3DTouch Auto Leveling Sensor

User Manual

1. Introduction

3DTouch is an auto leveling sensor for 3D Printers that can precisely measure the tilt

of your print surface. It can greatly improve the printing precision of your 3D Printer.

3DTouch features simple, smart and precise. It could work with nearly any kind of

bed materials, such as glasses, woods, metals and so on.

The main functions and controls of 3DTouch are the same as most auto bed leveling

sensors, which consists of a RC servo and a micro switch, thus, 3DTouch can be used

on almost every 3D printer control board.

By using progressively designed solenoid and hall sensor, 3DTouch can integrate high

precision in such a simple structure. To make it more user-friendly and to bring you

more enjoyable printing experience we add many smart functions such as self-test,

false alarm, alarm release and test mode for M119.

Features:

1 Simple

3DTouch can be easily applied, since it has a small and simple structure. Gathering

information & firmware setting will be an easy task, because 3DTouch works as usual

auto bed leveling sensor.

�

SHENZHEN GETECH TECHNOLOGY CO,.LTD

2 Smart

Self-test: The push pin is operated two times to test when the power is on

Alarm: The LED light blinks if a problem found on a self-test or on an operation

3 High-precision

3DTouch’s Standard Deviation in repeatability is around 0.005mm, at that precise.

If you choose 3DTouch, your 3D printer will be high-class masterpiece, giving you an

enjoyable experience.

4. Innovative Solenoid: Ultra Power Saving

On idle state, while the push-pin is whether pulled out or retracted, there are not any

electric current flowing on solenoid, and standby electric current in the whole device

is below 15mA on average, whereas on working state, while the pin is moving in

sudden about 100ms, under 300mA flows in the device.

Low power consumption even further drops joule heating, preventing from heat

problem.

5 Technologies

3DTouch consists of Atmel ATtiny13A, solenoid, and a push pin.

6 wide Selection of Bed

3DTouch does not uses either optical, nor proximity (inductive/capacitive) sensor.

3DTouch is controlled by Hall Effect, providing high precision. Thus the bed material

can be selected freely.

7 Optimized structure: Larger Build Size

3DTouch is a small and technology-intensive one. Build size can be set larger than

other existing auto bed leveling sensor.

3DTouch uses existing RC Servo motor signal intactly, so just plug 3DTouch on the

same pins after removing servo motor.

Specifications:

Voltage: 5V

Current: 15mA

Max. Current: 300mA

Cable length: 150mm

Net Weight: 10g

Shipping weight: 25g

www.geeetech.com

�

SHENZHEN GETECH TECHNOLOGY CO,.LTD

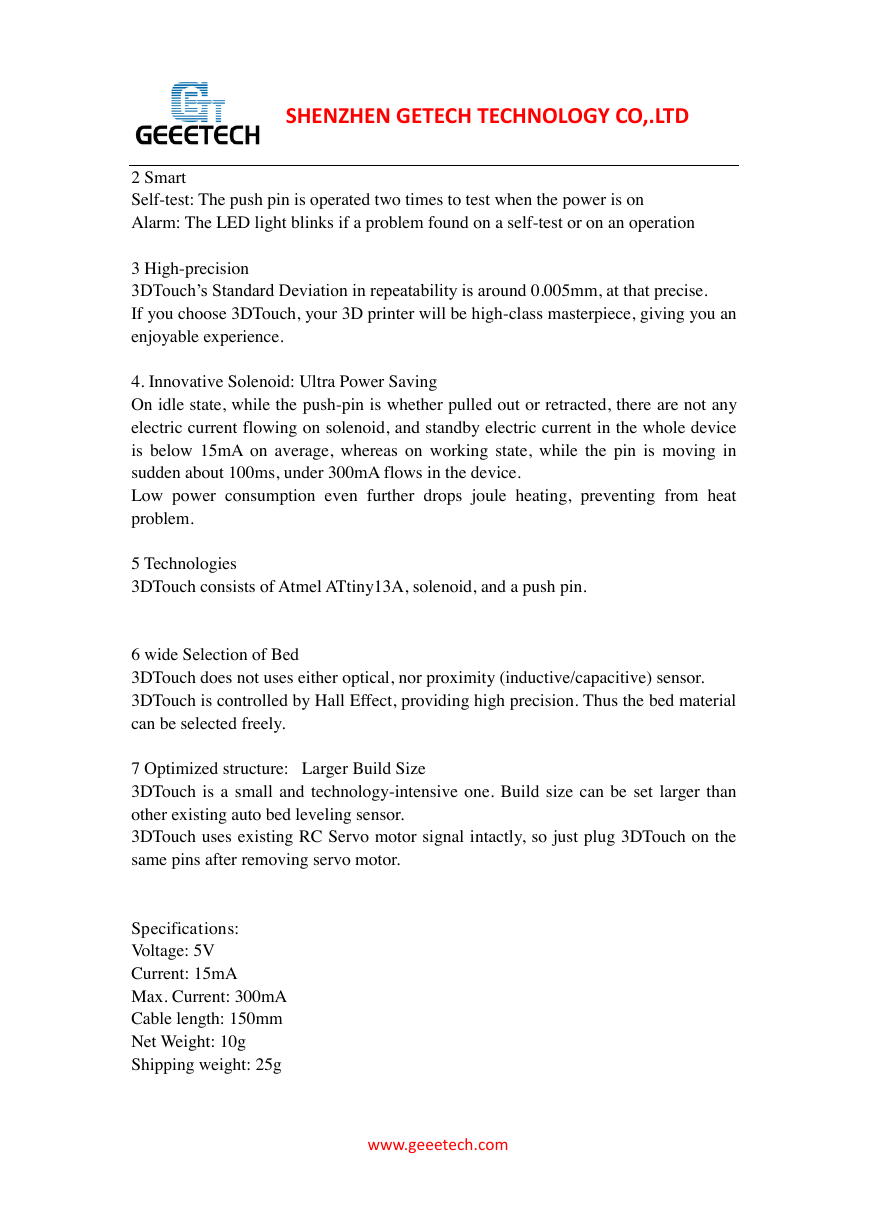

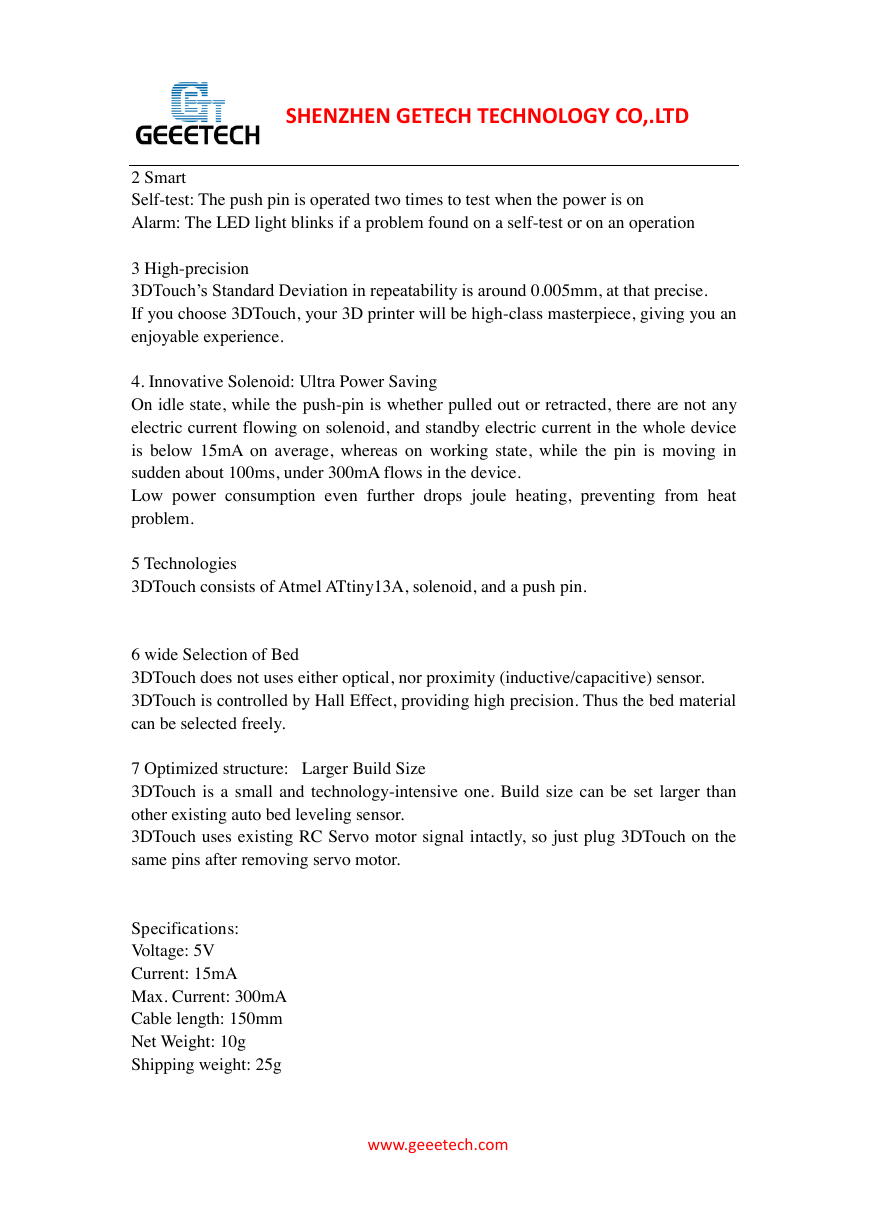

Wiring

3-pin: Brown (-, GND), Red (+5V), Orange (control signal)

2-pin: Black (-, GND), White (Z min)

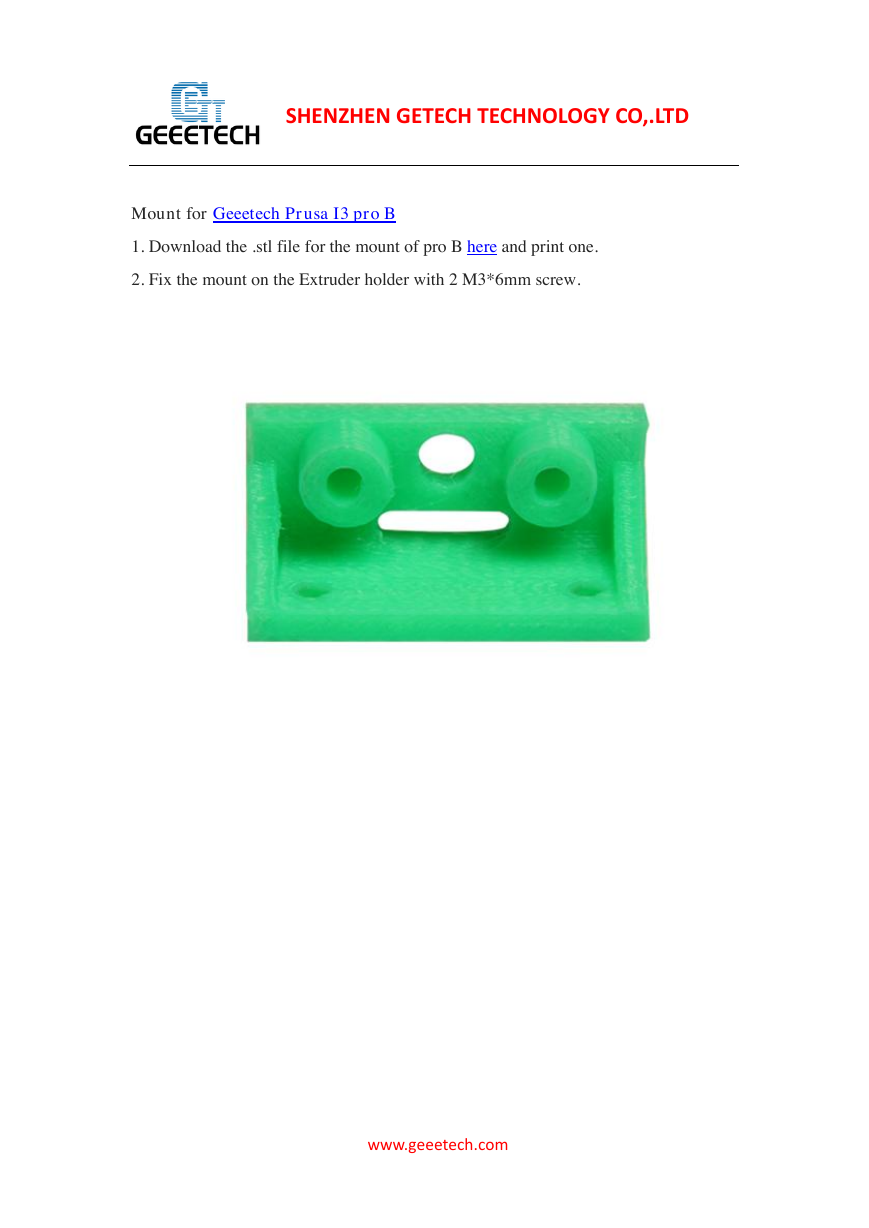

2. How to use it

2.1 mount the 3DTouch sensor

So far we have successfully tested our 3DTouch sensor on Geeetech Prusa I3 pro B,

Pro C and Pro X.

Here is a detailed instructions on how to use the 3DTouch sensor to your geeetech pro

B. For pro C and pro X, the steps are the same.

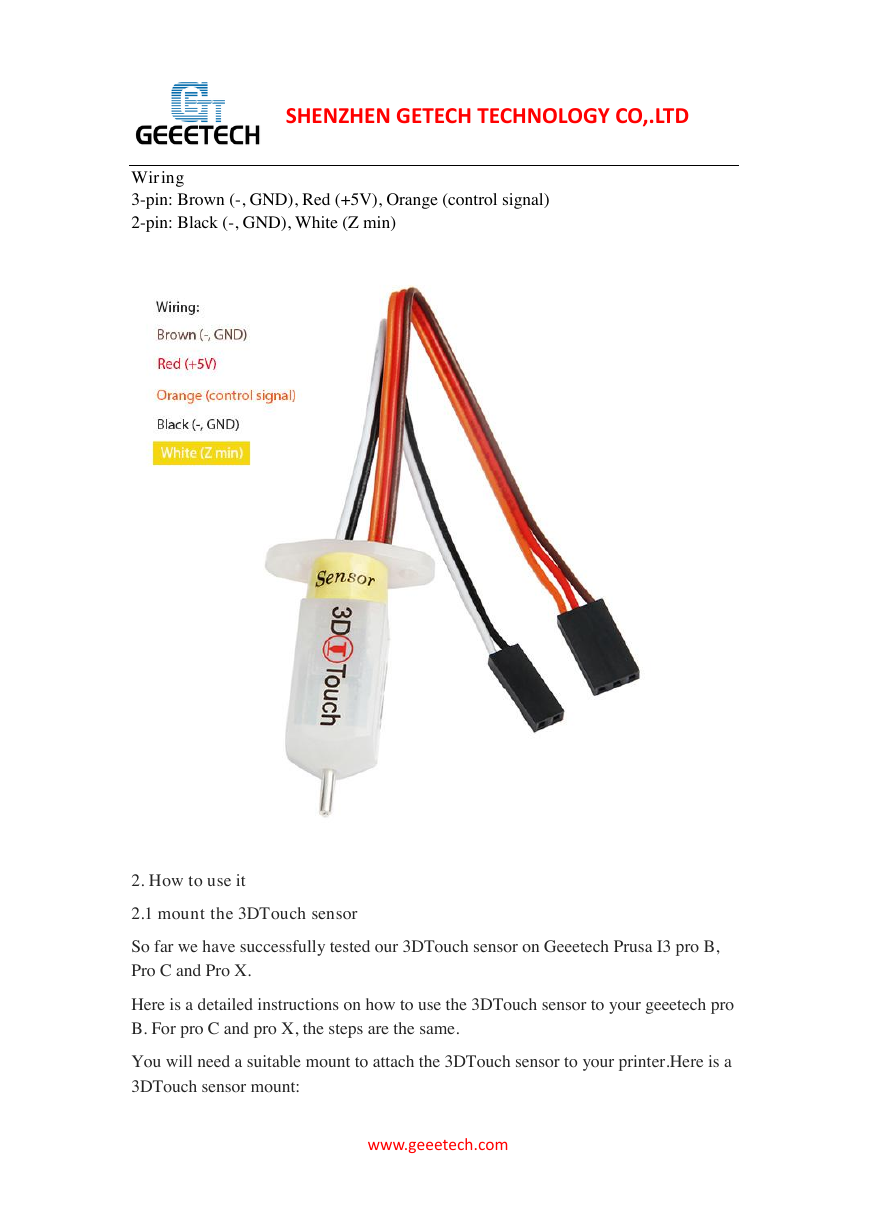

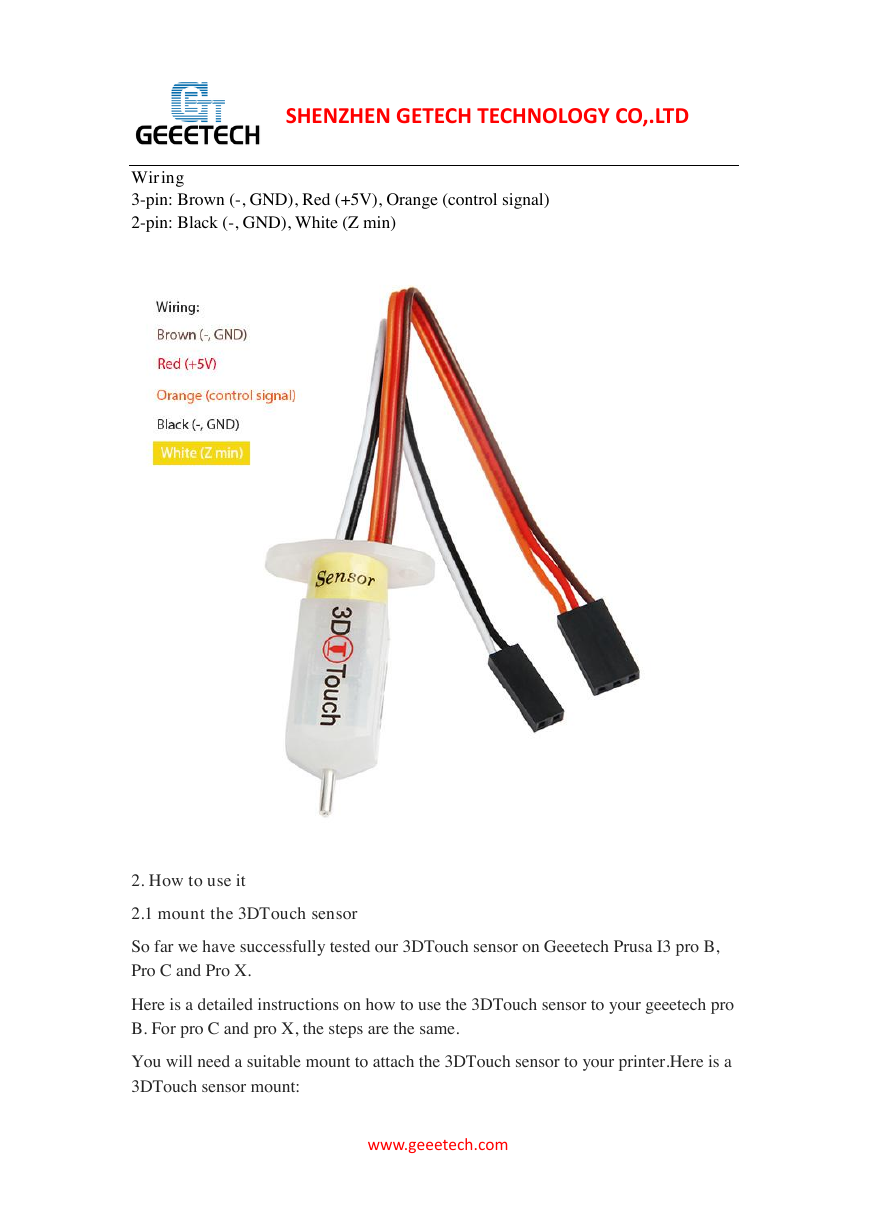

You will need a suitable mount to attach the 3DTouch sensor to your printer.Here is a

3DTouch sensor mount:

www.geeetech.com

�

SHENZHEN GETECH TECHNOLOGY CO,.LTD

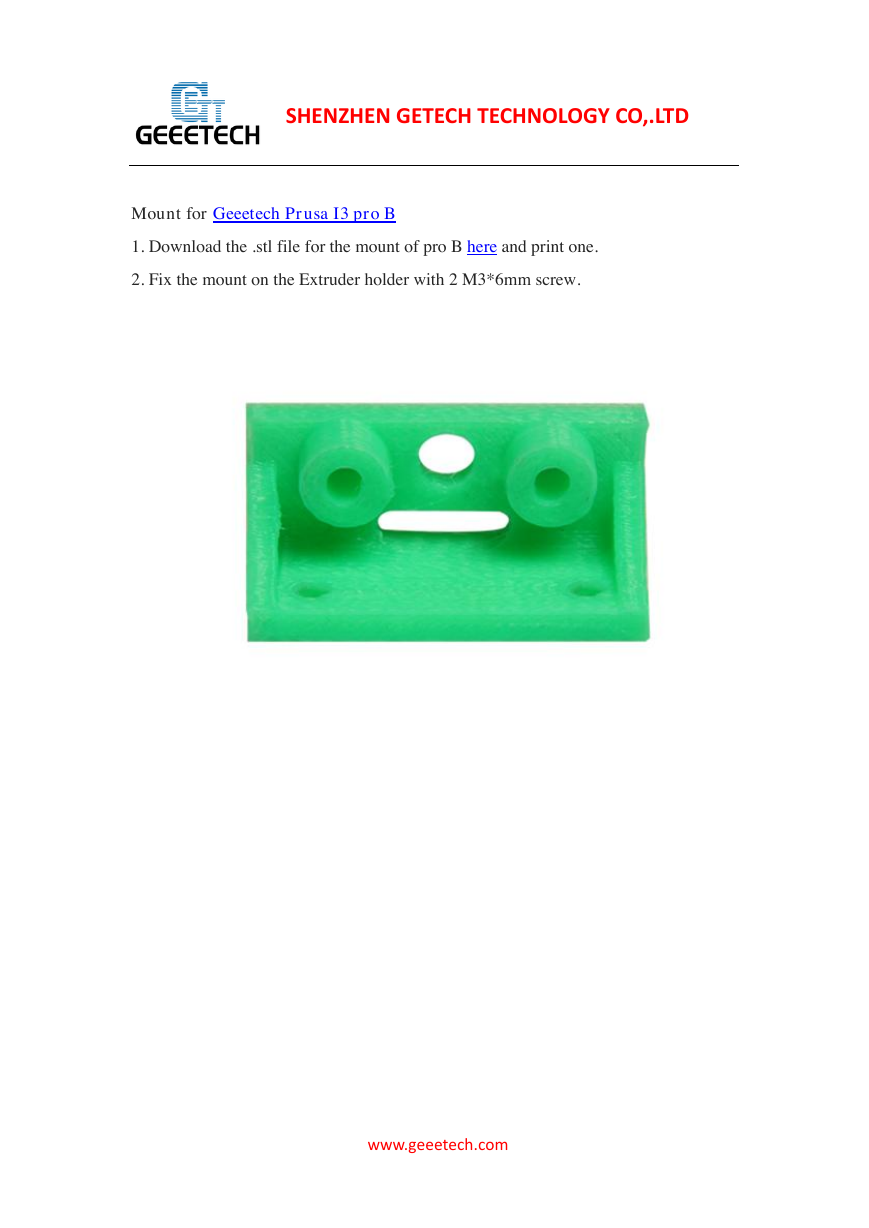

Mount for Geeetech Prusa I3 pro B

1. Download the .stl file for the mount of pro B here and print one.

2. Fix the mount on the Extruder holder with 2 M3*6mm screw.

www.geeetech.com

�

SHENZHEN GETECH TECHNOLOGY CO,.LTD

www.geeetech.com

�

SHENZHEN GETECH TECHNOLOGY CO,.LTD

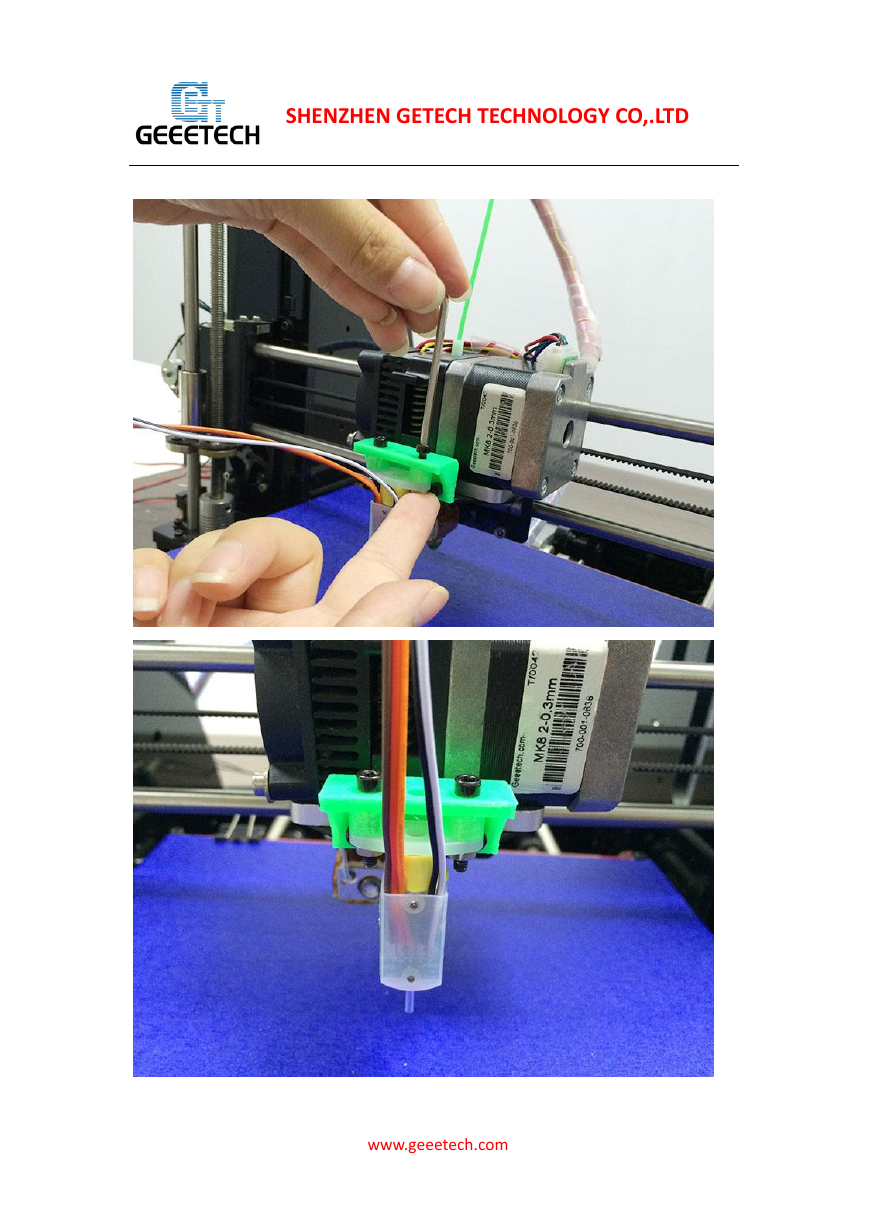

3. Fix the 3DTouch sensor on the sensor mount with 2 M3*16mm screws and 2 M3

nuts.

www.geeetech.com

�

SHENZHEN GETECH TECHNOLOGY CO,.LTD

www.geeetech.com

�

SHENZHEN GETECH TECHNOLOGY CO,.LTD

Mount for Geeetech Prusa I3 pro X

1. Download the .stl file for the mount of pro X here and print one.

2. Fix the mount on the Extruder holder with 2 M3*16mm screw and M3 square nut.

(Square nut are also ok)

www.geeetech.com

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc