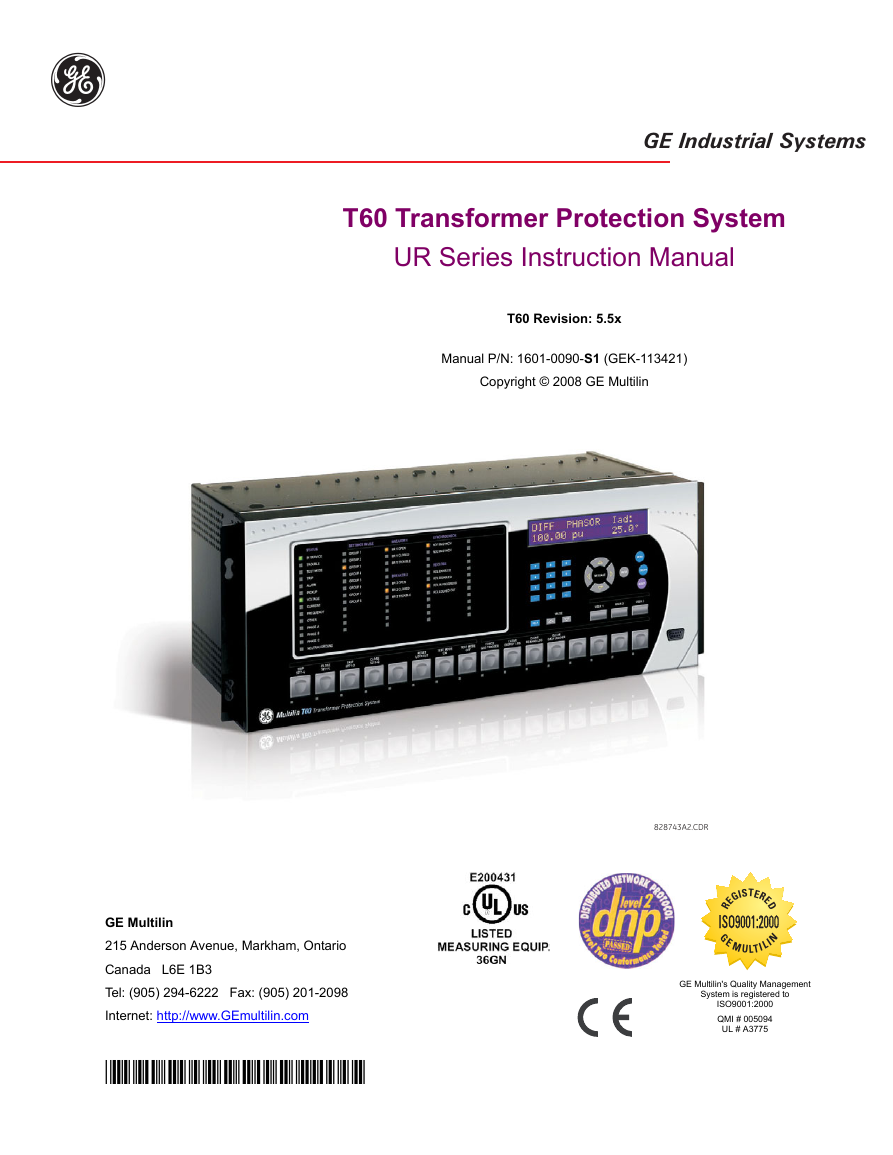

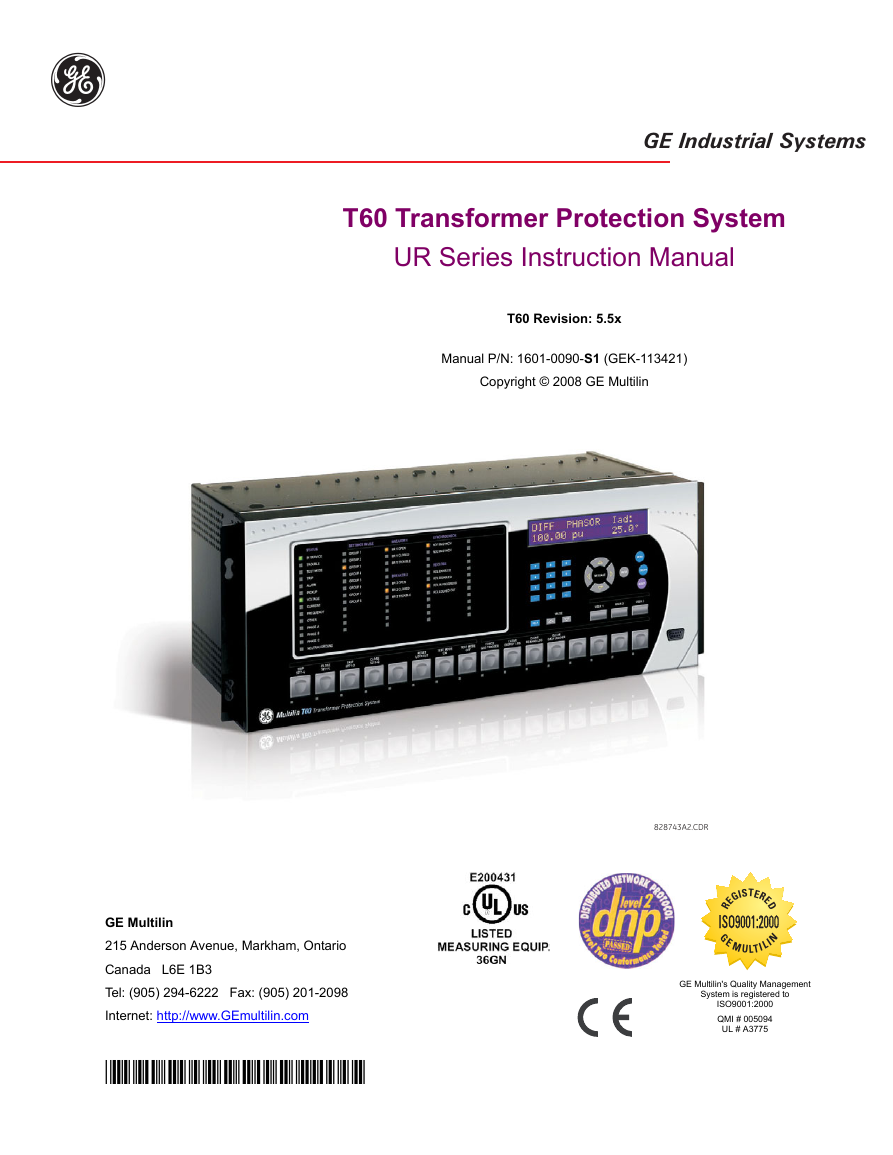

Title Page

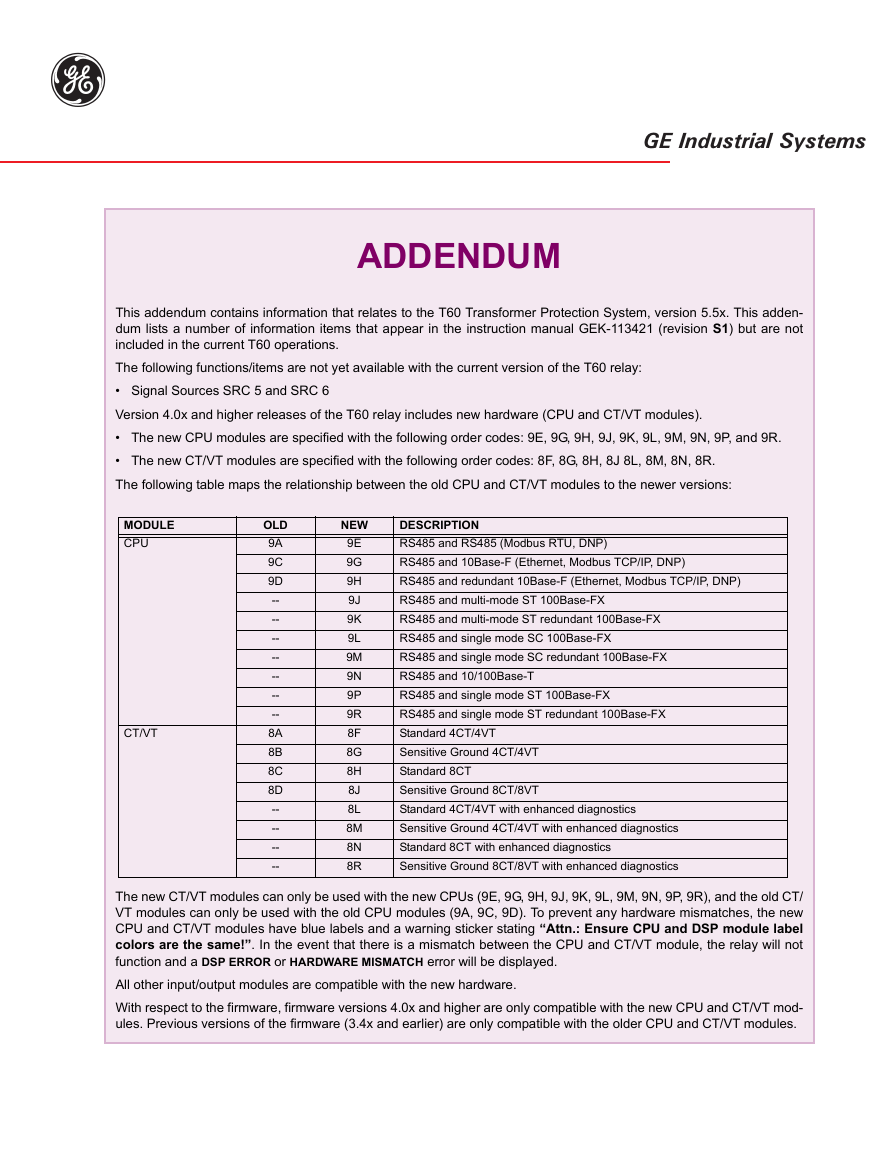

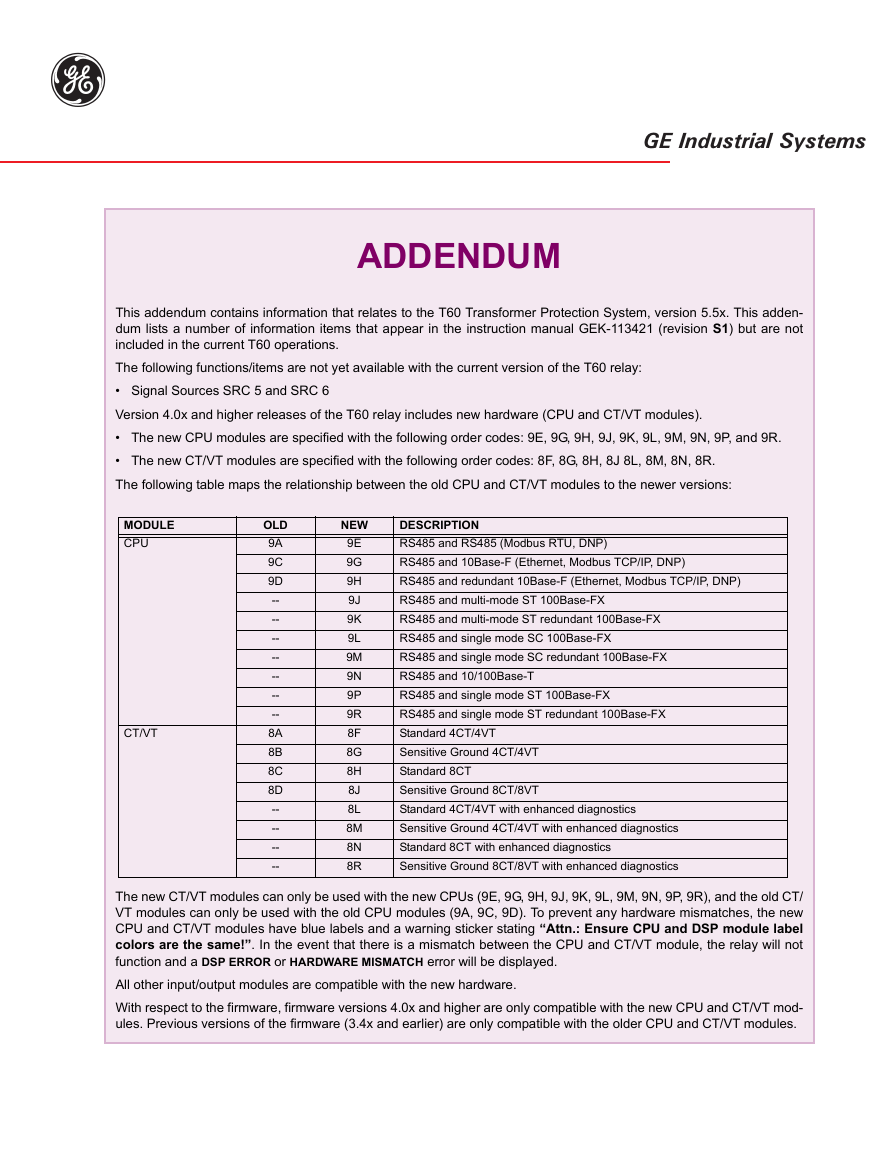

Addendum

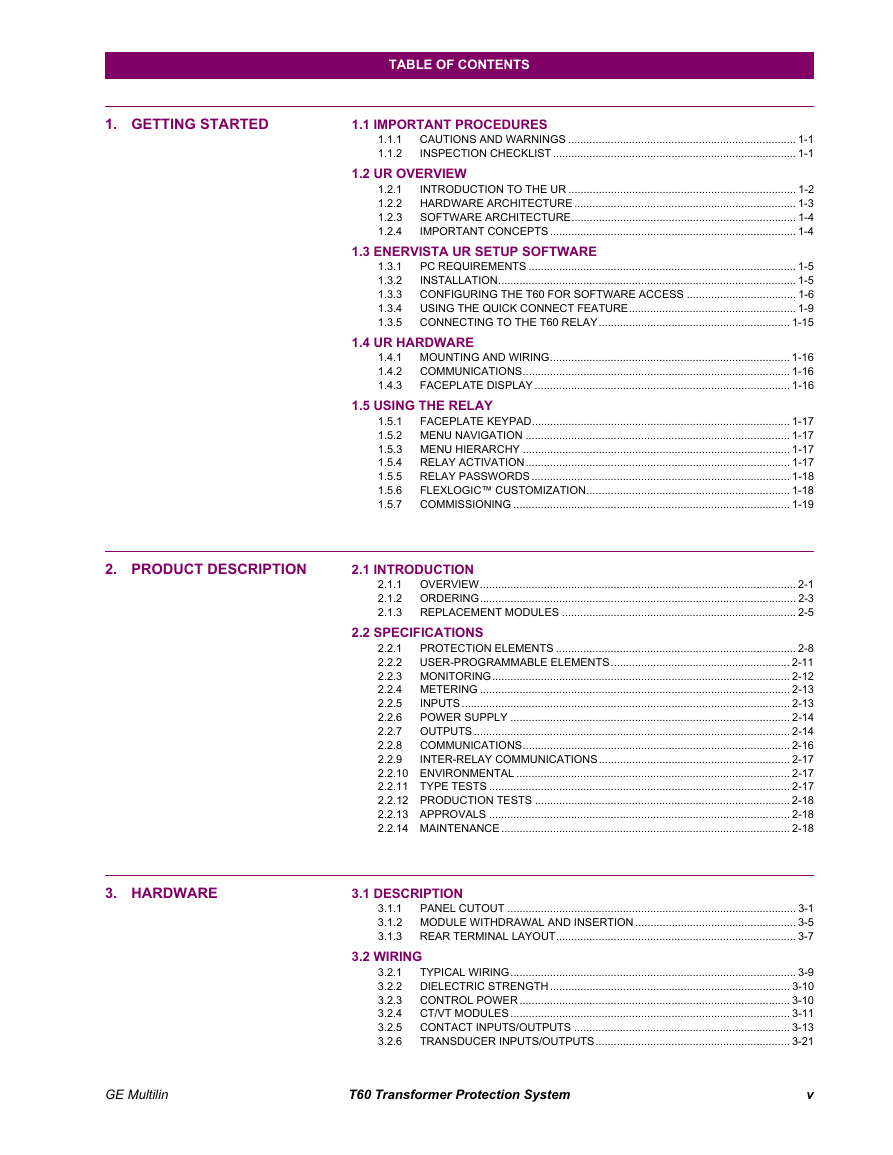

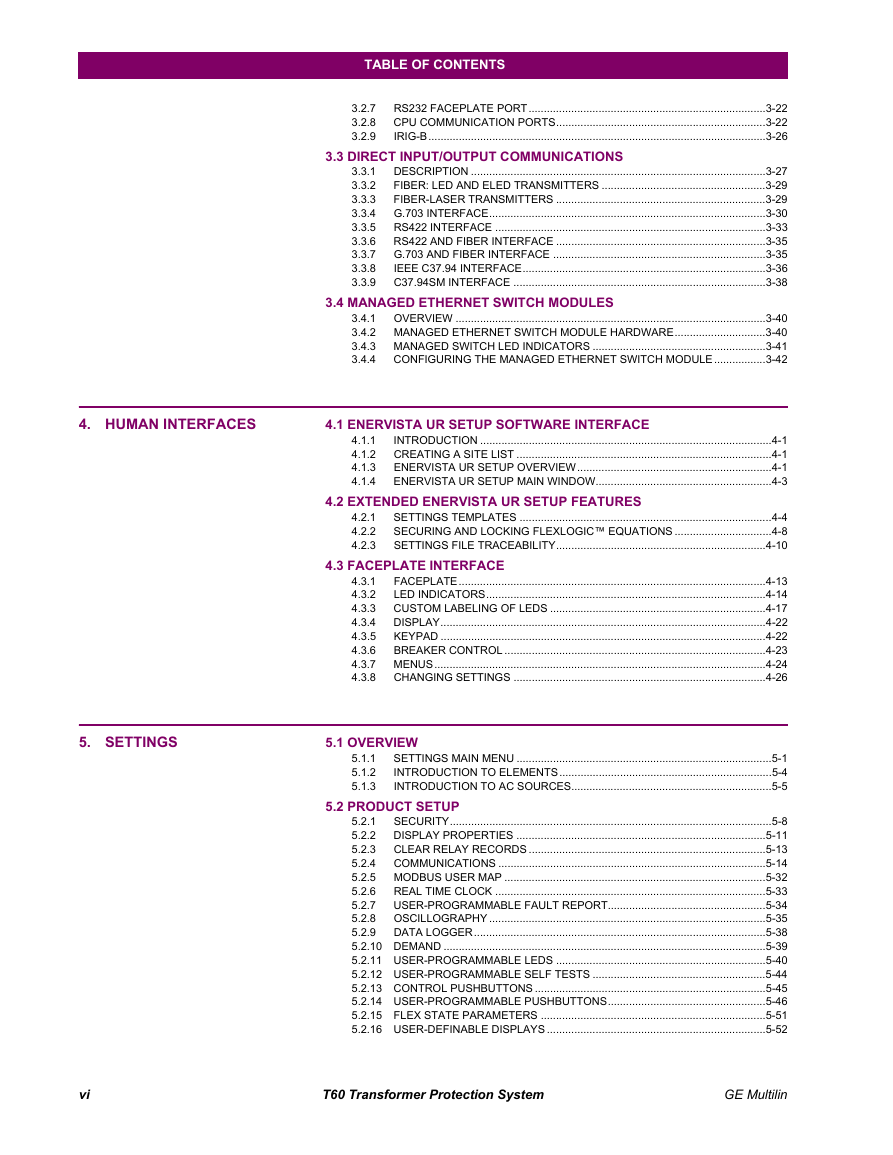

Table of Contents

Getting Started

Important Procedures

1.1.1 Cautions and Warnings

1.1.2 Inspection Checklist

UR Overview

1.2.1 Introduction to the UR

1.2.2 Hardware Architecture

a) UR Basic Design

b) UR Signal Types

c) UR Scan Operation

1.2.3 Software Architecture

1.2.4 Important Concepts

EnerVista UR Setup Software

1.3.1 PC Requirements

1.3.2 Installation

1.3.3 Configuring the T60 for Software Access

a) Overview

b) Configuring Serial Communications

c) Configuring Ethernet Communications

1.3.4 Using the Quick Connect Feature

a) Using Quick Connect via the Front Panel RS232 Port

b) Using Quick Connect via the Rear Ethernet Ports

1.3.5 Connecting to the T60 Relay

UR Hardware

1.4.1 Mounting and Wiring

1.4.2 Communications

1.4.3 Faceplate Display

Using the Relay

1.5.1 Faceplate Keypad

1.5.2 Menu Navigation

1.5.3 Menu Hierarchy

1.5.4 Relay Activation

1.5.5 Relay Passwords

1.5.6 FlexLogic™ Customization

1.5.7 Commissioning

Product Description

Introduction

2.1.1 Overview

2.1.2 Ordering

2.1.3 Replacement modules

Specifications

2.2.1 Protection Elements

2.2.2 User-Programmable Elements

2.2.3 Monitoring

2.2.4 Metering

2.2.5 Inputs

2.2.6 Power Supply

2.2.7 Outputs

2.2.8 Communications

2.2.9 Inter-Relay Communications

2.2.10 Environmental

2.2.11 Type Tests

2.2.12 Production Tests

2.2.13 Approvals

2.2.14 Maintenance

Hardware

Description

3.1.1 Panel Cutout

a) Horizontal Units

b) Vertical Units

3.1.2 Module Withdrawal and Insertion

3.1.3 Rear Terminal Layout

Wiring

3.2.1 Typical Wiring

3.2.2 Dielectric Strength

3.2.3 Control Power

3.2.4 CT/VT Modules

3.2.5 Contact Inputs/Outputs

3.2.6 Transducer Inputs/Outputs

3.2.7 RS232 Faceplate Port

3.2.8 CPU Communication Ports

a) Options

b) RS485 Ports

c) 10Base-FL and 100Base-FX Fiber Optic Ports

3.2.9 IRIG-B

Direct Input/Output Communications

3.3.1 Description

3.3.2 Fiber: LED and ELED Transmitters

3.3.3 Fiber-Laser Transmitters

3.3.4 G.703 Interface

a) Description

b) G.703 Selection Switch Procedures

c) G.703 Octet Timing

d) G.703 Timing Modes

e) G.703 Test Modes

3.3.5 RS422 Interface

a) Description

b) Two-channel Application via Multiplexers

c) Transmit Timing

d) Receive Timing

3.3.6 RS422 and Fiber Interface

3.3.7 G.703 and Fiber Interface

3.3.8 IEEE C37.94 Interface

3.3.9 C37.94SM Interface

Managed Ethernet Switch Modules

3.4.1 Overview

3.4.2 Managed Ethernet Switch Module Hardware

3.4.3 Managed Switch LED Indicators

3.4.4 Configuring the Managed Ethernet Switch Module

a) Configuring the Switch Module IP Settings

b) Saving the Ethernet Switch Settings to a Settings File

c) Uploding Ethernet Switch Settings Files to the Module

Human Interfaces

EnerVista UR Setup Software Interface

4.1.1 Introduction

4.1.2 Creating a Site List

4.1.3 EnerVista UR Setup Overview

a) Engaging a Device

b) Using Settings Files

c) Creating and Editing FlexLogic™

d) Viewing Actual Values

e) Viewing Triggered Events

f) File Support

g) Firmware Upgrades

4.1.4 EnerVista UR Setup Main Window

Extended EnerVista UR Setup Features

4.2.1 Settings Templates

a) Enabling the Settings Template

b) Editing the Settings Template

c) Adding Password Protection to a Template

d) Viewing the Settings Template

e) Removing the Settings Template

4.2.2 Securing and Locking FlexLogic™ Equations

a) Locking FlexLogic™ Equation Entries

b) Locking FlexLogic™ Equations to a Serial Number

4.2.3 Settings File Traceability

a) Settings File Traceability Information

b) Online Device Traceability Information

c) Additional Traceability Rules

Faceplate Interface

4.3.1 Faceplate

a) Enhanced Faceplate

b) Standard Faceplate

4.3.2 LED Indicators

a) Enhanced Faceplate

b) Standard Faceplate

4.3.3 Custom Labeling of LEDs

a) Enhanced Faceplate

b) Standard Faceplate

4.3.4 Display

4.3.5 Keypad

4.3.6 Breaker Control

a) Introduction

b) Control Mode Selection and Monitoring

c) Faceplate (User Key) Control

d) Control of Two Breakers

e) Control of One Breaker

4.3.7 Menus

a) Navigation

b) Hierarchy

c) Example Menu Navigation

4.3.8 Changing Settings

a) Entering Numerical Data

b) Entering Enumeration Data

c) Entering Alphanumeric Text

d) Activating the Relay

e) Entering Initial Passwords

f) Changing Existing Password

g) Invalid Password Entry

Settings

Overview

5.1.1 Settings Main Menu

5.1.2 Introduction to Elements

5.1.3 Introduction to AC Sources

a) Background

b) CT/VT Module Configuration

c) CT/VT Input Channel Configuration

Product Setup

5.2.1 Security

a) Main Menu

b) Local Passwords

c) Remote Passwords

d) Access Supervision

5.2.2 Display Properties

5.2.3 Clear Relay Records

5.2.4 Communications

a) Main Menu

b) Serial Ports

c) Network

d) Modbus Protocol

e) DNP Protocol

f) DNP / IEC 60870-5-104 Point Lists

g) IEC 61850 Protocol

h) Web Server HTTP Protocol

i) TFTP Protocol

j) IEC 60870-5-104 Protocol

k) SNTP Protocol

l) EGD Protocol

m) Ethernet Switch

5.2.5 Modbus User Map

5.2.6 Real Time Clock

5.2.7 User-Programmable Fault Report

5.2.8 Oscillography

a) Main Menu

b) Digital Channels

c) Analog Channels

5.2.9 Data Logger

5.2.10 Demand

5.2.11 User-Programmable LEDs

a) Main Menu

b) LED Test

c) Trip and Alarm LEDs

d) User-Programmable LED 1(48)

5.2.12 User-Programmable Self Tests

5.2.13 Control Pushbuttons

5.2.14 User-Programmable Pushbuttons

5.2.15 Flex State Parameters

5.2.16 User-Definable Displays

a) Main Menu

b) User Display 1(16)

5.2.17 Direct Inputs/Outputs

a) Main Menu

b) CRC Alarm 1(2)

c) Unreturned Messages Alarm 1(2)

5.2.18 Teleprotection

5.2.19 Installation

System Setup

5.3.1 AC Inputs

a) Current Banks

b) Voltage Banks

5.3.2 Power System

5.3.3 Signal Sources

5.3.4 Transformer

a) Main Menu

b) General Transformer Settings

c) Windings 1 to 4

d) Phase Relationships of Three-Phase Transformers

e) Magnitude Compensation

f) Phase and Zero Sequence Compensation

g) Magnitude, Phase Angle, and Zero Sequence Compensation

h) Differential and Restraint Current Calculations

i) Transformer Windings between Two Breakers

j) Transformer Thermal Inputs

5.3.5 Breakers

5.3.6 Disconnect Switches

5.3.7 FlexCurves™

a) Settings

b) FlexCurve™ Configuration with EnerVista UR Setup

c) Recloser Curve Editing

d) Example

e) Standard Recloser Curves

FlexLogic™

5.4.1 Introduction to FlexLogic™

5.4.2 FlexLogic™ Rules

5.4.3 FlexLogic™ Evaluation

5.4.4 FlexLogic™ Example

5.4.5 FlexLogic™ Equation Editor

5.4.6 FlexLogic™ Timers

5.4.7 FlexElements™

5.4.8 Non-Volatile Latches

Grouped Elements

5.5.1 Overview

5.5.2 Setting Group

5.5.3 Distance

a) Common Distance Settings

b) Phase Distance

c) Ground Distance

5.5.4 Power Swing Detect

5.5.5 Load Encroachment

5.5.6 Transformer Elements

a) Main Menu

b) Percent Differential

c) Instantaneous Differential

d) Hottest-Spot Temperature

e) Aging Factor

f) Loss of Life

5.5.7 Phase Current

a) Main Menu

b) Inverse TOC Characteristics

c) Phase Time Overcurrent

d) Phase Instantaneous Overcurrent

e) Phase Directional Overcurrent

5.5.8 Neutral Current

a) Main Menu

b) Neutral Time Overcurrent

c) Neutral Instantaneous Overcurrent

d) Neutral Directional Overcurrent

5.5.9 Ground Current

a) Main Menu

b) Ground Time Overcurrent

c) Ground Instantaneous Overcurrent

d) Restricted Ground Fault

5.5.10 Voltage Elements

a) Main Menu

b) Phase Undervoltage

c) Phase Overvoltage

d) Neutral Overvoltage

e) Auxiliary Undervoltage

f) Auxiliary Overvoltage

g) Volts Per Hertz

Control Elements

5.6.1 Overview

5.6.2 Setting Groups

5.6.3 Selector Switch

5.6.4 Underfrequency

5.6.5 Overfrequency

5.6.6 Synchrocheck

5.6.7 Digital Elements

5.6.8 Digital Counters

5.6.9 Monitoring Elements

a) Main Menu

b) Breaker Arcing Current

c) VT Fuse Failure

5.6.10 Trip Bus

Inputs/Outputs

5.7.1 Contact Inputs

5.7.2 Virtual Inputs

5.7.3 Contact Outputs

a) Digital Outputs

b) Latching Outputs

5.7.4 Virtual Outputs

5.7.5 Remote Devices

a) Remote Inputs/Outputs Overview

b) Local Devices: ID of Device for Transmitting GSSE Messages

c) Remote Devices - ID of Device for Receiving GSSE Messages

5.7.6 Remote Inputs

5.7.7 Remote Outputs

a) DNA Bit Pairs

b) UserSt Bit Pairs

5.7.8 Resetting

5.7.9 Direct Inputs/Outputs

a) Direct inputs

b) Direct outputs

c) Application examples

5.7.10 Teleprotection Inputs/Outputs

a) Overview

b) Teleprotection Inputs

c) Teleprotection Outputs

Transducer Inputs/Outputs

5.8.1 dcmA Inputs

5.8.2 RTD Inputs

5.8.3 dcmA Outputs

Testing

5.9.1 Test Mode

5.9.2 Force Contact Inputs

5.9.3 Force Contact Outputs

Actual Values

Overview

6.1.1 Actual Values Main Menu

Status

6.2.1 Contact Inputs

6.2.2 Virtual Inputs

6.2.3 Remote Inputs

6.2.4 Teleprotection Inputs

6.2.5 Contact Outputs

6.2.6 Virtual Outputs

6.2.7 Remote Devices

a) Status

b) Statistics

6.2.8 Digital Counters

6.2.9 Selector Switches

6.2.10 Flex States

6.2.11 Ethernet

6.2.12 Direct Inputs

6.2.13 Direct Devices Status

6.2.14 EGD Protocol Status

a) Fast Exchange

b) Slow Exchange

6.2.15 Teleprotection Channel Tests

6.2.16 Ethernet Switch

Metering

6.3.1 Metering Conventions

a) Power and Energy

b) Phase Angles

c) Symmetrical Components

6.3.2 Transformer

a) Differential and Restraint Currents

b) Thermal Elements

6.3.3 Sources

a) Main Menu

b) Phase current metering

c) Ground current metering

d) Phase voltage metering

e) Auxiliary voltage metering

f) Power metering

g) Energy metering

h) Demand metering

i) Frequency metering

j) Current harmonics and THD metering

6.3.4 Synchrocheck

6.3.5 Tracking Frequency

6.3.6 FlexElements™

6.3.7 IEC 61580 GOOSE Analog Values

6.3.8 Volts Per Hertz

6.3.9 Restricted Ground Fault

6.3.10 Transducer Inputs/Outputs

Records

6.4.1 User-Programmable Fault Reports

6.4.2 Event Records

6.4.3 Oscillography

6.4.4 Data Logger

6.4.5 Breaker Maintenance

Product Information

6.5.1 Model Information

6.5.2 Firmware Revisions

Commands and Targets

Commands

7.1.1 Commands Menu

7.1.2 Virtual Inputs

7.1.3 Clear Records

7.1.4 Set Date and Time

7.1.5 Relay Maintenance

Targets

7.2.1 Targets Menu

7.2.2 Target Messages

7.2.3 Relay Self-Tests

a) Description

b) Major Self-Test Error Messages

c) Minor Self-Test Error Messages

Commissioning

Differential Characteristic Test

8.1.1 Description

a) Overview

b) Minimum Pickup

c) Slope 1 / Breakpoint 1

d) Slope 2 / Breakpoint 2

Differential Characteristic Test Examples

8.2.1 Introduction

8.2.2 Test Example 1

a) Description

b) Test for Zero Differential Current

c) Minimum Pickup Test

d) Slope 1 Test

e) Intermediate Curve Between Breakpoint 1 and Breakpoint 2

f) Slope 2 Test

g) Summary

8.2.3 Test Example 2

8.2.4 Test Example 3

8.2.5 Test Example 4

Inrush Inhibit Test

8.3.1 Inrush Inhibit Test Procedure

Overexcitation Inhibit Test

8.4.1 Overexcitation Inhibit Test Procedure

Frequency Element Tests

8.5.1 Testing Underfreqency and Overfrequency Elements

Commissioning Test Tables

8.6.1 Differential Restraint Tests

8.6.2 Inrush Inhibit Tests

8.6.3 Overexcitation Inhibit Tests

Appendices

FlexAnalog Parameters

Parameter List

A.1.1 FlexAnalog List

Modbus Communications

Modbus RTU Protocol

A.1.1 Introduction

A.1.2 Physical Layer

A.1.3 Data Link Layer

A.1.4 CRC-16 Algorithm

Modbus Function Codes

A.2.1 Supported Function Codes

A.2.2 Read Actual Values or Settings (Function Code 03/04h)

A.2.3 Execute Operation (Function Code 05h)

A.2.4 Store Single Setting (Function Code 06h)

A.2.5 Store Multiple Settings (Function Code 10h)

A.2.6 Exception Responses

File Transfers

A.3.1 Obtaining Relay Files via Modbus

a) Description

b) Other Protocols

c) Comtrade, Oscillography, and Data Logger Files

d) Reading Oscillography Files

e) Reading Data Logger Files

f) Reading Event Recorder Files

A.3.2 Modbus Password Operation

Memory Mapping

A.4.1 Modbus Memory Map

A.4.2 Data Formats

IEC 61850 Communications

Overview

B.1.1 Introduction

B.1.2 Communication Profiles

Server Data Organization

B.2.1 Overview

B.2.2 GGIO1: Digital Status Values

B.2.3 GGIO2: Digital Control Values

B.2.4 GGIO3: Digital Status and Analog Values from Received GOOSE Data

B.2.5 GGIO4: Generic Analog Measured Values

B.2.6 MMXU: Analog Measured Values

B.2.7 Protection and Other Logical Nodes

Server Features and Configuration

B.3.1 Buffered/Unbuffered Reporting

B.3.2 File Transfer

B.3.3 Timestamps and Scanning

B.3.4 Logical Device Name

B.3.5 Location

B.3.6 Logical Node Name Prefixes

B.3.7 Connection Timing

B.3.8 Non-IEC 61850 Data

B.3.9 Communication Software Utilities

Generic Substation Event Services: GSSE and GOOSE

B.4.1 Overview

B.4.2 GSSE Configuration

B.4.3 Fixed GOOSE

B.4.4 Configurable GOOSE

B.4.5 Ethernet MAC Address for GSSE/GOOSE

B.4.6 GSSE ID and GOOSE ID Settings

IEC 61850 Implementation via EnerVista UR Setup

B.5.1 Overview

B.5.2 Configuring IEC 61850 Settings

B.5.3 About ICD Files

B.5.4 Creating an ICD file with EnerVista UR Setup

B.5.5 About SCD Files

B.5.6 Importing an SCD File with EnerVista UR Setup

ACSI Conformance

B.6.1 ACSI Basic Conformance Statement

B.6.2 ACSI Models Conformance Statement

B.6.3 ACSI Services Conformance Statement

Logical Nodes

B.7.1 Logical Nodes Table

IEC 60870-5-104 Comms.

IEC 60870-5-104 Protocol

C.1.1 Interoperability Document

C.1.2 Point List

DNP Communications

Device Profile Document

D.1.1 DNP V3.00 Device Profile

D.1.2 Implementation Table

DNP Point Lists

D.2.1 Binary Input Points

D.2.2 Binary and Control Relay Output

D.2.3 Counters

D.2.4 Analog Inputs

Miscellaneous

Change Notes

E.1.1 Revision History

E.1.2 Changes to the T60 Manual

Abbreviations

E.2.1 Standard Abbreviations

Warranty

E.3.1 GE Multilin Warranty

Index

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc