a Low Cost, Low Power,

True RMS-to-DC Converter

AD736

FEATURES

COMPUTES

True RMS Value

Average Rectified Value

Absolute Value

PROVIDES

200 mV Full-Scale Input Range

(Larger Inputs with Input Attenuator)

High Input Impedance of 1012 ⍀

Low Input Bias Current: 25 pA max

High Accuracy: ⴞ0.3 mV ⴞ0.3% of Reading

RMS Conversion with Signal Crest Factors Up to 5

Wide Power Supply Range: +2.8 V, –3.2 V to ⴞ16.5 V

Low Power: 200 A max Supply Current

Buffered Voltage Output

No External Trims Needed for Specified Accuracy

AD737—An Unbuffered Voltage Output Version with

Chip Power Down Is Also Available

PRODUCT DESCRIPTION

The AD736 is a low power, precision, monolithic true

rms-to-dc converter. It is laser trimmed to provide a maximum

error of – 0.3 mV – 0.3% of reading with sine-wave inputs. Fur-

thermore, it maintains high accuracy while measuring a wide

range of input waveforms, including variable duty cycle pulses

and triac (phase) controlled sine waves. The low cost and small

physical size of this converter make it suitable for upgrading the

performance of non-rms “precision rectifiers” in many applica-

tions. Compared to these circuits, the AD736 offers higher ac-

curacy at equal or lower cost.

The AD736 can compute the rms value of both ac and dc input

voltages. It can also be operated ac coupled by adding one ex-

ternal capacitor. In this mode, the AD736 can resolve input sig-

nal levels of 100 m V rms or less, despite variations in

temperature or supply voltage. High accuracy is also maintained

for input waveforms with crest factors of 1 to 3. In addition,

crest factors as high as 5 can be measured (while introducing

only 2.5% additional error) at the 200 mV full-scale input level.

The AD736 has its own output buffer amplifier, thereby provid-

ing a great deal of design flexibility. Requiring only 200 m A of

power supply current, the AD736 is optimized for use in por-

table multimeters and other battery powered applications.

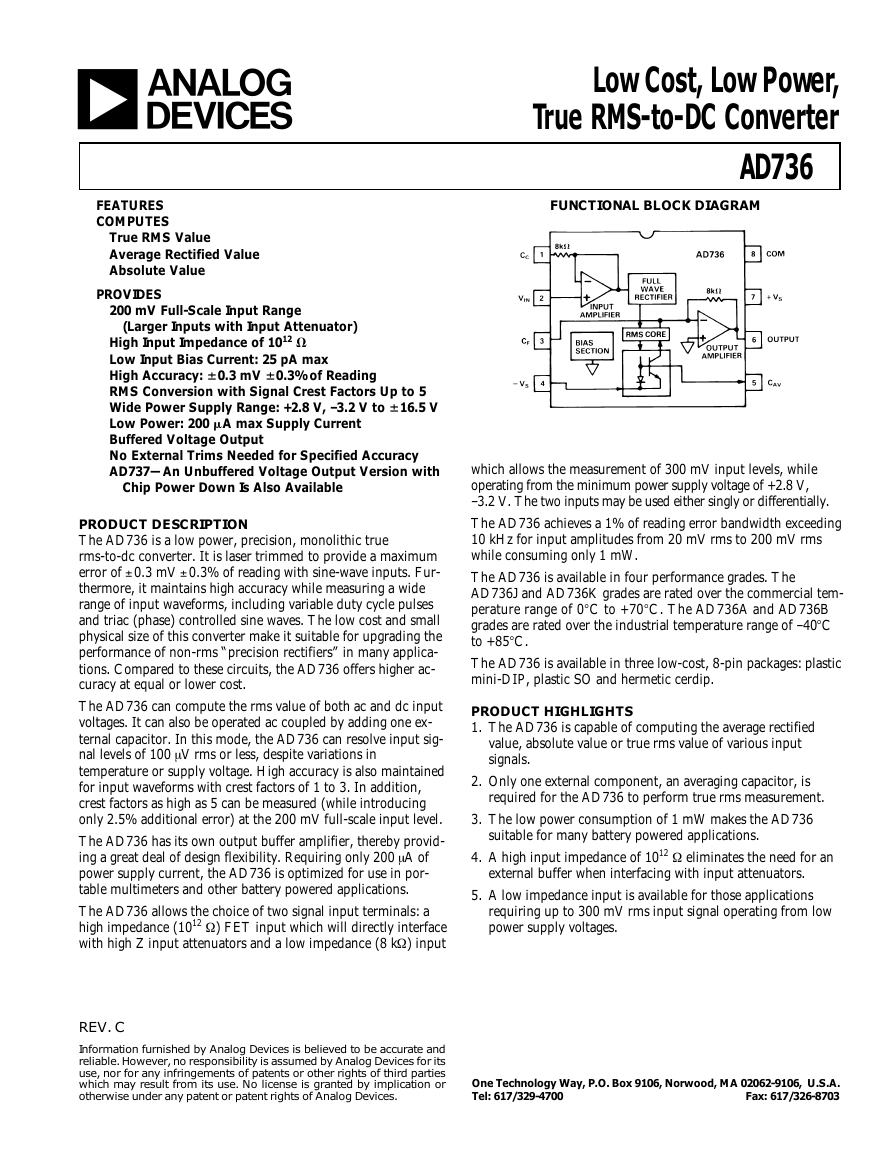

The AD736 allows the choice of two signal input terminals: a

high impedance (1012 W

with high Z input attenuators and a low impedance (8 kW

) FET input which will directly interface

) input

FUNCTIONAL BLOCK DIAGRAM

which allows the measurement of 300 mV input levels, while

operating from the minimum power supply voltage of +2.8 V,

–3.2 V. The two inputs may be used either singly or differentially.

The AD736 achieves a 1% of reading error bandwidth exceeding

10 kHz for input amplitudes from 20 mV rms to 200 mV rms

while consuming only 1 mW.

The AD736 is available in four performance grades. The

AD736J and AD736K grades are rated over the commercial tem-

perature range of 0 C to +70 C. The AD736A and AD736B

grades are rated over the industrial temperature range of –40 C

to +85 C.

The AD736 is available in three low-cost, 8-pin packages: plastic

mini-DIP, plastic SO and hermetic cerdip.

PRODUCT HIGHLIGHTS

1. The AD736 is capable of computing the average rectified

value, absolute value or true rms value of various input

signals.

2. Only one external component, an averaging capacitor, is

required for the AD736 to perform true rms measurement.

3. The low power consumption of 1 mW makes the AD736

suitable for many battery powered applications.

4. A high input impedance of 1012 W

eliminates the need for an

external buffer when interfacing with input attenuators.

5. A low impedance input is available for those applications

requiring up to 300 mV rms input signal operating from low

power supply voltages.

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700

Fax: 617/326-8703

�

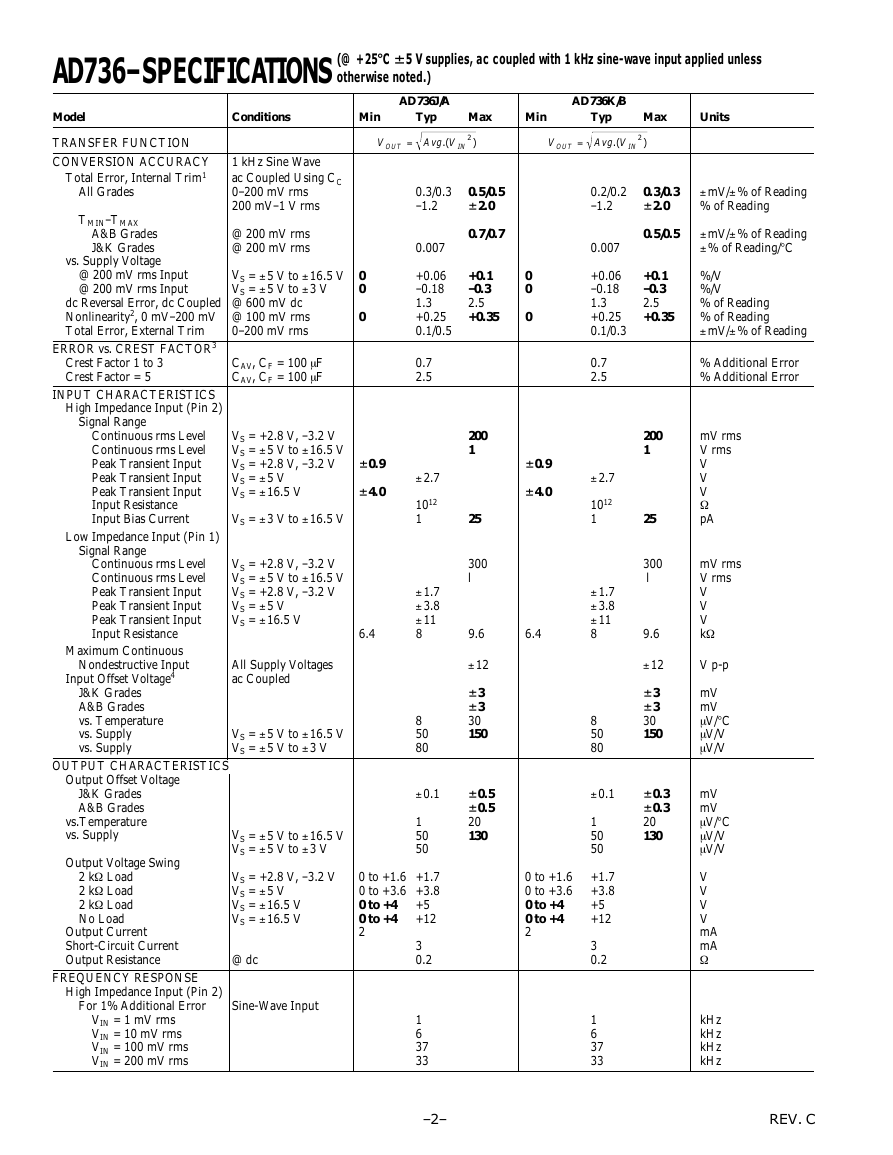

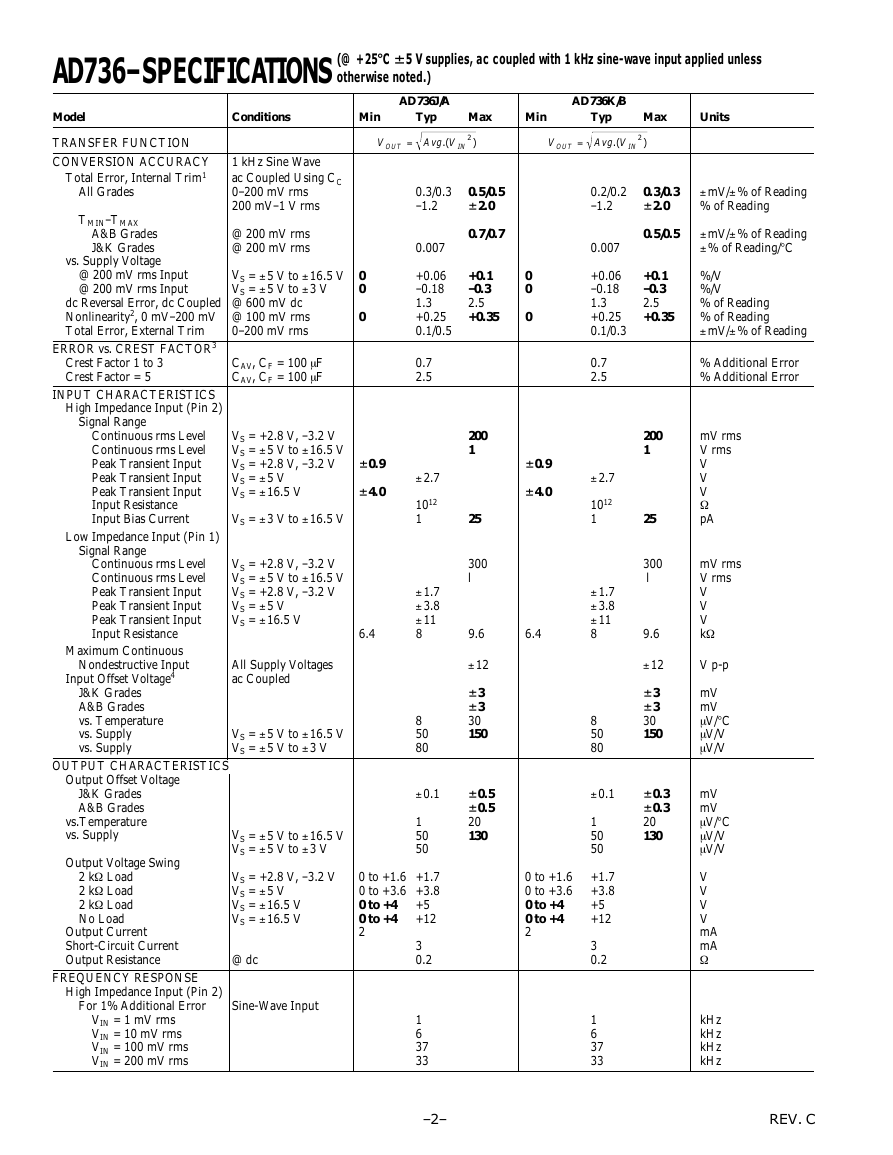

AD736–SPECIFICATIONS

(@ +25ⴗC ⴞ5 V supplies, ac coupled with 1 kHz sine-wave input applied unless

otherwise noted.)

Model

Conditions

Min

Typ

Max

Min

Typ

Max

Units

AD736J/A

AD736K/B

TRANSFER FUNCTION

CONVERSION ACCURACY

Total Error, Internal Trim1

All Grades

TMIN–TMAX

A&B Grades

J&K Grades

vs. Supply Voltage

@ 200 mV rms Input

@ 200 mV rms Input

1 kHz Sine Wave

ac Coupled Using CC

0–200 mV rms

200 mV–1 V rms

@ 200 mV rms

@ 200 mV rms

VS = – 5 V to – 16.5 V 0

VS = – 5 V to – 3 V

0

dc Reversal Error, dc Coupled @ 600 mV dc

Nonlinearity2, 0 mV–200 mV @ 100 mV rms

Total Error, External Trim

0–200 mV rms

ERROR vs. CREST FACTOR3

Crest Factor 1 to 3

Crest Factor = 5

INPUT CHARACTERISTICS

CAV, CF = 100 m F

CAV, CF = 100 m F

0

VOUT = Avg.(V IN

2 )

VOUT = Avg.(V IN

2 )

0.5/0.5

ⴞ2.0

0.7/0.7

+0.1

–0.3

2.5

+0.35

0

0

0

0.3/0.3

–1.2

0.007

+0.06

–0.18

1.3

+0.25

0.1/0.5

0.7

2.5

0.3/0.3

ⴞ2.0

0.5/0.5

+0.1

–0.3

2.5

+0.35

0.2/0.2

–1.2

0.007

+0.06

–0.18

1.3

+0.25

0.1/0.3

0.7

2.5

– mV/– % of Reading

% of Reading

– mV/– % of Reading

– % of Reading/ C

%/V

%/V

% of Reading

% of Reading

– mV/– % of Reading

% Additional Error

% Additional Error

High Impedance Input (Pin 2)

Signal Range

Continuous rms Level

Continuous rms Level

Peak Transient Input

Peak Transient Input

Peak Transient Input

Input Resistance

Input Bias Current

Low Impedance Input (Pin 1)

Signal Range

Continuous rms Level

Continuous rms Level

Peak Transient Input

Peak Transient Input

Peak Transient Input

Input Resistance

Maximum Continuous

Nondestructive Input

Input Offset Voltage4

J&K Grades

A&B Grades

vs. Temperature

vs. Supply

vs. Supply

OUTPUT CHARACTERISTICS

Output Offset Voltage

J&K Grades

A&B Grades

vs.Temperature

vs. Supply

Output Voltage Swing

Load

Load

Load

2 kW

2 kW

2 kW

No Load

Output Current

Short-Circuit Current

Output Resistance

FREQUENCY RESPONSE

High Impedance Input (Pin 2)

For 1% Additional Error

VIN = 1 mV rms

VIN = 10 mV rms

VIN = 100 mV rms

VIN = 200 mV rms

VS = +2.8 V, –3.2 V

VS = – 5 V to – 16.5 V

VS = +2.8 V, –3.2 V

VS = – 5 V

VS = – 16.5 V

VS = – 3 V to – 16.5 V

ⴞ0.9

ⴞ4.0

VS = +2.8 V, –3.2 V

VS = – 5 V to – 16.5 V

VS = +2.8 V, –3.2 V

VS = – 5 V

VS = – 16.5 V

All Supply Voltages

ac Coupled

6.4

VS = – 5 V to – 16.5 V

VS = – 5 V to – 3 V

VS = – 5 V to – 16.5 V

VS = – 5 V to – 3 V

VS = +2.8 V, –3.2 V

VS = – 5 V

VS = – 16.5 V

VS = – 16.5 V

@ dc

Sine-Wave Input

200

1

25

300

l

9.6

– 12

ⴞ3

ⴞ3

30

150

ⴞ0.5

ⴞ0.5

20

130

– 2.7

1012

1

– 1.7

– 3.8

– 11

8

8

50

80

– 0.1

1

50

50

0 to +1.6 +1.7

0 to +3.6 +3.8

0 to +4

0 to +4

2

+5

+12

3

0.2

1

6

37

33

–2–

ⴞ0.9

ⴞ4.0

6.4

0 to +1.6

0 to +3.6

0 to +4

0 to +4

2

– 2.7

1012

1

– 1.7

– 3.8

– 11

8

8

50

80

– 0.1

1

50

50

+1.7

+3.8

+5

+12

3

0.2

1

6

37

33

200

1

mV rms

V rms

V

V

V

25

pA

300

l

9.6

– 12

ⴞ3

ⴞ3

30

150

ⴞ0.3

ⴞ0.3

20

130

mV rms

V rms

V

V

V

kW

V p-p

mV

mV

m V/ C

m V/V

m V/V

mV

mV

m V/ C

m V/V

m V/V

V

V

V

V

mA

mA

kHz

kHz

kHz

kHz

REV. C

W

W

�

Conditions

Sine-Wave Input

Sine-Wave Input

Sine-Wave Input

AD736J/A

AD736K/B

Min

Typ

Max

Min

Typ

Max

Units

AD736

5

55

170

190

1

6

90

90

5

55

350

460

5

55

170

190

1

6

90

90

5

55

350

460

kHz

kHz

kHz

kHz

kHz

kHz

kHz

kHz

kHz

kHz

kHz

kHz

Zero Signal

Sine-Wave Input

+2.8, –3.2 – 5

160

230

– 16.5

200

270

+2.8, –3.2 – 5

160

230

– 16.5

200

270

Volts

m A

m A

AD736J

AD736A

AD736K

AD736B

Model

– 3 dB Bandwidth

VIN = 1 mV rms

VIN = 10 mV rms

VIN = 100 mV rms

VIN = 200 mV rms

FREQUENCY RESPONSE

Low Impedance Input (Pin 1)

For 1% Additional Error

VIN = 1 mV rms

VIN = 10 mV rms

VIN = 100 mV rms

VIN = 200 mV rms

– 3 dB Bandwidth

VIN = l mV rms

VIN = 10 mV rms

VIN = 100 mV rms

VIN = 200 mV rms

POWER SUPPLY

OperatingVoltageRange

Quiescent Current

200 mV rms, No Load

TEMPERATURE RANGE

Operating, Rated Performance

Commercial (0 C to +70 C)

Industrial (–40 C to +85 C)

NOTES

lAccuracy is specified with the AD736 connected as shown in Figure 16 with capacitor CC.

2Nonlinearity is defined as the maximum deviation (in percent error) from a straight line connecting the readings at 0 and 200 mV rms. Output offset voltage is adjusted to zero.

3Error vs. Crest Factor is specified as additional error for a 200 mV rms signal. C.F. = VPEAK/V rms.

4DC offset does not limit ac resolution.

Specifications are subject to change without notice.

Specifications shown in boldface are tested on all production units at final electrical test.

Results from those tests are used to calculate outgoing quality levels.

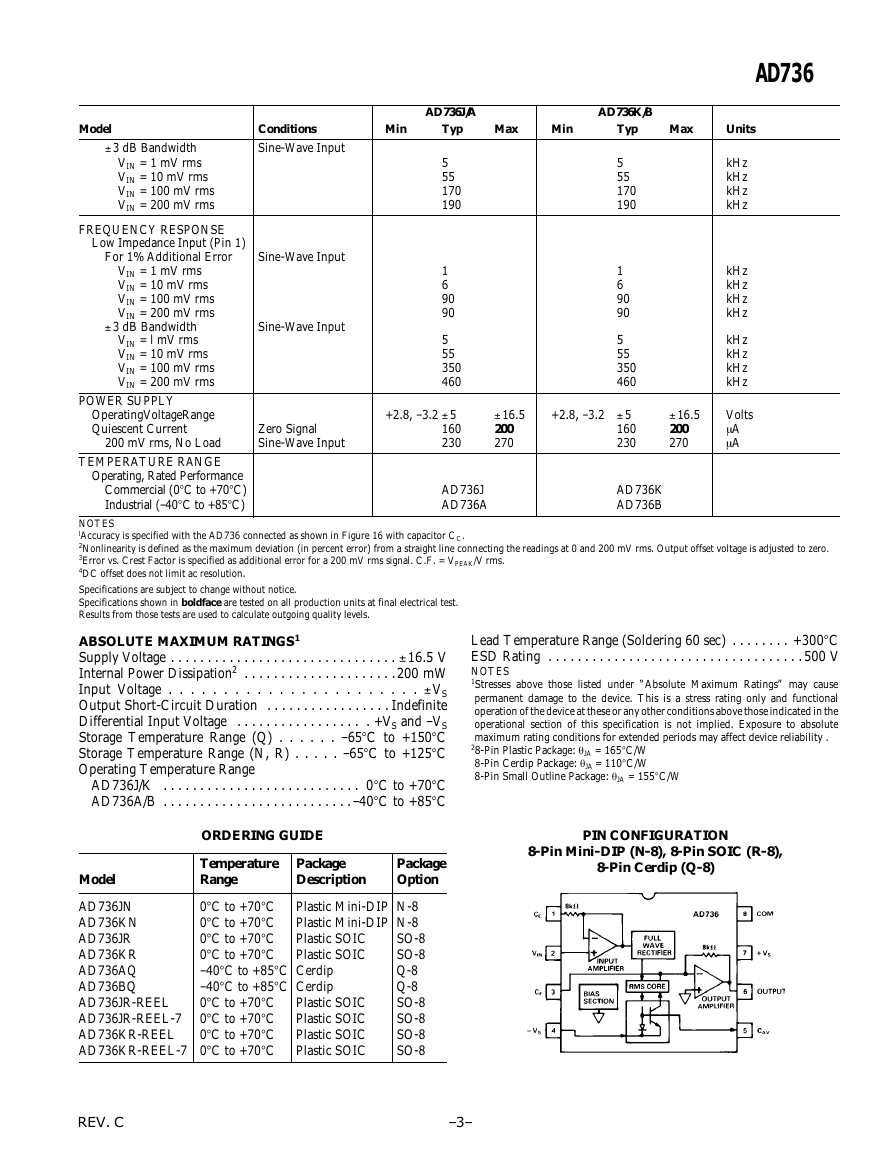

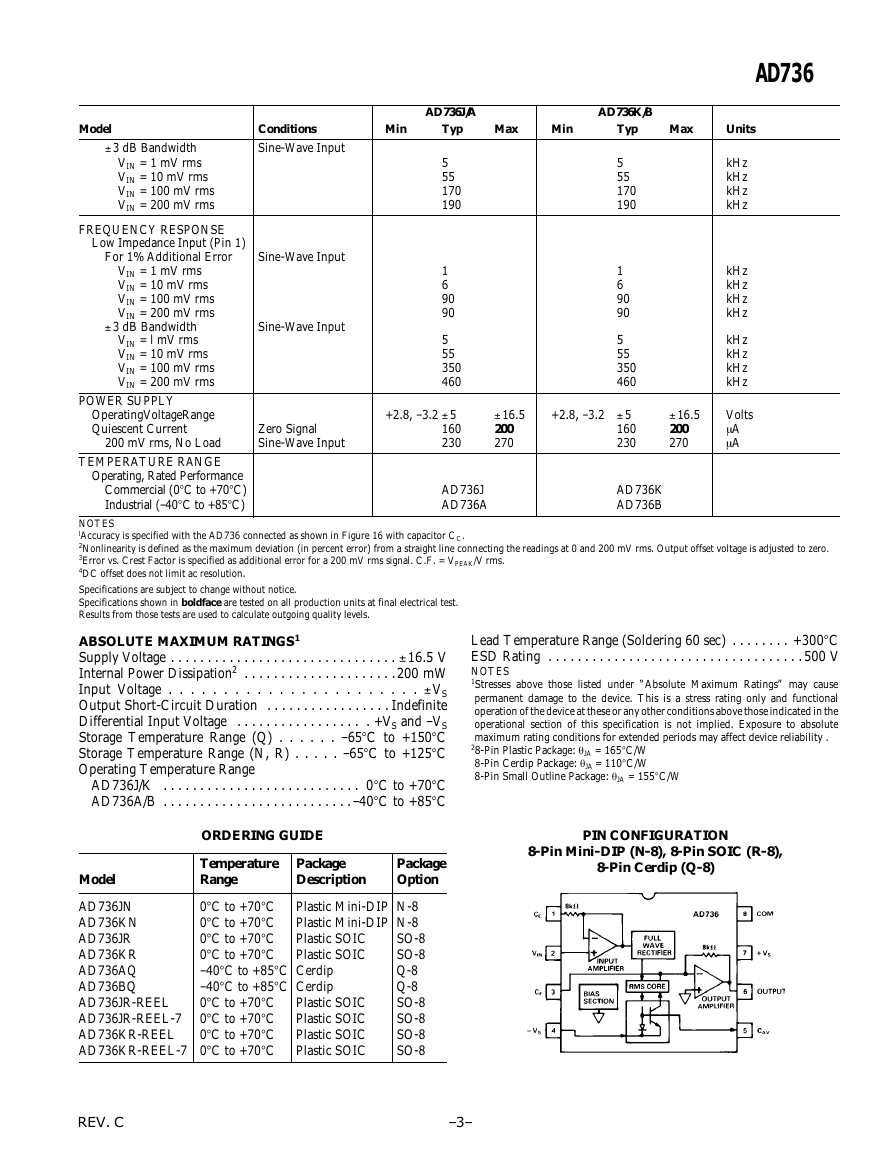

ABSOLUTE MAXIMUM RATINGS1

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . – 16.5 V

Internal Power Dissipation2 . . . . . . . . . . . . . . . . . . . . . 200 mW

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . – VS

Output Short-Circuit Duration . . . . . . . . . . . . . . . . . Indefinite

Differential Input Voltage . . . . . . . . . . . . . . . . .

. +VS and –VS

Storage Temperature Range (Q) . . . . . . –65 C to +150 C

Storage Temperature Range (N, R) . . . . . –65 C to +125 C

Operating Temperature Range

AD736J/K . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 C to +70 C

AD736A/B . . . . . . . . . . . . . . . . . . . . . . . . . . –40 C to +85 C

Lead Temperature Range (Soldering 60 sec) . . . . . . . . +300 C

ESD Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 V

NOTES

1Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in the

operational section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability .

28-Pin Plastic Package: q

8-Pin Cerdip Package: q

8-Pin Small Outline Package: q

JA = 165 C/W

JA = 110 C/W

JA = 155 C/W

Package

Option

PIN CONFIGURATION

8-Pin Mini-DIP (N-8), 8-Pin SOIC (R-8),

8-Pin Cerdip (Q-8)

ORDERING GUIDE

Model

Package

Description

Temperature

Range

0 C to +70 C

AD736JN

0 C to +70 C

AD736KN

0 C to +70 C

AD736JR

0 C to +70 C

AD736KR

–40 C to +85 C Cerdip

AD736AQ

–40 C to +85 C Cerdip

AD736BQ

0 C to +70 C

AD736JR-REEL

0 C to +70 C

AD736JR-REEL-7

0 C to +70 C

AD736KR-REEL

AD736KR-REEL-7 0 C to +70 C

Plastic Mini-DIP N-8

Plastic Mini-DIP N-8

SO-8

Plastic SOIC

SO-8

Plastic SOIC

Q-8

Q-8

SO-8

SO-8

SO-8

SO-8

Plastic SOIC

Plastic SOIC

Plastic SOIC

Plastic SOIC

REV. C

–3–

�

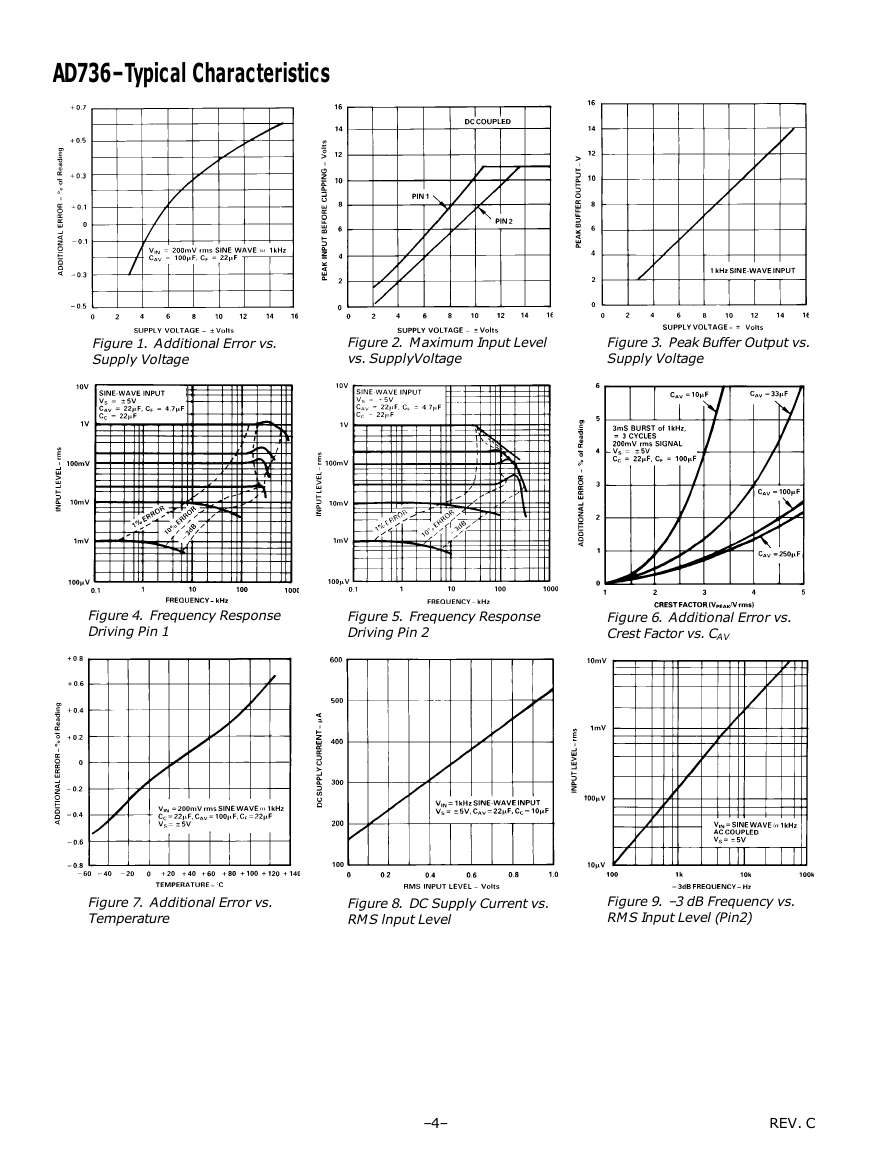

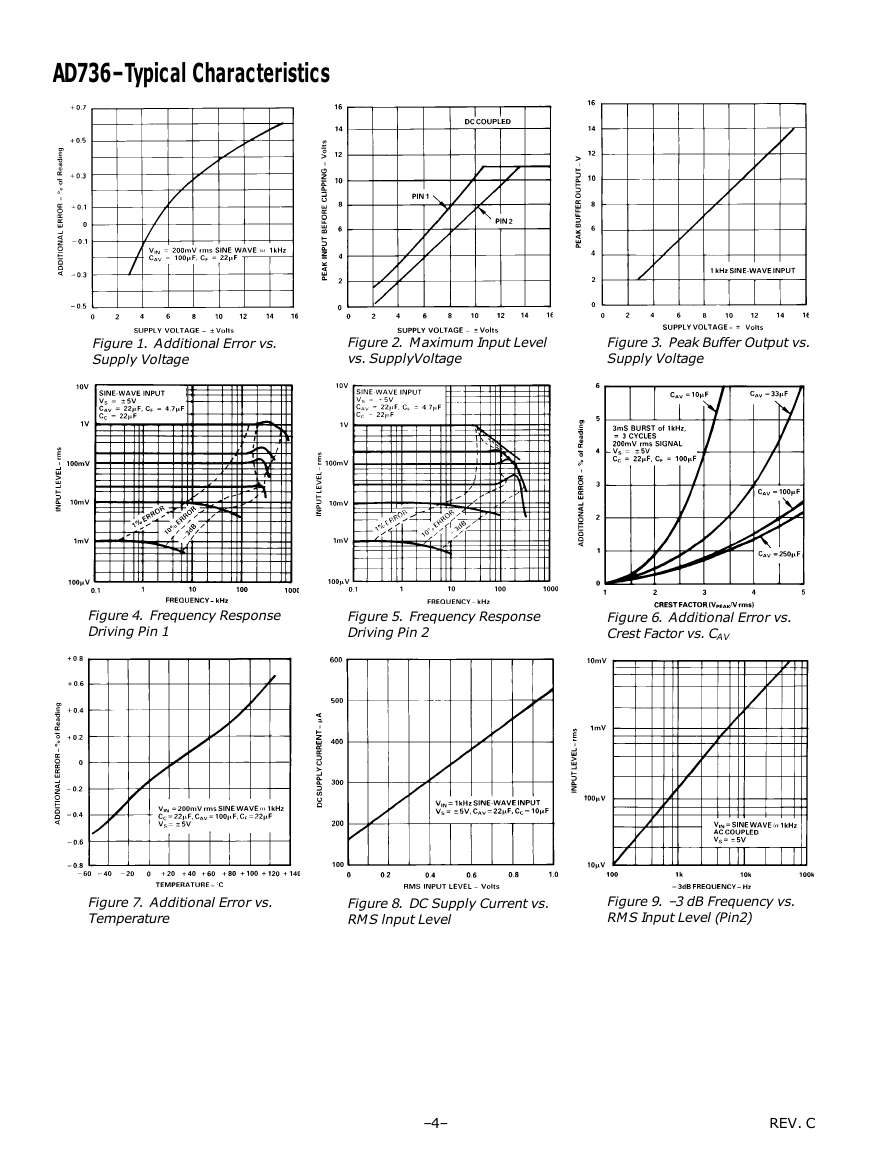

AD736

–Typical Characteristics

Figure 1. Additional Error vs.

Supply Voltage

Figure 2. Maximum Input Level

vs. SupplyVoltage

Figure 3. Peak Buffer Output vs.

Supply Voltage

Figure 4. Frequency Response

Driving Pin 1

Figure 5. Frequency Response

Driving Pin 2

Figure 6. Additional Error vs.

Crest Factor vs. CAV

Figure 7. Additional Error vs.

Temperature

Figure 8. DC Supply Current vs.

RMS lnput Level

Figure 9. –3 dB Frequency vs.

RMS Input Level (Pin2)

–4–

REV. C

�

Typical Characteristics–

AD736

Figure 10. Error vs. RMS Input

Voltage (Pin 2), Output Buffer Off-

set Is Adjusted To Zero

Figure 11. CAV vs. Frequency for

Specified Averaging Error

Figure 12. RMS Input Level vs.

Frequency for Specified Averag-

ing Error

Figure 13. Pin 2 Input Bias Current

vs. Supply Voltage

Figure 14. Settling Time vs. RMS

Input Level for Various

Values of CAV

Figure 15. Pin 2 Input Bias Cur-

rent vs. Temperature

CALCULATING SETTLING TIME USING FIGURE 14

The graph of Figure 14 may be used to closely approximate the

time required for the AD736 to settle when its input level is re-

duced in amplitude. The net time required for the rms converter

to settle will be the difference between two times extracted from

the graph – the initial time minus the final settling time. As an

example, consider the following conditions: a 33 m F averaging

capacitor, an initial rms input level of 100 mV and a final (re-

duced) input level of 1 mV. From Figure 14, the initial settling

time (where the 100 mV line intersects the 33 m F line) is around

80 ms.

The settling time corresponding to the new or final input level

of 1 mV is approximately 8 seconds. Therefore, the net time for

the circuit to settle to its new value will be 8 seconds minus

80 ms which is 7.92 seconds. Note that, because of the smooth

decay characteristic inherent with a capacitor/diode combina-

tion, this is the total settling time to the final value (i.e., not the

settling time to 1%, 0.1%, etc., of final value). Also, this graph

provides the worst case settling time, since the AD736 will settle

very quickly with increasing input levels.

REV. C

–5–

�

AD736

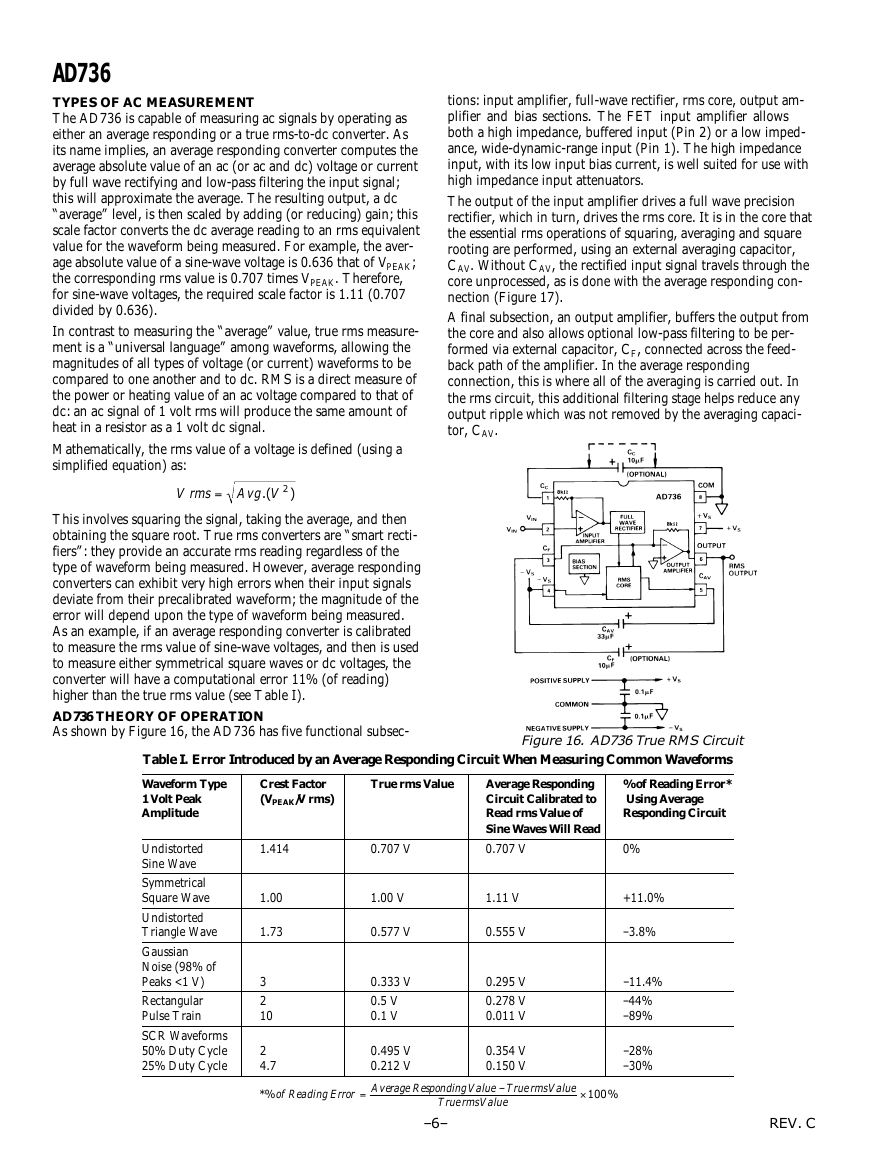

TYPES OF AC MEASUREMENT

The AD736 is capable of measuring ac signals by operating as

either an average responding or a true rms-to-dc converter. As

its name implies, an average responding converter computes the

average absolute value of an ac (or ac and dc) voltage or current

by full wave rectifying and low-pass filtering the input signal;

this will approximate the average. The resulting output, a dc

“average” level, is then scaled by adding (or reducing) gain; this

scale factor converts the dc average reading to an rms equivalent

value for the waveform being measured. For example, the aver-

age absolute value of a sine-wave voltage is 0.636 that of VPEAK;

the corresponding rms value is 0.707 times VPEAK. Therefore,

for sine-wave voltages, the required scale factor is 1.11 (0.707

divided by 0.636).

In contrast to measuring the “average” value, true rms measure-

ment is a “universal language” among waveforms, allowing the

magnitudes of all types of voltage (or current) waveforms to be

compared to one another and to dc. RMS is a direct measure of

the power or heating value of an ac voltage compared to that of

dc: an ac signal of 1 volt rms will produce the same amount of

heat in a resistor as a 1 volt dc signal.

Mathematically, the rms value of a voltage is defined (using a

simplified equation) as:

V rms = Avg.(V 2 )

This involves squaring the signal, taking the average, and then

obtaining the square root. True rms converters are “smart recti-

fiers”: they provide an accurate rms reading regardless of the

type of waveform being measured. However, average responding

converters can exhibit very high errors when their input signals

deviate from their precalibrated waveform; the magnitude of the

error will depend upon the type of waveform being measured.

As an example, if an average responding converter is calibrated

to measure the rms value of sine-wave voltages, and then is used

to measure either symmetrical square waves or dc voltages, the

converter will have a computational error 11% (of reading)

higher than the true rms value (see Table I).

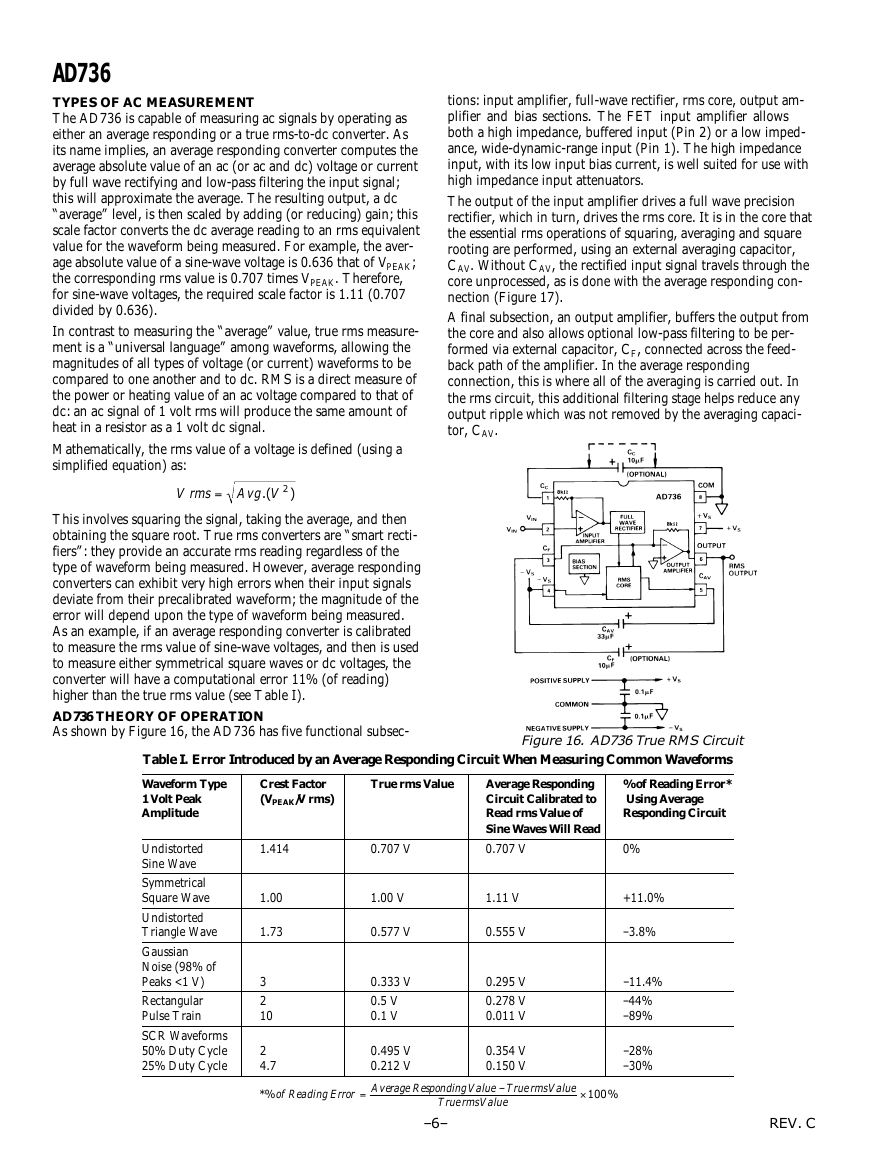

AD736 THEORY OF OPERATION

As shown by Figure 16, the AD736 has five functional subsec-

tions: input amplifier, full-wave rectifier, rms core, output am-

plifier and bias sections. The FET input amplifier allows

both a high impedance, buffered input (Pin 2) or a low imped-

ance, wide-dynamic-range input (Pin 1). The high impedance

input, with its low input bias current, is well suited for use with

high impedance input attenuators.

The output of the input amplifier drives a full wave precision

rectifier, which in turn, drives the rms core. It is in the core that

the essential rms operations of squaring, averaging and square

rooting are performed, using an external averaging capacitor,

CAV. Without CAV, the rectified input signal travels through the

core unprocessed, as is done with the average responding con-

nection (Figure 17).

A final subsection, an output amplifier, buffers the output from

the core and also allows optional low-pass filtering to be per-

formed via external capacitor, CF, connected across the feed-

back path of the amplifier. In the average responding

connection, this is where all of the averaging is carried out. In

the rms circuit, this additional filtering stage helps reduce any

output ripple which was not removed by the averaging capaci-

tor, CAV.

Figure 16. AD736 True RMS Circuit

Table I. Error Introduced by an Average Responding Circuit When Measuring Common Waveforms

Waveform Type

1 Volt Peak

Amplitude

Undistorted

Sine Wave

Symmetrical

Square Wave

Undistorted

Triangle Wave

Gaussian

Noise (98% of

Peaks <1 V)

Rectangular

Pulse Train

SCR Waveforms

50% Duty Cycle

25% Duty Cycle

Crest Factor

(VPEAK/V rms)

True rms Value

1.414

0.707 V

Average Responding

Circuit Calibrated to

Read rms Value of

Sine Waves Will Read

0.707 V

1.00

1.73

3

2

10

1.00 V

0.577 V

0.333 V

0.5 V

0.1 V

1.11 V

0.555 V

0.295 V

0.278 V

0.011 V

0.495 V

0.212 V

2

4.7

*%of Reading Error = Average Responding Value – True rmsValue

0.354 V

0.150 V

True rmsValue

· 100%

% of Reading Error*

Using Average

Responding Circuit

0%

+11.0%

–3.8%

–11.4%

–44%

–89%

–28%

–30%

–6–

REV. C

�

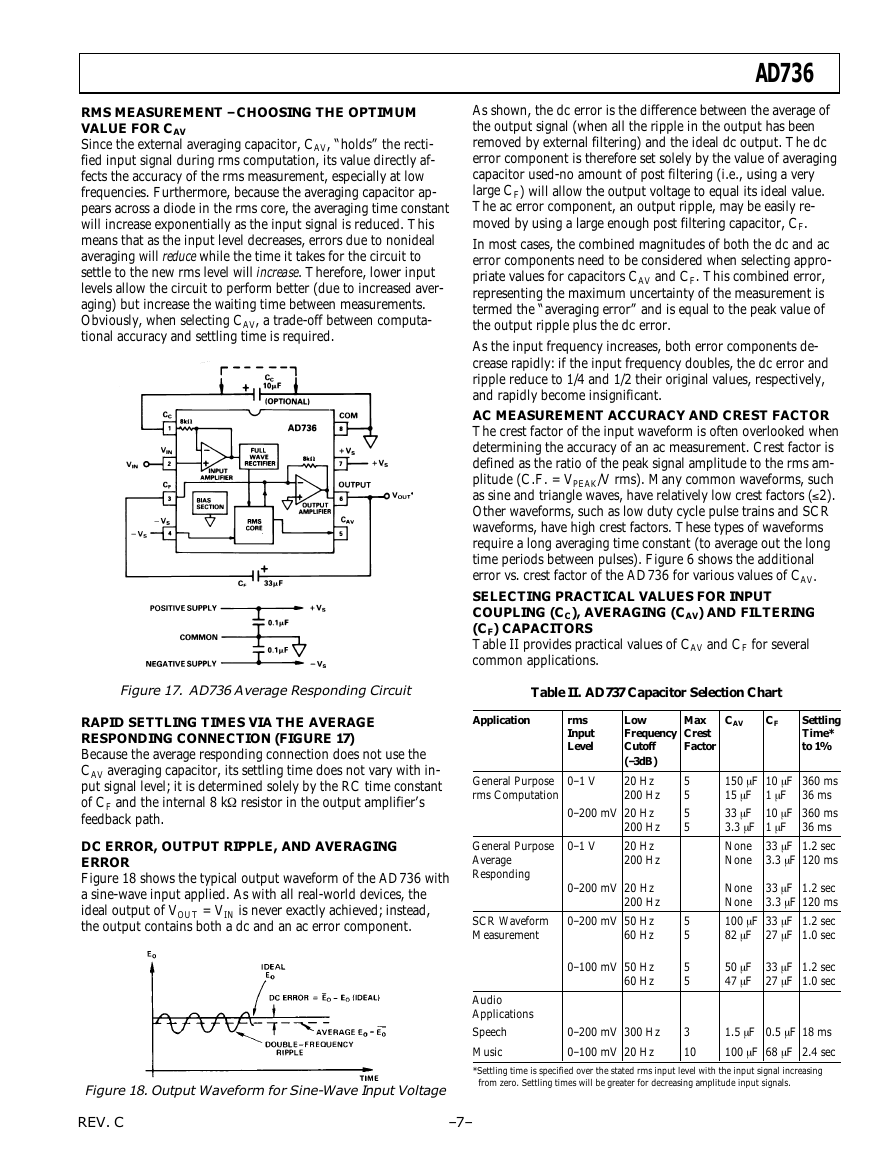

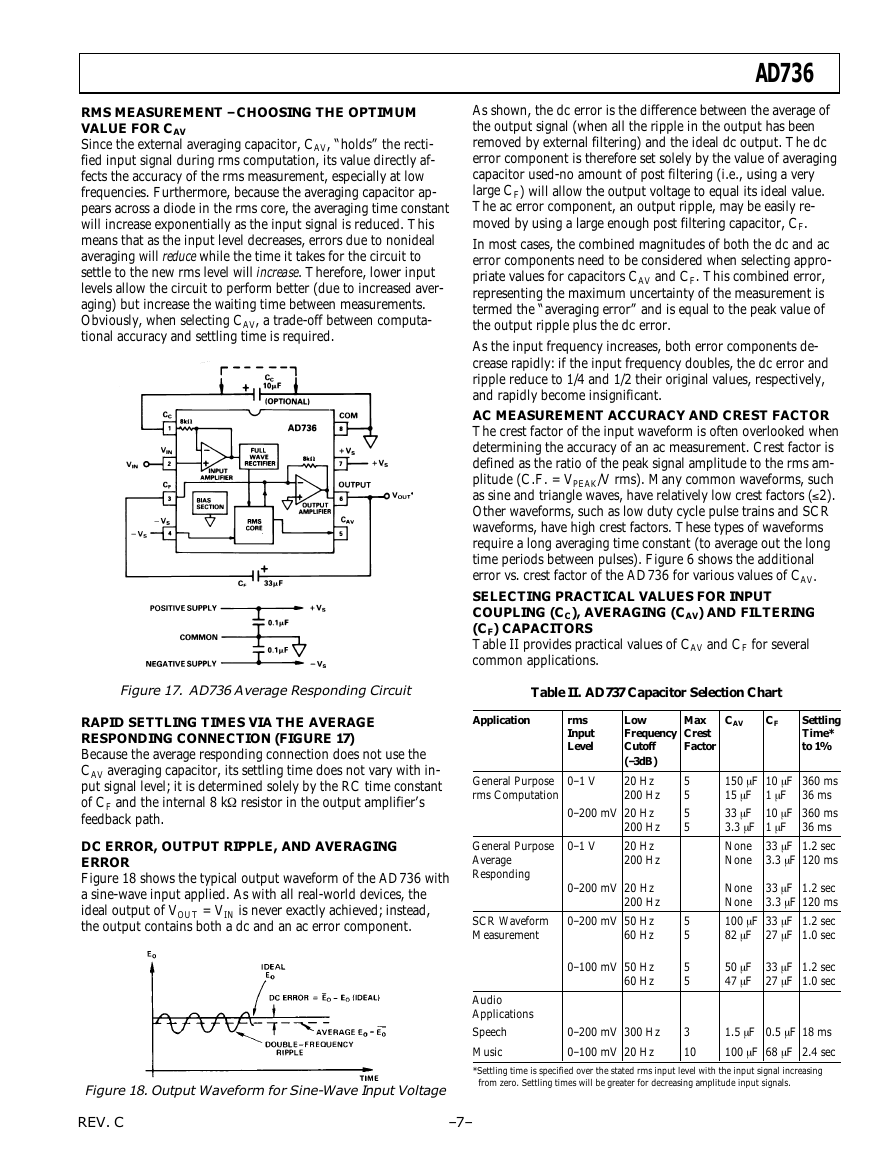

RMS MEASUREMENT – CHOOSING THE OPTIMUM

VALUE FOR CAV

Since the external averaging capacitor, CAV, “holds” the recti-

fied input signal during rms computation, its value directly af-

fects the accuracy of the rms measurement, especially at low

frequencies. Furthermore, because the averaging capacitor ap-

pears across a diode in the rms core, the averaging time constant

will increase exponentially as the input signal is reduced. This

means that as the input level decreases, errors due to nonideal

averaging will reduce while the time it takes for the circuit to

settle to the new rms level will increase. Therefore, lower input

levels allow the circuit to perform better (due to increased aver-

aging) but increase the waiting time between measurements.

Obviously, when selecting CAV, a trade-off between computa-

tional accuracy and settling time is required.

AD736

As shown, the dc error is the difference between the average of

the output signal (when all the ripple in the output has been

removed by external filtering) and the ideal dc output. The dc

error component is therefore set solely by the value of averaging

capacitor used-no amount of post filtering (i.e., using a very

large CF) will allow the output voltage to equal its ideal value.

The ac error component, an output ripple, may be easily re-

moved by using a large enough post filtering capacitor, CF.

In most cases, the combined magnitudes of both the dc and ac

error components need to be considered when selecting appro-

priate values for capacitors CAV and CF. This combined error,

representing the maximum uncertainty of the measurement is

termed the “averaging error” and is equal to the peak value of

the output ripple plus the dc error.

As the input frequency increases, both error components de-

crease rapidly: if the input frequency doubles, the dc error and

ripple reduce to 1/4 and 1/2 their original values, respectively,

and rapidly become insignificant.

AC MEASUREMENT ACCURACY AND CREST FACTOR

The crest factor of the input waveform is often overlooked when

determining the accuracy of an ac measurement. Crest factor is

defined as the ratio of the peak signal amplitude to the rms am-

plitude (C.F. = VPEAK/V rms). Many common waveforms, such

as sine and triangle waves, have relatively low crest factors (£ 2).

Other waveforms, such as low duty cycle pulse trains and SCR

waveforms, have high crest factors. These types of waveforms

require a long averaging time constant (to average out the long

time periods between pulses). Figure 6 shows the additional

error vs. crest factor of the AD736 for various values of CAV.

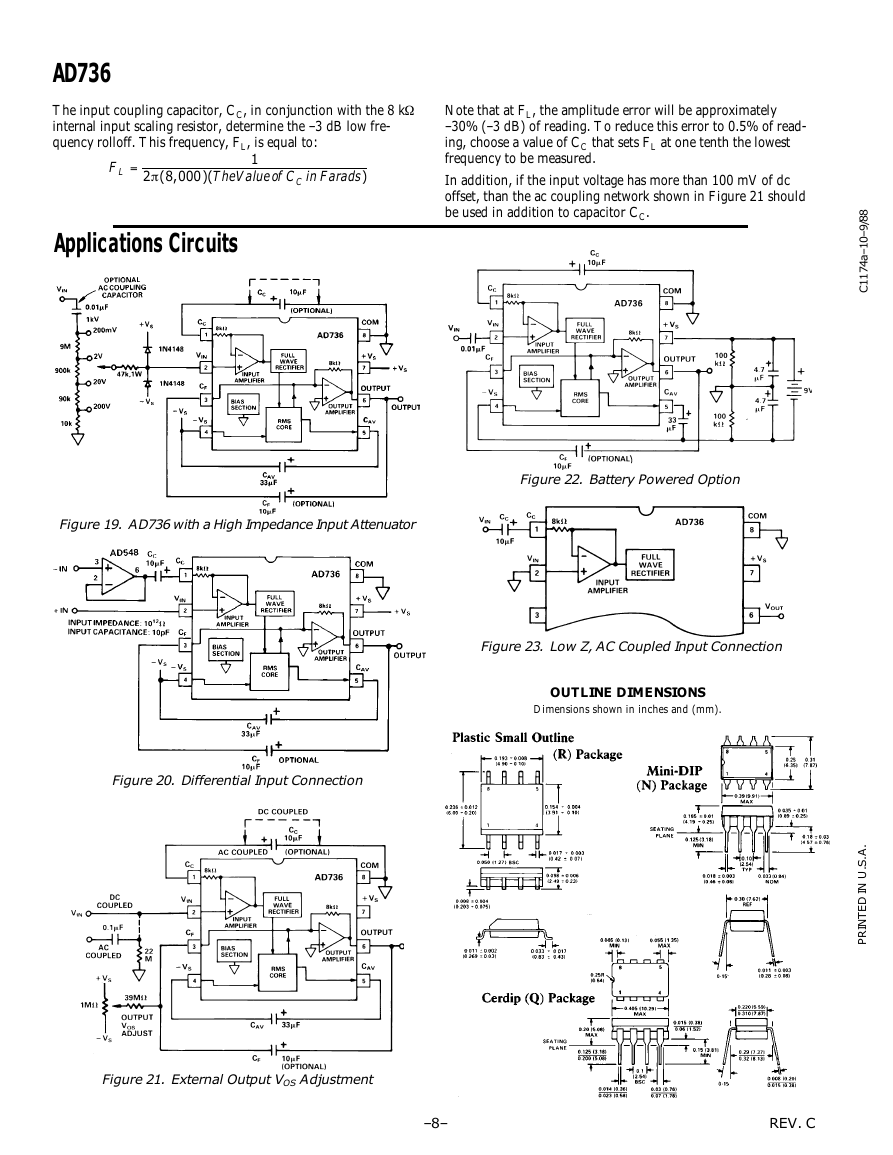

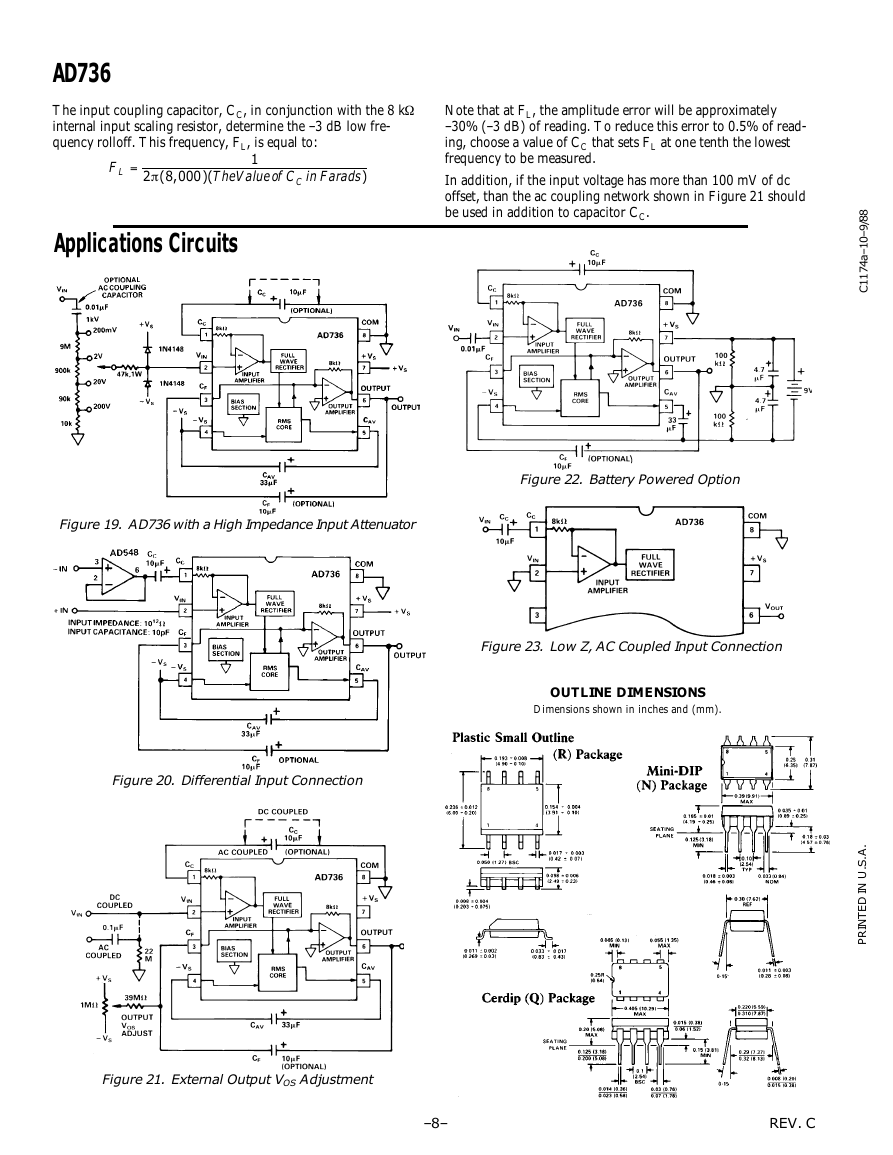

SELECTING PRACTICAL VALUES FOR INPUT

COUPLING (CC), AVERAGING (CAV) AND FILTERING

(CF) CAPACITORS

Table II provides practical values of CAV and CF for several

common applications.

Figure 17. AD736 Average Responding Circuit

Table II. AD737 Capacitor Selection Chart

RAPID SETTLING TIMES VIA THE AVERAGE

RESPONDING CONNECTION (FIGURE 17)

Because the average responding connection does not use the

CAV averaging capacitor, its settling time does not vary with in-

put signal level; it is determined solely by the RC time constant

of CF and the internal 8 kW

feedback path.

resistor in the output amplifier’s

DC ERROR, OUTPUT RIPPLE, AND AVERAGING

ERROR

Figure 18 shows the typical output waveform of the AD736 with

a sine-wave input applied. As with all real-world devices, the

ideal output of VOUT = VIN is never exactly achieved; instead,

the output contains both a dc and an ac error component.

Application

General Purpose

rms Computation

General Purpose

Average

Responding

rms

Input

Level

Low

Max

Frequency Crest

Cutoff

Factor

(–3dB)

20 Hz

200 Hz

0–200 mV 20 Hz

200 Hz

20 Hz

200 Hz

5

5

5

5

0–1 V

0–1 V

0–200 mV 20 Hz

200 Hz

SCR Waveform 0–200 mV 50 Hz

60 Hz

Measurement

0–100 mV 50 Hz

60 Hz

5

5

5

5

CAV

CF

Settling

Time*

to 1%

150 m F 10 m F 360 ms

15 m F 1 m F

36 ms

33 m F 10 m F 360 ms

3.3 m F 1 m F

36 ms

33 m F 1.2 sec

None

3.3 m F 120 ms

None

33 m F 1.2 sec

None

3.3 m F 120 ms

None

100 m F 33 m F 1.2 sec

82 m F 27 m F 1.0 sec

50 m F 33 m F 1.2 sec

47 m F 27 m F 1.0 sec

Figure 18. Output Waveform for Sine-Wave Input Voltage

REV. C

–7–

Audio

Applications

Speech

Music

0–200 mV 300 Hz

0–100 mV 20 Hz

3

10

1.5 m F 0.5 m F 18 ms

100 m F 68 m F 2.4 sec

*Settling time is specified over the stated rms input level with the input signal increasing

from zero. Settling times will be greater for decreasing amplitude input signals.

�

AD736

The input coupling capacitor, CC, in conjunction with the 8 kW

internal input scaling resistor, determine the –3 dB low fre-

quency rolloff. This frequency, FL, is equal to:

FL =

2p (8,000)(TheValue of CC in Farads )

1

Note that at FL, the amplitude error will be approximately

–30% (–3 dB) of reading. To reduce this error to 0.5% of read-

ing, choose a value of CC that sets FL at one tenth the lowest

frequency to be measured.

In addition, if the input voltage has more than 100 mV of dc

offset, than the ac coupling network shown in Figure 21 should

be used in addition to capacitor CC.

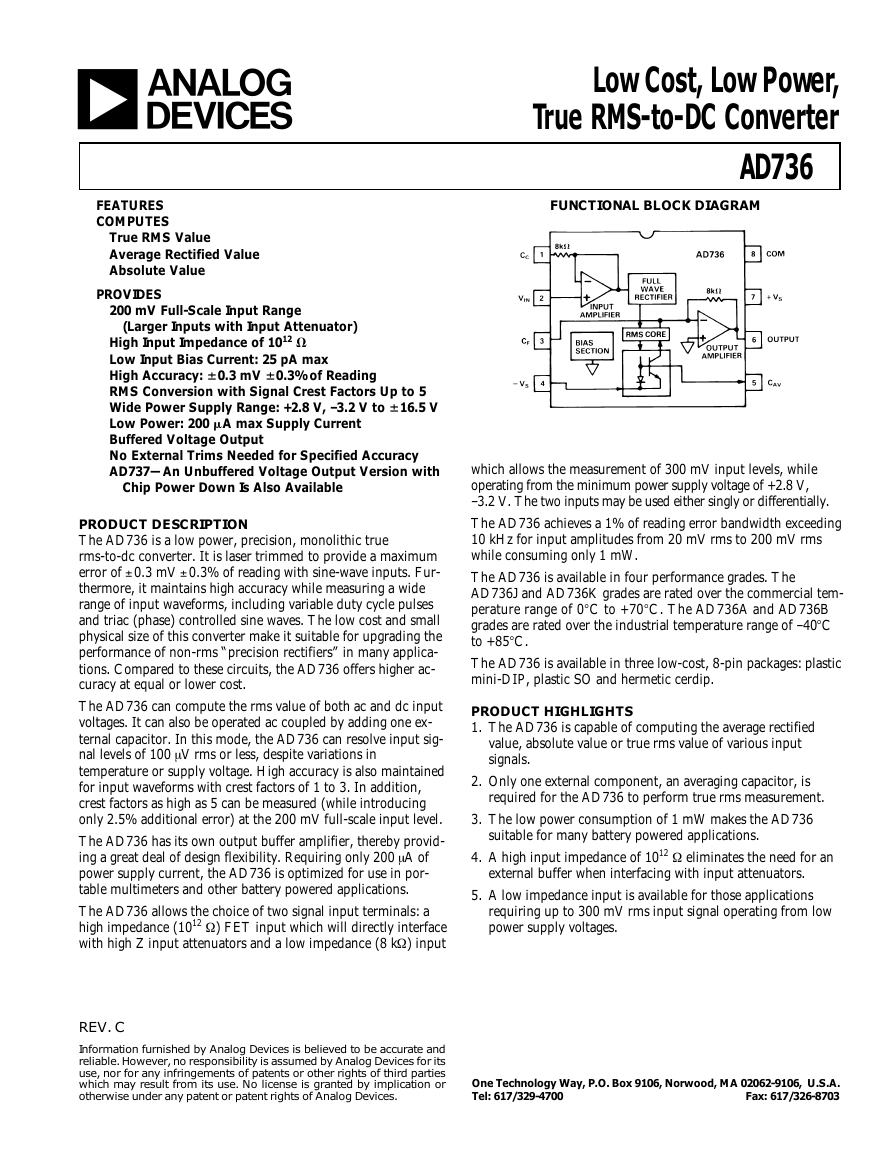

Applications Circuits

Figure 19. AD736 with a High Impedance Input Attenuator

Figure 22. Battery Powered Option

Figure 23. Low Z, AC Coupled Input Connection

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

Figure 20. Differential Input Connection

8

8

/

9

–

0

1

–

a

4

7

1

1

C

.

.

.

A

S

U

N

I

D

E

T

N

R

P

I

Figure 21. External Output VOS Adjustment

–8–

REV. C

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc