PLCopen

for efficiency in automation

Technical Specification

PLCopen - Technical Committee 2 – Task Force

Function blocks for motion control

(Formerly Part 1 and Part 2)

Version 2.0, Published

DISCLAIMER OF WARANTIES

THIS DOCUMENT IS PROVIDED ON AN “AS IS” BASIS AND MAY BE SUBJECT TO FUTURE ADDITIONS,

MODIFICATIONS, OR CORRECTIONS. PLCOPEN HEREBY DISCLAIMS ALL WARRANTIES OR

CONDITIONS OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, ANY

WARRANTIES, OR CONDITIONS OF TITLE, NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE, FOR THIS DOCUMENT. IN NO EVENT WILL PLCOPEN BE RESPONSIBLE FOR

ANY LOSS OR DAMAGE ARISING OUT OR RESULTING FROM ANY DEFECT, ERROR OR OMISSION IN

THIS DOCUMENT OR FROM ANYONE’S USE OF OR RELIANCE ON THIS DOCUMENT.

Copyright © 2009 – 2011 by PLCopen. All rights reserved.

March 17, 2011.

TC2 Task Force Motion Control

Function Blocks for Motion Control

March 17, 2011

Version 2.0, Published

© 1999 - 2011 copyright by PLCopen

page 1/ 141

�

PLCopen

for efficiency in automation

Function blocks for motion control

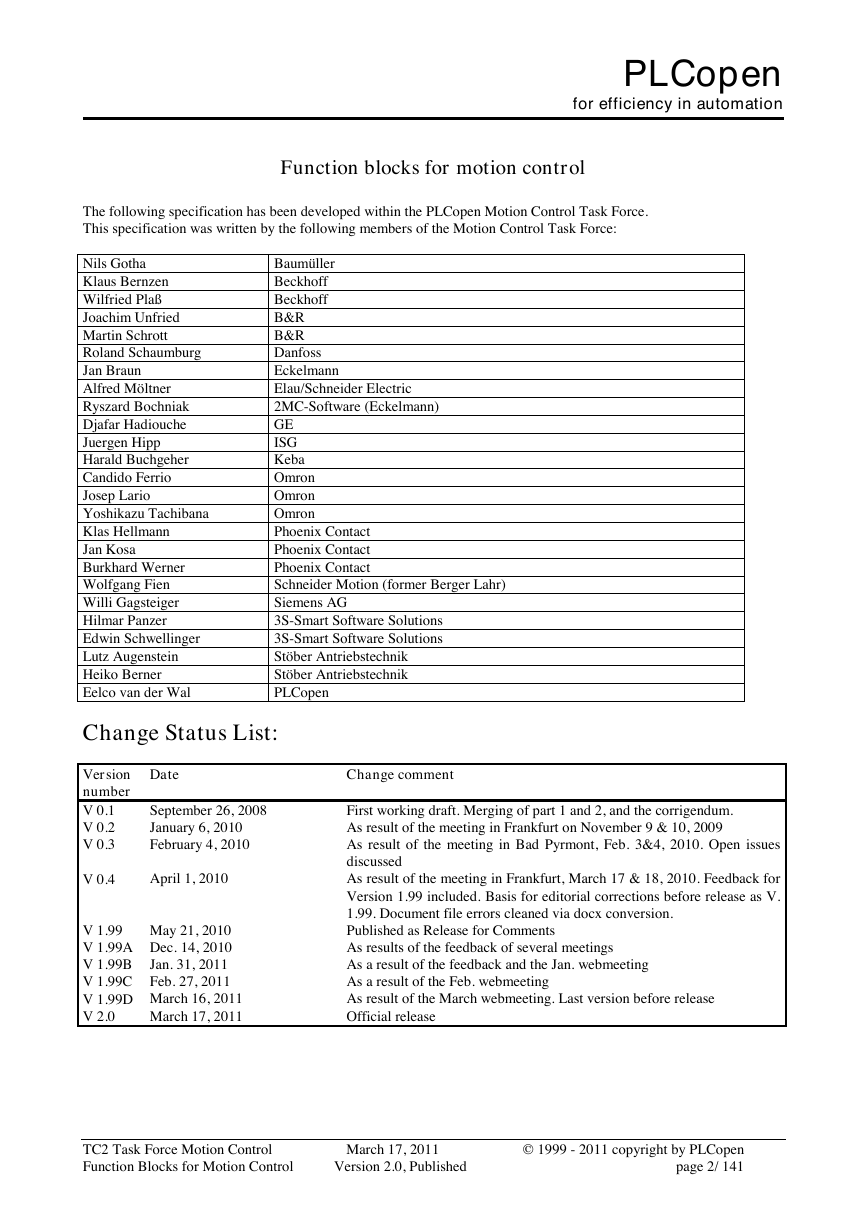

The following specification has been developed within the PLCopen Motion Control Task Force.

This specification was written by the following members of the Motion Control Task Force:

Nils Gotha

Klaus Bernzen

Wilfried Plaß

Joachim Unfried

Martin Schrott

Roland Schaumburg

Jan Braun

Alfred Möltner

Ryszard Bochniak

Djafar Hadiouche

Juergen Hipp

Harald Buchgeher

Candido Ferrio

Josep Lario

Yoshikazu Tachibana

Klas Hellmann

Jan Kosa

Burkhard Werner

Wolfgang Fien

Willi Gagsteiger

Hilmar Panzer

Edwin Schwellinger

Lutz Augenstein

Heiko Berner

Eelco van der Wal

Change Status List:

Baumüller

Beckhoff

Beckhoff

B&R

B&R

Danfoss

Eckelmann

Elau/Schneider Electric

2MC-Software (Eckelmann)

GE

ISG

Keba

Omron

Omron

Omron

Phoenix Contact

Phoenix Contact

Phoenix Contact

Schneider Motion (former Berger Lahr)

Siemens AG

3S-Smart Software Solutions

3S-Smart Software Solutions

Stöber Antriebstechnik

Stöber Antriebstechnik

PLCopen

Date

Change comment

First working draft. Merging of part 1 and 2, and the corrigendum.

As result of the meeting in Frankfurt on November 9 & 10, 2009

As result of the meeting in Bad Pyrmont, Feb. 3&4, 2010. Open issues

discussed

As result of the meeting in Frankfurt, March 17 & 18, 2010. Feedback for

Version 1.99 included. Basis for editorial corrections before release as V.

1.99. Document file errors cleaned via docx conversion.

Published as Release for Comments

As results of the feedback of several meetings

As a result of the feedback and the Jan. webmeeting

As a result of the Feb. webmeeting

As result of the March webmeeting. Last version before release

Official release

Version

number

V 0.1

V 0.2

V 0.3

September 26, 2008

January 6, 2010

February 4, 2010

V 0.4

April 1, 2010

V 1.99

May 21, 2010

V 1.99A Dec. 14, 2010

V 1.99B Jan. 31, 2011

V 1.99C Feb. 27, 2011

V 1.99D March 16, 2011

V 2.0

March 17, 2011

TC2 Task Force Motion Control

Function Blocks for Motion Control

March 17, 2011

Version 2.0, Published

© 1999 - 2011 copyright by PLCopen

page 2/ 141

�

PLCopen

for efficiency in automation

Table of Contents

2.3.

2.4.

2.2.1.

2.2.2.

2.2.3.

2.4.1.

2.4.2.

2.4.3.

2.4.4.

2.4.5.

2.4.6.

1.1.1.

1.1.2.

1.1.3.

1.1.4.

1.1.5.

1.1.6.

1. GENERAL.................................................................................................................................................................8

OBJECTIVES.............................................................................................................................................................9

1.1.

Language context goals ..................................................................................................................................9

Definition of a set of Function Blocks.............................................................................................................9

Overview of the defined Function Blocks .....................................................................................................10

Compliance and Portability..........................................................................................................................10

Length of names and ways to shorten them ..................................................................................................11

History ..........................................................................................................................................................11

2. MODEL...................................................................................................................................................................13

THE STATE DIAGRAM ............................................................................................................................................13

2.1.

ERROR HANDLING..................................................................................................................................................16

2.2.

Centralized versus Decentralized .................................................................................................................16

Buffered Commands......................................................................................................................................17

Timing example for the ‘Enable’ input .........................................................................................................17

DEFINITIONS ..........................................................................................................................................................19

FB INTERFACE .......................................................................................................................................................19

General rules ................................................................................................................................................19

Aborting versus Buffered modes ...................................................................................................................22

AXIS_REF Data type ....................................................................................................................................24

Technical Units.............................................................................................................................................24

Why the command input is edge sensitive.....................................................................................................25

The input ‘ContinuousUpdate’ .....................................................................................................................25

EXAMPLE 1: THE SAME FUNCTION BLOCK INSTANCE CONTROLS DIFFERENT MOTIONS OF AN AXIS ........................26

EXAMPLE 2: DIFFERENT FUNCTION BLOCK INSTANCES CONTROL THE MOTIONS OF AN AXIS..................................27

SINGLE-AXIS FUNCTION BLOCKS.................................................................................................................29

MC_POWER .....................................................................................................................................................29

MC_HOME.......................................................................................................................................................30

MC_STOP.........................................................................................................................................................31

MC_HALT ........................................................................................................................................................33

MC_MOVEABSOLUTE......................................................................................................................................35

MC_MOVERELATIVE .......................................................................................................................................37

MC_MOVEADDITIVE .......................................................................................................................................39

MC_MOVESUPERIMPOSED...............................................................................................................................41

MC_HALTSUPERIMPOSED................................................................................................................................44

MC_MOVEVELOCITY.......................................................................................................................................45

MC_MOVECONTINUOUSABSOLUTE.................................................................................................................47

MC_MOVECONTINUOUSRELATIVE ..................................................................................................................50

MC_TORQUECONTROL ....................................................................................................................................53

MC_POSITIONPROFILE .....................................................................................................................................56

MC_VELOCITYPROFILE....................................................................................................................................58

MC_ACCELERATIONPROFILE ...........................................................................................................................60

MC_SETPOSITION ............................................................................................................................................63

MC_SETOVERRIDE ..........................................................................................................................................64

MC_READPARAMETER & MC_READBOOLPARAMETER..................................................................................66

MC_WRITEPARAMETER & MC_WRITEBOOLPARAMETER ..............................................................................68

MC_READDIGITALINPUT .................................................................................................................................70

MC_READDIGITALOUTPUT..............................................................................................................................71

MC_WRITEDIGITALOUTPUT ............................................................................................................................72

MC_READACTUALPOSITION............................................................................................................................73

MC_READACTUALVELOCITY ..........................................................................................................................74

MC_READACTUALTORQUE .............................................................................................................................75

MC_READSTATUS............................................................................................................................................76

MC_READMOTIONSTATE ................................................................................................................................77

2.5.

2.6.

3.

3.1.

3.2.

3.3.

3.4.

3.5.

3.6.

3.7.

3.8.

3.9.

3.10.

3.11.

3.12.

3.13.

3.14.

3.15.

3.16.

3.17.

3.18.

3.19.

3.20.

3.21.

3.22.

3.23.

3.24.

3.25.

3.26.

3.27.

3.28.

TC2 Task Force Motion Control

Function Blocks for Motion Control

March 17, 2011

Version 2.0, Published

© 1999 - 2011 copyright by PLCopen

page 3/ 141

�

PLCopen

for efficiency in automation

MC_READAXISINFO ........................................................................................................................................78

3.29.

MC_READAXISERROR.....................................................................................................................................79

3.30.

MC_RESET.......................................................................................................................................................80

3.31.

MC_DIGITALCAMSWITCH................................................................................................................................81

3.32.

MC_TOUCHPROBE...........................................................................................................................................85

3.33.

3.34.

MC_ABORTTRIGGER........................................................................................................................................87

4. MULTI-AXIS FUNCTION BLOCKS ..................................................................................................................88

REMARKS TO CAMMING ...................................................................................................................................88

4.1.

MC_CAMTABLESELECT...................................................................................................................................90

4.2.

MC_CAMIN......................................................................................................................................................91

4.3.

4.4.

MC_CAMOUT ..................................................................................................................................................93

MC_GEARIN ....................................................................................................................................................94

4.5.

MC_GEAROUT.................................................................................................................................................96

4.6.

MC_GEARINPOS..............................................................................................................................................97

4.7.

4.8.

MC_PHASINGABSOLUTE................................................................................................................................101

MC_PHASINGRELATIVE .................................................................................................................................104

4.9.

4.10.

MC_COMBINEAXES.......................................................................................................................................105

5. APPLICATION OF MC FB – A DRILLING EXAMPLE WITH ‘ABORTING’ VERSUS ‘BLENDING’.109

5.1.

SOLUTION WITH FUNCTION BLOCK DIAGRAM .................................................................................................110

5.2.

SOLUTION WITH SEQUENTIAL FUNCTION CHART ............................................................................................110

APPENDIX A. EXAMPLES OF THE DIFFERENT BUFFER MODES............................................................111

APPENDIX B. COMPLIANCE PROCEDURE AND COMPLIANCE LIST.....................................................118

STATEMENT OF SUPPLIER ....................................................................................................................119

APPENDIX B 1.

APPENDIX B 2.

SUPPORTED DATA TYPES.....................................................................................................................120

APPENDIX B 3. OVERVIEW OF THE FUNCTION BLOCKS................................................................................................121

APPENDIX B 4. THE PLCOPEN MOTION CONTROL LOGO AND ITS USAGE ...................................................................141

TC2 Task Force Motion Control

Function Blocks for Motion Control

March 17, 2011

Version 2.0, Published

© 1999 - 2011 copyright by PLCopen

page 4/ 141

�

PLCopen

for efficiency in automation

Table of Figures

FIGURE 1: THE TRIANGLE WITH USER OPTIONS ..............................................................................................8

FIGURE 2: FB STATE DIAGRAM..............................................................................................................................15

FIGURE 3: FUNCTION BLOCKS WITH CENTRALIZED ERROR HANDLING...............................................16

FIGURE 4: FUNCTION BLOCKS WITH DECENTRALIZED ERROR HANDLING .........................................16

FIGURE 5: EXAMPLE OF ERROR HANDLING WITH ‘ENABLE’ INPUT........................................................17

FIGURE 6: SECOND EXAMPLE OF AN ERROR BEHAVIOR WITH AN ‘ENABLE’ INPUT.........................18

FIGURE 7: THE BEHAVIOR OF THE ‘EXECUTE’ / ‘DONE’ IN RELEVANT FBS ..........................................21

FIGURE 8: THE BEHAVIOR OF THE ‘EXECUTE’ / ‘INXXX’ IN RELEVANT FBS.........................................22

FIGURE 9: FUNCTION BLOCKS TO PERFORM A COMPLEX MOVEMENT ................................................25

FIGURE 10: SINGLE FB USAGE WITH A SFC .......................................................................................................26

FIGURE 11: TIMING DIAGRAM FOR A USAGE OF A SINGLE FB...................................................................27

FIGURE 12: EXAMPLE OF CASCADED FUNCTION BLOCKS ..........................................................................27

FIGURE 13: TIMING DIAGRAM OF EXAMPLE CASCADED FUNCTION BLOCKS .....................................28

FIGURE 14: EXAMPLE OF CASCADED FUNCTION BLOCKS WITH LD........................................................28

FIGURE 15: MC_STOP TIMING DIAGRAM ...........................................................................................................31

FIGURE 16: BEHAVIOR OF MC_STOP IN COMBINATION WITH MC_MOVEVELOCITY........................32

FIGURE 17: EXAMPLE OF MC_HALT ....................................................................................................................34

FIGURE 18: TIMING DIAGRAM FOR MC_MOVEABSOLUTE ..........................................................................36

FIGURE 19: TIMING DIAGRAM FOR MC_MOVERELATIVE ...........................................................................38

FIGURE 20: TIMING DIAGRAM FOR MC_MOVEADDITIVE............................................................................40

FIGURE 21: TIMING DIAGRAM FOR MC_MOVESUPERIMPOSED ................................................................42

FIGURE 22: EXAMPLE OF THE EFFECT OF MC_MOVESUPERIMPOSED ON A SLAVE AXIS................43

FIGURE 23: EXAMPLE OF THE EFFECT OF MC_MOVESUPERIMPOSED ON MC_MOVEABSOLUTE.43

FIGURE 24: MC_MOVEVELOCITY TIMING DIAGRAM ....................................................................................46

FIGURE 25: EXAMPLE MC_MOVECONTINUOUSABSOLUTE .........................................................................49

FIGURE 26: MC_MOVECONTINUOUSABSOLUTE TIMING DIAGRAM FOR EXAMPLE ABOVE ...........49

FIGURE 27: MC_MOVECONTINUOUSRELATIVE TIMING DIAGRAM WITH POSITIVE DIRECTION..51

TC2 Task Force Motion Control

Function Blocks for Motion Control

March 17, 2011

Version 2.0, Published

© 1999 - 2011 copyright by PLCopen

page 5/ 141

�

PLCopen

for efficiency in automation

FIGURE 28: MC_MOVECONTINUOUSRELATIVE TIMING DIAGRAM WITH NEGATIVE DIRECTION51

FIGURE 29: EXAMPLE OF MC_MOVECONTINUOUSRELATIVE....................................................................52

FIGURE 30: FIRST EXAMPLE OF MC_TORQUECONTROL..............................................................................54

FIGURE 31: PROGRAM OF EXAMPLE OF MC_TORQUECONTROL..............................................................55

FIGURE 32: SECOND EXAMPLE OF MC_TORQUECONTROL.........................................................................55

FIGURE 33: EXAMPLE OF TIME / MC_POSITIONPROFILE.............................................................................57

FIGURE 34: MC_ACCELERATIONPROFILE, 10 SEGMENTS ONLY ...............................................................61

FIGURE 35: RESULTING MC_POSITIONPROFILE..............................................................................................62

FIGURE 36: GRAPHICAL EXPLANATION OF MC_SETOVERRIDE ................................................................65

FIGURE 37: EXAMPLE OF MC_DIGITALCAMSWITCH.....................................................................................83

FIGURE 38: DETAILED DESCRIPTION OF SWITCH01.......................................................................................83

FIGURE 39: EXAMPLE IN NEGATIVE DIRECTION ............................................................................................84

FIGURE 40: TIMING EXAMPLE MC_TOUCHPROBE .........................................................................................86

FIGURE 41: EXAMPLES OF WINDOWS, WHERE TRIGGER EVENTS ARE ACCEPTED (FOR MODULO

AXES) ......................................................................................................................................................................86

FIGURE 42: CAM PROFILE ILLUSTRATION........................................................................................................88

FIGURE 43: GEAR TIMING DIAGRAM...................................................................................................................95

FIGURE 44: TIMING DIAGRAM OF MC_GEARINPOS .......................................................................................99

FIGURE 45: EXAMPLE OF THE DIFFERENCE BETWEEN ‘SYNCMODES’ ‘SLOWDOWN’ (GREEN) AND

‘CATCHUP’ (RED) WITH DIFFERENT INITIAL VELOCITIES OF THE SLAVE....................................99

FIGURE 46: EXAMPLE OF MC_GEARINPOS WHERE THE INITIAL VELOCITY OF THE SLAVE IS IN

THE SAME DIRECTION OF THE MASTER..................................................................................................100

FIGURE 47: EXAMPLE OF MC_GEARINPOS WHERE THE INITIAL VELOCITY OF THE SLAVE IS IN

THE INVERSE DIRECTION OF THE MASTER............................................................................................100

FIGURE 48: TIMING EXAMPLE OF MC_PHASING – BOTH FOR ABSOLUTE AND RELATIVE ............102

FIGURE 49: EXAMPLE OF MC_PHASING – BOTH FOR ABSOLUTE AND RELATIVE.............................103

FIGURE 50: APPLICATION EXAMPLE OF MC_COMBINEAXES...................................................................107

FIGURE 51: THE CORRESPONDING TIMING DIAGRAM FOR MC_COMBINEAXES EXAMPLE..........108

FIGURE 52: EXAMPLE OF A SIMPLE DRILLING UNIT ...................................................................................109

FIGURE 53: TIMING DIAGRAMS FOR DRILLING. LEFT SIDE NO BLENDING, RIGHT SIDE WITH

BLENDING...........................................................................................................................................................109

FIGURE 54: SOLUTION WITH FUNCTION BLOCK DIAGRAM ......................................................................110

TC2 Task Force Motion Control

Function Blocks for Motion Control

© 1999 - 2011 copyright by PLCopen

page 6/ 141

March 17, 2011

Version 2.0, Published

�

PLCopen

for efficiency in automation

FIGURE 55: STRAIGHT FORWARD STEP-TRANSITION CHAIN FOR DRILLING EXAMPLE IN SFC ..110

FIGURE 56: BASIC EXAMPLE WITH TWO MC_MOVEABSOLUTE ON SAME AXIS ................................111

FIGURE 57: TIMING DIAGRAM FOR EXAMPLE ABOVE WITHOUT INTERFERENCE BETWEEN FB1

AND FB2 (‘ABORTING’ MODE) ......................................................................................................................111

FIGURE 58: TIMING DIAGRAM FOR EXAMPLE ABOVE WITH FB2 INTERRUPTING FB1 (‘ABORTING’

MODE) ..................................................................................................................................................................112

FIGURE 59: TIMING DIAGRAM FOR EXAMPLE ABOVE IN ‘BUFFERED’ MODE ....................................113

FIGURE 60: TIMING DIAGRAM FOR EXAMPLE ABOVE WITH MODE ‘BLENDINGLOW’....................114

FIGURE 61: TIMING DIAGRAM FOR EXAMPLE ABOVE WITH MODE ‘MERGING1’.............................115

FIGURE 62: TIMING DIAGRAM FOR EXAMPLE ABOVE WITH MODE ‘BLENDINGNEXT’ MOTION.116

FIGURE 63: TIMING DIAGRAM FOR EXAMPLE ABOVE WITH MODE ‘BLENDINGHIGH’ MOTION.117

FIGURE 64: THE PLCOPEN MOTION CONTROL LOGO .................................................................................141

Table of Tables

TABLE 1: OVERVIEW OF THE DEFINED FUNCTION BLOCKS.......................................................................10

TABLE 2: GENERAL RULES......................................................................................................................................21

TABLE 3: THE ENUM TYPE MC_BUFFER_MODE ..............................................................................................23

TABLE 4: OVERVIEW OF THE BUFFERED COMMANDS ON THE RELEVANT FBS..................................23

TABLE 5: PARAMETERS FOR MC_READPARAMETER AND MC_WRITEPARAMETER .........................67

TABLE 6: SUPPORTED DATATYPES ....................................................................................................................120

TABLE 7: SUPPORTED DERIVED DATATYPES .................................................................................................120

TABLE 8: SHORT OVERVIEW OF THE FUNCTION BLOCKS.........................................................................121

TABLE 9: PARAMETERS FOR MC_READ(BOOL)PARAMETER AND MC_WRITE(BOOL)PARAMETER130

TC2 Task Force Motion Control

Function Blocks for Motion Control

March 17, 2011

Version 2.0, Published

© 1999 - 2011 copyright by PLCopen

page 7/ 141

�

PLCopen

for efficiency in automation

General

1.

The motion control market displays a wide variety of incompatible systems and solutions. In businesses where different

systems are used, this incompatibility induces considerable costs for the end-users, learning is confusing, engineering

becomes difficult, and the process of market growth slows down.

Standardization would certainly reduce these negative factors. Standardization means not only the programming lan-

guages themselves, (as standardization is achieved using the worldwide IEC 61131-3 standard) but also standardizing

the interface towards different motion control solutions. In this way the programming of these motion control solutions

is less hardware dependent. The reusability of the application software is increased, and the costs involved in training

and support are reduced.

Users have requested that PLCopen helps to solve this problem, which initiated the Motion Control Task Force. This

Task Force has defined the programmer’s interface by standardizing the Function Blocks for Motion Control.

Figure 1: The triangle with user options

For the positioning of this activity, please check figure 1. This triangle has the following user options at its corners:

Performance

Functionality

Standardization.

In practice, users write their programs very closely coupled to the hardware with dedicated functions, in order to get the

highest performance possible as dictated by their environment. This limits the user in his options with respect to the

target hardware and the reusability of the control software and raises the training investment.

The second user option enables a very broad range of software functionality to be offered. This can be very helpful to

the user, but will seldom lead to high performance. Also the training costs are increased.

The third corner, standardization, is primarily focused on reusability across different systems from different suppliers,

including integrated, distributed and networked systems, as well as reduction in training investments. Due to the general

character of this definition, the performance on different architectures can be less optimal than hard coding. Due to this,

standardization should not be expected to offer maximum performance but can closely approach maximum functional-

ity, meaning that the bottom of the triangle is very short.

The first specification was released as an independent library of function blocks for motion control. It included motion

functionality for single axes and multiple axes, several administrative tasks, as well as a state diagram. This specifica-

tion provides the user with a standard command set and structure independent of the underlying architecture.

This structure can be used on many platforms and architectures. In this way one can decide which architecture will be

used at a later stage of the development cycle. Advantages for the machine builder are, amongst others, lower costs for

supporting the different platforms and the freedom to develop application software in a more independent way, without

limiting the productivity of the machine. In addition to those benefits, system maintenance is easier and the education

period is shorter. This is a major step forward, and is more and more accepted by users as well as suppliers.

With the release of part 1, it was understood that additional functionality was needed. Part 1 provides the basis for a set

TC2 Task Force Motion Control

Function Blocks for Motion Control

March 17, 2011

Version 2.0, Published

© 1999 - 2011 copyright by PLCopen

page 8/ 141

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc