- a collection of simulation tools for refrigeration -

Tutorial - Version 1.46

Authors:

Arne Jakobsen

Bjarne Dindler Rasmussen

Morten Juel Skovrup

Simon Engedal Andersen

Department of Energy Engineering

Technical University of Denmark (DTU)

CoolPack@et.dtu.dk www.et.dtu.dk/CoolPack

May 2001

�

�

SysSim

CoolPack – a collection of simulation programs for refrigeration

Table of Contents

1

INTRODUCTION .............................................................................................................. 3

2 DESCRIPTION OF COOLPACK ..................................................................................... 3

3 COOLPACK CONTACT ................................................................................................... 5

4

INSTALLATION.................................................................................................................. 7

5

EXERCISES .......................................................................................................................... 8

5.1

Overview of exercises in this tutorial...................................................................................8

Exercise 1: Fundamental concepts in CoolPack ..............................................................................9

Exercise 2: Fundamental concepts in EESCoolTools ...................................................................10

Exercise 3: Fundamental concepts in Refrigeration Utilities......................................................15

Exercise 4: Short EESCoolTools exercise........................................................................................19

Exercise 5: Short Refrigeration Utilities exercise...........................................................................21

Exercise 6: Creation of property plots and drawing refrigeration cycles..................................23

Exercise 7: One-stage cycle with dry expansion evaporator.........................................................27

Exercise 8: One-stage cycle with flooded evaporator ....................................................................29

Exercise 9: Designing a one-stage refrigeration system.................................................................31

Exercise 10: Energy analysis of a system with on/off-type capacity control ............................36

Exercise 11: Liquid flow in pipes (pressure drop and heat transfer) .........................................38

Exercise 12: Transient cooling of goods in a refrigerated room ................................................40

6 CONCEPTS, SHORTCUTS, AND OTHER HINTS.................................................... 42

7 OVERVIEW OF PROGRAMS IN COOLPACK ........................................................... 44

PROGRAMS IN REFRIGERATION UTILITIES............................................................................44

PROGRAMS IN EESCOOLTOOLS: CYCLE ANALYSIS (C-TOOLS) ..........................................44

PROGRAMS IN EESCOOLTOOLS: DESIGN ............................................................................44

PROGRAMS IN EESCOOLTOOLS: EVALUATION (E-TOOLS) ................................................45

PROGRAMS IN EESCOOLTOOLS: AUXILIARY TOOLS (A-TOOLS) .......................................45

PROGRAMS IN DYNAMIC ........................................................................................................45

7.1

7.2

7.3

7.4

7.5

7.6

Printouts from catalogs (used in exercise 9) can be found in the separate

appendix.

CoolPack Tutorial

Rev. 05-03-01

Page i

�

CoolPack – a collection of simulation programs for refrigeration

Page ii

Rev. 17-05-01

CoolPack Tutorial

�

CoolPack – a collection of simulation programs for refrigeration

1 INTRODUCTION

This tutorial gives a general introduction to CoolPack and contains a number of exercises

demonstrating how the programs in CoolPack should be used.

The exercises are organized in groups representing the various types of investigations for which

CoolPack can be used. The first exercises are introductory, focussing on how to use the various

types of programs in CoolPack and how to navigate between them. The following exercises are

more detailed and aimed at demonstrating the use of CoolPack for analyzing refrigeration

systems.

Once you have become familiar with the programs in CoolPack, we hope that you will use

CoolPack for solving the refrigeration-oriented tasks related to your job/education. If you have

any comments or questions about CoolPack we encourage you to contact us – your comments

and ideas will be very helpful to us in making CoolPack an even better program.

2 DESCRIPTION OF COOLPACK

The development of CoolPack started in spring of 1998 as a part of a research project. The

objective of this project was to develop simulation models to be used for energy optimization

of refrigeration systems. The users of these models would be refrigeration technicians,

engineers, students etc. in short all the persons with influence on the present and future energy

consumption of refrigeration systems.

The first idea was to make a general and comprehensive simulation program that would give

the user all the flexibility he/she could wish for in terms of handling many different system

designs and investigation purposes. Some of the characteristics of very general and flexible

programs are that they require many user inputs/selections and that their numerical robustness

is rather low. Experience with this type of programs has shown that this type of simulation

programs is far from ideal for the main part of the users mentioned above. Since most of these

users have limited time for carrying out the investigation, general and comprehensive programs

will in many cases be very ineffective to use and they are therefore often discarded by the users.

The idea behind the development of CoolPack is different from the idea described above.

Instead of creating a large, general and comprehensive simulation program we have chosen to

create a collection of small, easy to use, and numerically robust simulation programs.

The typical simulation program in CoolPack deals with only on type of refrigeration system

and has a specific investigation purpose. It therefore only requires the user inputs/selections

necessary to describe operating conditions etc. and not any inputs for describing the system

design or for specifying the input/output structure associated with the simulation purpose.

When developing the programs for CoolPack we have focused on making the underlying

system models as simple, relevant and numerically robust as possible. We have preserved some

flexibility in that the user can select refrigerant and also specify inputs (like pressure) in more

than one way (saturation temperature or pressure).

The programs in CoolPack covers the following simulation purposes:

• Calculation of refrigerant properties (property plots, thermodynamic & thermophysical

data, refrigerant comparisons)

• Cycle analysis – e.g. comparison of one- and two-stage cycles

•

System dimensioning – calculation of component sizes from general dimensioning

criteria

System simulation – calculation of operating conditions in a system with known

components

•

CoolPack Tutorial

Rev. 03-06-00

Page 3

�

CoolPack – a collection of simulation programs for refrigeration

• Evaluation of operation – evaluation of system efficiency and suggestions for reducing

the energy consumption

• Component calculations – calculation of component efficiencies

• Transient simulation of cooling of an object – e.g. for evaluation of cooling down

periods

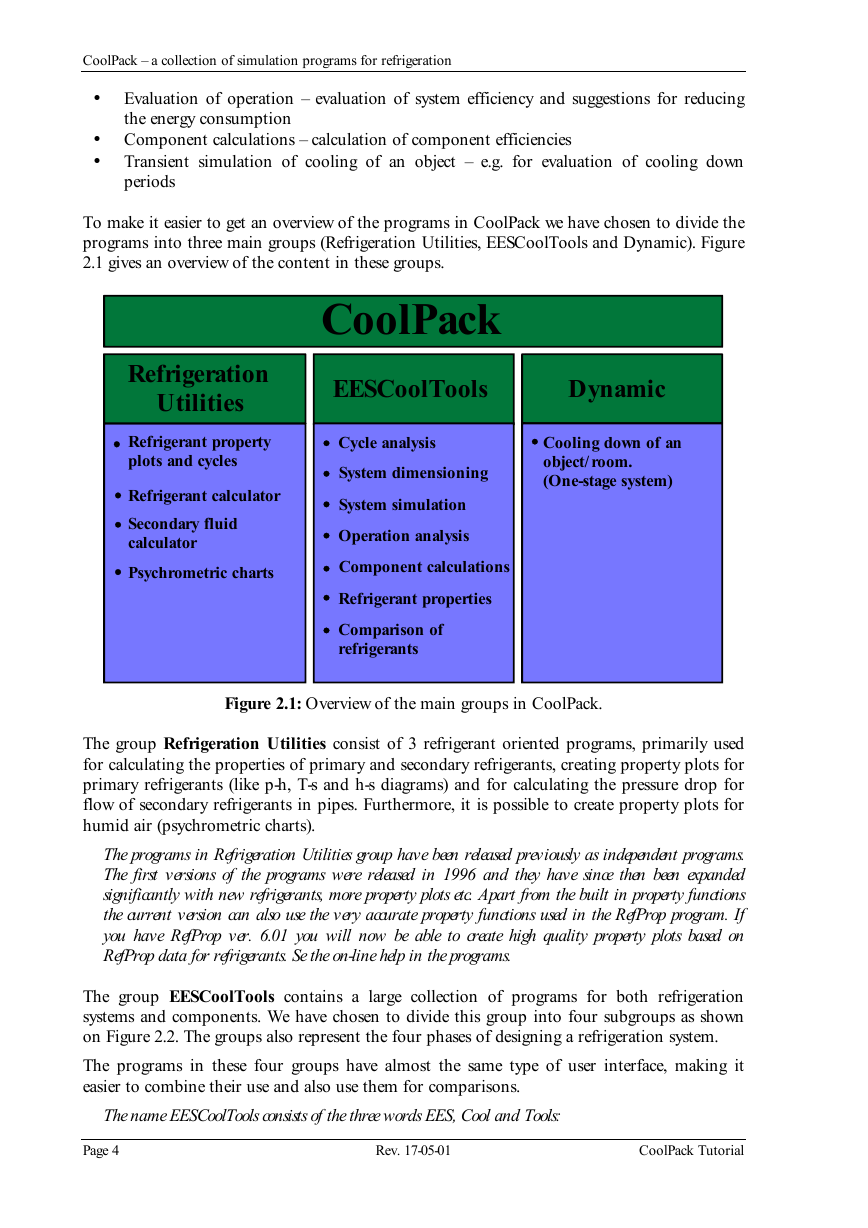

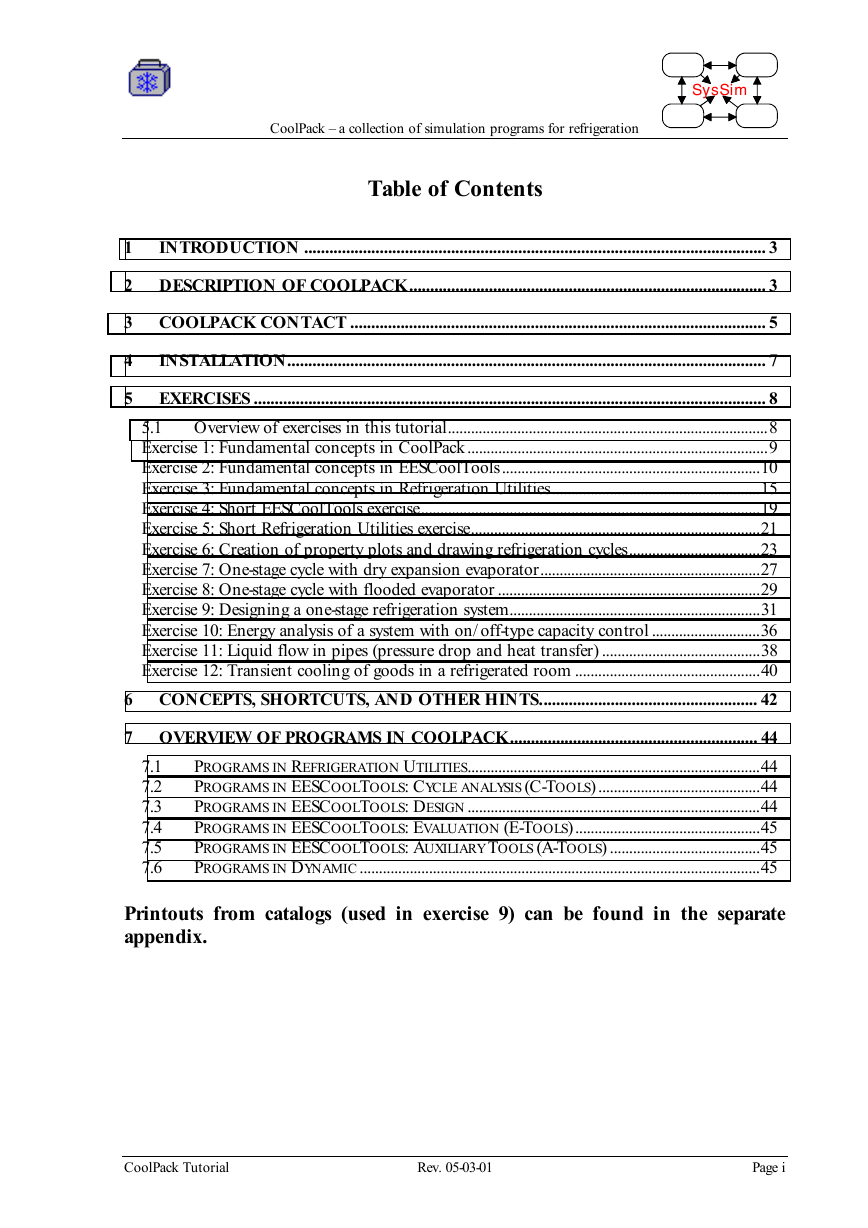

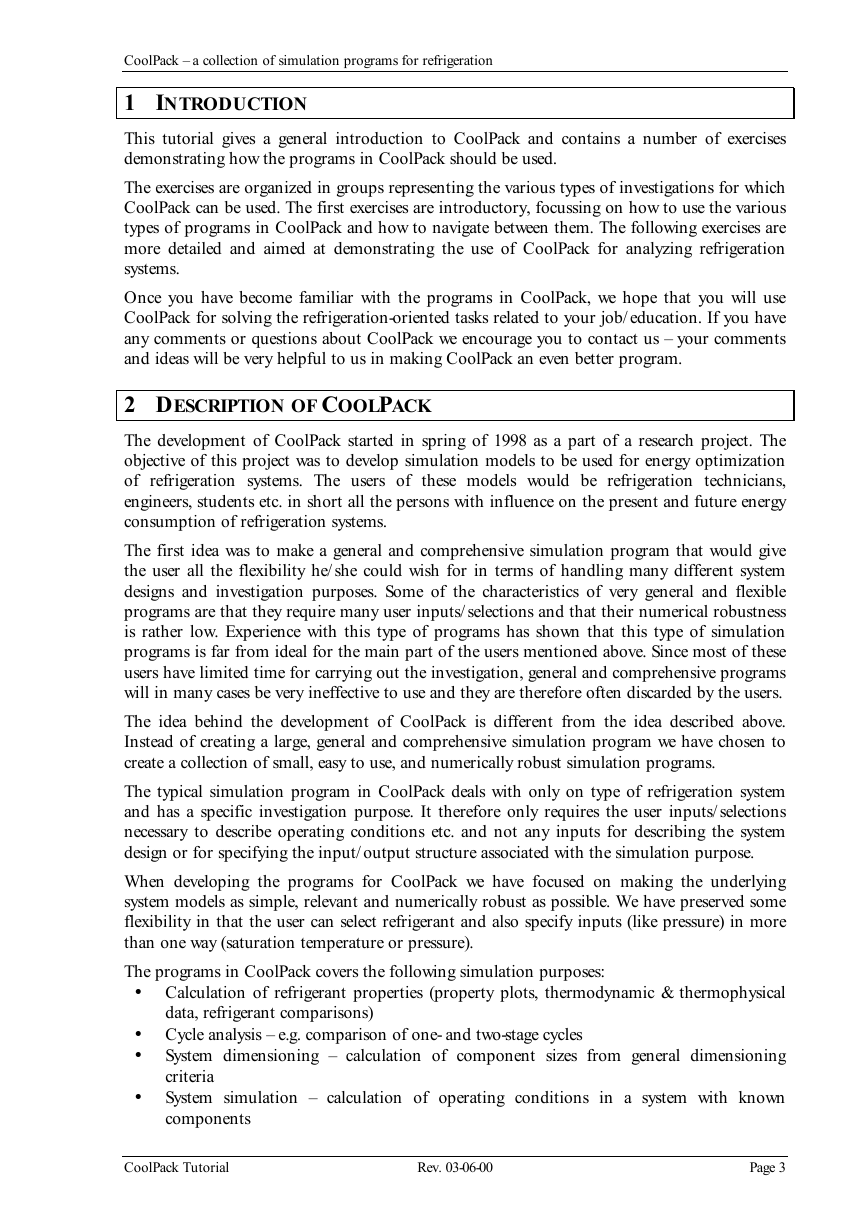

To make it easier to get an overview of the programs in CoolPack we have chosen to divide the

programs into three main groups (Refrigeration Utilities, EESCoolTools and Dynamic). Figure

2.1 gives an overview of the content in these groups.

Refrigeration

Utilities

Refrigerant property

plots and cycles

Refrigerant calculator

Secondary fluid

calculator

Psychrometric charts

CoolPack

EESCoolTools

Dynamic

Cooling down of an

object/room.

(One-stage system)

Cycle analysis

System dimensioning

System simulation

Operation analysis

Component calculations

Refrigerant properties

Comparison of

refrigerants

Figure 2.1: Overview of the main groups in CoolPack.

The group Refrigeration Utilities consist of 3 refrigerant oriented programs, primarily used

for calculating the properties of primary and secondary refrigerants, creating property plots for

primary refrigerants (like p-h, T-s and h-s diagrams) and for calculating the pressure drop for

flow of secondary refrigerants in pipes. Furthermore, it is possible to create property plots for

humid air (psychrometric charts).

The programs in Refrigeration Utilities group have been released previously as independent programs.

The first versions of the programs were released in 1996 and they have since then been expanded

significantly with new refrigerants, more property plots etc. Apart from the built in property functions

the current version can also use the very accurate property functions used in the RefProp program. If

you have RefProp ver. 6.01 you will now be able to create high quality property plots based on

RefProp data for refrigerants. Se the on-line help in the programs.

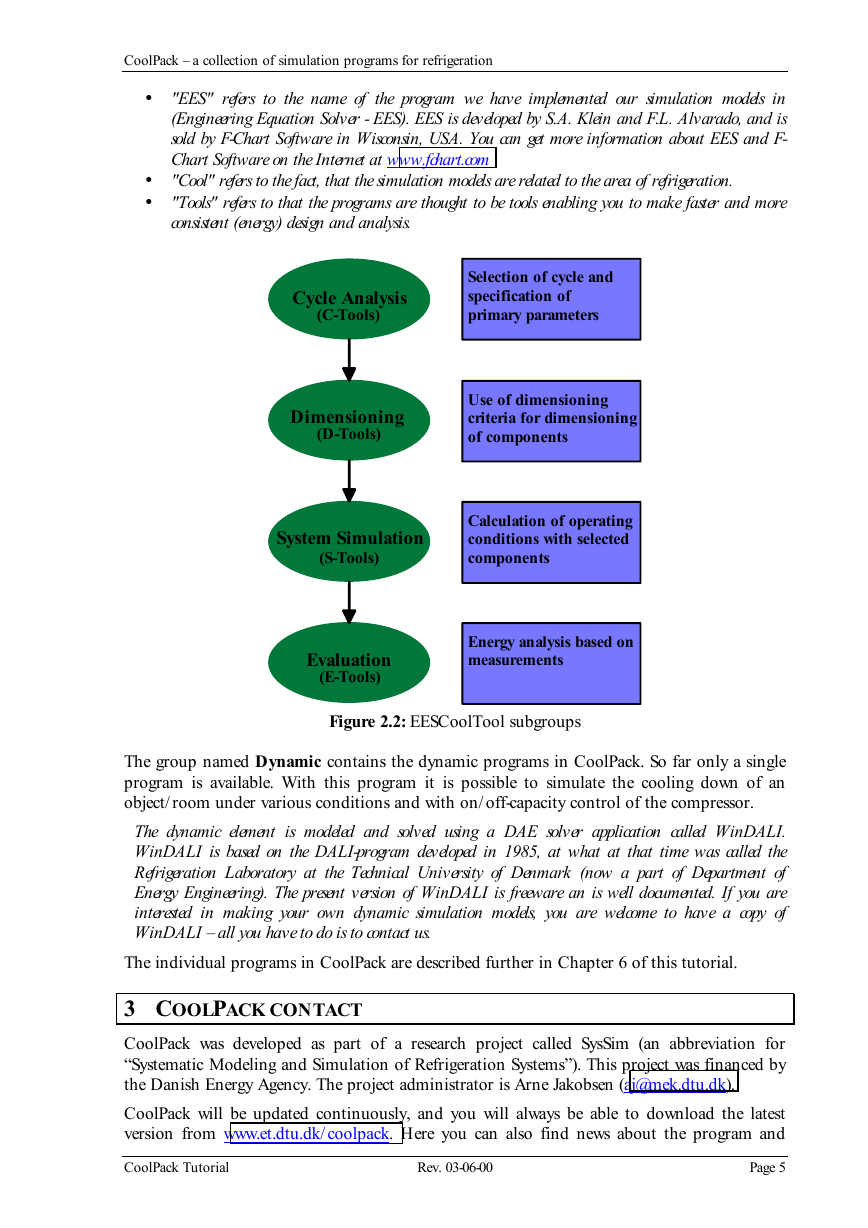

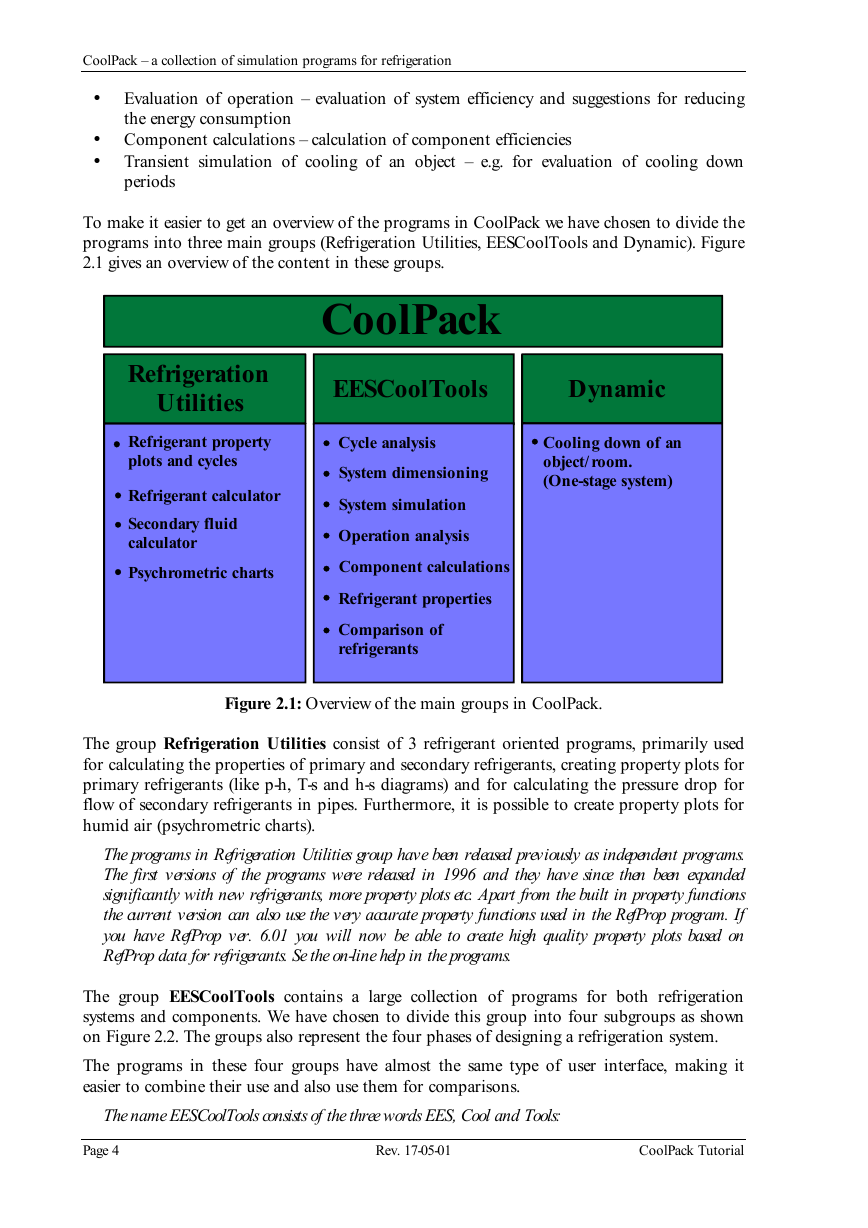

The group EESCoolTools contains a large collection of programs for both refrigeration

systems and components. We have chosen to divide this group into four subgroups as shown

on Figure 2.2. The groups also represent the four phases of designing a refrigeration system.

The programs in these four groups have almost the same type of user interface, making it

easier to combine their use and also use them for comparisons.

The name EESCoolTools consists of the three words EES, Cool and Tools:

Page 4

Rev. 17-05-01

CoolPack Tutorial

�

CoolPack – a collection of simulation programs for refrigeration

• "EES" refers to the name of the program we have implemented our simulation models in

(Engineering Equation Solver - EES). EES is developed by S.A. Klein and F.L. Alvarado, and is

sold by F-Chart Software in Wisconsin, USA. You can get more information about EES and F-

Chart Software on the Internet at www.fchart.com

• "Cool" refers to the fact, that the simulation models are related to the area of refrigeration.

• "Tools" refers to that the programs are thought to be tools enabling you to make faster and more

consistent (energy) design and analysis.

Cycle Analysis

(C-Tools)

Selection of cycle and

specification of

primary parameters

Dimensioning

(D-Tools)

Use of dimensioning

criteria for dimensioning

of components

System Simulation

(S-Tools)

Calculation of operating

conditions with selected

components

Evaluation

(E-Tools)

Energy analysis based on

measurements

Figure 2.2: EESCoolTool subgroups

The group named Dynamic contains the dynamic programs in CoolPack. So far only a single

program is available. With this program it is possible to simulate the cooling down of an

object/room under various conditions and with on/off-capacity control of the compressor.

The dynamic element is modeled and solved using a DAE solver application called WinDALI.

WinDALI is based on the DALI-program developed in 1985, at what at that time was called the

Refrigeration Laboratory at the Technical University of Denmark (now a part of Department of

Energy Engineering). The present version of WinDALI is freeware an is well documented. If you are

interested in making your own dynamic simulation models, you are welcome to have a copy of

WinDALI – all you have to do is to contact us.

The individual programs in CoolPack are described further in Chapter 6 of this tutorial.

3 COOLPACK CONTACT

CoolPack was developed as part of a research project called SysSim (an abbreviation for

“Systematic Modeling and Simulation of Refrigeration Systems”). This project was financed by

the Danish Energy Agency. The project administrator is Arne Jakobsen (aj@mek.dtu.dk).

CoolPack will be updated continuously, and you will always be able to download the latest

version from www.et.dtu.dk/coolpack. Here you can also find news about the program and

CoolPack Tutorial

Rev. 03-06-00

Page 5

�

CoolPack – a collection of simulation programs for refrigeration

technical support. CoolPack is freeware and you are welcome to pass on you copy of the

program to colleagues and friends. We encourage all who use CoolPack to register so that we

can inform them about new versions and CoolPack-related arrangements.

In the process of updating and expanding CoolPack we need your feedback. All comments and

suggestions are welcome and are also highly appreciated! General questions, comments or

requests for support should be directed to CoolPack@et.dtu.dk or they can be faxed to us on

+45 4593 5215.

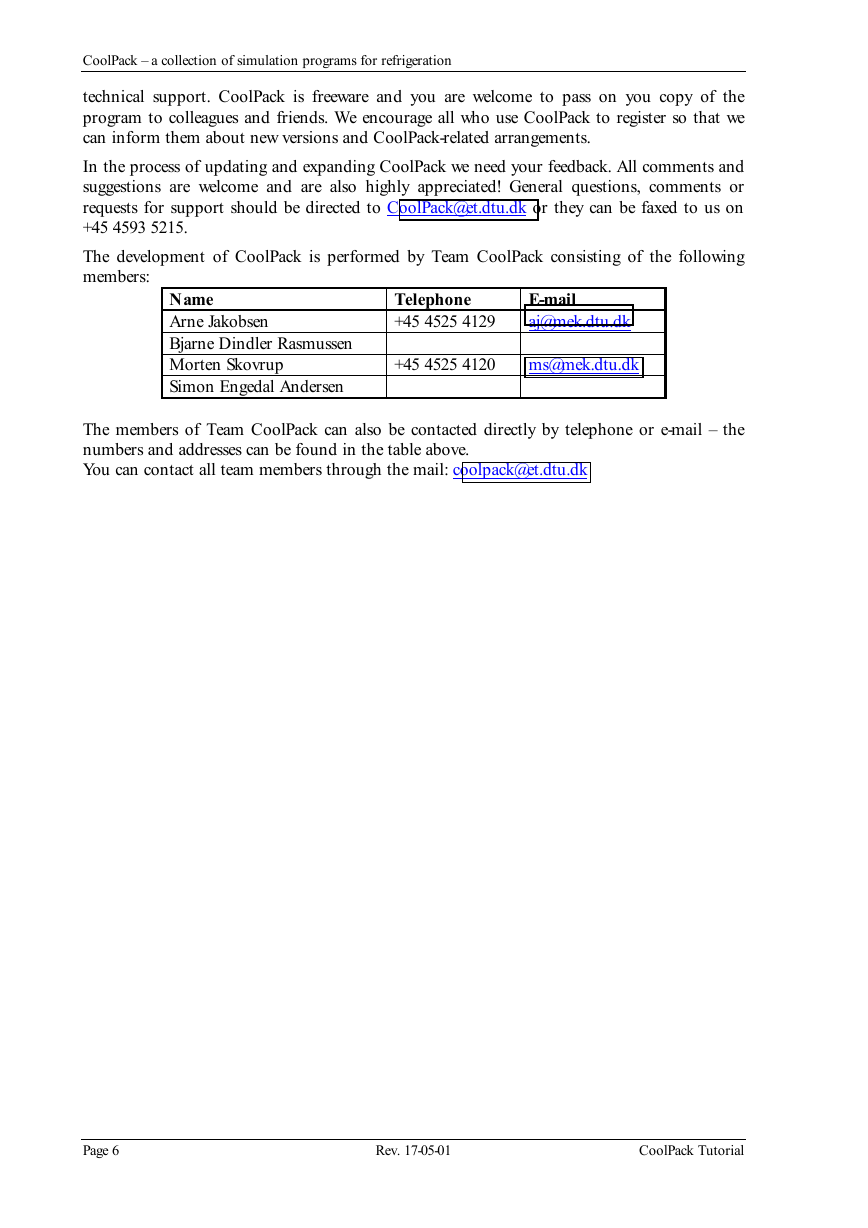

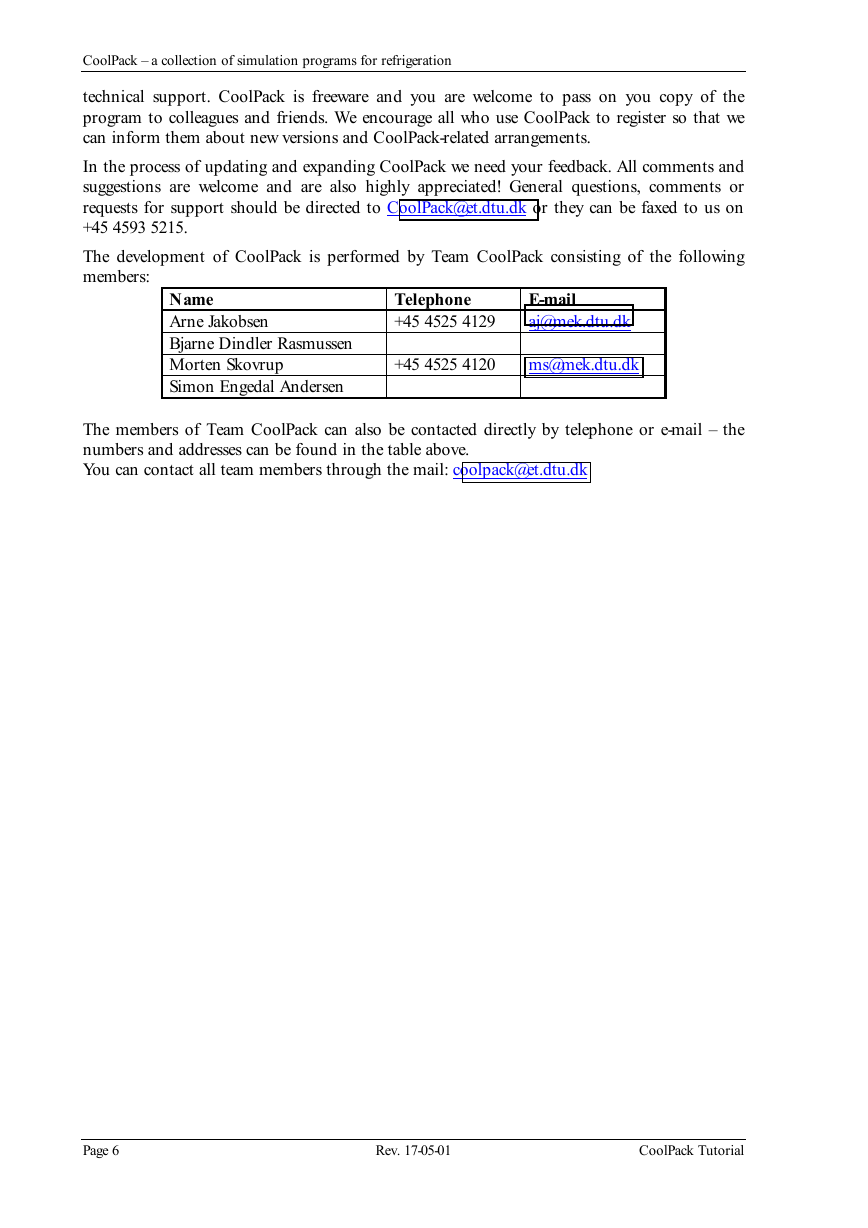

The development of CoolPack is performed by Team CoolPack consisting of the following

members:

Name

Arne Jakobsen

Bjarne Dindler Rasmussen

Morten Skovrup

Simon Engedal Andersen

Telephone

+45 4525 4129

+45 4525 4120

E-mail

aj@mek.dtu.dk

ms@mek.dtu.dk

The members of Team CoolPack can also be contacted directly by telephone or e-mail – the

numbers and addresses can be found in the table above.

You can contact all team members through the mail: coolpack@et.dtu.dk

Page 6

Rev. 17-05-01

CoolPack Tutorial

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc