CAPL Callback Interface in CANoe

Version 1.3

2017-04-11

Application Note AN-IND-1-012

Author

Vector Informatik GmbH

Restrictions Public Document

Abstract

Information and explanation on the CAPL Callback Interface (CCI) for diagnostics in

CANoe, including examples and references

Table of Contents

1.0 Overview ........................................................................................................................................ 2

2.0 Background ................................................................................................................................... 2

2.1 What is the CCI? .................................................................................................................. 2

2.2 Why use the CCI? ................................................................................................................ 2

2.3

Alternatives to using the CCI ............................................................................................... 2

2.4 What can you do with the CCI? ........................................................................................... 3

3.0 Basic concept of the CAPL callback interface for diagnostics ................................................ 3

CAPL functions called by the CCI ........................................................................................ 3

3.1

CCI functions called by CAPL .............................................................................................. 3

3.2

Additional configuration steps necessary ............................................................................ 4

3.3

Configuration parameters provided by CANoe .................................................................... 4

3.4

3.5 Walkthrough: Basic CCI for ISO TP on CAN ....................................................................... 5

3.5.1 Tester side ........................................................................................................................... 5

3.5.2 ECU simulation side ............................................................................................................. 6

4.0 Concrete implementations for several bus types and protocols ............................................. 6

Example how to use the CCI include files in an ECU simulation ......................................... 6

Example how to use the CCI include files in a Test Module ................................................ 9

Additional hints when using the LIN CCI ...........................................................................10

Additional hints when using VW TP 2.0 on CAN ...............................................................10

5.0 Additional functionality (independent of bus type) .................................................................11

Session management ........................................................................................................11

Simulate special ECU response timing behavior ...............................................................11

6.0 Advanced feature: Fault injection .............................................................................................12

Background ........................................................................................................................12

6.1

Fault injection without the need to use the CCI .................................................................12

6.2

Example using OSEK_TP.DLL ..........................................................................................13

6.3

6.3.1 Basic concept and more information..................................................................................13

6.3.2 Dropping a TP frame ..........................................................................................................13

7.0 Additional Resources .................................................................................................................14

8.0 Contacts .......................................................................................................................................14

4.1

4.2

4.3

4.4

5.1

5.2

�

CAPL Callback Interface in CANoe

1.0 Overview

This document explains the background and usage of the “CAPL callback interface for diagnostics”

(CCI, first introduced in CANoe 5.1), for CANoe 8.5 and later versions. It will assist a developer in

deciding whether using the CCI is the right choice, and help implement it in that case.

2.0 Background

This section gives high-level answers the following questions:

> What is the CCI?

> Why use it?

> What are the alternatives?

> What can you do with it?

2.1 What is the CCI?

The CCI is a completely generic way to connect the diagnostics layer of a CAPL program with the

transport layer: A separate set of CAPL functions is used to forward diagnostics data to the network,

receive data from the network and process it as diagnostics data.

Once a diagnostics description database is configured to be used either by a tester node or a

simulation node, the CCI for diagnostics becomes available in the respective CAPL programs.

Diagnostics descriptions can be either Basic Diagnostic Descriptions, CANdela “.cdd” files, ODX

databases - typically provided as “.pdx” archives – or “.mdx”-Files.

The CCI has a very small interface, which requires the implementation of only a few CAPL functions

for ECU simulations and diagnostics testers.

2.2 Why use the CCI?

CANoe provides standard channels for diagnostic communication with ECUs as a diagnostics tester

(since CANoe 5.2) and ECU simulation (since CANoe 10.0). These built-in channels are supported on

> CAN (ISO TP/VW TP2.0)

> LIN

> K-Line

> FlexRay (several TP standards) and

> DoIP/HSFZ.

They handle the transfer and reception of diagnostic requests and responses on the network. In the

CAPL code the developer can completely focus on the application itself e.g. define a request, modify

its symbolical parameters as defined in the diagnostic database and send the request.

In some use cases though using the CCI is recommended:

> Advanced simulation of a diagnostics ECU in a CAPL program (use case “test the tester”).

> Using a transport protocol (version) that is not yet supported directly in CANoe.

> Changing protocol parameters and behavior in a way not supported by standard CANoe means.

> Perform violations of the diagnostics protocol in order to implement special tests of the diagnostics

functionality of an ECU.

2.3 Alternatives to using the CCI

For most use cases, it is not necessary to implement the CCI in a diagnostics tester or ECU

simulation.

Note

If the callback functions are not present in the tester CAPL code, CANoe will automatically

use the built-in diagnostics communication channel.

Copyright © 2017 - Vector Informatik GmbH

Contact Information: www.vector.com or +49-711-80 670-0

2

�

CAPL Callback Interface in CANoe

In some cases it is possible to use a gateway or proxy on a supported bus technology (e.g. CAN) with

a supported transport protocol (e.g. ISO TP). All CANoe features are available in this case, only the

gateway or proxy has to forward the data to and from the ECU.

You may want to read the application note AN-IND-1-004 “Diagnostics via Gateway in CANoe”, which

lists different concepts of implementing such gateway nodes. This use case of CANoe is also of

special interest for users who need a diagnostic gateway e.g. in early development stages where the

gateway hardware to access the ECU is not readily available to developers or testers.

Finally in rare cases it may be more efficient to implement the communication on transport protocol

level directly, especially if no (standard) diagnostics description can be used.

2.4 What can you do with the CCI?

The following is a list of tasks possible once the CCI is implemented:

> Change CAN identifiers to test if the ECU only responds to the IDs it was assigned to.

> Delay response messages from an ECU simulation for an arbitrary amount of time to test the

timeout implementation in a tester.

> Delay transport protocol messages individually to check the transport protocol implementation in

the ECU for correct handling of timeouts.

> Change the content of individual transport protocol messages, like padding byte values.

> Make the tester or ECU simulation send transport protocol messages which do not conform to the

specification and should cause some error reaction in the receiver.

> Any use-case specific non-standard handling that needs direct access to the transport protocol

layer, and non-standard changes to the diagnostics protocol.

3.0 Basic concept of the CAPL callback interface for diagnostics

The CCI works as glue between the diagnostics and transport protocol layers: Whenever a diagnostics

object (diagRequest or diagResponse) is sent by the CAPL program, its data is forwarded to the

transport protocol, which transfers it on the bus. In addition there are CAPL functions that control the

setup and status of the communication connections, and functions that provide information to the CCI.

3.1 CAPL functions called by the CCI

The following CAPL functions are called by the CCI when specific events occur. The functions are

denoted by a underscore “_” at the start of the function name. The CAPL program has to perform

actions that depend on the concrete transport protocol or use case.

> void _Diag_SetChannelParameters()

The CAPL program is instructed to configure a communications channel to the peer (in a tester

node to the ECU, and vice versa). The transport protocol parameters are typically retrieved from

CANoe or hard-coded values might be used as well.

In a tester, this function is called every time DiagSetTarget is called, in an ECU simulation it is

called during measurement start.

> void _Diag_DataRequest (BYTE data[], DWORD count, long furtherSegments);

The provided data has to be sent to the peer. If the argument furtherSegments is non-zero, the

data is segmented and may be sent in a special way. Please refer to section 4.4 for details.

> void _Diag_SetupChannelReq();

Called only in a tester before the first request is sent to indicate that a communications channel to

the ECU should be established. Connection-oriented protocols need to perform a “channel setup”

step, while for most connection-less protocols (like ISO/OSEK TP), nothing has to be done. In

latter case it suffices to call Diag_SetupChannelCon() immediately.

> void _Diag_SendFunctional();

Called only in a tester, when a functional request is sent (by the CAPL function

DiagSendFunctional).

3.2 CCI functions called by CAPL

The following functions are implemented by CANoe and can be called from the CAPL code. Note the

prefix Diag_ differentiating the functions from other diagnostics related CAPL functions.

Copyright © 2017 - Vector Informatik GmbH

Contact Information: www.vector.com or +49-711-80 670-0

3

�

CAPL Callback Interface in CANoe

> long Diag_ClosedChannelInd ();

This function communicates to CANoe that the communication channel is no longer available, e.g.

the tester closed the channel or a non-reparable error occurred. The CAPL program has to call

Diag_SetupChannelCon before further data can be sent.

> void Diag_DataCon (long count);

Tells the diagnostic layer that the given number of bytes of data were transmitted successfully.

> void Diag_DataInd (byte rxBuffer[], long count, long sender);

The given amount of data was received from the peer.

> void Diag_ErrorInd( long error);

Forwards errors to the diagnostics layer, e.g. to stop a function waiting for a diagnostics response.

> void Diag_FirstFrameInd( long source, long dest, long totalLength);

The peer has started to send data of given total length. In a tester node the timer waiting for a

reaction from the ECU can be stopped. In an ECU simulation the session timer can be stopped.

> long Diag_SetDataSegmentation( long mode, DWORD maxSegmentSize,

DWORD segmentSeparationTime);

Configure the handling of diagnostics data segmentation. Almost no protocol uses segmentation;

therefore it is deactivated per default. Please refer to section 4.4 for details.

> long Diag_SetupChannelCon();

The tester has established a connection to the ECU successfully, or it is not necessary to open a

connection at all. This function is not needed in an ECU simulation.

3.3 Additional configuration steps necessary

The following configuration steps have to be performed to allow the CCI to take configuration

parameters from the settings of a specific diagnostics description.

>

“Configuration | Diagnostics/ISO TP…”: Configure the diagnostics description that should be used

in the tester or simulation node. The setting for “Usage of the diagnostics description” must not be

“Interpretation only”. For all other settings, the CCI is available; for an ECU simulation the

simulation node has to be assigned here. Alternatively, an ECU simulation node can call the CAPL

function DiagInitEcuSimulation in its 'on prestart' handler.

> Simulation node “Configuration…” dialog: On page “Modules”, the respective transport protocol

nodelayer DLL has to be configured. It is also possible to specify this DLL in a DBC file of a

network via the attribute NodeLayerModules e.g. entering osek_tp.dll there.

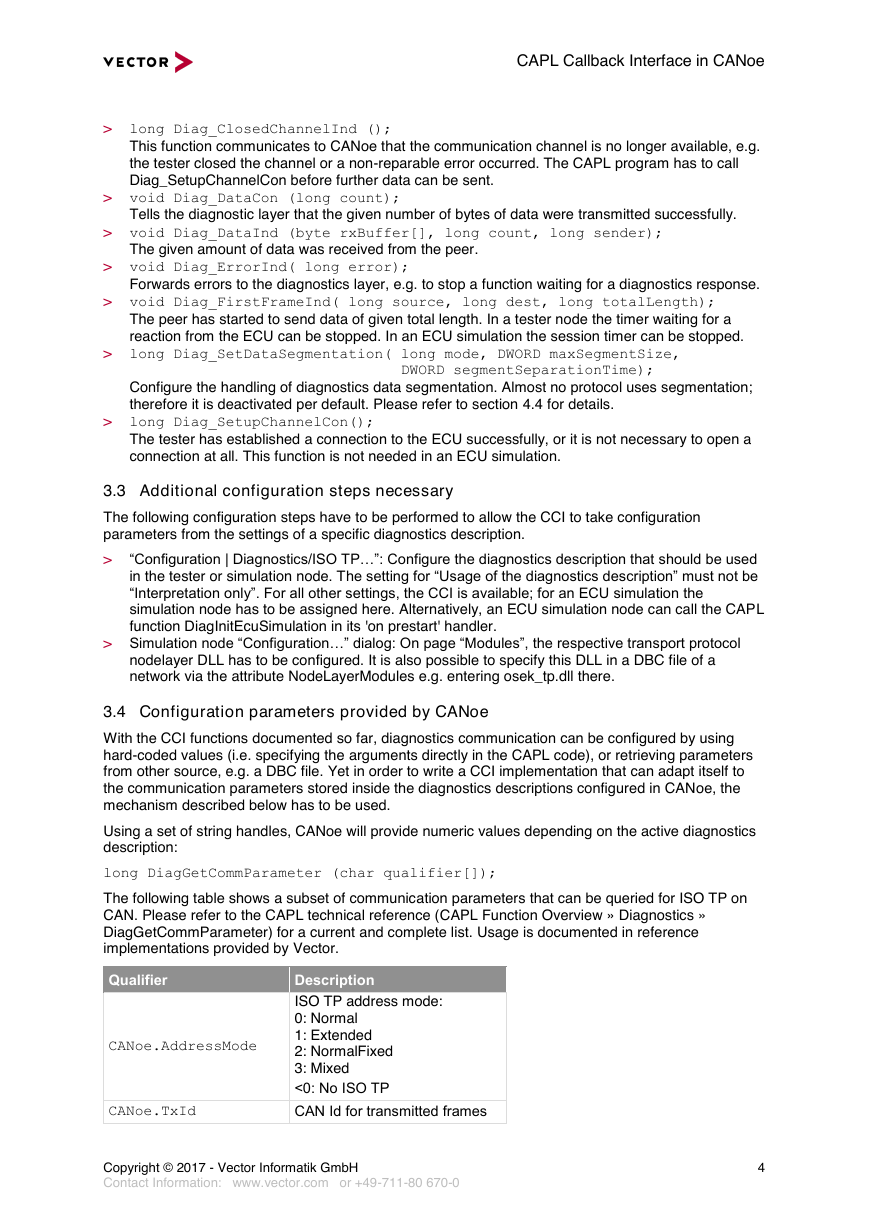

3.4 Configuration parameters provided by CANoe

With the CCI functions documented so far, diagnostics communication can be configured by using

hard-coded values (i.e. specifying the arguments directly in the CAPL code), or retrieving parameters

from other source, e.g. a DBC file. Yet in order to write a CCI implementation that can adapt itself to

the communication parameters stored inside the diagnostics descriptions configured in CANoe, the

mechanism described below has to be used.

Using a set of string handles, CANoe will provide numeric values depending on the active diagnostics

description:

long DiagGetCommParameter (char qualifier[]);

The following table shows a subset of communication parameters that can be queried for ISO TP on

CAN. Please refer to the CAPL technical reference (CAPL Function Overview » Diagnostics »

DiagGetCommParameter) for a current and complete list. Usage is documented in reference

implementations provided by Vector.

Qualifier

Description

CANoe.AddressMode

ISO TP address mode:

0: Normal

1: Extended

2: NormalFixed

3: Mixed

<0: No ISO TP

CANoe.TxId

CAN Id for transmitted frames

Copyright © 2017 - Vector Informatik GmbH

Contact Information: www.vector.com or +49-711-80 670-0

4

�

CAPL Callback Interface in CANoe

Qualifier

CANoe.RxId

Description

CAN Id for received frames

CANoe.BaseAddress

TP base address

CANoe.EcuAddr

CANoe.TgtAddr

Number of this node

Target node number

CANoe.AddrExt

Address extension byte

CANoe.TxPrio

Frame transmit priority

Table 1 - Communication parameters for ISO TP connections on CAN

3.5 Walkthrough: Basic CCI for ISO TP on CAN

In this section the workflow of a basic CCI for ISO TP on CAN is explained in detail.

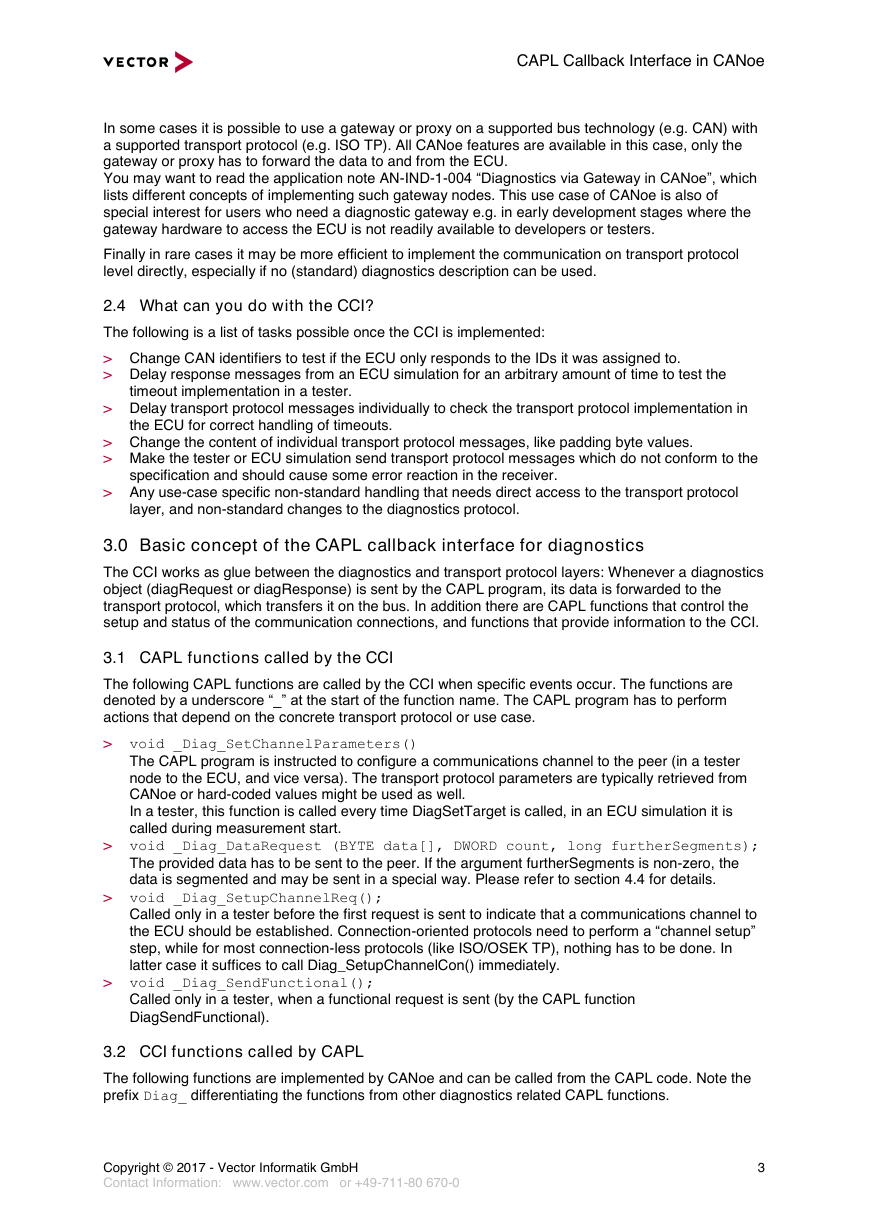

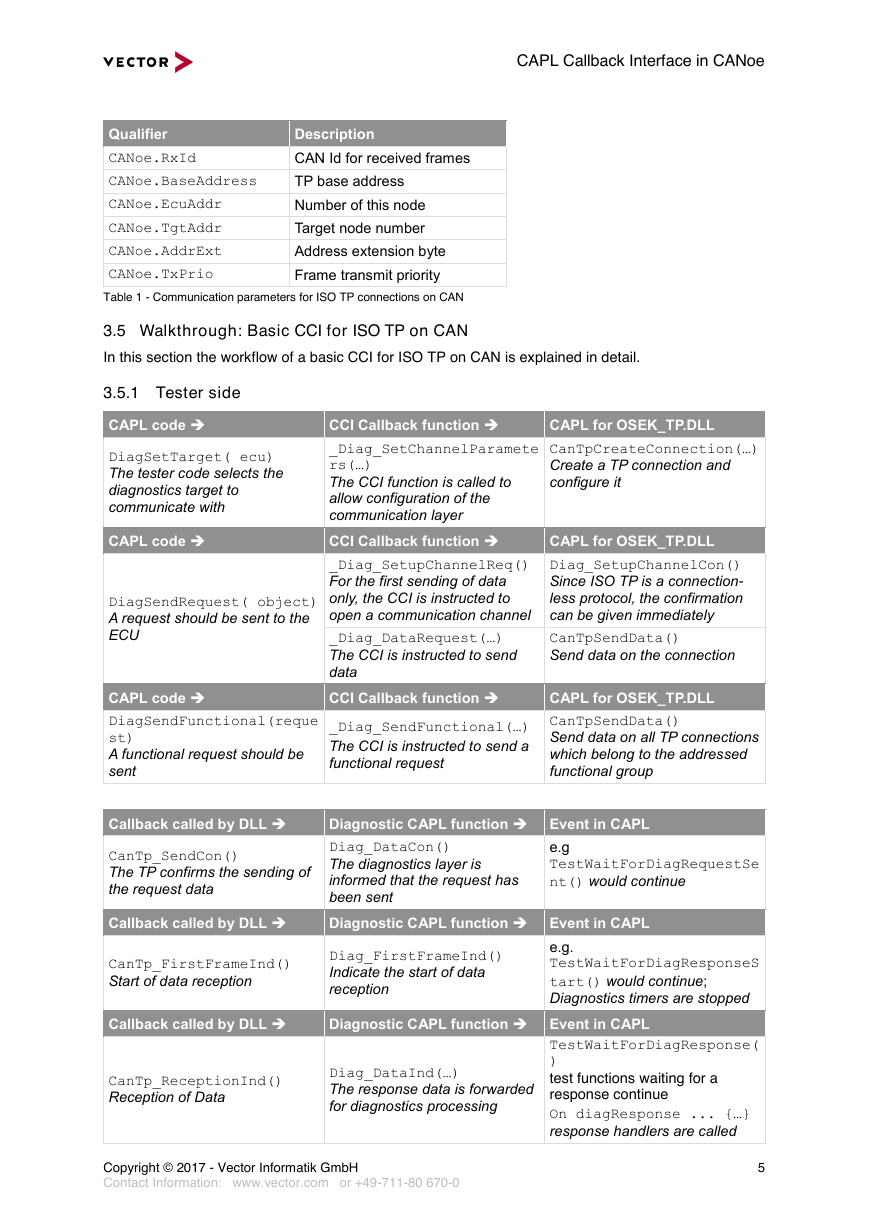

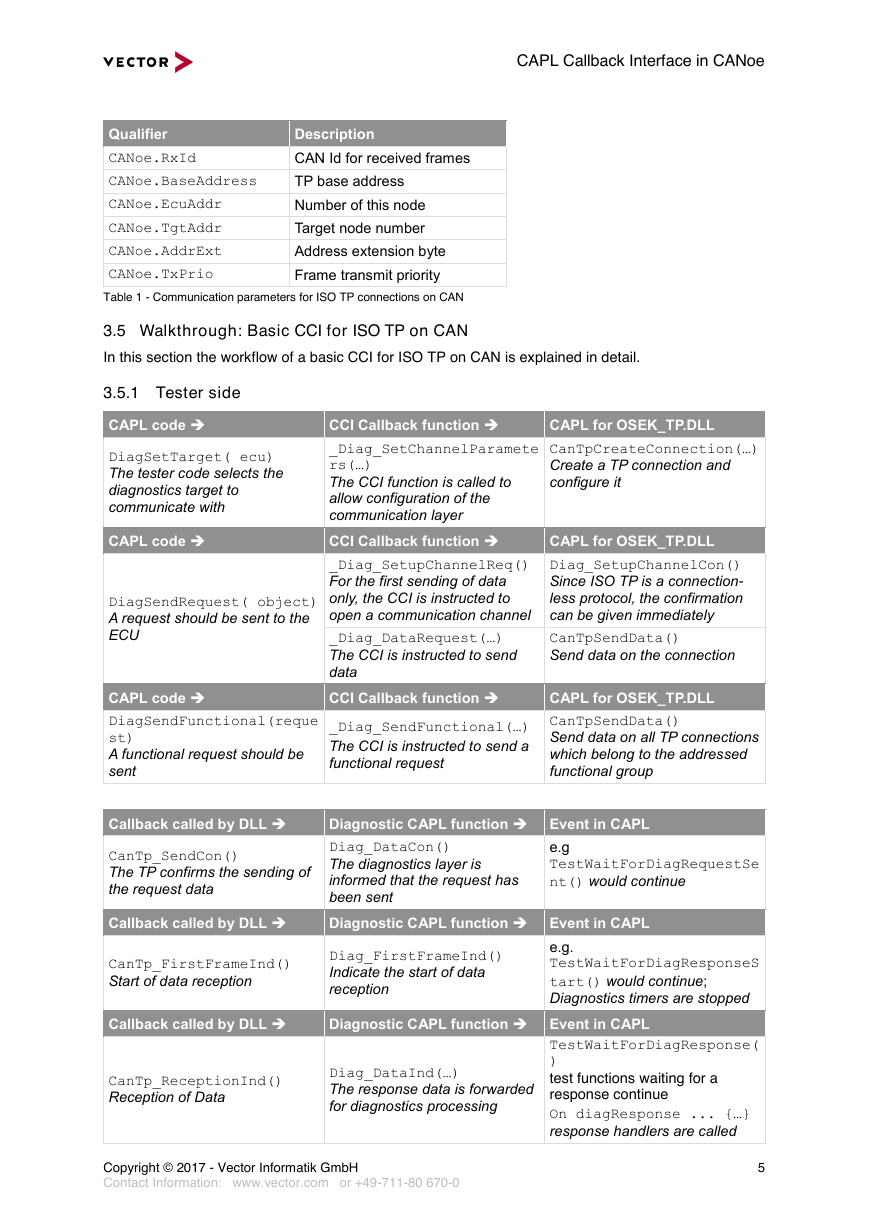

3.5.1 Tester side

CAPL code

CCI Callback function

CAPL for OSEK_TP.DLL

DiagSetTarget( ecu)

The tester code selects the

diagnostics target to

communicate with

_Diag_SetChannelParamete

rs(…)

The CCI function is called to

allow configuration of the

communication layer

CanTpCreateConnection(…)

Create a TP connection and

configure it

CAPL code

CCI Callback function

CAPL for OSEK_TP.DLL

DiagSendRequest( object)

A request should be sent to the

ECU

_Diag_SetupChannelReq()

For the first sending of data

only, the CCI is instructed to

open a communication channel

Diag_SetupChannelCon()

Since ISO TP is a connection-

less protocol, the confirmation

can be given immediately

_Diag_DataRequest(…)

The CCI is instructed to send

data

CanTpSendData()

Send data on the connection

CAPL code

CCI Callback function

CAPL for OSEK_TP.DLL

DiagSendFunctional(reque

st)

A functional request should be

sent

_Diag_SendFunctional(…)

The CCI is instructed to send a

functional request

CanTpSendData()

Send data on all TP connections

which belong to the addressed

functional group

Callback called by DLL

Diagnostic CAPL function Event in CAPL

CanTp_SendCon()

The TP confirms the sending of

the request data

Diag_DataCon()

The diagnostics layer is

informed that the request has

been sent

e.g

TestWaitForDiagRequestSe

nt() would continue

Callback called by DLL

Diagnostic CAPL function Event in CAPL

CanTp_FirstFrameInd()

Start of data reception

Diag_FirstFrameInd()

Indicate the start of data

reception

e.g.

TestWaitForDiagResponseS

tart() would continue;

Diagnostics timers are stopped

Callback called by DLL

Diagnostic CAPL function Event in CAPL

CanTp_ReceptionInd()

Reception of Data

Diag_DataInd(…)

The response data is forwarded

for diagnostics processing

TestWaitForDiagResponse(

)

test functions waiting for a

response continue

On diagResponse ... {…}

response handlers are called

Copyright © 2017 - Vector Informatik GmbH

Contact Information: www.vector.com or +49-711-80 670-0

5

�

CAPL Callback Interface in CANoe

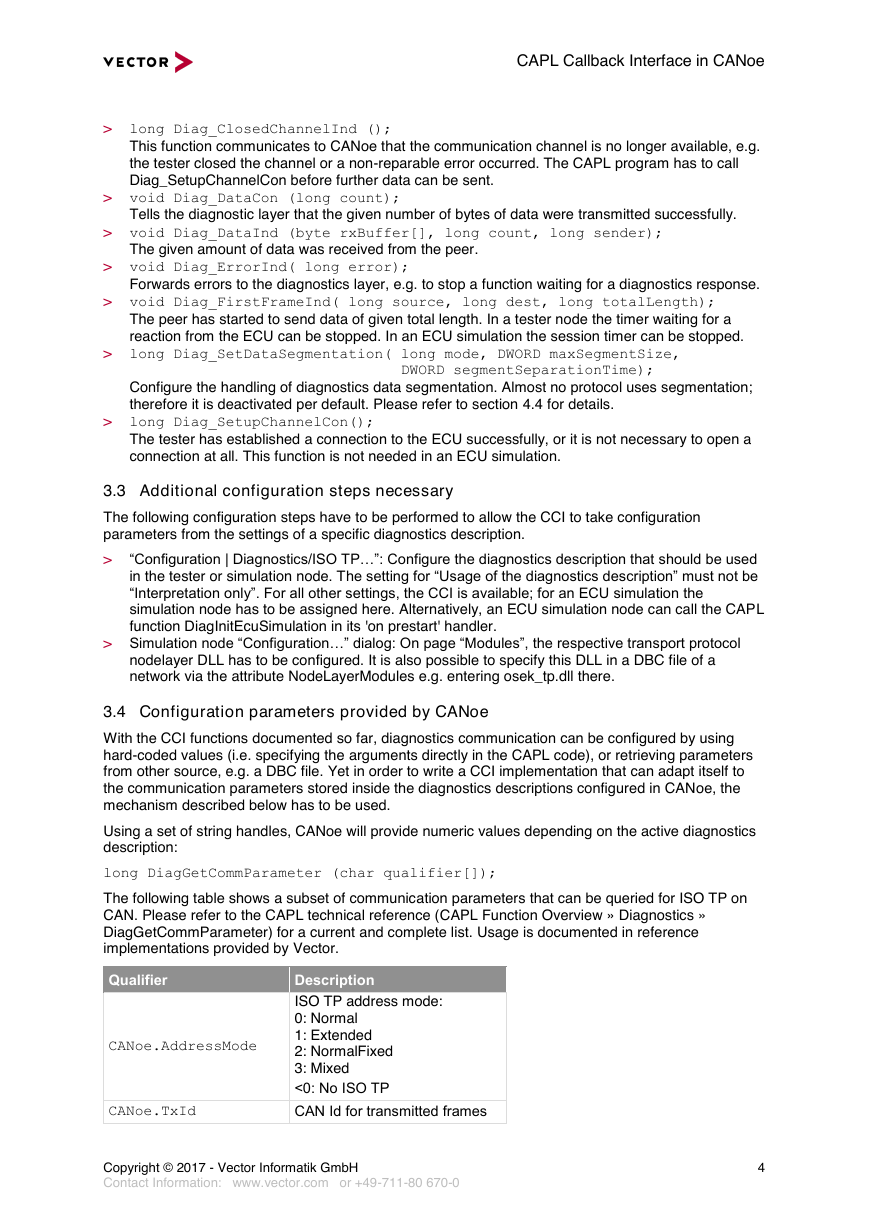

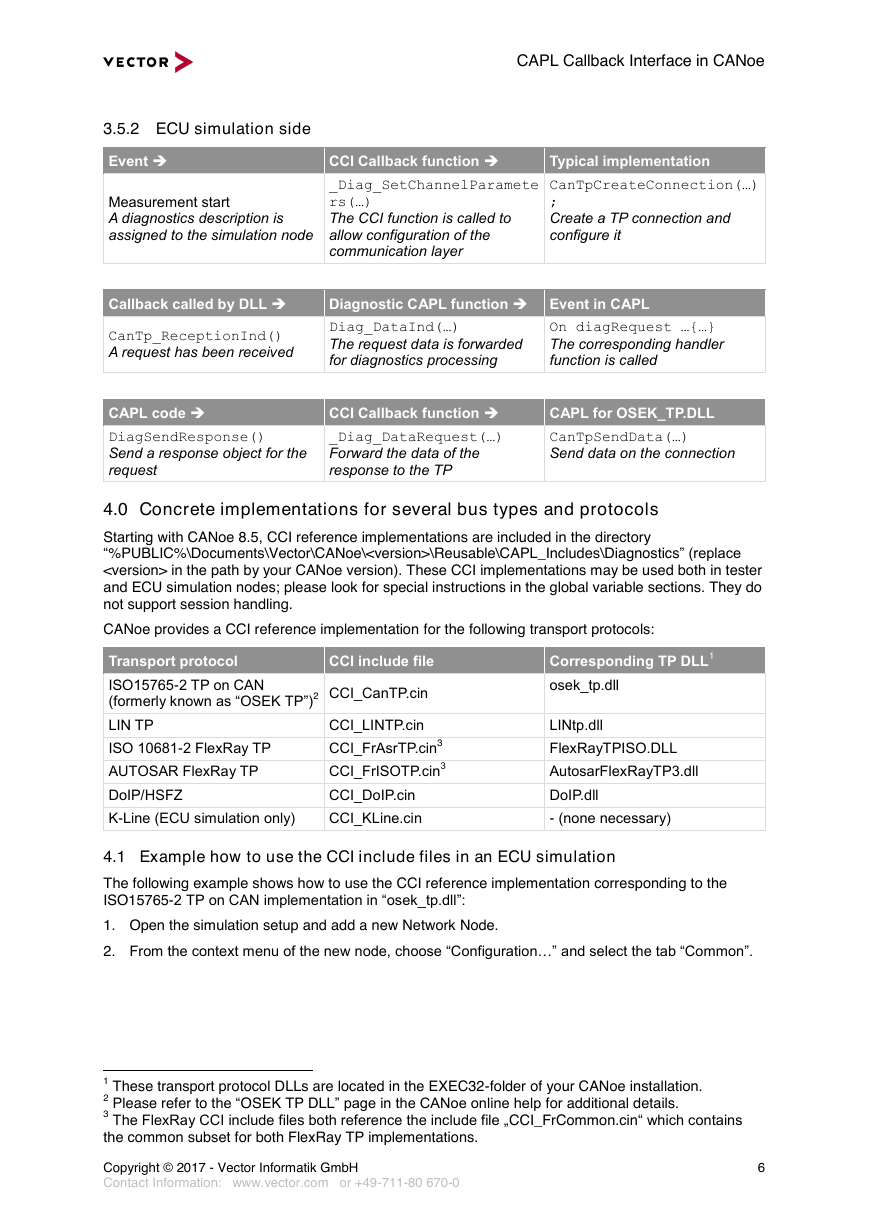

3.5.2 ECU simulation side

Event

CCI Callback function

Typical implementation

Measurement start

A diagnostics description is

assigned to the simulation node

_Diag_SetChannelParamete

rs(…)

The CCI function is called to

allow configuration of the

communication layer

CanTpCreateConnection(…)

;

Create a TP connection and

configure it

Callback called by DLL

Diagnostic CAPL function Event in CAPL

CanTp_ReceptionInd()

A request has been received

Diag_DataInd(…)

The request data is forwarded

for diagnostics processing

On diagRequest …{…}

The corresponding handler

function is called

CAPL code

CCI Callback function

CAPL for OSEK_TP.DLL

DiagSendResponse()

Send a response object for the

request

_Diag_DataRequest(…)

Forward the data of the

response to the TP

CanTpSendData(…)

Send data on the connection

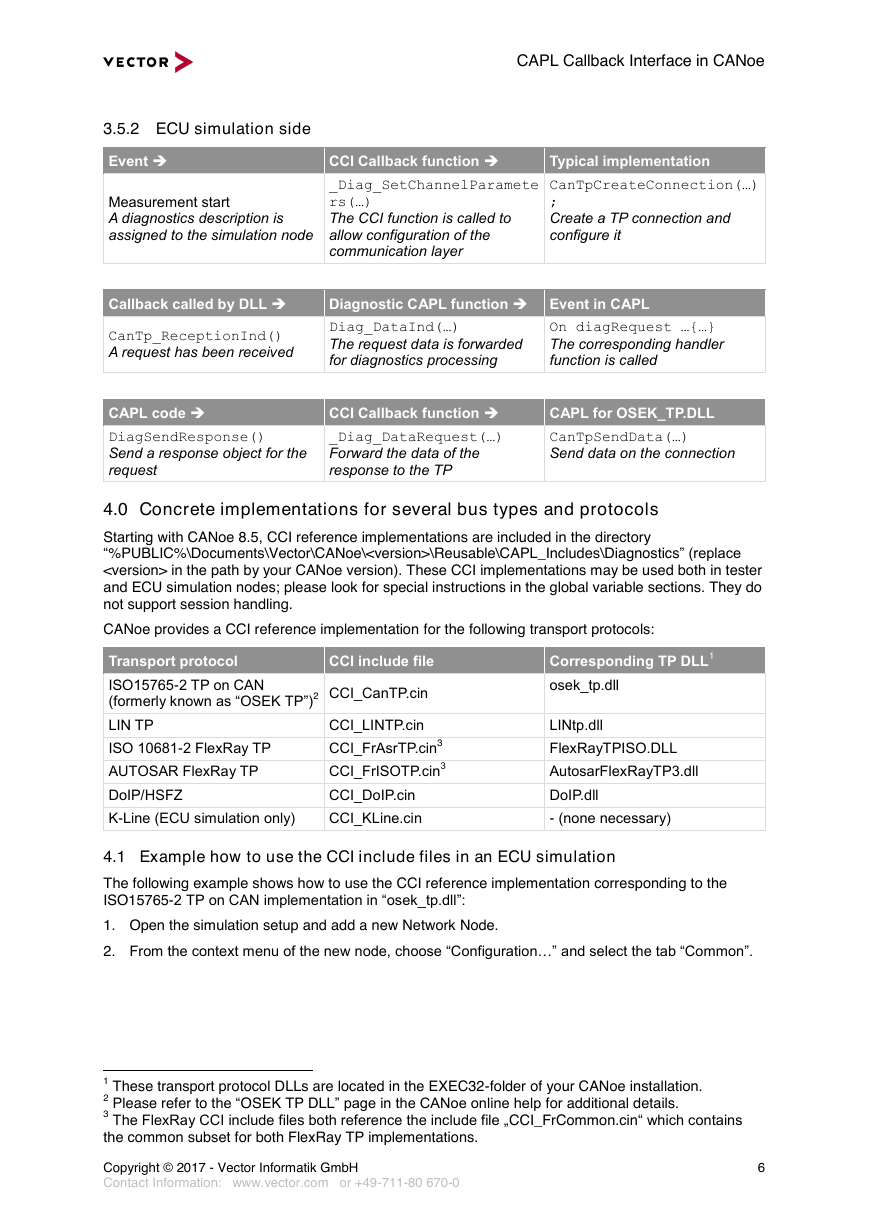

4.0 Concrete implementations for several bus types and protocols

Starting with CANoe 8.5, CCI reference implementations are included in the directory

“%PUBLIC%\Documents\Vector\CANoe\\Reusable\CAPL_Includes\Diagnostics” (replace

in the path by your CANoe version). These CCI implementations may be used both in tester

and ECU simulation nodes; please look for special instructions in the global variable sections. They do

not support session handling.

CANoe provides a CCI reference implementation for the following transport protocols:

Transport protocol

CCI include file

Corresponding TP DLL1

ISO15765-2 TP on CAN

(formerly known as “OSEK TP”)2

CCI_CanTP.cin

LIN TP

ISO 10681-2 FlexRay TP

AUTOSAR FlexRay TP

DoIP/HSFZ

CCI_LINTP.cin

CCI_FrAsrTP.cin3

CCI_FrISOTP.cin3

CCI_DoIP.cin

osek_tp.dll

LINtp.dll

FlexRayTPISO.DLL

AutosarFlexRayTP3.dll

DoIP.dll

K-Line (ECU simulation only)

CCI_KLine.cin

- (none necessary)

4.1 Example how to use the CCI include files in an ECU simulation

The following example shows how to use the CCI reference implementation corresponding to the

ISO15765-2 TP on CAN implementation in “osek_tp.dll”:

1. Open the simulation setup and add a new Network Node.

2. From the context menu of the new node, choose “Configuration…” and select the tab “Common”.

1 These transport protocol DLLs are located in the EXEC32-folder of your CANoe installation.

2 Please refer to the “OSEK TP DLL” page in the CANoe online help for additional details.

3 The FlexRay CCI include files both reference the include file „CCI_FrCommon.cin“ which contains

the common subset for both FlexRay TP implementations.

Copyright © 2017 - Vector Informatik GmbH

Contact Information: www.vector.com or +49-711-80 670-0

6

�

CAPL Callback Interface in CANoe

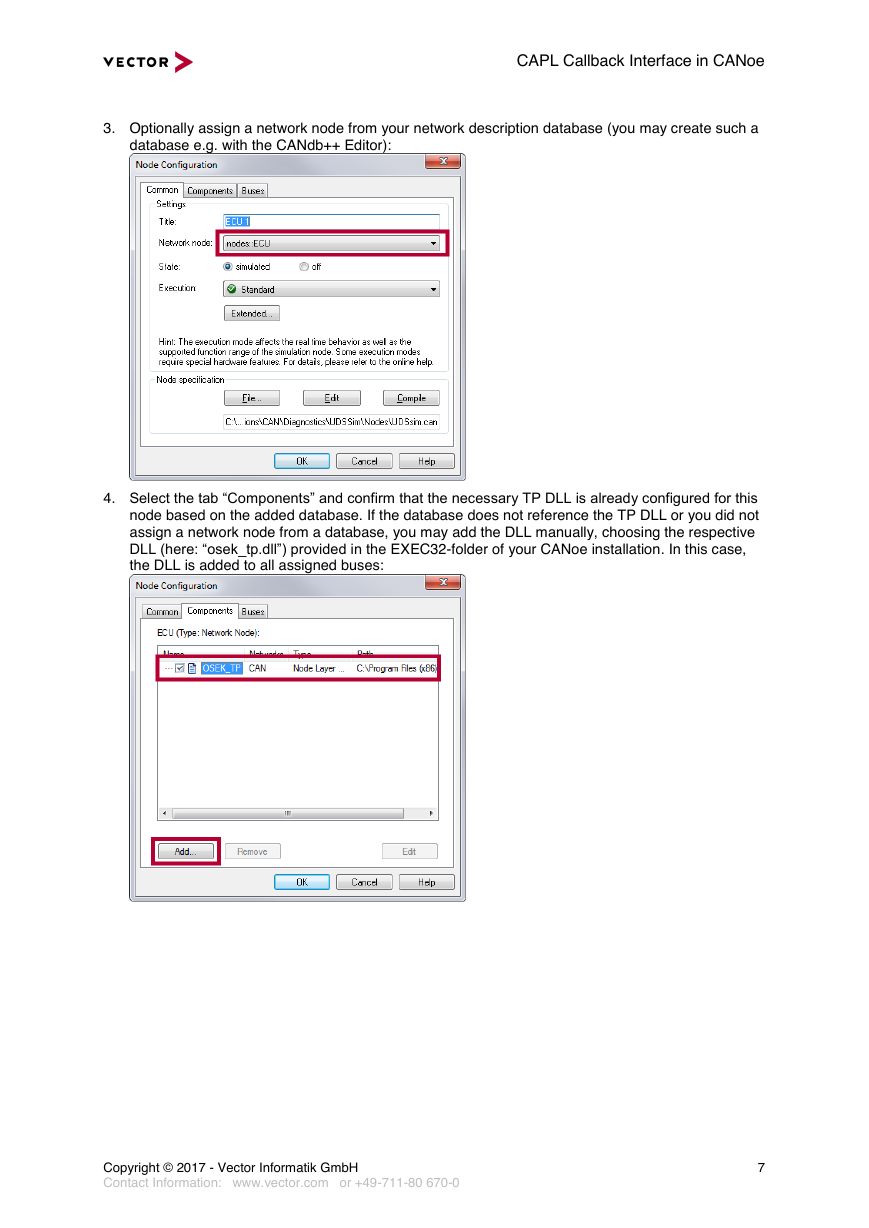

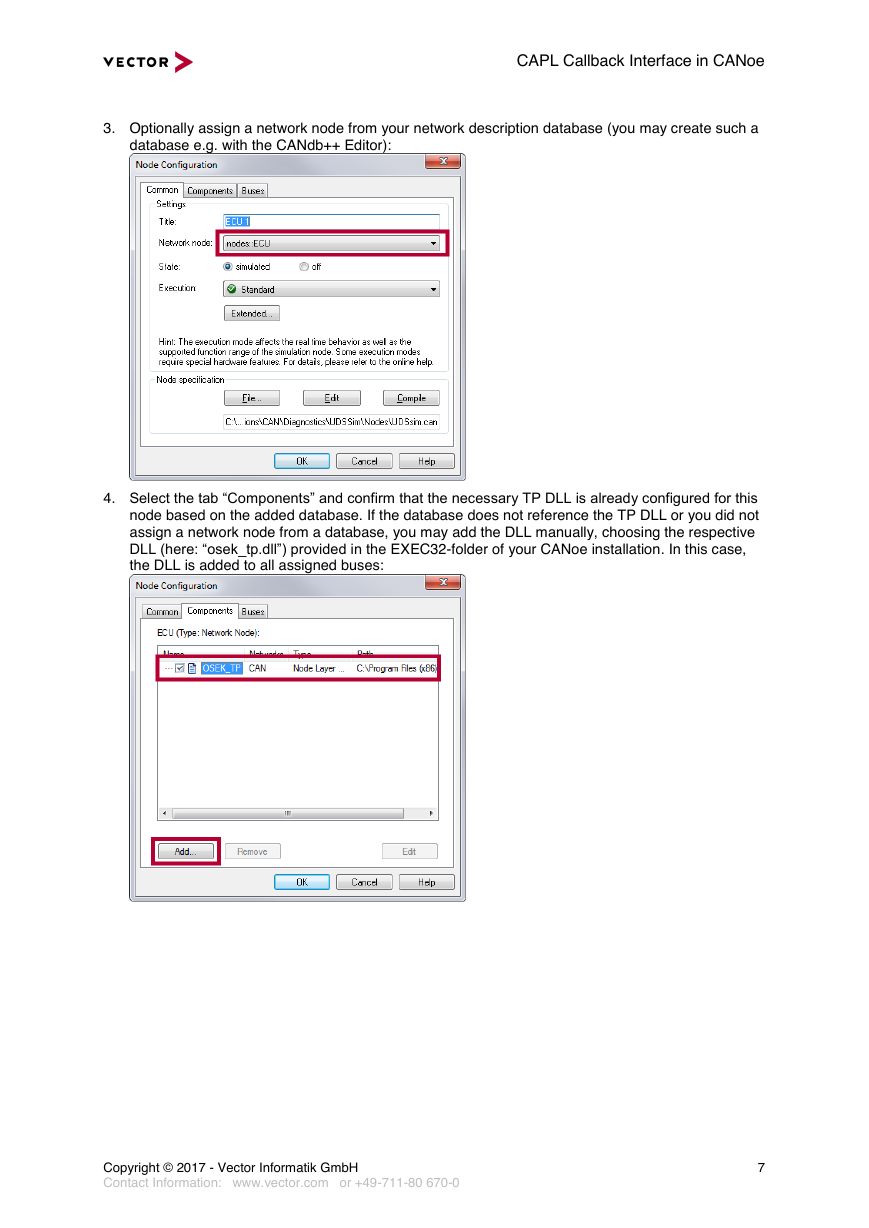

3. Optionally assign a network node from your network description database (you may create such a

database e.g. with the CANdb++ Editor):

4. Select the tab “Components” and confirm that the necessary TP DLL is already configured for this

node based on the added database. If the database does not reference the TP DLL or you did not

assign a network node from a database, you may add the DLL manually, choosing the respective

DLL (here: “osek_tp.dll”) provided in the EXEC32-folder of your CANoe installation. In this case,

the DLL is added to all assigned buses:

Copyright © 2017 - Vector Informatik GmbH

Contact Information: www.vector.com or +49-711-80 670-0

7

�

CAPL Callback Interface in CANoe

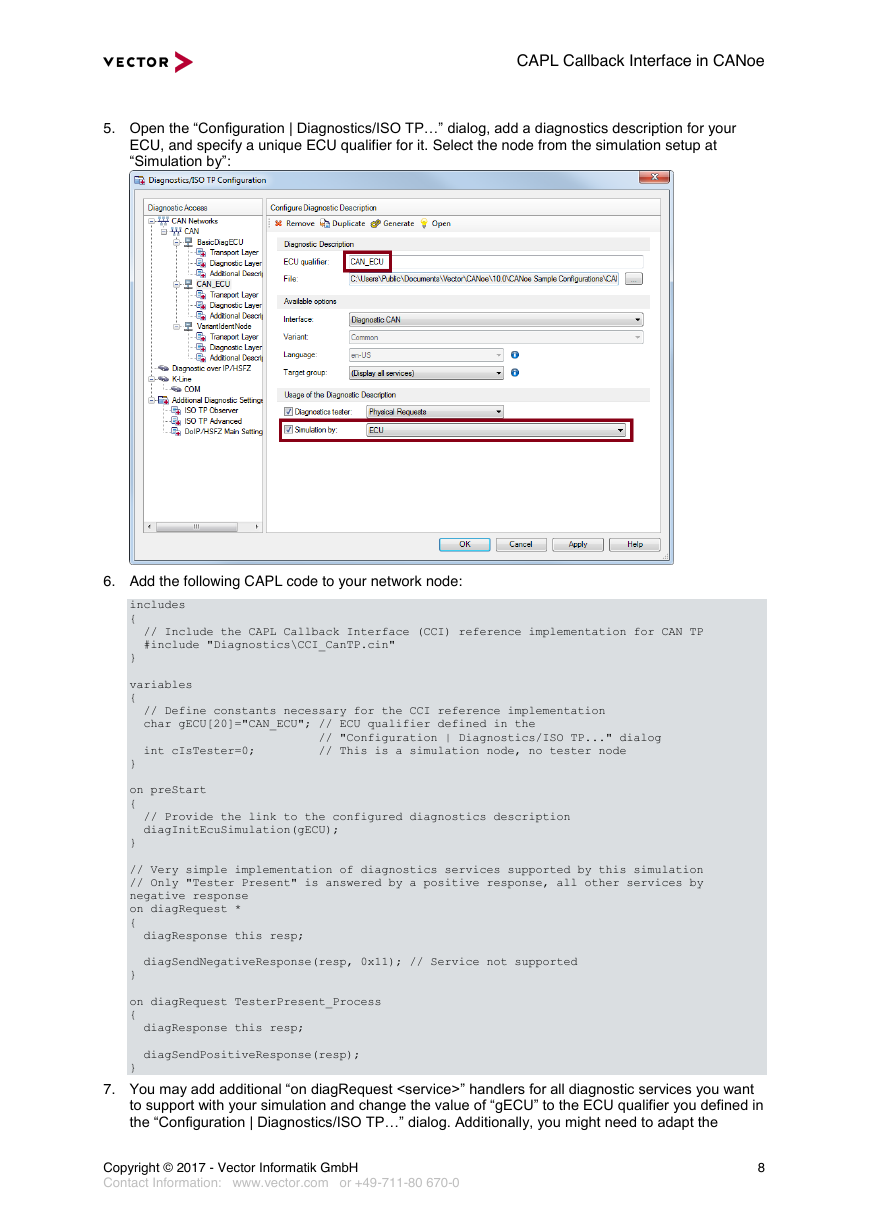

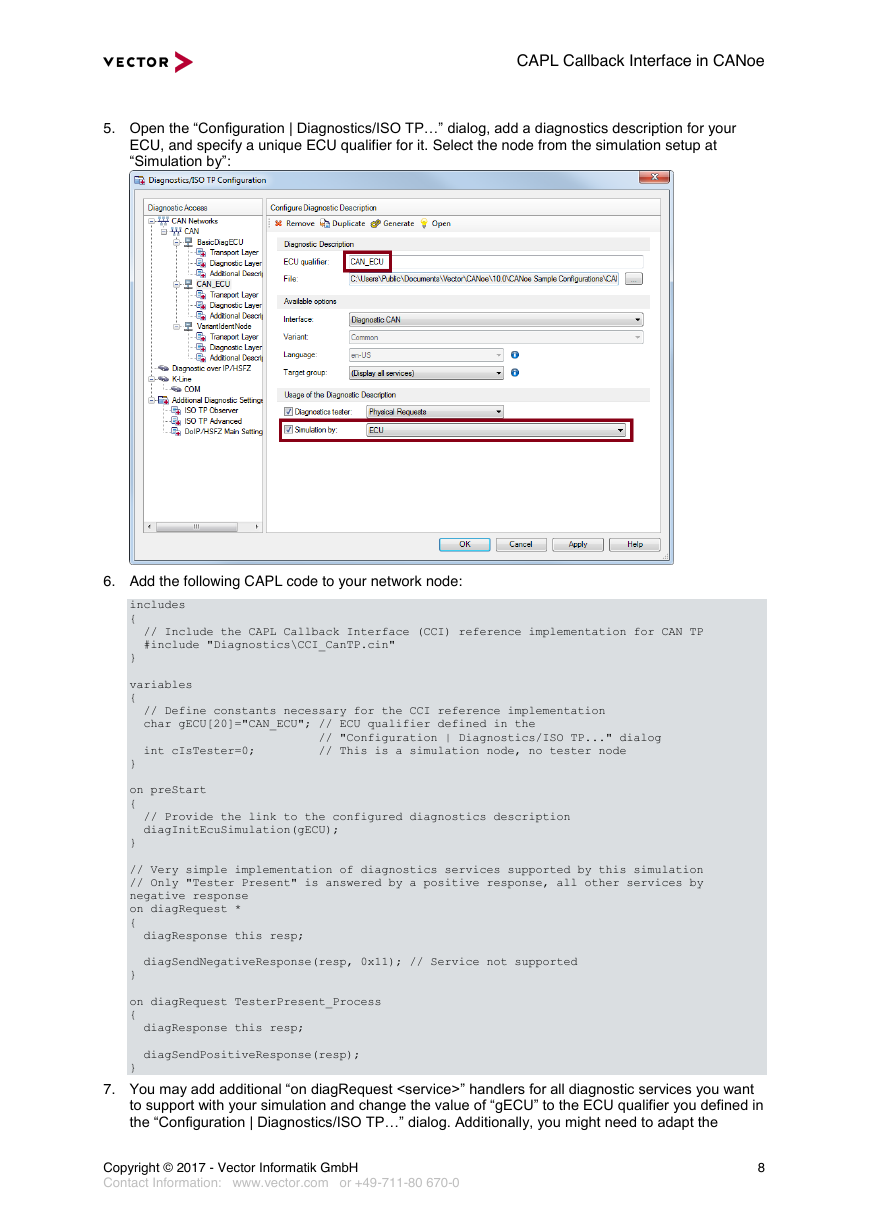

5. Open the “Configuration | Diagnostics/ISO TP…” dialog, add a diagnostics description for your

ECU, and specify a unique ECU qualifier for it. Select the node from the simulation setup at

“Simulation by”:

6. Add the following CAPL code to your network node:

includes

{

// Include the CAPL Callback Interface (CCI) reference implementation for CAN TP

#include "Diagnostics\CCI_CanTP.cin"

}

variables

{

// Define constants necessary for the CCI reference implementation

char gECU[20]="CAN_ECU"; // ECU qualifier defined in the

// "Configuration | Diagnostics/ISO TP..." dialog

int cIsTester=0; // This is a simulation node, no tester node

}

on preStart

{

// Provide the link to the configured diagnostics description

diagInitEcuSimulation(gECU);

}

// Very simple implementation of diagnostics services supported by this simulation

// Only "Tester Present" is answered by a positive response, all other services by

negative response

on diagRequest *

{

diagResponse this resp;

diagSendNegativeResponse(resp, 0x11); // Service not supported

}

on diagRequest TesterPresent_Process

{

diagResponse this resp;

diagSendPositiveResponse(resp);

}

7. You may add additional “on diagRequest ” handlers for all diagnostic services you want

to support with your simulation and change the value of “gECU” to the ECU qualifier you defined in

the “Configuration | Diagnostics/ISO TP…” dialog. Additionally, you might need to adapt the

Copyright © 2017 - Vector Informatik GmbH

Contact Information: www.vector.com or +49-711-80 670-0

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc