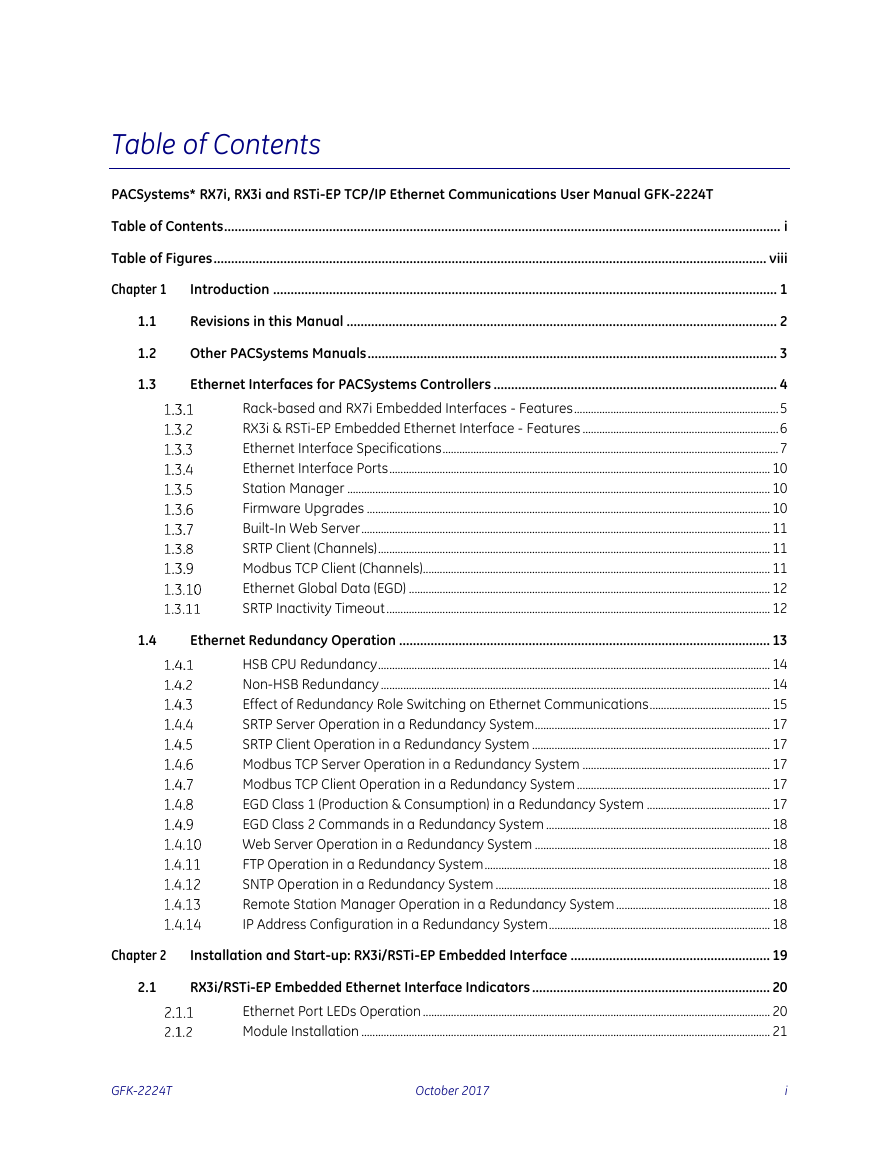

PACSystems* RX7i, RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual GFK-2224T

Table of Contents

Table of Figures

Chapter 1 Introduction

1.1 Revisions in this Manual

1.2 Other PACSystems Manuals

1.3 Ethernet Interfaces for PACSystems Controllers

1.3.1 Rack-based and RX7i Embedded Interfaces - Features

1.3.2 RX3i & RSTi-EP Embedded Ethernet Interface - Features

CPE305/310

CPE330/CPE400

RSTi-EP CPE100

1.3.3 Ethernet Interface Specifications

All RX7i Ethernet Interface Modules and RX3i Rack-Based Ethernet Interface Modules

RX3i Embedded Interface

1.3.4 Ethernet Interface Ports

Ethernet Media

1.3.5 Station Manager

1.3.6 Firmware Upgrades

1.3.7 Built-In Web Server

1.3.8 SRTP Client (Channels)

1.3.9 Modbus TCP Client (Channels)

1.3.10 Ethernet Global Data (EGD)

1.3.11 SRTP Inactivity Timeout

1.4 Ethernet Redundancy Operation

1.4.1 HSB CPU Redundancy

1.4.2 Non-HSB Redundancy

1.4.3 Effect of Redundancy Role Switching on Ethernet Communications

Role Switching in HSB Redundancy Systems

Role Switching in Non-HSB Redundancy Systems

Going to Stop Mode

Stop/IO Scan Enabled Mode

Commanding a Role Switch in a Non-HSB Redundancy System

1.4.4 SRTP Server Operation in a Redundancy System

1.4.5 SRTP Client Operation in a Redundancy System

1.4.6 Modbus TCP Server Operation in a Redundancy System

1.4.7 Modbus TCP Client Operation in a Redundancy System

1.4.8 EGD Class 1 (Production & Consumption) in a Redundancy System

1.4.9 EGD Class 2 Commands in a Redundancy System

1.4.10 Web Server Operation in a Redundancy System

1.4.11 FTP Operation in a Redundancy System

1.4.12 SNTP Operation in a Redundancy System

1.4.13 Remote Station Manager Operation in a Redundancy System

1.4.14 IP Address Configuration in a Redundancy System

Chapter 2 Installation and Start-up: RX3i/RSTi-EP Embedded Interface

2.1 RX3i/RSTi-EP Embedded Ethernet Interface Indicators

2.1.1 Ethernet Port LEDs Operation

CPE305/CPE310 Ethernet LED Operation

CPE330 Ethernet LED Operation

CPE400 Ethernet LED Operation (LAN1, LAN2, LAN3)

CPE100 Ethernet LED Operation (LAN1, LAN2)

2.1.2 Module Installation

2.2 Ethernet Port Connector

2.2.1 Connection to a 10Base-T / 100Base Tx Network

2.2.2 10Base-T/100Base Tx Port Pinouts

2.3 Pinging TCP/IP Ethernet Interfaces on the Network

2.3.1 Pinging the Ethernet Interface from a UNIX Host or Computer Running TCP/IP Software

2.3.2 Determining if an IP Address is Already Being Used

Chapter 3 Installation and Start-up: Rack-based and RX7i Embedded Interface

3.1 Ethernet Interface Controls and Indicators

3.1.1 Ethernet LEDs

LAN LED Operation

STAT LED Operation

EOK LED Operation

Ethernet Port LEDs Operation (100Mb and Link/Activity)

3.1.2 Ethernet Restart Pushbutton

Restart Pushbutton Operation for Version 3.6 and Later

Restart Pushbutton Operation Prior to Version 3.6

3.2 Module Installation

3.2.1 Installing an RX7i CPU with Embedded Ethernet Interface

3.2.2 Installing an RX7i Ethernet Interface Module

3.2.3 Installing an RX3i Ethernet Interface Module

3.3 Ethernet Port Connectors

3.3.1 Embedded Switch

3.3.2 Connection to a 10Base-T / 100Base Tx Network

10Base-T/100Base Tx Port Pinouts

Connection Using a Hub/Switch/Repeater

Direct Connection to the PACSystems Ethernet Interface

3.4 Station Manager Port

3.4.1 Port Settings

Station Manager (RS-232) Port Pin Assignment

3.5 Verifying Proper Power-Up of the Ethernet Interface after Configuration

3.6 Pinging TCP/IP Ethernet Interfaces on the Network

3.6.1 Pinging the Ethernet Interface from a UNIX Host or Computer Running TCP/IP Software

3.6.2 Determining if an IP Address is Already Being Used

3.7 Ethernet Plug-in Applications

Chapter 4 Configuration

4.1 RX3i/RSTi-EP Embedded Ethernet Interfaces

4.1.1 Ethernet Configuration Data

Generating / Storing / Loading the Configuration

Backup Configuration Data

Locally Edited Configuration Data

4.1.2 Initial IP Address Assignment

4.1.3 Configuring the Ethernet Interface Parameters

Configuring an RX3i/RSTi-EP Embedded Ethernet Interface

Ethernet Parameters (Settings Tab)

CPE330/CPE400/CPE100 Settings Tab

CPE330/CPE400/CPE100 LAN1 and LAN2 Advanced EGD Settings

Terminals Tab

Configuring Embedded Ethernet for Ethernet Global Data (EGD)

4.2 Rack-based and RX7i Embedded Interfaces

4.2.1 Ethernet Configuration Data

Generating / Storing / Loading the Configuration

Backup Configuration Data

Locally Edited Configuration Data

4.2.2 Initial IP Address Assignment

Assigning a Temporary IP Address Using the Programming Software

Assigning a Temporary IP Address Using BOOTP

Assigning a Temporary IP Address Using Telnet

4.2.3 Configuring Ethernet Interface Parameters

Configuring an RX7i Embedded Ethernet Interface

Configuring a Rack-based Ethernet Interface Module

Ethernet Parameters (Settings Tab)

RS-232 Port (Station Manager) Tab

Terminals Tab

4.2.4 Configuring Ethernet Global Data

Basic EGD Configuration

EGD Configuration for Redundancy Systems

Exchange ID Offset in an Ethernet Redundancy System

Using Signatures in Ethernet Global Data

Using Signatures with Run Mode Stores of EGD

Configuring EGD Signatures

Configuring Ethernet Global Data Using the EGD Configuration Server

Installing the EGD Configuration Server

Configuring the EGD Configuration Server

Enabling the use of the EGD Configuration Server for a Device

Network Names and Collections

Setting up Collections for the EGD Management Tool

Configuring an Ethernet Global Data Exchange for a Producer

Configuring the Exchange Variables

Configuring an Ethernet Global Data Exchange for a Consumer

Name Generation for Consumed Variables

Synchronizing a Consumed Exchange with Changes in the Producer

Validating the EGD for a Device

Looking at the Entire EGD Network

Configuring EGD Devices Not Supported by the EGD Configuration Server

Installing the EGD Generic Device Editor

Running the EGD Generic Device Editor

Configuring Ethernet Global Data without Using the EGD Configuration Server

Configuring an Ethernet Global Data Exchange for a Producer

Configuring an Ethernet Global Data Exchange for a Consumer

Selective Consumption

Chapter 5 Ethernet Global Data

5.1 Ethernet Global Data Operation

5.1.1 EGD Producer

5.1.2 EGD Consumers

5.2 EGD Exchanges

5.2.1 Content of an Ethernet Global Data Exchange

5.2.2 Data Ranges (Variables) in an Ethernet Global Data Exchange

5.2.3 Valid Memory Types for Ethernet Global Data

5.2.4 Planning Exchanges

5.2.5 Using Ethernet Global Data in a Redundancy System

5.3 Sending an Ethernet Global Data Exchange to Multiple Consumers

5.3.1 Multicasting Ethernet Global Data

5.3.2 Broadcasting Ethernet Global Data

5.3.3 Changing Group ID in Run Mode

Broadcast

Multicast

Unicast

5.4 Ethernet Global Data Timing

5.4.1 EGD Synchronization

5.4.2 Configurable Producer Period for an EGD Exchange

5.4.3 Consumer Update Timeout Period

Producer Period Guidelines for PLCs

Timing Example 1

Timing Example 2

5.5 Time-Stamping of Ethernet Global Data Exchanges

5.5.1 Obtaining Timestamps from the Ethernet Interface Clock

5.5.2 Obtaining Timestamps from the CPU TOD Clock

Synchronizing the CPU TOD Clock to an SNTP Server

Operating Sequence for CPU Clock Synchronization

Steps to Synchronize the CPU TOD Clock to an SNTP Server

SNTP Time Transfer COMMREQs

Read Ethernet Clock Status and Stratum COMMREQ (5001)

Command Block for Read Ethernet Clock Status and Stratum COMMREQ

Clock Status and Stratum Format

Clock Status Word Values

Enable or Disable PLC Time Update COMMREQ (5002)

Command Block for Enable/Disable PLC Time Update COMMREQ

COMMREQ Status Word Values

5.5.3 SNTP Operation

Normal SNTP Operation

SNTP Broadcast and Multicast Operation Mode

SNTP Unicast Operation Mode

Multiple SNTP Servers (Applies only to SNTP Broadcast and Multicast Mode)

Local Time and Daylight Saving Time Corrections

Loss or Absence of SNTP Timing Signals

5.6 Effect of PLC Modes and Actions on EGD Operations

5.6.1 Run Mode Store of EGD

Modifying an Exchange’s Parameters

Common EGD Parameters

Effects of Modifying Consumed Exchange Parameters

Effects of Modifying Produced Exchange Parameters

Modifying an Exchange’s Variable Lists

Modifying Exchange Variable Lists with EGD Signatures Enabled

Modifying Exchange Variable Lists without EGD Signatures Enabled

Modifying Exchange Variables on Targets that use EGD Commands

5.7 Monitoring Ethernet Global Data Exchange Status

5.7.1 Exchange Status Word Error Codes

Chapter 6 Programming EGD Commands

6.1 General Use of EGD Commands

6.2 Using EGD Commands in a Redundancy System

6.3 COMMREQ Format for Programming EGD Commands

6.4 COMMREQ Status for the EGD Commands

6.4.1 COMMREQ Status Values

6.5 Read PLC Memory (4000)

6.5.1 Read PLC Memory Command Block

6.6 Write PLC Memory (4001)

6.6.1 Write PLC Memory Command Block

6.7 Read EGD Exchange (4002)

6.7.1 Read EGD Exchange Command Block

6.8 Write EGD Exchange (4003)

6.8.1 Write EGD Exchange Command Block

6.9 Masked Write to EGD Exchange (4004)

6.9.1 Masked Write EGD Exchange Command Block

Masked Write to EGD Exchange Bit Mask and Data Bits

Chapter 7 Programming SRTP Channel Commands

7.1 SRTP Channel Commands

7.1.1 Channel Operations

7.1.2 Aborting and Re-tasking a Channel

7.1.3 Monitoring the Channel Status

7.1.4 SRTP Channel Commands in a Redundant System

7.1.5 Executing a Channel Command

7.2 COMMREQ Format for Programming Channel Commands

7.2.1 The COMMREQ Command Block: General Description

Using COMMREQs for Channel Commands

7.2.2 Establish Read Channel (2003)

Example Command Block

7.2.3 Establish Write Channel (2004)

Example Command Block

7.2.4 Send Information Report (2010)

Example Command Block

7.2.5 Abort Channel (2001)

Example Command Block

7.2.6 Retrieve Detailed Channel Status (2002)

Example Command Block

Monitoring the Detailed Channel Status Words

Format of the Detailed Channel Status Words (DCS Words)

7.3 Programming for Channel Commands

7.3.1 COMMREQ Sample Logic

7.3.2 Sequencing Communications Requests

7.3.3 Managing Channels and TCP Connections

7.3.4 Use “Channel Re-Tasking” To Avoid Using Up TCP Connections

How to Re-Task a Channel

7.3.5 Client Channels TCP Resource Management

7.3.6 SRTP Application Timeouts

7.4 Monitoring Channel Status

7.4.1 Format of the COMMREQ Status Word

Differences between Series 90 and PACSystems SRTP Channels

Chapter 8 Modbus/TCP Server

8.1 Modbus/TCP Server

8.1.1 Modbus/TCP Server Connections

8.1.2 Modbus Conformance Classes

8.1.3 Server Protocol Services

8.1.4 Station Manager Support

8.2 Reference Mapping

8.2.1 Modbus Reference Tables

Modbus File Access Table

Applicable Functions

Translating %W Reference Addresses

Modbus Holding Register Table

Applicable Functions

Modbus Input Register Table

Applicable Functions

Modbus Input Discrete Table

Applicable Functions

Modbus Coil Table

Applicable Functions

8.2.2 Address Configuration

8.3 Modbus Function Codes

Chapter 9 Modbus/TCP Client

9.1 The Communications Request

9.1.1 Structure of the Communications Request

9.1.2 COMMREQ Function Block

9.1.3 COMMREQ Command Block

9.1.4 Modbus/TCP Channel Commands

9.1.5 Status Data

The Logic Program Controlling Execution of the COMMREQ Function Block

9.1.6 Operation of the Communications Request

9.2 COMMREQ Function Block and Command Block

9.2.1 The COMMREQ Function Block

9.2.2 The COMMREQ Command Block

9.3 Modbus/TCP Channel Commands

9.3.1 Open a Modbus/TCP Client Connection (3000)

Command 3000 Example

9.3.2 Close a Modbus/TCP Client Connection (3001)

Command 3001 Example

9.3.3 Read Data from a Modbus/TCP Device (3003)

Command 3003, Example 1

Command 3003, Example 2

Command 3003, Example 3 – Read Exception Status

9.3.4 Write Data to a Modbus/TCP Device (3004)

Command 3004, Example 1 – Set Single Register

Command 3004, Example 2 – Write Single Coil

Command 3004, Example 3 – Set Multiple Registers

9.3.5 Mask Write Register Request to a Modbus Server Device (3009)

Command 3009, Example – Mask Write Register

9.3.6 Read/Write Multiple Registers to/from a Modbus Server Device (3005)

Command 3005, Example – Read/Write Multiple Register

9.4 Status Data

9.4.1 Types of Status Data

Ethernet Interface Status Bits

FT Output of the COMMREQ Function Block

COMMREQ Status Word

9.5 Controlling Communications in the Ladder Program

9.5.1 Essential Elements of the Ladder Program

9.5.2 COMMREQ Ladder Logic Example

9.5.3 Troubleshooting a Ladder Program

FT Output is ON

COMMREQ Status Word is Zero (0) and FT Output is OFF

COMMREQ Status Word is Not One (1)

9.5.4 Monitoring the Communications Channel

Monitoring the COMMREQ Status Word

Monitoring the Channel Open Bit

Sequencing Communications Requests

9.6 Differences between Series 90 and PACSystems Modbus/TCP Channels

CMM321 Modbus Client Endian Conversion Example

PACSystems Modbus Client Endian Conversion Example

Chapter 10 OPC UA Server

10.1 Application Logic to Control the OPC UA Server

10.1.1 OPC UA Server Service Request

OPC UA Server – Service Request – START

Example:

OPC UA Server – Service Request – STOP

Example:

OPC UA Server – Service Request – CLEAR

Example:

OPC UA Server – Service Request – RESTART

Example:

OPC UA Server – Service Request – SERVER_STATUS

Example:

OPC UA Server – Service Request – CONFIG_STATUS

Example of Config Status Request:

10.1.2 OPC UA Server Subroutine

Inputs

Outputs

10.1.3 Connect OPC UA Client to OPC UA Server

10.1.4 OPC UA Client Authentication Settings

10.1.5 Anonymous Authentication

10.1.6 Username/Password Authentication

10.1.7 OPC UA Security Settings

10.1.8 OPC UA Address Space

10.1.9 Publish Application Variables to OPC UA Address Space

10.1.10 OPC UA Server Information in Address Space

10.1.11 OPC UA Server – Application Information

10.1.12 OPC UA Server – GE Device Information

10.1.13 OPC UA Automatic Restart Function

10.1.14 OPC UA Server Certificates

10.1.15 OPC UA Performance Considerations

10.1.16 Sessions and Subscriptions for OPC UA

Chapter 11 RX7i PLC Monitoring Via the Web

11.1 System Requirements

11.2 Disabling Pop-up Blocking

11.3 Web Server Operation in a Redundant System

11.4 Standard Web Pages

11.4.1 RX7i Home Page

11.4.2 Factory Default Web Page

11.4.3 Reference Tables Viewer Page

Selecting Reference Table Data

Saving Reference Table Settings

Display Formats

11.4.4 PLC Fault Table Viewer Page

11.4.5 I/O Fault Table Viewer Page

11.5 Downloading PLC Web Pages

11.5.1 FTP Connect and Login

11.5.2 Changing the Password

Changing the Password from the Advanced User Parameters File

Changing the Password from the Station Manager

11.5.3 Web Page File Transfer

11.6 Viewing the RX7i PLC Web Pages

Chapter 12 Diagnostics

12.1 What to do if You Cannot Solve the Problem

12.2 Diagnostic Tools Available for Troubleshooting

12.3 States of the Ethernet Interface (Rack-based and RX7i Embedded Interfaces)

12.4 EOK LED Blink Codes for Hardware Failures (Rack-based and RX7i Embedded Interfaces)

12.5 Controller Fault Table

12.5.1 Controller Fault Table Descriptions

12.6 Monitoring the Ethernet Interface Status Bits

12.6.1 LAN Interface Status (LIS) Bits

12.6.2 Channel Status Bits

12.7 Monitoring the FT Output of the COMMREQ Function Block.

12.8 Monitoring the COMMREQ Status Word

12.8.1 Format of the COMMREQ Status Word

12.8.2 Major Error Codes in the COMMREQ Status Word

12.8.3 Minor Error Codes for Major Error Codes 05H (at Remote Server PLC) and 85H (at Client PLC)

12.8.4 Minor Error Codes for Major Error Code 11H (at Remote Server PLC)

12.8.5 Minor Error Codes for Major Error Code 90H (at Client PLC)

12.8.6 Minor Error Codes for Major Error Code 91H (at Remote Modbus/TCP Server)

12.8.7 Minor Error Codes for Major Error Code A0H (at Client PLC)

12.9 Using the EGD Management Tool (Rack-based and RX7i Embedded)

12.9.1 Installing the EGD Management Tool

12.9.2 Launching the EGD Management Tool

12.9.3 Monitoring EGD Devices

12.9.4 Monitoring Status of Ethernet Global Data for a Device

Configuration Summary

Online EGD Statistics

Produced Variables

12.10 Troubleshooting Common Ethernet Difficulties

12.10.1 COMMREQ Fault Errors

12.10.2 PLC Timeout Errors

12.10.3 Application Timeout Errors

12.10.4 EGD Configuration Mismatch Errors

12.10.5 Station Manager Lockout under Heavy Load

12.10.6 PING Restrictions

12.10.7 SRTP and Modbus/TCP Connection Timeout

12.10.8 Sluggish Programmer Response after Network Disruption

12.10.9 EGD Command Session Conflicts

12.10.10 SRTP Request Incompatibility with Existing Host Communications Toolkit Devices or Other SRTP Clients

12.10.11 COMMREQ Flooding Can Interrupt Normal Operation

12.10.12 Accelerated EGD Consumption Can Interfere with EGD Production

12.10.13 Channels Operation Depends Upon PLC Input Scanning

Chapter 13 Network Administration

13.1 IP Addressing

13.1.1 IP Address Format for Network Classes A, B, C

13.1.2 IP Addresses Reserved for Private Networks

13.1.3 Multicast IP Addresses

13.1.4 Loopback IP Addresses

13.1.5 Overlapping Subnets

Problem example #2:

13.2 Gateways

13.2.1 Networks Connected by a Gateway

13.3 Subnets and Supernets

13.3.1 Subnet Addressing and Subnet Masks

Example: Network Divided into Two Subnets

Example: Two Networks Combined into a Supernet

Appendix A Configuring Advanced User Parameters

A-1 Format of the Advanced User Parameters File

Example:

A-2 Advanced User Parameter Definitions

A-3 AUPs Supported by RX3i CPE305/CPE310 Embedded Ethernet Interface

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc