Estimating Rotational Speed with a Phase-Locked Loop

Abstract

1. Introduction

2. The current method for measuring rotational speed

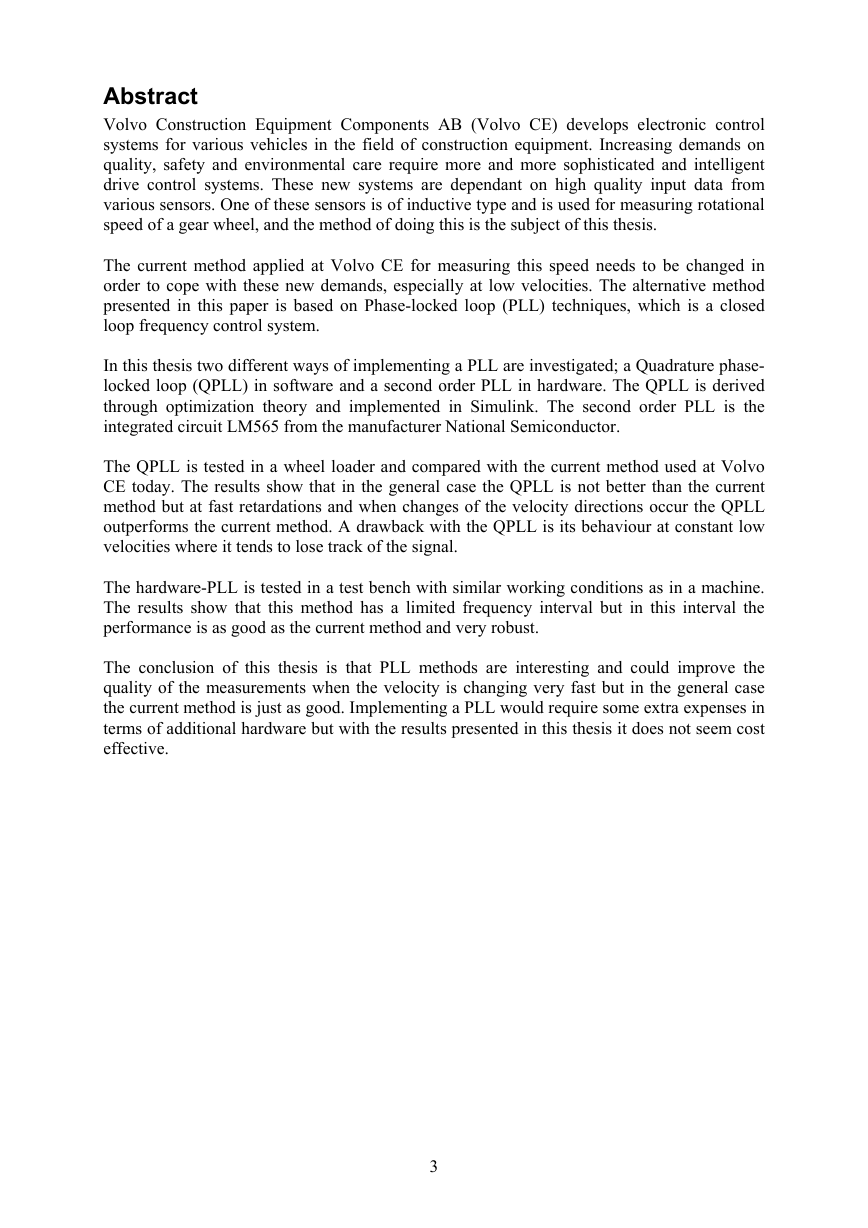

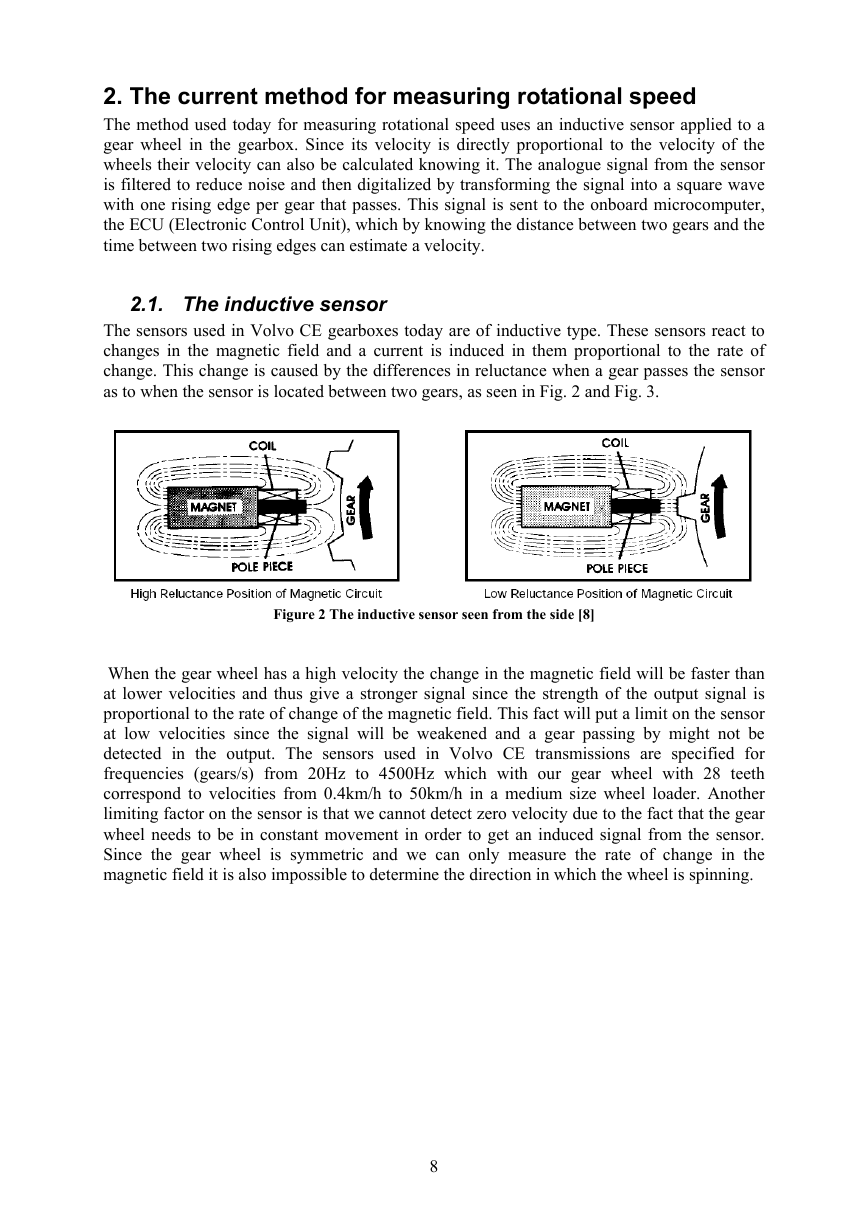

2.1. The inductive sensor

2.2. From sensor output to velocity estimation

2.2.1. Filtering and signal adaptation

2.2.2. Time delays caused by filtering and signal adaptation

2.2.3. The interrupt routine

2.2.4. Algorithms used in the ECU

3. The Sensor Output

4. Phase-locked loops – Theory

4.1. Basic working principles of a PLL

4.2. Mathematical derivation of a first order PLL

4.3. The second order PLL

4.4. Previous use of PLL’s in the automotive industry

4.5. How can a PLL improve our measurements of rotational speed?

4.6. The gradient descent method for design of a more complete PLL

4.6.1. The algorithm

4.6.2. Simulations

4.7. The quadrature phase-locked loop (QPLL)

4.7.1. The algorithm

5. Implementation of a PLL in hardware

5.1. Necessary components

5.1.1. The phase detector

5.1.2. The voltage controlled oscillator (VCO)

5.1.3. The PI-controller/Loop filter

5.2. The LM565C Phase-locked loop integrated circuit

5.2.1. Limitations and tuning

5.2.2. Comments

6. The QPLL – Machine testing

6.1. Previous results

6.2. Signal processing

6.2.1. The current ECU estimation

6.2.2. The QPLL estimation

6.3. Results from machine testing

6.3.1. A hard brake

6.3.2. A Hard brake and change of direction

6.3.3. Periodic change in velocity

6.3.4. A constant very low velocity

7. The PLL in hardware – Results from a test bench

7.1. The test bench

7.2. Signal processing

7.2.1. The current ECU estimation

7.2.2. The PLL in hardware

7.2.3. The Encoder estimate

7.3. Results from the test bench

7.3.1. Periodic change in velocity

7.3.2. Step changes in velocity

7.3.3. Testing the limits

7.4. Robustness

8. Discussion and conclusion

8.1. The QPLL

8.2. The hardware-PLL

8.3. Other possible improvements

9. Future work

10. Bibliography

10.1. Scientific papers

10.2. Web pages

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc