1

Introduction

1.1

INTRODUCTION TO POWER PROCESSING

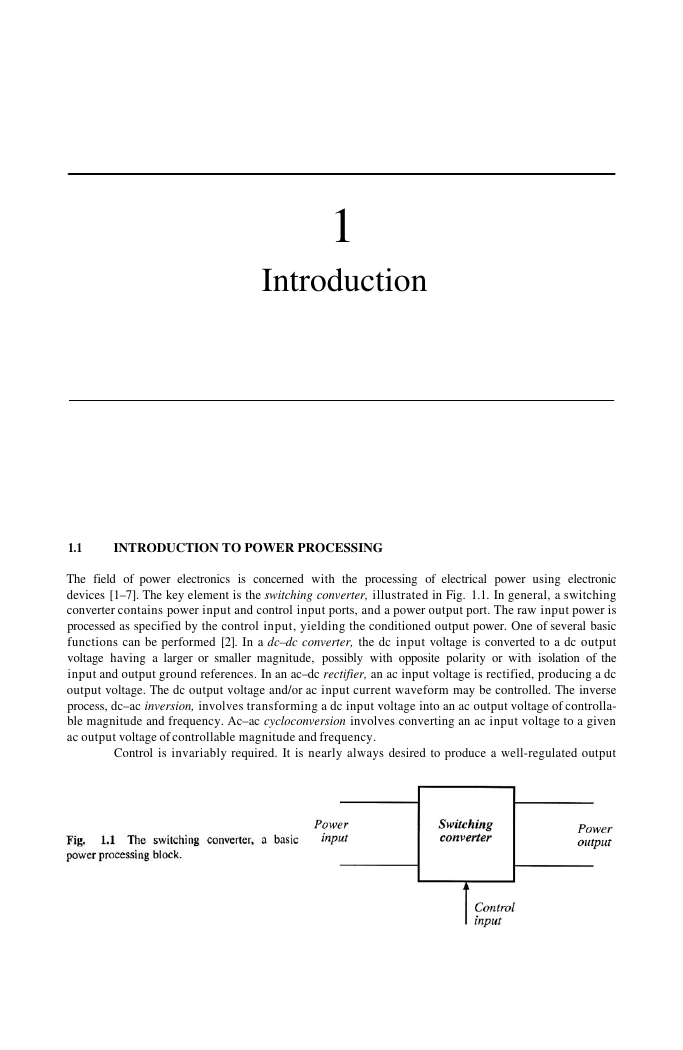

The field of power electronics is concerned with the processing of electrical power using electronic

devices [1–7]. The key element is the switching converter, illustrated in Fig. 1.1. In general, a switching

converter contains power input and control input ports, and a power output port. The raw input power is

processed as specified by the control input, yielding the conditioned output power. One of several basic

functions can be performed [2]. In a dc–dc converter, the dc input voltage is converted to a dc output

voltage having a larger or smaller magnitude, possibly with opposite polarity or with isolation of the

input and output ground references. In an ac–dc rectifier, an ac input voltage is rectified, producing a dc

output voltage. The dc output voltage and/or ac input current waveform may be controlled. The inverse

process, dc–ac inversion, involves transforming a dc input voltage into an ac output voltage of controlla-

ble magnitude and frequency. Ac–ac cycloconversion involves converting an ac input voltage to a given

ac output voltage of controllable magnitude and frequency.

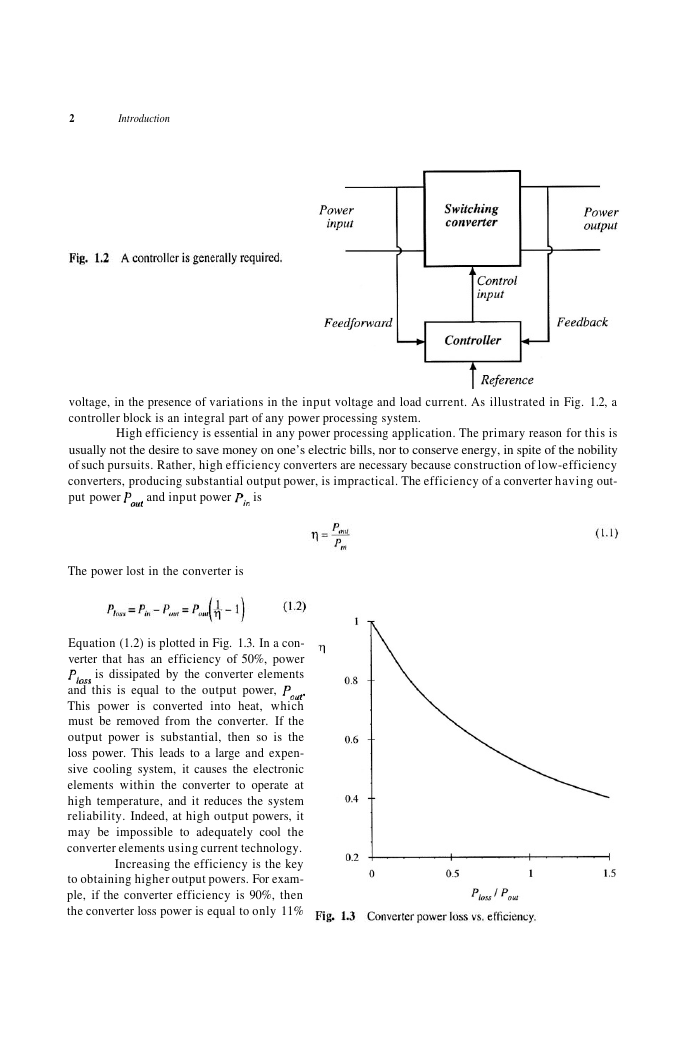

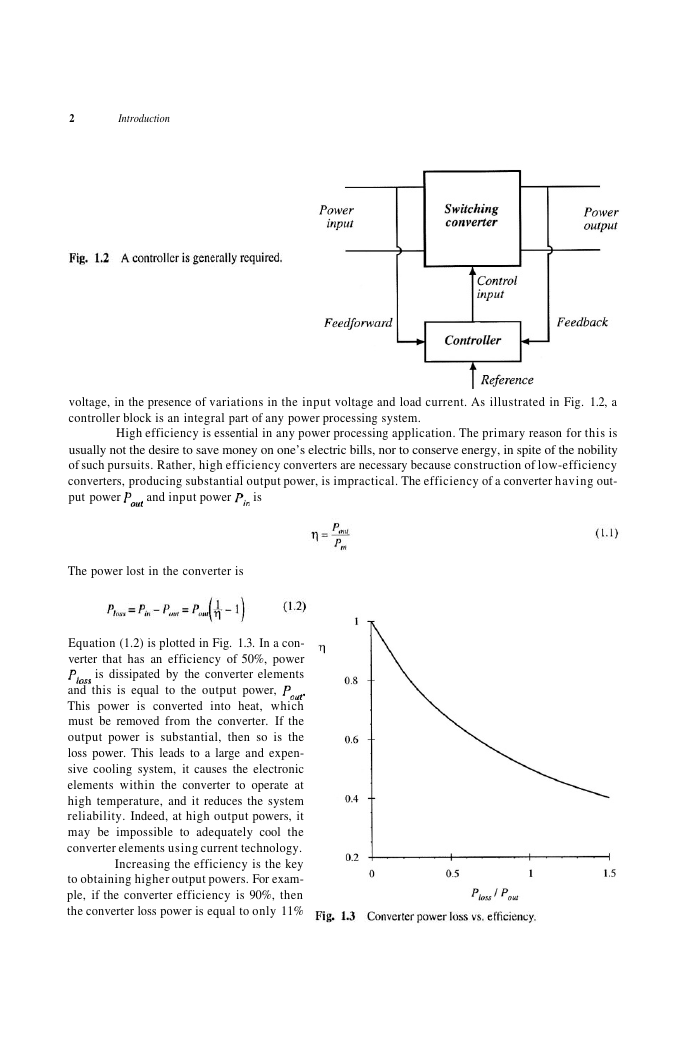

Control is invariably required. It is nearly always desired to produce a well-regulated output

�

2

Introduction

voltage, in the presence of variations in the input voltage and load current. As illustrated in Fig. 1.2, a

controller block is an integral part of any power processing system.

High efficiency is essential in any power processing application. The primary reason for this is

usually not the desire to save money on one’s electric bills, nor to conserve energy, in spite of the nobility

of such pursuits. Rather, high efficiency converters are necessary because construction of low-efficiency

converters, producing substantial output power, is impractical. The efficiency of a converter having out-

put power

and input power

is

The power lost in the converter is

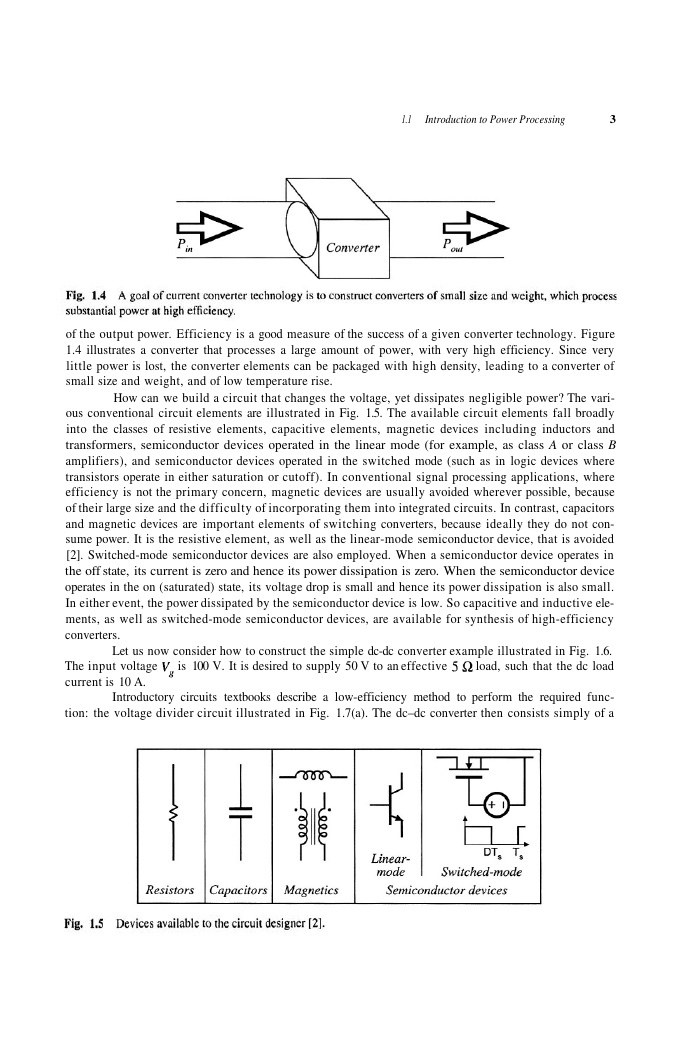

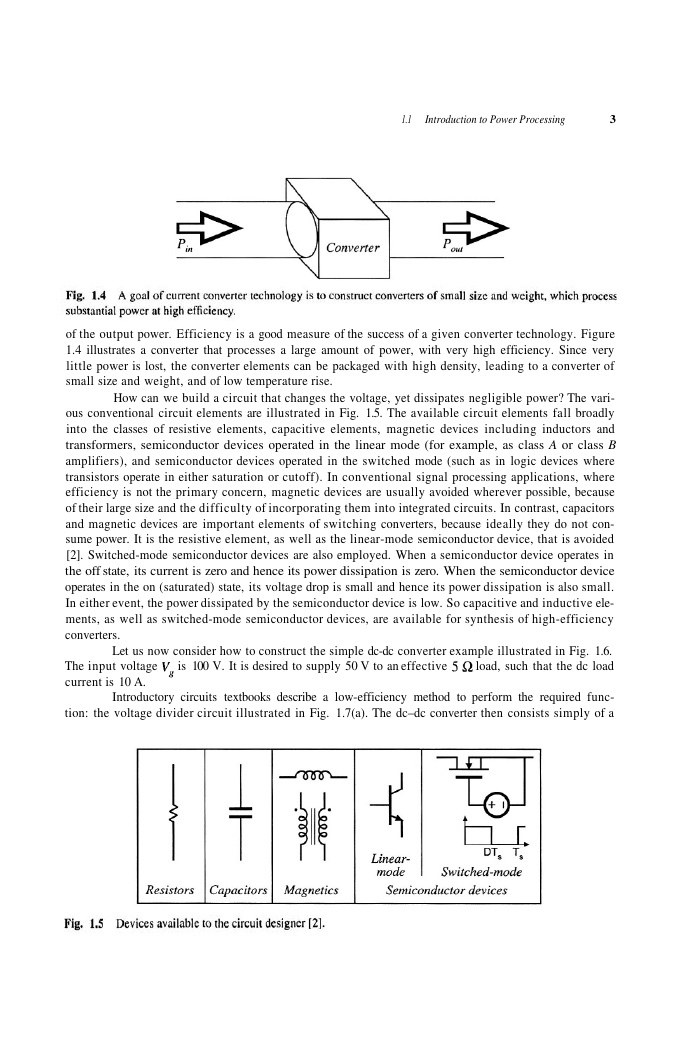

Equation (1.2) is plotted in Fig. 1.3. In a con-

verter that has an efficiency of 50%, power

is dissipated by the converter elements

and this is equal to the output power,

This power is converted into heat, which

must be removed from the converter. If the

output power is substantial, then so is the

loss power. This leads to a large and expen-

sive cooling system, it causes the electronic

elements within the converter to operate at

high temperature, and it reduces the system

reliability. Indeed, at high output powers, it

may be impossible to adequately cool the

converter elements using current technology.

Increasing the efficiency is the key

to obtaining higher output powers. For exam-

ple, if the converter efficiency is 90%, then

the converter loss power is equal to only 11%

�

1.1

Introduction to Power Processing

3

of the output power. Efficiency is a good measure of the success of a given converter technology. Figure

1.4 illustrates a converter that processes a large amount of power, with very high efficiency. Since very

little power is lost, the converter elements can be packaged with high density, leading to a converter of

small size and weight, and of low temperature rise.

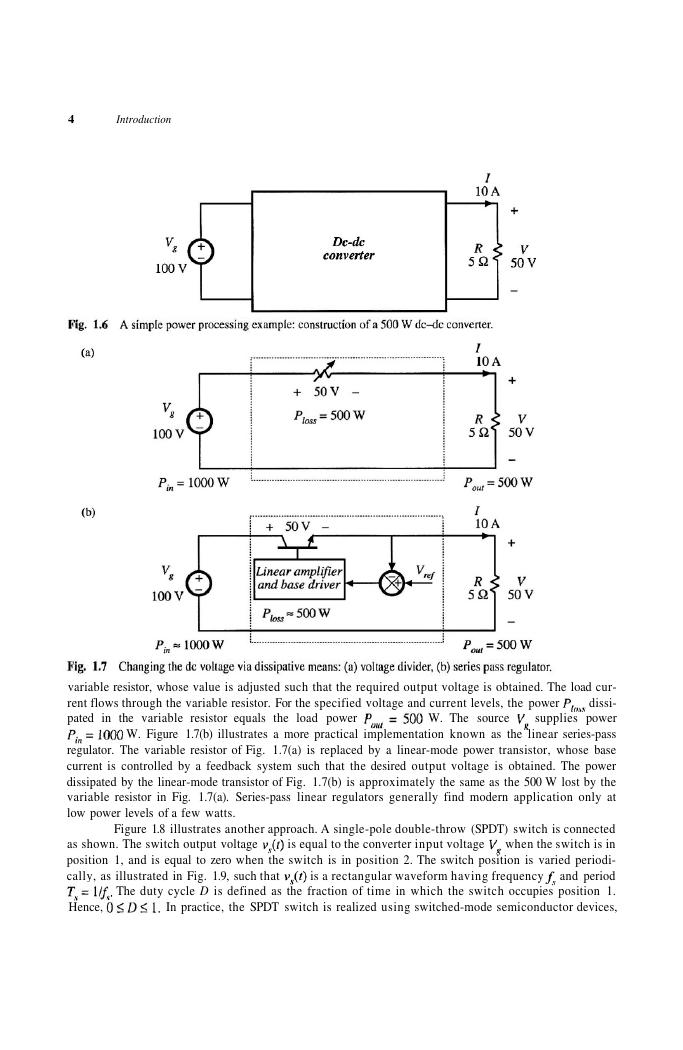

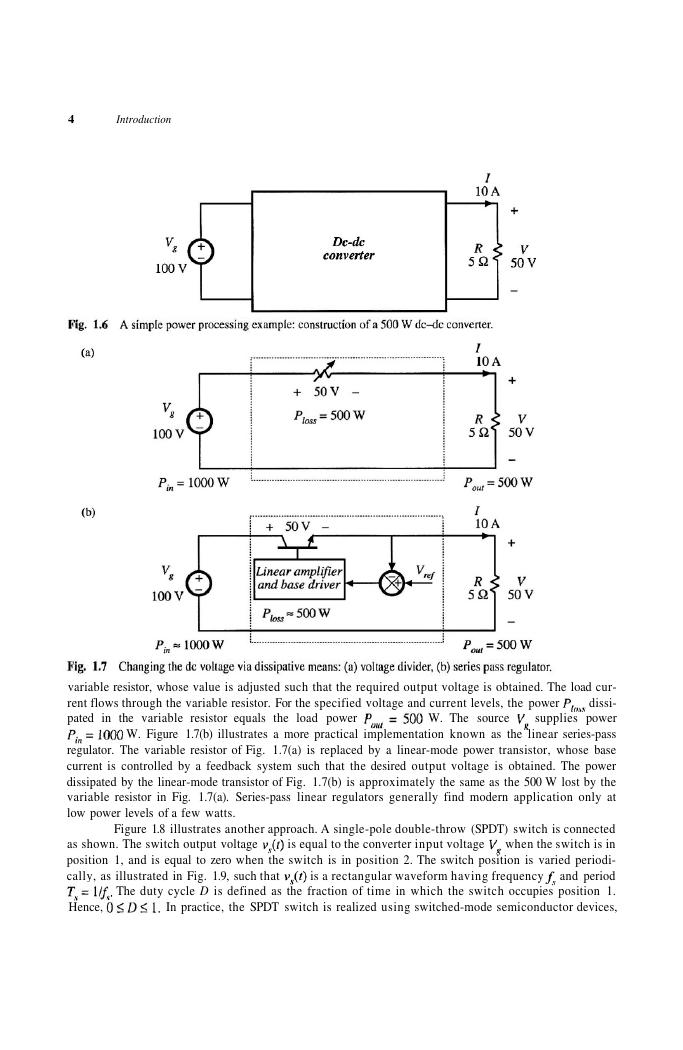

How can we build a circuit that changes the voltage, yet dissipates negligible power? The vari-

ous conventional circuit elements are illustrated in Fig. 1.5. The available circuit elements fall broadly

into the classes of resistive elements, capacitive elements, magnetic devices including inductors and

transformers, semiconductor devices operated in the linear mode (for example, as class A or class B

amplifiers), and semiconductor devices operated in the switched mode (such as in logic devices where

transistors operate in either saturation or cutoff). In conventional signal processing applications, where

efficiency is not the primary concern, magnetic devices are usually avoided wherever possible, because

of their large size and the difficulty of incorporating them into integrated circuits. In contrast, capacitors

and magnetic devices are important elements of switching converters, because ideally they do not con-

sume power. It is the resistive element, as well as the linear-mode semiconductor device, that is avoided

[2]. Switched-mode semiconductor devices are also employed. When a semiconductor device operates in

the off state, its current is zero and hence its power dissipation is zero. When the semiconductor device

operates in the on (saturated) state, its voltage drop is small and hence its power dissipation is also small.

In either event, the power dissipated by the semiconductor device is low. So capacitive and inductive ele-

ments, as well as switched-mode semiconductor devices, are available for synthesis of high-efficiency

converters.

Let us now consider how to construct the simple dc-dc converter example illustrated in Fig. 1.6.

load, such that the dc load

is 100 V. It is desired to supply 50 V to an effective

The input voltage

current is 10 A.

Introductory circuits textbooks describe a low-efficiency method to perform the required func-

tion: the voltage divider circuit illustrated in Fig. 1.7(a). The dc–dc converter then consists simply of a

�

4

Introduction

variable resistor, whose value is adjusted such that the required output voltage is obtained. The load cur-

rent flows through the variable resistor. For the specified voltage and current levels, the power

dissi-

supplies power

pated in the variable resistor equals the load power

W. Figure 1.7(b) illustrates a more practical implementation known as the linear series-pass

regulator. The variable resistor of Fig. 1.7(a) is replaced by a linear-mode power transistor, whose base

current is controlled by a feedback system such that the desired output voltage is obtained. The power

dissipated by the linear-mode transistor of Fig. 1.7(b) is approximately the same as the 500 W lost by the

variable resistor in Fig. 1.7(a). Series-pass linear regulators generally find modern application only at

low power levels of a few watts.

W. The source

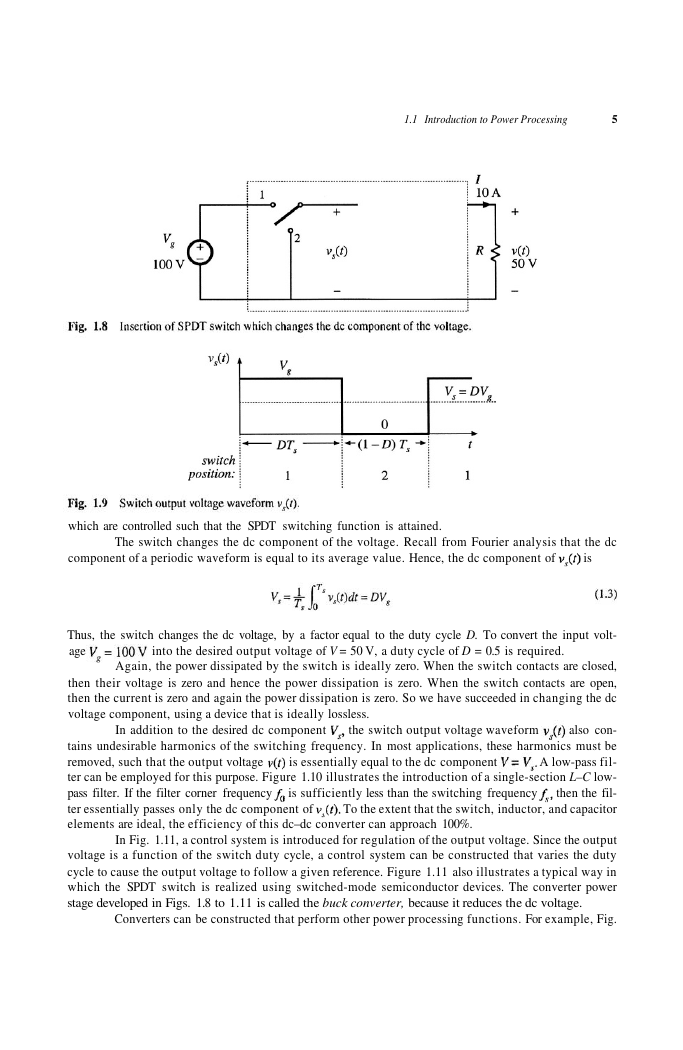

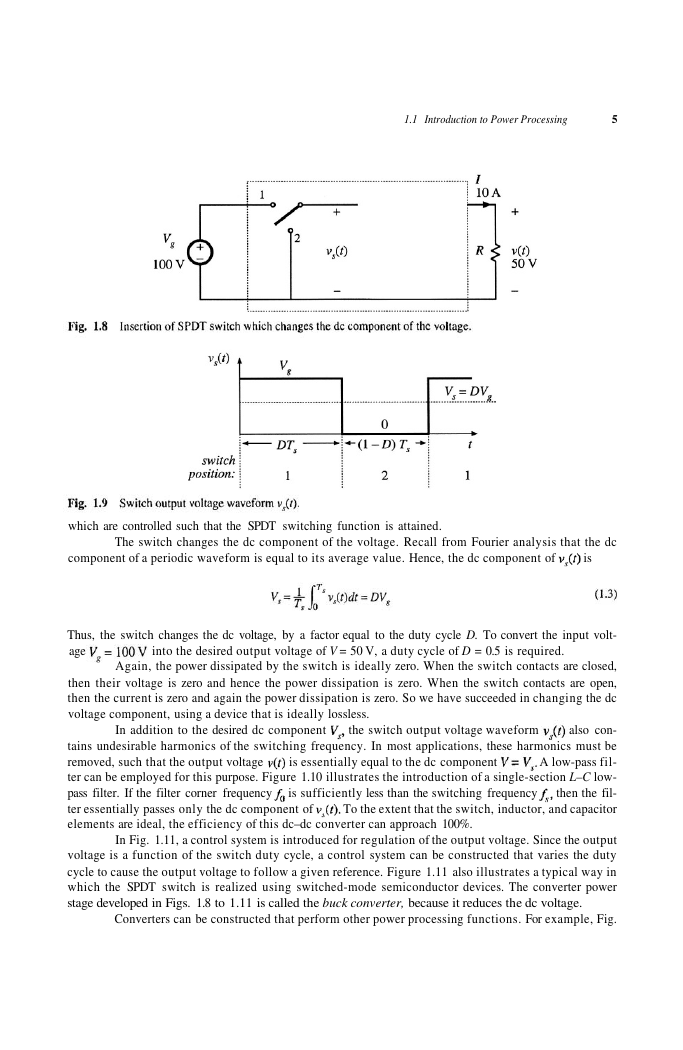

Figure 1.8 illustrates another approach. A single-pole double-throw (SPDT) switch is connected

as shown. The switch output voltage

is equal to the converter input voltage when the switch is in

position 1, and is equal to zero when the switch is in position 2. The switch position is varied periodi-

cally, as illustrated in Fig. 1.9, such that

and period

The duty cycle D is defined as the fraction of time in which the switch occupies position 1.

In practice, the SPDT switch is realized using switched-mode semiconductor devices,

is a rectangular waveform having frequency

Hence,

�

1.1 Introduction to Power Processing

5

which are controlled such that the SPDT switching function is attained.

The switch changes the dc component of the voltage. Recall from Fourier analysis that the dc

component of a periodic waveform is equal to its average value. Hence, the dc component of

is

Thus, the switch changes the dc voltage, by a factor equal to the duty cycle D. To convert the input volt-

age

into the desired output voltage of V = 50 V, a duty cycle of D = 0.5 is required.

Again, the power dissipated by the switch is ideally zero. When the switch contacts are closed,

then their voltage is zero and hence the power dissipation is zero. When the switch contacts are open,

then the current is zero and again the power dissipation is zero. So we have succeeded in changing the dc

voltage component, using a device that is ideally lossless.

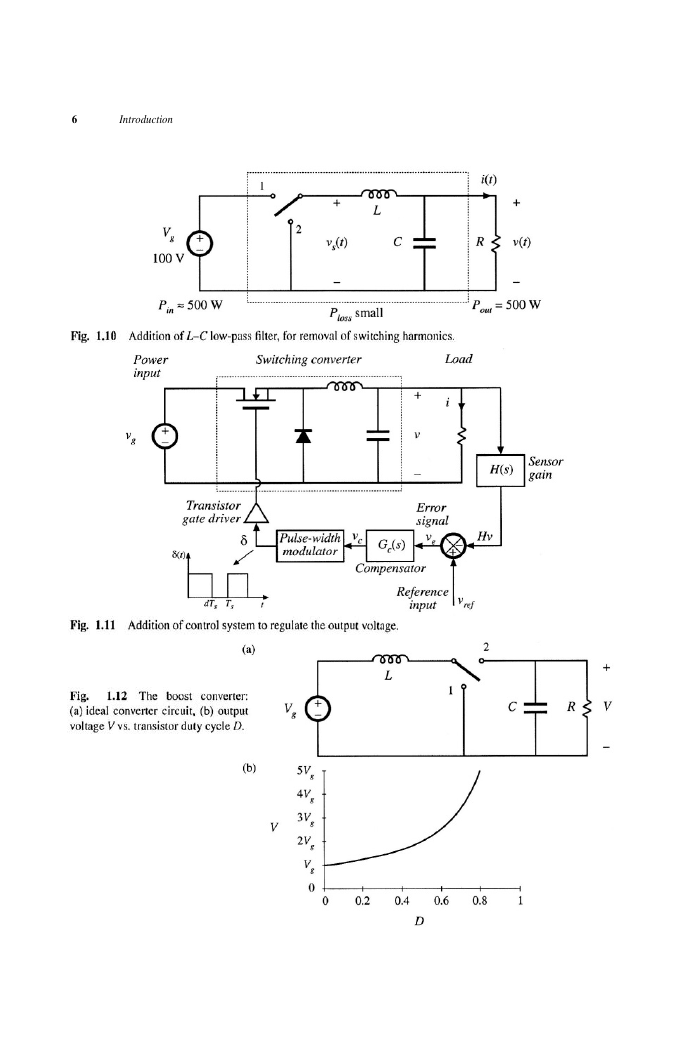

In addition to the desired dc component

the switch output voltage waveform

also con-

tains undesirable harmonics of the switching frequency. In most applications, these harmonics must be

removed, such that the output voltage

A low-pass fil-

ter can be employed for this purpose. Figure 1.10 illustrates the introduction of a single-section L–C low-

pass filter. If the filter corner frequency

then the fil-

To the extent that the switch, inductor, and capacitor

ter essentially passes only the dc component of

elements are ideal, the efficiency of this dc–dc converter can approach 100%.

is sufficiently less than the switching frequency

is essentially equal to the dc component

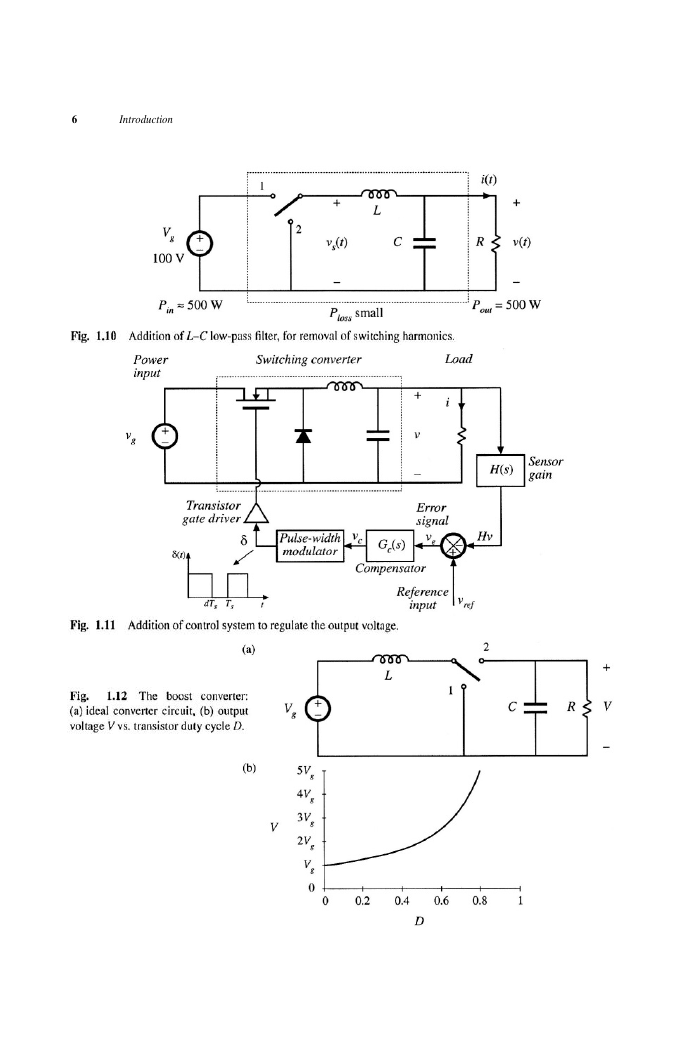

In Fig. 1.11, a control system is introduced for regulation of the output voltage. Since the output

voltage is a function of the switch duty cycle, a control system can be constructed that varies the duty

cycle to cause the output voltage to follow a given reference. Figure 1.11 also illustrates a typical way in

which the SPDT switch is realized using switched-mode semiconductor devices. The converter power

stage developed in Figs. 1.8 to 1.11 is called the buck converter, because it reduces the dc voltage.

Converters can be constructed that perform other power processing functions. For example, Fig.

�

6

Introduction

�

1.2

Several Applications of Power Electronics

7

1.12 illustrates a circuit known as the boost converter, in which the positions of the inductor and SPDT

switch are interchanged. This converter is capable of producing output voltages that are greater in magni-

tude than the input voltage. In general, any given input voltage can be converted into any desired output

voltage, using a converter containing switching devices embedded within a network of reactive elements.

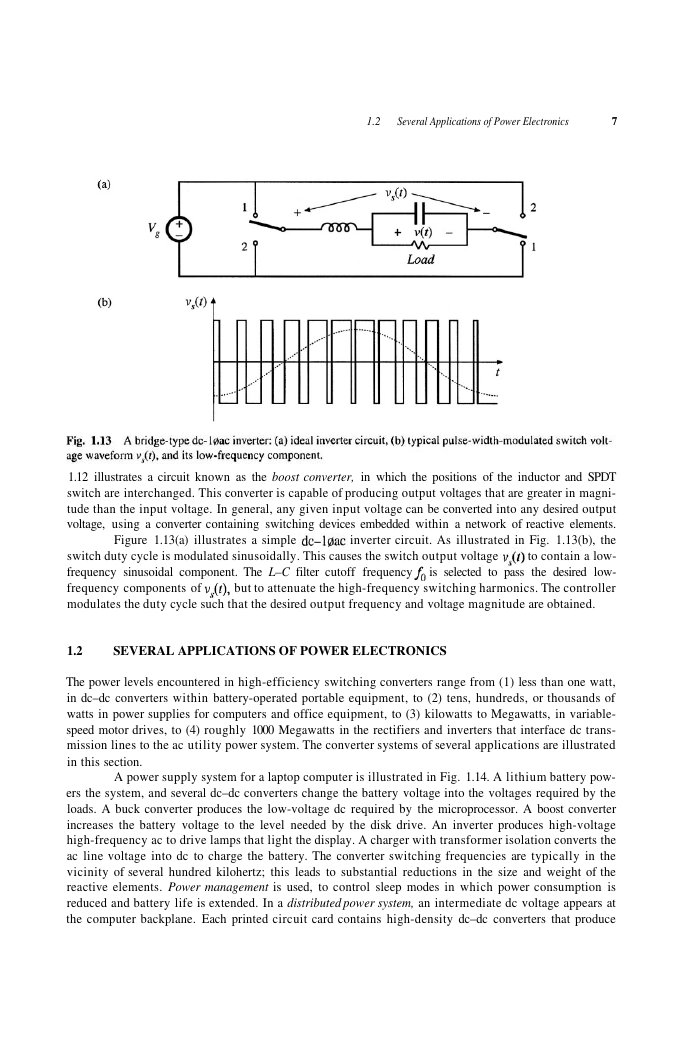

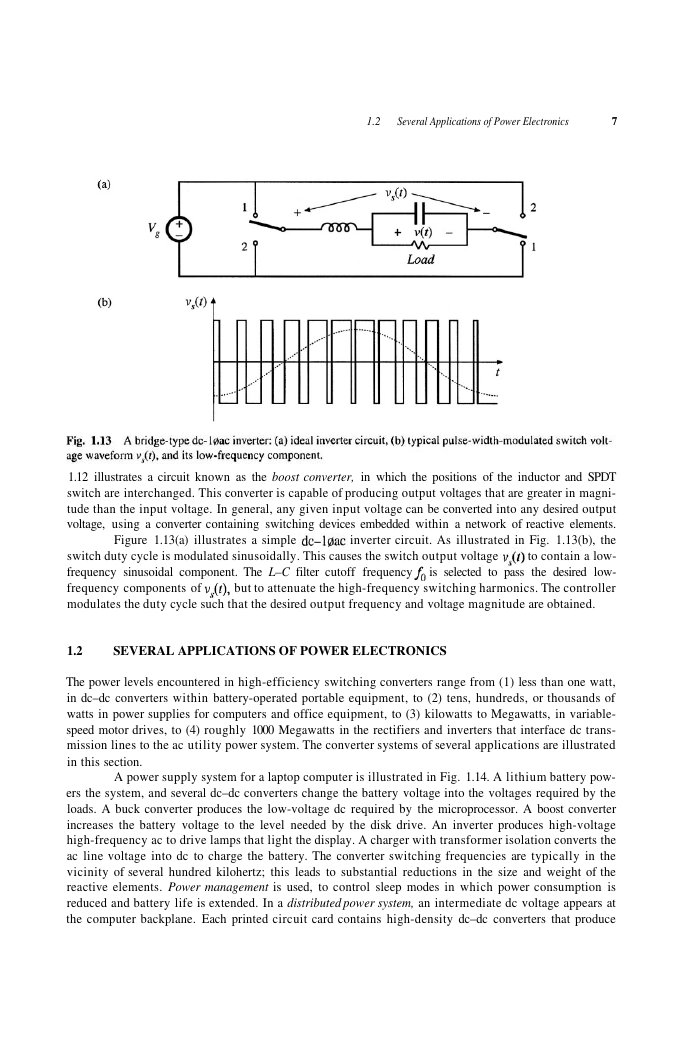

inverter circuit. As illustrated in Fig. 1.13(b), the

to contain a low-

is selected to pass the desired low-

but to attenuate the high-frequency switching harmonics. The controller

switch duty cycle is modulated sinusoidally. This causes the switch output voltage

frequency sinusoidal component. The L–C filter cutoff frequency

frequency components of

modulates the duty cycle such that the desired output frequency and voltage magnitude are obtained.

Figure 1.13(a) illustrates a simple

1.2

SEVERAL APPLICATIONS OF POWER ELECTRONICS

The power levels encountered in high-efficiency switching converters range from (1) less than one watt,

in dc–dc converters within battery-operated portable equipment, to (2) tens, hundreds, or thousands of

watts in power supplies for computers and office equipment, to (3) kilowatts to Megawatts, in variable-

speed motor drives, to (4) roughly 1000 Megawatts in the rectifiers and inverters that interface dc trans-

mission lines to the ac utility power system. The converter systems of several applications are illustrated

in this section.

A power supply system for a laptop computer is illustrated in Fig. 1.14. A lithium battery pow-

ers the system, and several dc–dc converters change the battery voltage into the voltages required by the

loads. A buck converter produces the low-voltage dc required by the microprocessor. A boost converter

increases the battery voltage to the level needed by the disk drive. An inverter produces high-voltage

high-frequency ac to drive lamps that light the display. A charger with transformer isolation converts the

ac line voltage into dc to charge the battery. The converter switching frequencies are typically in the

vicinity of several hundred kilohertz; this leads to substantial reductions in the size and weight of the

reactive elements. Power management is used, to control sleep modes in which power consumption is

reduced and battery life is extended. In a distributed power system, an intermediate dc voltage appears at

the computer backplane. Each printed circuit card contains high-density dc–dc converters that produce

�

8

Introduction

locally-regulated low voltages. Commercial applications of power electronics include off-line power sys-

tems for computers, office and laboratory equipment, uninterruptable ac power supplies, and electronic

ballasts for gas discharge lighting.

Figure 1.15 illustrates a power system of an earth-orbiting spacecraft. A solar array produces

the main power bus voltage

to the regulated voltages required by

the spacecraft payloads. Battery charge/discharge controllers interface the main power bus to batteries;

these controllers may also contain dc–dc converters. Aerospace applications of power electronics include

the power systems of aircraft, spacecraft, and other aerospace vehicles.

DC–DC converters convert

Figure 1.16 illustrates an electric vehicle power and drive system. Batteries are charged by a

converter that draws high power-factor sinusoidal current from a single-phase or three-phase ac line. The

batteries supply power to variable-speed ac motors to propel the vehicle. The speeds of the ac motors are

controlled by variation of the electrical input frequency. Inverters produce three-phase ac output voltages

of variable frequency and variable magnitude, to control the speed of the ac motors and the vehicle. A

dc–dc converter steps down the battery voltage to the lower dc levels required by the electronics of the

system. Applications of motor drives include speed control of industrial processes, such as control of

compressors, fans, and pumps; transportation applications such as electric vehicles, subways, and loco-

motives; and motion control applications in areas such as computer peripherals and industrial robots.

Power electronics also finds application in other diverse industries, including dc power supplies,

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc