Battery Energy Storage Systems and Electric Vehicles Power Systems

A New Battery Model for use with

H.L. Chan, D. Sutanto

Department of Electrical Engineering,

The Hong Kong Polytechnic University,

Hung Hom. Hong Kong.

FCZX : (852) 2330-1514

eesritantG3ii)oolvu edu hk

Abstract: This paper will initially present a review of the several

battery models used for Electric Vehicles and Battery Energy Storage

System applications. A model will be discussed which takes into

account the non-linear characteristics of the battery with respect to

the battery’s state of charge. Comparisons between simulation and

laboratory measurements will be presented. The effects of high

frequency switching on the battery performance will also be

discussed. A strategy to reduce the high frequency charging and

discharging curre‘nt will be proposed.

Keywords: Battery Model, Battery Energy Storage Systems, Electric

Vehicles, Battery Management.

I. INTRODUCTION

The development of electric vehicle has been accelerated by

the recent “California Initiative” which has required increasing

proportions of new vehicles in Los Angeles area to be Zero

Emission vehicles. Similar legislation has now been passed in

several other US states. This has impelled car manufacturers

throughout the world to have Electric Vehicles ready for the

market when the legislation is enforced. General Motors, for

example, has recently released the new EV 1 in USA. The

possibility of large amounts of Electric Vehicles on the road,

has also created interest in making better use of the spare

batteries that each Electric Vehicle must have. It has been

suggested that a Battery Charging station be made available by

the electric utilities, so that cars can come into the charging

station and have they batteries replaced in a short time.

While extensive research has been carried out to develop new

types of batteriks and converters to convert the batteries output

into useful work, very little work has been done in modeling

the battery itself. The fact that most power converters are now

switched at relatively very high frequency (much higher than

50Hz), will require new model of the batteries to take into

account the operation of the battery under this high switching

mode. This paper will initially present the current state-of-the

art of battery modeling for use in Electric Vehicles and Battery

Energy Storage System. A new model will be introduced

which takes into account the response of the batteries to high

frequency switching in the converter. Impact of battery

chargers will be also be discussed. Comparisons between

simulation and laboratory measurements will be presented.

Some of the issues that will be considered are given below.

11. FACTORS DETERMINING BATTERY CAPACITY

To have better performance of EV, the energy utilization of

battery capacity must be ensured. The following factors are

critical to determine battery capacity and must be considered

in any battery model:

1. Internal Resistance

Self-discharge Resistance which takes account of

resistances in (a) electrolysis of water at high voltage

and (b) slow leakage across the battery terminal at low

voltage. This resistance is more temperature-sensitive

and inversely proportional to the temperature change.

Resistances for Charge and Discharge: These are the

resistances associated with electrolyte resistance, plates

resistance and fluid resistance, however all these

resistances can be different

in charging and

discharging.

Overcharge and Overdischarge Resistance: When the

battery is overcharged or overdischarged, the internal

resistance will be increased significantly due to the

electrolyte diffusion.

2. Discharge Type:

- _

-

Continuous Discharging: When battery continuously

delivers energy to load without rest, and the battery

capacity is dropping continuously.

Intermittent Discharging: When a battery drives a load

for a period and is disconnected from the load for some

time, then voltage recovery will be took place in the

battery to increase its voltage with some amount. When

the battery is operating in this intermittent manner, it

will give a longer discharge time.

3. Discharge Mode:

Constant Load: When a battery delivers energy to a

load of constant resistance, so the load current is

decreasing as battery voltage does.

Constant Current: Current drawn from a battery is kept

constant to a load that continuously reduces its

resistance, the discharge duration in this mode is

shorter due to the average current is higher. The

voltage drops more faster than that in constant load.

Constant Power: A constant electrical power is drawn

by load from a battery, such that the load current will

be increasing to compensate for the decreasing battery

voltage. This mode has the shortest discharge time.

0-7803-5935-6/00/$10.00 (c) 2000 IEEE

470

�

4. Rate of Charge/Discharge: To extend the service life of

battery the rate of charge and discharge can not be too

high. Excessive overcharging and over-discharging can

reduce battery life. Further, the frequency of switching

needs to be taken into account, particularly now when the

EV or BESS batteries are subjected to high switching

frequency associated with the converters in the control

system.

111. BATTERY MODEL

In the following section, six battery models will be described

briefly. One of these is found to be simple and yet represents

many of the important features of the EV batteries.

A. Simple Battery Model

This model has been used by many battery manufacturers for

battery monitoring purposes.

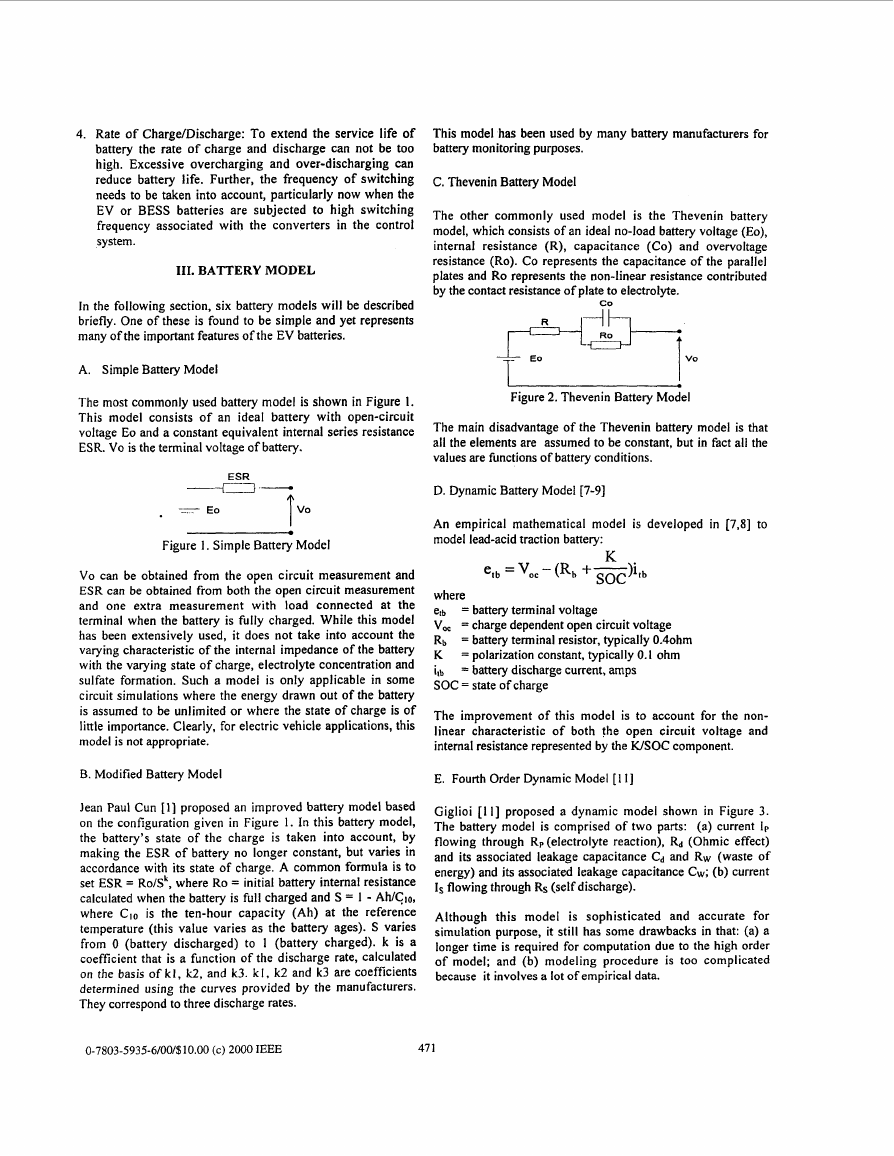

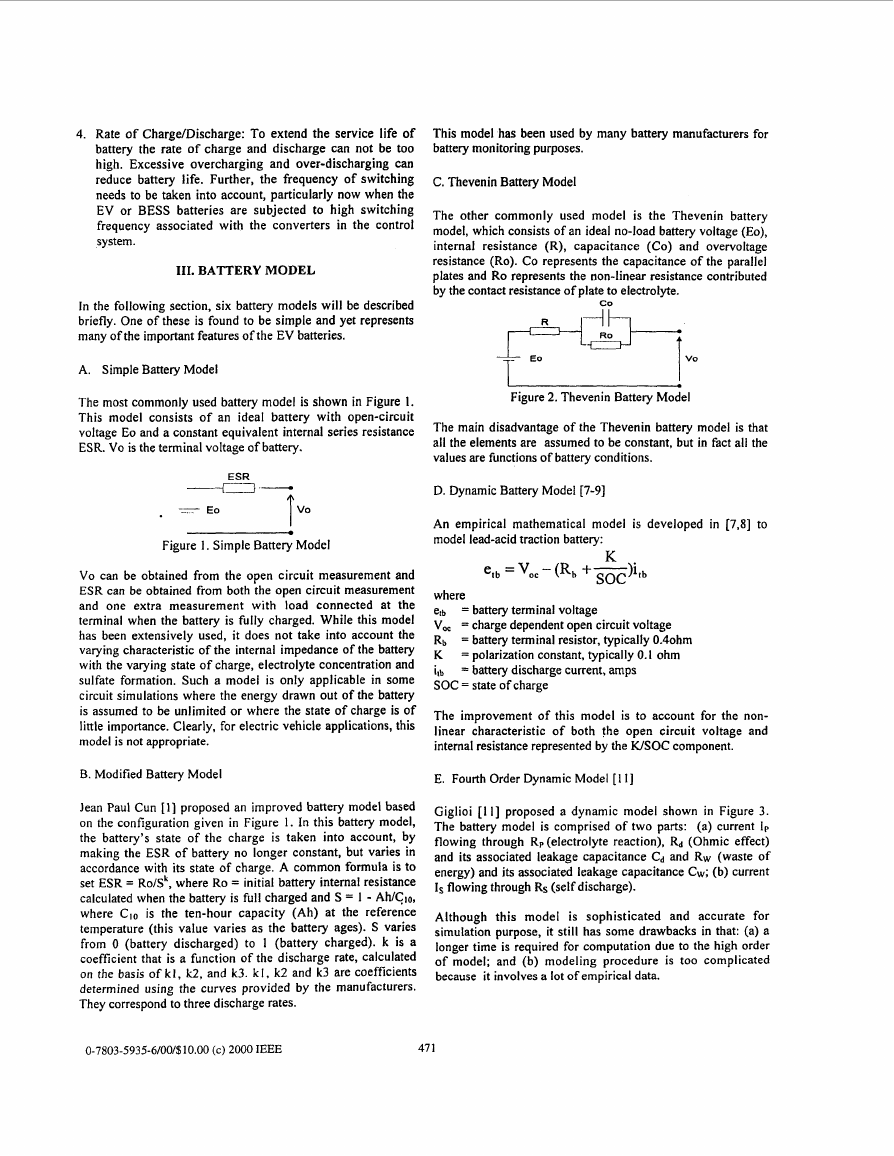

C. Thevenin Battery Model

The other commonly used model is the Thevenin battery

model, which consists of an ideal no-load battery voltage (Eo),

internal resistance (R), capacitance (CO) and overvoltage

resistance (Ro). CO represents the capacitance of the parallel

plates and Ro represents the non-linear resistance contributed

by the contact resistance of plate to electrolyte.

CO

I

"O

The most commonly used battery model is shown in Figure 1.

This model consists of an ideal battery with open-circuit

voltage Eo and a constant equivalent internal series resistance

ESR. Vo is the terminal voltage of battery.

Figure 2. Thevenin Battery Model

The main disadvantage of the Thevenin battery model is that

all the elements are assumed to be constant, but in fact all the

values are functions of battery conditions.

ESR

'--i.-4

--

Eo

I

v0

Figure I . Simple Battery Model

0

Vo can be obtained from the open circuit measurement and

ESR can be obtained from both the open circuit measurement

and one extra measurement with load connected at the

terminal when the battery is fully charged. While this model

has been extensively used, it does not take into account the

varying characteristic of the internal impedance of the battery

with the varying state of charge, electrolyte concentration and

sulfate formation. Such a model is only applicable in some

circuit simulations where the energy drawn out of the battery

is assumed to be unlimited or where the state of charge is of

little importance. Clearly, for electric vehicle applications, this

model is not appropriate.

B. Modified Battery Model

Jean Paul Cun [I] proposed an improved battery model based

on the configuration given in Figure 1. In this battery model,

the battery's state of the charge is taken into account, by

making the ESR of battery no longer constant, but varies in

accordance with its state of charge. A common formula is to

set ESR = Ro/Sk, where Ro = initial battery internal resistance

calculated when the battery is full charged and S = 1 - Ah/Clo,

where Clo is the ten-hour capacity (Ah) at the reference

temperature (this value varies as the battery ages). S varies

from 0 (battery discharged) to 1 (battery charged). k is a

coefficient that is a function of the discharge rate, calculated

on the basis of kl, k2, and k3. kl. k2 and k3 are coefficients

determined using the curves provided by the manufacturers.

They correspond to three discharge rates.

D. Dynamic Battery Model [7-91

An empirical mathematical model is developed in [7,8] to

model lead-acid traction battery:

K

e t b = - (Rb +=litb

= charge dependent open circuit voltage

where

etb = battery terminal voltage

V,

RI, = battery terminal resistor, typically OAohm

K = polarization constant, typically 0.1 ohm

i,b = battery discharge current, amps

SOC = state of charge

The improvement of this model is to account for the non-

linear characteristic of both the open circuit voltage and

internal resistance represented by the WSOC component.

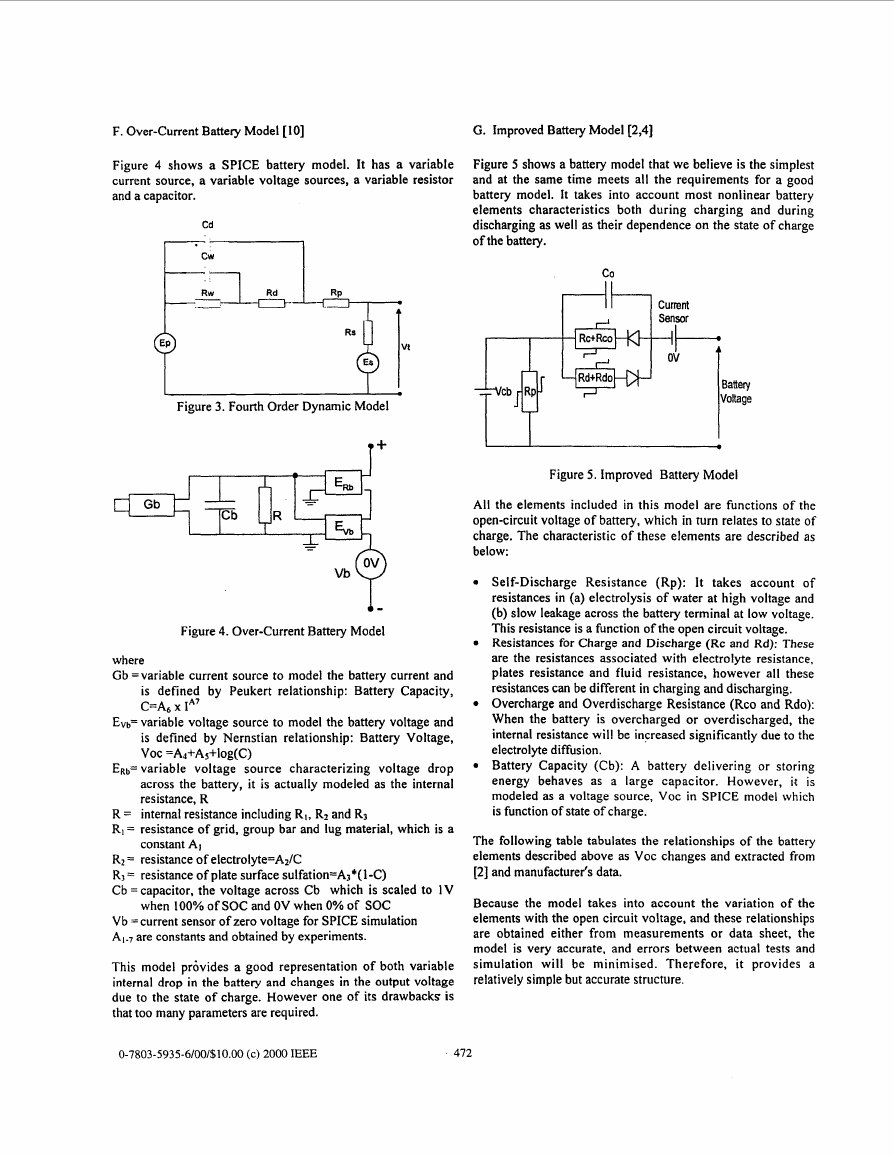

E. Fourth Order Dynamic Model [ 1 I]

Giglioi [I I] proposed a dynamic model shown in Figure 3.

The battery model is comprised of two parts: (a) current Ip

flowing through RP (electrolyte reaction), Rd (Ohmic effect)

and its associated leakage capacitance Ca and RW (waste of

energy) and its associated leakage capacitance CW; (b) current

Is flowing through RS (self discharge).

Although this model is sophisticated and accurate for

simulation purpose, it still has some drawbacks in that: (a) a

longer time is required for computation due to the high order

of model; and (b) modeling procedure is too complicated

because it involves a lot of empirical data.

0-7803-5935-6/00/$10.00 (c) 2000 IEEE

47 1

�

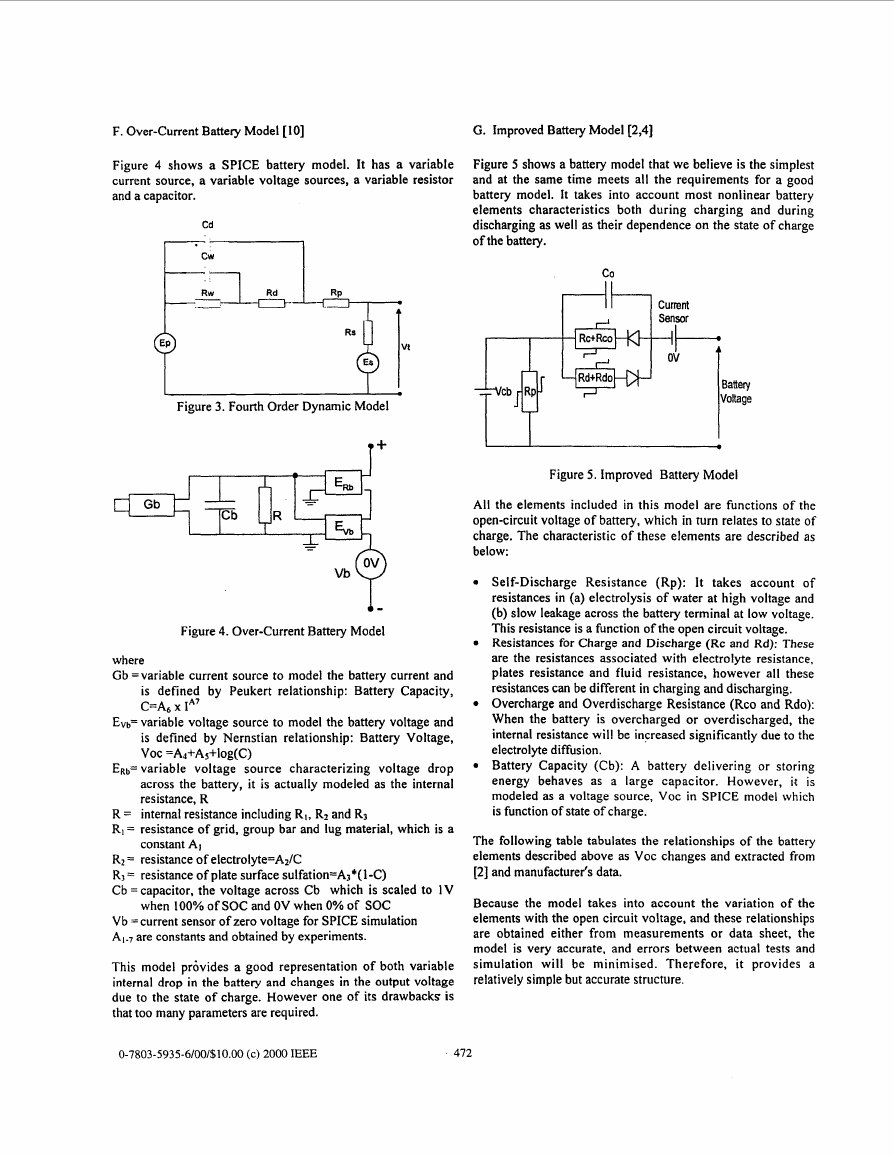

F. Over-Current Battery Model [IO]

G. Improved Battery Model [2,4]

Figure 4 shows a SPICE battery model. It has a variable

current source, a variable voltage sources, a variable resistor

and a capacitor.

Figure 5 shows a battery model that we believe is the simplest

and at the same time meets all the requirements for a good

battery model. It takes into account most nonlinear battery

elements characteristics both during charging and during

discharging as well as their dependence on the state of charge

of the battery. fiji

Current

Sensor

L

Figure 3. Fourth Order Dynamic Model

I

.

I

I

1

'

2

Battery

Voltage

Gb

t+ - I

T J E m L

* -

Y

Evb A

vb

4-

Figure 4. Over-Current Battery Model

where

Gb =variable current source to model the battery current and

is defined by Peukert relationship: Battery Capacity,

C = A ~ x I*'

EVb= variable voltage source to model the battery voltage and

is defined by Nernstian relationship: Battery Voltage,

VOC =Ad+As+log(C)

ERI,= variable voltage source characterizing voltage drop

across the battery, it is actually modeled as the internal

resistance, R

constant AI

R = internal resistance including RI, R2 and Rs

RI = resistance of grid, group bar and lug material, which is a

R2 = resistance of electrolyte=Az/C

R3 = resistance of plate surface sulfation=AJ*(l-C)

Cb =capacitor, the voltage across Cb which is scaled to 1V

when 100% of SOC and OV when 0% of SOC

Vb =current sensor of zero voltage for SPICE simulation

A,-, are constants and obtained by experiments.

This model provides a good representation of both variable

internal drop in the battery and changes in the output voltage

due to the state of charge. However one of its drawbacks is

that too many parameters are required.

Figure 5 . Improved Battery Model

All the elements included in this model are functions of the

open-circuit voltage of battery, which in turn relates to state of

charge. The characteristic of these elements are described as

below:

Self-Discharge Resistance (Rp): It takes account of

resistances in (a) electrolysis of water at high voltage and

(b) slow leakage across the battery terminal at low voltage.

This resistance is a function of the open circuit voltage.

Resistances for Charge and Discharge (Rc and Rd): These

are the resistances associated with electrolyte resistance,

plates resistance and fluid resistance, however all these

resistances can be different in charging and discharging.

Overcharge and Overdischarge Resistance (Rco and Rdo):

When the battery is overcharged or overdischarged, the

internal resistance will be increased significantly due to the

electrolyte diffusion.

Battery Capacity (Cb): A battery delivering or storing

energy behaves as a large capacitor. However, it i s

modeled as a voltage source, VOC in SPICE model which

is function of state of charge.

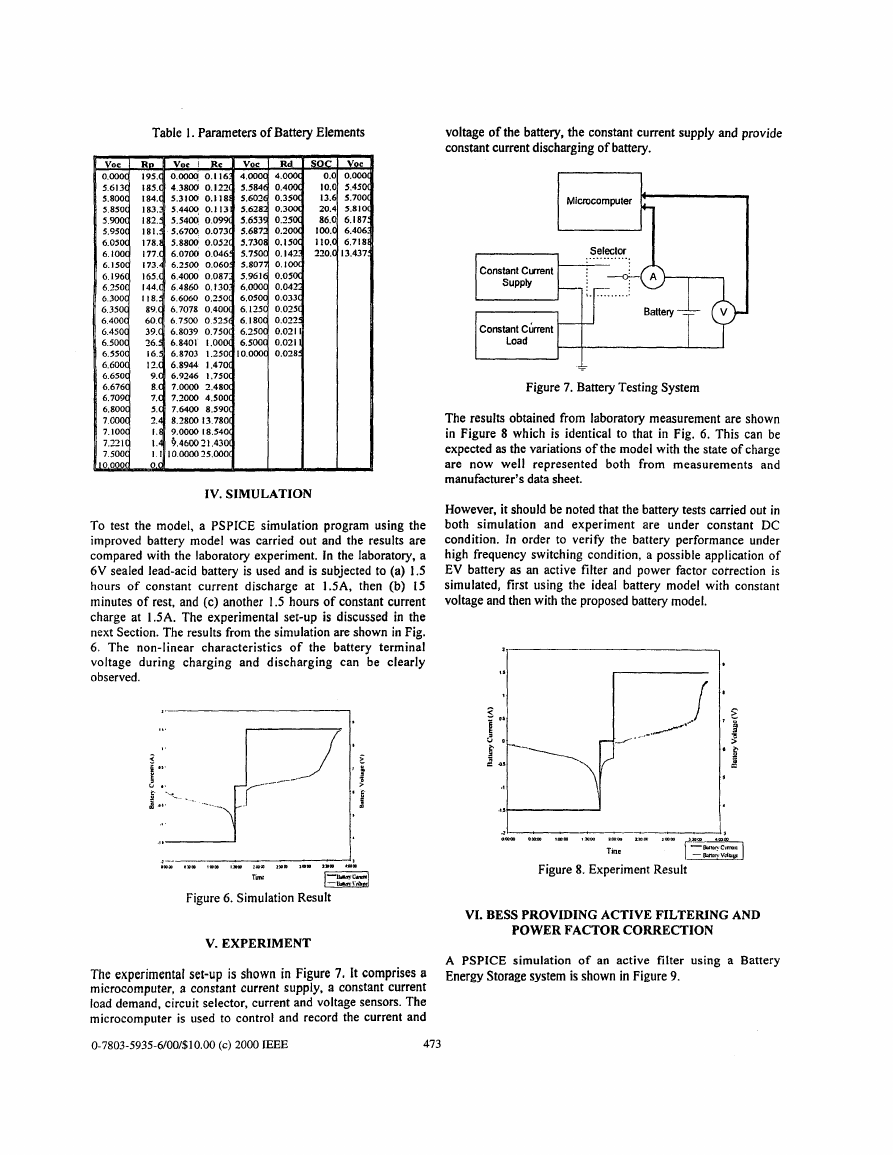

The following table tabulates the relationships of the battery

elements described above as VOC changes and extracted from

[2] and manufacturer's data.

Because the model takes into account the variation of the

elements with the open circuit voltage. and these relationships

are obtained either from measurements or data sheet, the

model is very accurate, and errors between actual tests and

simulation will be minimised. Therefore, it provides a

relatively simple but accurate structure.

0-7803-5935-6/00/$10.00 (c) 2000 IEEE

47 2

�

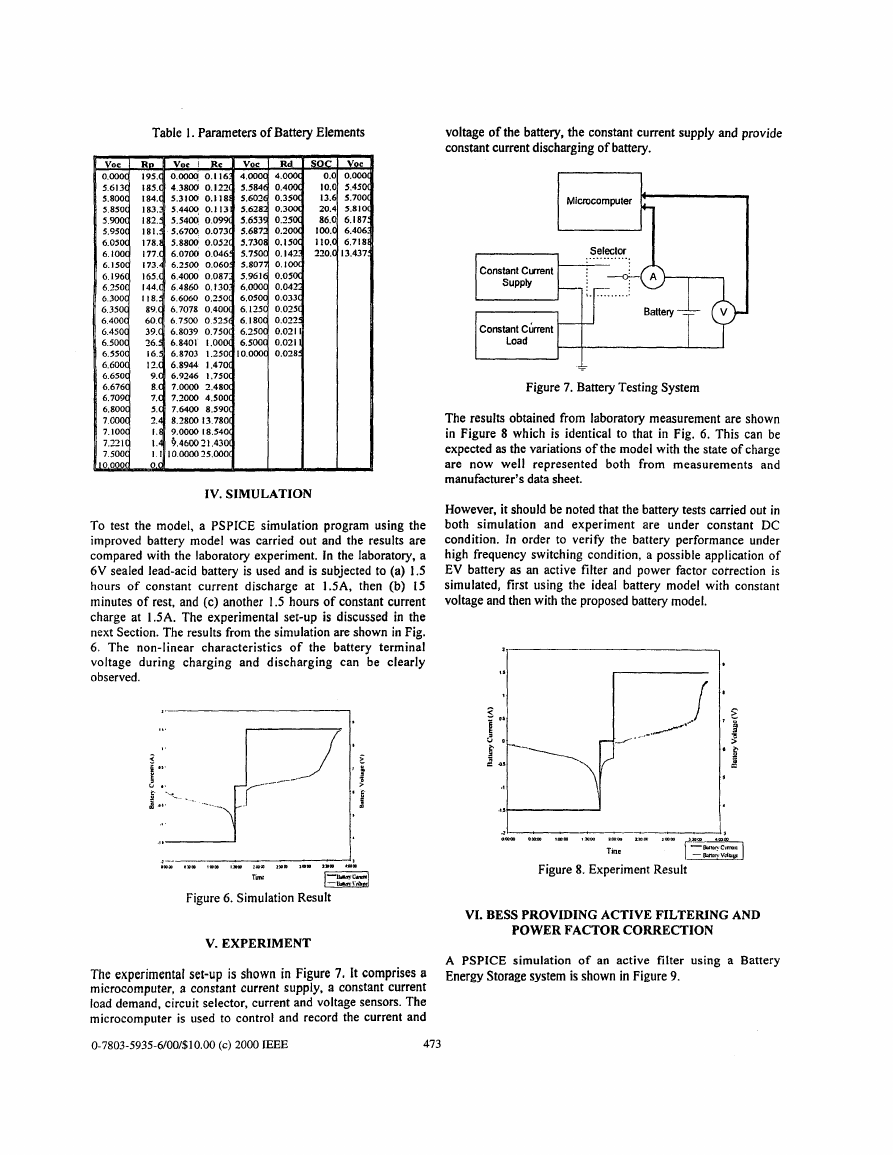

Table I. Parameters of Battery Elements -

voc I Rp n voc I Rc I voc I Rd I soc,

O.OOoc(

195.d O.OO@ 0.1164 4.0000( 4 . 0 4

0.d

3%

0.000

5.450

5.700

5.8 IO

6. I87

6.406

6.718

3.437

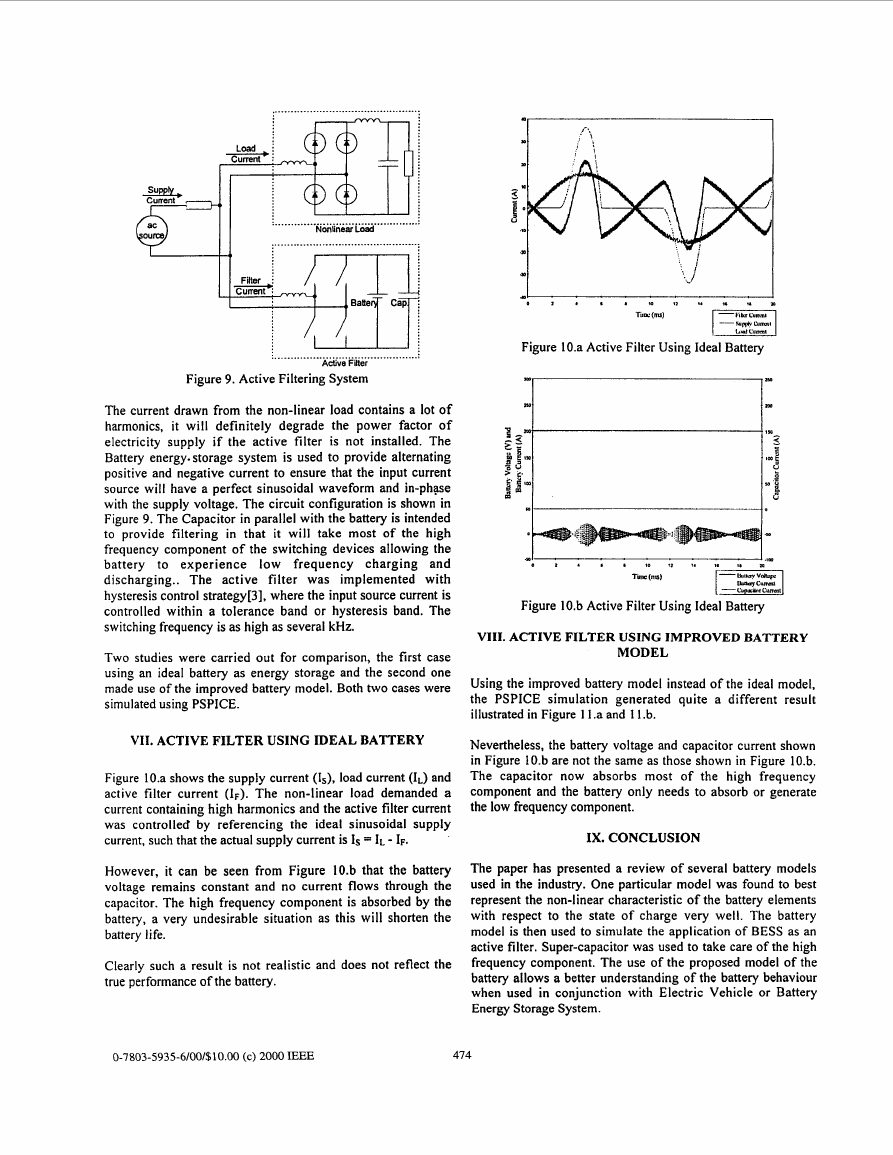

voltage of the battery, the constant current supply and provide

constant current discharging of battery.

Microcomputer m

,

Load

i [ . l ..........

Constant Chent

,

Figure 7. Battery Testing System

--

The results obtained from laboratory measurement are shown

in Figure 8 which is identical to that in Fig. 6. This can be

expected as the variations of the model with the state of charge

are now well represented both from measurements and

manufacturer's data sheet.

However, it should be noted that the battery tests carried out in

both simulation and experiment are under constant DC

condition. in order to verify the battery performance under

high frequency switching condition, a possible application of

EV battery as an active filter and power factor correction is

simulated, first using the ideal battery model with constant

voltage and then withthe proposed battery model.

'I

*mm

0"

,mm I"

*"

2"

Tine

Figure 8. Experiment Result

VI. BESS PROVIDING ACTIVE FILTERING AND

POWER FACTOR CORRECTION

A PSPICE simulation of an active filter using a Battery

Energy Storage system is shown in Figure 9.

poood

0.d

I

I

IV. SIMULATION

To test the model, a PSPICE simulation program using the

improved battery model was carried out and the results are

compared with the laboratory experiment. In the laboratory, a

6V sealed lead-acid battery is used and is subjected to (a) 1.5

hours of constant current discharge at 1.5A. then (b) 15

minutes of rest, and (c) another 1.5 hours of constant current

charge at 1.5A. The experimental set-up is discussed in the

next Section. The results from the simulation are shown in Fig.

6. The non-linear characteristics of the battery terminal

voltage during charging and discharging can be clearly

observed.

1.

V. EXPERIMENT

The experimental set-up is shown in Figure 7. It comprises a

microcomputer, a constant current supply. a constant current

load demand, circuit selector, current and voltage sensors. The

microcomputer is used to control and record the current and

0-7803-5935-6/00/$10.00 (c) 2000 IEEE

473

�

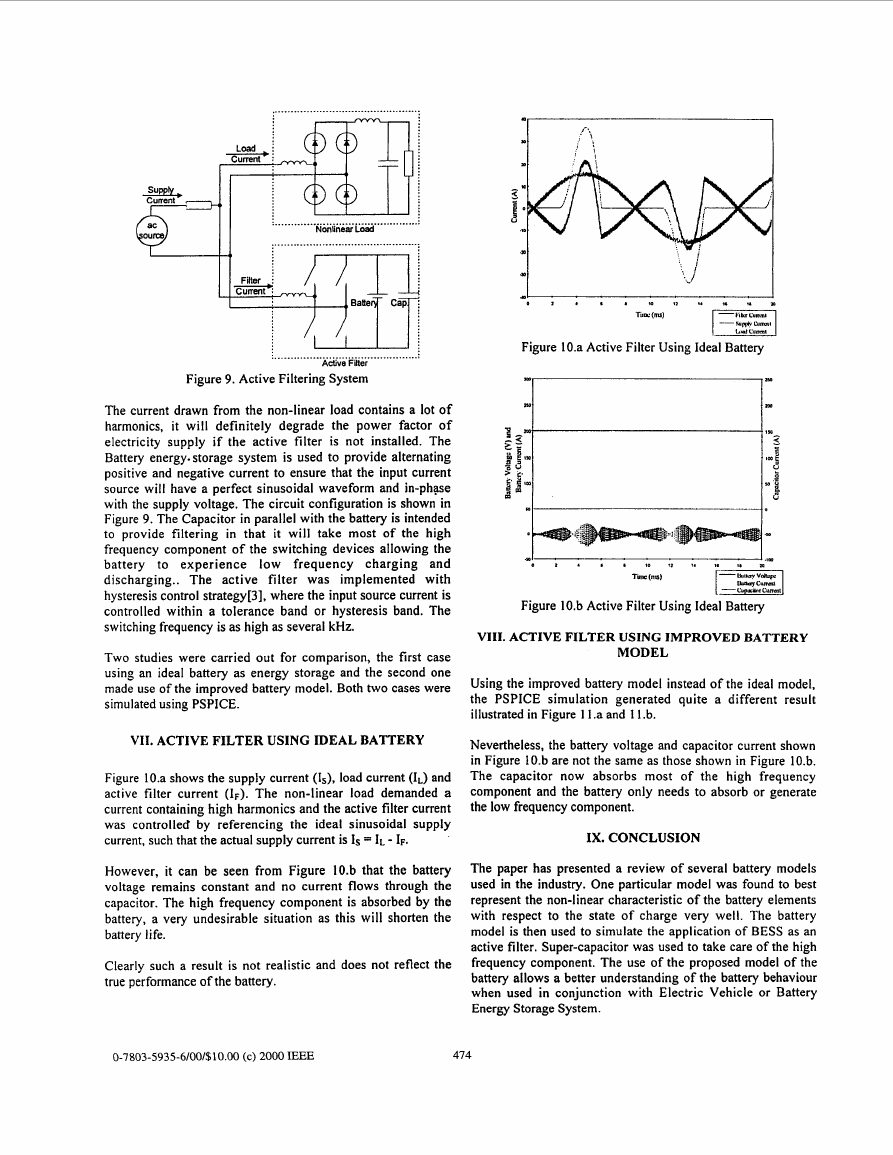

..............................................

Active Filter

Figure 9. Active Filtering System

8

The current drawn from the non-linear load contains a lot of

harmonics, it will definitely degrade the power factor of

electricity supply if the active filter is not installed. The

Battery energy. storage system is used to provide alternating

positive and negative current to ensure that the input current

source will have a perfect sinusoidal waveform and in-phase

with the supply voltage. The circuit configuration is shown in

Figure 9. The Capacitor in parallel with the battery is intended

to provide filtering in that it will take most of the high

frequency component of the switching devices allowing the

battery

low frequency charging and

discharging.. The active filter was implemented with

hysteresis control strategy[3], where the input source current is

controlled within a tolerance band or hysteresis band. The

switching frequency is as high as several kHz.

to experience

Two studies were carried out for comparison, the first case

using an ideal battery as energy storage and the second one

made use of the improved battery model. Both two cases were

simulated using PSPICE.

VII. ACTIVE FILTER USING IDEAL BATTERY

Figure 10.a shows the supply current (Is),

load current (IL) and

active filter current (IF). The non-linear load demanded a

current containing high harmonics and the active filter current

was controlled by referencing the ideal sinusoidal supply

current, such that the actual supply current is IS = I t - IF.

However, it can be seen from Figure 1O.b that the battery

voltage remains constant and no current flows through the

capacitor. The high frequency component is absorbed by the

battery, a very undesirable situation as this will shorten the

battery life.

Clearly such a result is not realistic and does not reflect the

true performance of the battery.

0

I

.

' I

,

0

1

,

*

.

Tim (nu)

Figure 10.a Active Filter Using Ideal Battery

I

. ' I

4 1

0

2

Tinu! (nu)

I

4

------+

Figure 10.b Active Filter Using Ideal Battery

VJII. ACTIVE FILTER USING IMPROVED BATTERY

MODEL

Using the improved battery model instead of the ideal model,

the PSPICE simulation generated quite a different result

illustrated in Figure 1 1 .a and 1 1 .b.

Nevertheless, the battery voltage and capacitor current shown

in Figure 10.b are not the same as those shown in Figure 10.b.

The capacitor now absorbs most of the high frequency

component and the battery only needs to absorb or generate

the low frequency component.

IX. CONCLUSION

The paper has presented a review of several battery models

used in the industry. One particular model was found to best

represent the non-linear characteristic of the battery elements

with respect to the state of charge very well. The battery

model is then used to simulate the application of BESS as an

active filter. Super-capacitor was used to take care of the high

frequency component. The use of the proposed model of the

battery allows a better understanding of the battery behaviour

when used in conjunction with Electric Vehicle or Battery

Energy Storage System.

0-7803-5935-6/001$10.00 (c) 2000 IEEE

474

�

Ziyad M. Salameh, Margaret A. Casacca and William

A. Lynch, "A Mathematical Model for Lead-Acid

Batteries", IEEE Trans. on Energy Conversion. Vol. 7,

No. 1, March 1992

C. E. Lin, M. T. Tsai, Y. S. Shiao and C. L. Huang,

"An Active Filter for Reactive and Harmonic

Compensation Using Voltage Source Inverter", IEE

Int'l Conference on Advances in Power System

Control, Operation and Management, November

199 1, Hong Kong.

Margaret A. Casacca and Ziyad M. Salameh,

"Determination of Lead-Acid Battery Capacity

Via Mathematical Modeling Techniques", IEEE

Trans. on Energy Conversion. Vol. 7, No. 3, Sept.

1992

"Rechargeable Batteries Applications Handbook",

TK294 I .R43 1991, Technical Marketing Staff of

Gates Energy Products, Inc.

David Linden, "Handbook of Batteries" Second

Edition, TK290 1 .H36 1994, McGraw-Hill, 1994

and Morgan, C., "A N e w

Jayne, M.G.,

Mathematical Model of a Lead Acid Battery for

Electric Vehicles", Eighth Int'l Electric Vehicle

Conference, Washington, D.C., October 1986.

Sims, R.I., Carnes, J.C., Dzieciuch, M.A. and

Fenton, J.E., "Computer Modeling of Automotive

Lead Acid Batteries", Ford Research Laboratories

Technical Report SR-90- 154, Sept., 25, I990

Jayanths, M.S., Hayhoe, G.F., and Henry, J.J.,

"Modeling and Digital Computer Simulation of an

Electric Vehicle", Technical Report, Pennsylvania

Transportation Institute, Pennsylvania State

University, University Park Pennsylvania, August,

1979.

Robbins, T.; Hawkins, J. "Battery model for

Overcurrent Protection Simulation of DC

Di s t r i but i o n System S",

INTEL E C . S i x t e e n t h

International Telecommunications Energy

Conference, p307- 14.

Giglioli R., Cerolo P., "Charge and Discharge Fourth

Order Dynamic Model of the Lead Battery", 10Ih Int'l

Electric Vehicle Symposium, Hong Kong, 1990, p. 1-9.

4

1

D

,

.

.

I

W

I

I

~

.

Tinw(mr)

I

[41

Figure 1 1 .a Active Filter Using Improved Model

The supply current, load current and filter current in Figure

10.a follows similar pattern as before.

rm-

i m

t-

.

,

0

2

4

2

,

.

7

6

m

*

T k (m)

r61

171

r81

[91

Figure 1 I .b Active Filter Using Improved Model

X. ACKNOWLEDGMENTS

The authors gratefully acknowledge the financial contributions

of the Hong Kong University Grants Committee and the Hong

Kong Polytechnic University to the project and to Mr. Jim

McDowall, Chair, PES Stationary Battery Committee for his

comments on the abstract of the paper.

XI. REFERENCES

[I]

Jean Paul CUN, Jean No FIORINA, Michael

FRAISSE, Henri MABBOUX, "The Experience of a

UPS Company in Advanced Battery Monitoring",

MGE UPS Systems, Grenoble, France,'http://www-

merlin-gerin.eunet.fr/news/techpap/tp02us.ht'

0-7803-5935-6/00/$10.00 (c) 2000 IEEE

475

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc