CiA Draft Standard 406

CANopen

Device profile for encoders

Version: 3.2

18 December 2006

CAN in Automation (CiA) e. V.

�

HISTORY

Date

1997-05-05

1998-05-11

2002-05-17

2003-12-20

2006-12-18

2

Device profile for encoders

Changes

Publication of Version 1.0

Publication of Version 2.0

Publication of version 3.0

The version 3.0 of this specification has been re-chaptered. In addition, all object

descriptions and entry descriptions have been reviewed and edited in accordance to

CiA DS-301 version 4.01. In particular, all Array objects have been reviewed. Type

error corrections and other editorial changes (mostly clarifications and rewordings) are

not listed in detail, only changes with technical content are recorded in the following

table:

Error behavior

TPDO

Object 1029h definitions have been added.

The event timer of the TPDO 1 shall be hard-wired with the cyclic

timer (object 6200h). They may be used alternatively.

The TPDO 2 is now compliant to CiA DS-301 version 4.01

meaning that this PDO shall use 1801h PDO communication

parameter set object and 1A01h PDO mapping parameter set.

This TPDO shall be transmitted when the device enters the

Operational state.

Additional parameter definition

Additional parameter definition

New object: offset values for multi-sensor device

TPDO 1

Object 6000h

Object 6500h

Object 65C0h

Publication of version 3.1

The version 3.1 of this specification includes besides some minor editorial

clarifications the following changes:

Object 6000h

Object 6005h

Object 6008h

Object 6009h

Object 6010h

Object 6020h

Object 6040h

Object 6050h

Object 6502h

Object 6510h

Publication of version 3.2

Measuring direction definition included

Sub-objects for acceleration and jerk step settings added

High precision position value object added

High precision preset value added

Data type changed to Integer32

Data type changed to Integer32

Acceleration value object added

Jerk value object added

Value definition for 0 included

Number of high precision revolutions object added

-

-

Detailed PDO specification

Editorial changes

CiA 2008 – All rights reserved

�

Device profile for encoders

General information on licensing and patents

CAN in AUTOMATION (CiA) calls attention to the possibility that some of the elements of this

CiA specification may be subject of patent rights. CiA shall not be responsible for identifying

any or all such patent rights.

Because this specification is licensed free of charge, there is no warranty for this

specification, to the extent permitted by applicable law. Except when otherwise stated in

writing the copyright holder and/or other parties provide this specification “as is” without

warranty of any kind, either expressed or implied, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. The entire risk as to the

correctness and completeness of the specification is with you. Should this specification prove

failures, you assume the cost of all necessary servicing, repair or correction.

© CiA 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or

utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm,

without permission in writing from CiA at the address below.

CAN in Automation e. V.

Kontumazgarten 3

DE - 90429 Nuremberg, Germany

Tel.: +49-911-928819-0

Fax: +49-911-928819-79

Url: www.can-cia.org

Email: headquarters@can-cia.org

CiA 2008 – All rights reserved

3

�

Device profile for encoders

CONTENTS

1 Scope ............................................................................................................................... 6

2 Normative references........................................................................................................ 6

3 Abbreviations and definitions ............................................................................................ 6

4 Operating principle............................................................................................................ 6

4.1 General ................................................................................................................... 6

4.2 C1 encoders ............................................................................................................ 6

4.3 C2 encoders ............................................................................................................ 7

4.4 Diagnostic area ....................................................................................................... 7

4.5 Functional overview................................................................................................. 7

5 Error handling ................................................................................................................... 7

5.1 General ................................................................................................................... 7

5.2 Error behavior.......................................................................................................... 7

5.3 Additional error code meanings ............................................................................... 7

6 Pre-defined communication objects................................................................................... 8

6.1 General ................................................................................................................... 8

6.2 Object 1000h: Device type ....................................................................................... 8

6.3 Object 1001h: Error register ..................................................................................... 8

6.4 Object 1029h: Error behaviour.................................................................................. 9

6.5 Process data objects ............................................................................................... 9

6.5.1 General ....................................................................................................... 9

6.5.2 TPDO 1 ....................................................................................................... 9

6.5.3 TPDO 2 ..................................................................................................... 11

6.5.4 TPDO 3 ..................................................................................................... 13

7 Application object definitions........................................................................................... 15

7.1 General ................................................................................................................. 15

7.2 Overview on encoder application objects ............................................................... 15

7.3 Encoder parameters .............................................................................................. 17

7.3.1 General ..................................................................................................... 17

7.3.2 Object 6000h: Operating parameters .......................................................... 17

7.3.3 Object 6001h: Measuring units per revolution............................................. 18

7.3.4 Object 6002h: Total measuring range in measuring units............................ 19

7.3.5 Object 6003h: Preset value ........................................................................ 19

7.3.6 Object 6004h: Position value...................................................................... 20

7.3.7 Object 6005h: Linear encoder measuring step settings............................... 20

7.3.8 Object 6008h: High precision position value ............................................... 22

7.3.9 Object 6009h: High precision preset value ................................................. 22

7.3.10 Object 6010h: Preset values for multi-sensor devices ................................ 22

7.3.11 Object 6020h: Position values for multi-sensor devices .............................. 24

7.3.12 Object 6030h: Speed value ........................................................................ 25

7.3.13 Object 6040h: Acceleration value ............................................................... 26

7.3.14 Object 6050h: Jerk value............................................................................ 27

7.3.15 Object 6200h: Cyclic timer ......................................................................... 28

7.4 Encoder Cams ....................................................................................................... 29

7.4.1 General ..................................................................................................... 29

7.4.2 Object 6300h: Cam state register ............................................................... 30

7.4.3 Object 6301h: Cam enable register ............................................................ 32

CiA 2008 – All rights reserved

4

�

Device profile for encoders

7.4.4 Object 6302h: Cam polarity register ........................................................... 33

7.4.5 Object 6310h: Cam 1 low limit .................................................................... 34

7.4.6 Object 6311h: Cam 2 low limit .................................................................... 35

7.4.7 Object 6312h: Cam 3 low limit .................................................................... 36

7.4.8 Object 6313h: Cam 4 low limit .................................................................... 37

7.4.9 Object 6314h: Cam 5 low limit .................................................................... 38

7.4.10 Object 6315h: Cam 6 low limit.................................................................... 39

7.4.11 Object 6316h: Cam 7 low limit.................................................................... 40

7.4.12 Object 6317h: Cam 8 low limit.................................................................... 41

7.4.13 Object 6320h: Cam 1 high limit .................................................................. 42

7.4.14 Object 6321h: Cam 2 high limit .................................................................. 43

7.4.15 Object 6322h: Cam 3 high limit .................................................................. 44

7.4.16 Object 6323h: Cam 4 high limit .................................................................. 45

7.4.17 Object 6324h: Cam 5 high limit .................................................................. 46

7.4.18 Object 6325h: Cam 6 high limit .................................................................. 47

7.4.19 Object 6326h: Cam 7 high limit .................................................................. 48

7.4.20 Object 6327h: Cam 8 high limit .................................................................. 49

7.4.21 Object 6330h: Cam 1 hysteresis................................................................. 50

7.4.22 Object 6331h: Cam 2 hysteresis................................................................. 51

7.4.23 Object 6332h: Cam 3 hysteresis................................................................. 52

7.4.24 Object 6333h: Cam 4 hysteresis................................................................. 54

7.4.25 Object 6334h: Cam 5 hysteresis................................................................. 55

7.4.26 Object 6335h: Cam 6 hysteresis................................................................. 56

7.4.27 Object 6336h: Cam 7 hysteresis................................................................. 57

7.4.28 Object 6337h: Cam 8 hysteresis................................................................. 58

7.5 Work area supervision ........................................................................................... 59

7.5.1 General ..................................................................................................... 59

7.5.2 Object 6400h: Area state register ............................................................... 59

7.5.3 Object 6401h: Work area low limit .............................................................. 61

7.5.4 Object 6402h: Work area high limit............................................................. 62

7.6 Encoder diagnostics .............................................................................................. 63

7.6.1 General ..................................................................................................... 63

7.6.2 Object 6500h: Operating status .................................................................. 63

7.6.3 Object 6501h: Single-turn resolution and Measuring step ........................... 64

7.6.4 Object 6502h: Number of distinguishable revolutions ................................. 65

7.6.5 Object 6503h: Alarms ................................................................................. 65

7.6.6 Object 6504h: Supported alarms ................................................................ 66

7.6.7 Object 6505h: Warnings ............................................................................. 67

7.6.8 Object 6506h: Supported warnings............................................................. 68

7.6.9 Object 6507h: Profile and software version ................................................ 69

7.6.10 Object 6508h: Operating time..................................................................... 70

7.6.11 Object 6509h: Offset value......................................................................... 70

7.6.12 Object 650Ah: Module identification ........................................................... 71

7.6.13 Object 650Bh: Serial number ..................................................................... 72

7.6.14 Object 650Ch: Offset values for multi-sensor devices................................. 73

7.7 Object 6510h: Number of high precision revolutions ............................................... 74

7.7.1 Object 67FFh: Device type ......................................................................... 75

CiA 2008 – All rights reserved

5

�

1 Scope

Device profile for encoders

This document represents the CANopen device profile for incremental and absolute, linear

and rotary encoders. Besides position, velocity, acceleration, and jerk output possibility

complete cam functionality is covered. In addition, it is possible to handle multi-sensors

through one CANopen device.

All the above mentioned devices use communication techniques, which conform to those

described in the CANopen application layer and communication profile specification /CiA301/.

This document should be consulted in parallel to this profile.

2 Normative references

/CiA301/

CiA 301, CANopen application layer and communication profile

3 Abbreviations and definitions

Class 1

Class 2

Clock wise

C1

C2

CW

CCW Counter Clock wise

Abbreviations and definitions defined in /CiA301/ apply for this document too.

4 Operating principle

4.1 General

The purpose of encoders is to detect positions of any kind of machine tools. Encoders detect

positions and transmit the position values across the CANopen network. Optionally the

encoder may provide speed, acceleration, and jerk values. The encoder may receive

configuration information via SDO, e.g. conversion parameters for calculating an - to the

application adapted - position value. In the NMT state operational, the position value may be

transmitted by synchronous PDO. Additionally, the encoders may transmit asynchronously a

PDO scheduled by the elapsing of the event timer.

The CANopen device profile defines two encoder classes, a standard device class 1 (C1) and

an extended device class 2 (C2). The standard device C1 specifies basic functionality, which

shall be provided by each device. The C2 extended device provides a variety of features with

mandatory and optional functions. The mandatory functions of both, C1 and C2, are

necessary to ensure non-manufacturer specific operations of a device.

By defining mandatory device characteristics in C1, basic network and encoder operation is

guaranteed. By defining extended C2, a degree of defined flexibility may be built in. By

leaving ‘hooks’ for optional and manufacturer-specific functionality, the device developer will

not be constrained to an out-of-date standard.

4.2 C1 encoders

C1 is the mandatory class with a basic range of functions that all encoders shall support. The

C1 encoders may optionally support C2 functions, however these functions shall be

implemented according to the profile.

6

CiA 2008 – All rights reserved

�

4.3 C2 encoders

Device profile for encoders

C2 encoders support all C1 functions and extended functions defined in C2.

4.4 Diagnostic area

In addition to the classes C1 and C2, there are pre-defined areas and reserved parameters

for manufacturer-specific functions in this device profile.

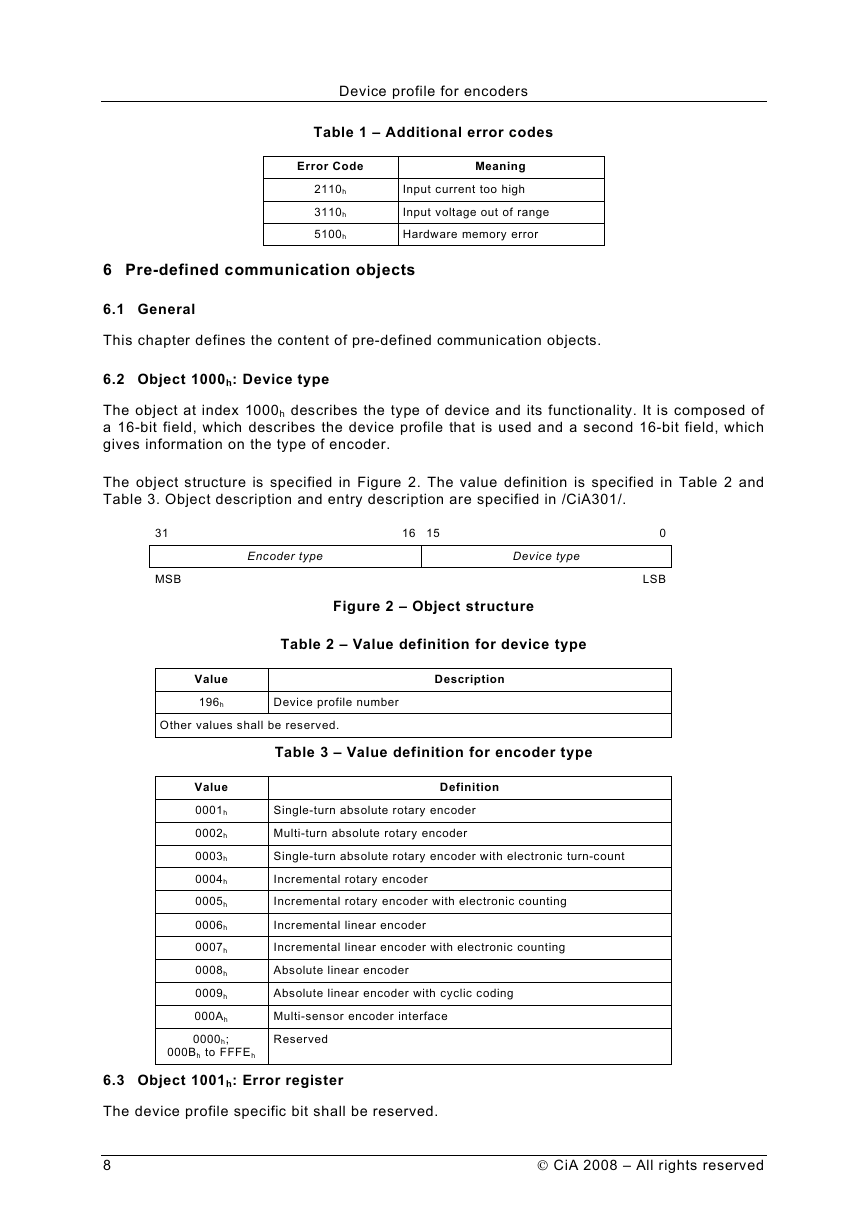

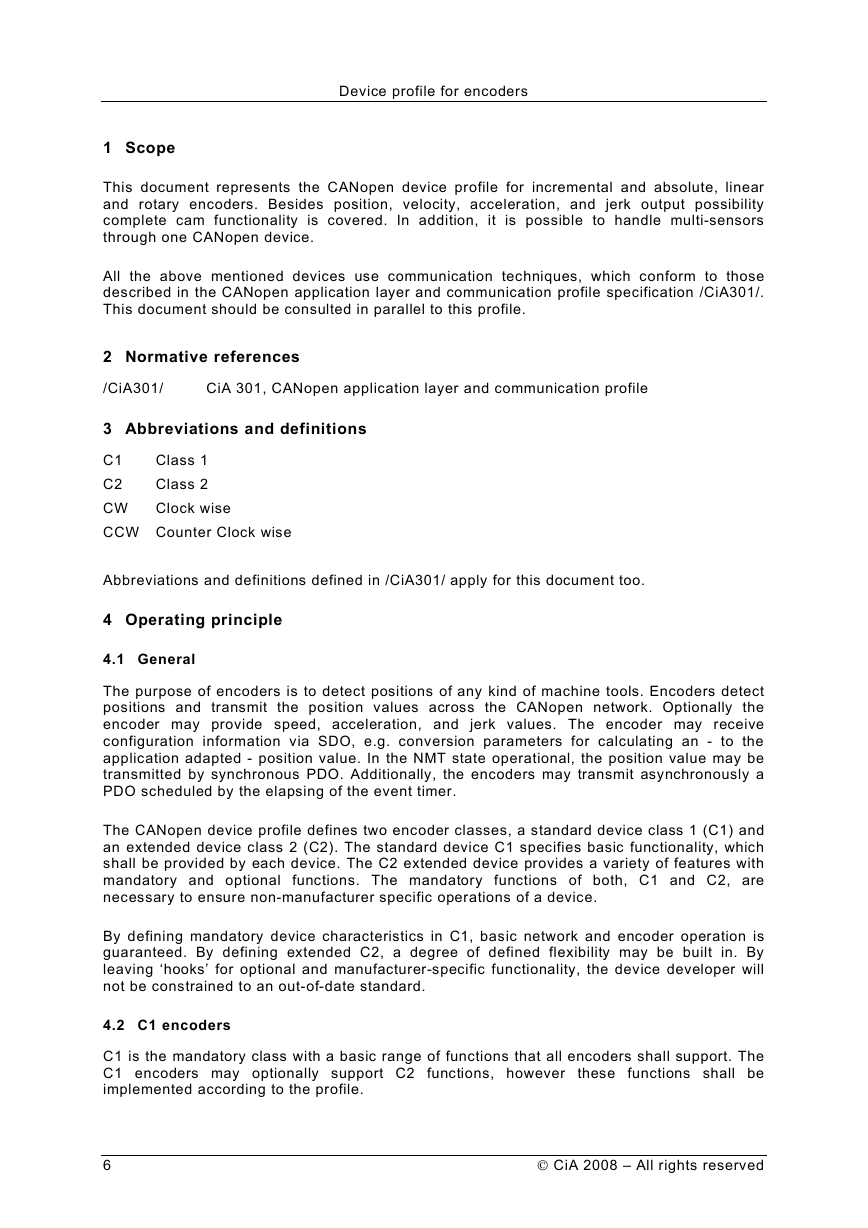

4.5 Functional overview

The functional overview is shown in Figure 1.

Class C1

Class C2

Class C2

Physical position

Basic function

Absolute position

Scaling function

Preset function

Output position value

Figure 1 – Class C1 and class C2 functions

5 Error handling

5.1 General

Emergency messages are triggered by internal errors in the device and they are assigned the

highest possible priority to ensure that they get access to the bus without latency. By default,

the emergency messages contain the error field with pre-defined error numbers and additional

information.

5.2 Error behavior

If a serious device failure is detected the module shall enter by default autonomously the pre-

operational state. If object 1029h is implemented, the device may be configured to enter

alternatively the NMT stopped state or remain in the current NMT state in case of a device

failure. Device failures include the following communication errors:

• Bus-off conditions of the CAN interface

• Life guarding event with the state ‘occurred’

• Heartbeat event with state ‘occurred’

Severe device errors also may be caused by device internal failures.

The value definition as well as the object description and the entry description are specified in

/CiA301/.

5.3 Additional error code meanings

Additional error codes are defined in Table 1.

CiA 2008 – All rights reserved

7

�

Device profile for encoders

Table 1 – Additional error codes

Error Code

2110h

3110h

5100h

Meaning

Input current too high

Input voltage out of range

Hardware memory error

6 Pre-defined communication objects

6.1 General

This chapter defines the content of pre-defined communication objects.

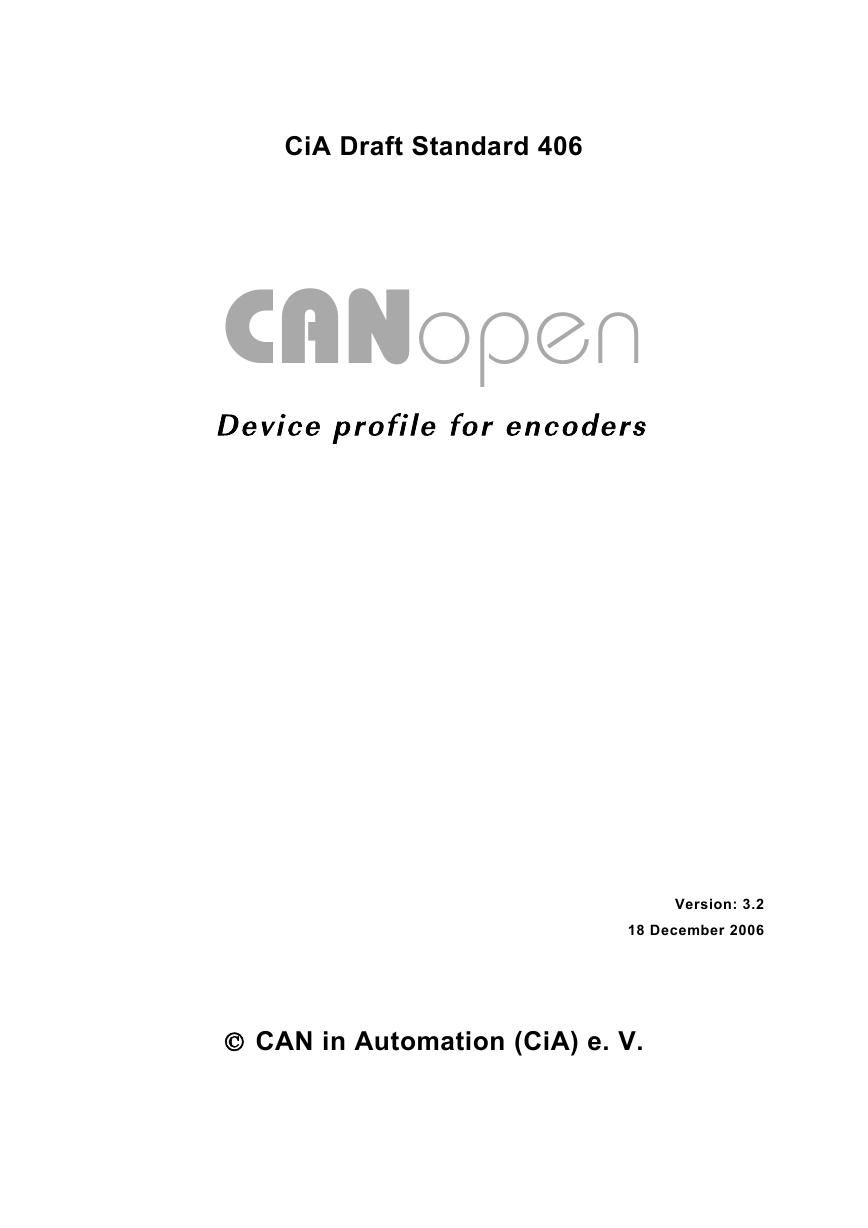

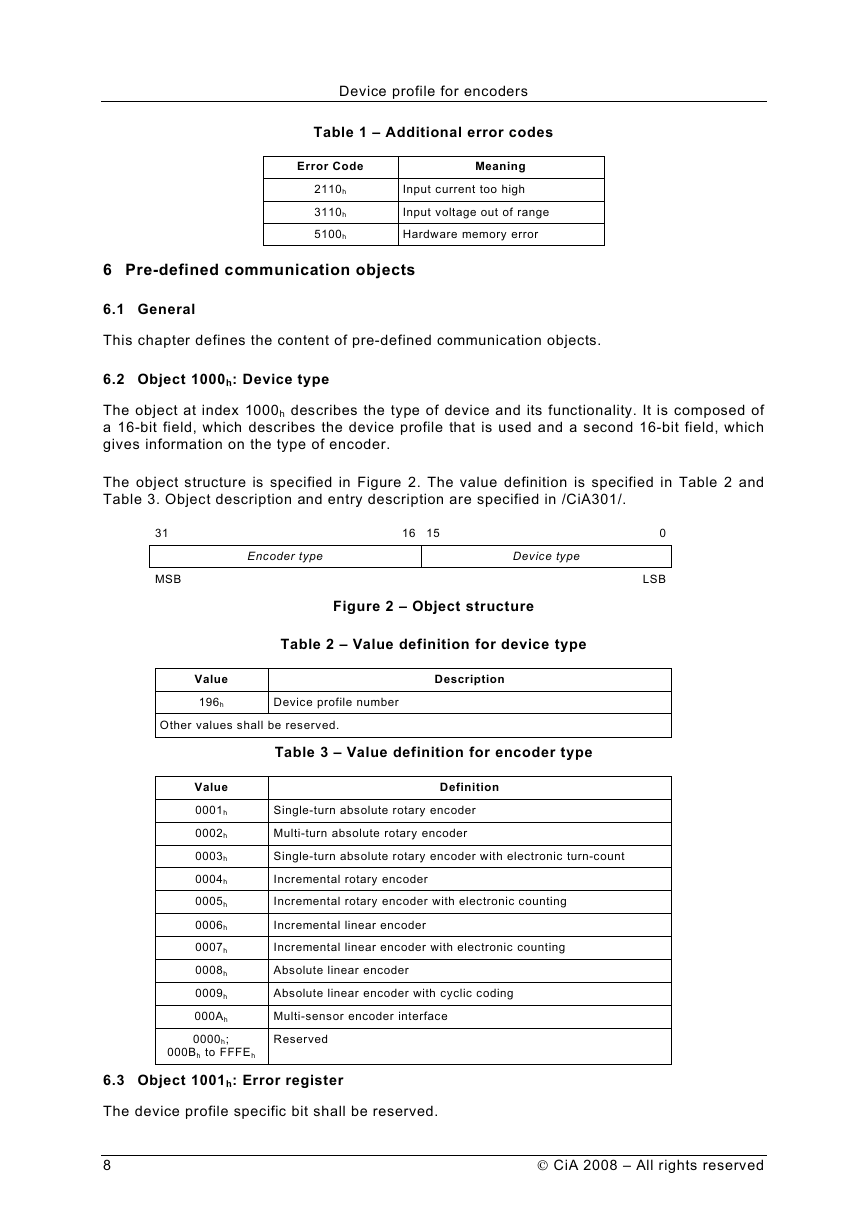

6.2 Object 1000h: Device type

The object at index 1000h describes the type of device and its functionality. It is composed of

a 16-bit field, which describes the device profile that is used and a second 16-bit field, which

gives information on the type of encoder.

The object structure is specified in Figure 2. The value definition is specified in Table 2 and

Table 3. Object description and entry description are specified in /CiA301/.

31

MSB

Encoder type

16 15

Device type

0

LSB

Figure 2 – Object structure

Table 2 – Value definition for device type

Value

196h

Device profile number

Description

Other values shall be reserved.

Table 3 – Value definition for encoder type

Definition

Single-turn absolute rotary encoder

Multi-turn absolute rotary encoder

Single-turn absolute rotary encoder with electronic turn-count

Incremental rotary encoder

Incremental rotary encoder with electronic counting

Incremental linear encoder

Incremental linear encoder with electronic counting

Absolute linear encoder

Absolute linear encoder with cyclic coding

Multi-sensor encoder interface

Reserved

Value

0001h

0002h

0003h

0004h

0005h

0006h

0007h

0008h

0009h

000Ah

0000h;

000Bh to FFFEh

6.3 Object 1001h: Error register

The device profile specific bit shall be reserved.

8

CiA 2008 – All rights reserved

�