Design and Implementation of A Remote Equipment Monitoring and

Management System Based on IOT

Naren Gaowa1, Ying Liu1 , Mu-yan Li2

1School of Electronic and Information Engineering, Beijing Jiaotong University, Beijing, China

2School of Computer Science and Engineering, Beihang University, Beijing, China

(narengaowa1989@gmail.com)

Abstract - Equipment monitoring and management

based on IOT technology

improves the efficiency of

equipment monitoring and management, makes equipment

management intelligent. A remote equipment monitoring

and management system based on IOT is introduced in this

paper. It is used in the lab of Beijing Jiaotong University.

This system consists of three parts. First is a perception node

module, second is a wireless multi-hop data transmission

module and last is a center management server. The design

of those three parts is introduced in the paper. The real

performance

and

management system shows that the system works effectively

and efficiently. This system can be expanded to suitable

management systems in various trades and industries.

implemented monitoring

the

of

Keywords

- Equipment,

IOT, monitoring

management, multi-hop networks, RFID

and

I. INTRODUCTION

Due to considerations of costs, technology and other

traditional barcode is popular in the general

factors,

approach of equipment monitoring and management for

fixed assets. In the process of equipment monitoring and

management, the administrator first inputs the equipment

information to the computer management systems, then

fixes barcode on equipment. In order to monitor the

performance of equipment, the administrator has to go to

the lab and check the equipments on regular time schedule.

By

the

inspection of assets costs a lot of time every year. And

during the interval of inspection, equipment file will not

be updated timely if the equipment is missing or has been

taken away for personal business. So it is difficult to

manage equipments [1].

this manual-based management approach,

infrared

IOT (Internet of Things) aims to achieve automatic

recognition of goods through the RFID (radio frequency

sensors, etc. and achieve

identification),

information sharing by connecting

the Internet.

to

Ultimately,

intelligent and

it makes management

constitutes a more intelligent system of production and

living [2]. It is a very complex, various-formed and

systemic technology. IOT connects the separated physical

world with information space and represents the trend of

development of future network. The physical world will

form a huge net by IOT. The integration of IntelliSense

technology, network technology and software technology

in IOT is widely used in transportation control, parking

___________________________________

978-1-4673-2460-1/12/$31.00 ©2012 IEEE

management, warehouse management

automated fields [3].

and

other

Internet

database and

Equipment monitoring and management based on

IOT can combine equipment management with IOT and

ensure the optimal use of resources. It can solve the

complex problems of equipment management. The most

fundamental purpose of equipment management based on

IOT is to achieve real-time equipment monitoring and

improve the speed and accuracy of the equipment asset

management and improve the efficiency of management.

A design of remote equipment monitoring and

management system based on IOT

technology for

university lab is introduced in this paper. It is applied in

the lab of Beijing Jiaotong University. The design

transmission

combines RFID, wireless multi-hop

networks,

technology. An

application system based on IOT, including a perception

node module, a wireless multi-hop data transmission

module and a center management server, is implemented

by authors. Regarded flexibility and general-purpose as

the main design ideas, the system can also be expanded to

suitable management systems in various trades and

improve management

industries. The system will

efficiency and

the

administrator. In this paper, the first section introduces the

concept, main applications, current status of IOT,

problems of equipment management and illustrates the

significance of equipment management in IOT. The

framework of overall design of this remote equipment

monitoring and management system based on IOT is

introduced in the second section. The third section

concentrates on the hardware design of the perception

node module. Section IV mainly introduces the wireless

multi-hop transmission routing strategy of the data

transmission module. The software architecture of the

center management server is presented in section V.

Finally,

and

management system is concluded.

equipment monitoring

intensity of

remote

labor

reduce

the

the

II. FRAMEWORK OF THE SYSTEM

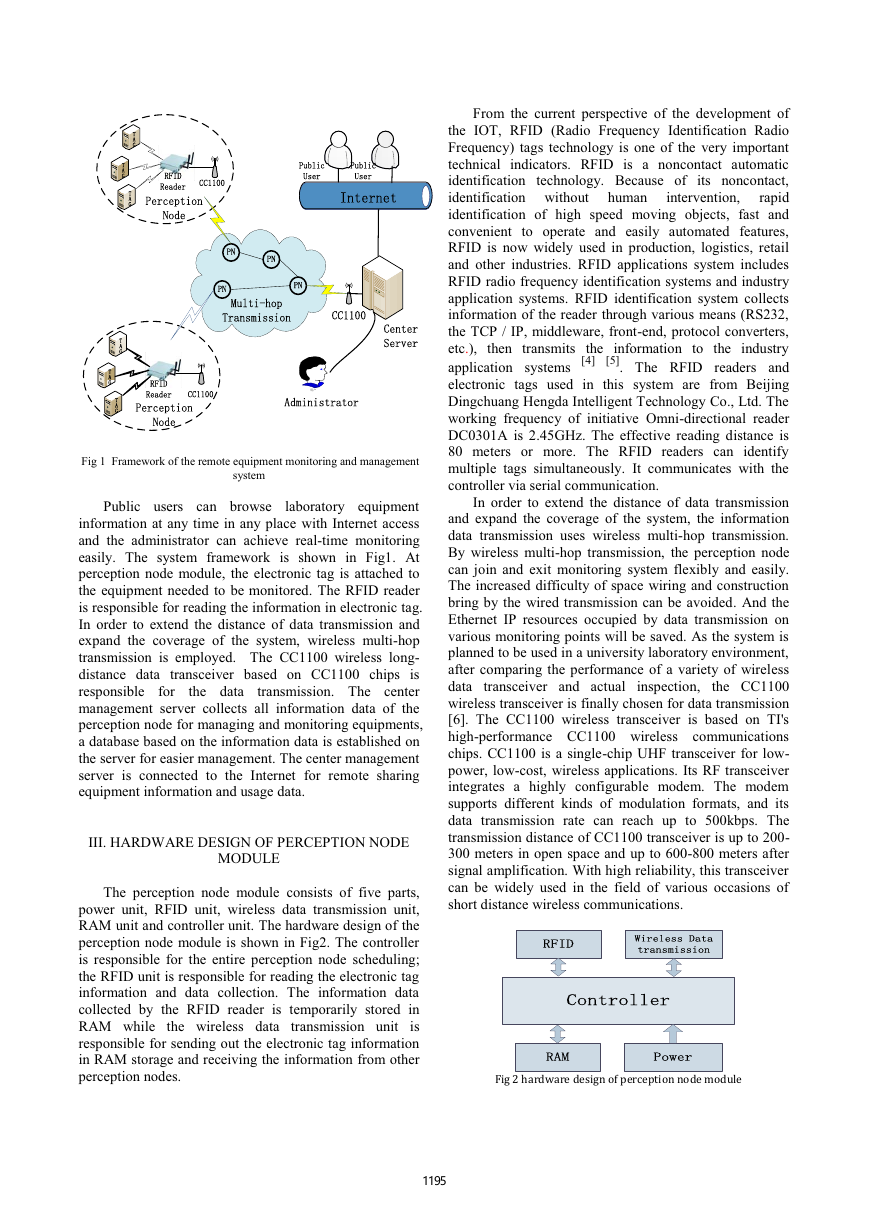

The remote equipment monitoring and management

system consists of perception node module, wireless

multi-hop data

center

management server three parts, achieves the goal of

university laboratory equipment management in IOT

approach.

transmission module

and

1194�

system

Fig 1 Framework of the remote equipment monitoring and management

Public users can browse

laboratory equipment

information at any time in any place with Internet access

and the administrator can achieve real-time monitoring

easily. The system framework is shown in Fig1. At

perception node module, the electronic tag is attached to

the equipment needed to be monitored. The RFID reader

is responsible for reading the information in electronic tag.

In order to extend the distance of data transmission and

expand the coverage of the system, wireless multi-hop

transmission is employed. The CC1100 wireless long-

distance data transceiver based on CC1100 chips is

responsible

transmission. The center

management server collects all information data of the

perception node for managing and monitoring equipments,

a database based on the information data is established on

the server for easier management. The center management

server is connected to the Internet for remote sharing

equipment information and usage data.

the data

for

III. HARDWARE DESIGN OF PERCEPTION NODE

MODULE

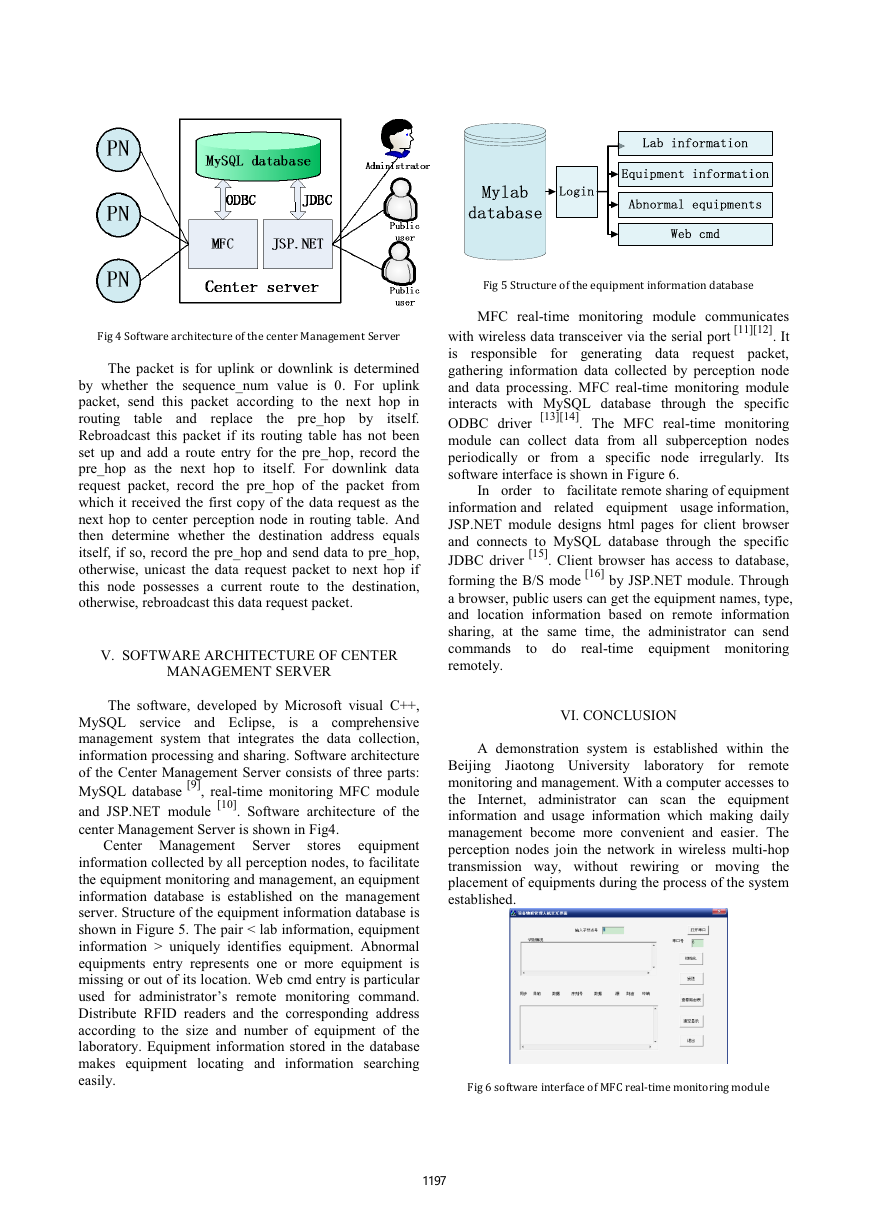

The perception node module consists of five parts,

power unit, RFID unit, wireless data transmission unit,

RAM unit and controller unit. The hardware design of the

perception node module is shown in Fig2. The controller

is responsible for the entire perception node scheduling;

the RFID unit is responsible for reading the electronic tag

information and data collection. The information data

collected by the RFID reader is temporarily stored in

RAM while the wireless data transmission unit is

responsible for sending out the electronic tag information

in RAM storage and receiving the information from other

perception nodes.

human

intervention,

From the current perspective of the development of

the IOT, RFID (Radio Frequency Identification Radio

Frequency) tags technology is one of the very important

technical indicators. RFID is a noncontact automatic

identification technology. Because of its noncontact,

identification without

rapid

identification of high speed moving objects, fast and

convenient to operate and easily automated features,

RFID is now widely used in production, logistics, retail

and other industries. RFID applications system includes

RFID radio frequency identification systems and industry

application systems. RFID identification system collects

information of the reader through various means (RS232,

the TCP / IP, middleware, front-end, protocol converters,

etc.), then transmits the information to the industry

application systems [4] [5]. The RFID readers and

electronic tags used in this system are from Beijing

Dingchuang Hengda Intelligent Technology Co., Ltd. The

working frequency of initiative Omni-directional reader

DC0301A is 2.45GHz. The effective reading distance is

80 meters or more. The RFID readers can identify

multiple tags simultaneously. It communicates with the

controller via serial communication.

In order to extend the distance of data transmission

and expand the coverage of the system, the information

data transmission uses wireless multi-hop transmission.

By wireless multi-hop transmission, the perception node

can join and exit monitoring system flexibly and easily.

The increased difficulty of space wiring and construction

bring by the wired transmission can be avoided. And the

Ethernet IP resources occupied by data transmission on

various monitoring points will be saved. As the system is

planned to be used in a university laboratory environment,

after comparing the performance of a variety of wireless

data transceiver and actual inspection, the CC1100

wireless transceiver is finally chosen for data transmission

[6]. The CC1100 wireless transceiver is based on TI's

high-performance CC1100 wireless communications

chips. CC1100 is a single-chip UHF transceiver for low-

power, low-cost, wireless applications. Its RF transceiver

integrates a highly configurable modem. The modem

supports different kinds of modulation formats, and its

data transmission rate can reach up to 500kbps. The

transmission distance of CC1100 transceiver is up to 200-

300 meters in open space and up to 600-800 meters after

signal amplification. With high reliability, this transceiver

can be widely used in the field of various occasions of

short distance wireless communications.

Fig 2 hardware design of perception node module

1195�

Fig 3 the process after receiving data requests

The task of the controller in perception node module

is

to control RFID reader reading and collecting

information in electronic tags based on the command

received from center management server and store the

collected information in RAM, then inform the wireless

data transmission unit to send the data. The working

mechanism is simple, and does not need a very high

requirement of execution speed and storage space. A

simple microcontroller can complete the above task well.

To this end, the simple microcontroller STC12C5A60S2

control chip is taken as the perception node controller in

this system. STC12C5A60S2 is a low-power high-speed

general MCU with a 24.5MHz oscillator, and a

programmable flash memory of 32KB. The flash memory

has a security option, which can avoid its data be

modified and erased maliciously. It has dual serial ports

and with excellent performance.

IV. WIRELESS MULTI-HOP TRANSMISSION

ROUTING STRATEGY

the

link

Due to unpredictable nature of wireless environment,

link breakage, disorder packets and other issues may

occur during the data transmission process. In order to

improve

reliability, a wireless multi-hop

transmission strategy is specifically designed for this

system to ensure the reliability of the data transmission

based on the ad hoc network routing strategy of AODV

and the DSDV[7][8]. Set the perception node connected to

center data management server as center perception node

and other perception nodes as subperception nodes.

Center perception node requests to obtain data of

subperception nodes in the entire wireless network, and

subperception nodes response to center perception nodes

passively. Center perception node asks for data from all

subperception nodes periodically or requests data from a

specific node irregularly. Define data transmission from

the center perception node to subperception nodes as the

the data

in contrast,

transmission from

downlink;

subperception nodes to center perception node is uplink.

Each perception node maintains a routing table and each

route table entry contain the following two fields.

- Destination

- Next hop

the next hop to destination

The data packets in transmission follow a unified

format. The format of the data packets is illustrated as

follow, and contains the following fields:

set AA as packet header

the next hop to destination

< header, next_hop, sequence_num, pre_hop, destination,

data>

-

header

-

next_hop

-

sequence_num

unique identifier for each packet

that center perception node sends at downlink, set to

0 at uplink and incremented at downlink

pre_hop

comes from

destination

data

sub perception nodes, set to 0 at downlink

the equipment information collected by the

the previous hop where the data packet

the final destination of packets

-

-

-

The following two subsections describe how to

generate data requests and the process after receiving data

requests, respectively.

A. Generating Data Requests

The center perception node sends a data request

packet when it requires data of a subperception node with

no route to. Set the next_hop field as broadcast address

and broadcast the data request packet.

B. Receiving Data Requests

When a subperception node receives a data request

packet, the process is shown in Fig 3.When a sub

perception node receives a data request packet, the node

first checks whether the next_hop is a broadcast address

or not. If the next_hop is a broadcast address, the node

will only respond to the packets with an unreceived

sequence_num , and drop the packet if the sequence_num

had been received. A perception node records the pre_hop

of the packet from which it received the first copy of the

data request as the next hop to center perception node in

routing table. And then determine whether the node itself

is the destination node or not, if so, that means the

broadcast data request packet find a destination, the node

will record the pre_hop and send data to pre_hop.

Otherwise, the node just plays a forwarding node role,

replaces the pre_hop of the data request packet by its own

address and rebroadcasts the packet. If the next_hop in the

packet equals to the perception node address, indicating

that the node is the next hop in this route path.

1196�

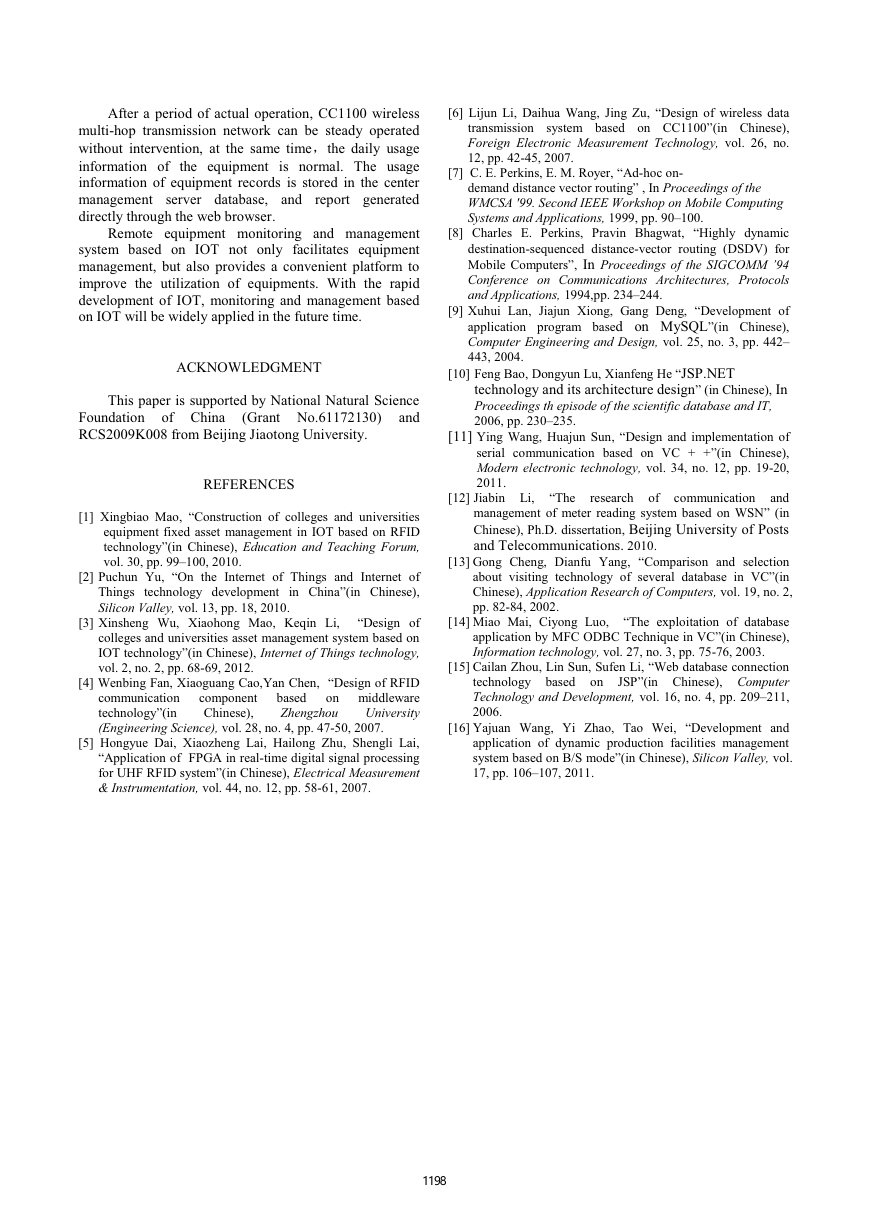

Fig 5 Structure of the equipment information database

MFC real-time monitoring module communicates

with wireless data transceiver via the serial port [11][12]. It

is responsible for generating data request packet,

gathering information data collected by perception node

and data processing. MFC real-time monitoring module

interacts with MySQL database through the specific

ODBC driver [13][14]. The MFC real-time monitoring

module can collect data from all subperception nodes

periodically or from a specific node irregularly. Its

software interface is shown in Figure 6.

In order

to facilitate remote sharing of equipment

information and related equipment usage information,

JSP.NET module designs html pages for client browser

and connects to MySQL database through the specific

JDBC driver [15]. Client browser has access to database,

forming the B/S mode [16] by JSP.NET module. Through

a browser, public users can get the equipment names, type,

and location information based on remote information

sharing, at the same time, the administrator can send

commands

real-time equipment monitoring

remotely.

to do

VI. CONCLUSION

for

laboratory

A demonstration system is established within the

remote

Beijing Jiaotong University

monitoring and management. With a computer accesses to

the Internet, administrator can scan

the equipment

information and usage information which making daily

management become more convenient and easier. The

perception nodes join the network in wireless multi-hop

transmission way, without rewiring or moving

the

placement of equipments during the process of the system

established.

Fig 6 software interface of MFC real-time monitoring module

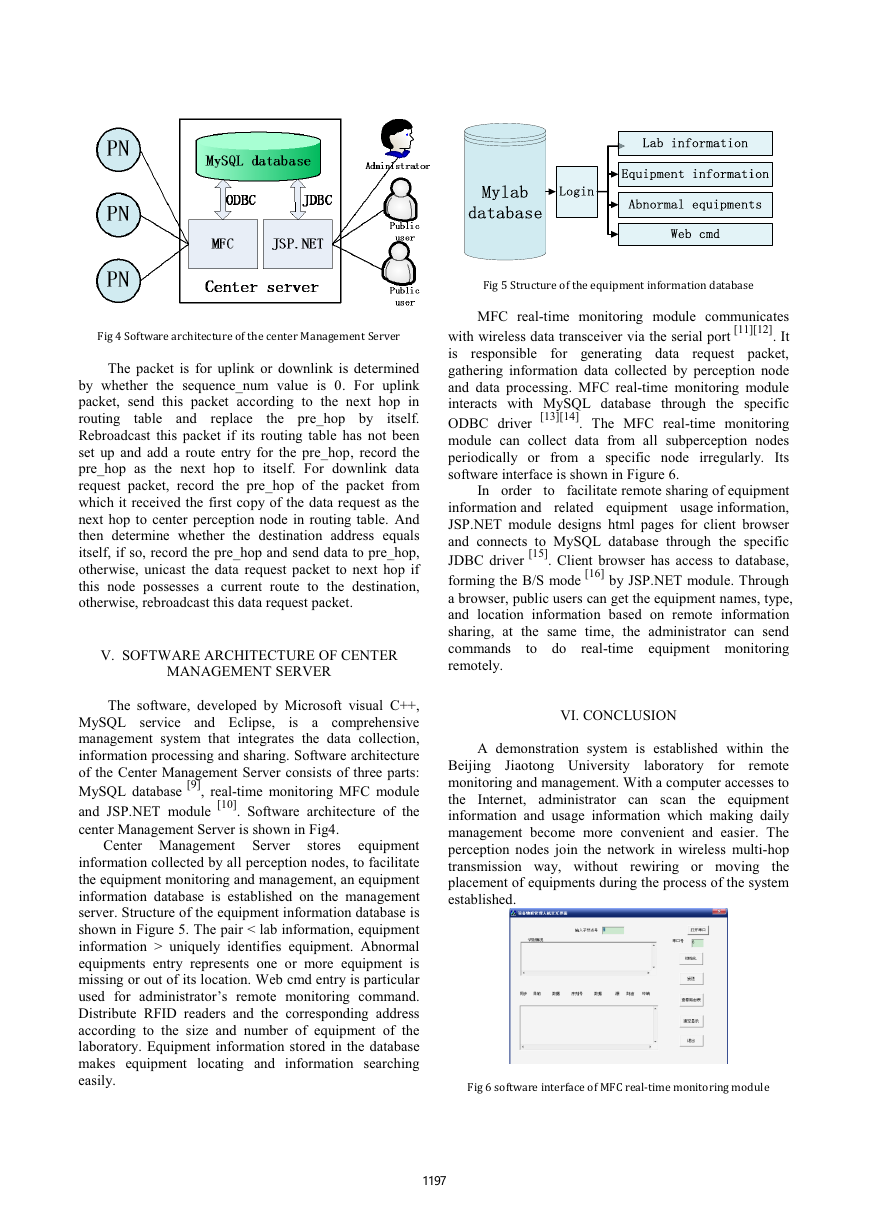

Fig 4 Software architecture of the center Management Server

replace

table and

the pre_hop by

The packet is for uplink or downlink is determined

by whether the sequence_num value is 0. For uplink

packet, send this packet according to the next hop in

routing

itself.

Rebroadcast this packet if its routing table has not been

set up and add a route entry for the pre_hop, record the

pre_hop as the next hop to itself. For downlink data

request packet, record the pre_hop of the packet from

which it received the first copy of the data request as the

next hop to center perception node in routing table. And

then determine whether the destination address equals

itself, if so, record the pre_hop and send data to pre_hop,

otherwise, unicast the data request packet to next hop if

this node possesses a current route to the destination,

otherwise, rebroadcast this data request packet.

V. SOFTWARE ARCHITECTURE OF CENTER

MANAGEMENT SERVER

Center Management Server

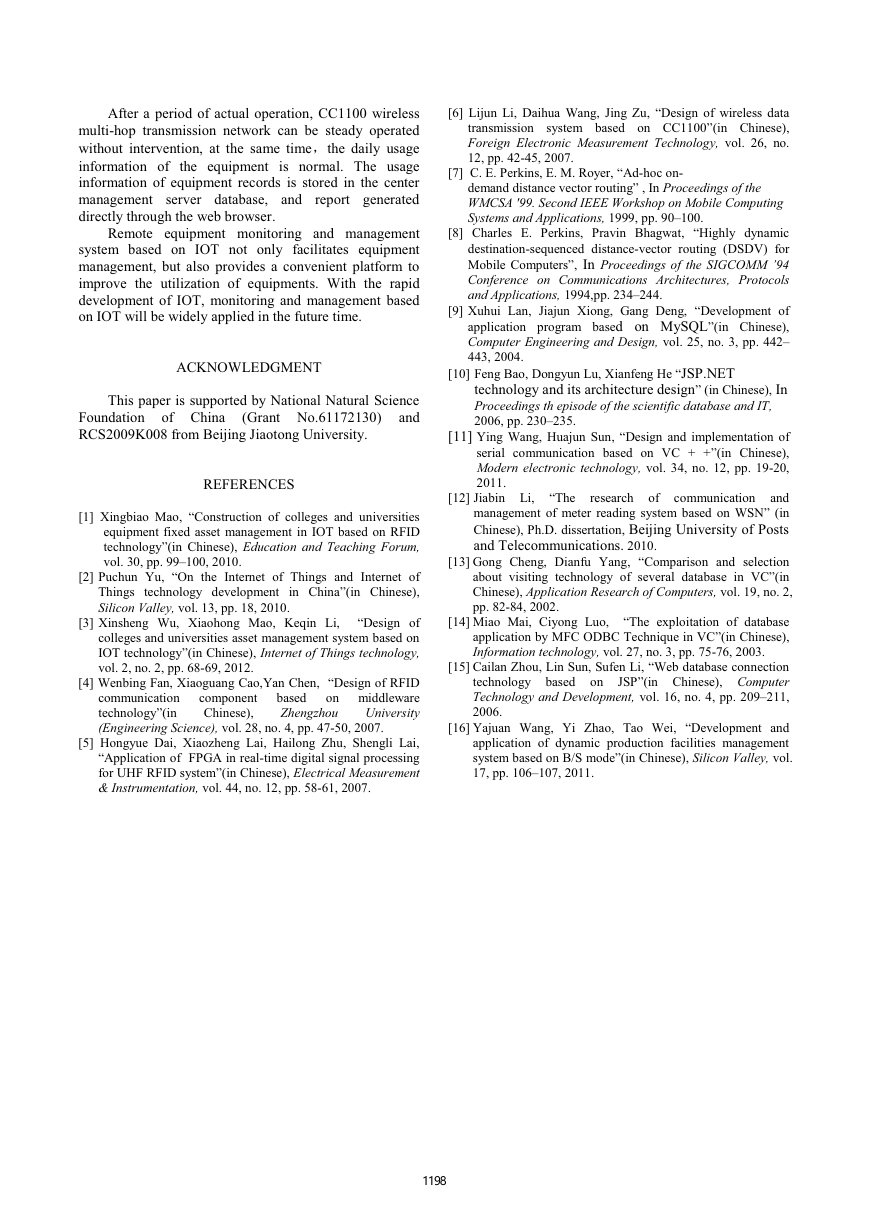

The software, developed by Microsoft visual C++,

MySQL service and Eclipse,

is a comprehensive

management system that integrates the data collection,

information processing and sharing. Software architecture

of the Center Management Server consists of three parts:

MySQL database [9], real-time monitoring MFC module

and JSP.NET module [10]. Software architecture of the

center Management Server is shown in Fig4.

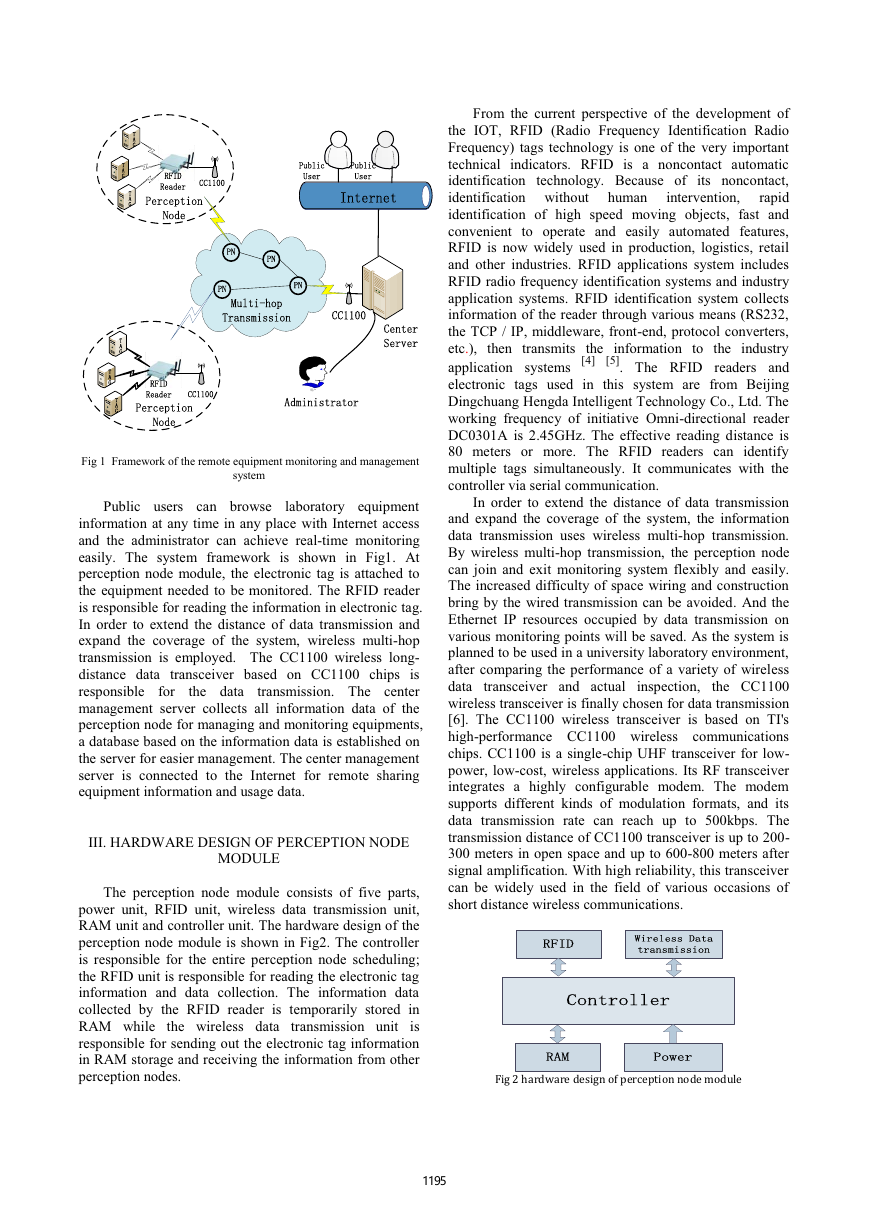

stores

equipment

information collected by all perception nodes, to facilitate

the equipment monitoring and management, an equipment

information database is established on the management

server. Structure of the equipment information database is

shown in Figure 5. The pair < lab information, equipment

information > uniquely identifies equipment. Abnormal

equipments entry represents one or more equipment is

missing or out of its location. Web cmd entry is particular

used for administrator’s remote monitoring command.

Distribute RFID readers and the corresponding address

according to the size and number of equipment of the

laboratory. Equipment information stored in the database

makes equipment locating and information searching

easily.

1197�

ACKNOWLEDGMENT

[6] Lijun Li, Daihua Wang, Jing Zu, “Design of wireless data

transmission system based on CC1100”(in Chinese),

Foreign Electronic Measurement Technology, vol. 26, no.

12, pp. 42-45, 2007.

[7] C. E. Perkins, E. M. Royer, “Ad-hoc on-

demand distance vector routing” , In Proceedings of the

WMCSA '99. Second IEEE Workshop on Mobile Computing

Systems and Applications, 1999, pp. 90–100.

[8] Charles E. Perkins, Pravin Bhagwat, “Highly dynamic

destination-sequenced distance-vector routing (DSDV) for

Mobile Computers”, In Proceedings of the SIGCOMM ’94

Conference on Communications Architectures, Protocols

and Applications, 1994,pp. 234–244.

[9] Xuhui Lan, Jiajun Xiong, Gang Deng, “Development of

application program based on MySQL”(in Chinese),

Computer Engineering and Design, vol. 25, no. 3, pp. 442–

443, 2004.

[10] Feng Bao, Dongyun Lu, Xianfeng He “JSP.NET

technology and its architecture design” (in Chinese), In

Proceedings th episode of the scientific database and IT,

2006, pp. 230–235.

[11] Ying Wang, Huajun Sun, “Design and implementation of

serial communication based on VC + +”(in Chinese),

Modern electronic technology, vol. 34, no. 12, pp. 19-20,

2011.

[12] Jiabin Li, “The

research of communication and

management of meter reading system based on WSN” (in

Chinese), Ph.D. dissertation, Beijing University of Posts

and Telecommunications. 2010.

[13] Gong Cheng, Dianfu Yang, “Comparison and selection

about visiting technology of several database in VC”(in

Chinese), Application Research of Computers, vol. 19, no. 2,

pp. 82-84, 2002.

[14] Miao Mai, Ciyong Luo, “The exploitation of database

application by MFC ODBC Technique in VC”(in Chinese),

Information technology, vol. 27, no. 3, pp. 75-76, 2003.

[15] Cailan Zhou, Lin Sun, Sufen Li, “Web database connection

JSP”(in Chinese), Computer

technology based on

Technology and Development, vol. 16, no. 4, pp. 209–211,

2006.

[16] Yajuan Wang, Yi Zhao, Tao Wei, “Development and

application of dynamic production facilities management

system based on B/S mode”(in Chinese), Silicon Valley, vol.

17, pp. 106–107, 2011.

After a period of actual operation, CC1100 wireless

multi-hop transmission network can be steady operated

without intervention, at the same timethe daily usage

information of the equipment is normal. The usage

information of equipment records is stored in the center

management server database, and report generated

directly through the web browser.

Remote equipment monitoring and management

system based on IOT not only facilitates equipment

management, but also provides a convenient platform to

improve the utilization of equipments. With the rapid

development of IOT, monitoring and management based

on IOT will be widely applied in the future time.

This paper is supported by National Natural Science

and

(Grant No.61172130)

Foundation of China

RCS2009K008 from Beijing Jiaotong University.

REFERENCES

[1] Xingbiao Mao, “Construction of colleges and universities

equipment fixed asset management in IOT based on RFID

technology”(in Chinese), Education and Teaching Forum,

vol. 30, pp. 99–100, 2010.

[2] Puchun Yu, “On the Internet of Things and Internet of

Things technology development in China”(in Chinese),

Silicon Valley, vol. 13, pp. 18, 2010.

[3] Xinsheng Wu, Xiaohong Mao, Keqin Li, “Design of

colleges and universities asset management system based on

IOT technology”(in Chinese), Internet of Things technology,

vol. 2, no. 2, pp. 68-69, 2012.

[4] Wenbing Fan, Xiaoguang Cao,Yan Chen, “Design of RFID

on middleware

University

communication

technology”(in

(Engineering Science), vol. 28, no. 4, pp. 47-50, 2007.

based

Zhengzhou

component

Chinese),

[5] Hongyue Dai, Xiaozheng Lai, Hailong Zhu, Shengli Lai,

“Application of FPGA in real-time digital signal processing

for UHF RFID system”(in Chinese), Electrical Measurement

& Instrumentation, vol. 44, no. 12, pp. 58-61, 2007.

1198�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc