TABLE OF CONTENTS

Foreword

DISCLAIMER OF WARRANTY

On this Operation Manual

FCC Statement (USA)

Interference to televisions and radios

Features

How to read this Operation Manual

Display on the LCD and indication of the keys

How to read this Operation Manual

Safety symbols used in this Manual

Structure of this Manual

For safe operation

Pictorial signs

Warnings in use

Precautions in use

Position of the warning label

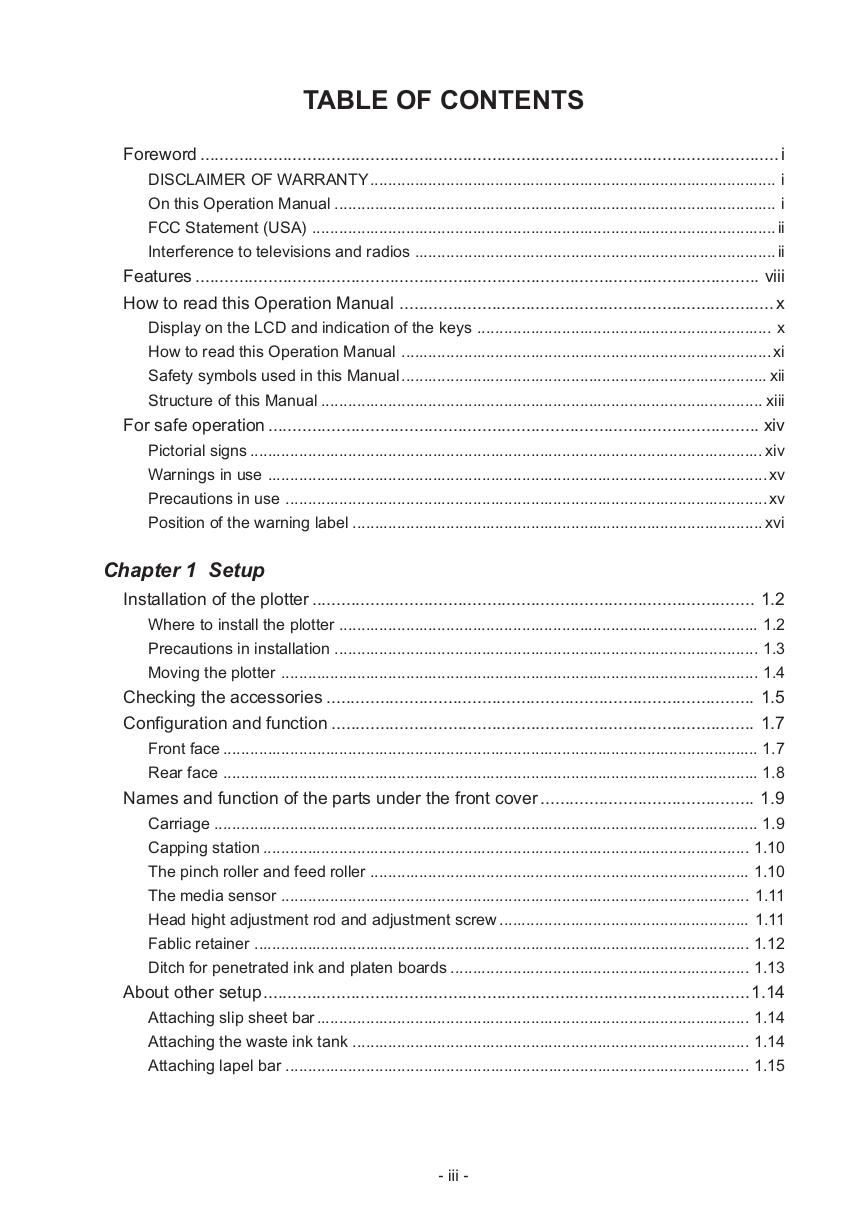

Chapter 1

Setup

Installation of the plotter

Where to install the plotter

Precautions in installation

Moving the plotter

Checking the accessories

Configuration and function

Front face

Rear face

Names and function of the parts under the front cover

Carriage

Capping station

The pinch roller and feed roller

The media sensor

Head hight adjustment rod and adjustment screw

Fablic retainer

Ditch for penetrated ink and platen boards

About other setup

Attaching slip sheet bar

Attaching the waste ink tank

Attaching lapel bar

Attaching the platen boards

Changing gap for fablic retainers

Installing IEEE1394 output driver

Installing USB output driver

Connecting the cables

Connecting the interface cable

For Windows 2000, XP (IEEE1394 or USB2.0)

For other operating system (IEEE1284)

Connecting the power cable

Switching ON/OFF the power supply

Turning the power on

Turning the power off

Front cover and maintenance cover

Opening/closing the cover

Ink cartridges

Types of ink

Precautions in handling the ink cartridge

Ink stations

Display of ink type

Setting ink cartridges

Fabric for printing

Types of fablic that can be used

Precautions in handling the fabric

Limited media

Before setting the fabric on the plotter

Adjusting the head height according to the fablic [HEAD HEIGHT]

Points in head height adjustment

Setting the slip sheet

Setting the fabric to the plotter

Setting a roll fablic (In case of DS-1600/1800AMF model)

Removing pinch roller and preventing wrinkle of fablic

Adjusting friction of the tension bar

Specifying the scope of printing on the fabric used

(Effective printing area)

Origin setting

Setting of an origin

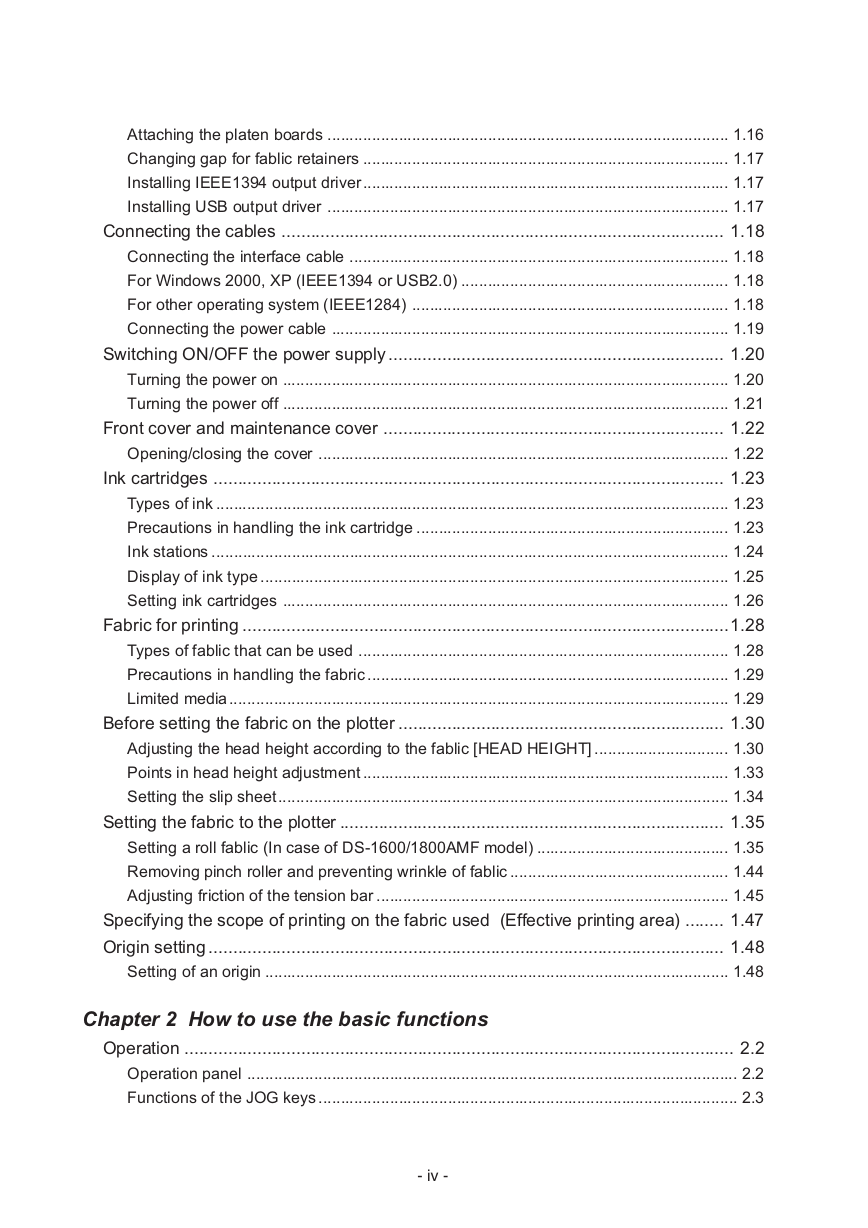

Chapter 2

How to use the basic functions

Operation

Operation panel

Functions of the JOG keys

MENU mode

Menu tree

Setting the display language

Printing an image from saurce data

Starting the plotter operation

Correcting the media feed rate during printing [Feed Comp.]

Interrupting the printing operation

Checking nozzle in ink firing condition

Executing the test draw [TEST DRAW]

Checking the test patterns

If there are nozzle clogging in ink firing condition

Cleaning ink heads

Routine maintenance

When the device is left unused for a long period of time

Notes on cleaning

Cleaning ink at the bottom of the slider

Cleaning wiper

Cleaning the wiper shaft

Cleaning penetrated ink

Cleaning penetrated ink

Maintenance for frame components

To replenish ink, set a new ink cartridge in the ink station

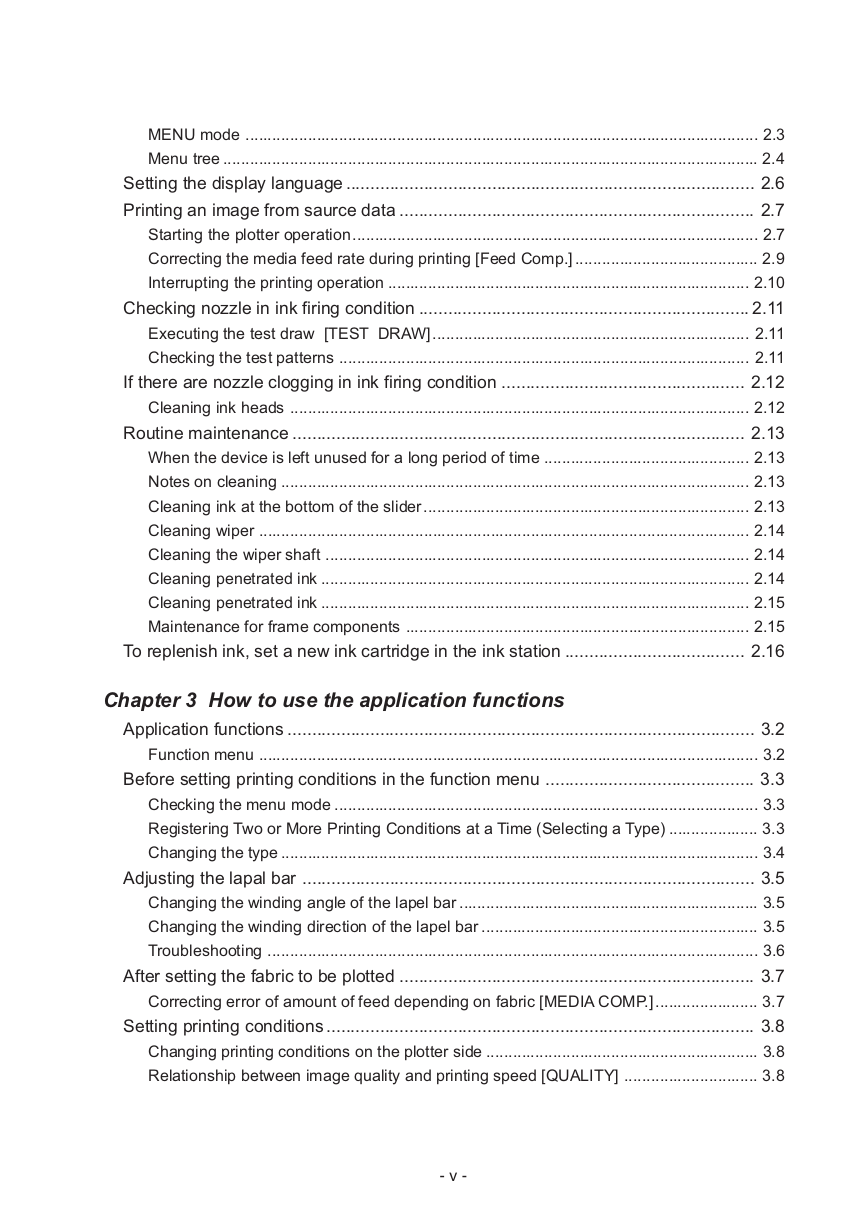

Chapter 3

How to use the application functions

Application functions

Function menu

Before setting printing conditions in the function menu

Checking the menu mode

Registering Two or More Printing Conditions at a Time (Selecting a Type)

Changing the type

Adjusting the lapal bar

Changing the winding angle of the lapel bar

Changing the winding direction of the lapel bar

Troubleshooting

After setting the fabric to be plotted

Correcting error of amount of feed depending on fabric [MEDIA COMP.]

Setting printing conditions

Changing printing conditions on the plotter side

Relationship between image quality and printing speed [QUALITY]

Printing direction [DIRECTION]

Returning speed up [RET. SPD UP]

Improving the density of ink color [INK LAYERS]

Setting the ink drying time [DRYING TIME]

Deciding the priority of settings by the computer or the plotter [PRIORITY]

Increasing (decreasing) the right and left margins of the fabric

[RIGHTmargin]/[LEFTmargin]

Setting [RIGHTmargin]

Setting [LEFTmargin]

When using the plotter in an extremely dusty or dry place [REFRESH]

Setting a unit of length displayed on the LCD [MM/INCH]

Setting the type of ink to be used [INK TYPE]

Setting up auto-cleaning function [AUTO CLEAN]

Setting up auto-cleaning function [AUTO CLEAN2]

Continuing printing after [Ink Near End] [PRINT CONT.]

Setting the print end operation. [EndOf PRINT]

Enabling the feeding unit [FEEDING]

Enabling the take-up unit [TAKE-UP]

Resetting printing conditions by type [SETUP RESET]

Chapter 4

Maintenance functions

Maintenance of the plotter

Function menu [MAINTENANCE]

Before starting maintenance

Checking the menu mode

Invoking a maintenance function

Maintenance functions

Drawing setup conditions [LIST]

Printing HEX code of printing command [DATA DUMP]

Correcting the dot positions after adjusting the head height [PRINTadjust]

Moving the carriage to clean the station interior [CARRIAGEout]

If a defective printing is not corrected even after the cleaning function is executed

Periodical cleaning of the wiper

Notes on handling the wipers

When the message [Replace Wiper] is displayed [WIPER EXCHG]

When the message [Clean Wiper Shaft] is displayed

Cleaning the nozzle [NOZZLE CLN]

Ink discharge way cleaning [DRAIN WASH]

When not in use the machine over the long term [STORAGE WSH]

Move the carriage to the left maintenance station [CARRIAGE]

Adjusting the head height when the fabric used is changed [HEAD HEIGHT]

Menu displayed after the ink cartridge is installed [FILL UP INK]

When charging ink different from the one in use [INK CHANGE]

Selecting ink head [USE HEAD]

Check the stretch and shrink of fabric after the printing [STRETCH CHK]

Execute the flushing and cleaning regularly [ROUTINE CTR]

Setting the machine name [MACHINE NAME]

Displaying the plotter information [INFORMATION]

Chapter 5

When abnormal conditions

are encountered

Before taking a phenomenon as a sign of failure

The plotter cannot be energized

The plotter cannot perform printing

Paper jamming arises/fabric is soiled

If image quality declines

White lines/thin spots are obvious (In the direction of travel of the head)

Displacement is observed between outward and inward printing

The respective color ink injected by the respective color heads do not properly

overlap

Troubles for which error message are given on the LCD

Warning message

Error messages

Chapter 6

Ink guidance

Emergency measures

Printing procedures

Printing procedures by ink type

Sublimation dye ink recipe

Textile pigment ink recipe

Appendix

Basic specifications

Speification for ink

Optional extras

Function flow chart

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc