SIMATIC FM 353 Stepper Drive Positioning Module

Preface

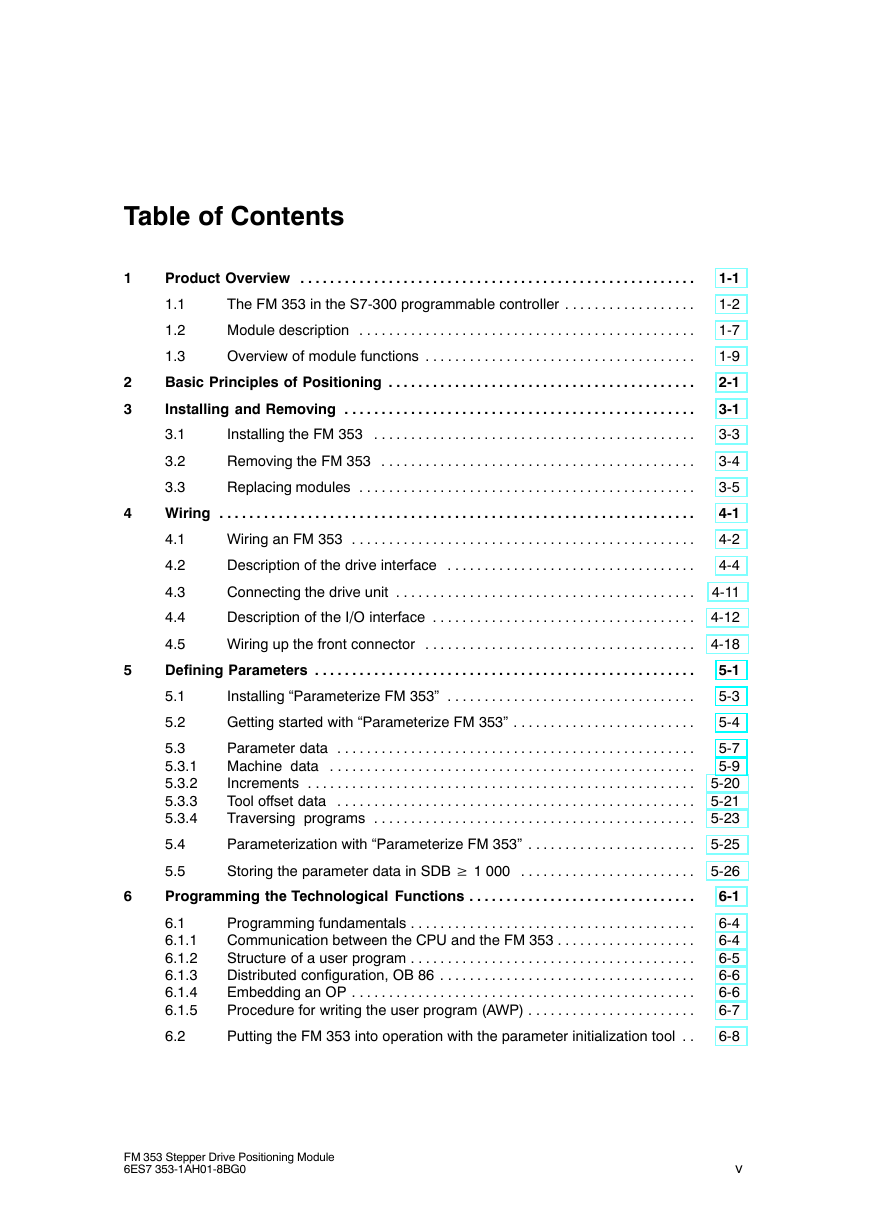

Table of Contents

1 Product Overview

1.1 The FM 353 in the S7-300 programmable controller

1.2 Module description

1.3 Overview of module functions

2 Basic Principles of Positioning

3 Installing and Removing

3.1 Installing the FM 353

3.2 Removing the FM 353

3.3 Replacing modules

4 Wiring

4.1 Wiring an FM 353

4.2 Description of the drive interface

4.3 Connecting the drive unit

4.4 Description of the I/O interface

4.5 Wiring up the front connector

5 Defining Parameters

5.1 Installing “Parameterize FM 353”

5.2 Getting started with “Parameterize FM 353”

5.3 Parameter data

5.3.1 Machine data

5.3.2 Increments

5.3.3 Tool offset data

5.3.4 Traversing programs

5.4 Parameterization with “Parameterize FM 353”

5.5 Storing the parameter data in SDB >= 1 000

6 Programming the Technological Functions

6.1 Programming fundamentals

6.1.1 Communication between the CPU and the FM 353

6.1.2 Structure of a user program

6.1.3 Distributed configuration, OB 86

6.1.4 Embedding an OP

6.1.5 Procedure for writing the user program (AWP)

6.2 Putting the FM 353 into operation with the parameter initialization tool

6.3 Standard function blocks of the “FMSTSV_L” block library

6.3.1 Overview of the “FMSTSV_L” function block library

6.3.2 The POS_INIT (FC 0) block - Initialization

6.3.3 The POS_CTRL (FC 1) block - Data exchange

6.3.4 The POS_DIAG (FC 2) block - Read diagnostic interrupt data

6.3.5 The POS_MSRM (FC 3) block - Read measured values

6.3.6 Interface, user data blocks (AW-DBs)

6.4 Standard function blocks of the “FM353_354” block li-brary ( also for PROFINET, upon request)

6.4.1 Overview of the “FM353_354” block library

6.4.2 The POS_INIT (FC 0) block - Initialization

6.4.3 The POS_CTRL (FC 1) block - Data exchange

6.4.4 The POS_DIAG (FC 2) block - Read diagnostic interrupt data

6.4.5 The POS_MSRM (FC 3) block - Read measured values

6.4.6 Interface, user DBs (AW-DBs)

6.5 Interrupts

6.6 User data block (AW-DB)

6.7 Sample applications

6.8 Error list, system messages (CPU)

6.9 Technical specifications

7 Starting up

7.1 Installation and wiring

7.2 Initial values for testing and optimization

7.3 Testing and optimization

7.3.1 Activating the machine data

7.3.2 Evaluating the characteristics of the stepper motor

7.3.3 Basic startup of stepper motor control

7.3.4 Optimization of dynamic response

7.3.5 Realigning the reference point coordinates

7.3.6 Activating stepper motor diagnostics

7.3.7 Activating the software limit switches and backlash compensa-tion

7.3.8 Optimized motion profile

8 Human-machine Interface

8.1 Standard HMI (human-machine interface) for the OP 07 and the OP 17

8.1.1 Standard user interface for the OP 07

8.1.2 Standard user interface for the OP 17

8.2 Analysis of the user DB by the user program for operator control

8.3 Data block for status messages (DB-SS)

9 Description of Functions

9.1 Control and checkback signals

9.1.1 Control signals

9.1.2 Checkback signals

9.1.3 General handling information

9.2 Operating modes

9.2.1 Jogging

9.2.2 Open-loop control

9.2.3 Reference point approach

9.2.4 Incremental relative

9.2.5 MDI (Manual Data Input)

9.2.6 Automatic

9.2.7 Automatic single block

9.3 System data

9.3.1 Change parameters/data (Write request in user DB, DBX39.3)

9.3.2 Single functions (user DB, DBB34 and 35)

9.3.3 Single functions (user DB, DBB36 and 37)

9.3.4 Zero offset (Write request in the user DB, DBX39.1)

9.3.5 Set actual value (Write request in the user DB, DBX38.7)

9.3.6 Set actual value on-the-fly (Write request in the user DB, DBX39.0)

9.3.7 Request application data (Write request in the user DB, DBX39.6)

9.3.8 Teach in (Write request in the user DB, DBX39.7)

9.3.9 Set reference point (Write request in the user DB, DBX38.6)

9.3.10 Measured values

9.3.11 Basic operating data (Read request in the user DB, DBX42.0)

9.3.12 Active NC block (Read request in the user DB, DBX42.1), next NC block ( Read request in the user DB, DBX42.2)

9.3.13 Application data (Read request in the user DB, DBX43.6)

9.3.14 Actual value block change (Read request in the user DB, DBX42.3)

9.3.15 Servicing data (Read request in the user DB, DBX42.4)

9.3.16 Additional operating data (Read request in the user DB, DBX43.5)

9.3.17 Parameters/data (Read request in the user DB, DBX43.3)

9.4 System of measurement

9.5 Axis type

9.6 Determining the position

9.6.1 Synchronizing the stepper motor axis

9.7 Stepper motor control system

9.7.1 Frequency generation

9.7.2 Drive interface

9.7.3 Rotation monitoring

9.8 Digital inputs/outputs (Read request user DB, DBX43.4)

9.8.1 Function description for digital inputs

9.8.2 Function description for digital outputs (Write request in the user DB, DBX39.4)

9.9 Software limit switches

9.10 Process interrupts

10 Writing Traversing Programs

10.1 Traversing blocks

10.2 Program execution and direction of processing

10.3 Block transitions

11 Troubleshooting

11.1 Error classes and module responses

11.2 Error messages

11.2.1 Fault indication by LED

11.2.2 Diagnostic interrupts

11.2.3 Error messages in checkback signals

11.2.4 Message in data block

11.2.5 Viewing the diagnostic buffer (PG/PC)

11.3 Error lists

11.3.1 Diagnostic interrupts

11.3.2 Error messages

A Technical Specifications

B User Data Block (AW-DB)

C List of Abbreviations

Index

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc