400 Commonwealth Drive, Warrendale, PA 15096-0001

SURFACE

VEHICLE

RECOMMENDED

PRACTICE

Submitted for recognition as an American National Standard

J1766

REV.

JUN1998

Issued

Revised

1996-02

1998-06

Superseding J1766 FEB96

(R) RECOMMENDED PRACTICE FOR ELECTRIC AND HYBRID ELECTRIC VEHICLE BATTERY

SYSTEMS CRASH INTEGRITY TESTING

Foreword—This SAE Recommended Practice describes methods for evaluating Electric Vehicle (EV) performance

when subjected to various FMVSS crash test procedures. It addresses battery retention, electrical isolation and

electrolyte spillage. It is intended to provide Electric Vehicle designers with recommended tests and performance

criteria relating to Electric and Hybrid Electric Vehicles. This document is the first of this type for Electric Vehicles

and is based on limited test data. Accordingly, test personnel should exercise extreme caution when conducting

the procedures described in this document. Each testing organization is encouraged, upon experience, to send

comments and suggested revisions to these procedures. Please send comments or suggestions to: Society of

Automotive Engineers, 400 Commonwealth Drive, Warrendale, PA 15096-0001, attention: Electric Vehicle Safety

Committee.

TABLE OF CONTENTS

1.

1.1

1.2

1.3

1.4

2.

2.1

2.1.1

2.1.2

2.2

2.2.1

3.

4.

4.1

4.1.1

4.1.2

4.1.3

4.2

4.3

Scope ....................................................................................................................................................... 2

Purpose .................................................................................................................................................... 2

Field of Application ................................................................................................................................... 2

Product Classification ............................................................................................................................... 2

Form ......................................................................................................................................................... 2

References ............................................................................................................................................... 2

Applicable Publications............................................................................................................................. 2

SAE Publications ...................................................................................................................................... 2

Federal Motor Vehicle Safety Standards .................................................................................................. 2

Related Publications................................................................................................................................. 3

SAE Publications ...................................................................................................................................... 3

Definitions................................................................................................................................................. 3

Technical Requirements........................................................................................................................... 3

Electric and Hybrid Electric Vehicle Testing Battery Preparation ............................................................. 3

Battery Coolant......................................................................................................................................... 3

Battery State-of-Charge ........................................................................................................................... 3

Environmental Preparation ....................................................................................................................... 3

Static Rollover Procedure......................................................................................................................... 3

Crash Test Procedures............................................................................................................................. 3

SAE Technical Standards Board Rules provide that: “This report is published by SAE to advance the state of technical and engineering sciences. The use of this report is entirely

voluntary, and its applicability and suitability for any particular use, including any patent infringement arising therefrom, is the sole responsibility of the user.”

SAE reviews each technical report at least every five years at which time it may be reaffirmed, revised, or cancelled. SAE invites your written comments and suggestions.

QUESTIONS REGARDING THIS DOCUMENT: (724) 772-8512 FAX: (724) 776-0243

TO PLACE A DOCUMENT ORDER; (724) 776-4970 FAX: (724) 776-0790

SAE WEB ADDRESS http://www.sae.org

Copyright 1998 Society of Automotive Engineers, Inc.

All rights reserved.

Printed in U.S.A.

�

SAE J1766 Revised JUN1998

4.4

4.4.1

4.4.1.1

4.4.1.2

4.4.1.3

4.4.2

4.4.3

Performance Criteria................................................................................................................................. 4

Electrolyte Spillage ................................................................................................................................... 4

Spillage Identification................................................................................................................................ 4

Electrolyte Spillage Inside the Occupant Compartment ........................................................................... 4

Electrolyte Spillage Outside the Occupant Compartment......................................................................... 4

Battery Retention ...................................................................................................................................... 4

Electrical Isolation..................................................................................................................................... 4

Appendix A Measurement Of Electrical Isolation ......................................................................................................... 5

1.

Scope—Electric and Hybrid Electric Vehicles contain many types of battery systems. Adequate barriers

between occupants and battery systems are necessary to provide protection from potentially harmful factors

and materials within the battery system that can cause injury to occupants of the vehicle during a crash. This

SAE Recommended Practice is applicable to all Electric Vehicle and Hybrid Electric Vehicle battery designs,

including those described in SAE J1797. The potentially harmful factors and materials addressed by this

document include electrical isolation integrity, electrolyte spillage, and retention of the battery system.

1.1 Purpose—The purpose of this document is to define test methods and performance criteria which evaluate

battery system spillage, battery retention, and electrical system isolation in Electric and Hybrid Electric

Vehicles during specified crash tests.

1.2

Field of Application—The vehicles covered in this document are Electric and Hybrid Electric Vehicles with a

gross vehicle weight of 4536 kg (10 000 lb) or less.

1.3 Product Classification—Not available.

1.4

Form—Not available.

2.

References

2.1 Applicable Publications—The following publications form a part of this specification to the extent specified

herein. The latest issue of Federal Motor Vehicle Safety Standards or SAE publications shall apply.

Applicable FMVSS standards and regulations shall supersede any SAE Recommended Practices referenced

in this document.

2.1.1

SAE PUBLICATIONS—Available from SAE, 400 Commonwealth Drive, Warrendale, PA 15096-0001.

SAE J1715—Electric Vehicle Terminology

SAE J2344—Guidelines for Electric Vehicle Safety

2.1.2

FEDERAL MOTOR VEHICLE SAFETY STANDARDS—Code of Federal Regulations, Title 49, Part 400-499 which

contains the current FMVSS regulations issued under Chapter V - National Highway Traffic Safety

Administration—Available from Superintendent of Documents, Government Printing Office, Washington, DC

20408, Phone: 202-366-3238.

FMVSS Test Procedures

Available from Administration/Technical Reference Division, NHTSA, NAD-52. Phone: 202-366-4946

FMVSS 571.208 Standard No. 208—Occupant Crash Protection

FMVSS 571.214 Standard No. 214—Side Impact Protection

FMVSS 571.301 Standard No. 301—Fuel System Integrity

-2-

�

SAE J1766 Revised JUN1998

2.2 Related Publications—The following publications are provided for information purposes only and are not a

required part of this document.

2.2.1

SAE PUBLICATIONS—Available from SAE, 400 Commonwealth Drive, Warrendale, PA 15096-0001.

SAE TSB 001—SAE Technical Standards Board Rules and Regulations

SAE TSB 002—SAE Preparation of SAE Technical Reports

SAE TSB 003—Rules for the SAE Use of SI (Metric) Units

SAE J1115—Guidelines for Developing and Revising SAE Nomenclature and Definitions

SAE J1772— Electric Vehicle Conductive Coupling

SAE J1773— Electric Vehicle Inductive Coupling

SAE J1797— Packaging of Electric Vehicle Battery Modules

SAE J1798—Electric Vehicle Battery Performance

SAE Report—Format Guidelines for Electronic Capture of SAE Documents

SAE Committee Guidelines Manual

3.

Definitions—The definitions provided in SAE J1715, shall apply to this document. The following definitions,

which are not provided in SAE J1715, also apply:

3.1 Charging System—Means the device(s) and associated equipment necessary to properly recharge the

traction battery in an Electric or Hybrid Electric Vehicle.

3.2 Battery System Components—Means the components comprising a traction battery system in an Electric or

Hybrid Electric Vehicle. These include the battery modules, interconnects, venting systems, battery restraint

devices, and battery box or container that holds the individual battery modules.

4.

Technical Requirements

NOTE—During, before, and after functional Electric Vehicle crash testing, appropriate safety precautions

must be taken to prevent possible injury to test personnel. Proper battery safety hazard training

should be given to test personnel before testing.

4.1 Electric and Hybrid Electric Vehicle Testing Battery Preparation—The battery system in the test vehicle

shall be in an operational configuration.

4.1.1

4.1.2

4.1.3

BATTERY COOLANT—For purposes of 4.4.1, battery coolant is not considered electrolyte. When necessary, a

colorant, chemical analysis, or some other means may be used to distinguish between electrolyte and

coolant spillage.

BATTERY STATE-OF-CHARGE—The battery system shall be fully charged prior to the crash test using the

vehicle manufacturer’s recommended charging procedures.

ENVIRONMENTAL PREPARATION—The environmental conditions shall be those specified in the relevant

FMVSS test procedures.

4.2 Static Rollover Procedure—After each of the crash tests described in 4.3, the vehicle is statically rolled on a

fixture according to the rollover procedure specified in FMVSS 571.301.

4.3 Crash Test Procedures—Electric and Hybrid Electric Vehicles shall meet the performance criteria established

in 4.4 tested to the following crash procedures:

a. FMVSS 208 frontal impact (including the full frontal and 30 degree front angle impacts)

b. FMVSS 214 side impact

c. FMVSS 301 rear impact

-3-

�

SAE J1766 Revised JUN1998

4.4 Performance Criteria

4.4.1

ELECTROLYTE SPILLAGE

4.4.1.1

Spillage Identification—Before and after each of the test procedures in 4.2 and 4.3, the vehicle shall be

inspected for electrolyte spillage. Verification of electrolyte may be determined by visual inspection, litmus

paper testing, and/or chemical analysis of the fluid.

4.4.1.2

Electrolyte Spillage Inside the Occupant Compartment—No spillage of electrolyte is permitted into the

occupant compartment when tested to the procedures specified in 4.2 and 4.3 of this document.

4.4.1.3

4.4.2

4.4.3

Electrolyte Spillage Outside the Occupant Compartment—When tested to any one of the crash tests

specified in 4.3 and the subsequent vehicle rollover procedure specified in 4.2, the total electrolyte spillage

from an Electric Vehicle or Hybrid Electric Vehicle shall not exceed 5.0 L. Total electrolyte spillage is

determined from measurements taken from the time vehicle motion ceases after the crash test, during a

30-min period after vehicle motion ceases, and throughout the post-crash rollover test. This 5 L limit is

intended to constrain electrolyte spillage only.

BATTERY RETENTION—Battery modules must stay restrained to the vehicle throughout the test procedures

described in 4.2 and 4.3. Intrusion of battery system components into the occupant compartment is not

permitted before, during, or after any of the crash and rollover tests.

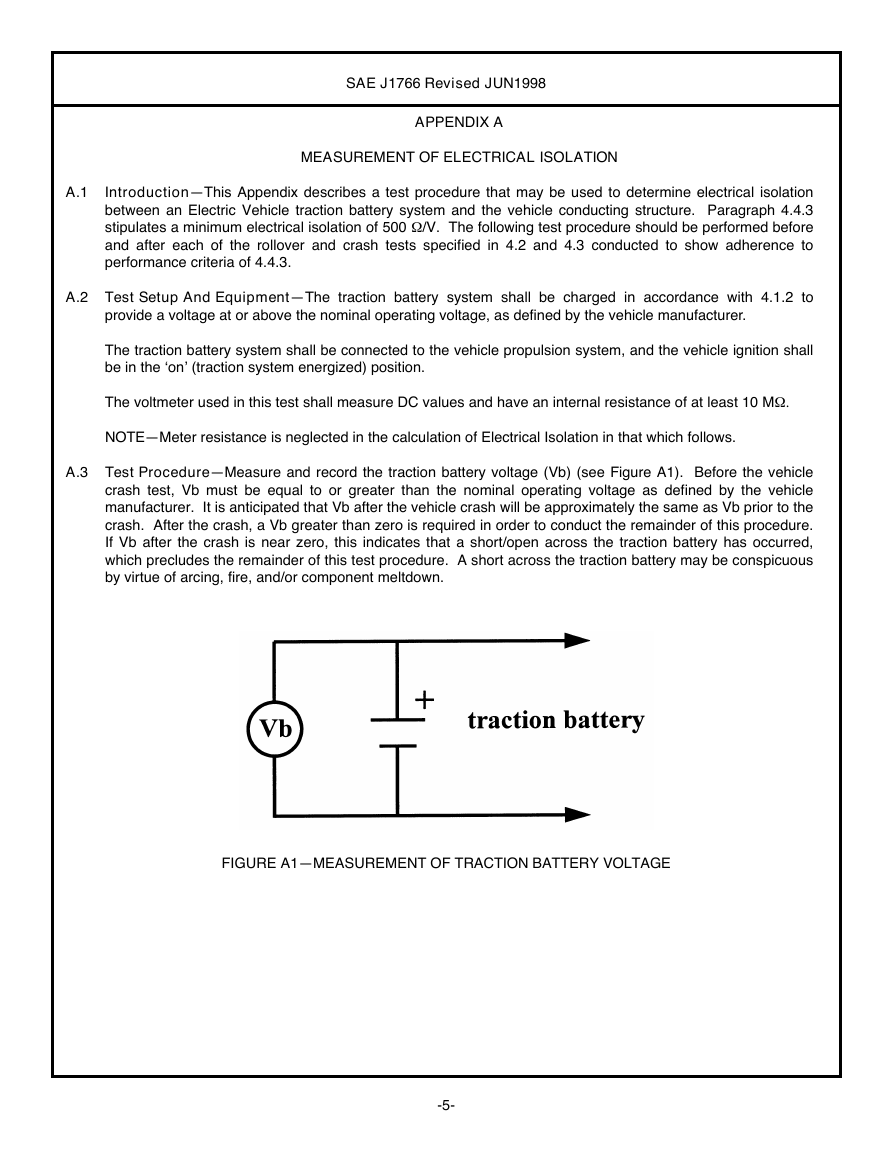

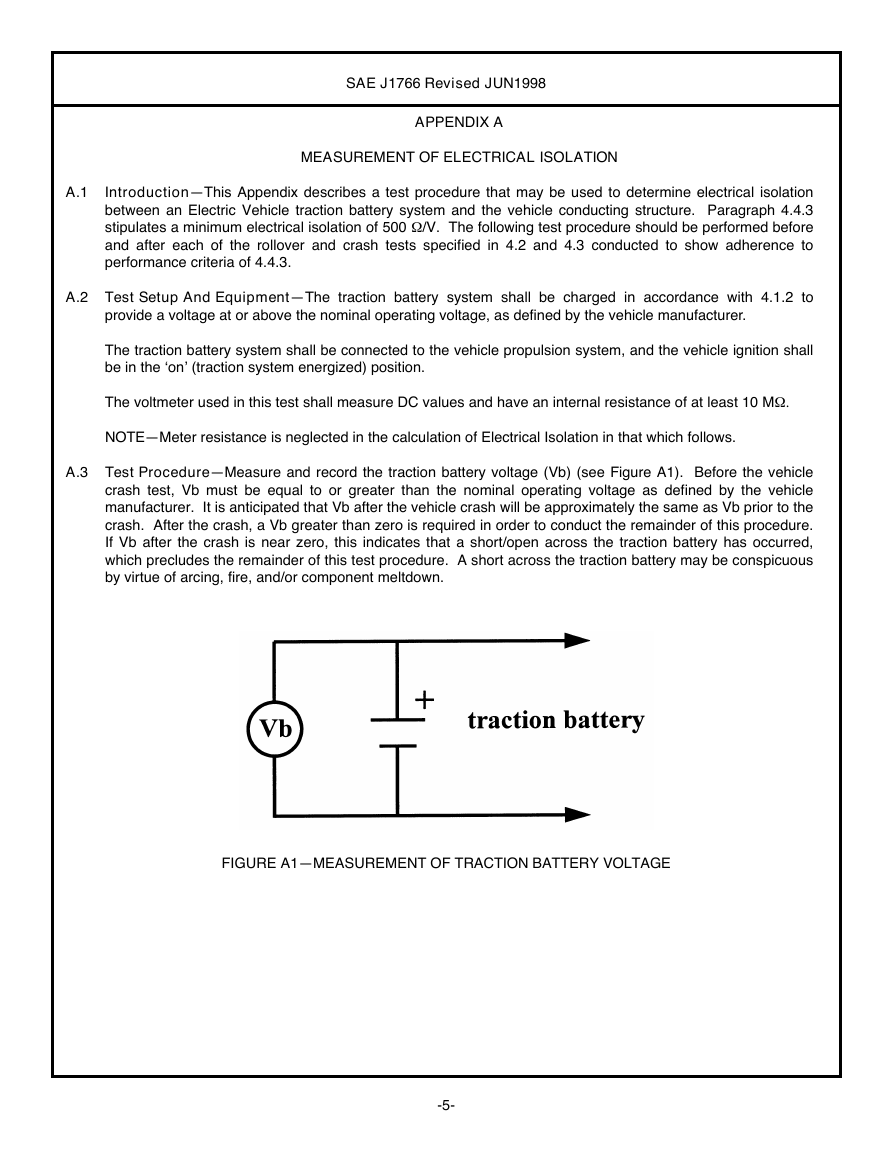

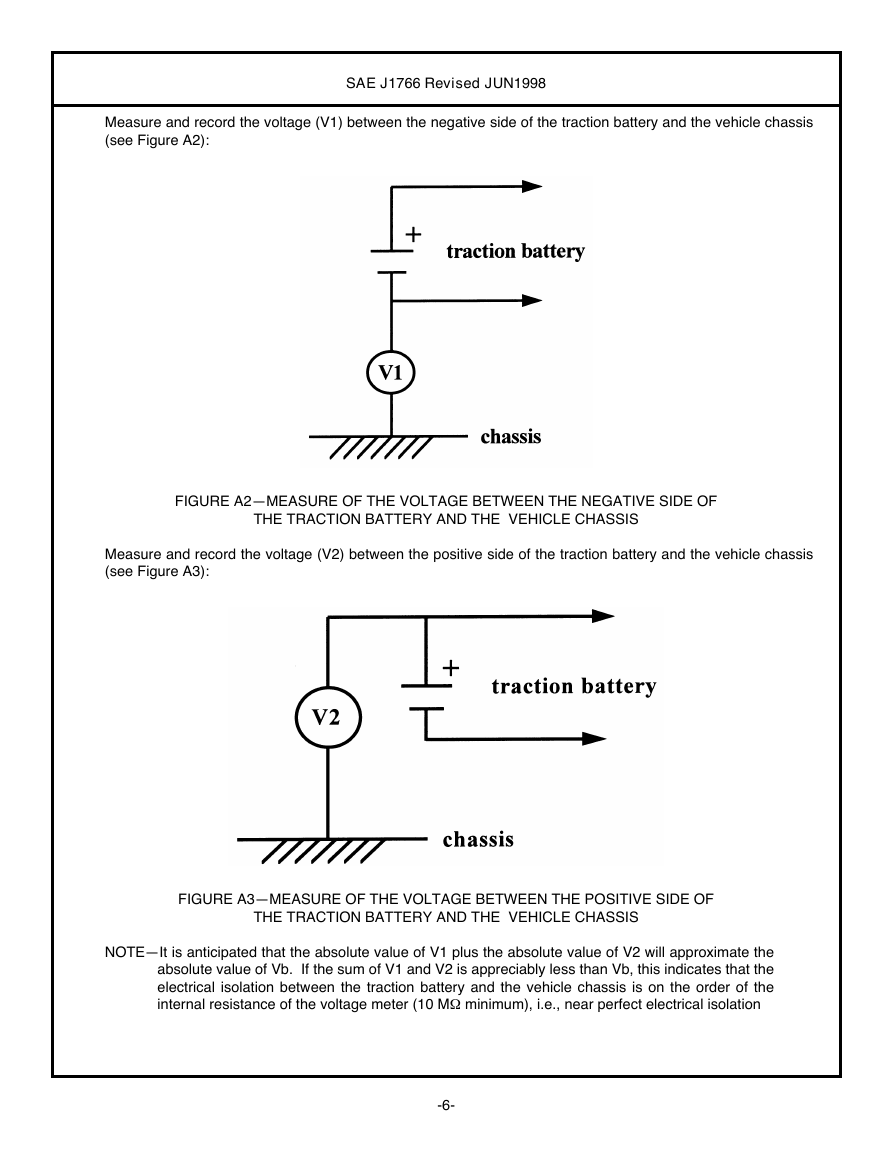

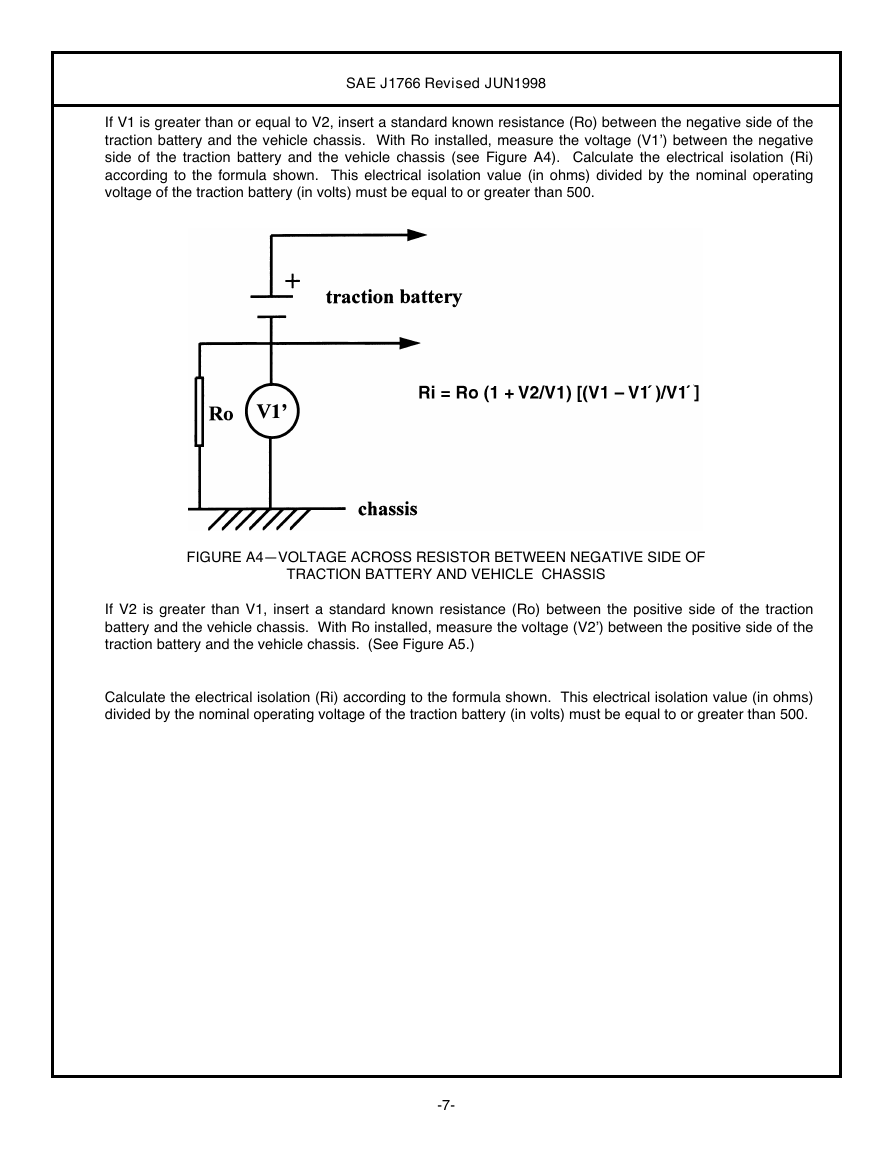

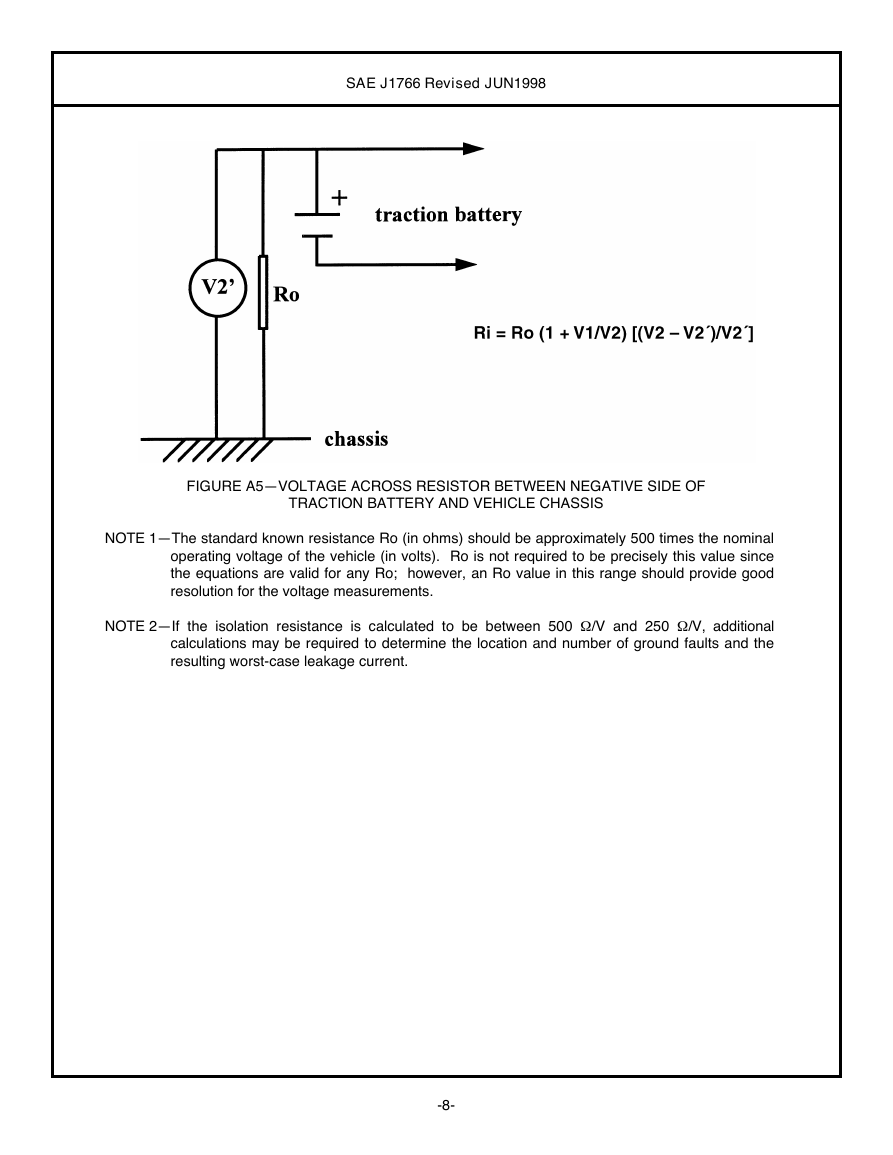

ELECTRICAL ISOLATION—Electrical isolation between the traction battery system and vehicle conducting

structure must be maintained at a minimum of 500 W

/V (at the nominal traction voltage specified by the

vehicle manufacturer) before and after each of the crash tests described in 4.3 and after the rollover test

described in 4.2. For example, an Electric Vehicle having a nominal traction voltage of 300 V would be

required to have a minimum of 150 000 W

resistance between the battery system and the vehicle conducting

structure. It is understood that during a crash, electrical isolation may be lost momentarily provided that it is

subsequently restored. Appendix A describes a test procedure for determining electrical isolation. Vehicles,

which by design have the traction batteries referenced to conducting portions of the vehicle structure, are

excluded from the requirements of this section if the nominal traction voltage from both positive and negative

terminals to conducting structure is less than hazardous voltage (as defined in SAE J2344).

PREPARED BY THE SAE ELECTRIC VEHICLE SAFETY COMMITTEE OF THE

SAE ELECTRIC VEHICLE STANDARDS FORUM COMMITTEE

-4-

�

###E###

###E###

###E###

###E###

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc