Pattern Recognition 51 (2016) 242–254

Contents lists available at ScienceDirect

Pattern Recognition

journal homepage: www.elsevier.com/locate/pr

Detection of bird nests in overhead catenary system images

for high-speed rail

Xiao Wu a,n, Ping Yuan a, Qiang Peng a, Chong-Wah Ngo b, Jun-Yan He a

a School of Information Science and Technology, Southwest Jiaotong University, No. 111, North Section 1, 2nd Ring Road, Chengdu, China

b Department of Computer Science, City University of Hong Kong, #83, Tat Chee Avenue, Kowloon, Hong Kong

a r t i c l e i n f o

a b s t r a c t

Article history:

Received 5 September 2014

Received in revised form

13 June 2015

Accepted 13 September 2015

Available online 28 September 2015

Keywords:

Bird nest detection

Image classification

Overhead catenary system

High-speed rail

Intelligent transportation system

The high-speed rail system provides a fast, reliable and comfortable means to transport large number of

travelers over long distances. The existence of bird nests in overhead catenary system (OCS) can hazard

to the safety of the high-speed rails, which will potentially result in long time delays and expensive

damages. A vision-based intelligent inspection system capable of automatic detection of bird nests built

on overhead catenary would avoid the damages and increase the reliability and punctuality, and

therefore is attractive for a high-speed railway system. However, OCS images exhibit great variations

with lighting changes, illumination conditions and complex backgrounds, which pose great difficulty for

automatic recognition. This paper addresses the problem of automatic recognition of bird nests for OCS

images. Based on the unique properties of bird nests, we propose a novel framework, which is composed

of five steps: adaptive binarization, trunk/branch detection, hovering point detection, streak extraction

and pattern learning, for bird nest detection. Two histograms, Histogram of Orientation of Streaks (HOS)

and Histogram of Length of Streaks (HLS), are novelly proposed to capture the distributions of orienta-

tions and lengths of detected twig streaks, respectively. They are modeled with Support Vector Machine

to learn the patterns of bird nests. Experiments on different high-speed train lines demonstrate the

effectiveness and efficiency of the proposed work.

& 2015 Elsevier Ltd. All rights reserved.

1.

Introduction

High-speed trains are well developed around the world due to

their numerous advantages. Indeed, they are safe, reliable, sus-

tainable, convenient and comfortable for passengers. Over the past

few years, China's high-speed rail (HSR) network has progressively

expanded and now become the world's longest high-speed rail

network with around 9300 km of routes [1]. With the fast devel-

opment of high-speed rail network, railway officials and managers

are facing arduous tasks to ensure that the high-speed rail system

is operating in an orderly and reliable way. Among them, safety

has the highest priority for high-speed rail system, especially after

a fatal high-speed railway accident happened near Wenzhou,

China on July 23, 2011, which has caused great concerns on the

safety of high-speed rail network.

The Pantograph–Catenary (PAC) system is the dominant form for

supplying the vital power to railway electrical trains. A pantograph is

an apparatus mounted on the roof of an electric train to collect power

through contact with an overhead catenary equipment called the

n Corresponding author.

E-mail address: wuxiaohk@home.swjtu.edu.cn (X. Wu).

http://dx.doi.org/10.1016/j.patcog.2015.09.010

0031-3203/& 2015 Elsevier Ltd. All rights reserved.

Overhead Catenary System (OCS) [2]. The steel rails on the tracks act

as the electrical return. The OCS is a high voltage system consisting of

contact wire and catenary wire suspended via supports primarily on

poles placed along the railway. The OCS includes messenger wire,

contact wire, droppers, and supporting structure, which consists of

metallic poles, cross-arms, and running rails. The structure of OCS is

illustrated in Fig. 1. In order to achieve good current collection, the

contact wire has to be placed geometrically within defined limits,

which is usually achieved by supporting the contact wire from above

by a second wire known as the messenger wire or catenary. This wire

is attached to the contact wire at regular intervals by vertical wires

known as droppers or drop wires. The messenger wire is supported

regularly at structures, by a pulley, link, or clamp. Due to space lim-

itation, we will not elaborate the details of each component.

Despite offering a balance in cost effectiveness and system

reliability, the important railway power supply chain is a major

cause of train failure faults. The defects in OCS, for example, down

hanging, ripped off droppers, bondings, broken insulators and bird

nests, can result in long time delays, expensive damages, and even

disasters. The existence of bird nests greatly threats the safety of

the high-speed rail network. It will lead to a defective uptake of

energy by the locomotive, resulting in significant energy loss and

damage to the overhead contact wire and pantograph. While this

�

X. Wu et al. / Pattern Recognition 51 (2016) 242–254

243

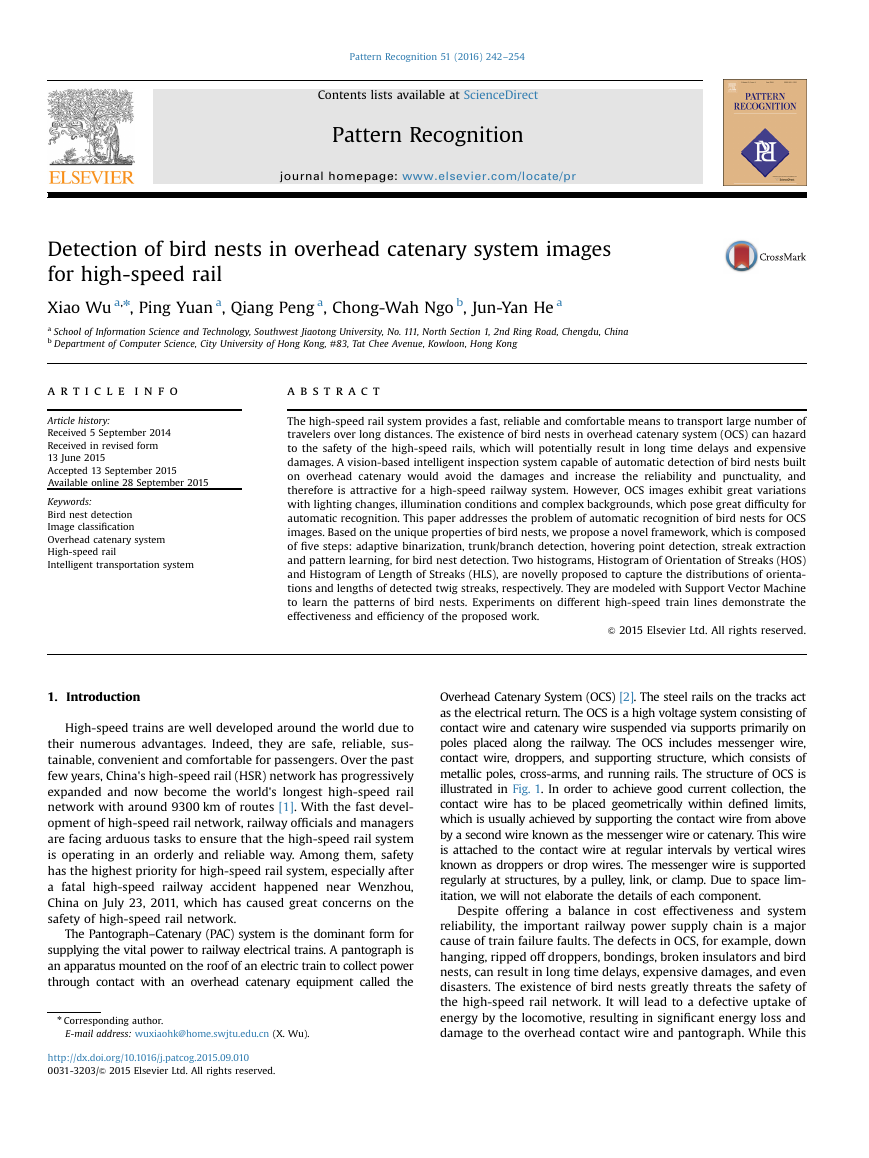

and overlapped. Moreover, discerning catenary system from

complex background such as mountains, trees and buildings, is

generally difficult. Therefore, it is extremely challenging for an

automatic OCS image inspection system to function as expected

under various practical concerns. Several representative OCS

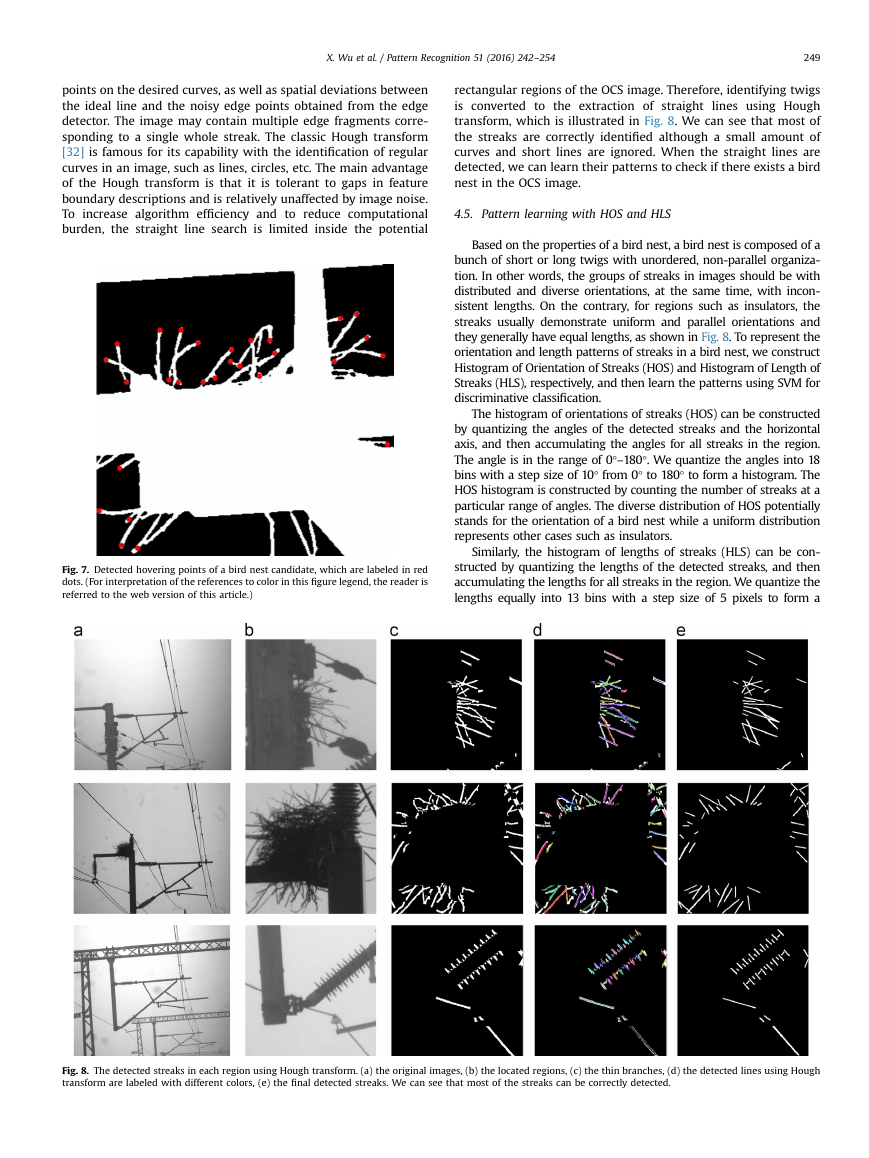

images with bird nests are demonstrated in Fig. 2, while some

difficult examples are also shown in Fig. 10.

In this paper, we explore an automatic detection of bird nests

for high-speed rails, which analyzes the captured OCS images and

assists technicians to make decisions. Experiments demonstrate

that the proposed approach achieves a promising performance for

bird nest recognition. The contributions of this paper are as

follows:

� To the best of our knowledge, this is the first work to system-

atically analyze the properties of bird nests in OCS images, and

the first to automatically detect bird nests by image processing

technology for OCS inspection in high-speed rail system.

� Based on the features of bird nests in OCS system, a five-phase

framework is novelly proposed to detect bird nests in image

sequences, which includes binarization,

trunk and branch

identification, hovering point detection, streak extraction and

pattern learning.

� To model the properties of unordered, non-parallel, distributed

and diverse twigs of bird nests, HOS and HLS histograms are

proposed to represent the distributions of orientations and

lengths of detected streaks, which are exploited to detect the

presence of bird nests.

� Experiments on multiple sequences of images from real high-

speed rail lines demonstrate the effectiveness and efficiency of

the proposed approach.

This paper is organized as follows. Section 2 gives a brief

overview of related work. Section 3 introduces the system archi-

tecture of the OCS inspection system, and the proposed framework

of automatic bird nest detection system. Section 4 elaborates the

detailed process of bird nest detection. Section 5 describes the

experimental setup and empirical results. Finally, Section 6 con-

cludes this paper.

2. Related work

2.1. Pantograph-Catenary inspection system

to monitor

Conventional OCS inspection systems use physical instruments

mounted on an inspection vehicle to measure the status of pan-

tograph and catenary. The Fiber Bragg Grating (FBG) sensors on a

pantograph are used in [3]

the underground

pantograph-catenary system, which measure the contact force and

the vertical acceleration of the pantograph head. An automatic

diagnostic system is installed in a special trolley running up to

100 km/h to check the health conditions of catenary [4]. Particular

considerations are given on the values and the trends of voltage,

height, stagger, wear, forces and so on. These instruments are

mounted on the pantograph itself and signal wires are attached to

each instrument [4,5], which affect the dynamic characteristics of

the pantograph. An optical radar system [6] is equipped on the

inspection vehicle to record catenary related parameters like

contact wire position, wire wear, pole position as well as distance

between pole and track. However, these physical inspection sys-

tems mainly focus on checking the status and properties of

catenary systems, which are not applicable for bird nest detection.

With the recent development of computerized image recogni-

tion, current works begin to focus on video based detection to

discover defects in OCS [7–15], taking advantage of the video

Fig. 1. Structure of overhead catenary system of high-speed rail.

is a problem common to all trains of electric traction, it is espe-

cially critical for high speed tracks, since the reliability of power

collection decreases as train speed increases. It is the permanent

aim of all railway line operators to detect faults at an early stage,

and to correct any damage, fault or wear on time in order to

prevent serious disturbances of railway traffic. Therefore, it is

greatly desired that intelligent approaches can be designed and

implemented to provide support for technicians. In this paper, we

will focus on the automatic detection of bird nests for high-

speed rails.

The demand for safety and high reliability grows with the

development of high-speed railway lines, leading to the invention

of new monitoring devices. The OCS inspection system is one of

the key items for high-speed rail system. Traditionally,

it is

implemented by laser scanner on top of the train. Compared to the

extremely expensive laser scanner, a breakthrough video mon-

itoring system with on-board high-resolution cameras equipped in

the high-speed trains becomes a promising solution due to its high

functionality, flexibility and interoperability. It can directly capture

the OCS images/videos to ensure the reliability of the OCS. Con-

ventionally, the images/videos have to be visually checked and

evaluated offline by trained technicians, often frame by frame, to

inspect the status of the OCS. It is time-consuming, laborious, and

impractical to manually monitor millions of overhead catenary

supporters along thousand miles of railways. In this work, we

deploy an OCS image inspection system featured with non-contact

cameras for high-speed trains.

Unfortunately, we notice that OCS images exhibit great varia-

tions in lighting changes,

illumination conditions, occlusion,

complex structures, and mixture of foreground and background,

which make automatic detection of bird nests a challenging task.

First, the images from different train lines are captured with varied

weather, lighting changes, viewpoints and illumination conditions.

Second, bird nests exist at different locations of the OCS. And the

regions having bird nests are relatively small and not easy to be

noticed. Third, the overhead catenary structures are complex with

messy crossing lines, especially when the foreground and back-

ground are mixed together, so that many lines are crossed over

�

244

X. Wu et al. / Pattern Recognition 51 (2016) 242–254

Fig. 2. Examples of bird nests appearing at different locations of the overhead catenary system of high-speed rail. The image qualities are suffered from different variations in

lighting changes, complex structures, mixture of foreground and background, which make automatic detection of bird nests a challenging task.

camera that offers higher resolution and lower cost. The most

related works to our research are [8,9]. With IRIS 320 inspection

vehicle in France [8],

image analysis strategy is adopted for

catenary inspection for preventive maintenance. It locates the

catenary sections between two supporting arms, and extracts all

surrounding elements such as contact wire, carrying wire, sup-

porting arms and simple droppers. The work [9] deals with the

automatic recognition of the catenary elements, such as support-

ing arms, droppers, and droppers with electrical connection. It

consists of two steps: a classical scene analysis is conducted to

identify elements by segmentation in vertical and horizontal

components, followed by feature extraction and classification.

Next, the results are checked and analyzed by analyzing the

catenary element sequence using a Markov model. In [11], a video-

based obstacle detection system is developed in Germany, which

automatically detects obstacles in the pantograph gauge and

retracts the pantograph before collision with an obstacle. With the

recognition of steady arms,

the system is

improved considerably. A system for the automatic detection of

droppers in catenary staves is proposed in [13]. Based on a

the reliability of

�

X. Wu et al. / Pattern Recognition 51 (2016) 242–254

245

top-down approach, the system exploits priori knowledge to

perform reliable extraction of droppers. In [10], the problematic of

contact wire wear in railways is first presented and a computer

vision system is studied to improve the precision of the systems

for wear measurement of contact wire. A sensor system with a

line-scan camera is used to monitor the interaction between the

catenary and the pantograph [14], which can detect the occurrence

of defects in the catenary-pantograph interaction. In [15], the

pantograph-overhead contact wire system is investigated by using

an infrared camera. In order to detect the temperature along the

strip from a sequence of infrared images, a segment-tracking

algorithm based on the Hough transform is employed. It helps

maintenance operations in the case of overheating of the panto-

graph strip, bursts of arcing, or an irregular positioning of the

contact line. Although the aforementioned works focus on iden-

tification of the components and defects for OCS systems, direct

comparison with them is not possible because these works are not

tailored for bird nest detection. To the best of our knowledge, few

research works and systems are dedicated to the bird nest detec-

tion for the topic of automatic video based diagnostics at

catenaries.

2.2.

Image classification and abnormal pattern detection

Bird nest detection for OCS images belongs to the research

issues of image classification and object detection, which are key

research areas in computer vision and image processing. Image

classification [16] and object detection [17,18] have been exten-

sively studied for decades and been applied to different areas, such

as adverse weather detection [19], human detection [20–22], and

intelligent transportation [23,24]. An image is classified according

to its visual content, e.g., the existence of bird nests or not.

Element-independent features such as color, shape, texture, gra-

dient or contour [16] are extracted from the image in the first

place. Then in the recognition process, these features are gathered

and knowledge is incorporated in order to identify the objects.

Recently, an object detection system is described in [17], which

represents highly variable objects using mixtures of multiscale

deformable part models. These models are trained using a dis-

criminative procedure that only requires bounding boxes for the

objects in a set of images. The system attains state-of-the-art

results in terms of efficiency and accuracy. In order to localize and

segment objects, R-CNN is proposed in [18], which applies high-

capacity convolutional neural networks (CNNs) for bottom-up

region proposals. In addition, supervised pre-training on a large

auxiliary dataset, followed by domain-specific fine-tuning on a

small dataset, is an effective paradigm for learning high-capacity

CNNs when data are scarce. This method yields a significant per-

formance boost compared to state-of-the-art technologies. A

compositional model for human detection is built in [20] by

exploiting the analogy between human body and text. A dis-

criminative alphabet is automatically learnt to represent body

parts. Based on this alphabet, the flexible structure of human body

is expressed by means of symbolic sequences, which correspond to

various human poses and allow for robust and efficient matching.

Experiments on standard benchmarks demonstrate that the pro-

posed algorithm achieves state-of-the-art or competitive perfor-

mance. A simple yet effective detector for pedestrian detection is

proposed in [21], which incorporates common sense and everyday

knowledge into the design of simple and computationally efficient

features. A statistical model of the up-right human body is

deployed where the head, the upper body, and the lower body are

treated as three distinct components, from which a pool of rec-

tangular templates is tailored to this shape model. Since different

kinds of low-level measurements are incorporated, the resulting

multi-modal and multi-channel Haar-like features represent

characteristic differences between parts of the human body, which

are robust against variations in clothing or environmental settings.

To identify bird nests in an image of OCS scene, previously

explored works on image classification and object detection could

be beneficial for our study. To represent the distinct patterns of

various applications, different kinds of histograms are extracted

and trained for image classification. A system based on computer

vision is presented in [19] to detect the presence of rain or snow. A

histogram of orientations of rain or snow streaks is computed with

the method of geometric moments, which is assumed to follow a

model of Gaussian uniform mixture. The orientation of the rain or

the snow is represented with Gaussian distribution whereas the

orientation of the noises is represented with uniform distribution.

Expectation maximization (EM) is used to separate these two

distributions. An image-based vehicle-type recognition is pro-

posed in [24], which uses Gabor wavelet transform and the Pyr-

amid Histogram of Oriented Gradients (PHOG) features. A reliable

classification scheme is proposed by cascade classifier ensembles.

A novel approach for near-duplicate keyframe identification is

proposed in [25] by matching, filtering and learning of local

interest points. Owing to the robustness consideration,

the

matching of local points across keyframes forms vivid patterns.

Pattern entropy is proposed to capture the matching patterns with

the histogram of matching orientation, and then learn the patterns

with SVM for discriminative classification. Although the existing

approaches on image classification may not be directly applicable

for bird nest detection of OCS images, the idea of capturing the

patterns in the form of histograms enlightens this research. In [26],

a robust abnormal event detection framework based on sparse

reconstruction over the normal bases is proposed. Given a col-

lection of normal training examples, the sparse reconstruction cost

(SRC) is proposed to measure the normalness of the testing sam-

ple. By introducing the prior weight of each basis during sparse

reconstruction, the proposed measurement is more robust com-

pared to other outlier detection criteria. An approach is proposed

in [27] to detect aberrations in video streams using Entropy. It is

estimated on the statistical treatments of the spatiotemporal

information of a set of interest points within a region of interest,

by measuring their degree of randomness of both directions and

displacements. A framework is proposed in [28] to robustly

identify local motions of interest in an unsupervised manner by

taking advantage of group sparsity. In order to robustly classify

action types,

local motion is emphasized by combining local

motion descriptors and full motion descriptors, and then group

sparsity is applied to emphasize motion features using the mul-

tiple kernel method. Overall, there is no prior works on bird nest

detection system presently available. The feasibility and effec-

tiveness of the commonly used features and classification solu-

tions are worth exploration.

3. System architecture and framework

In this section, we will first present the system architecture of

the adopted OCS inspection system, followed by an introduction of

the properties of bird nest. Finally, we will describe the proposed

framework for the automatic detection of bird nests.

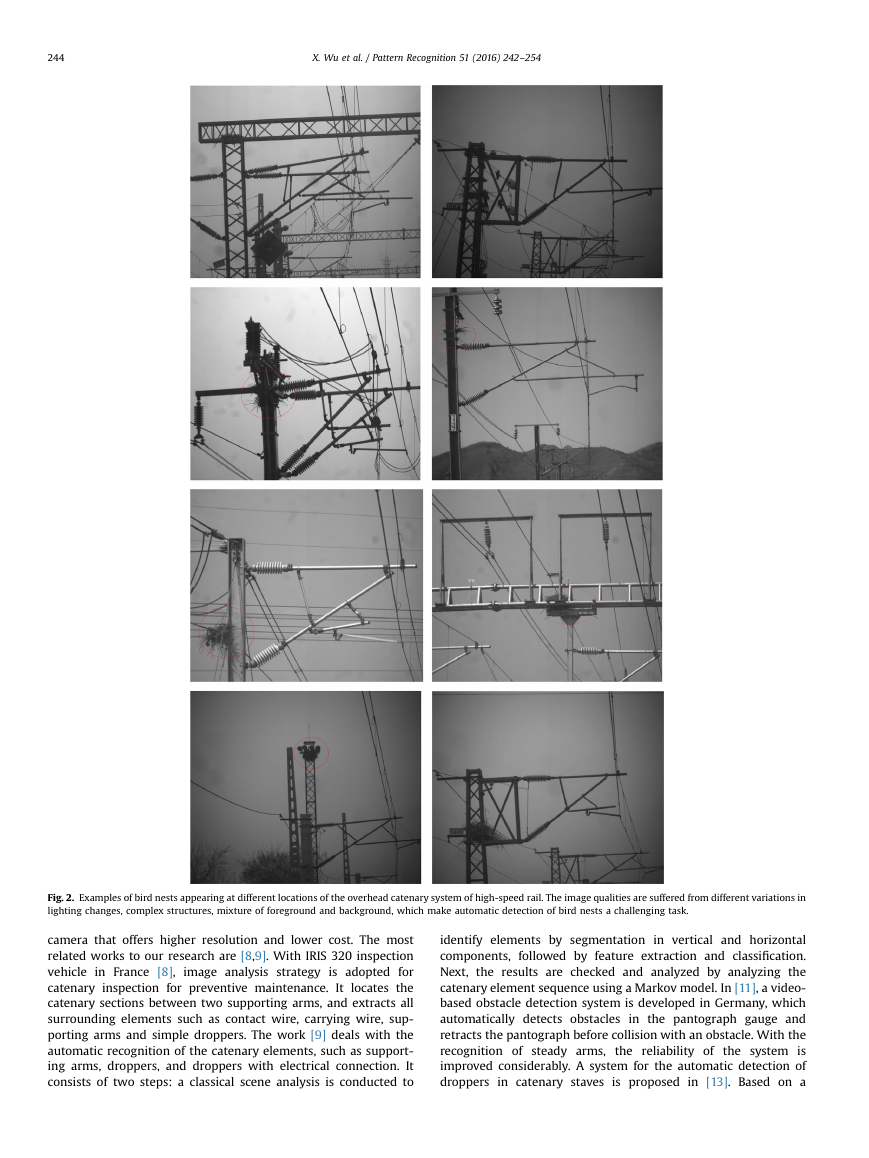

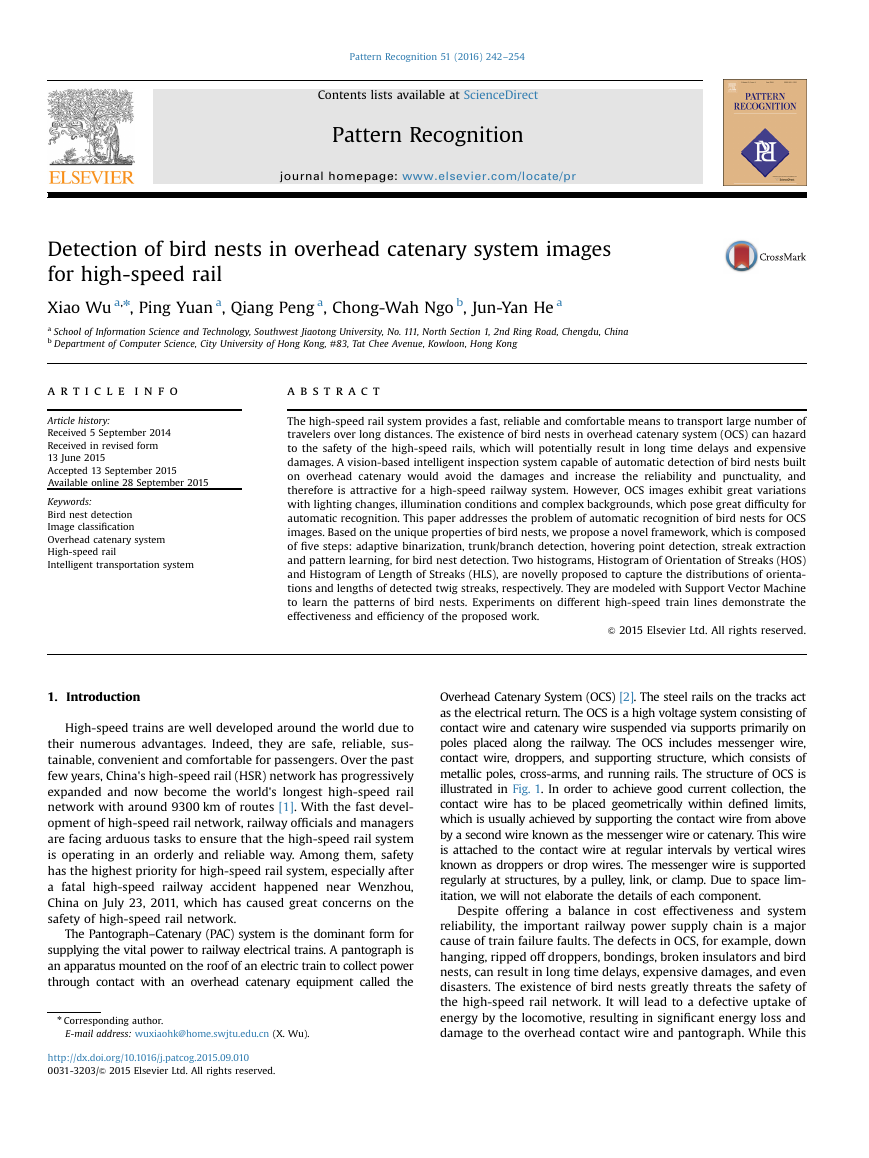

3.1. Architecture of OCS inspection system

The architecture of OCS inspection system is shown in Fig. 3.

The inspection system is equipped with two on-board CCD cam-

eras with resolutions of 2456 � 2058 (5 million pixels) and

1392 � 1040 (1 million pixels), respectively. The high resolution

camera points toward the catenary to capture the images of OCS,

while the low resolution one focuses on the supporter to capture

�

246

X. Wu et al. / Pattern Recognition 51 (2016) 242–254

Fig. 3. System architecture of OCS inspection system.

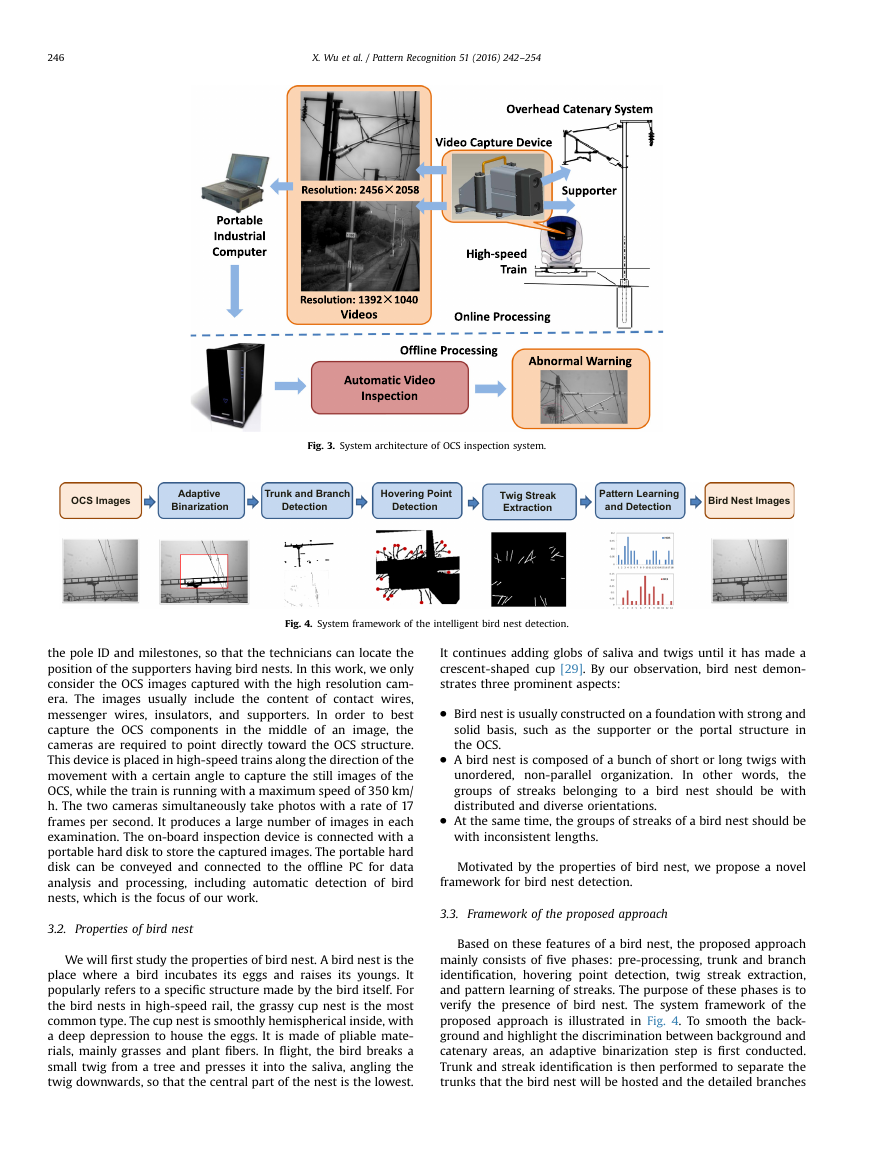

OCS Images

Adaptive

Binarization

Trunk and Branch

Detection

Hovering Point

Detection

Twig Streak

Extraction

Pattern Learning

and Detection

Bird Nest Images

Fig. 4. System framework of the intelligent bird nest detection.

insulators, and supporters.

the pole ID and milestones, so that the technicians can locate the

position of the supporters having bird nests. In this work, we only

consider the OCS images captured with the high resolution cam-

era. The images usually include the content of contact wires,

messenger wires,

In order to best

capture the OCS components in the middle of an image, the

cameras are required to point directly toward the OCS structure.

This device is placed in high-speed trains along the direction of the

movement with a certain angle to capture the still images of the

OCS, while the train is running with a maximum speed of 350 km/

h. The two cameras simultaneously take photos with a rate of 17

frames per second. It produces a large number of images in each

examination. The on-board inspection device is connected with a

portable hard disk to store the captured images. The portable hard

disk can be conveyed and connected to the offline PC for data

analysis and processing, including automatic detection of bird

nests, which is the focus of our work.

3.2. Properties of bird nest

We will first study the properties of bird nest. A bird nest is the

place where a bird incubates its eggs and raises its youngs. It

popularly refers to a specific structure made by the bird itself. For

the bird nests in high-speed rail, the grassy cup nest is the most

common type. The cup nest is smoothly hemispherical inside, with

a deep depression to house the eggs. It is made of pliable mate-

rials, mainly grasses and plant fibers. In flight, the bird breaks a

small twig from a tree and presses it into the saliva, angling the

twig downwards, so that the central part of the nest is the lowest.

It continues adding globs of saliva and twigs until it has made a

crescent-shaped cup [29]. By our observation, bird nest demon-

strates three prominent aspects:

� Bird nest is usually constructed on a foundation with strong and

solid basis, such as the supporter or the portal structure in

the OCS.

� A bird nest is composed of a bunch of short or long twigs with

the

unordered, non-parallel organization.

groups of streaks belonging to a bird nest should be with

distributed and diverse orientations.

� At the same time, the groups of streaks of a bird nest should be

In other words,

with inconsistent lengths.

Motivated by the properties of bird nest, we propose a novel

framework for bird nest detection.

3.3. Framework of the proposed approach

Based on these features of a bird nest, the proposed approach

mainly consists of five phases: pre-processing, trunk and branch

identification, hovering point detection, twig streak extraction,

and pattern learning of streaks. The purpose of these phases is to

verify the presence of bird nest. The system framework of the

proposed approach is illustrated in Fig. 4. To smooth the back-

ground and highlight the discrimination between background and

catenary areas, an adaptive binarization step is first conducted.

Trunk and streak identification is then performed to separate the

trunks that the bird nest will be hosted and the detailed branches

�

X. Wu et al. / Pattern Recognition 51 (2016) 242–254

247

that are the potential twigs of a bird nest. The hovering points are

detected so that the twigs can be located. After that, the streaks

are extracted using Hough transform to convert the twigs to

straight lines. Two histograms, so-called HOS and HLS, are built by

accumulating the orientations and lengths of different compo-

nents obtained by the hovering point detection. The distributions

of HOS and HLS are then modeled using SVM to discriminate the

potential regions with or without a bird nest. A decision criterion

on the histograms allows detecting the presence or absence of a

bird nest. In this paper, branches, twigs and streaks have the same

meaning, and are interchangeably mentioned depending on

context.

Fig. 5. Trunk and branch identification after image binarization. (a) Original images (b) Images after binarization. (c) Detected trunks (d) Detected branches.

�

248

X. Wu et al. / Pattern Recognition 51 (2016) 242–254

4. Automatic bird nest detection for OCS images

4.1. Pre-Processing: Image binarization

Due to the convenience of non-contact on-board OCS inspection

system, the portable device with high resolution cameras is mounted

inside the driver's cabin instead of mounted on the roof of the train.

Therefore, the dusts on the train windows are easily captured by the

high-resolution cameras. In addition, the OCS images are always suf-

fering from noises, uneven lighting and compression artifacts. The

brightness distribution of various positions in an OCS image may vary

because of the condition of catenary and the effect of lighting envir-

onment. These reasons make noise a crucial factor affecting the

performance.

Binarization is the initial and a key step for automatic detection

of bird nests, since it is the base for successful localization and

recognition of bird nests. Its purpose is to distinguish the overhead

catenary areas from the background areas and remove noises. In

order to avoid the disadvantage of global threshold methods,

which use a single threshold value to classify image pixels into

objects and background classes, we use local adaptive binarization.

It deploys multiple values selected according to the local area

information. An OCS image is divided into multiple blocks

according to an n � n sliding window, and for each block, the

average value of all pixels in the sliding window is selected as the

threshold.

In addition, we adopt two granularities of block size for the sliding

window to detect the main structures and small details, respectively.

The one with a larger size (e.g., 400� 400) is to retain the shape of

relatively large objects, such as the supporter and the portal structure,

but ignore small details. On the contrary, the other one with a smaller

size (e.g., 10� 10) is to keep details and thin edge information, such as

the streaks of bird nests. These two binarized images are then com-

bined by a union operation to form the final image. Their combination

perfectly contains the complete content of the overhead catenary and

the details such as lines and strokes of bird nests, which improves the

quality of catenary regions and preserves stroke connectivity by

removing isolated pixels. A post-processing technique is used to

eliminate noise pixels. Small connected regions with connected

component labeling [30] are treated as noises and then removed. The

original images and the effects after adaptive binarization are shown

in Fig. 5(a and b), respectively. After this step, each image is converted

from a gray scale to a binary image IB with reduced noises and shar-

pened objects.

4.2. Trunk and branch identification

After image binarization, the next step is to identify the trunk

and branch regions, which are the potential foundation of a bird

nest built and the twigs of a bird nest, respectively. The trunk in

the OCS images refers to the large regions such as the supporter

and the portal structure of the overhead catenary system. Mean-

while, the branch denotes thin lines and small details.

To identify the trunk and branch, Canny edge detector [31] is

performed on the binarized image to detect the edges, forming the

edge image IE, which makes the identification of the overhead contact

lines, the poles, and the streaks of bird nests easier. The main part of

the catenary and the portal structure is detected by morphological

opening operation with rectangle kernel of n� n, which tends to

enlarge small holes, remove small objects, and separate objects. The

pixels between two edges whose distance is less than n/2 will be

filled. Otherwise, it will be kept unchanged. Finally, the trunk IT can be

achieved by combining the image IE after the aforementioned opera-

tions with the binarized image IB by a logical union operation. That is,

the intersection of the detected main part and the binarized image

will form the trunk regions, which is shown in Fig. 5(c). From this

figure, we can see that the main part of the supporter and the portal

structure of OCS can be correctly detected, which are the base where

bird nests will be built up. Once the trunks are extracted, the left part

is the thin lines and the twigs. The binarized image IB is subtracted

with the trunk image IT, which forms the branches and the thin lines.

The detected branch lines are shown in Fig. 5(d). We can see that the

thin structures, including the streaks of bird nests, are well identified.

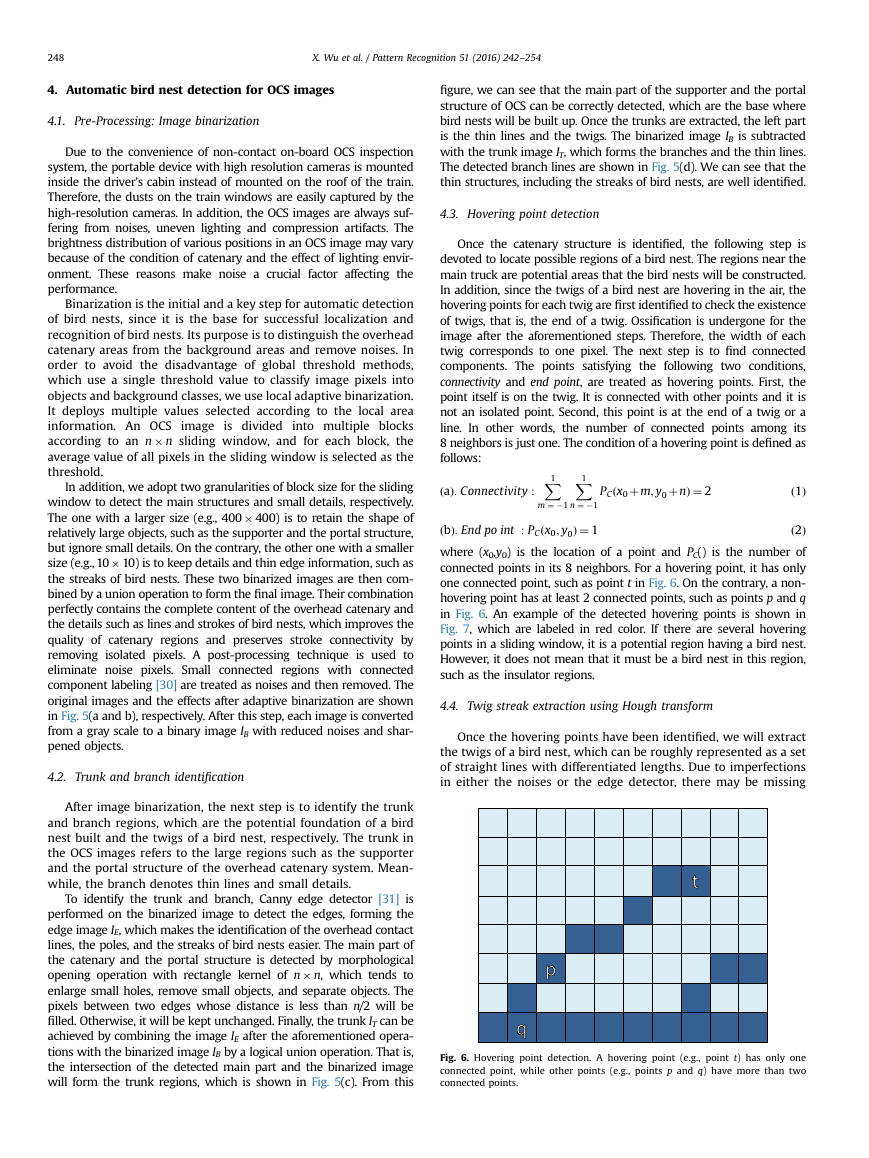

4.3. Hovering point detection

Once the catenary structure is identified, the following step is

devoted to locate possible regions of a bird nest. The regions near the

main truck are potential areas that the bird nests will be constructed.

In addition, since the twigs of a bird nest are hovering in the air, the

hovering points for each twig are first identified to check the existence

of twigs, that is, the end of a twig. Ossification is undergone for the

image after the aforementioned steps. Therefore, the width of each

twig corresponds to one pixel. The next step is to find connected

components. The points satisfying the following two conditions,

connectivity and end point, are treated as hovering points. First, the

point itself is on the twig. It is connected with other points and it is

not an isolated point. Second, this point is at the end of a twig or a

line. In other words, the number of connected points among its

8 neighbors is just one. The condition of a hovering point is defined as

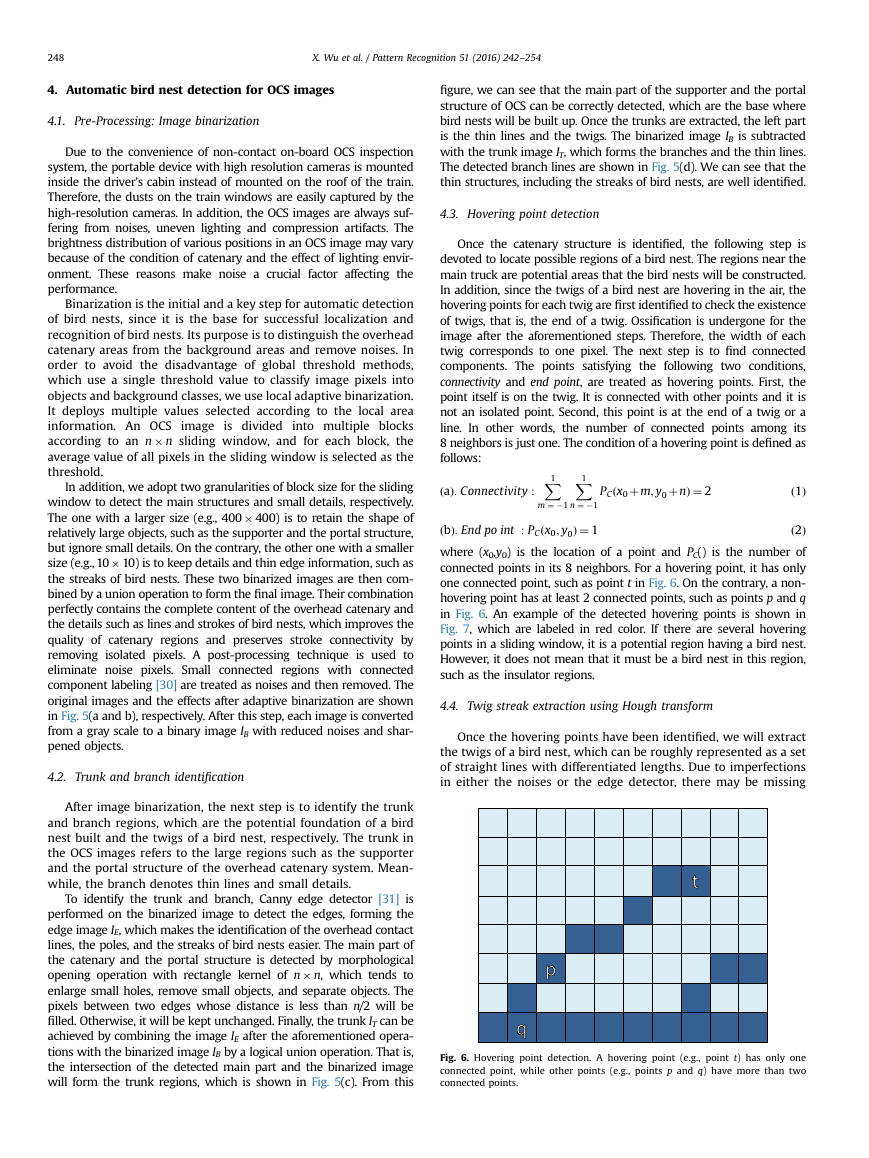

follows:

ðaÞ: Connectivity :

PCðx0 þm; y0 þnÞ ¼ 2

ð1Þ

m ¼ �1

n ¼ �1

ðbÞ: End po int : PCðx0; y0Þ ¼ 1

ð2Þ

where (x0,y0) is the location of a point and PC() is the number of

connected points in its 8 neighbors. For a hovering point, it has only

one connected point, such as point t in Fig. 6. On the contrary, a non-

hovering point has at least 2 connected points, such as points p and q

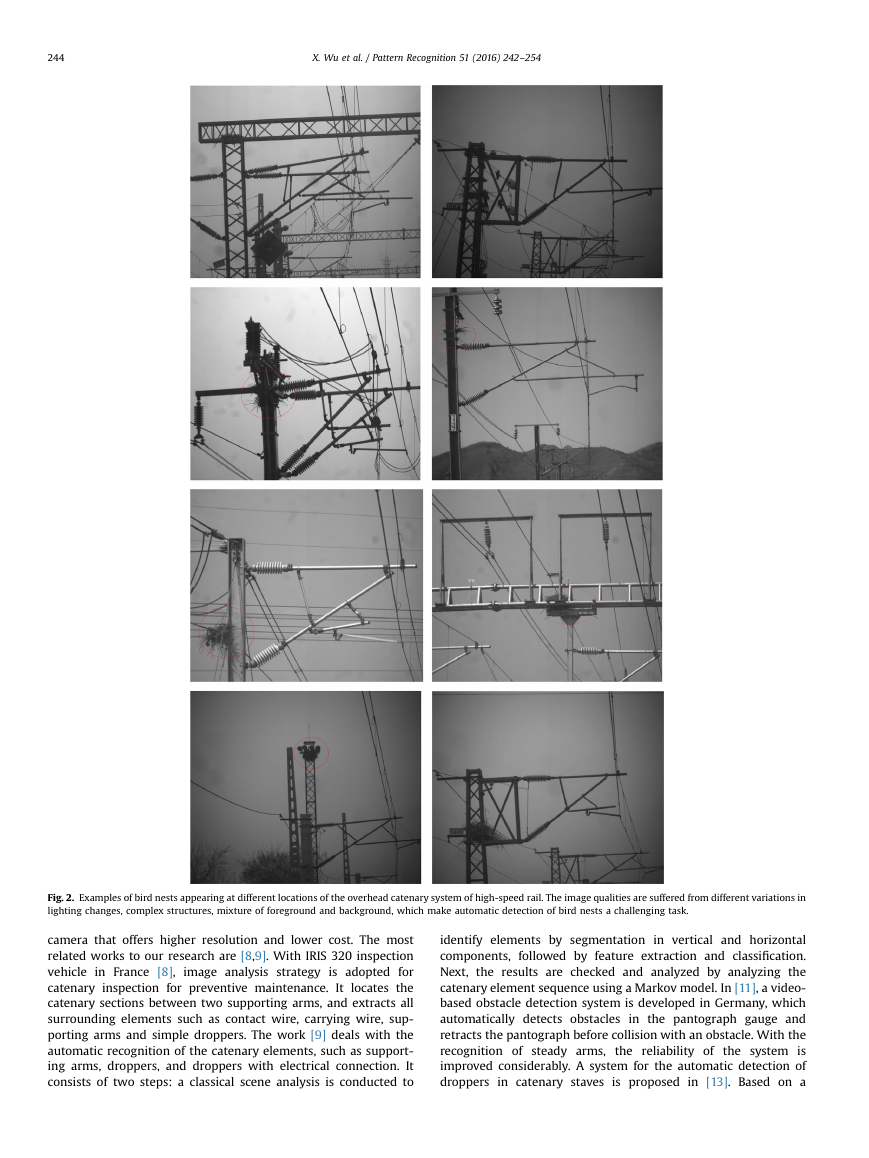

in Fig. 6. An example of the detected hovering points is shown in

Fig. 7, which are labeled in red color. If there are several hovering

points in a sliding window, it is a potential region having a bird nest.

However, it does not mean that it must be a bird nest in this region,

such as the insulator regions.

X1

X1

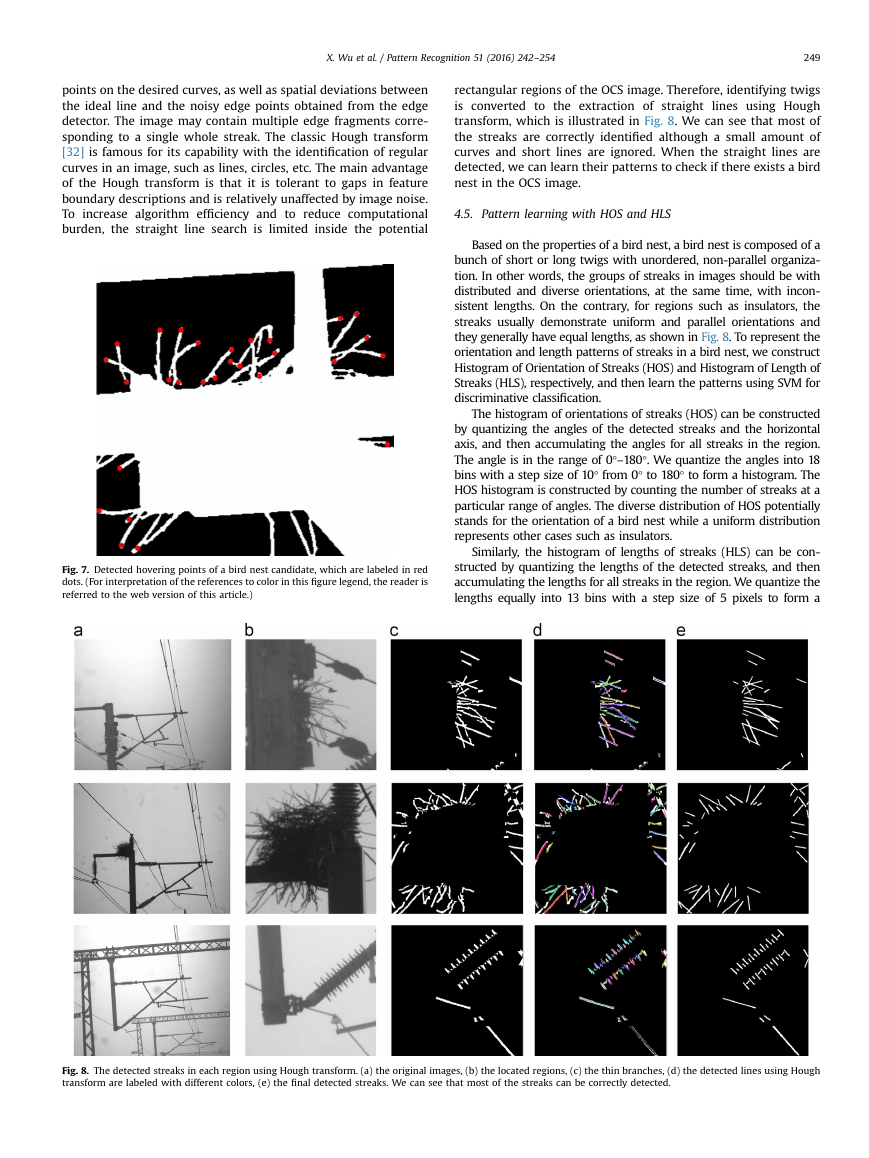

4.4. Twig streak extraction using Hough transform

Once the hovering points have been identified, we will extract

the twigs of a bird nest, which can be roughly represented as a set

of straight lines with differentiated lengths. Due to imperfections

in either the noises or the edge detector, there may be missing

Fig. 6. Hovering point detection. A hovering point (e.g., point t) has only one

connected point, while other points (e.g., points p and q) have more than two

connected points.

�

X. Wu et al. / Pattern Recognition 51 (2016) 242–254

249

points on the desired curves, as well as spatial deviations between

the ideal line and the noisy edge points obtained from the edge

detector. The image may contain multiple edge fragments corre-

sponding to a single whole streak. The classic Hough transform

[32] is famous for its capability with the identification of regular

curves in an image, such as lines, circles, etc. The main advantage

of the Hough transform is that it is tolerant to gaps in feature

boundary descriptions and is relatively unaffected by image noise.

To increase algorithm efficiency and to reduce computational

burden, the straight line search is limited inside the potential

Fig. 7. Detected hovering points of a bird nest candidate, which are labeled in red

dots. (For interpretation of the references to color in this figure legend, the reader is

referred to the web version of this article.)

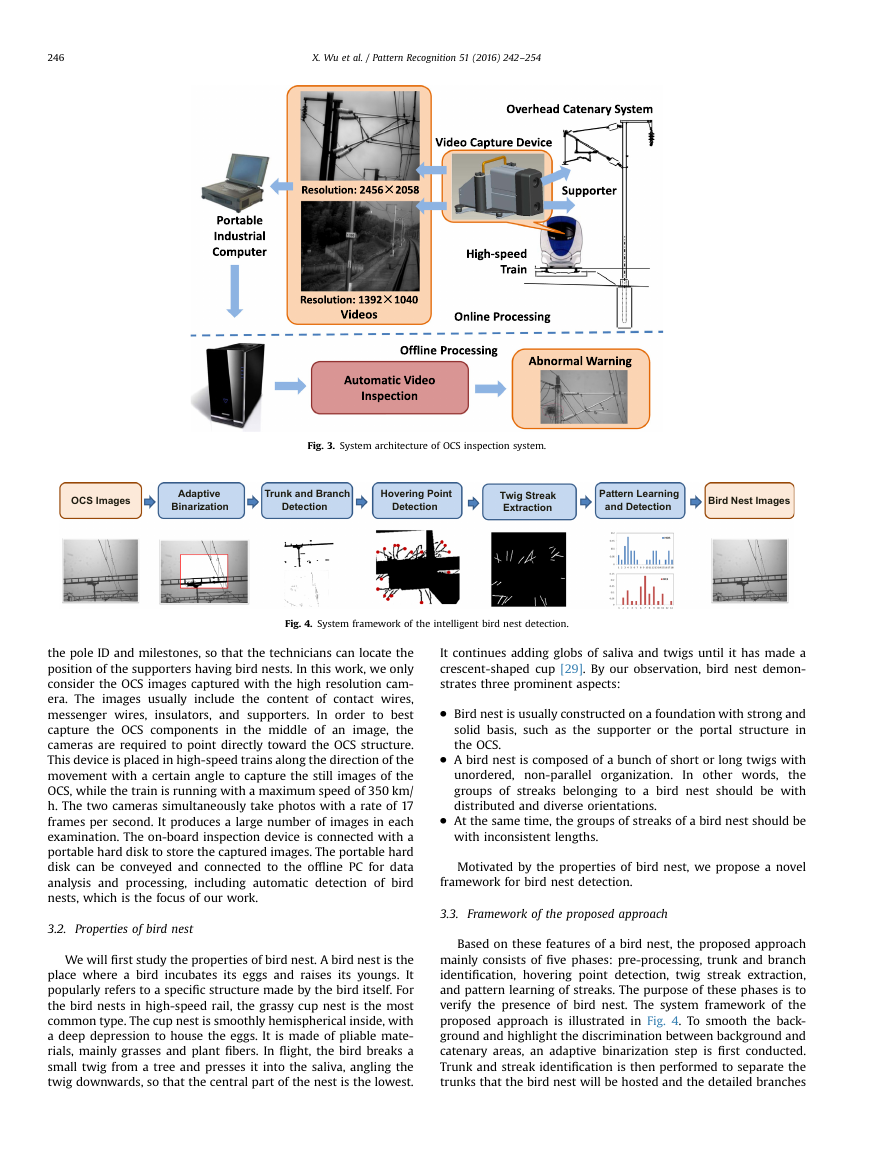

rectangular regions of the OCS image. Therefore, identifying twigs

is converted to the extraction of straight lines using Hough

transform, which is illustrated in Fig. 8. We can see that most of

the streaks are correctly identified although a small amount of

curves and short lines are ignored. When the straight lines are

detected, we can learn their patterns to check if there exists a bird

nest in the OCS image.

4.5. Pattern learning with HOS and HLS

Based on the properties of a bird nest, a bird nest is composed of a

bunch of short or long twigs with unordered, non-parallel organiza-

tion. In other words, the groups of streaks in images should be with

distributed and diverse orientations, at the same time, with incon-

sistent lengths. On the contrary, for regions such as insulators, the

streaks usually demonstrate uniform and parallel orientations and

they generally have equal lengths, as shown in Fig. 8. To represent the

orientation and length patterns of streaks in a bird nest, we construct

Histogram of Orientation of Streaks (HOS) and Histogram of Length of

Streaks (HLS), respectively, and then learn the patterns using SVM for

discriminative classification.

The histogram of orientations of streaks (HOS) can be constructed

by quantizing the angles of the detected streaks and the horizontal

axis, and then accumulating the angles for all streaks in the region.

The angle is in the range of 0°–180°. We quantize the angles into 18

bins with a step size of 10° from 0° to 180° to form a histogram. The

HOS histogram is constructed by counting the number of streaks at a

particular range of angles. The diverse distribution of HOS potentially

stands for the orientation of a bird nest while a uniform distribution

represents other cases such as insulators.

Similarly, the histogram of lengths of streaks (HLS) can be con-

structed by quantizing the lengths of the detected streaks, and then

accumulating the lengths for all streaks in the region. We quantize the

lengths equally into 13 bins with a step size of 5 pixels to form a

Fig. 8. The detected streaks in each region using Hough transform. (a) the original images, (b) the located regions, (c) the thin branches, (d) the detected lines using Hough

transform are labeled with different colors, (e) the final detected streaks. We can see that most of the streaks can be correctly detected.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc