Answers for industry.

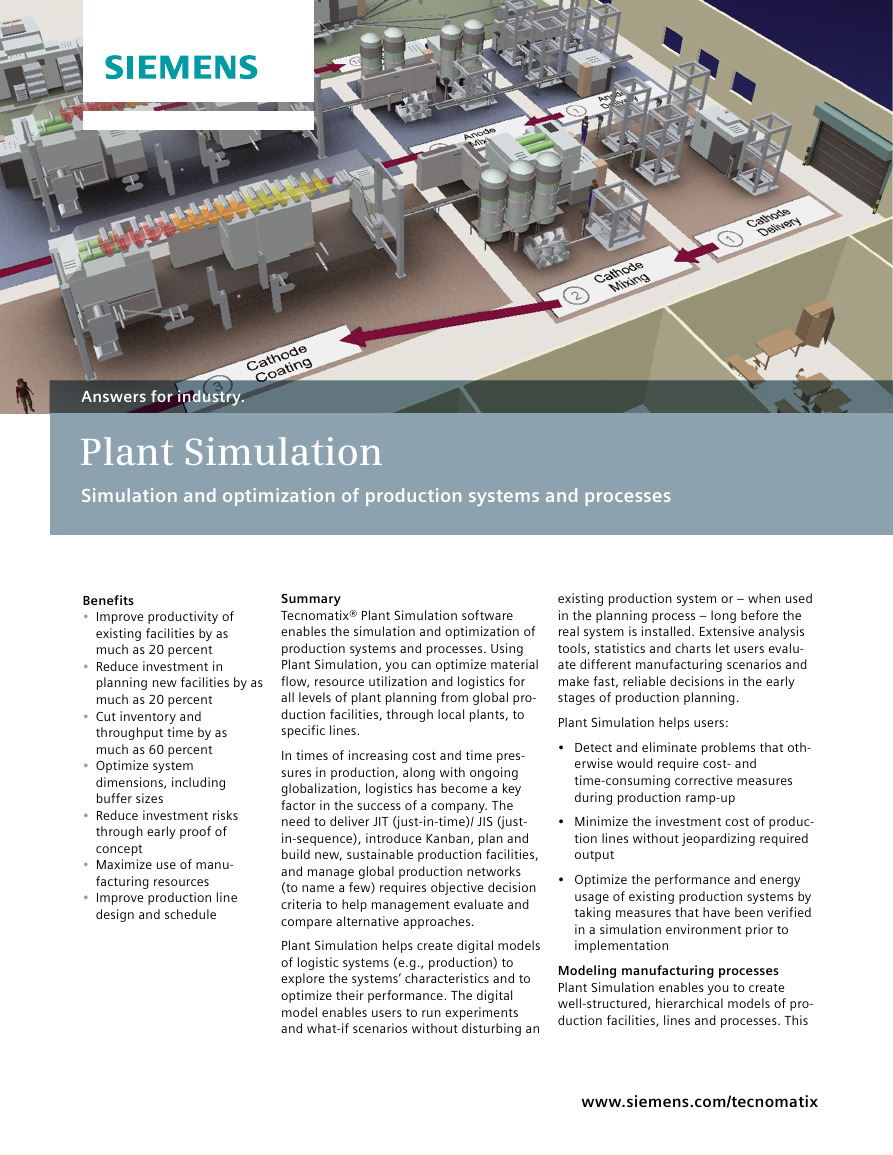

Plant Simulation

Simulation and optimization of production systems and processes

Benefits

• Improve productivity of

existing facilities by as

much as 20 percent

• Reduce investment in

planning new facilities by as

much as 20 percent

• Cut inventory and

throughput time by as

much as 60 percent

• Optimize system

dimensions, including

buffer sizes

• Reduce investment risks

through early proof of

concept

• Maximize use of manu-

facturing resources

• Improve production line

design and schedule

Summary

Tecnomatix® Plant Simulation software

enables the simulation and optimization of

production systems and processes. Using

Plant Simulation, you can optimize material

flow, resource utilization and logistics for

all levels of plant planning from global pro-

duction facilities, through local plants, to

specific lines.

In times of increasing cost and time pres-

sures in production, along with ongoing

globalization, logistics has become a key

factor in the success of a company. The

need to deliver JIT (just-in-time)/ JIS (just-

in-sequence), introduce Kanban, plan and

build new, sustainable production facilities,

and manage global production networks

(to name a few) requires objective decision

criteria to help management evaluate and

compare alternative approaches.

Plant Simulation helps create digital models

of logistic systems (e.g., production) to

explore the systems’ characteristics and to

optimize their performance. The digital

model enables users to run experiments

and what-if scenarios without disturbing an

existing production system or – when used

in the planning process – long before the

real system is installed. Extensive analysis

tools, statistics and charts let users evalu-

ate different manufacturing scenarios and

make fast, reliable decisions in the early

stages of production planning.

Plant Simulation helps users:

• Detect and eliminate problems that oth-

erwise would require cost- and

time-consuming corrective measures

during production ramp-up

• Minimize the investment cost of produc-

tion lines without jeopardizing required

output

• Optimize the performance and energy

usage of existing production systems by

taking measures that have been verified

in a simulation environment prior to

implementation

Modeling manufacturing processes

Plant Simulation enables you to create

well-structured, hierarchical models of pro-

duction facilities, lines and processes. This

www.siemens.com/tecnomatix

�

Plant Simulation

Features

• Optimize systems for

reduced energy usage

• Simulation of complex

production systems and

control strategies

• Object-oriented, hierarchical

models encompassing

business, logistics and

production processes

• Dedicated application object

libraries for fast and

efficient system modeling

• Graphical outputs for

analysis of throughput,

resources and bottlenecks

• Automatic bottleneck

detection, Sankey diagrams

and Gantt charts

• 3D online visualization and

animation

• Integrated neural networks

and experiment handling

• Automated system

optimization via genetic

algorithms

• Value stream mapping and

simulation

• Open system architecture

supporting multiple

interfaces and integration

capacities (ActiveX, CAD,

Oracle SQL, ODBC, XML,

Socket, OPC, etc.)

is achieved through powerful object-ori-

ented architecture and modeling

capabilities that enable you to create and

maintain even highly complex systems,

including advanced control mechanisms.

Plant Simulation’s user interface follows

Microsoft Windows standards, making it

easy to get familiar and productive quickly.

Simulation models can be created quickly

by using components from application

object libraries dedicated to specific busi-

ness processes, such as assembly or

carbody manufacturing processes. Users

can choose from predefined resources,

order lists, operation plans and control

rules. By extending the library with your

own objects you can capture best-practice

engineering experiences for further simula-

tion studies.

Complex and detailed simulations can be

handled, understood and maintained much

better than in conventional simulation tools

by using Plant Simulation architectural

advantages like capsulation, inheritance

and hierarchy.

Simulating and analyzing system

performance

Plant Simulation models are used to opti-

mize throughput, relieve bottlenecks and

minimize work-in-process. The simulation

models take into consideration internal and

external supply chains, production

resources and business processes, allowing

you to analyze the impact of different

TECNOMATIX

production variations. Statistical analysis,

graphs and charts display the utilization of

buffers, machines and personnel. You can

generate extensive statistics and charts to

support dynamic analysis of performance

parameters including line workload, break-

downs, idle and repair time and proprietary

key performance factors.

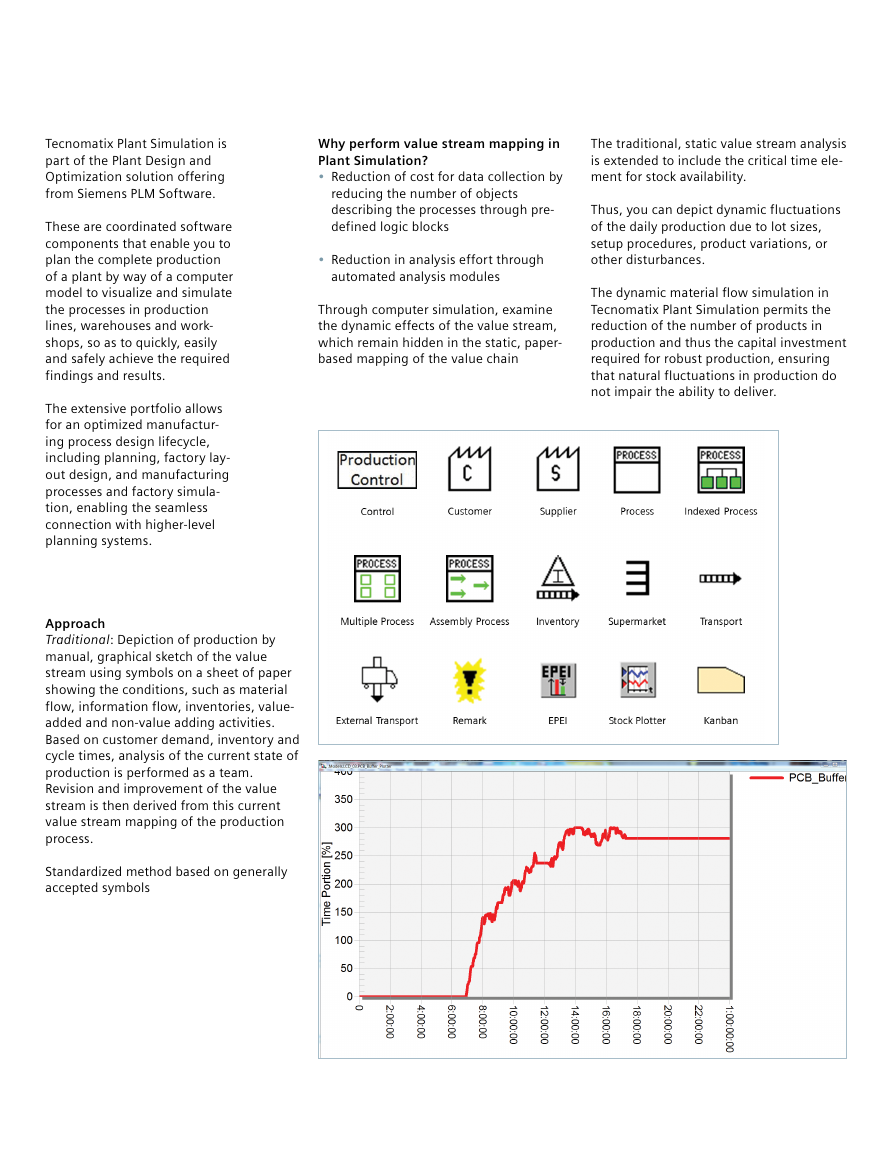

Model visualization

In addition to the highly efficient 2D model

view of Plant Simulation, models may be

visualized in a 3D virtual environment using

Plant Simulation’s included libraries or your

own CAD data. The result is impressive 3D

virtual models that are synchronized at all

times with their 2D counterparts, allowing

you the flexibility to choose the appropriate

method of visualization without compro-

mising simulation and analysis needs.

Contact

Siemens Industry Software

Americas

Europe

Asia-Pacific +852 2230 3308

+1 314-264-8499

+44 (0) 1276 413200

www.siemens.com/tecnomatix

© 2013 Siemens Product Lifecycle Management

Software Inc. Siemens and the Siemens logo are

registered trademarks of Siemens AG. D-Cubed,

Femap, Geolus, GO PLM, I-deas, Insight, JT, NX,

Parasolid, Solid Edge, Teamcenter, Tecnomatix

and Velocity Series are trademarks or registered

trademarks of Siemens Product Lifecycle Man-

agement Software Inc. or its subsidiaries in the

United States and in other countries. All other

logos, trademarks, registered trademarks or ser-

vice marks used herein are the property of their

respective holders.

Y3 7541 4/13 B

�

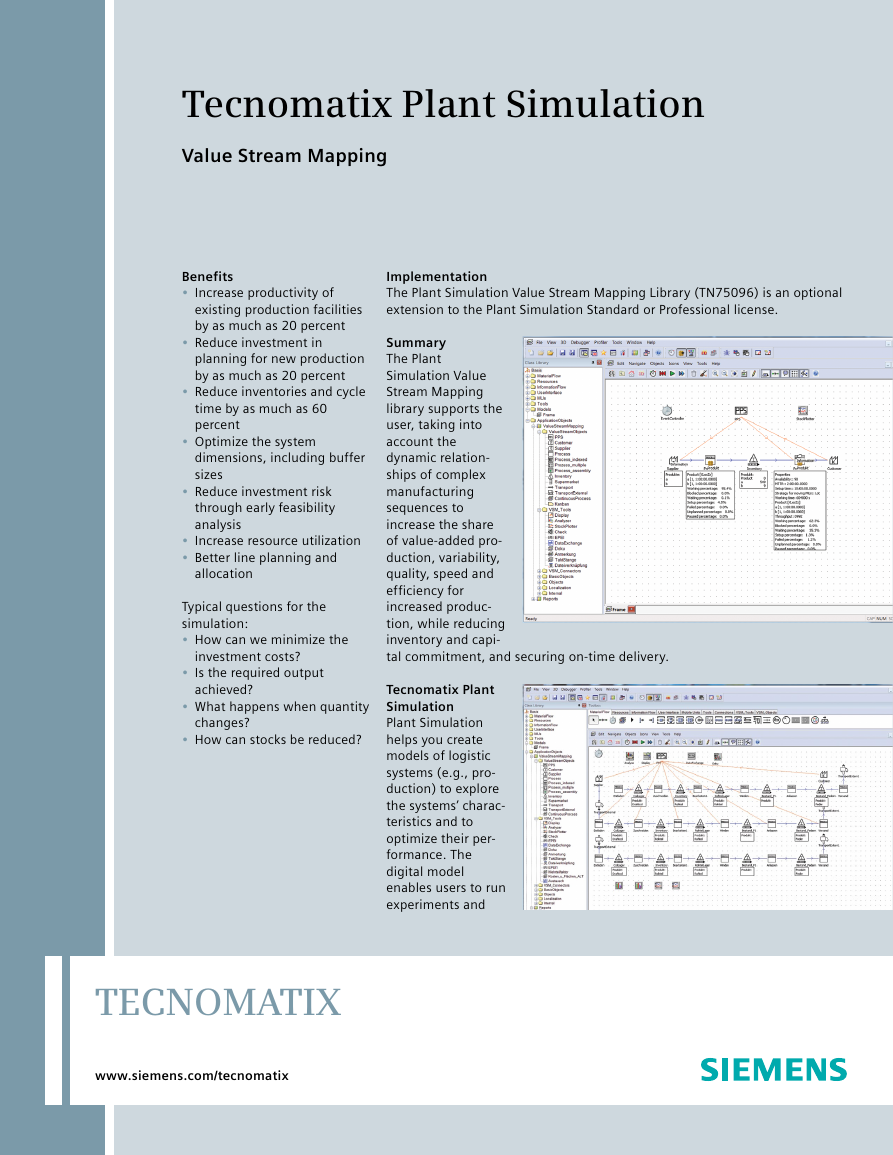

Tecnomatix Plant Simulation

Value Stream Mapping

Implementation

The Plant Simulation Value Stream Mapping Library (TN75096) is an optional

extension to the Plant Simulation Standard or Professional license.

Summary

The Plant

Simulation Value

Stream Mapping

library supports the

user, taking into

account the

dynamic relation-

ships of complex

manufacturing

sequences to

increase the share

of value-added pro-

duction, variability,

quality, speed and

efficiency for

increased produc-

tion, while reducing

inventory and capi-

tal commitment, and securing on-time delivery.

Tecnomatix Plant

Simulation

Plant Simulation

helps you create

models of logistic

systems (e.g., pro-

duction) to explore

the systems’ charac-

teristics and to

optimize their per-

formance. The

digital model

enables users to run

experiments and

Benefits

• Increase productivity of

existing production facilities

by as much as 20 percent

• Reduce investment in

planning for new production

by as much as 20 percent

• Reduce inventories and cycle

time by as much as 60

percent

• Optimize the system

dimensions, including buffer

sizes

• Reduce investment risk

through early feasibility

analysis

• Increase resource utilization

• Better line planning and

allocation

Typical questions for the

simulation:

• How can we minimize the

investment costs?

• Is the required output

achieved?

• What happens when quantity

changes?

• How can stocks be reduced?

TECNOMATIX

www.siemens.com/tecnomatix

�

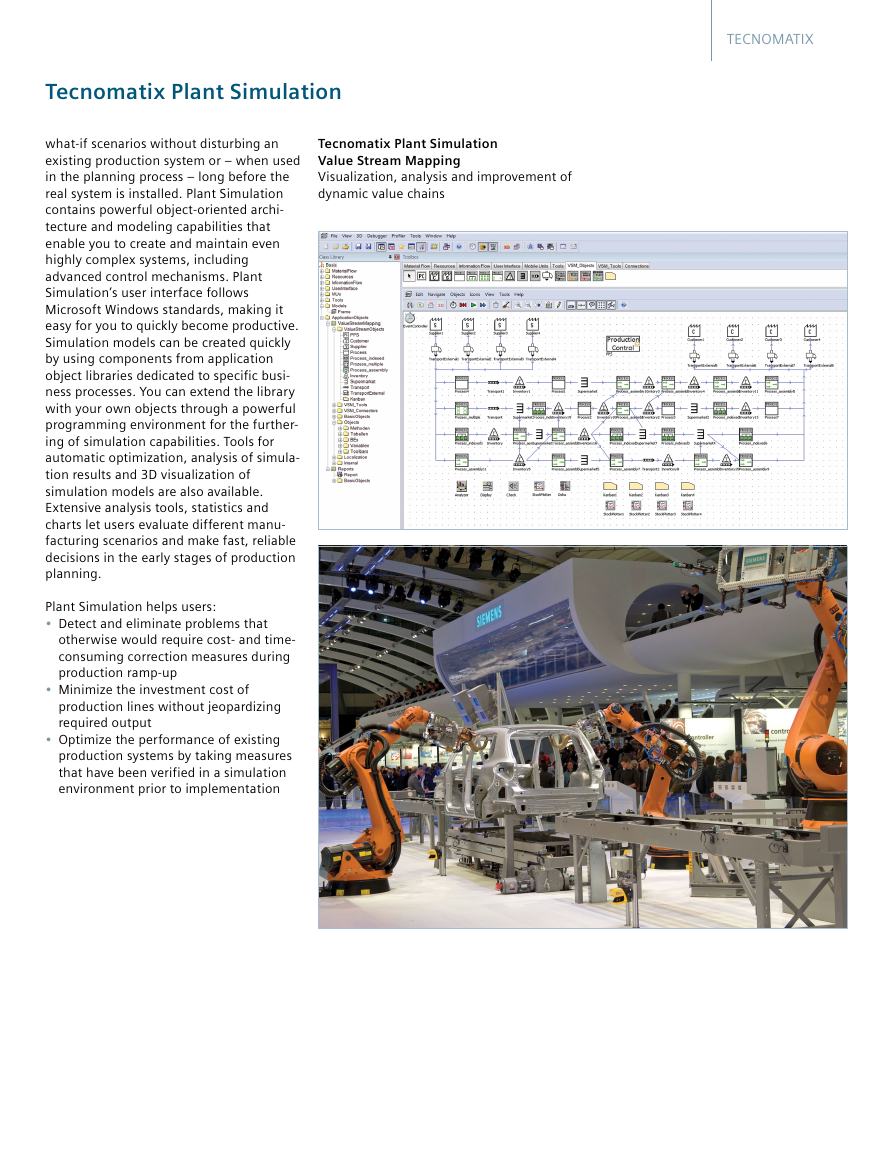

Tecnomatix Plant Simulation

TECNOMATIX

Tecnomatix Plant Simulation

Value Stream Mapping

Visualization, analysis and improvement of

dynamic value chains

what-if scenarios without disturbing an

existing production system or – when used

in the planning process – long before the

real system is installed. Plant Simulation

contains powerful object-oriented archi-

tecture and modeling capabilities that

enable you to create and maintain even

highly complex systems, including

advanced control mechanisms. Plant

Simulation’s user interface follows

Microsoft Windows standards, making it

easy for you to quickly become productive.

Simulation models can be created quickly

by using components from application

object libraries dedicated to specific busi -

ness processes. You can extend the library

with your own objects through a powerful

programming environment for the further-

ing of simulation capabilities. Tools for

automatic optimization, analysis of simula -

tion results and 3D visualization of

simulation models are also available.

Extensive analysis tools, statistics and

charts let users evaluate different manu -

facturing scenarios and make fast, reliable

decisions in the early stages of production

planning.

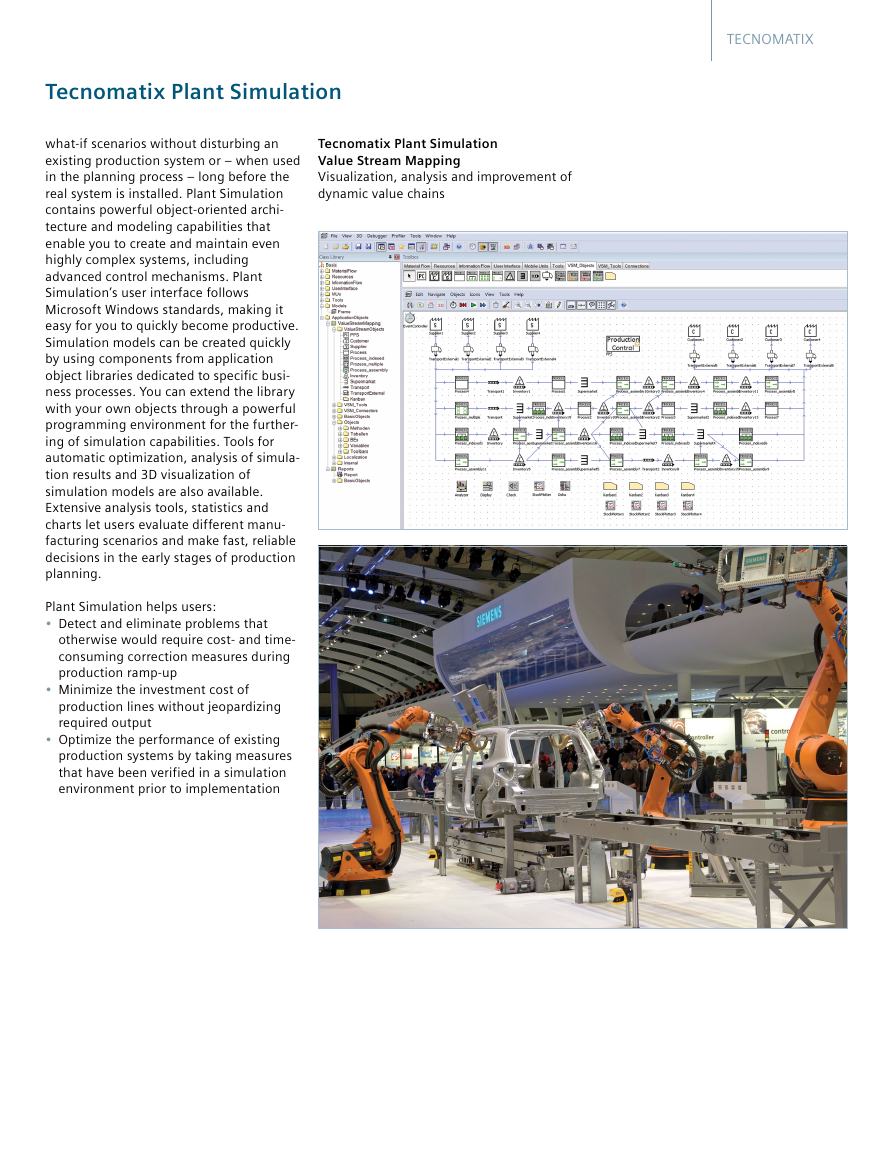

Plant Simulation helps users:

• Detect and eliminate problems that

otherwise would require cost- and time-

consuming correction measures during

production ramp-up

• Minimize the investment cost of

production lines without jeopardizing

required output

• Optimize the performance of existing

production systems by taking measures

that have been verified in a simulation

environment prior to implementation

�

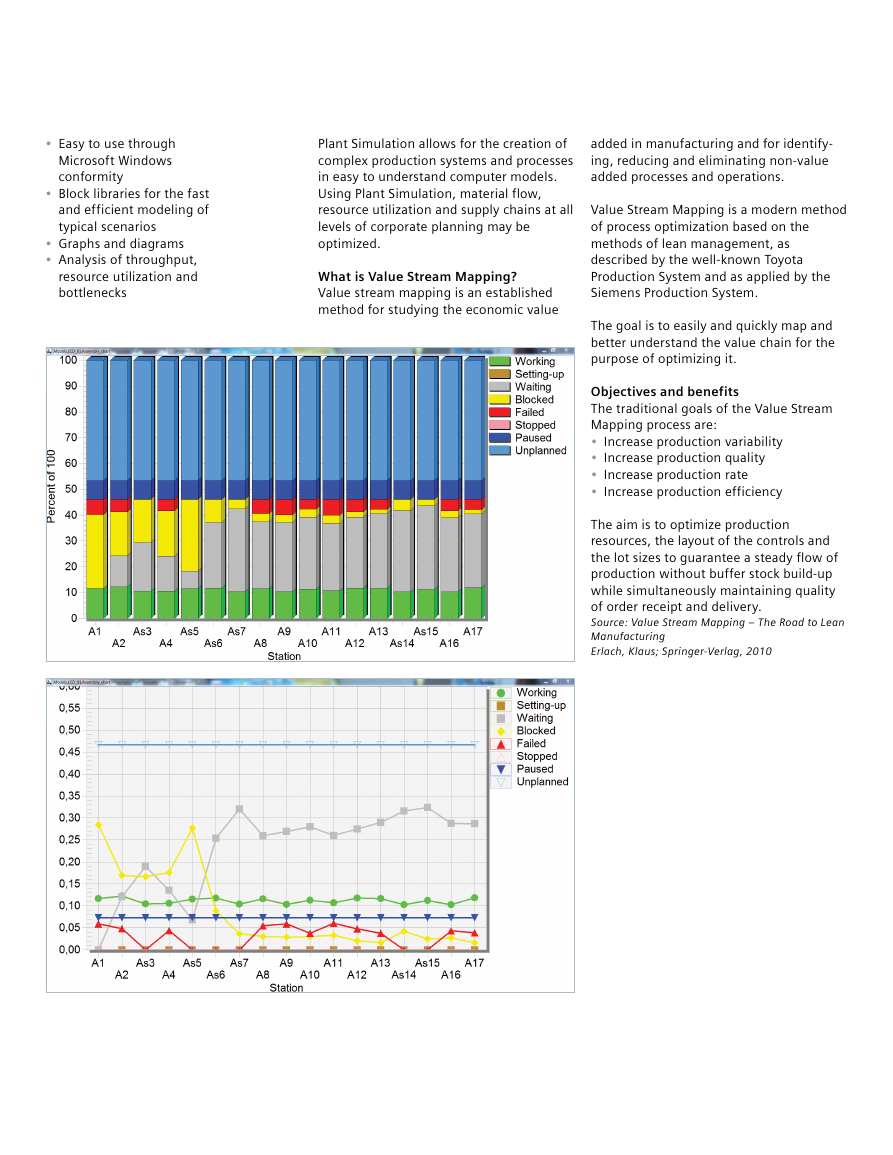

• Easy to use through

Microsoft Windows

conformity

• Block libraries for the fast

and efficient modeling of

typical scenarios

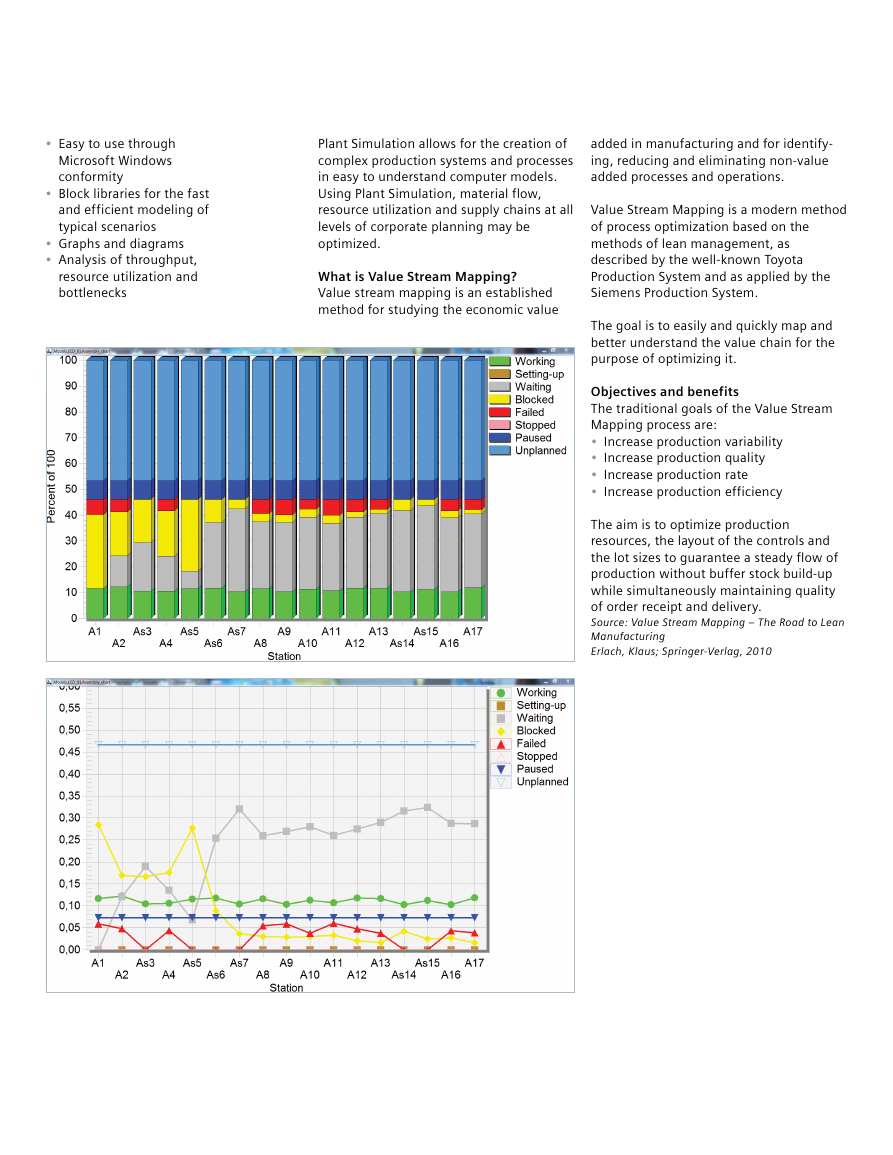

• Graphs and diagrams

• Analysis of throughput,

resource utilization and

bottlenecks

Plant Simulation allows for the creation of

complex production systems and processes

in easy to understand computer models.

Using Plant Simulation, material flow,

resource utilization and supply chains at all

levels of corporate planning may be

optimized.

What is Value Stream Mapping?

Value stream mapping is an established

method for studying the economic value

added in manufacturing and for identify -

ing, reducing and eliminating non-value

added processes and operations.

Value Stream Mapping is a modern method

of process optimization based on the

methods of lean management, as

described by the well-known Toyota

Production System and as applied by the

Siemens Production System.

The goal is to easily and quickly map and

better understand the value chain for the

purpose of optimizing it.

Objectives and benefits

The traditional goals of the Value Stream

Mapping process are:

• Increase production variability

• Increase production quality

• Increase production rate

• Increase production efficiency

The aim is to optimize production

resources, the layout of the controls and

the lot sizes to guarantee a steady flow of

production without buffer stock build-up

while simultaneously maintaining quality

of order receipt and delivery.

Source: Value Stream Mapping – The Road to Lean

Manufacturing

Erlach, Klaus; Springer-Verlag, 2010

�

Why perform value stream mapping in

Plant Simulation?

• Reduction of cost for data collection by

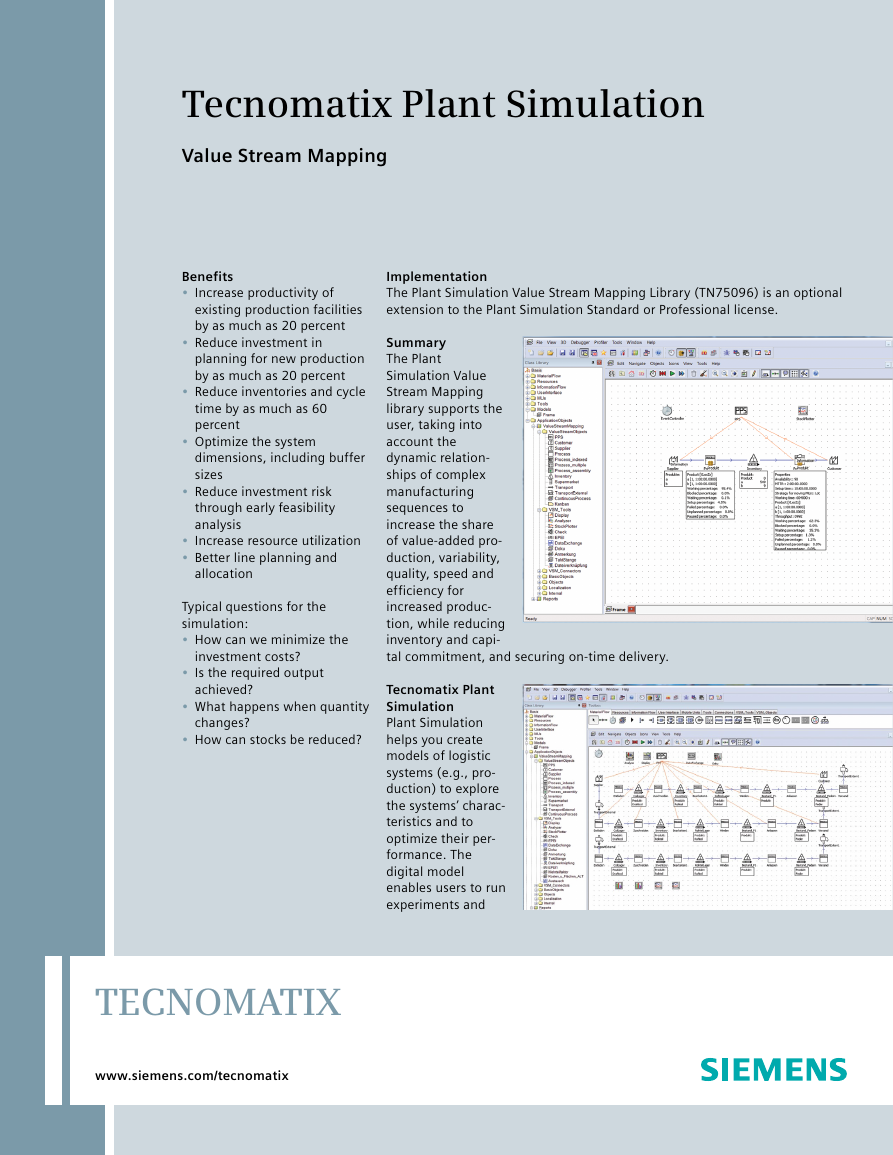

The traditional, static value stream analysis

is extended to include the critical time ele -

ment for stock availability.

reducing the number of objects

describing the processes through pre-

defined logic blocks

• Reduction in analysis effort through

automated analysis modules

Through computer simulation, examine

the dynamic effects of the value stream,

which remain hidden in the static, paper-

based mapping of the value chain

Thus, you can depict dynamic fluctuations

of the daily production due to lot sizes,

setup procedures, product variations, or

other disturbances.

The dynamic material flow simulation in

Tecnomatix Plant Simulation permits the

reduction of the number of products in

production and thus the capital investment

required for robust production, ensuring

that natural fluctuations in production do

not impair the ability to deliver.

Tecnomatix Plant Simulation is

part of the Plant Design and

Optimization solution offering

from Siemens PLM Software.

These are coordinated software

components that enable you to

plan the complete production

of a plant by way of a computer

model to visualize and simulate

the processes in production

lines, warehouses and work-

shops, so as to quickly, easily

and safely achieve the required

findings and results.

The extensive portfolio allows

for an optimized manufactur-

ing process design lifecycle,

including planning, factory lay -

out design, and manufacturing

processes and factory simula-

tion, enabling the seamless

connection with higher-level

planning systems.

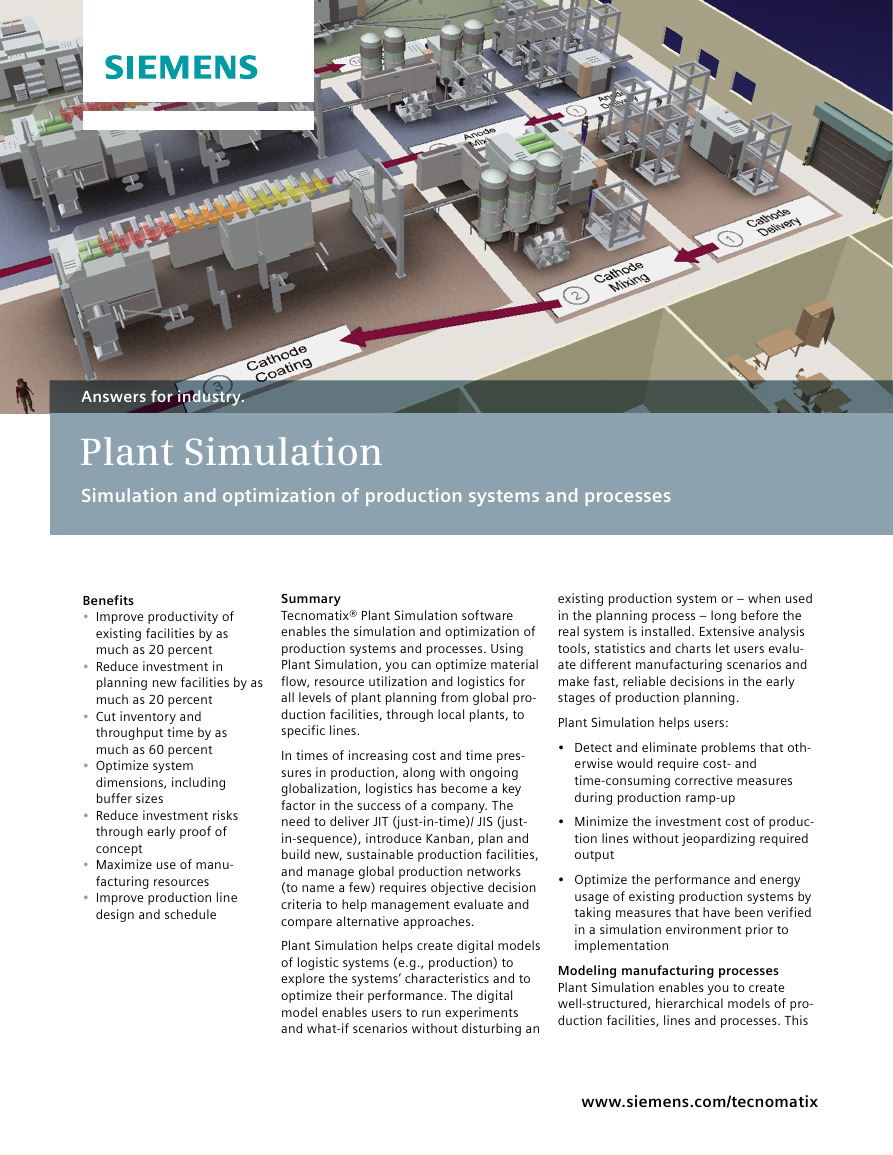

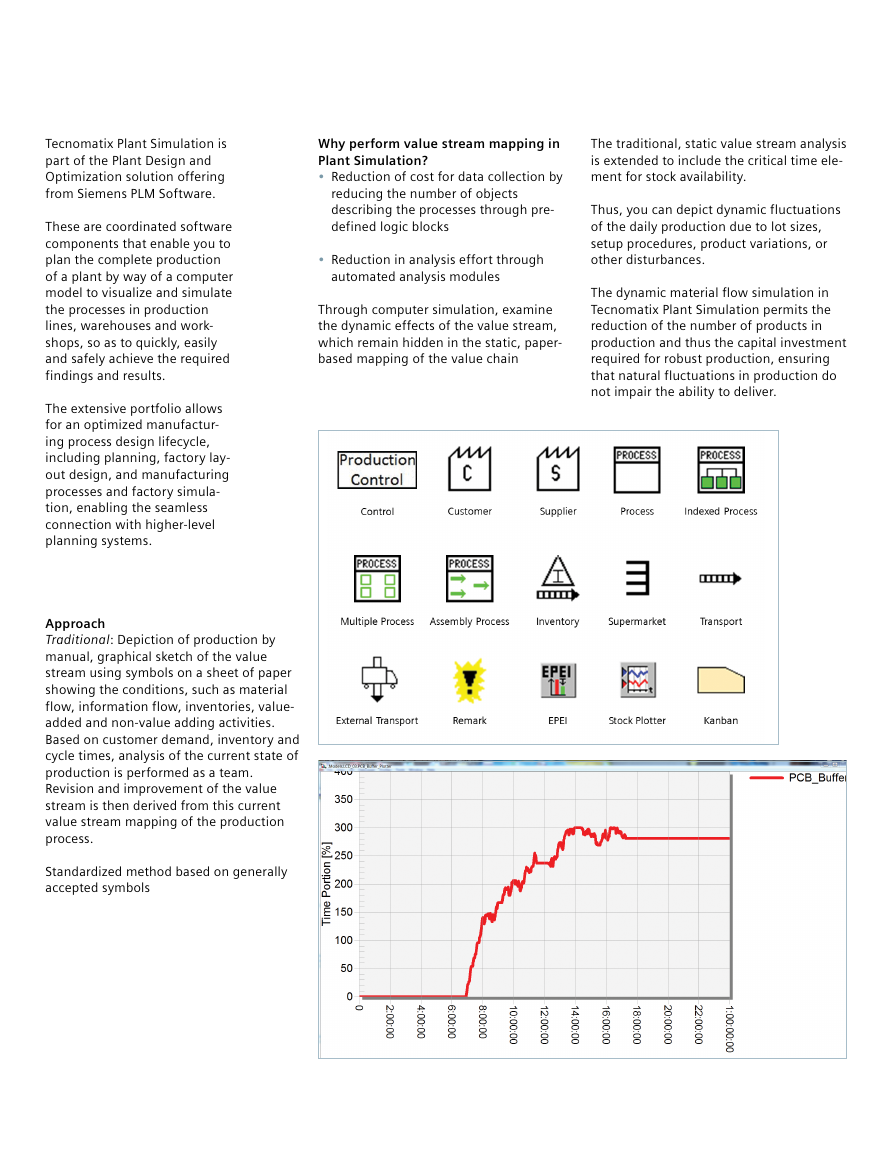

Approach

Traditional: Depiction of production by

manual, graphical sketch of the value

stream using symbols on a sheet of paper

showing the conditions, such as material

flow, information flow, inventories, value-

added and non-value adding activities.

Based on customer demand, inventory and

cycle times, analysis of the current state of

production is performed as a team.

Revision and improvement of the value

stream is then derived from this current

value stream mapping of the production

process.

Standardized method based on generally

accepted symbols

�

TECNOMATIX

Predefined core objects:

• Process

• Supplier

• Customer

• Stock

• Supermarket

• Internal and external

transport

• Predefined controls for

mapping of:

- Kanban processes

- Heijunka Box

- Compensation box

Predefined objects for analysis

and evaluation of:

• Throughput time

• Loading/unloading or waiting

time

• Value-added time

• Analysis of the process

utilization

• Availability of resources

(time sensitive)

Value Stream Mapping Library in Plant

Simulation

Predefined symbols based on the general

standard:

• Quick and easy to learn

• Predefined dialogs with configurable

user objects

• Control logics

• Analysis objects

Application

The Plant Simulation Value Stream

Mapping Library allows users to quickly

and easily map and improve their supply

chains with real dynamic behavior.

The Plant Simulation Value Stream

Mapping Library was developed in collabo -

ration with industry practitioners for use

by industry practitioners, providing the

necessary objects.

Contact

Siemens Industry Software

Americas

Europe

Asia-Pacific +852 2230 3333

+1 800 498 5351

+44 (0) 1276 702000

www.siemens.com/plm

© 2012 Siemens Product Lifecycle Management Software

Inc. All rights reserved. Siemens and the Siemens logo are

registered trademarks of Siemens AG. D-Cubed, Femap,

Geolus, GO PLM, I-deas, Insight, JT, NX, Parasolid, Solid

Edge, Teamcenter, Tecnomatix and Velocity Series are

trademarks or registered trademarks of Siemens Product

Lifecycle Management Software Inc. or its subsidiaries in

the United States and in other countries. All other logos,

trademarks, registered trademarks or service marks used

herein are the property of their respective holders.

X3 00000 7/12 B

�

Aerospace

Business challenges

Plan for airport upgrade and

passenger traffic increase

Keys to success

Use Tecnomatix Plant

Simulation for modeling air

cargo handling, passenger

flows in the international

terminal, as well as various

terminal performance

scenarios

Start with single application;

with success, implement

simulation across projects

Results

Bottlenecks identified at the

design stage and timely

corrections made

Investment risks reduced for

reconstruction of the

international terminal

Airport attained a

leadership position in the

Russian civil aviation market

Renovating Russia’s largest airport – virtually

Tecnomatix provides the tools to simulate optimum passenger and cargo handling workflows,

helping airport become a leader in the Russian civil aviation market

MOSCOW DOMODEDOVO AIRPORT

Moscow Domodedovo Airport is Russia’s largest airport. Handling 46 percent of air passengers in

Moscow, the airport is used by 74 airlines and serves 228 destinations across the globe, with 91

destinations exclusive to the Moscow region. The airport works with 46 foreign and 28 domestic

airlines. This includes 11 countries from the Commonwealth of Independent States (CIS). In 2009

Moscow Domodedovo Airport handled 18.7 million passengers.

The cooperation between Domodedovo and Siemens PLM Software began in 1999, when Moscow

Domodedovo Airport implemented a major redevelopment program – among the largest European civil

aviation investment projects of the decade – with a proposed series of airport infrastructure upgrades

that required the development and evaluation of various designs.

Moscow Domodedovo Airport selected Siemens PLM Software as an instrumental technology provider

for its reconstruction program.

To effectively plan for the airport renovation, qualitative and quantitative efficiency indicators needed

to be set. In addition, the equipment, floor space and transport requirements needed to be determined.

Moscow Domodedovo Airport’s experts used advanced computer-aided design (CAD) tools and some of

the best practices of airports

globally to address these

requirements. Among Moscow

Domodedovo Airport’s strategic

tools for design and analysis is

the Plant Simulation solution,

part of Tecnomatix® software

from Siemens PLM Software.

The first assignment for

Tecnomatix was a cargo

handling simulation project. The

objective was to model the

handling of incoming air cargo

in order to identify bottlenecks

and to improve overall

efficiency. Within three weeks

the model had been developed.

Key information included the

aircraft landing schedule, the

TECNOMATIX

www.siemens.com/tecnomatix

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc