\)

Advanced

PID Control

Karl J. Astrom Tore Hdgglund

Department of Automatic Control

Lund Institute of Technology

Lund Uniuersity

z\

Jlsnr

,?

Systems,

ISA-The

Instrumentalion,

and Automation Society

�

Copyright @ 2006 by

ISA - Instrumentation, Systems, and Automation Society

67 Alexander Drive

P.O. Box 12277

Research Triangle Park, NC 27709

All rights reserved.

Printed in the United States of America.

1 0 9 8 7 6 5 4 3 2

ISBN r-55617-942-r

No part of this work may be reproduced, stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical, photocopying, recording or

otherwise, without the prior written permission of the publisher.

Notice

The information presented in this publication is for the general education of the

reader. Because neither the author nor the publisher has any control over the use of

the information by the reader, both the author and the publisher disclaim any and all

liability of any kind arising out of such use. The reader is expected to exercise sound

professional judgment in using any of the information presented in a particular

application.

Additionally, neither the author nor the publisher have investigated or considered

the effect of any patents on the ability of the reader to use any of the information in a

particular application. The reader is responsible for reviewing any possible patents

that may affect any particular use of the information presented.

Any references to commercial products in the work are cited as examples only.

Neither the author nor the publisher endorses any referenced commercial product. Any

trademarks or tradenames referenced belong to the respective owner of the mark or

name. Neither the author nor the publisher makes any representation regarding the

availability of any referenced commercial product at any time. The manufacturer's

instructions on use of any commercial product must be followed at all times, even if in

conflict with the information in this publication.

Library of Congress Cataloging-in-Publication Data

Astrtjm, Karl J. (Karl Johan), lg34-

Advanced PID control / Karl Johan Astrom and Tore Hagglund.

p. cm.

Includes bibliographical references and index.

ISBN 1-55617-942-1 (pbk.)

1. PID controllers. I. Hrigglund, Tore. II. Title.

TJ223.P55A85 2006

629.8'3--dc22

20050r4664

�

Preface

The PID controller is the most common solution to practical control problems.

Although controllers with proportional and integral action have been used from

the time when windmills and steam engines were the dominant technologies,

the current form of the PID controller emerged with the pneumatic controllers

in the 1930s. The controllers have been implemented in many different ways

using mechanical, pneumatic, electronic, and computer technolory. The devel-

opment accelerated when the microprocessor implementations appeared in the

1980s. One reason was that the computer implementations made it possible

to add features like auto-tuning and diagnostics, which are very beneficial for

users. From an engineering perspective, it is particularly interesting to ana-

lyze what happened at the technology shifts, when some important features

were rediscovered and others were added.

This book has grown out of more than 25 years of development of auto-

tuners for PID controllers in close collaboration with industry. Through this

work, we have been exposed to a large number of real industrial control prob-

lems. We have benefited much from participating in development, commission-

ing, and troubleshooting of industrial controllers. The practical work has also

inspired research.

This book is the last part of a trilogy. The first book, Automatic Tfu.ning of

PID Controllers, 1988, which had 6 chapters, gave a short description of our

early experiences with development of relay auto-tuners. The second book, PID

Controllers: Theory, Design,, and Tfu.ning, 1995, which has 7 chapters, grew out

of the need for a broader coverage of many aspects of PID control. In particular,

it reviews many design methods for PID controllers that we investigated in

connection with our work on auto-tuners.

The knowledge about PID control in 1995 still was not satisfactory for de-

sign of auto-tuners. One drawback was that the user had to provide the con-

troller with design choices. It is particularly difficult for a user to assess if

dynamics is dead-time or lag dominated. This question stimulated further re-

search. Because of the drastic increase in computing power, it was also possible

to use design algorithms that require more computations.

Thning and design of PID controllers have traditionally been based on spe-

cial techniques. Robust control was a major development of control theory that

matured in the late 1990s, resulting in powerful design methods based on ro-

bust loop shaping. This stimulated us to initiate a research program to adapt

�

Preface

these methods to PID control. At the same time, it seemed natural to bring

PID control closer to the mainstream ideas in control. When working with in-

dustrial auto-tuners, we also saw a great need to include diagnostics in the

controller, because it is no use to tune a controller if the process has severe

malfunctions. The present book, Aduanced PID Control, is the result of this

effort.

With a total of 13 chapters, this new book substantially expands on some of

the topics covered in the previous versions and provides several new chapters

that deal with controller design, feedforward design, replacement of the Ziegler-

Nichols tuning rules, predictive control, loop and performanee asqeqqrnnnr ?-i

interaction. At this point in our book trilogy, we assume that the reader rb

highly familiar with control theory.

Our research has given a deeper understanding of the trade-offs between

load disturbance attenuation, injection of measurement noise, and set-point

response. We have also been able to answer questions like: Should a controller

be tuned for response to load disturbances or set points? What information

is

required to design a PID controller? When can derivative action give signif-

icant improvements? When are more complicated controllers justified? When

is it justified to develop more accurate process models? With the knowledge

developed, it is now possible to design auto-tuners that can make these assess-

ments autonomously. In addition, we have developed new simple methods for

designing PID controllers.

As an example of the insight gained we can mention that control theory

tells that it is not necessary to make a compromise between tuning for load

disturbance response and set-point response. Both requirements can be satis-

fied by using a controller with two degrees of freedom, which combines feedback

and feedforward. The feedback gains should be chosen to satisfy requirements

on disturbance attenuation and robustness. The desired response to set-point

changes can then be obtained by proper use of feedforward. Set-point weighting

is a simple form of feedforward for PID control. In some cases, it is justified to

use more elaborate feedforward. For this reason, we have included a chapter

on controller design and another chapter on feedforward in the new book.

The robustness analysis also shows the advantage of having low controller

gain at high frequency, high frequency roll-off. This can be accomplished by

flltering the process output by a second order filter. Based on the insight ob-

tained, we recommend extended use of set-point weighting or more advanced

feedforward. We also recommend that the process output is fiItered using a

second order filter.

We would like to thank many people who have given knowledge, insight,

and inspiration. Our interest in PID control was inspired by Axel Westrenius

and Mike Somerville of Eurotherm in the early 1980s. We have learned much

from working with students; particular

thanks are due to Lars Gdran Elfgren

(Eurotherm), Giiran Grtinhammar (LTH), Ari Ingimundarson (UPC), Oskar

Nordin (Volvo), Helene Panagopoulos (Volvo), Per Persson (Volvo), Mikael Pe-

tersson (ABB), Ola Slattke (ABB), and Anders Wall6n (Ericsson Mobile Plat-

forms), who continue to give us valuable insight even if they are now pursuing

careers in industry.

We are very grateful to Sune Larsson and Lars Beath, formerly of NAF

vi

�

Controls, with whom we developed the first industrial relay auto-tuner. The

company NAF Controls was merged several times and is now part of ABB,

where we have enjoyed interactions with Gdran Arinder, Alf Isaksson, Per Erik

Mod6n, Lars Pernebo, and Thomas Vonheim. We have shared the joy and chal-

lenges in moving techniques for auto-tuning and diagnostics into a wide range

of industrial products. Many stimulating discussions with our colleagues Anton

Cervin (LTH), Sebastian Dormido (UNED), Gty Dumont (UBC), Chang Chieh

Hang (NUS), Karl Henrik Johansson (KTH), Birgitta Kristiansson (CTH),

Bengt Lennartsson (CTH), Manfred Morari (ETH), Dale Seborg (UCSB), Sig-

(LTH), and Karl-Erik Arz6n (LTH)

urd Skogestad (NTNU), Bjiirn Wittenmark

from academia are also highly appreciated.

Our friends in industry Bill Bialkowski, Terry Blevins, Greg McMillan,

and Willy Wojsznis from Emerson, Edgar Bristol, Sigifredo Niflo, and Greg

Shinskey from Foxboro, Bdrje Eriksson (M-real), Krister Forsman (Perstorp),

Ken Goff (Leeds and Northrup), Niklas Karlsson (Evolution Robotics), Joseph

Lu (Honeywell), Tor Steinar Schei (Cybernetica), Stefan Rtrnnbiick (Optima-

tion), have generously shared their knowledge and insight with us. We are

particularly grateful to Peter Hansen, formerly of Foxboro, who read the com-

plete manuscript and gave us very good feedback.

We are very grateful to Leif Andersson who made the layout of the text and

gave much assistance with TbX, Agneta T\rszyriski who translated much of the

text to I4rIbX, and Eva Dagnegfird who drew several of the figures.

Finally, we would like to thank the Swedish Research Council (VR), the

Swedish Agency for Innovation Systems (VINNOVA), and the Swedish Foun-

dation for Strategic Research (SSF) who have supported our research for many

years.

Kanr, JoHaN AsrnOnt

Tonn HAccluNn

Department of Automatic Control

Lund Institute of Technology

Box 118, SE-22I00 Lund, Sweden

karl-j ohan. astrom@control . Ith. se

tore . hagglund@control . lth. se

vu

�

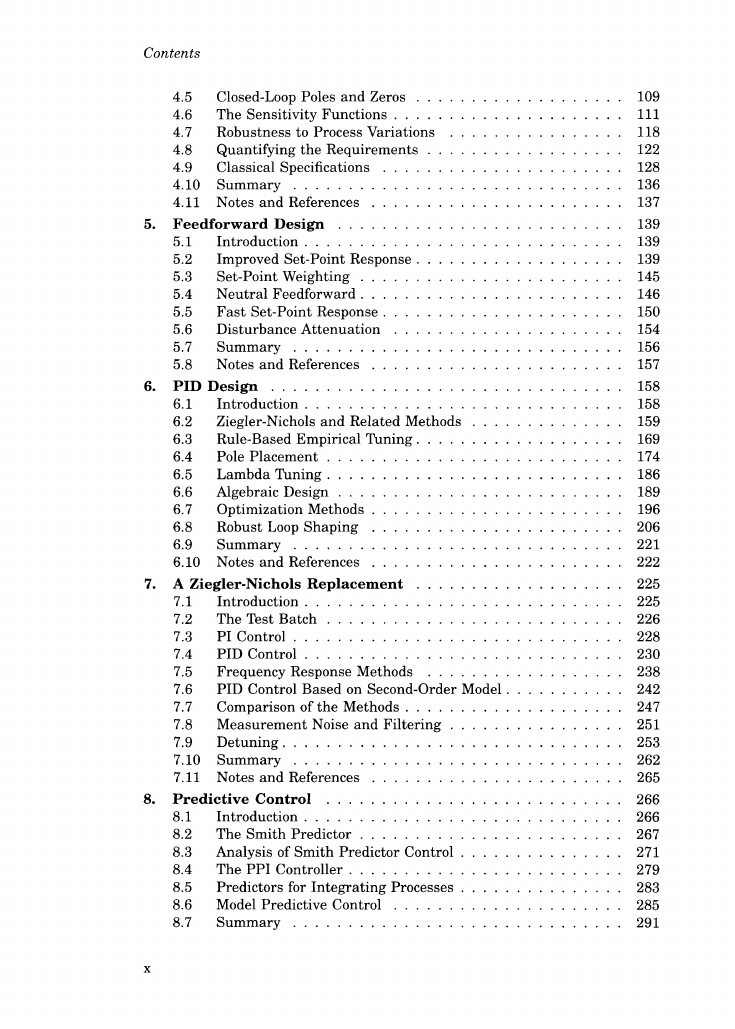

Contents

1 .

2.

3.

4.

Technology Changes and Knowledge Thansfer

Summary

.

Introduction .

Static Models

Feature-Based Models

Tlpical Process Models

. : . : . : .

Introductio"

Feedback

Simple Forms of Feedback

Introduction

1.1

1.2

1.3

1.4 How the PID Controller Developed

1.5

1.6 Outline of the Contents of the Book .

I.7

1.8 Notes and References

Process Models

2.1

2.2

2.3 Dynamic Models

2.4

2.5

2.6 Models for Disturbances .

2.7

How to Obtain the Models

2.8 Model Reduction

2.9

2.t0 Notes and References

PID Control

3.1

3.2

3.3

3.4

3.5

3.6 When Can PID Control Be Used?

3.7

3.8 Notes and References

Controller Design

4.1

4.2

4.3

4.4

Introduction .

A Rich Variety of Control Problems

Feedback Fundamentals .

Stability

Introduction .

The PID Controller .

Filtering the Derivative

Set-Point Weighting

Integrator Windup

Summary

.

Summary

1

1

2

3

5

7

8

10

10

t2

t2

13

T4

23

28

44

47

56

6 1

62

64

64

64

73

74

76

87

92

93

95

95

96

96

r02

ix

�

Contents

6.

7.

Classical Specifications

Introduction .

Improved Set-Point Response .

Set-Point Weighting

Fast Set-Point Response .

Summary

Notes and References

Closed-Loop Poles and Zeros

The Sensitivity Functions .

Robustness to Process Variations

Introduction .

Ziegler-Nichols and Related Methods

Rule-Based Empirical T\rning.

Pole Placement

Lambda T\rning .

Algebraic Design

4.5

4.6

4.7

4.8 Quantifying the Requirements

4.9

4.10 Summary

A.LI Notes and References

Feedforward Design

5.1

5.2

5.3

5.4 Neutral Feedforward .

5.5

5.6 DisturbanceAttenuation

5.7

5.8

PID Design

6.1

6.2

6.3

6.4

6.5

6.6

6.7 Optimization Methods

Robust Loop Shaping

6.8

6.9

Summary

6.10 Notes and References

A Ziegler-Nichols Replacement

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8 Measurement Noise and Filtering

7.9 Detuning .

7.10 Summary

7.1I Notes and References

Predictive Control

Introduction .

8.1

8.2 The Smith Predictor

8.3 Analysis of Smith Predictor Control .

8.4 The PPI Controller .

8.5 Predictors for Integrating Processes

8.6 Model Predictive Control

8.7 Summarv

Introduction .

The Test Batch

PI Control .

PID Control

Frequency Response Methods

PID Control Based on Second-Order Model

Comparison of the Methods .

109

1 1 1

1 1 8

122

128

136

137

139

139

139

I45

I46

150

154

156

157

158

158

159

169

t74

186

189

196

206

221

222

225

225

226

228

230

238

242

247

251

253

262

265

266

266

267

271

279

283

285

291

�

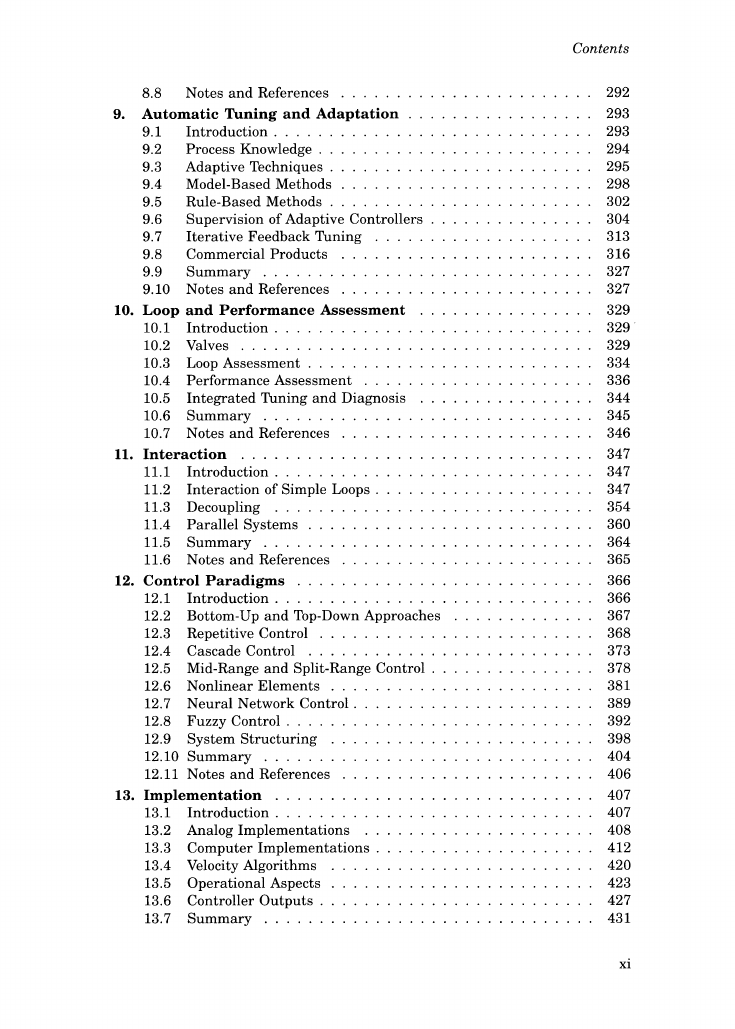

Introduction .

Integrated Ttrning and Diagnosis

Introduction .

Interaction of Simple Loops .

.

Notes and References

Supervision of Adaptive Controllers

Iterative Feedback Ttrning

Commercial Products

Summary

8.8

Automatic Thning and Adaptation

Introduction .

9.1

Process Knowledge .

9.2

Adaptive Techniques .

9.3

9.4 Model-Based Methods

9.5 Rule-Based Methods

9.6

9.7

9.8

9.9

9.10 Notes and References

Loop and Performance Assessment

10.1

I0.2 Valves

10.3 Loop Assessment

10.4 Performance Assessment

10.5

10.6 Summary

10.7 Notes and References

Interaction

11.1

LI.2

11.3 Decoupling

1I.4 Parallel Systems

11.5 Summary

11.6 Notes and References

Control Paradigms

12.1

Introduction

I2.2 Bottom-Up and Top-Down Approaches

12.3 Repetitive Control

12.4 Cascade Control

I2.5 Mid-Range and Split-Range Control .

12.6 Nonlinear Elements

I2.7 Neural Network Control .

I2.8 Fuzzy Control .

I2.9 System Structuring

12.10 Summary

t2.II Notes and References

Implementation

13.1

I3.2 Analog Implementations

13.3 Computer Implementations .

13.4 Velocity Algorithms

13.5 OperationalAspects

13.6 Controller Outputs .

L3.7 Summarv

Introduction .

10.

l l .

12.

13.

Contents

292

293

293

294

295

298

302

304

3 1 3

3 1 6

327

327

329

329

329

334

336

344

345

346

347

347

347

354

360

364

365

366

366

367

368

373

378

3 8 1

389

392

398

404

406

407

407

408

4r2

420

423

427

43r

xi

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc