上一次发过《ABAQUS 初学者用户子程序小例子》,給学习

UMAT 的初学者带来了一定的帮助。现在用到 VUMAT,发现网上

这种小例子很少,关于 VUMAT 的资料也不多。摸索了一天,做个

VUMAT 的小例子供大家分享。

实例:简单的平面平板拉伸,材料本构模型采用随动强化模型,

E=210000MPa, ν=0.3,fy=200MPa, E’=10000MPa。左端约束,

右端施加位移载荷 V=0.2mm。

Author: xueweek@163.com

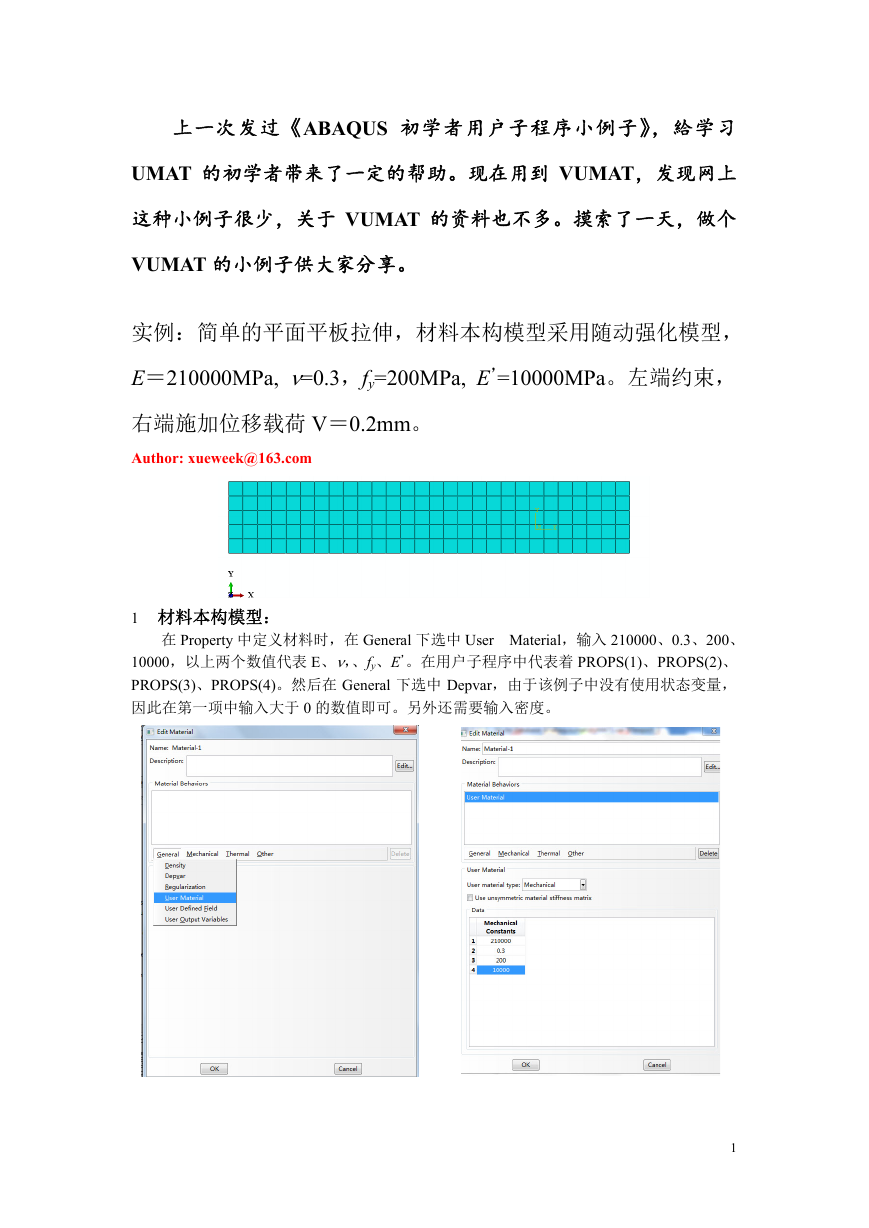

1 材料本构模型:

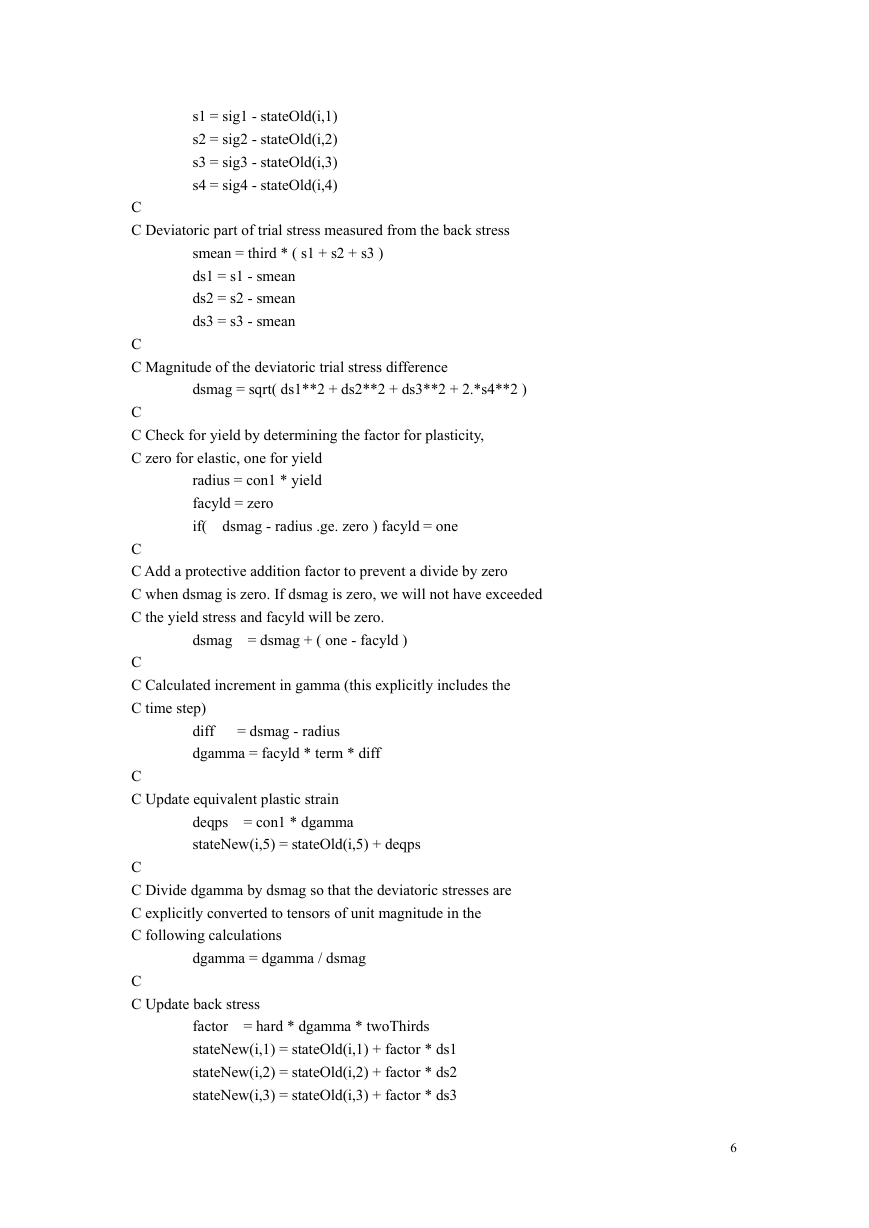

在 Property 中定义材料时,在 General 下选中 User Material,输入 210000、0.3、200、

10000,以上两个数值代表 E、ν,、fy、E’。在用户子程序中代表着 PROPS(1)、PROPS(2)、

PROPS(3)、PROPS(4)。然后在 General 下选中 Depvar,由于该例子中没有使用状态变量,

因此在第一项中输入大于 0 的数值即可。另外还需要输入密度。

1

�

建模大家都会,故省略

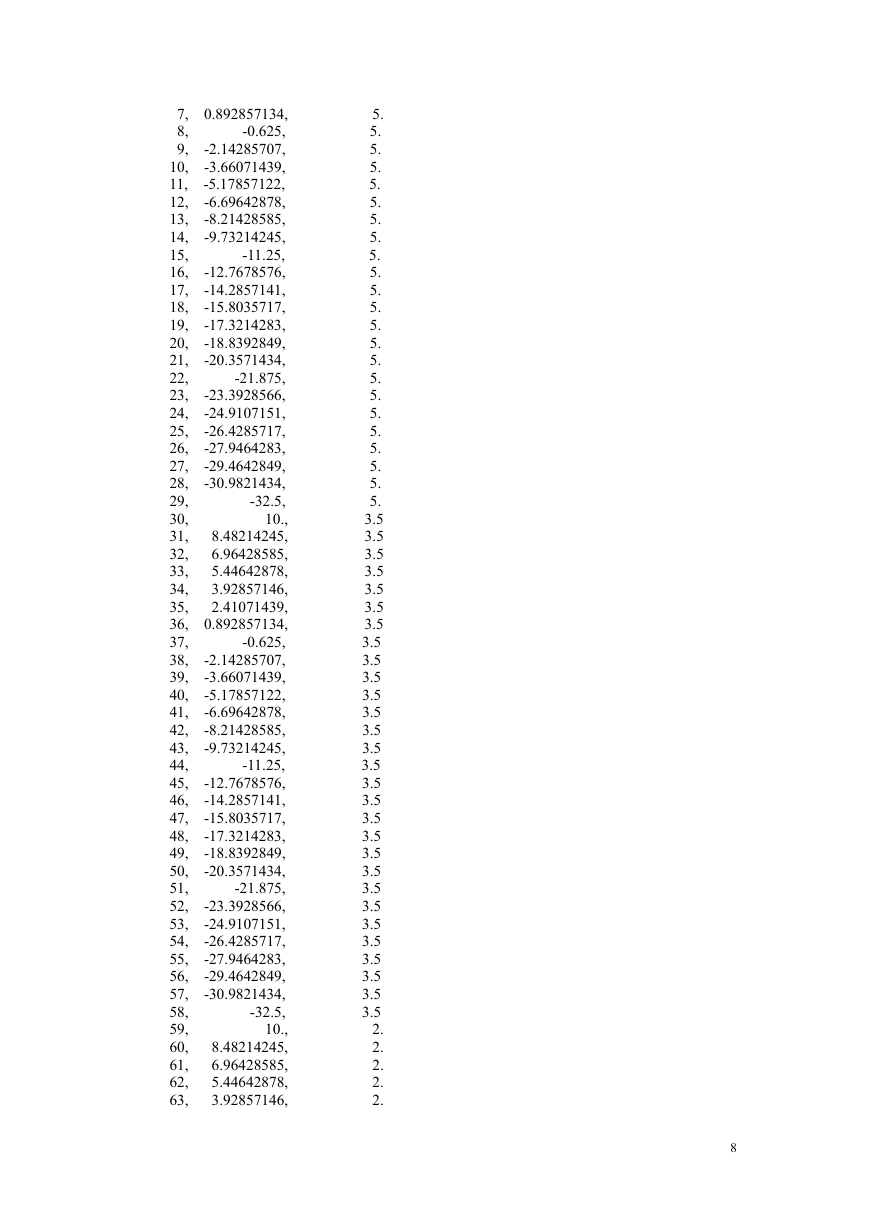

2 ABAQUS 中 STEP 的设置

由于 VUMAT 需要用到 Explicit 求解,因此需要在 step 步骤中设置 explicit 选项,如下图,

其设置可以用默认设置。

2

�

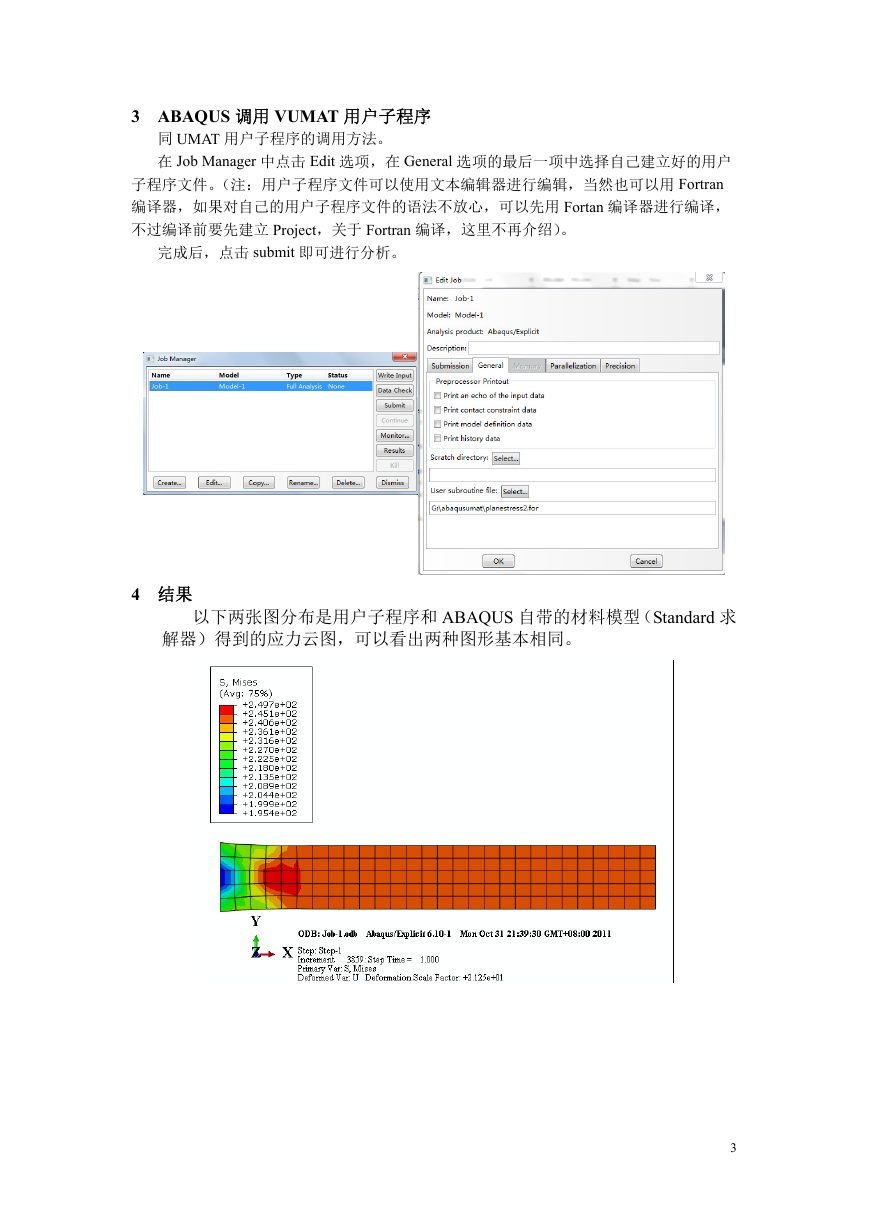

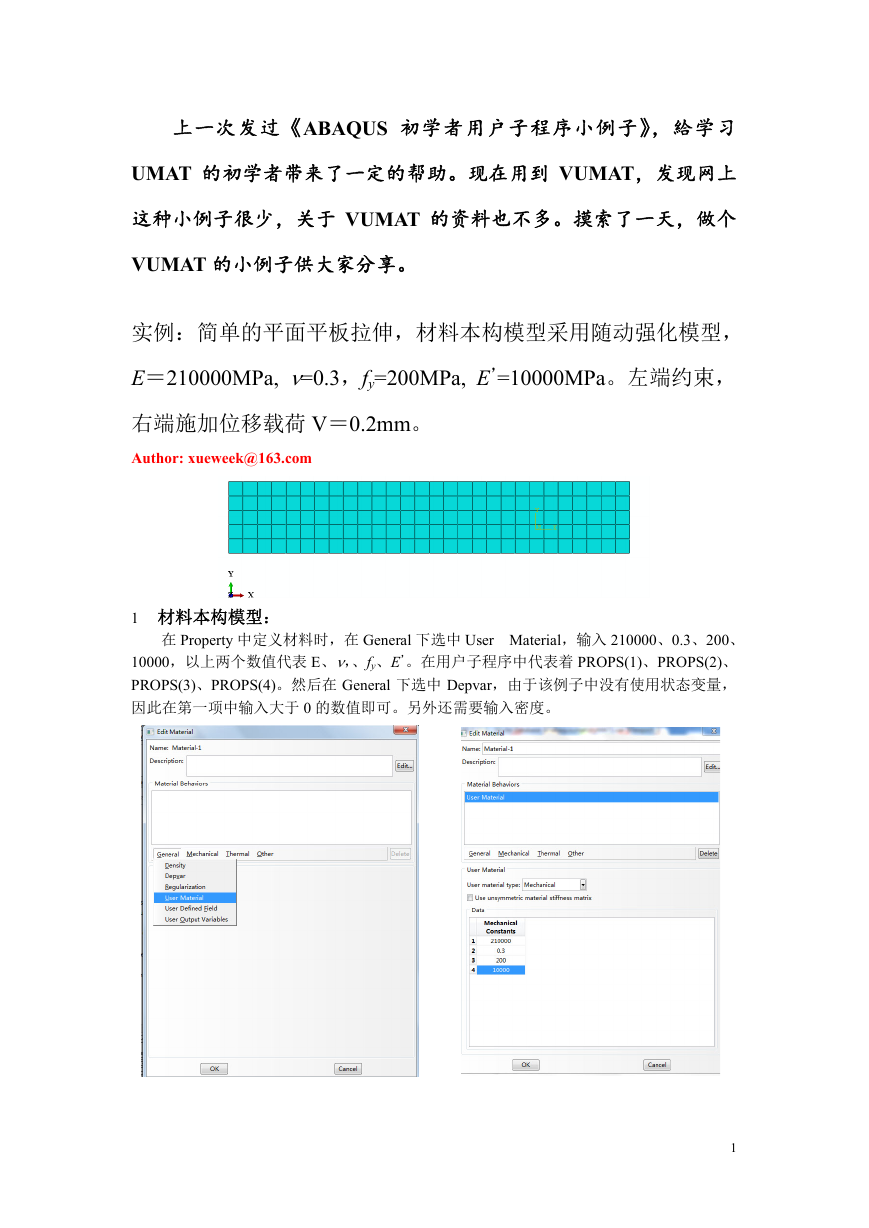

3 ABAQUS 调用 VUMAT 用户子程序

同 UMAT 用户子程序的调用方法。

在 Job Manager 中点击 Edit 选项,在 General 选项的最后一项中选择自己建立好的用户

子程序文件。(注:用户子程序文件可以使用文本编辑器进行编辑,当然也可以用 Fortran

编译器,如果对自己的用户子程序文件的语法不放心,可以先用 Fortan 编译器进行编译,

不过编译前要先建立 Project,关于 Fortran 编译,这里不再介绍)。

完成后,点击 submit 即可进行分析。

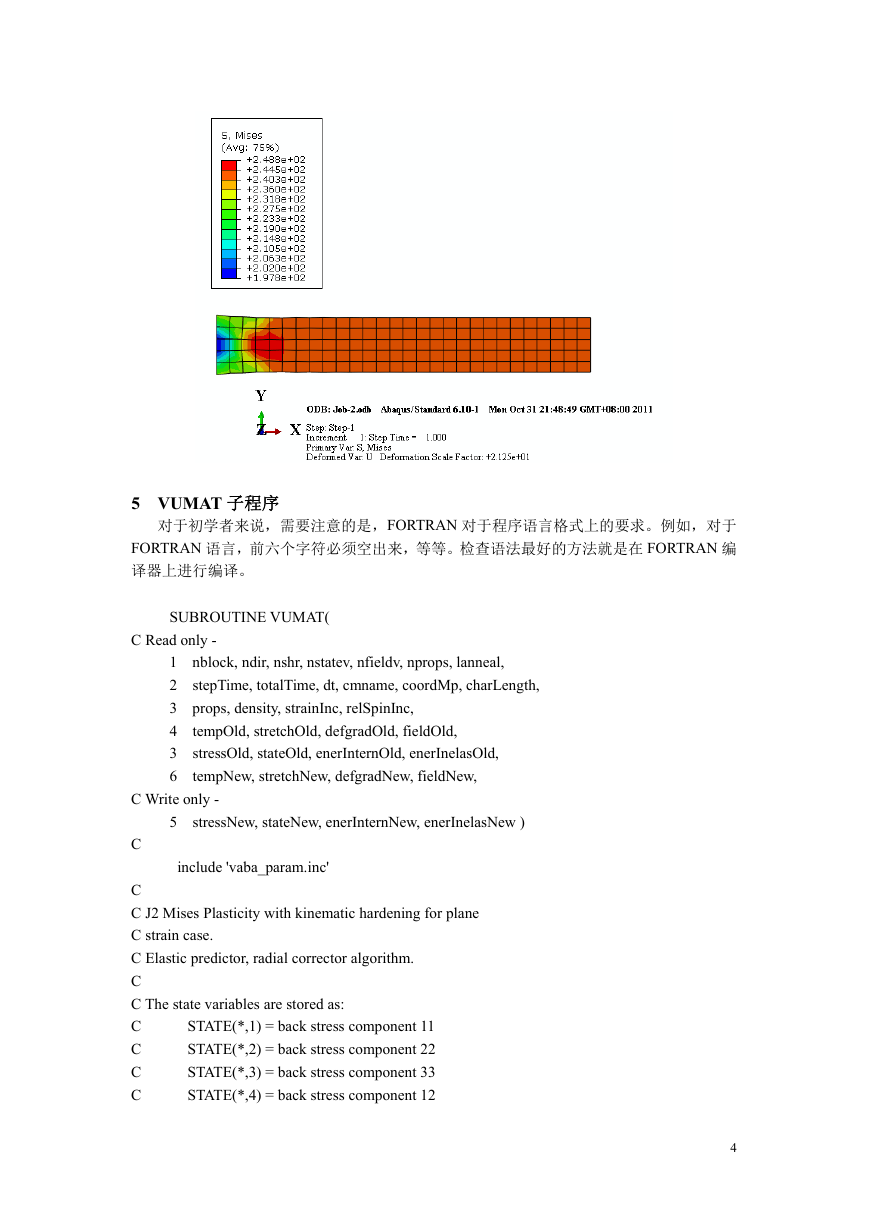

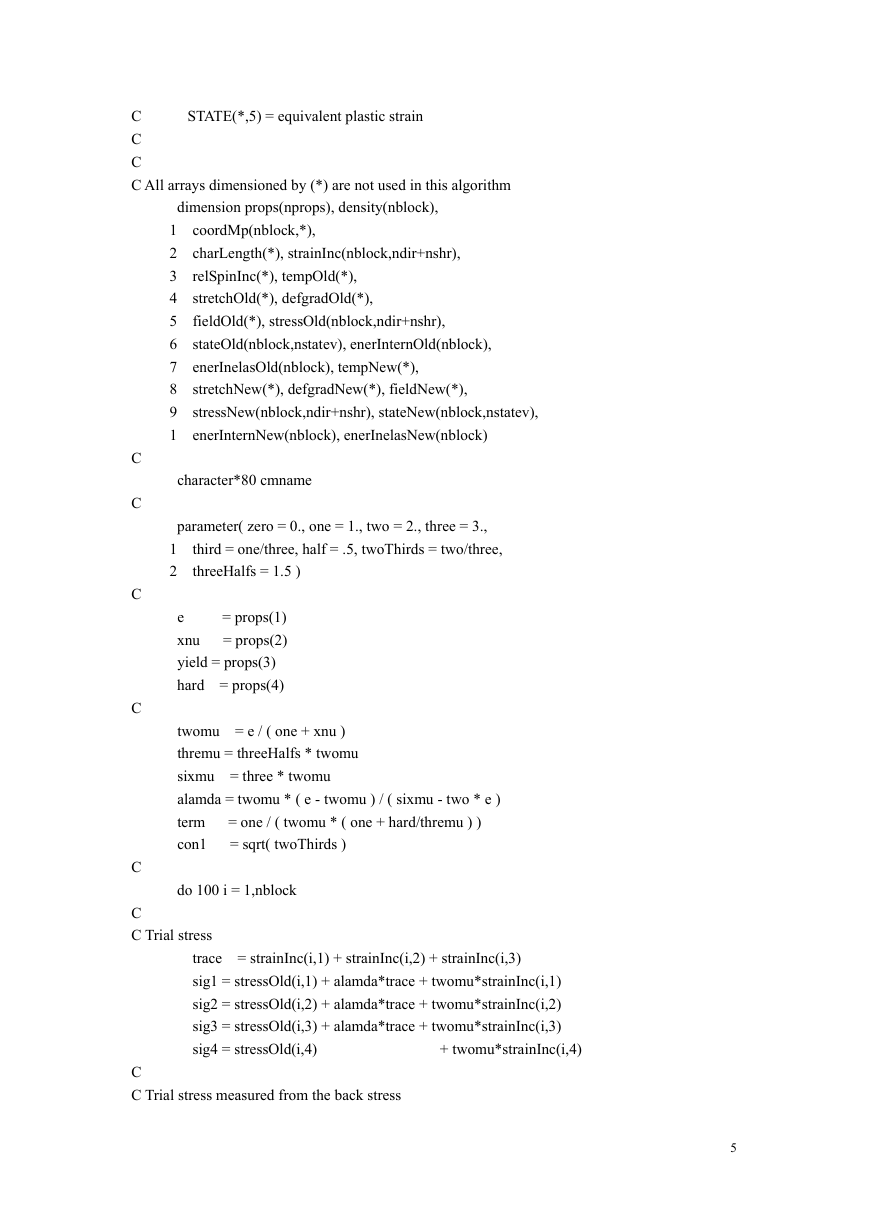

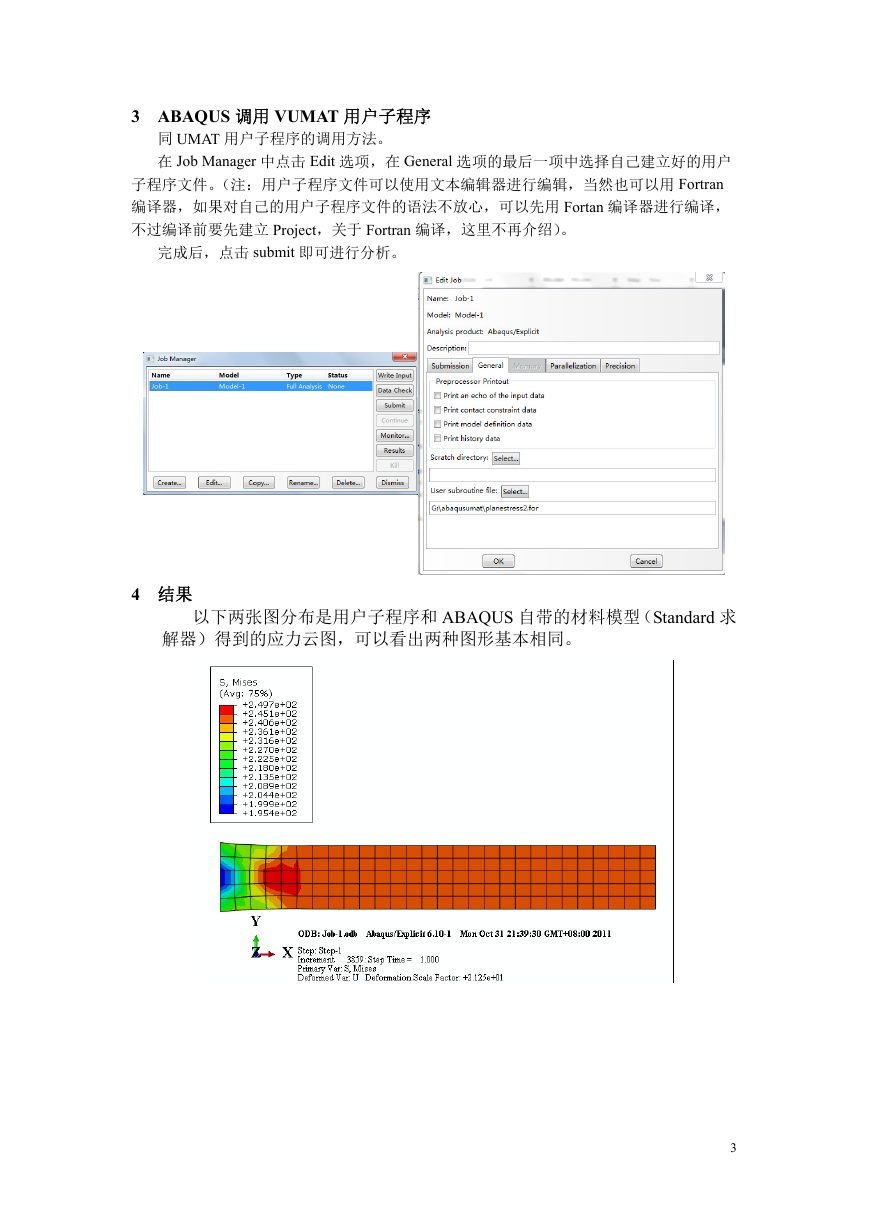

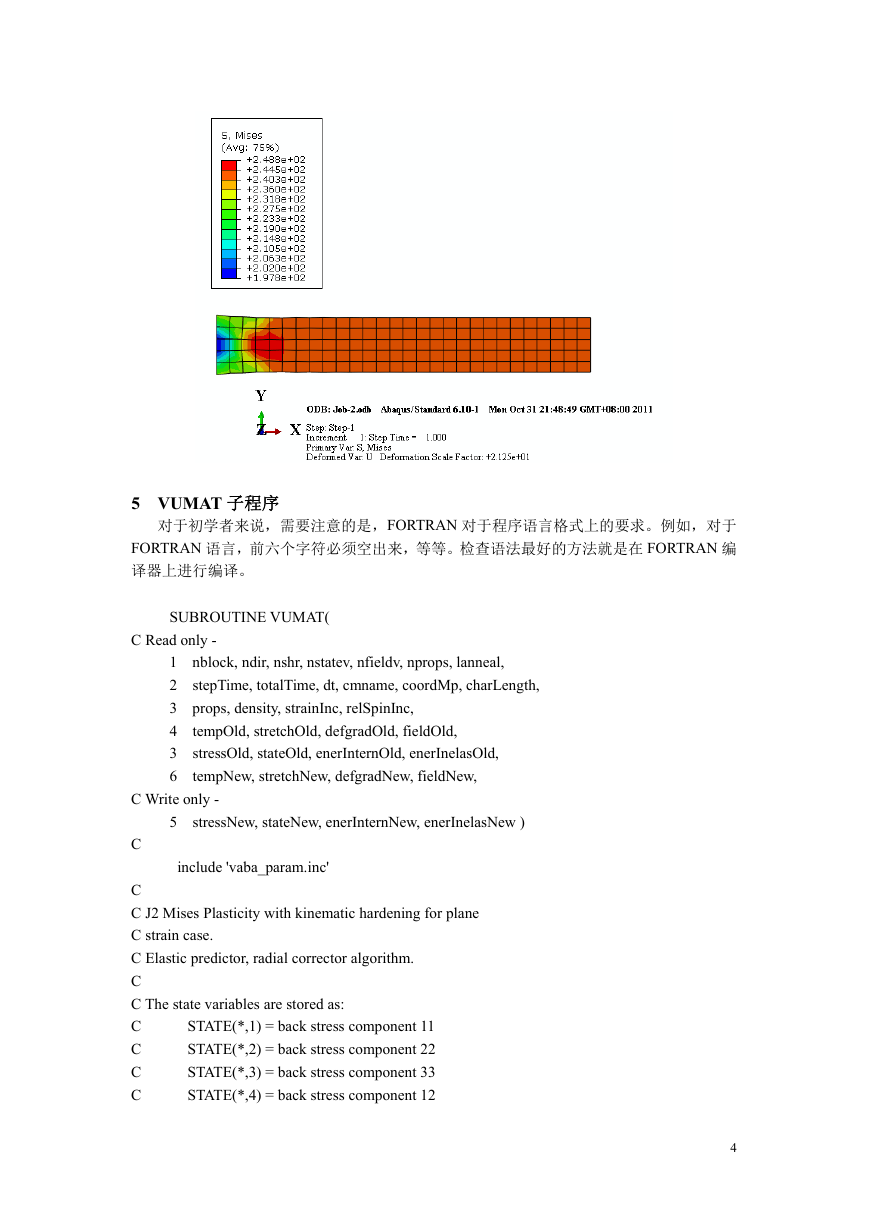

4 结果

以下两张图分布是用户子程序和 ABAQUS 自带的材料模型(Standard 求

解器)得到的应力云图,可以看出两种图形基本相同。

3

�

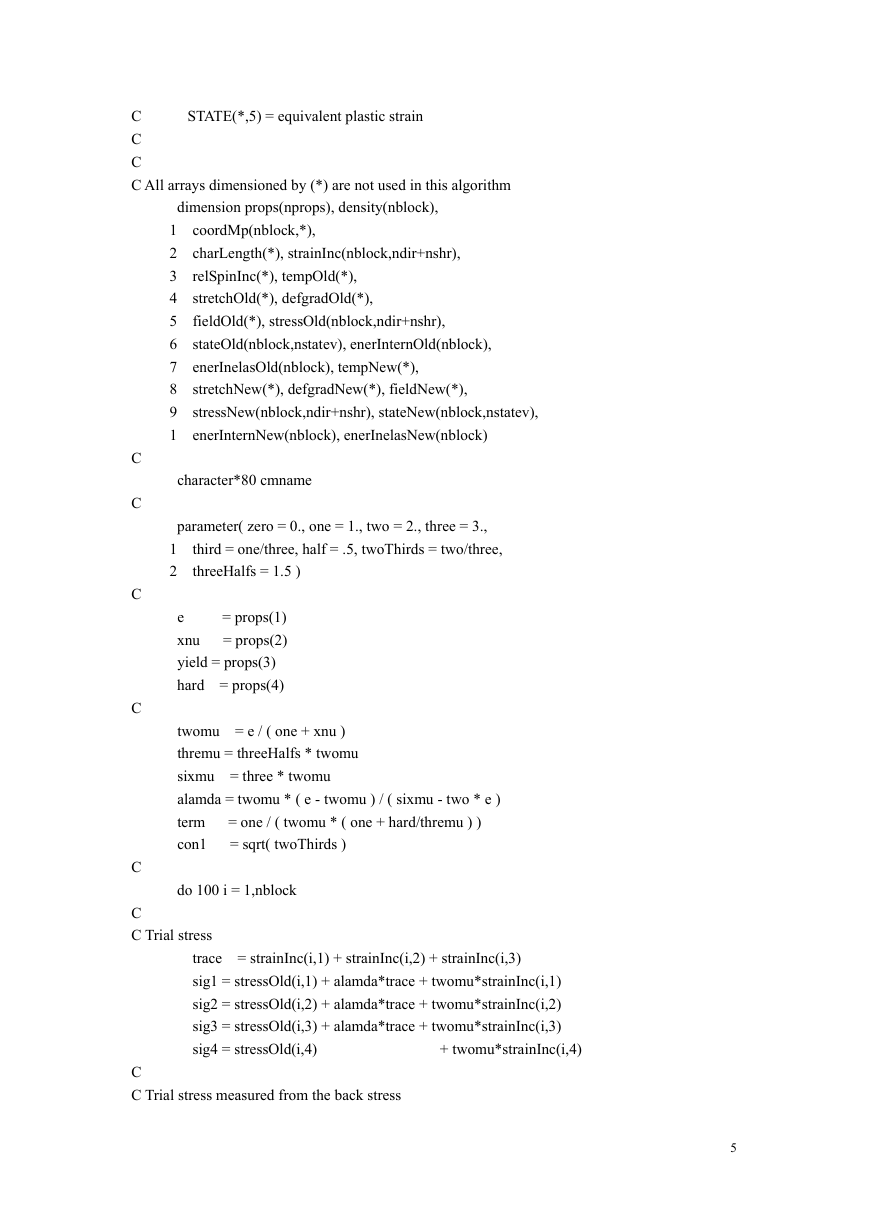

5 VUMAT 子程序

对于初学者来说,需要注意的是,FORTRAN 对于程序语言格式上的要求。例如,对于

FORTRAN 语言,前六个字符必须空出来,等等。检查语法最好的方法就是在 FORTRAN 编

译器上进行编译。

SUBROUTINE VUMAT(

C Read only -

1 nblock, ndir, nshr, nstatev, nfieldv, nprops, lanneal,

2 stepTime, totalTime, dt, cmname, coordMp, charLength,

3 props, density, strainInc, relSpinInc,

4 tempOld, stretchOld, defgradOld, fieldOld,

3 stressOld, stateOld, enerInternOld, enerInelasOld,

6 tempNew, stretchNew, defgradNew, fieldNew,

C Write only -

5 stressNew, stateNew, enerInternNew, enerInelasNew )

C

include 'vaba_param.inc'

C

C J2 Mises Plasticity with kinematic hardening for plane

C strain case.

C Elastic predictor, radial corrector algorithm.

C

C The state variables are stored as:

C STATE(*,1) = back stress component 11

C STATE(*,2) = back stress component 22

C STATE(*,3) = back stress component 33

C STATE(*,4) = back stress component 12

4

�

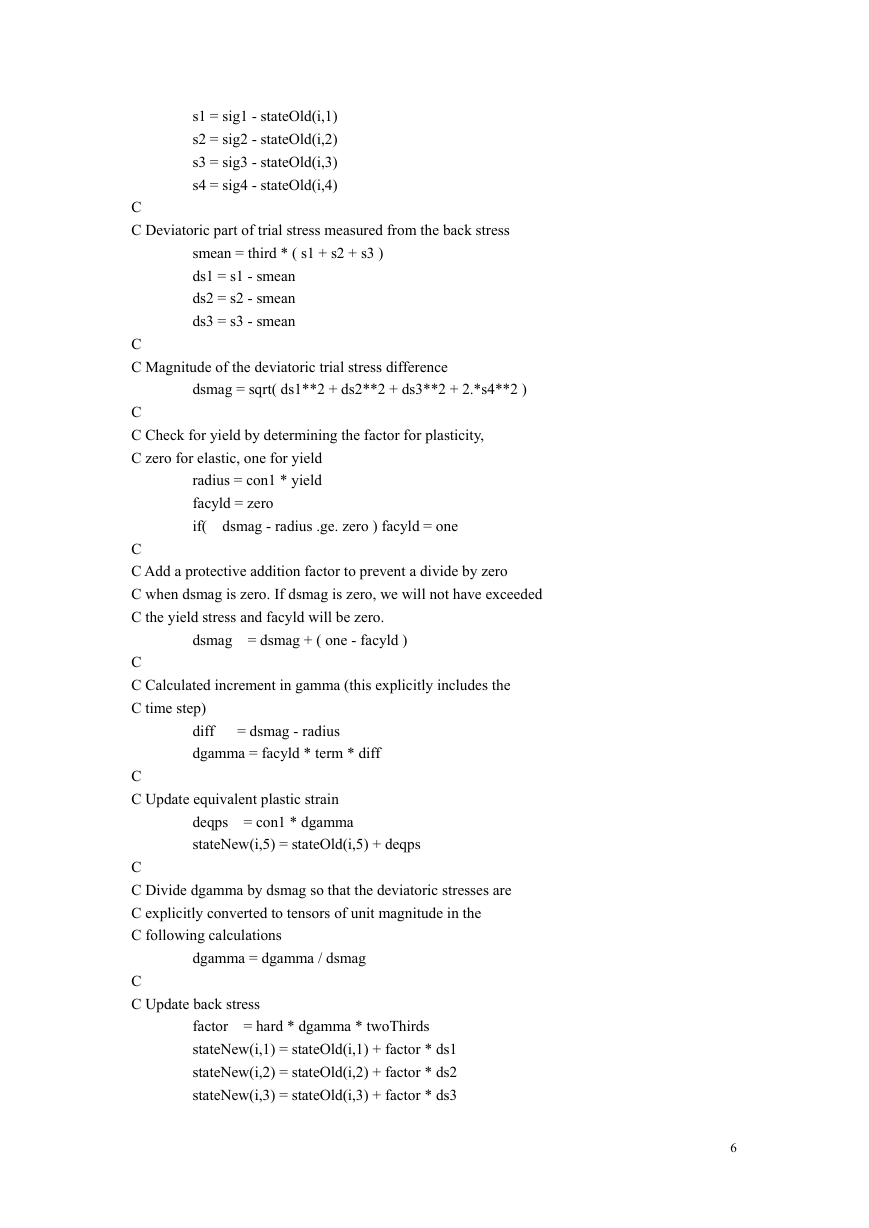

C STATE(*,5) = equivalent plastic strain

C

C

C All arrays dimensioned by (*) are not used in this algorithm

dimension props(nprops), density(nblock),

1 coordMp(nblock,*),

2 charLength(*), strainInc(nblock,ndir+nshr),

3 relSpinInc(*), tempOld(*),

4 stretchOld(*), defgradOld(*),

5 fieldOld(*), stressOld(nblock,ndir+nshr),

6 stateOld(nblock,nstatev), enerInternOld(nblock),

7 enerInelasOld(nblock), tempNew(*),

8 stretchNew(*), defgradNew(*), fieldNew(*),

9 stressNew(nblock,ndir+nshr), stateNew(nblock,nstatev),

1 enerInternNew(nblock), enerInelasNew(nblock)

C

character*80 cmname

C

parameter( zero = 0., one = 1., two = 2., three = 3.,

1 third = one/three, half = .5, twoThirds = two/three,

2 threeHalfs = 1.5 )

C

e = props(1)

xnu = props(2)

yield = props(3)

hard = props(4)

C

twomu = e / ( one + xnu )

thremu = threeHalfs * twomu

sixmu = three * twomu

alamda = twomu * ( e - twomu ) / ( sixmu - two * e )

term = one / ( twomu * ( one + hard/thremu ) )

con1 = sqrt( twoThirds )

C

do 100 i = 1,nblock

C

C Trial stress

trace = strainInc(i,1) + strainInc(i,2) + strainInc(i,3)

sig1 = stressOld(i,1) + alamda*trace + twomu*strainInc(i,1)

sig2 = stressOld(i,2) + alamda*trace + twomu*strainInc(i,2)

sig3 = stressOld(i,3) + alamda*trace + twomu*strainInc(i,3)

sig4 = stressOld(i,4) + twomu*strainInc(i,4)

C

C Trial stress measured from the back stress

5

�

s1 = sig1 - stateOld(i,1)

s2 = sig2 - stateOld(i,2)

s3 = sig3 - stateOld(i,3)

s4 = sig4 - stateOld(i,4)

C

C Deviatoric part of trial stress measured from the back stress

smean = third * ( s1 + s2 + s3 )

ds1 = s1 - smean

ds2 = s2 - smean

ds3 = s3 - smean

C

C Magnitude of the deviatoric trial stress difference

dsmag = sqrt( ds1**2 + ds2**2 + ds3**2 + 2.*s4**2 )

C

C Check for yield by determining the factor for plasticity,

C zero for elastic, one for yield

radius = con1 * yield

facyld = zero

if( dsmag - radius .ge. zero ) facyld = one

C

C Add a protective addition factor to prevent a divide by zero

C when dsmag is zero. If dsmag is zero, we will not have exceeded

C the yield stress and facyld will be zero.

dsmag = dsmag + ( one - facyld )

C

C Calculated increment in gamma (this explicitly includes the

C time step)

diff = dsmag - radius

dgamma = facyld * term * diff

C

C Update equivalent plastic strain

deqps = con1 * dgamma

stateNew(i,5) = stateOld(i,5) + deqps

C

C Divide dgamma by dsmag so that the deviatoric stresses are

C explicitly converted to tensors of unit magnitude in the

C following calculations

dgamma = dgamma / dsmag

C

C Update back stress

factor = hard * dgamma * twoThirds

stateNew(i,1) = stateOld(i,1) + factor * ds1

stateNew(i,2) = stateOld(i,2) + factor * ds2

stateNew(i,3) = stateOld(i,3) + factor * ds3

6

�

stateNew(i,4) = stateOld(i,4) + factor * s4

C

C Update the stress

factor = twomu * dgamma

stressNew(i,1) = sig1 - factor * ds1

stressNew(i,2) = sig2 - factor * ds2

stressNew(i,3) = sig3 - factor * ds3

stressNew(i,4) = sig4 - factor * s4

C

C Update the specific internal energy -

stressPower = half * (

1 ( stressOld(i,1)+stressNew(i,1) )*strainInc(i,1)

1 + ( stressOld(i,2)+stressNew(i,2) )*strainInc(i,2)

1 + ( stressOld(i,3)+stressNew(i,3) )*strainInc(i,3)

1 + two*( stressOld(i,4)+stressNew(i,4) )*strainInc(i,4) )

C

C enerInternNew(i) = enerInternOld(i)

C 1 + stressPower / density(i)

C

C Update the dissipated inelastic specific energy -

plasticWorkInc = dgamma * half * (

1 ( stressOld(i,1)+stressNew(i,1) )*ds1

1 + ( stressOld(i,2)+stressNew(i,2) )*ds2

1 + ( stressOld(i,3)+stressNew(i,3) )*ds3

1 + two*( stressOld(i,4)+stressNew(i,4) )*s4 )

C enerInelasNew(i) = enerInelasOld(i)

C 1 + plasticWorkInc / density(i)

100 continue

C

return

end

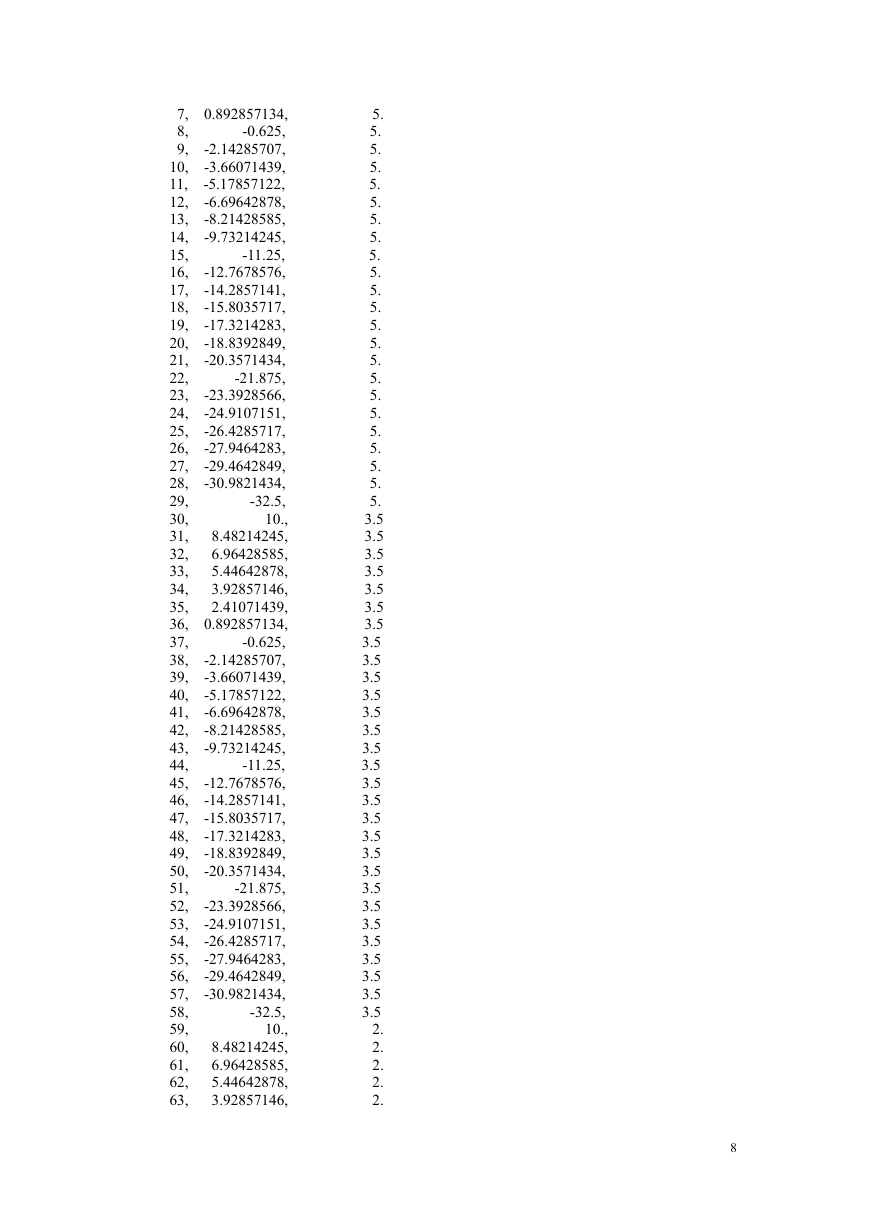

6 INP 输入文件

*Heading

** Job name: Job-1 Model name: Model-1

** Generated by: Abaqus/CAE 6.10-1

*Preprint, echo=NO, model=NO, history=NO, contact=NO

**

** PARTS

**

*Part, name=Part-1

*Node

1, 10., 5.

2, 8.48214245, 5.

3, 6.96428585, 5.

4, 5.44642878, 5.

5, 3.92857146, 5.

6, 2.41071439, 5.

7

�

7, 0.892857134, 5.

8, -0.625, 5.

9, -2.14285707, 5.

10, -3.66071439, 5.

11, -5.17857122, 5.

12, -6.69642878, 5.

13, -8.21428585, 5.

14, -9.73214245, 5.

15, -11.25, 5.

16, -12.7678576, 5.

17, -14.2857141, 5.

18, -15.8035717, 5.

19, -17.3214283, 5.

20, -18.8392849, 5.

21, -20.3571434, 5.

22, -21.875, 5.

23, -23.3928566, 5.

24, -24.9107151, 5.

25, -26.4285717, 5.

26, -27.9464283, 5.

27, -29.4642849, 5.

28, -30.9821434, 5.

29, -32.5, 5.

30, 10., 3.5

31, 8.48214245, 3.5

32, 6.96428585, 3.5

33, 5.44642878, 3.5

34, 3.92857146, 3.5

35, 2.41071439, 3.5

36, 0.892857134, 3.5

37, -0.625, 3.5

38, -2.14285707, 3.5

39, -3.66071439, 3.5

40, -5.17857122, 3.5

41, -6.69642878, 3.5

42, -8.21428585, 3.5

43, -9.73214245, 3.5

44, -11.25, 3.5

45, -12.7678576, 3.5

46, -14.2857141, 3.5

47, -15.8035717, 3.5

48, -17.3214283, 3.5

49, -18.8392849, 3.5

50, -20.3571434, 3.5

51, -21.875, 3.5

52, -23.3928566, 3.5

53, -24.9107151, 3.5

54, -26.4285717, 3.5

55, -27.9464283, 3.5

56, -29.4642849, 3.5

57, -30.9821434, 3.5

58, -32.5, 3.5

59, 10., 2.

60, 8.48214245, 2.

61, 6.96428585, 2.

62, 5.44642878, 2.

63, 3.92857146, 2.

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc