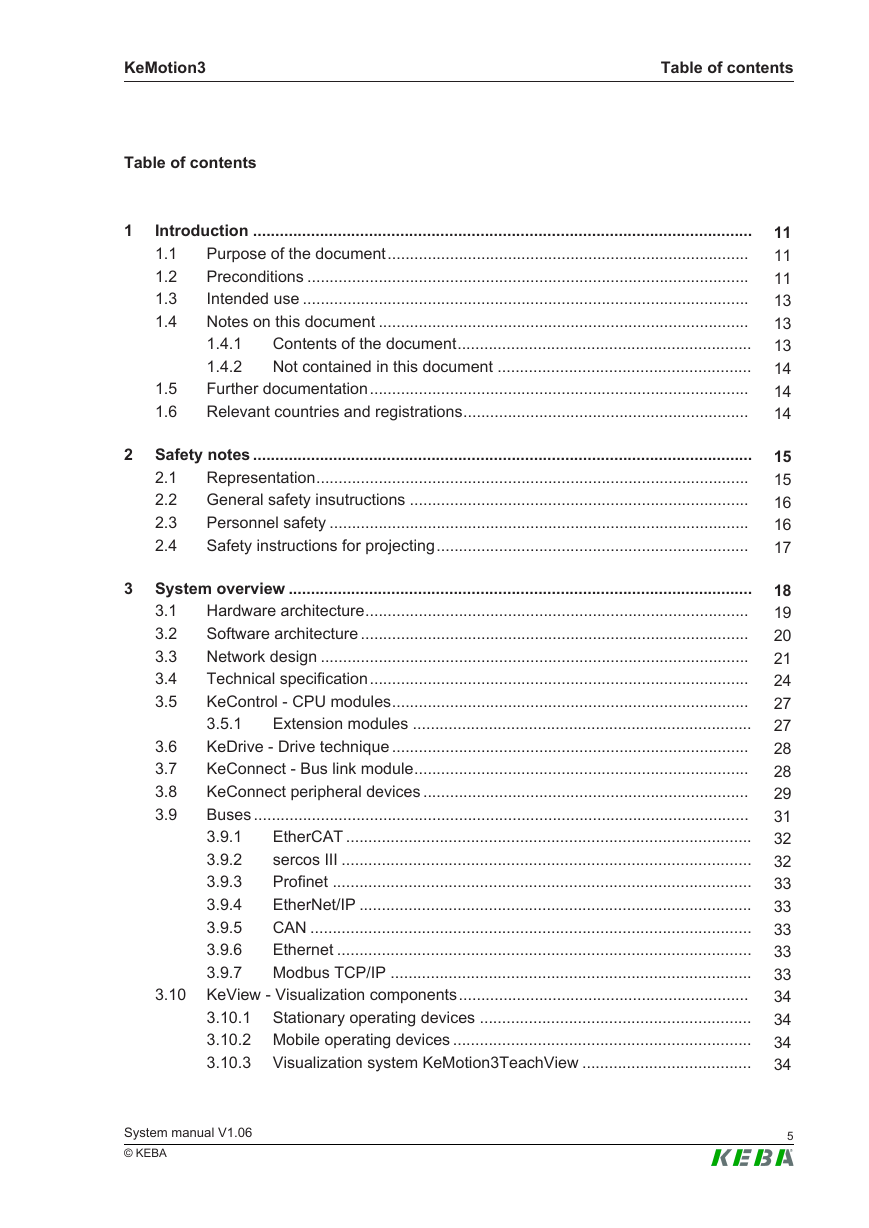

Table of contents

1 Introduction

1.1 Purpose of the document

1.2 Preconditions

1.3 Intended use

1.4 Notes on this document

1.4.1 Contents of the document

1.4.2 Not contained in this document

1.5 Further documentation

1.6 Relevant countries and registrations

2 Safety notes

2.1 Representation

2.2 General safety insutructions

2.3 Personnel safety

2.4 Safety instructions for projecting

3 System overview

3.1 Hardware architecture

3.2 Software architecture

3.3 Network design

3.4 Technical specification

3.5 KeControl - CPU modules

3.5.1 Extension modules

3.6 KeDrive - Drive technique

3.7 KeConnect - Bus link module

3.8 KeConnect peripheral devices

3.9 Buses

3.9.1 EtherCAT

3.9.2 sercos III

3.9.3 Profinet

3.9.4 EtherNet/IP

3.9.5 CAN

3.9.6 Ethernet

3.9.7 Modbus TCP/IP

3.10 KeView - Visualization components

3.10.1 Stationary operating devices

3.10.2 Mobile operating devices

3.10.3 Visualization system KeMotion3TeachView

3.10.4 Visualization systems

3.11 KeStudio tool suite

3.11.1 KeStudio

3.11.2 ViewEdit

3.11.3 DriveManager

3.11.4 CppEdit

3.11.5 KeStudio UosDiagnostic

3.11.6 KeStudio Scope

3.11.7 Robot programming with KAIROEdit

3.12 Libraries and interfaces

3.12.1 IEC standard libraries

3.12.2 KeStudio libraries

3.12.3 OPC UA interface

3.13 Robot macros instruction set

4 Assembly and removal

4.1 Space requirement

4.2 Air conditioning, ventilation

4.3 Use of air filters

5 Connections and wiring

5.1 Interfaces

5.1.1 CAN

5.1.2 RS-232-C

5.1.3 RS-485/422

5.1.4 Ethernet, Gigabit-Ethernet, EtherCAT, PROFINET

5.1.5 Graphic interface

5.1.6 USB

5.2 Inputs/outputs

5.2.1 Front panel connectors

5.2.2 Power supply

5.2.3 Digital inputs

5.2.4 Digital outputs

5.2.5 Analog input (current or voltage input)

5.2.6 Analog output (current or voltage output)

5.2.7 Transducer power supply and reference voltage

5.2.8 Input for thermo couples

5.2.9 Incremental encoder input

5.2.10 PWM output

5.3 Connecting the bus link module

5.4 Connecting the stationary operating panel

5.5 Connecting the Handterminal

5.6 Connecting axis modules

5.7 Test of interference immunity

6 Displays and operating elements

6.1 Button and display, general information

7 Operating behavior

7.1 Start-up

7.1.1 Display during start-up

8 Software installation

8.1 Install firmware of the control

8.2 Install simulation on the PC

9 Configuration

9.1 Data exchange between control and visualization

9.2 Device configuration via static operating device

9.2.1 Diagnosis Data

9.2.2 Display

9.2.3 Licenses

9.2.4 Network

9.2.5 Reboot

9.2.6 Version info

10 Device Administration (DevAdmin)

10.1 Tab "Diagnostics"

10.2 Tab "Configuration"

10.3 Tab "Backup/Restore"

10.4 Change password for DevAdmin

11 Program development

11.1 Task priorities

11.2 Fast control

11.3 Sample projects

12 Diagnosis

12.1 Control diagnosis

12.1.1 Error codes

12.2 Drive diagnosis

12.3 Diagnosis data for KEBA

12.3.1 Status report

12.3.2 Crashreport

12.3.3 Access to flash storage medium

13 Maintenance

13.1 Executing a firmware update of the system components

13.1.1 Firmware update for control and handheld terminal

13.1.2 Firmware update for KeTop T70

13.1.3 Manual update via boot-up visualization

13.1.4 Automatic update during boot-up

13.1.5 Diagnostic information for the firmware update

14 Disposal

14.1 Disposal of the module

14.2 Disposal of the battery

15 Technical data

15.1 Ambient conditions

16 EC directives and standards

17 Appendix: EMC-resistant wiring

17.1 Basic structure of EMC measures

17.2 Which EMC measures must be taken?

17.3 Checklist of EMC measures

18 Appendix: Tutorial - creating an IEC project

18.1 Creating a new project

18.2 Creating a simple program

18.3 Saving KeStudio U4 project

18.4 Configuration of the control

18.5 Compiling project and uploading onto control

18.6 Starting the project

19 Appendix: Tutorial - creating a visualization

19.1 Selecting variables for visualization

19.2 Adding the visualization to the control configuration

19.3 Creating a new visualization project

19.4 Edit mask

19.5 Generating code for the visualization project

19.6 Load visualization onto the control

19.7 Restart of the control

20 Appendix: Connection examples

20.1 D3-DU 3xx/x with connected axis group

20.2 D3-DU 3xx/x with directly added D3-DP 3xx/x with

power unit and separate D3-DP 3xx/x without power

unit

20.3 D3-DU 3xx/x with directly added D3-DP 3xx/x with power

unit and separate D3-DP 3xx/x with power unit

20.4 D3-DU 3xx/x connected bus coupler module

21 Appendix: Asynchronous motors requirements

22 Appendix: Addressing in the Ethernet (basics)

23 Appendix: Tutorial - Start-up of a KeDrive D3 drive (EtherCAT)

23.1 Preconditions

23.1.1 Hardware components for EtherCAT

23.1.2 Software components

23.2 Wiring

23.3 Configuration with KeStudio

23.3.1 Create project

23.3.2 Drive configuration on the control

23.3.3 Configuration of the control

23.3.4 Compiling project and uploading onto control

23.4 Drive configuration

23.5 Drive diagnosis

23.5.1 Ethernet over EtherCAT (EoE)

24 Appendix: Tutorial - fast control

24.1 Preconditions and needed components

24.2 Task

24.3 Wiring

24.4 Creating example application

25 Appendix: Tutorial - call C function from IEC

25.1 Preconditions and needed components

25.2 Task

25.3 Creation of IEC function

25.4 Creating the C function and download

25.5 Calling the IEC funtion in the IEC application and download

26 Appendix: Terminology

Index

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc