Computers & Fluids 38 (2009) 757–764

Contents lists available at ScienceDirect

Computers & Fluids

j o u r n a l h o m e p a g e : w w w . e l s e v i e r . c o m / l o c a t e / c o m p fl u i d

Dynamic contact angles in CFD simulations

Friedhelm Schönfeld a,*, Steffen Hardt b,1

a Institut für Mikrotechnik Mainz (IMM), Carl-Zeiss-Strasse 18-20, D-55129 Mainz, Germany

b Institut für Nano- und Mikroprozesstechnik, Leibniz Universität Hannover, Callinstr. 36, D-30167 Hannover, Germany

a r t i c l e

i n f o

a b s t r a c t

Article history:

Received 20 April 2007

Received in revised form 4 November 2007

Accepted 27 May 2008

Available online 10 October 2008

The accurate modelling of contact angle properties plays an important role in the simulation of free-sur-

face micro flows. Taking capillary filling as an example, we first discuss the analytical solutions of a cor-

responding 1D description in certain limits and then derive an approximate analytical expression for the

general case with constant contact angle. In case of a dynamic contact angle and contact line friction, the

model is beyond an analytical treatment. We show that computational fluid dynamics (CFD) results exhi-

bit a pronounced mesh dependence which is partly inherent to the modelling approach since the (non-

integrable) viscous stress divergence at the three-phase contact line is commonly neglected in standard

CFD simulations (see e.g. Hessel V, Hardt S, Löwe H. Chemical micro process engineering: fundamentals,

modelling and reactions. Weinheim: Wiley-VCH; 2004). Moreover, the numerical description of contact

angles suffers from artificial diffusion for the type of volume-of-fluid method used. Introduction of a mac-

roscopic slip range in combination with a localised body force close to the contact line turns out to rem-

edy both problems. Considering capillary filling as an example, we show that accurate, mesh independent

solutions of fluid dynamic problems involving contact angle dynamics are obtained already on coarse

meshes.

Ó 2008 Elsevier Ltd. All rights reserved.

1. Introduction

Micro flows and their applications have attracted an enhanced

interest in the past years. In this context, some of the largest eco-

nomical potentials lie in the fields of chemical process technology

[1] and micro total analysis systems (lTAS) [2,3]. lTAS are used for

biochemical analysis in medical diagnostics, pharmacological re-

search, environmental monitoring and other areas and allow to

process small sample amounts in an automated and parallel way.

In chemical process technology, microfluidics opens the door to

new process regimes, safe operation and microfluidic reactor com-

ponents often allow increased process yields and selectivities.

fluid

dynamical

for macroscopic

As far as modelling and simulation of micro flows are con-

cerned, the requirements are often different from those character-

istic

problems. While

computational fluid dynamics (CFD) is often confronted with the

problem of developing realistic turbulence models for specific

technologically relevant scenarios, micro flows are mostly laminar,

so a first-principle description can be used to model the flow. How-

ever, surface and interface effects become extremely important

and have to be included into the models in the most realistic man-

ner. Details of the dynamics of the 3-phase contact line of an

* Corresponding author. Tel.: +49 (0) 6131 990 411; fax: +49 (0) 6131 990 205.

E-mail addresses: schoenf@mnd-umwelttechnik.fh-wiesbaden.de (F. Schönfeld),

hardt@nmp.uni-hannover.de (S. Hardt).

1 Tel.: +49 (0) 511 7622 278; fax: +49 (0) 511 7622 167.

0045-7930/$ - see front matter Ó 2008 Elsevier Ltd. All rights reserved.

doi:10.1016/j.compfluid.2008.05.007

immiscible system of fluids on a solid surface are often neglected

in macroscopic simulations. Due to its scaling behaviour, surface

tension becomes important pre-dominantly in micro scale geome-

tries and is often supposed to be irrelevant in typical macroscopic

applications. However, from a fundamental point of view, the

physics on the micro scale in close vicinity to the 3-phase contact

line, i.e. the region of contact between gas, liquid and solid, dis-

plays the most interesting features and has an impact on macro-

scopic phenomena. Close to the 3-phase contact line the standard

continuum approach breaks down which reflects itself in a viscous

stress singularity leading to a diverging drag force on the solid

surface [4]. This phenomenon was described with the phrase

‘‘not even Herakles could sink a solid” in a paper by Huh and

Scriven [4], meaning that the no-slip boundary condition gives rise

to infinite forces at the three-phase contact line. Nevertheless, the

non-integrable singularity is neglected in most CFD approaches.

Relaxing the commonly used no-slip boundary condition removes

the singularity [5,6]. This concept of introducing a finite but micro-

scopic slip length at the contact line is feasible within analytical

approaches and helps to understand quite universal experimental

observations (see e.g. [7]) of dynamic contact angles, i.e. the veloc-

ity-dependent enclosed angle between the meniscus tangent at the

3-phase contact line and the wall. For details upon the analytical

approaches and on the dependence of the contact line dynamics

on the slip length the reader is referred to [8,9] and references

therein. Yet, the incorporation of a microscopic length scale that

is typically of the order of some ten nanometres into micro flow

�

758

F. Schönfeld, S. Hardt / Computers & Fluids 38 (2009) 757–764

CFD simulations is not practical for two major reasons. First, typical

outer dimensions of microfluidic systems are of the order of several

millimetres or larger. Thus, the detailed resolution of the region

around the contact line requires large numerical efforts. This is true

for the slip phenomena discussed above as well as for the micro-

scopic flow patterns around a moving contact line. Secondly, the

position of a contact line is a priori not known. Therefore, extre-

mely high grid resolution has to be provided along the wall bound-

ary if no adaptive grid refinement algorithms are used.

Since the incorporation of a realistic, microscopic slip condition

at the 3-phase contact line is usually not practical in CFD ap-

proaches, we present an alternative approach relying on the use

of a macroscopic slip range at the 3-phase contact line. By intro-

ducing a slip condition within that range the stress singularity is

released and the moving meniscus problem is no longer ill-posed.

That is reflected by the fact that the extraordinarily strong mesh

dependence that is found if the no-slip condition is applied is

eliminated.

Expressed in numerical terms, the strategy we pursue is ex-

plained as follows: We consider a problem that does not possess

a grid-independent numerical solution if no cut-off scale is intro-

duced. The physics of the problem suggests that there is in fact a

cut-off scale rendering the problem well-defined that is, however,

too small to be incorporated in a reasonable CFD framework. For

this reason we use a phenomenological model to describe the

problem that does not require the resolution of very small length

scales.

compares

to analytical

The specific aspects of the dynamics of the phase boundary

and their implementation into CFD solvers discussed in this arti-

cle are of particular importance for simulations of free-surface

flow in microfluidics. We address the question of how the numer-

ically observed wetting behaviour (without any slip length in-

cluded)

results and whether any

discrepancies in the results can be resolved by a phenomenolog-

ical approach, relying on a macroscopic range where boundary

slip occurs. Generally, several effects such as capillary filling, con-

tact angle hysteresis, dynamic contact angles, instabilities of an

advancing wetting front, or dewetting phenomena deserve close

investigation. Here the focus is put on a test case of capillary fill-

ing, the dynamical behaviour of which is directly related to dy-

namic contact angles. The presented approach is also relevant

for simulation of industrial processes such as, e.g., air entrain-

ment in context with liquid coating.

In the following section, the 1D model and certain limits of cap-

illary filling are discussed. This model is taken to benchmark corre-

sponding CFD results discussed in the second part where we

discuss how the extraordinary strong mesh dependence observed

in standard CFD simulations can be removed by introduction of a

macroscopic slip range in context with dynamic contact angles

and appropriate body forces.

2. Capillary filling with static contact angles

As a classical benchmark system we consider capillary filling

between vertical parallel plates, see Fig. 1. On one hand this sys-

tem is simple enough and allows to derive an analytical solution

for the filling height in certain limits. On the other hand the fill-

ing dynamics depends sensitively on the contact angle and thus

the systems allows to evaluate the CFD scheme for contact angle

dynamics developed in the following. Moreover a one-dimen-

sional differential equation governing the meniscus dynamics

can be derived facilitating analytical solutions in certain limits.

For the sake of clarity we start by formulating the Newton’s

equation of motion for capillary filling between vertical parallel

plates (cf. e.g. [10]):

d

θ

h

Fig. 1. Model geometry for studying capillary filling between parallel plates. h, h, d,

p0 denote the meniscus height, contact angle, distance between the plates and

counter pressure.

p0

� 12 _h

d

f _hqðhÞg ¼ 2r cos h

d2 gðhÞ � hgfql � qgg þ p0;

d

dt

where r, h, d, p0 are surface tension, contact angle, distance be-

tween the plates and counter pressure, respectively (cf. Fig. 1).

The term on the left-hand side denotes the inertial force per unit

area which is compensated by the Laplace pressure due to the

meniscus curvature, the viscous friction as well as hydrostatic

and counter pressure on the right hand side. The averaged density

and viscosity q, g are functions of the meniscus height h(t) and are

expressed via the liquid (l) and gas (g) densities ql and qg and

viscosities gl and gg as qðhÞ ¼ qlh þ qgðL � hÞÞ and gðhÞ ¼ glhþ

ggðL � hÞÞ. L is the height of the parallel plates arrangement. In

the case of a static contact angle and if the gas properties are neg-

ligible, Eq. (1) is of the general form

y€y þ _y2 ¼ ay _y þ by þ c:

ð2Þ

In order to facilitate the application of the subsequent discus-

sion of Eq. (2), the relations of the new parameters to the physical

and

viz.

; b ¼ �g and c ¼ 2r cos h=qld þ Po=ql. Eq. (2) re-

a ¼ �12gl=qld2

duces to the Lucas-Washburn equation in the quasi steady state

[11,12]

0 ¼ ay _y þ by þ c:

solved by yðtÞ ¼

ffiffiffi

p � t þ b=6 � t2;

ð3Þ

Two more limits deserve mentioning since they allow giving the

solution in a closed form. For inviscid liquids Eq. (2) reduces to the

Quéré equation (see, e.g.,[13])

y€y þ _y2 ¼ by þ c

ð4Þ

for initial conditions yð0Þ ¼ 0 and _yð0Þ ¼ 0. In case of a horizontal

meniscus movement the linear (gravitational) term in Eq. (2) van-

ishes and one is left with

ffiffiffi

p

p ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

y€y þ _y2 ¼ ay _y þ c

yðtÞ ¼ eat=2

c þ a � e�atfc þ act þ ag

:

a

geometrical

explicitly

given,

properties

are

solved by

2

ð1Þ

ð5Þ

c

The equilibrium position, i.e. the long-time limit of Eq. (2) is

given by y1 = -c/b. Applying an infinitesimal perturbation of the

equilibrium in the weekly damped limit (a � 1) yields an oscilla-

�

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi

p

�b=y1

tory behaviour with a characteristic frequency x0 ¼

[13].

In order to derive an approximate analytical expression for the full

dynamics it is helpful to cast Eq. (2) into the form

ð€y2Þ ¼ að _y2Þ þ 2by þ 2c:

ð6Þ

Replacing y2 by z and expanding the square-root term around

the equilibrium position y1 = �c/b yields an anharmonic-oscillator

equation for z(t). Note, the existence of an equilibrium position im-

plies non-vanishing gravity, i.e. b < 0.

€z ¼ a_z þ 2b

�

�

ffiffiffiffiffiffi

ffiffiffiffiffiffi

p þ z � z1

p þ Oðz2Þ

z1

z1

þ 2c:

ð7Þ

2

By numerical integration of Eq. (7), the linear term in z(t) is

found to be at least an order of magnitude larger than the quadratic

term for the set of parameters given below. This motivates us to

neglect the anharmonic terms. In this case the solution has the

general form of a damped oscillatory motion around the equilib-

rium position. Neglecting further the frequency shift due to the

damping the solution of Eq. (7) can be approximated by

(

b2 þ eat=2 cosðx0tÞ b2y2

yðtÞ ¼ c2

0 � c2

b2

)

1=2

:

ð8Þ

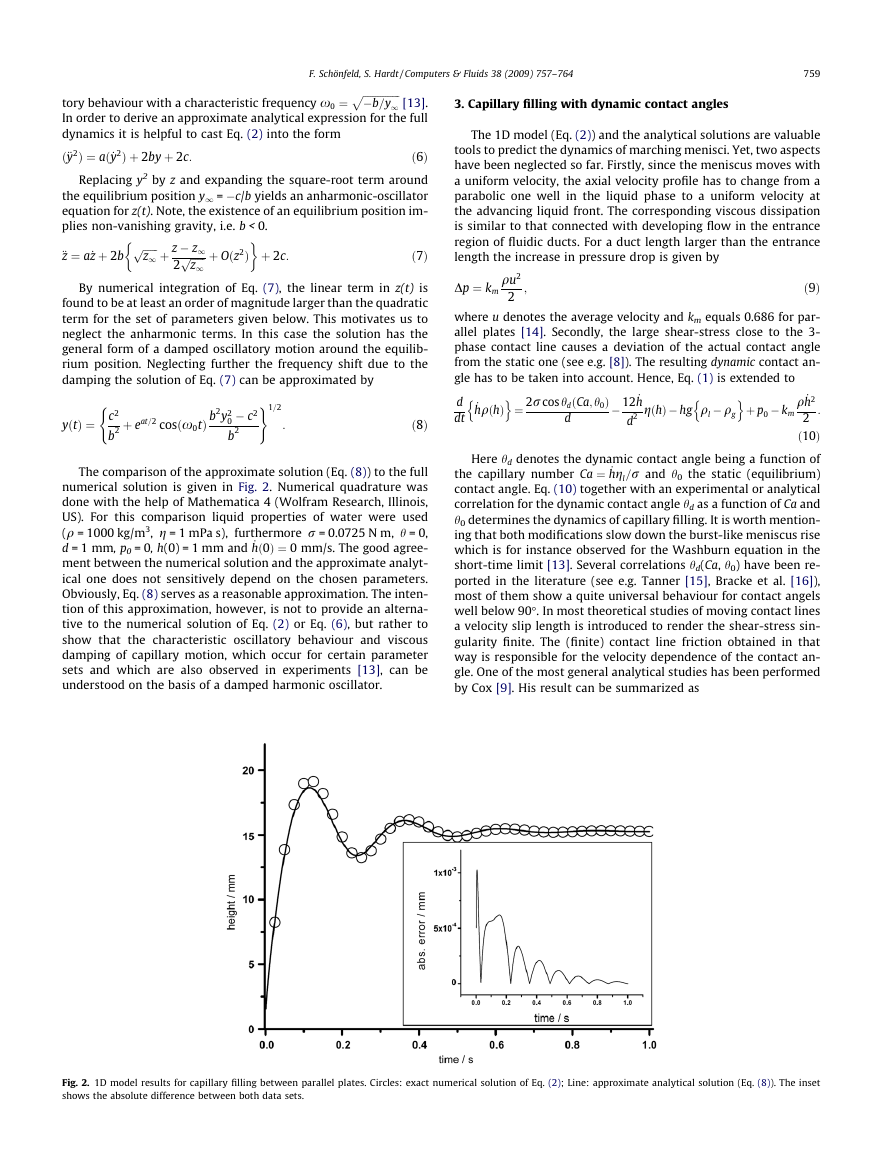

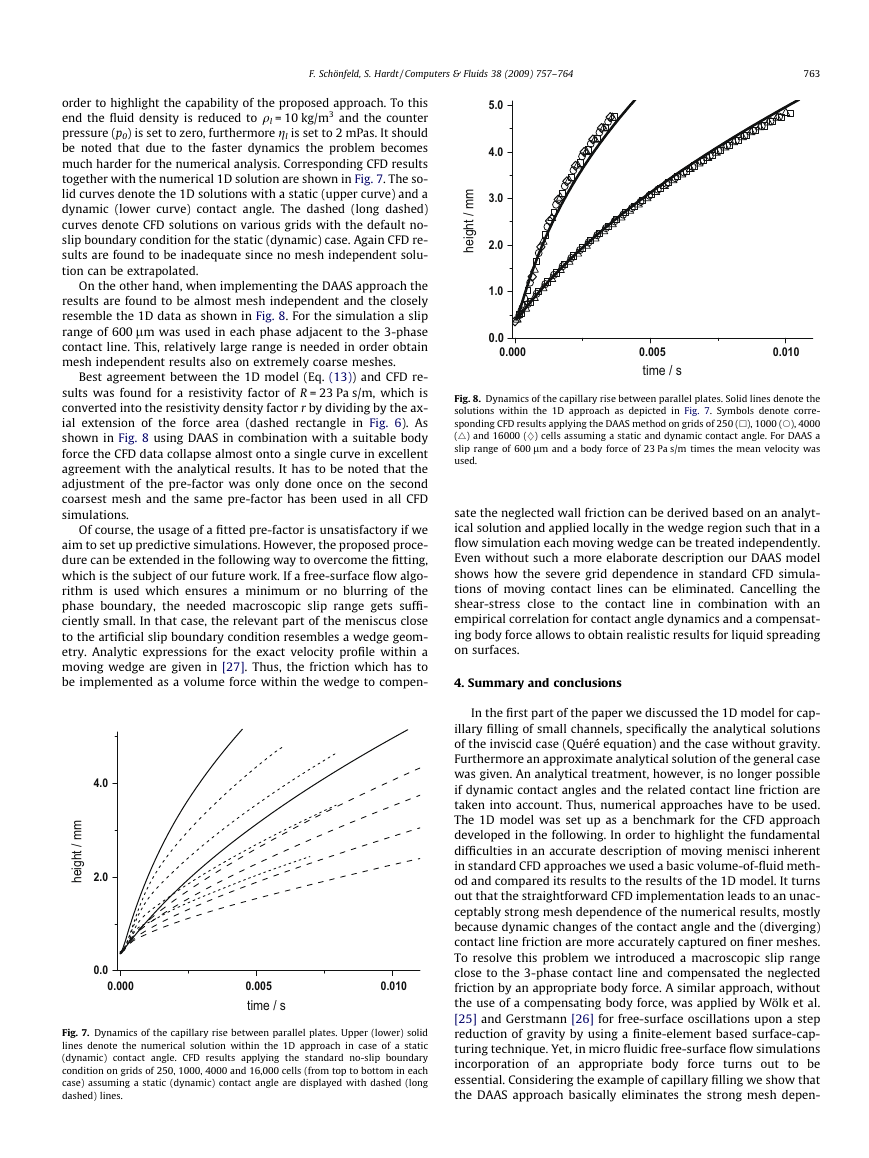

The comparison of the approximate solution (Eq. (8)) to the full

numerical solution is given in Fig. 2. Numerical quadrature was

done with the help of Mathematica 4 (Wolfram Research, Illinois,

US). For this comparison liquid properties of water were used

(q = 1000 kg/m3, g = 1 mPa s), furthermore r = 0.0725 N m, h = 0,

d = 1 mm, p0 = 0, h(0) = 1 mm and _hð0Þ ¼ 0 mm/s. The good agree-

ment between the numerical solution and the approximate analyt-

ical one does not sensitively depend on the chosen parameters.

Obviously, Eq. (8) serves as a reasonable approximation. The inten-

tion of this approximation, however, is not to provide an alterna-

tive to the numerical solution of Eq. (2) or Eq. (6), but rather to

show that the characteristic oscillatory behaviour and viscous

damping of capillary motion, which occur for certain parameter

sets and which are also observed in experiments [13], can be

understood on the basis of a damped harmonic oscillator.

F. Schönfeld, S. Hardt / Computers & Fluids 38 (2009) 757–764

759

3. Capillary filling with dynamic contact angles

The 1D model (Eq. (2)) and the analytical solutions are valuable

tools to predict the dynamics of marching menisci. Yet, two aspects

have been neglected so far. Firstly, since the meniscus moves with

a uniform velocity, the axial velocity profile has to change from a

parabolic one well in the liquid phase to a uniform velocity at

the advancing liquid front. The corresponding viscous dissipation

is similar to that connected with developing flow in the entrance

region of fluidic ducts. For a duct length larger than the entrance

length the increase in pressure drop is given by

Dp ¼ km

ð9Þ

qu2

2 ;

n

o

n

o

_hqðhÞ

where u denotes the average velocity and km equals 0.686 for par-

allel plates [14]. Secondly, the large shear-stress close to the 3-

phase contact line causes a deviation of the actual contact angle

from the static one (see e.g. [8]). The resulting dynamic contact an-

gle has to be taken into account. Hence, Eq. (1) is extended to

d

d

dt

þ p0 � km

¼ 2r cos hdðCa; h0Þ

� 12 _h

d2 gðhÞ� hg ql � qg

q _h2

2 :

ð10Þ

Here hd denotes the dynamic contact angle being a function of

the capillary number Ca ¼ _hgl=r and h0 the static (equilibrium)

contact angle. Eq. (10) together with an experimental or analytical

correlation for the dynamic contact angle hd as a function of Ca and

h0 determines the dynamics of capillary filling. It is worth mention-

ing that both modifications slow down the burst-like meniscus rise

which is for instance observed for the Washburn equation in the

short-time limit [13]. Several correlations hd(Ca, h0) have been re-

ported in the literature (see e.g. Tanner [15], Bracke et al. [16]),

most of them show a quite universal behaviour for contact angels

well below 90°. In most theoretical studies of moving contact lines

a velocity slip length is introduced to render the shear-stress sin-

gularity finite. The (finite) contact line friction obtained in that

way is responsible for the velocity dependence of the contact an-

gle. One of the most general analytical studies has been performed

by Cox [9]. His result can be summarized as

Fig. 2. 1D model results for capillary filling between parallel plates. Circles: exact numerical solution of Eq. (2); Line: approximate analytical solution (Eq. (8)). The inset

shows the absolute difference between both data sets.

�

760

F. Schönfeld, S. Hardt / Computers & Fluids 38 (2009) 757–764

gðhdÞ ¼ gðh0Þ þ Ca � lnðl�1

ð11Þ

s Þ;

where ls denotes the dimensionless length of the slip region and the

ffiffiffiffiffiffi

function g is given in [9]. In the following, the somewhat simpler

empirical correlation derived by Bracke et al. (1989) is used

p

cosðhdÞ ¼ cosðh0Þ � 2½1 þ cosðh0Þ

Ca

:

ð12Þ

It has to be stressed, however, that the CFD approach discussed

subsequently allows to implement other correlations as well and

does not depend on the particular choice of hd(Ca, h0). Inserting

Eq. (12) in Eq. (10) yields a highly non-linear differential equation

of the form

ffiffiffi

p

_y

;

the newly

introduced parameter

and

y€y ¼ ay _y þ by þ c0 þ d1 _y2 þ d2

ð13Þ

ffiffiffiffiffiffiffiffi

are defined as

where

d2 ¼ 4½1 þ cos h0

c0 ¼ 2r cos h0=qld þ P0=ql; d1 ¼ km=2 � 1,

p

rgl

=qld. The square-root term in Eq. (13) represents the friction

of the contact line motion. Interestingly, the square-root depen-

dence of the contact line friction was also derived independently

of any dynamic contact angle correlation by comparing numerical

solutions of the Navier–Stokes equations to experimental data

[17]. Since straightforward analytical approaches fail, Eq. (13) is

solved numerically (Mathematica 4, Wolfram Research, Illinois,

US). The solution of the 1D model is taken as a benchmark for the

CFD results discussed below. Already in the analysis of the 1D ap-

proach it will turn out that the dynamic behaviour is extremely

sensitive to details of the dynamic contact angle, thus facilitating

the evaluation of numerical accuracy. Such an indirect monitoring

of the contact angle is much more accurate than the direct quanti-

fication by numerical determination of the slope of the interface at

the wall.

3.1. CFD analysis

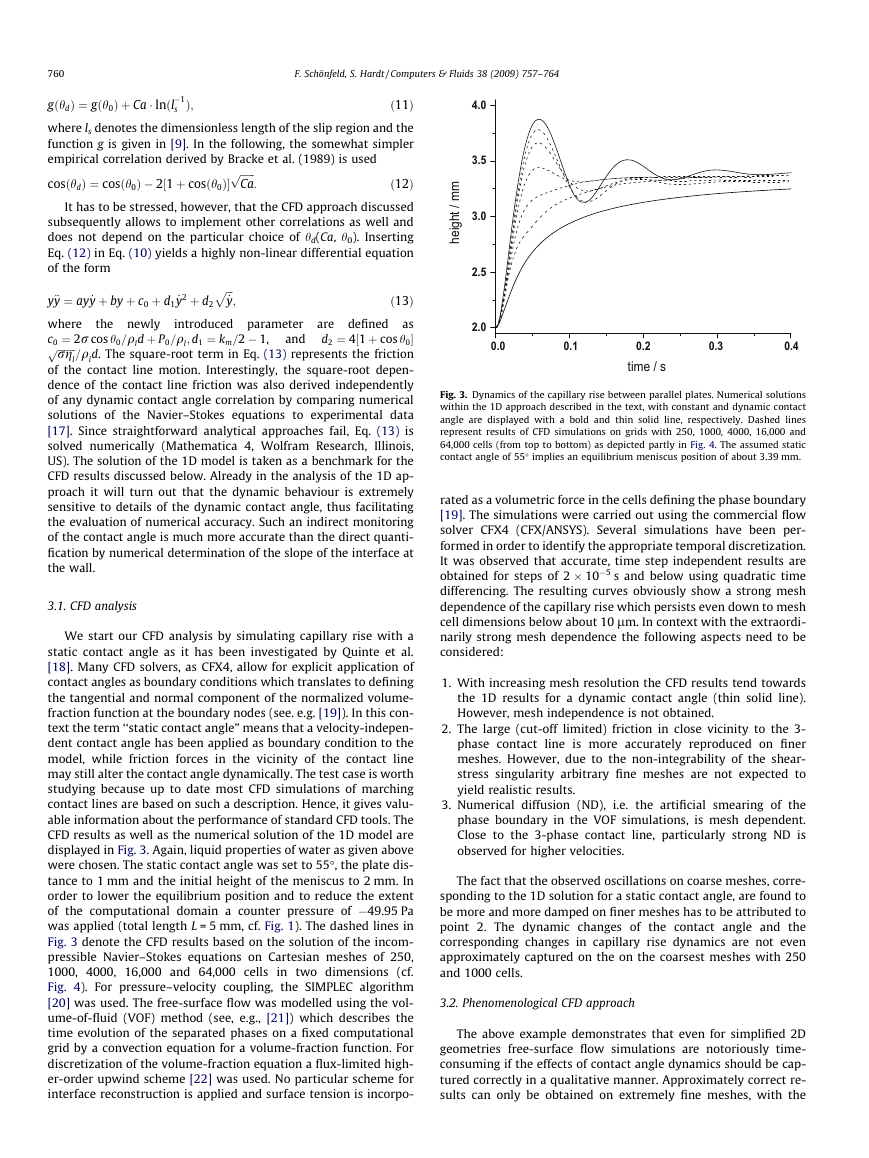

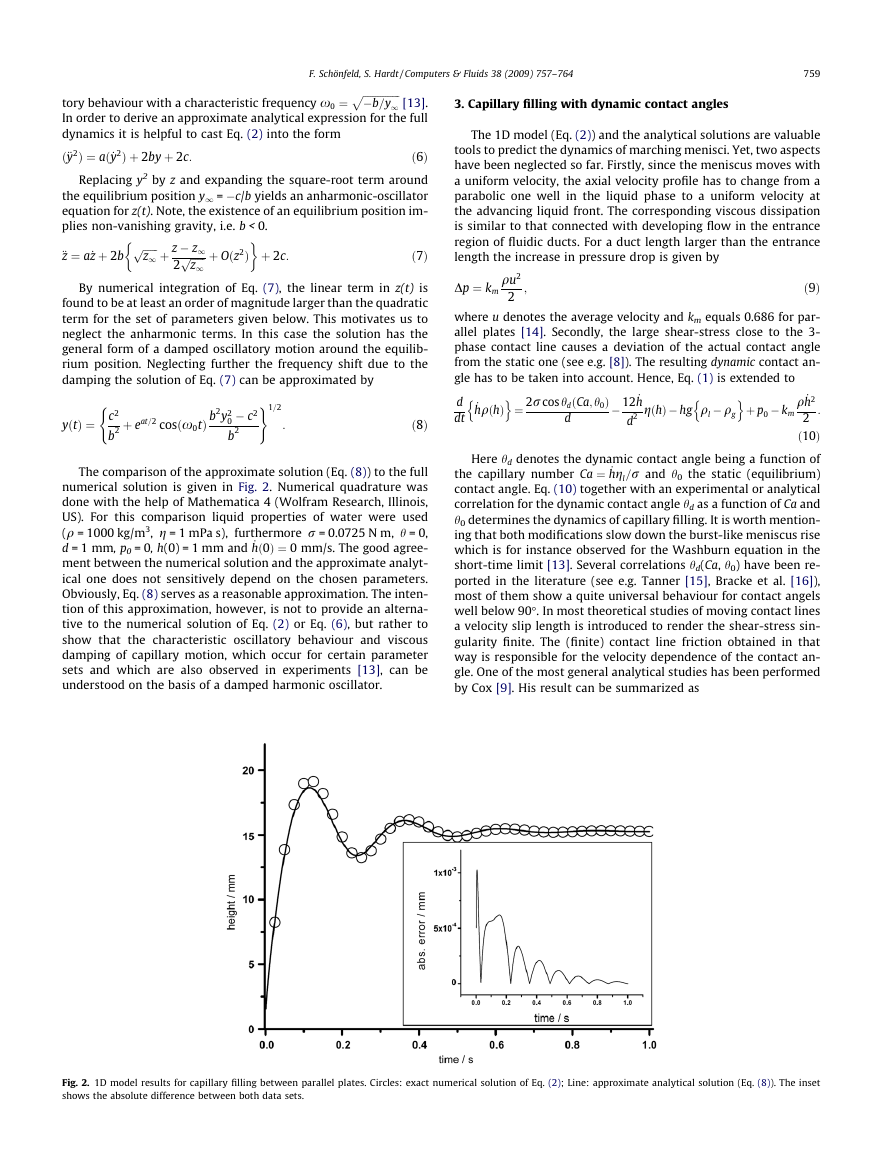

We start our CFD analysis by simulating capillary rise with a

static contact angle as it has been investigated by Quinte et al.

[18]. Many CFD solvers, as CFX4, allow for explicit application of

contact angles as boundary conditions which translates to defining

the tangential and normal component of the normalized volume-

fraction function at the boundary nodes (see. e.g. [19]). In this con-

text the term ‘‘static contact angle” means that a velocity-indepen-

dent contact angle has been applied as boundary condition to the

model, while friction forces in the vicinity of the contact line

may still alter the contact angle dynamically. The test case is worth

studying because up to date most CFD simulations of marching

contact lines are based on such a description. Hence, it gives valu-

able information about the performance of standard CFD tools. The

CFD results as well as the numerical solution of the 1D model are

displayed in Fig. 3. Again, liquid properties of water as given above

were chosen. The static contact angle was set to 55°, the plate dis-

tance to 1 mm and the initial height of the meniscus to 2 mm. In

order to lower the equilibrium position and to reduce the extent

of the computational domain a counter pressure of �49.95 Pa

was applied (total length L = 5 mm, cf. Fig. 1). The dashed lines in

Fig. 3 denote the CFD results based on the solution of the incom-

pressible Navier–Stokes equations on Cartesian meshes of 250,

1000, 4000, 16,000 and 64,000 cells in two dimensions (cf.

Fig. 4). For pressure–velocity coupling, the SIMPLEC algorithm

[20] was used. The free-surface flow was modelled using the vol-

ume-of-fluid (VOF) method (see, e.g., [21]) which describes the

time evolution of the separated phases on a fixed computational

grid by a convection equation for a volume-fraction function. For

discretization of the volume-fraction equation a flux-limited high-

er-order upwind scheme [22] was used. No particular scheme for

interface reconstruction is applied and surface tension is incorpo-

m

m

/

t

h

g

e

h

i

4.0

3.5

3.0

2.5

2.0

0.0 0.1 0.2 0.3 0.4

time / s

Fig. 3. Dynamics of the capillary rise between parallel plates. Numerical solutions

within the 1D approach described in the text, with constant and dynamic contact

angle are displayed with a bold and thin solid line, respectively. Dashed lines

represent results of CFD simulations on grids with 250, 1000, 4000, 16,000 and

64,000 cells (from top to bottom) as depicted partly in Fig. 4. The assumed static

contact angle of 55° implies an equilibrium meniscus position of about 3.39 mm.

rated as a volumetric force in the cells defining the phase boundary

[19]. The simulations were carried out using the commercial flow

solver CFX4 (CFX/ANSYS). Several simulations have been per-

formed in order to identify the appropriate temporal discretization.

It was observed that accurate, time step independent results are

obtained for steps of 2 � 10�5 s and below using quadratic time

differencing. The resulting curves obviously show a strong mesh

dependence of the capillary rise which persists even down to mesh

cell dimensions below about 10 lm. In context with the extraordi-

narily strong mesh dependence the following aspects need to be

considered:

1. With increasing mesh resolution the CFD results tend towards

the 1D results for a dynamic contact angle (thin solid line).

However, mesh independence is not obtained.

2. The large (cut-off limited) friction in close vicinity to the 3-

phase contact line is more accurately reproduced on finer

meshes. However, due to the non-integrability of the shear-

stress singularity arbitrary fine meshes are not expected to

yield realistic results.

3. Numerical diffusion (ND), i.e. the artificial smearing of the

phase boundary in the VOF simulations, is mesh dependent.

Close to the 3-phase contact line, particularly strong ND is

observed for higher velocities.

The fact that the observed oscillations on coarse meshes, corre-

sponding to the 1D solution for a static contact angle, are found to

be more and more damped on finer meshes has to be attributed to

point 2. The dynamic changes of the contact angle and the

corresponding changes in capillary rise dynamics are not even

approximately captured on the on the coarsest meshes with 250

and 1000 cells.

3.2. Phenomenological CFD approach

The above example demonstrates that even for simplified 2D

geometries free-surface flow simulations are notoriously time-

consuming if the effects of contact angle dynamics should be cap-

tured correctly in a qualitative manner. Approximately correct re-

sults can only be obtained on extremely fine meshes, with the

�

F. Schönfeld, S. Hardt / Computers & Fluids 38 (2009) 757–764

761

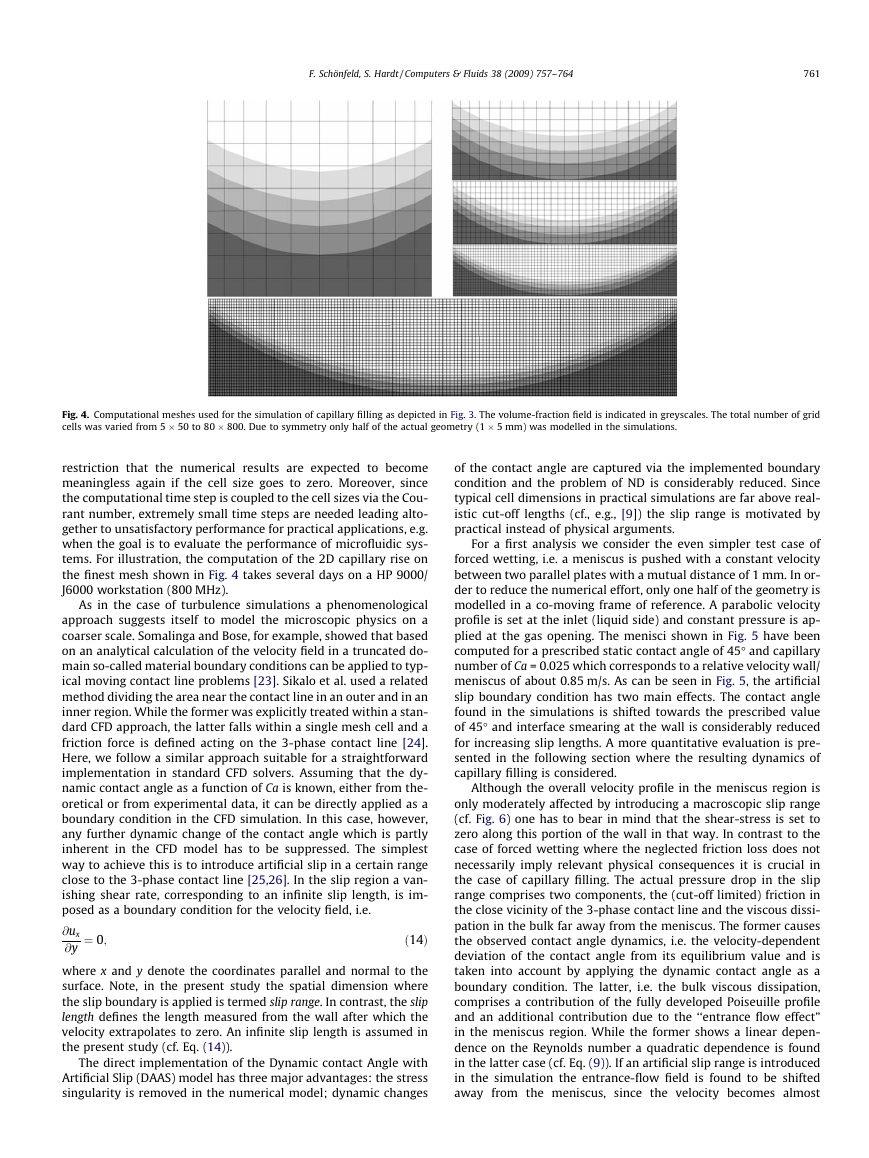

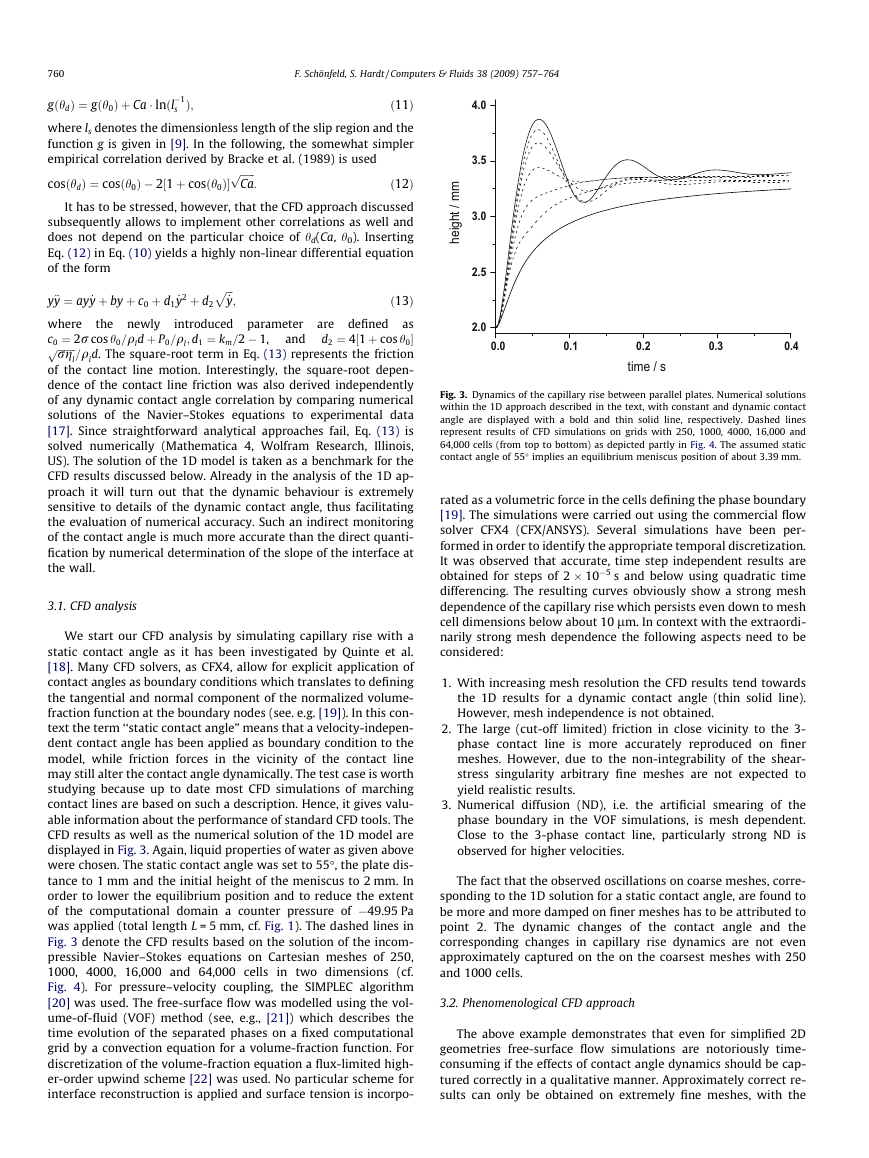

Fig. 4. Computational meshes used for the simulation of capillary filling as depicted in Fig. 3. The volume-fraction field is indicated in greyscales. The total number of grid

cells was varied from 5 � 50 to 80 � 800. Due to symmetry only half of the actual geometry (1 � 5 mm) was modelled in the simulations.

restriction that the numerical results are expected to become

meaningless again if the cell size goes to zero. Moreover, since

the computational time step is coupled to the cell sizes via the Cou-

rant number, extremely small time steps are needed leading alto-

gether to unsatisfactory performance for practical applications, e.g.

when the goal is to evaluate the performance of microfluidic sys-

tems. For illustration, the computation of the 2D capillary rise on

the finest mesh shown in Fig. 4 takes several days on a HP 9000/

J6000 workstation (800 MHz).

As in the case of turbulence simulations a phenomenological

approach suggests itself to model the microscopic physics on a

coarser scale. Somalinga and Bose, for example, showed that based

on an analytical calculation of the velocity field in a truncated do-

main so-called material boundary conditions can be applied to typ-

ical moving contact line problems [23]. Sikalo et al. used a related

method dividing the area near the contact line in an outer and in an

inner region. While the former was explicitly treated within a stan-

dard CFD approach, the latter falls within a single mesh cell and a

friction force is defined acting on the 3-phase contact line [24].

Here, we follow a similar approach suitable for a straightforward

implementation in standard CFD solvers. Assuming that the dy-

namic contact angle as a function of Ca is known, either from the-

oretical or from experimental data, it can be directly applied as a

boundary condition in the CFD simulation. In this case, however,

any further dynamic change of the contact angle which is partly

inherent in the CFD model has to be suppressed. The simplest

way to achieve this is to introduce artificial slip in a certain range

close to the 3-phase contact line [25,26]. In the slip region a van-

ishing shear rate, corresponding to an infinite slip length, is im-

posed as a boundary condition for the velocity field, i.e.

@ux

@y

ð14Þ

¼ 0;

where x and y denote the coordinates parallel and normal to the

surface. Note, in the present study the spatial dimension where

the slip boundary is applied is termed slip range. In contrast, the slip

length defines the length measured from the wall after which the

velocity extrapolates to zero. An infinite slip length is assumed in

the present study (cf. Eq. (14)).

The direct implementation of the Dynamic contact Angle with

Artificial Slip (DAAS) model has three major advantages: the stress

singularity is removed in the numerical model; dynamic changes

of the contact angle are captured via the implemented boundary

condition and the problem of ND is considerably reduced. Since

typical cell dimensions in practical simulations are far above real-

istic cut-off lengths (cf., e.g., [9]) the slip range is motivated by

practical instead of physical arguments.

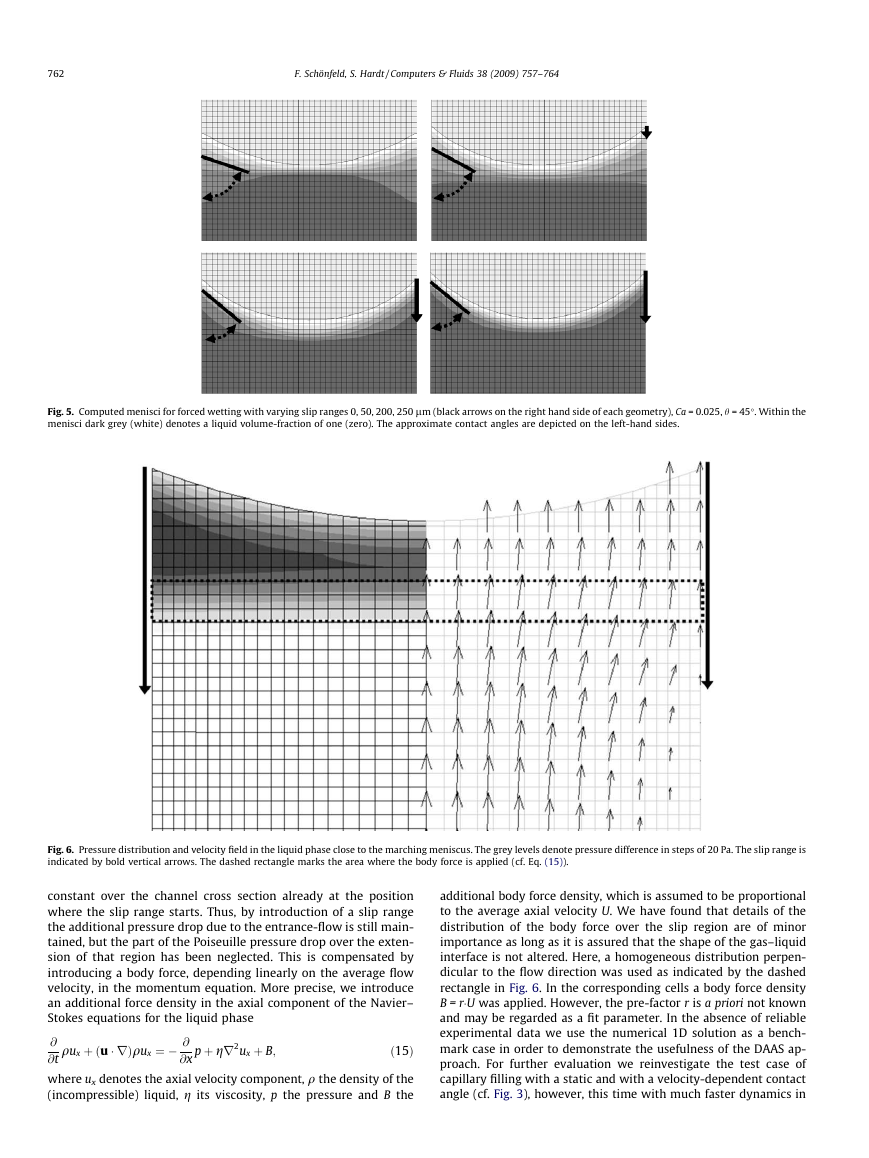

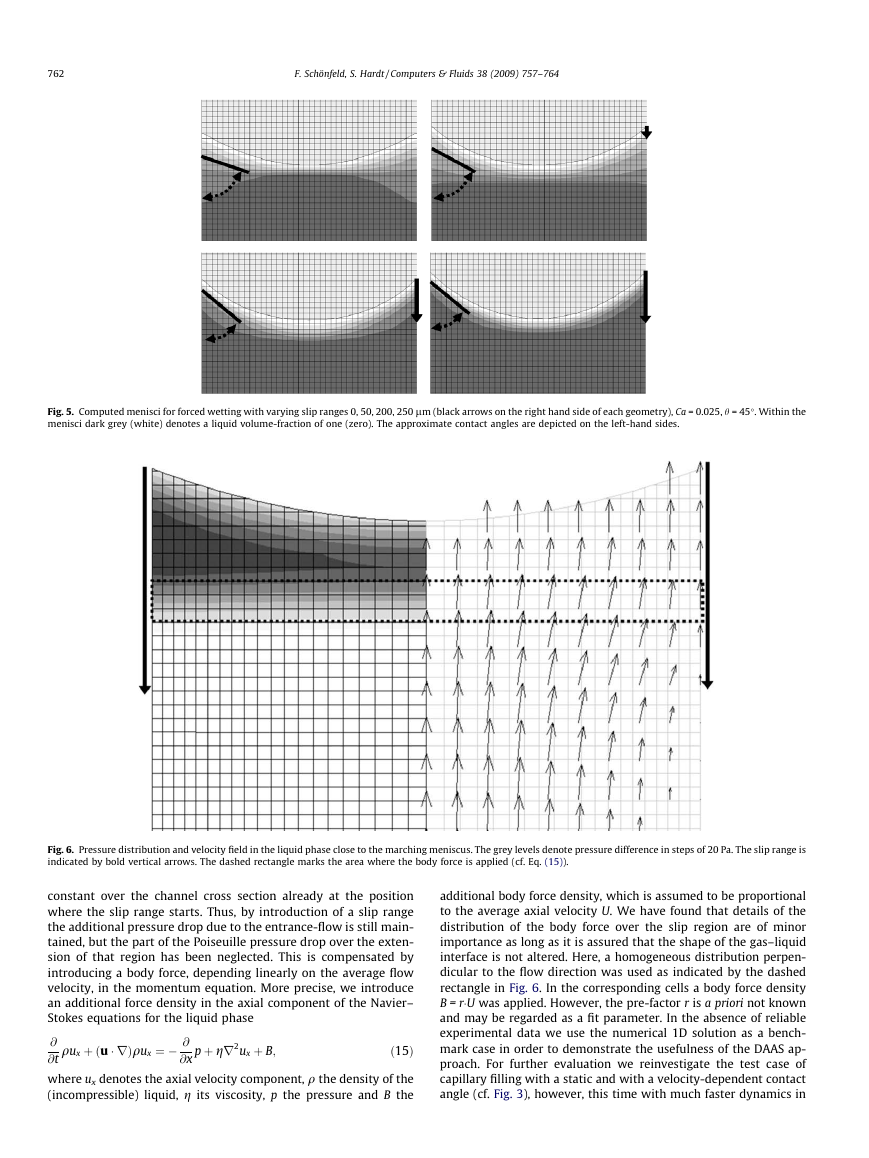

For a first analysis we consider the even simpler test case of

forced wetting, i.e. a meniscus is pushed with a constant velocity

between two parallel plates with a mutual distance of 1 mm. In or-

der to reduce the numerical effort, only one half of the geometry is

modelled in a co-moving frame of reference. A parabolic velocity

profile is set at the inlet (liquid side) and constant pressure is ap-

plied at the gas opening. The menisci shown in Fig. 5 have been

computed for a prescribed static contact angle of 45° and capillary

number of Ca = 0.025 which corresponds to a relative velocity wall/

meniscus of about 0.85 m/s. As can be seen in Fig. 5, the artificial

slip boundary condition has two main effects. The contact angle

found in the simulations is shifted towards the prescribed value

of 45° and interface smearing at the wall is considerably reduced

for increasing slip lengths. A more quantitative evaluation is pre-

sented in the following section where the resulting dynamics of

capillary filling is considered.

Although the overall velocity profile in the meniscus region is

only moderately affected by introducing a macroscopic slip range

(cf. Fig. 6) one has to bear in mind that the shear-stress is set to

zero along this portion of the wall in that way. In contrast to the

case of forced wetting where the neglected friction loss does not

necessarily imply relevant physical consequences it is crucial in

the case of capillary filling. The actual pressure drop in the slip

range comprises two components, the (cut-off limited) friction in

the close vicinity of the 3-phase contact line and the viscous dissi-

pation in the bulk far away from the meniscus. The former causes

the observed contact angle dynamics, i.e. the velocity-dependent

deviation of the contact angle from its equilibrium value and is

taken into account by applying the dynamic contact angle as a

boundary condition. The latter, i.e. the bulk viscous dissipation,

comprises a contribution of the fully developed Poiseuille profile

and an additional contribution due to the ‘‘entrance flow effect”

in the meniscus region. While the former shows a linear depen-

dence on the Reynolds number a quadratic dependence is found

in the latter case (cf. Eq. (9)). If an artificial slip range is introduced

in the simulation the entrance-flow field is found to be shifted

away from the meniscus, since the velocity becomes almost

�

762

F. Schönfeld, S. Hardt / Computers & Fluids 38 (2009) 757–764

Fig. 5. Computed menisci for forced wetting with varying slip ranges 0, 50, 200, 250 lm (black arrows on the right hand side of each geometry), Ca = 0.025, h = 45°. Within the

menisci dark grey (white) denotes a liquid volume-fraction of one (zero). The approximate contact angles are depicted on the left-hand sides.

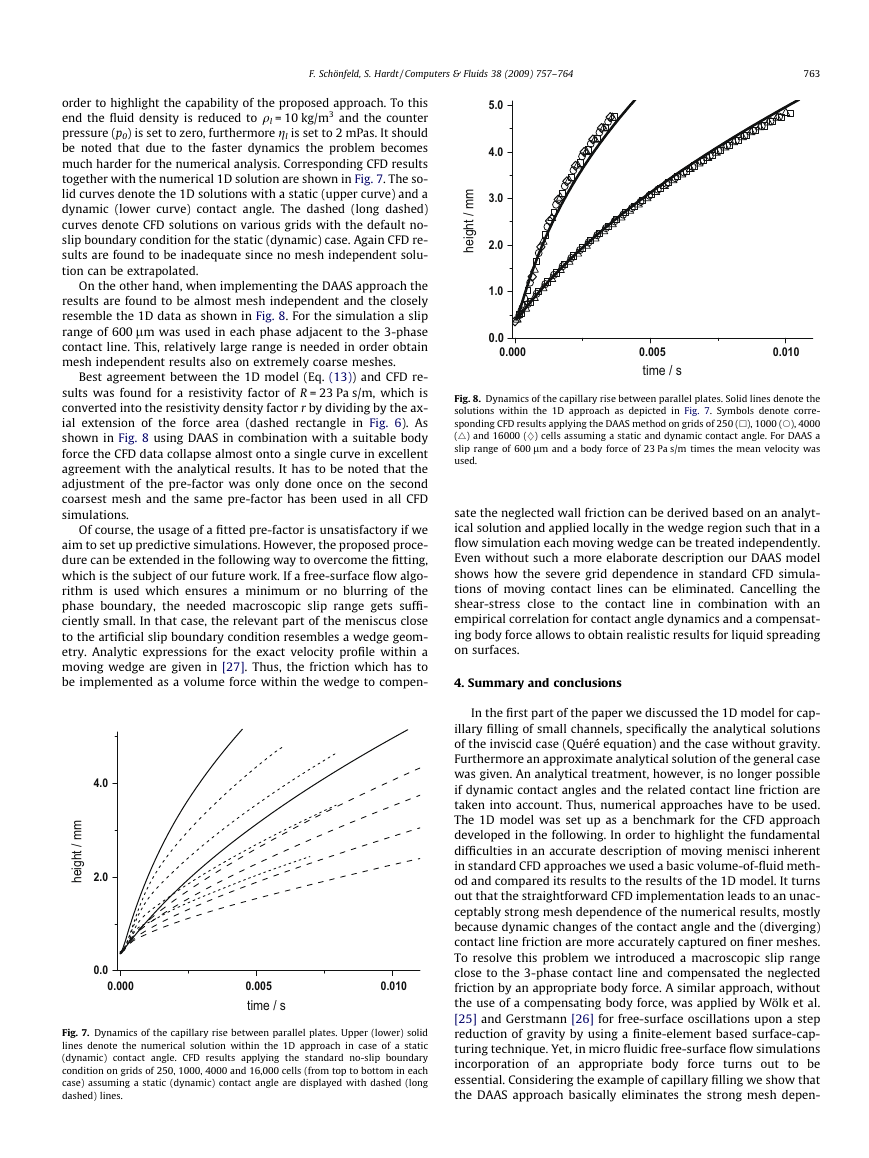

Fig. 6. Pressure distribution and velocity field in the liquid phase close to the marching meniscus. The grey levels denote pressure difference in steps of 20 Pa. The slip range is

indicated by bold vertical arrows. The dashed rectangle marks the area where the body force is applied (cf. Eq. (15)).

constant over the channel cross section already at the position

where the slip range starts. Thus, by introduction of a slip range

the additional pressure drop due to the entrance-flow is still main-

tained, but the part of the Poiseuille pressure drop over the exten-

sion of that region has been neglected. This is compensated by

introducing a body force, depending linearly on the average flow

velocity, in the momentum equation. More precise, we introduce

an additional force density in the axial component of the Navier–

Stokes equations for the liquid phase

qux þ ðu � rÞqux ¼ � @

@x

@

@t

where ux denotes the axial velocity component, q the density of the

(incompressible) liquid, g its viscosity, p the pressure and B the

p þ gr2ux þ B;

ð15Þ

additional body force density, which is assumed to be proportional

to the average axial velocity U. We have found that details of the

distribution of the body force over the slip region are of minor

importance as long as it is assured that the shape of the gas–liquid

interface is not altered. Here, a homogeneous distribution perpen-

dicular to the flow direction was used as indicated by the dashed

rectangle in Fig. 6. In the corresponding cells a body force density

B = r�U was applied. However, the pre-factor r is a priori not known

and may be regarded as a fit parameter. In the absence of reliable

experimental data we use the numerical 1D solution as a bench-

mark case in order to demonstrate the usefulness of the DAAS ap-

proach. For further evaluation we reinvestigate the test case of

capillary filling with a static and with a velocity-dependent contact

angle (cf. Fig. 3), however, this time with much faster dynamics in

�

F. Schönfeld, S. Hardt / Computers & Fluids 38 (2009) 757–764

763

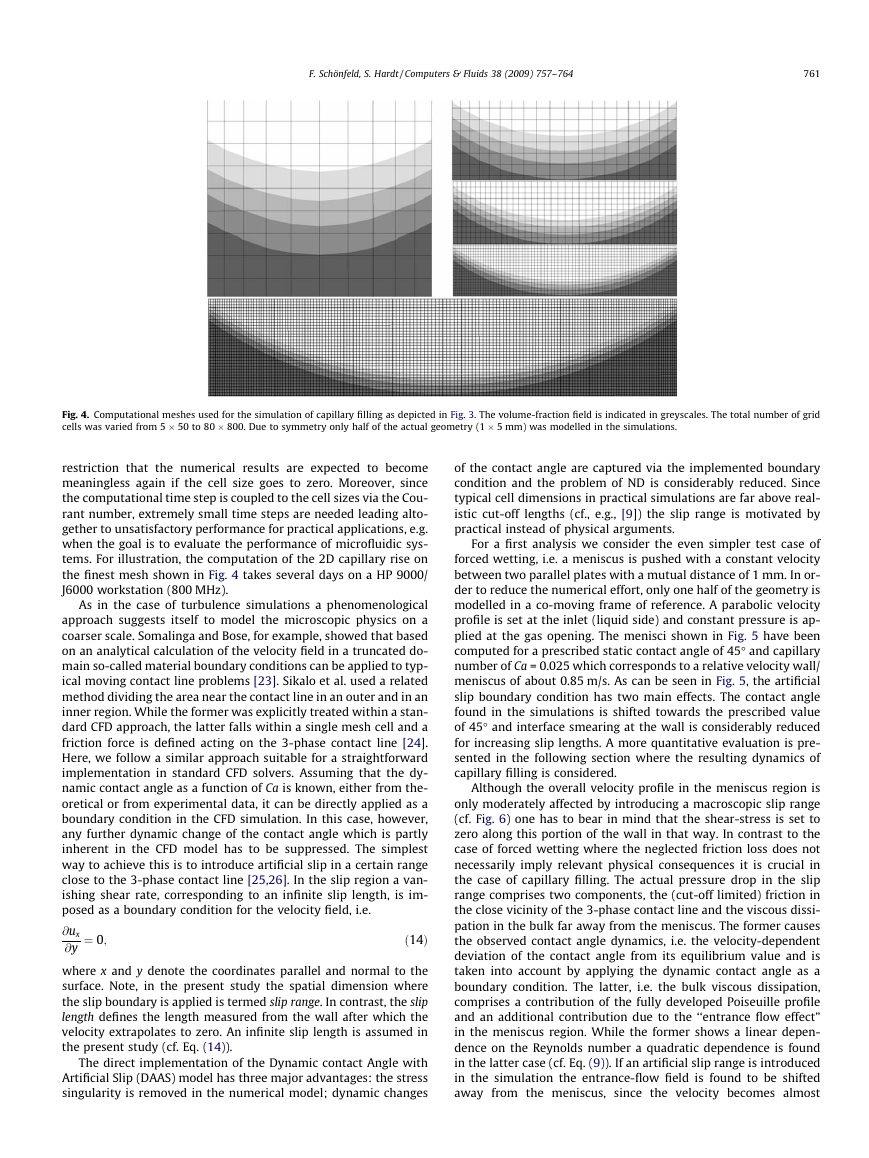

order to highlight the capability of the proposed approach. To this

end the fluid density is reduced to ql = 10 kg/m3 and the counter

pressure (p0) is set to zero, furthermore gl is set to 2 mPas. It should

be noted that due to the faster dynamics the problem becomes

much harder for the numerical analysis. Corresponding CFD results

together with the numerical 1D solution are shown in Fig. 7. The so-

lid curves denote the 1D solutions with a static (upper curve) and a

dynamic (lower curve) contact angle. The dashed (long dashed)

curves denote CFD solutions on various grids with the default no-

slip boundary condition for the static (dynamic) case. Again CFD re-

sults are found to be inadequate since no mesh independent solu-

tion can be extrapolated.

On the other hand, when implementing the DAAS approach the

results are found to be almost mesh independent and the closely

resemble the 1D data as shown in Fig. 8. For the simulation a slip

range of 600 lm was used in each phase adjacent to the 3-phase

contact line. This, relatively large range is needed in order obtain

mesh independent results also on extremely coarse meshes.

Best agreement between the 1D model (Eq. (13)) and CFD re-

sults was found for a resistivity factor of R = 23 Pa s/m, which is

converted into the resistivity density factor r by dividing by the ax-

ial extension of the force area (dashed rectangle in Fig. 6). As

shown in Fig. 8 using DAAS in combination with a suitable body

force the CFD data collapse almost onto a single curve in excellent

agreement with the analytical results. It has to be noted that the

adjustment of the pre-factor was only done once on the second

coarsest mesh and the same pre-factor has been used in all CFD

simulations.

Of course, the usage of a fitted pre-factor is unsatisfactory if we

aim to set up predictive simulations. However, the proposed proce-

dure can be extended in the following way to overcome the fitting,

which is the subject of our future work. If a free-surface flow algo-

rithm is used which ensures a minimum or no blurring of the

phase boundary, the needed macroscopic slip range gets suffi-

ciently small. In that case, the relevant part of the meniscus close

to the artificial slip boundary condition resembles a wedge geom-

etry. Analytic expressions for the exact velocity profile within a

moving wedge are given in [27]. Thus, the friction which has to

be implemented as a volume force within the wedge to compen-

4.0

2.0

m

m

/

t

h

g

e

h

i

0.0

0.000 0.005 0.010

time / s

Fig. 7. Dynamics of the capillary rise between parallel plates. Upper (lower) solid

lines denote the numerical solution within the 1D approach in case of a static

(dynamic) contact angle. CFD results applying the standard no-slip boundary

condition on grids of 250, 1000, 4000 and 16,000 cells (from top to bottom in each

case) assuming a static (dynamic) contact angle are displayed with dashed (long

dashed) lines.

5.0

4.0

3.0

2.0

1.0

m

m

/

t

h

g

e

h

i

0.0

0.000 0.005 0.010

time / s

Fig. 8. Dynamics of the capillary rise between parallel plates. Solid lines denote the

solutions within the 1D approach as depicted in Fig. 7. Symbols denote corre-

sponding CFD results applying the DAAS method on grids of 250 (h), 1000 (s), 4000

(4) and 16000 (}) cells assuming a static and dynamic contact angle. For DAAS a

slip range of 600 lm and a body force of 23 Pa s/m times the mean velocity was

used.

sate the neglected wall friction can be derived based on an analyt-

ical solution and applied locally in the wedge region such that in a

flow simulation each moving wedge can be treated independently.

Even without such a more elaborate description our DAAS model

shows how the severe grid dependence in standard CFD simula-

tions of moving contact lines can be eliminated. Cancelling the

shear-stress close to the contact line in combination with an

empirical correlation for contact angle dynamics and a compensat-

ing body force allows to obtain realistic results for liquid spreading

on surfaces.

4. Summary and conclusions

In the first part of the paper we discussed the 1D model for cap-

illary filling of small channels, specifically the analytical solutions

of the inviscid case (Quéré equation) and the case without gravity.

Furthermore an approximate analytical solution of the general case

was given. An analytical treatment, however, is no longer possible

if dynamic contact angles and the related contact line friction are

taken into account. Thus, numerical approaches have to be used.

The 1D model was set up as a benchmark for the CFD approach

developed in the following. In order to highlight the fundamental

difficulties in an accurate description of moving menisci inherent

in standard CFD approaches we used a basic volume-of-fluid meth-

od and compared its results to the results of the 1D model. It turns

out that the straightforward CFD implementation leads to an unac-

ceptably strong mesh dependence of the numerical results, mostly

because dynamic changes of the contact angle and the (diverging)

contact line friction are more accurately captured on finer meshes.

To resolve this problem we introduced a macroscopic slip range

close to the 3-phase contact line and compensated the neglected

friction by an appropriate body force. A similar approach, without

the use of a compensating body force, was applied by Wölk et al.

[25] and Gerstmann [26] for free-surface oscillations upon a step

reduction of gravity by using a finite-element based surface-cap-

turing technique. Yet, in micro fluidic free-surface flow simulations

incorporation of an appropriate body force turns out to be

essential. Considering the example of capillary filling we show that

the DAAS approach basically eliminates the strong mesh depen-

�

764

F. Schönfeld, S. Hardt / Computers & Fluids 38 (2009) 757–764

dence of CFD results for moving contact line problems. In other

words, the numerical results achieved on the coarsest mesh (250

cells) are almost indistinguishable from those computed on a finer

mesh with 64 times as much cells, while all of these data agree

well with the results of the 1D model. We believe that the pre-

sented approach shows a route to performing free-surface flow

CFD computations in micro fluidics with an accurate description

of contact angle dynamics and a reasonable use of CPU resources.

Moreover, the presented DAAS approach does not rely on the type

of numerical method for free-surface flow and can also be applied

in the context of, e.g., PLIC-VOF schemes [28], level-set schemes

[29] or interface-tracking techniques (see, e.g., [21]).

Clearly, more work needs to be done to corroborate the above

statements for arbitrary geometries and applications. The imple-

mentation of DAAS for 3D problems is in principle analogous to

the 2D example discussed above, since locally the pre-dominant

motion is 1D, perpendicular to the contact line. However, it re-

quires an efficient identification of the slip area close to the 3-

phase contact line which could be done based on the gradient of

the volume-fraction function. Moreover, in 3D and for complex

geometries the definition of a suitable body force compensating

for the neglected viscous friction will be less straightforward. A

possibility to obtain this force without a fitting procedure would

be to resort to analytical solutions for the velocity field in a moving

wedge, such as given by Dussan [27].

Acknowledgements

The work has been supported by the DFG-Forschergruppe FOR

516/1 and by the German Ministry of Research and Education,

Grant No. 16SV1355.

References

[1] Hessel V, Hardt S, Löwe H. Chemical micro process engineering: fundamentals,

modelling and reactions. Weinheim: Wiley-VCH; 2004.

[2] Reyes DR, Iossifidis D, Auroux PA, Manz A. Micro total analysis systems. 1.

Introduction, theory, and technology. Anal Chem 2002;74:2623–36.

[3] Auroux PA, Iossifidis D, Reyes DR, Manz A. Micro total analysis systems. 2.

Analytical standard operations and applications. Anal Chem 2002;74:2637–52.

[4] Huh C, Scriven LE. Hydrodynamic model of steady movement of a solid/liquid/

fluid contact line. J Colloid Interface Sci 1971;35:85–101.

[5] Hocking LM. A moving fluid interface. Part 2. The removal of the force

singularity by a slip flow. J Fluid Mech 1977;79:209–29.

[6] Huh C, Mason SG. The steady movement of a liquid meniscus in a capillary

tube. J Fluid Mech 1977;81:401–19.

[7] Kistler S. Hydrodynamics of wetting. In: Wettability S, Berg JC, editors. New

York: Dekker; 1993.

[8] De Gennes PG. Wetting: statics and dynamics. Rev Mod Phys 1985;57:827–63.

[9] Cox RG. The dynamics of the spreading of liquids on a solid surface. Part 1.

Viscous flow. J Fluid Mech 1986;168:169–94.

[10] Levine S, Reed P, Watson EJ, Neale G. A theory of the rate of rise of a liquid in a

capillary. In: Kerker M, editor. Colloid and interface science, vol. III. New

York: Academic Press; 1976. p. 403–19.

[11] Lucas R. Über das Zeitgesetz des Kapillaren Aufstiegs von Flussigkeiten. Kolloid

Z 1918;23:15–21.

[12] Washburn E. The dynamics of capillary flow. Phys Rev 1921;17:273–83.

[13] Zhmud BV, Tiberg F, Hallstensson K. Dynamics of capillary rise. J Colloid

Interface Sci 2000;228:263–9.

[14] Lundgren TS, Sparrow EM, Starr JB. Pressure drop due to the entrance region in

ducts of arbitrary cross section. J Basic Eng 1964;86:620–6.

[15] Tanner LH. The spreading of silicone oil drops on horizontal surfaces. J Phys D:

Appl Phys 1979;12:1473–84.

[16] Bracke M, de Voeght F, Joos P. The kinetics of wetting: the dynamic contact

angle. Prog Colloid Polym Sci 1989;79:142–9.

[17] Zhou MY, Sheng P. Dynamics of immiscible-fluid displacement in a capillary

tube. Phys Rev Lett 1990;64:882–5.

[18] Quinte A, Halstenberg S, Eggert H, Peters RP, Schön C. Mikrosystemtechnische

Realisierung von medizinischen Teststreifen, Proceedings 8. Workshop,

Methoden und Werkzeuge zum Entwurf von Mikrosystemen‘‘, Berlin,

December 2–3, 1999;13–22.

[19] Brackbill JU, Kothe DB, Zemach C. A continuum method for modeling surface

tension. J Comp Phys 1992;100:335–54.

[20] Van Doormal

JP, Raithby GD. Enhancements of the SIMPLE method for

predicting incompressible fluid flows. Numer Heat Transfer 1984;7:

147–63.

[21] Ferziger JH, Peric M. Computational methods for fluid dynamics. 3rd

ed. Heidelberg: Springer; 2002.

[22] Van Leer B. Towards the ultimate conservative difference scheme. A second

order Sequel to Godunov’s Method. J Comp Phys 1979;32:101–36.

[23] Somalinga S, Bose A. Numerical investigation of boundary conditions for

moving contact line problems. Phys Fluids 2000;12:499–510.

[24] Sikalo S, Wilhelm H-D, Roisman IV, Jakirlic S, Tropea C. Dynamic contact angle

of spreading droplets: Experiments and simulations. Phys Fluids 2005;17:

0621031–13.

[25] Wölk G, Dreyer M, Rath HJ, Weislogel MM. Damped oscillations of liquid/gas

surface upon step reduction in gravity. J Spacecraft Rockets 1997;34(1):

110–7.

[26] Gerstmann

zur

J. Numerische Untersuchungen

freier

Flüssigkeitsoberflächen. Ph.D. Thesis, Fortschritt-Berichte VDI 7, 2004; 464,

ISBN 3-18-346407-1.

Schwingung

[27] Dussan EB. The moving contact line: the slip boundary condition. J. Fluid Mech

1976;77:665–84.

[28] Rider WJ, Kothe DB. Reconstructing volume tracking.

J Comp Phys

1998;141:112–52.

[29] Osher S, Sethian JA. Fronts propagating with curvature-dependent speed:

J Comp Phys

formulations.

algorithms based on Hamilton–Jacobi

1988;79:12–49.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc