(k) − am

j (k))3

(bm

(bm

· ∂ ˆy(k)

∂hm

j (k)

j (k) · hm

j (k)

j (k)

· ∂ ˆy(k)

∂hm

j (k)

j (k) · hm

j (k)2

j (k)

The corresponding learning algorithm of GPFN1 are

given by the following expressions:

W m

j (k − 1) − W m

− ∂Jm

j (k − 1) + η(k) ·

j (k) = W m

∂W m

j (k)

j (k − 2)

+ α

W m

− ∂Jm

j (k) = am

j (k − 1) + η(k) ·

∂am

j (k)

j (k − 2)

j (k − 1) − am

+ α

j (k) = bm

j (k − 1) + η(k) ·

− ∂Jm

∂bm

j (k)

j (k − 2)

j (k − 1) − bm

+ α

am

bm

am

bm

(17)

(18)

(19)

where η(k) is the learning rate, 0 < η(k) < 1; α is pos-

itive factor.

Define a cost function for the online learning of

GPFN2 as:

∗

y

Jc = 1

2

(k) − y(k)

2 = 1

2

e2(k)

× ∂Φi (k)

∂ai (k)

= −e(k) · Ki (k) · Φi (k)

× (X(k) − ai (k))T

= −

b2

i (k)

(k) − y(k)

∗

y

· ∂y(k)

∂u(k)

· ∂y(k)

∂u(k)

· ∂hm

∂am

j (k)

j (k)

· ∂hm

∂bm

j (k)

j (k)

(15)

(16)

∂Jc

∂bi (k)

× ∂u(k)

∂Φi (k)

· ∂Φi (k)

∂bi (k)

= −e(k) · Ki · Φi (k)

× X(k) − ai (k)2

b3

i (k)

· ∂y(k)

∂u(k)

(23)

In these equations, ∂y(k)

∂u(k) denotes the sensitivity of

the plant with respect to its input, which is identified

using GPFN1 since after learning there is ˆy(k) ≈ y(k),

∂y(k)

∂u(k)

As

∂ ˆy(k)

∂u(k)

≈ ∂ ˆy(k)

∂u(k) .

= ∂ ˆy(k)

∂hm

j (k)

· ∂hm

j (k)

∂u(k)

j (k) · hm

W m

j (k) · hm

W m

= − M

j=1

= − M

j=1

j (k)

j (k) · X(k) − am

j (k)

j (k) · u(k) − am

j (k))2

(bm

(bm

j (k))2

therefore, the learning algorithms for GPFN2 are:

Ki (k) = Ki (k − 1) + η(k) ·

+ α

− ∂Jc

∂Ki (k)

Ki (k − 1) − Ki (k − 2)

− ∂Jc

∂ai (k)

ai (k − 1) − ai (k − 2)

ai (k) = ai (k − 1) + η(k) ·

(20)

+ α

(21)

(22)

(24)

(25)

(26)

�

390

bi (k) = bi (k − 1) + η(k) ·

− ∂Jc

∂bi (k)

bi (k − 1) − bi (k − 2)

+ α

(27)

where η(k) is the learning rate, 0 < η(k) < 1; α is pos-

itive factor.

For a proper understanding and applying the ap-

the more detailed procedures of the self-

proach,

learning PID control design are given below.

Step 1. Initial parameters: weights W m(0), K(0), pa-

i (0), bm

i (0), ai (0), bi (0), η = 0.35,

Step 2. Using (9) to compute the output of GPFN1

rameters am

α = 0.2.

ˆy(k).

Step 3. Using (14)–(16) and (17)–(19) to train the

weights and parameters of GPFN1.

Step 4. Compute ∂y(k)

Step 5. Sample y

∂u(k) using (24).

∗

(k), y(k), compute the control sig-

nal u(k) by (10).

Step 6. Update PID parameters (GPFN2) using (21)–

(23) and (25)–(27), go to Step 2.

3.4 Stability and convergence

The learning algorithms of GPFN2 in (25)–(27) can

be denoted as follows, that is, the weights can now be

adjusted following a gradient method as:

Wi (k) = Wi (k + 1) − Wi (k)

= −η(k) ·

∂Jc

∂Wi (k)

(28)

∂W (k) , g[ei (k)] = ∂Jc

where Wi (k) is the weights and parameters of GPFN2,

is, Wi (k) = [Ki (k), ai (k), bi (k)], η(k) is the

that

learning rate, 0 < η(k) < 1.

Let z(k) = ∂y(k)

learning rate as η(k) =

Therefore,

Wi (k + 1) = Wi (k) − η(k) ·

∂y(k) , and select the

1+z(k)2 , γ > 0 is a constant.

∂Jc

γ

∂Wi (k)

= Wi (k) − η(k) · ∂Jc

= Wi (k) − γ · g[e(k)]

1 + zT (k) · z(k)

∂y(k)

· ∂y(k)

∂W (k)

· z(k)

(29)

Assumption (1) 2 > γ > 0; (2) W (k) is very close to

optimal weights W

; (3) g(0) = 0.

∗

X. Yuan, Y. Wang

Theory Under Assumptions

is

limk→∞ g2[ei (k)]

= 0. And if z(k) is bounded,

1+zT (k)·z(k)

limk→∞ g[e(k)] = 0, limk→∞ e(k) → 0, and the learn-

ing algorithm is converged.

(1)–(3),

there

Proof Suppose weights W (k) are very close to opti-

mal weights W

be expressed by:

∗ = [ ¯W1, ¯W2, ¯W3], then (10) can

, W

∗

u(k) = 3

¯Wi (k) · Φi (k)

i=1

˜W (k) = W

∗ − W (k)

Define a Lyapunov function as

V (k) = ˜W (k)

2 ≥ 0

(30)

(31)

(32)

then

V (k + 1) = ˜W (k + 1)

2 = ˜W T (k + 1) ˜W (k + 1)

T

=

˜W (k) − γ · g[e(k)] · z(k)

1 + zT (k) · z(k)

˜W (k) − γ · g[e(k)] · z(k)

×

1 + zT (k) · z(k)

2 − 2γ ˜W T (k) · g[e(k)] · z(k)

= ˜W (k)

+ γ 2 · g2[e(k)] · zT (k) · z(k)

≤ V (k) − 2γ ˜W T (k) · g[e(k)] · z(k)

+ γ 2 · g2[e(k)]

1 + zT (k) · z(k)

[1 + zT (k) · z(k)]2

1 + zT (k) · z(k)

1 + zT (k) · z(k)

(33)

From Assumption (2) and (33), we can know

˜W T (k) · z(k) is the first order approximation of

that

g[e(k)], that is,

˜W T (k) · z(k) = ¯W − W (k)

+ o(1)

ei (k)

= g

T · ∂y(k)

∂W (k)

(34)

thus, the change of the Lyapunov function is obtained

by

�

Neural networks based self-learning PID control of electronic throttle

V (k) = V (k + 1) − V (k)

1 + zT (k) · z(k)

≥ − 2γ ˜W T (k) · g[e(k)] · z(k)

+ γ 2 · g2[e(k)]

1 + zT (k) · z(k)

≥ − γ (2 − γ ) · g2[e(k)]

1 + zT (k) · z(k)

(35)

When Assumption (1) is satisfied, 2 > γ > 0,

V (k) is negative definite. This also means that the

convergence is guaranteed, then limk→∞ g2[ei (k)]

=

1+zT (k)·z(k)

0, limk→∞ g[e(k)] = 0, limk→∞ e(k) → 0.

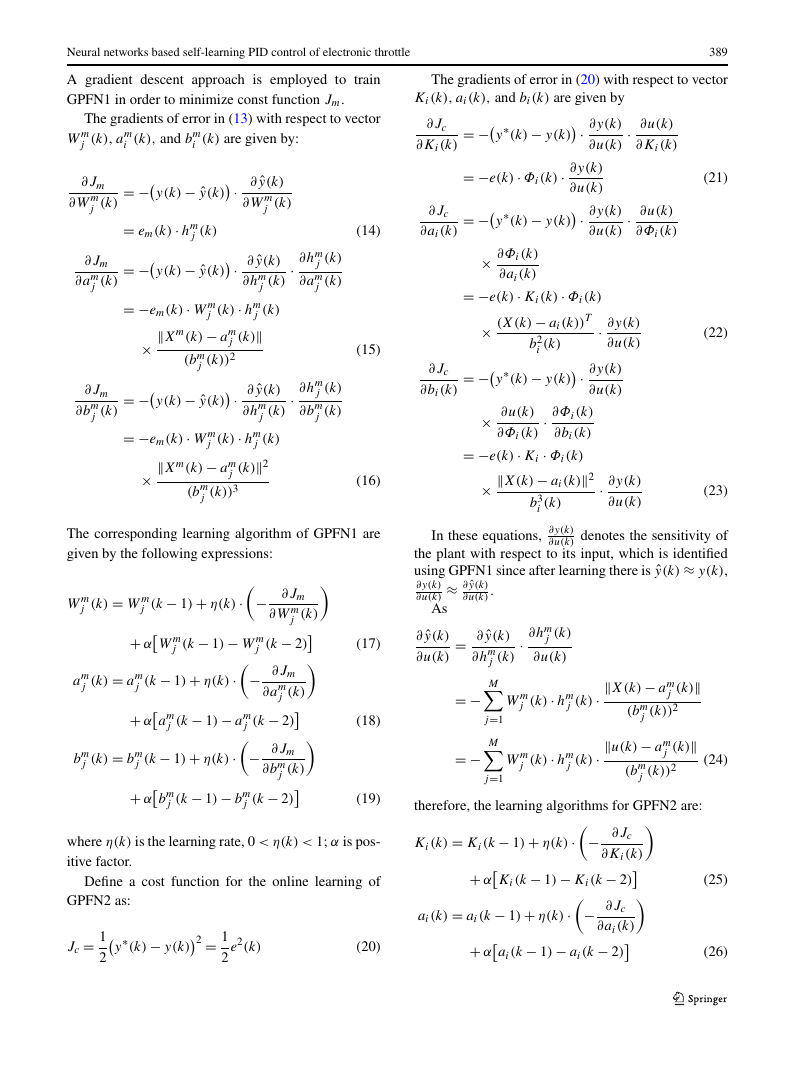

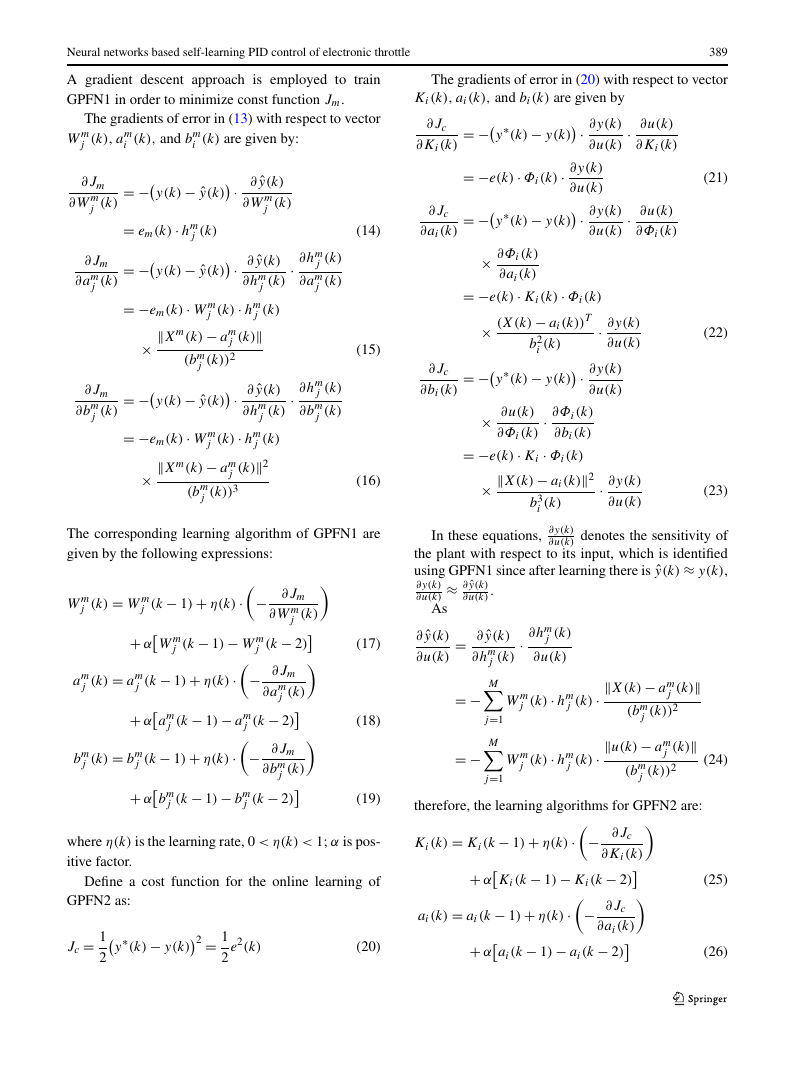

4 Simulation

d

J

= 2.01E02 rad/s2, K

= 3.30E01 s

= 2.50E01 rad/A · s2,

This section shows the application of the self-learning

PID controller on the electronic throttle. In this pa-

−2,

per, plant parameters values are: Ks

J

=

Cs

=

J

6.29E01 rad/s2, KT

J

3.0E01 A. Here, three kinds of controllers are com-

pared together. They are: PID controller with feed-

back compensator (PIDFC) in [3], recurrent neuro-

controller (RNC) in [9], and the proposed self-learning

PID controller (SLPID).

= 1.35E01 s

−1, Kf

Ra+RBat

J

VBat

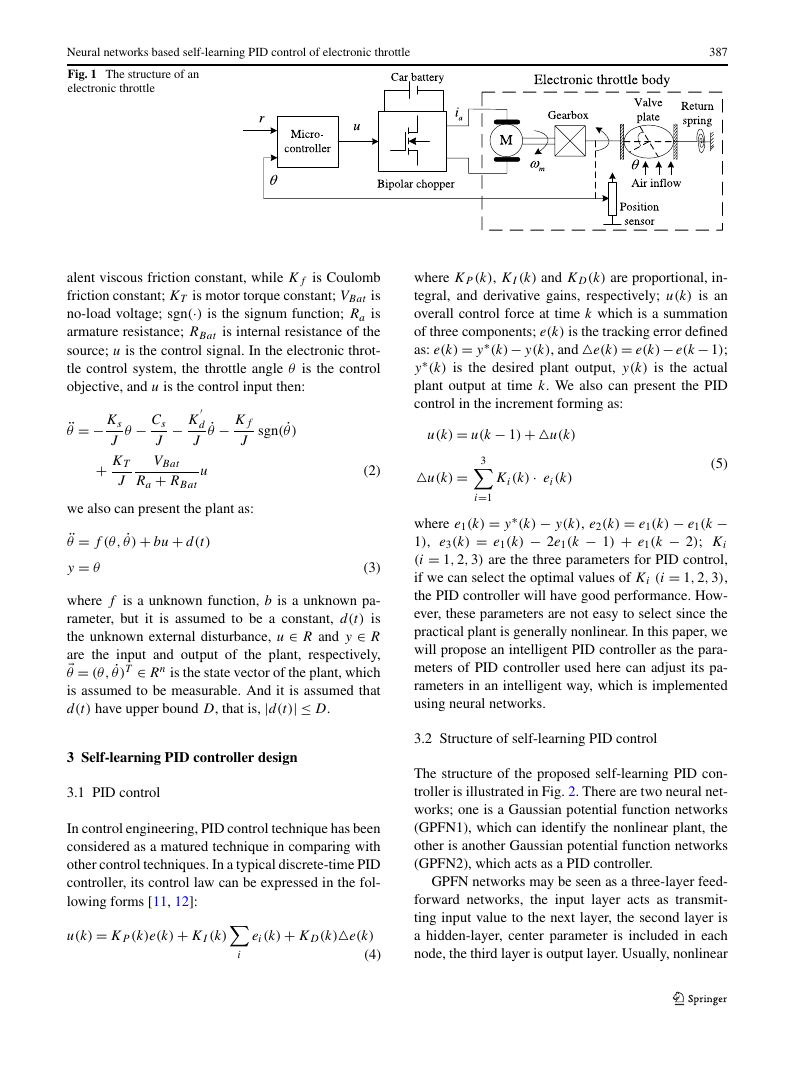

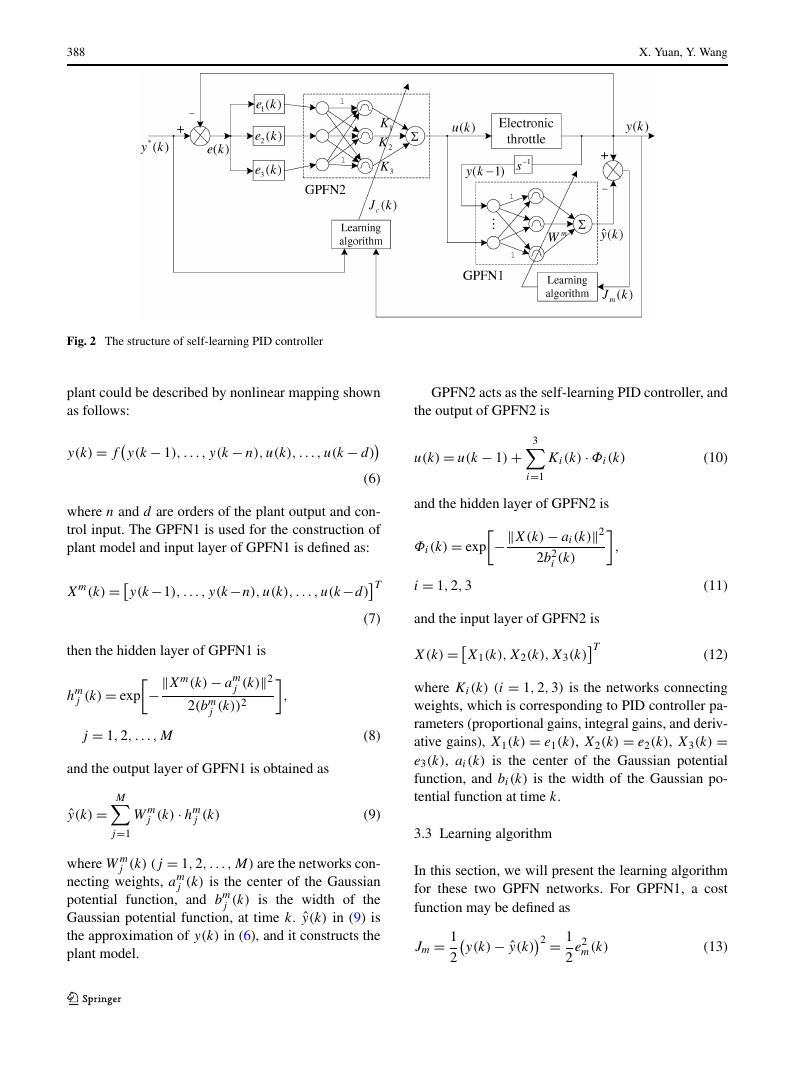

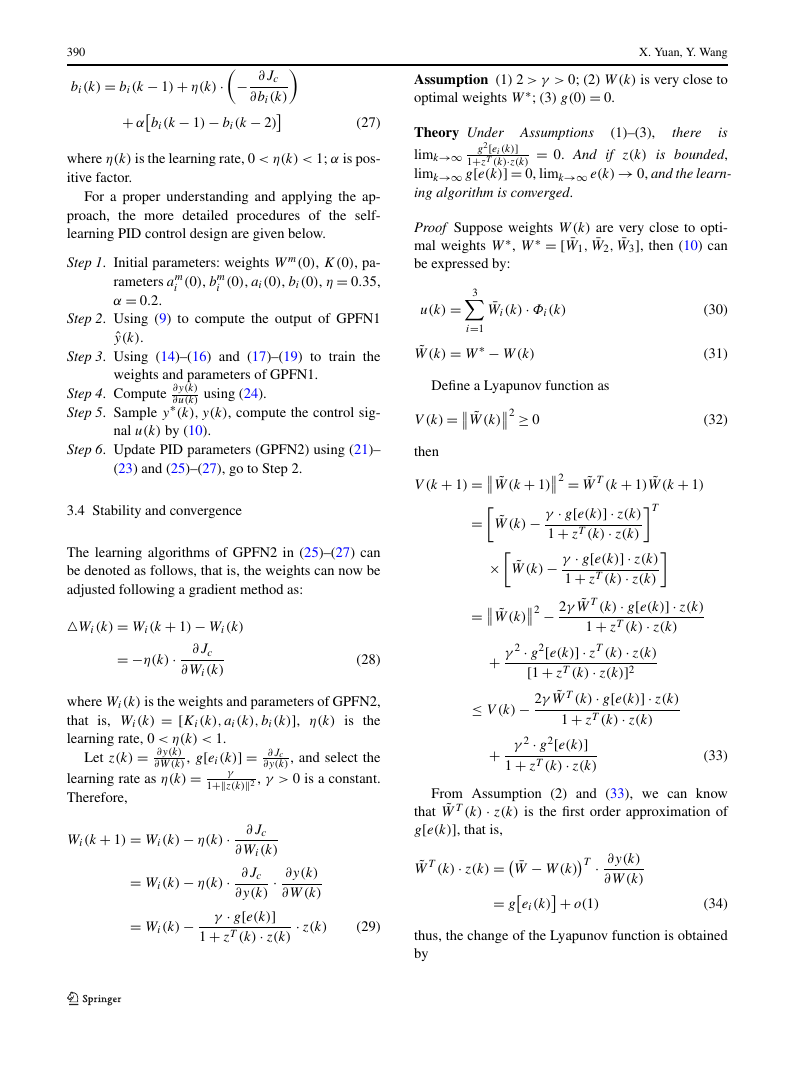

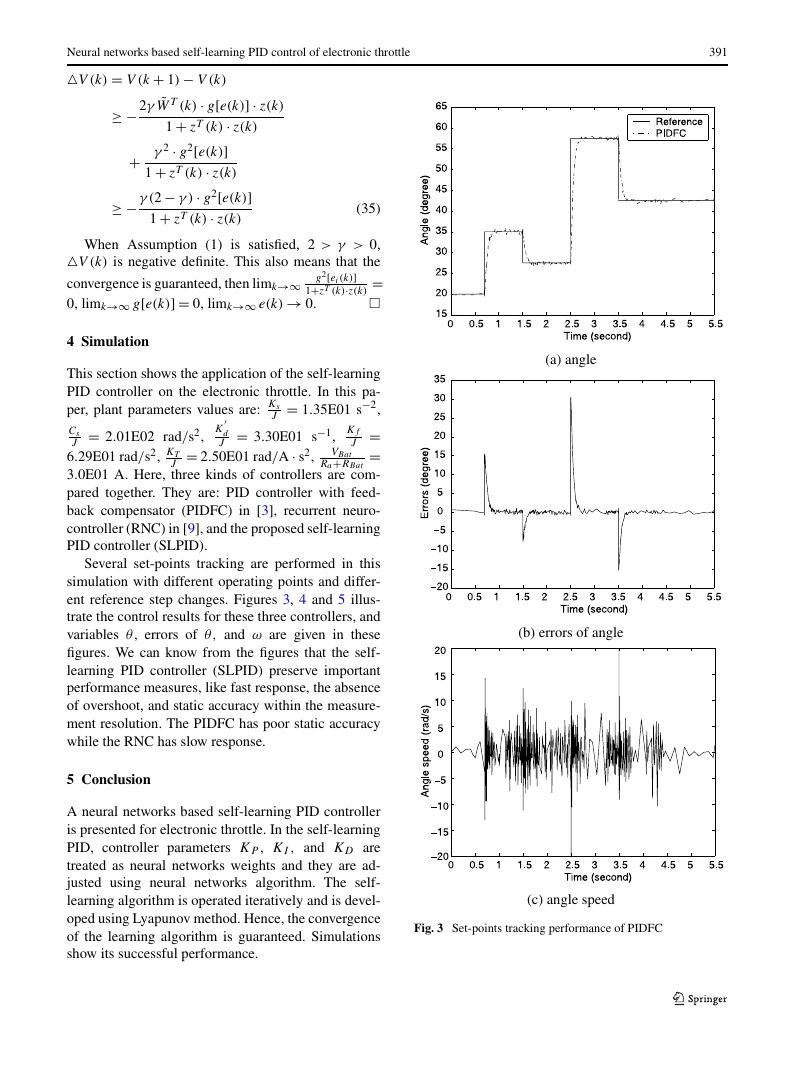

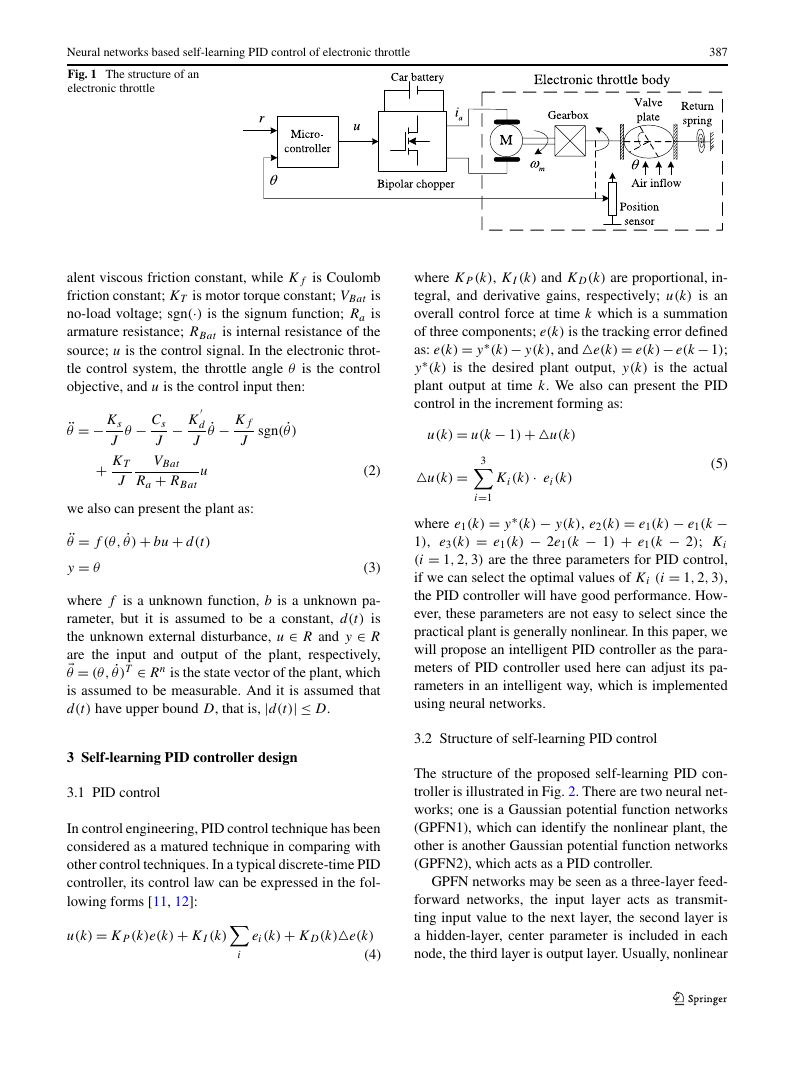

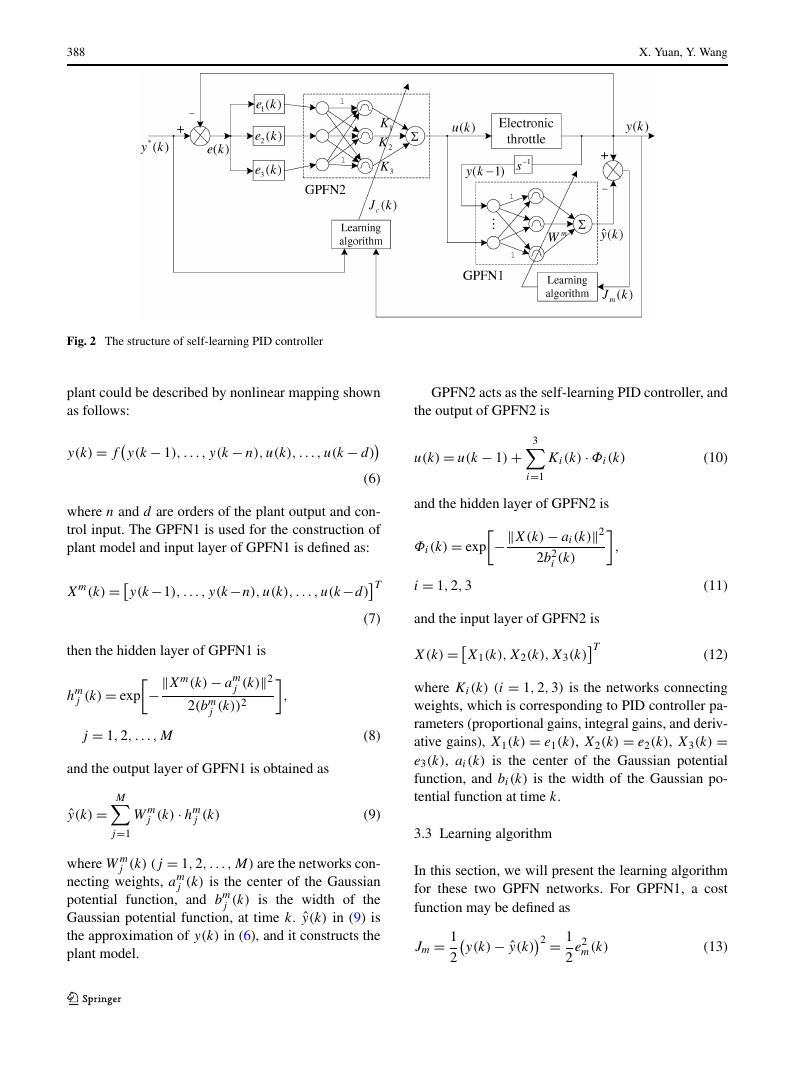

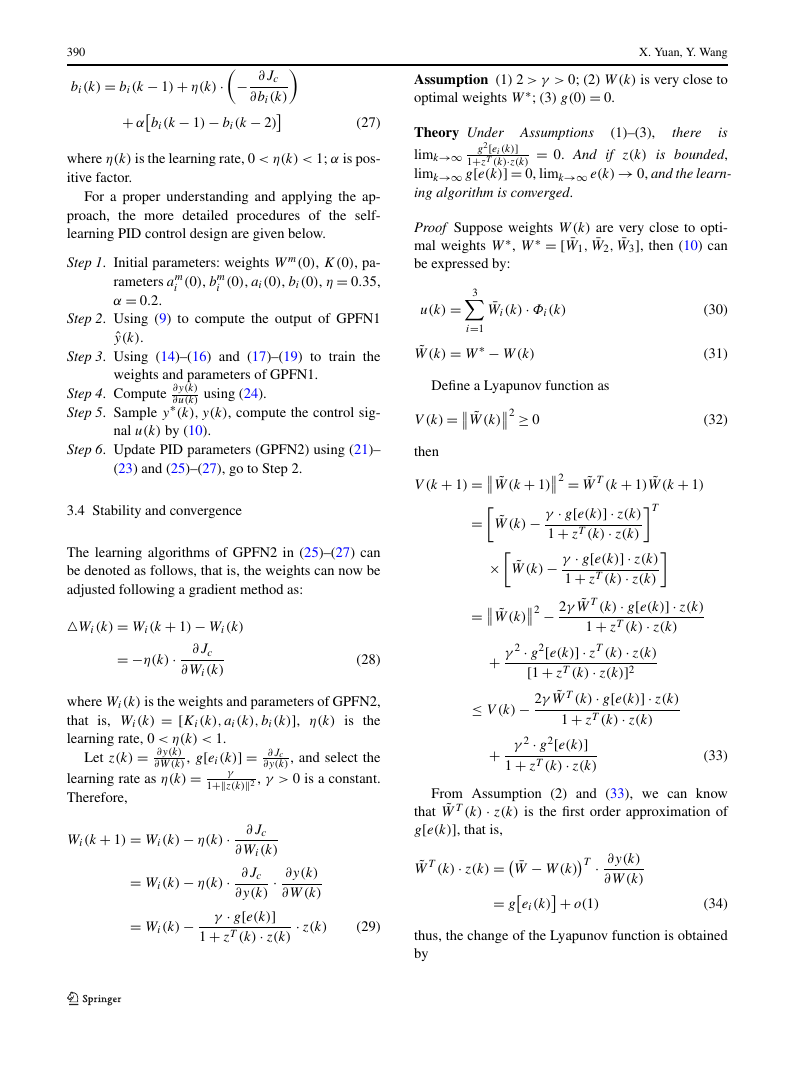

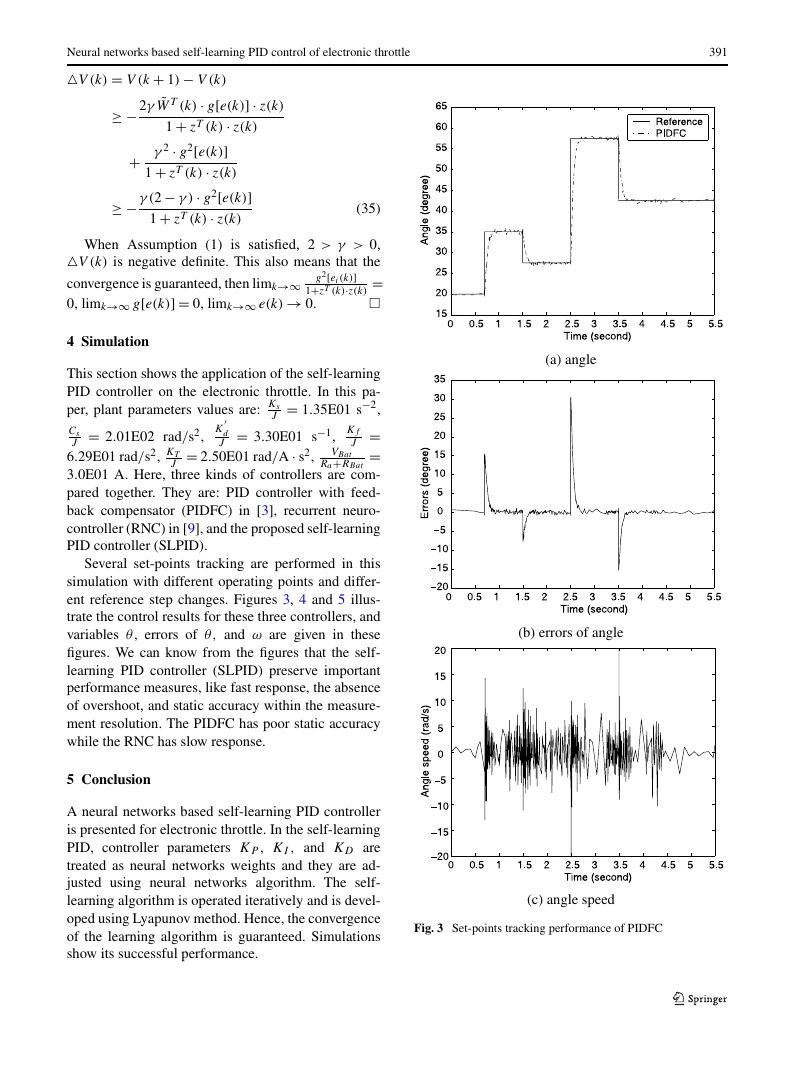

Several set-points tracking are performed in this

simulation with different operating points and differ-

ent reference step changes. Figures 3, 4 and 5 illus-

trate the control results for these three controllers, and

variables θ, errors of θ, and ω are given in these

figures. We can know from the figures that the self-

learning PID controller (SLPID) preserve important

performance measures, like fast response, the absence

of overshoot, and static accuracy within the measure-

ment resolution. The PIDFC has poor static accuracy

while the RNC has slow response.

5 Conclusion

A neural networks based self-learning PID controller

is presented for electronic throttle. In the self-learning

PID, controller parameters KP , KI , and KD are

treated as neural networks weights and they are ad-

justed using neural networks algorithm. The self-

learning algorithm is operated iteratively and is devel-

oped using Lyapunov method. Hence, the convergence

of the learning algorithm is guaranteed. Simulations

show its successful performance.

391

(a) angle

(b) errors of angle

(c) angle speed

Fig. 3 Set-points tracking performance of PIDFC

�

392

X. Yuan, Y. Wang

(a) angle

(a) angle

(b) errors of angle

(b) errors of angle

(c) angle speed

(c) angle speed

Fig. 4 Set-points tracking performance of RNC

Fig. 5 Set-points tracking performance of SLPID

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc