Thermal detectors

CHAPTER 07

1 Thermopile detectors

1-1 Features

1-2 Structure

1-3 Characteristics

1-4 How to use

1-5 New approaches

1-6 Applications

2 Bolometers

2-1 Operating principle and structure

2-2

Characteristics

1

�

Thermal detectors

Thermal detectors have an absorption layer that absorbs and converts light into heat, and provide an electric signal output that

represents the change in absorption layer temperature. Because thermal detectors have no wavelength dependence, they can

serve as infrared detectors when used with a window material such as Si that transmits infrared light.

Thermal detectors are mainly classified into: (1) thermopile detectors that change in electromotive force, (2) bolometers that

change in resistance, (3) pyroelectric detectors that change in dielectric surface charge, and (4) diodes that change in voltage-

current characteristics. Hamamatsu manufactures two types of thermal detectors: thermopile detectors and bolometers. These

two types of thermal detectors are different in terms of operating principle, structure, and characteristics.

Thermopile detectors have a structure in which a large number of thermocouples are serially connected on a silicon substrate

and their sensitivity increases as more thermocouples are used. This means that the larger the photosensitive area, the higher

the sensitivity, because the number of thermocouples is proportional to the size of the photosensitive area.

In bolometers, the photosensitive area uses a bolometer resistance made up of thermoelectric conversion materials, so the

resistance temperature coefficient is the primary cause in determining bolometer sensitivity. Since bolometer sensitivity does

not depend on the size of the photosensitive area, detectors can be fabricated that have a small photosensitive area yet no drop

in sensitivity.

Thermopile detectors are usually manufactured as single-element detectors with an ample photosensitive area or arrays with

a small number of elements, while bolometers are manufactured as arrays with a larger number of elements than thermopile

detectors.

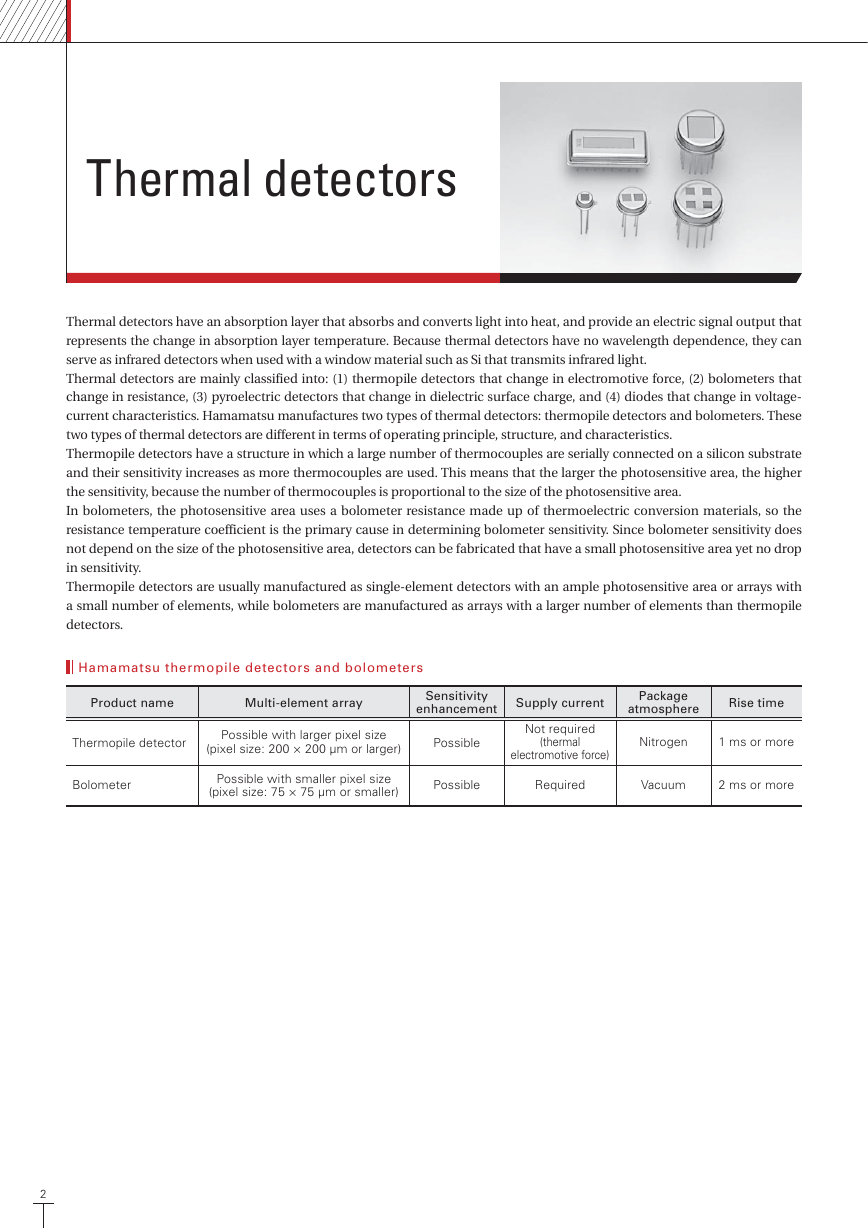

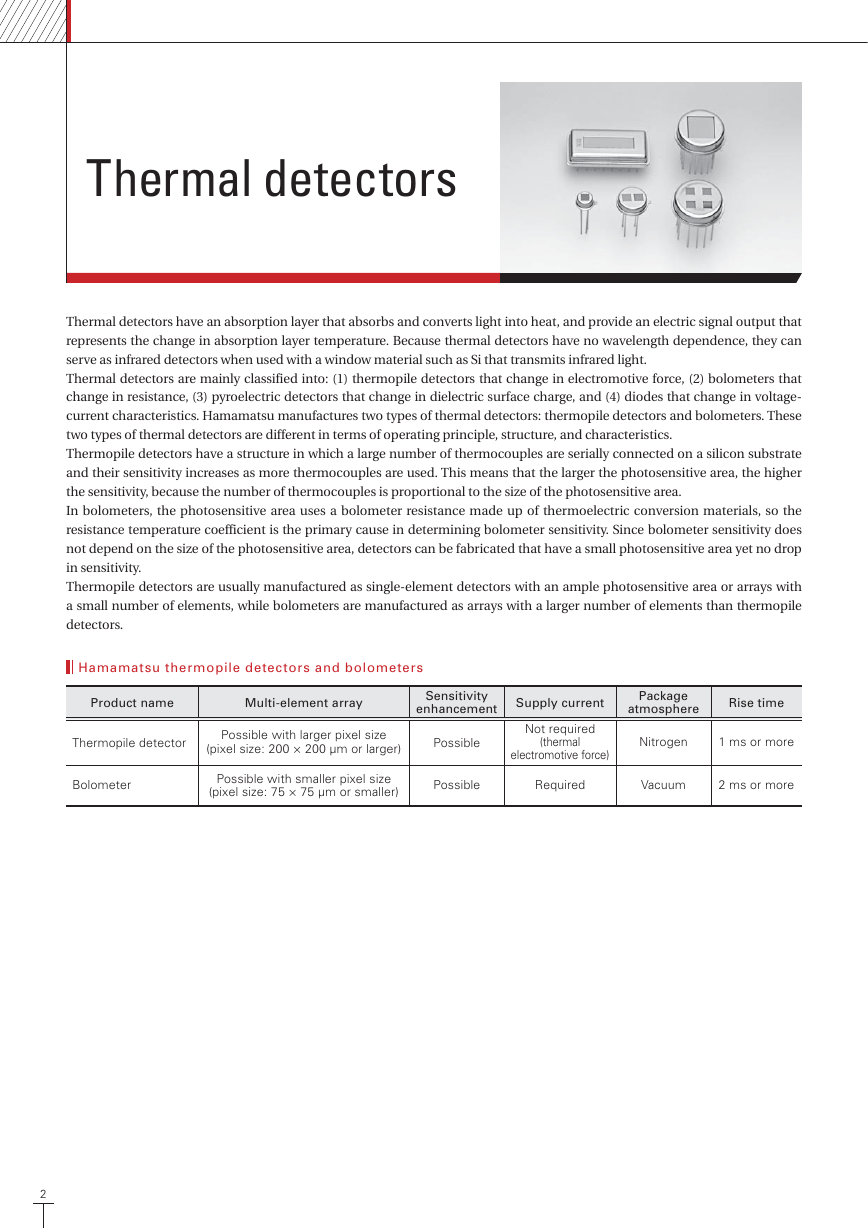

Hamamatsu thermopile detectors and bolometers

Product name

Multi-element array

Sensitivity

enhancement

Supply current

Package

atmosphere

Rise time

Thermopile detector

Possible with larger pixel size

(pixel size: 200 × 200 µm or larger)

Possible

Not required

(thermal

electromotive force)

Nitrogen

1 ms or more

Bolometer

Possible with smaller pixel size

(pixel size: 75 × 75 µm or smaller)

Possible

Required

Vacuum

2 ms or more

2

�

1.

Thermopile detectors

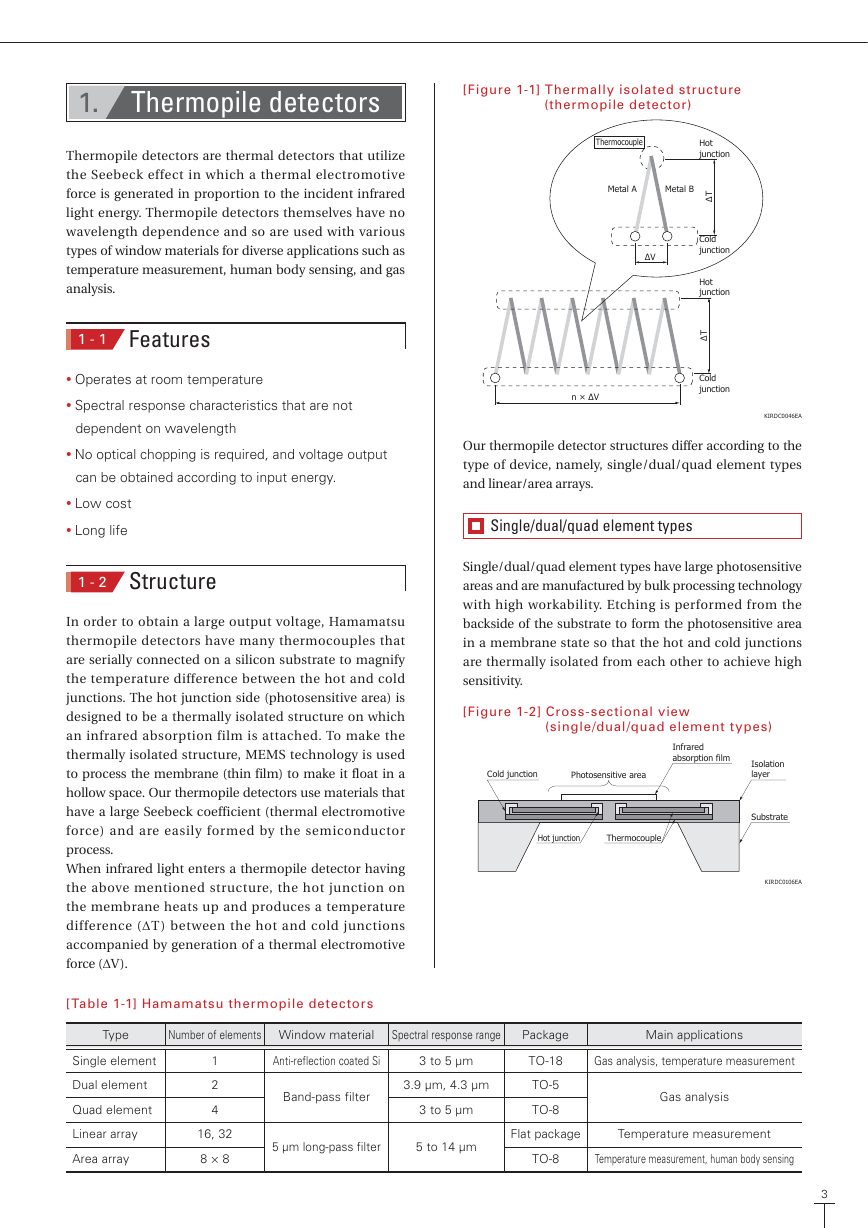

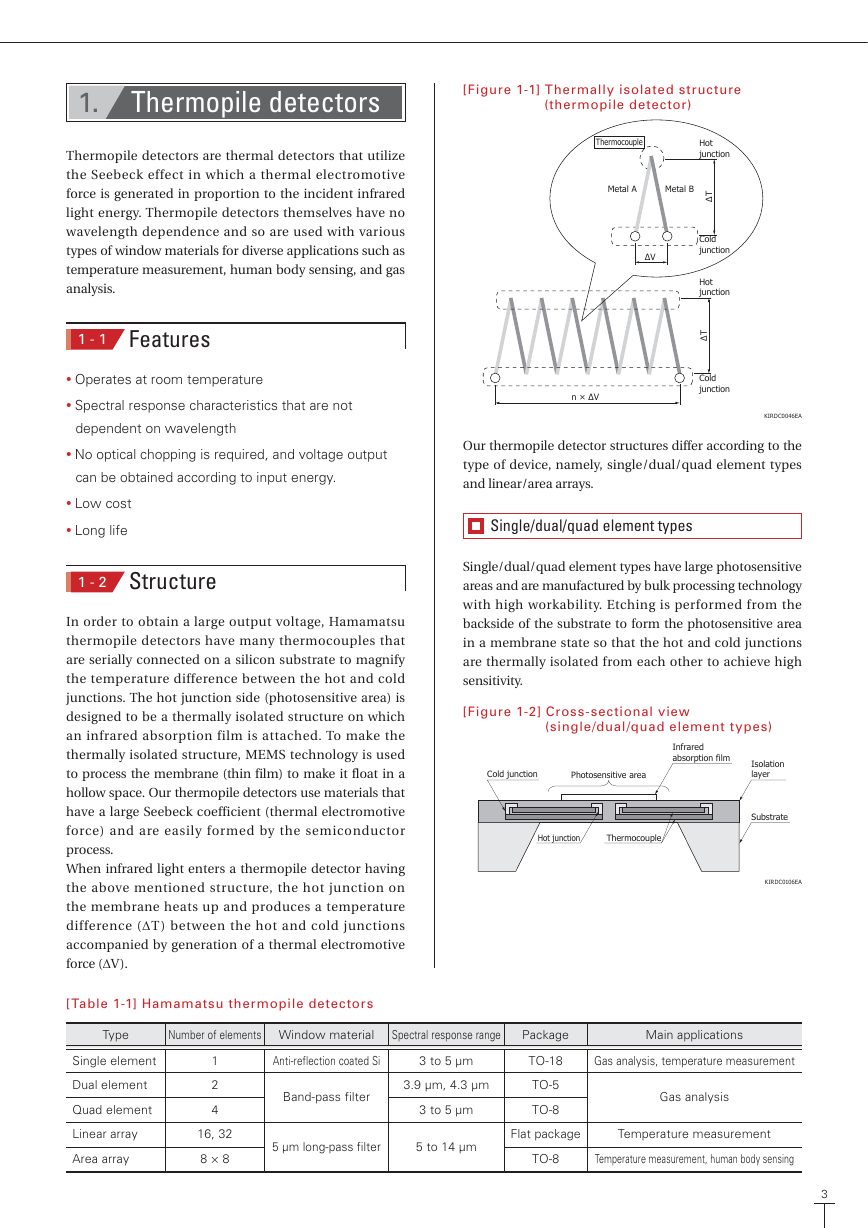

[Figure 1-1] Thermally isolated structure

(thermopile detector)

Thermocouple

Hot

junction

Metal A

Metal B

T

Δ

ΔV

Cold

junction

Hot

junction

T

Δ

Cold

junction

n × ΔV

Our thermopile detector structures differ according to the

type of device, namely, single/dual/quad element types

and linear/area arrays.

KIRDC0046EA

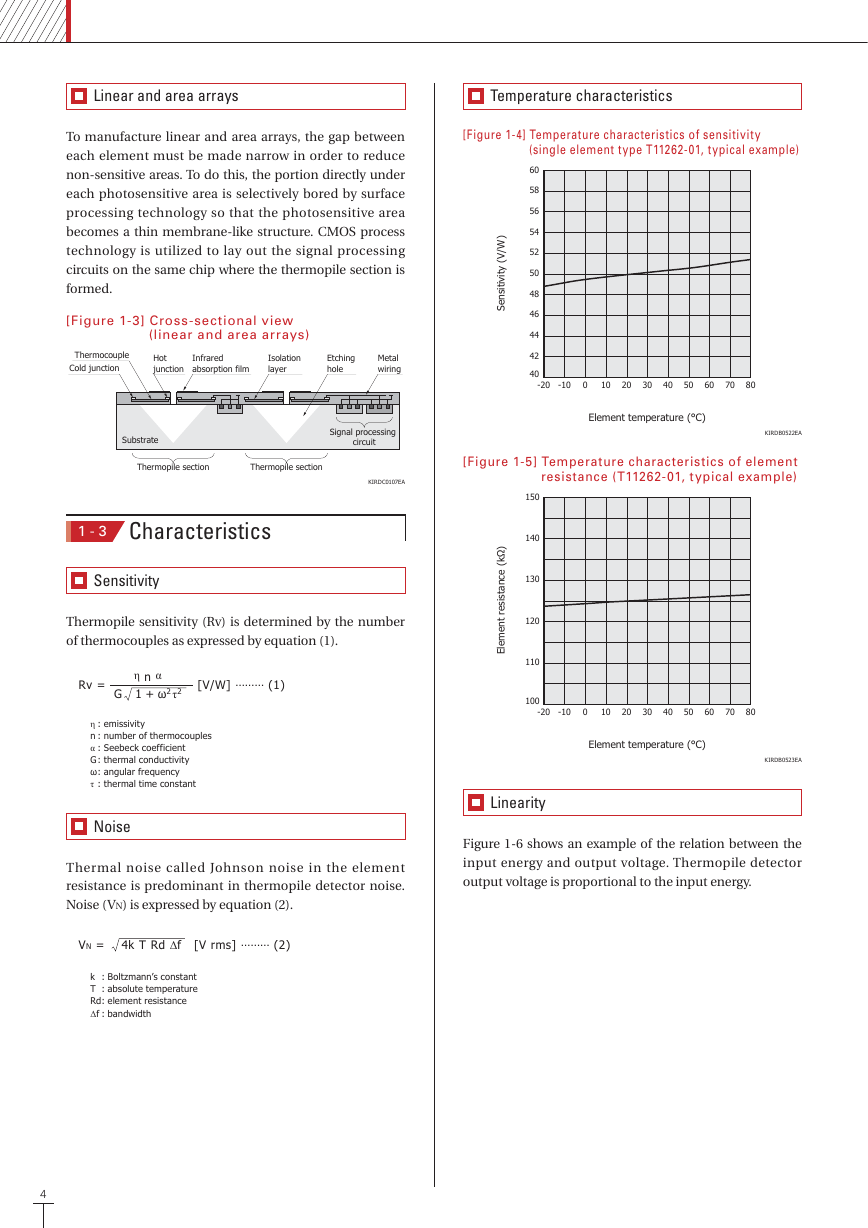

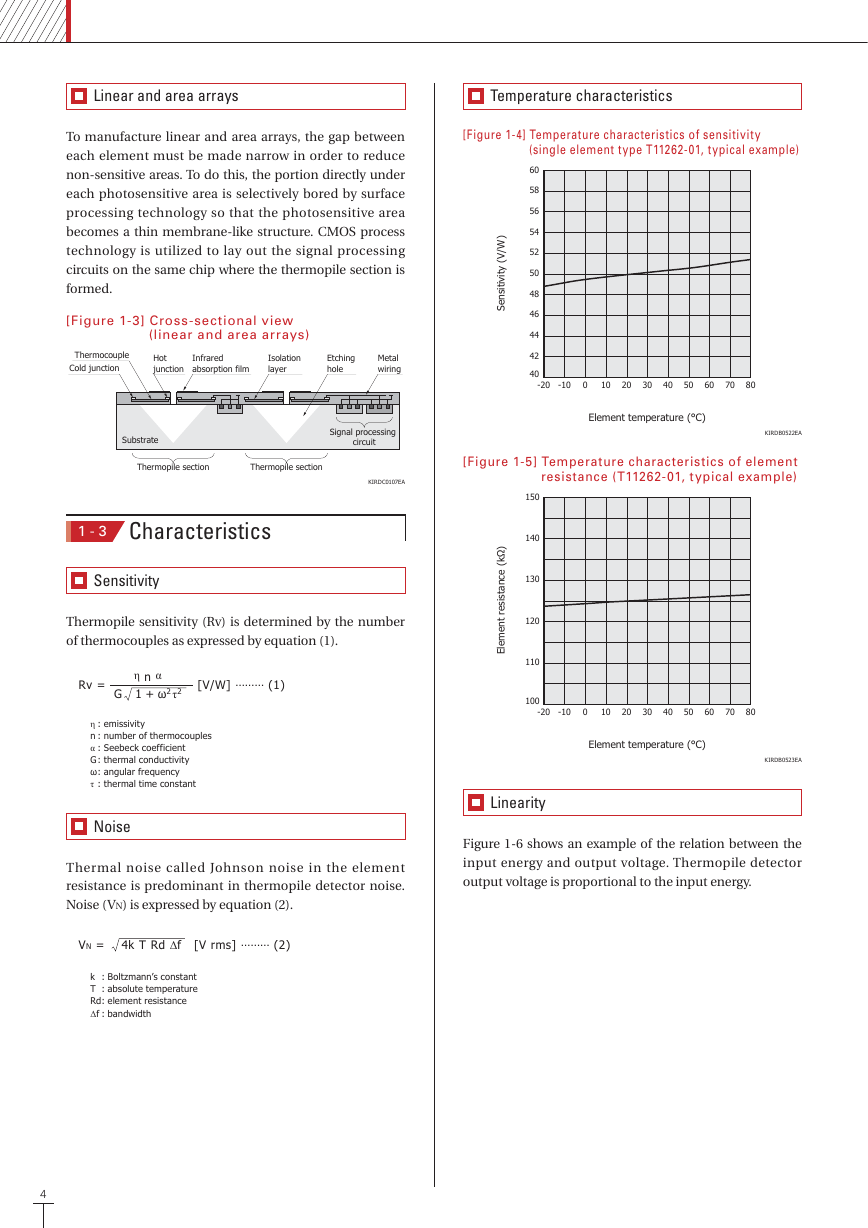

Single/dual/quad element types

Single/dual/quad element types have large photosensitive

areas and are manufactured by bulk processing technology

with high workability. Etching is performed from the

backside of the substrate to form the photosensitive area

in a membrane state so that the hot and cold junctions

are thermally isolated from each other to achieve high

sensitivity.

[Figure 1-2] Cross-sectional view

(single/dual/quad element types)

Cold junction

Photosensitive area

Infrared

absorption film

Hot junction

Thermocouple

Isolation

layer

Substrate

KIRDC0106EA

Thermopile detectors are thermal detectors that utilize

the Seebeck effect in which a thermal electromotive

force is generated in proportion to the incident infrared

light energy. Thermopile detectors themselves have no

wavelength dependence and so are used with various

types of window materials for diverse applications such as

temperature measurement, human body sensing, and gas

analysis.

1 - 1

Features

Operates at room temperature

Spectral response characteristics that are not

dependent on wavelength

No optical chopping is required, and voltage output

can be obtained according to input energy.

Low cost

Long life

1 - 2

Structure

In order to obtain a large output voltage, Hamamatsu

thermopile detectors have many thermocouples that

are serially connected on a silicon substrate to magnify

the temperature difference between the hot and cold

junctions. The hot junction side (photosensitive area) is

designed to be a thermally isolated structure on which

an infrared absorption film is attached. To make the

thermally isolated structure, MEMS technology is used

to process the membrane (thin film) to make it float in a

hollow space. Our thermopile detectors use materials that

have a large Seebeck coefficient (thermal electromotive

force) and are easily formed by the semiconductor

process.

When infrared light enters a thermopile detector having

the above mentioned structure, the hot junction on

the membrane heats up and produces a temperature

difference (ΔT) between the hot and cold junctions

accompanied by generation of a thermal electromotive

force (ΔV).

[Table 1-1] Hamamatsu thermopile detectors

Type

Number of elements Window material

Spectral response range

Package

Main applications

Single element

Dual element

Quad element

Linear array

Area array

1

2

4

16, 32

8 × 8

Anti-reflection coated Si

3 to 5 µm

TO-18

Gas analysis, temperature measurement

Band-pass filter

3.9 µm, 4.3 µm

3 to 5 µm

TO-5

TO-8

Gas analysis

5 µm long-pass filter

5 to 14 µm

Flat package

Temperature measurement

TO-8

Temperature measurement, human body sensing

3

�

Linear and area arrays

Temperature characteristics

[Figure 1-4] Temperature characteristics of sensitivity

(single element type T11262-01, typical example)

60

)

W

/

V

(

y

t

i

v

i

t

i

s

n

e

S

58

56

54

52

50

48

46

44

42

40

-20

-10

0

10

20

30

40

50

60

70

80

Element temperature (°C)

KIRDB0522EA

[Figure 1-5] Temperature characteristics of element

resistance (T11262-01, typical example)

150

140

130

120

110

)

Ω

k

(

e

c

n

a

t

s

i

s

e

r

t

n

e

m

e

E

l

100

-20

-10

0

10

20

30

40

50

60

70

80

Element temperature (°C)

KIRDB0523EA

Linearity

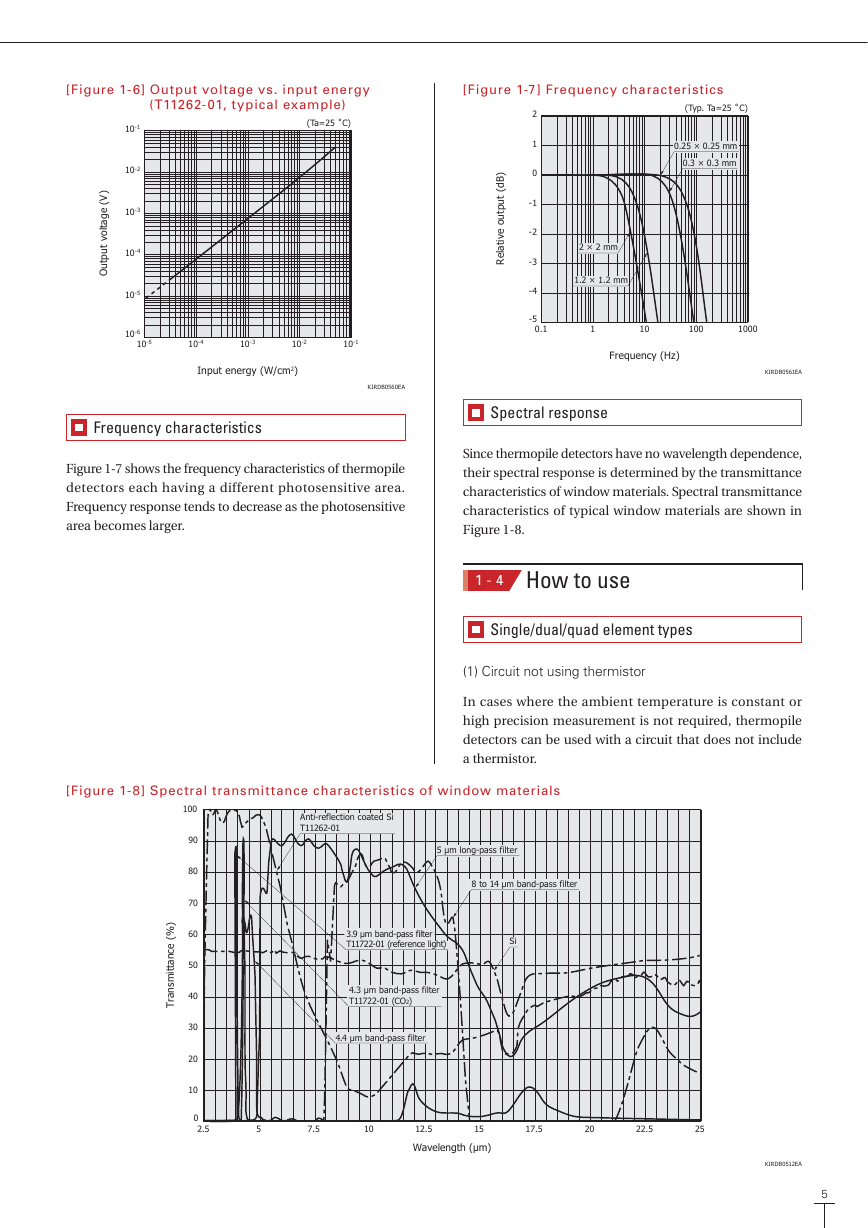

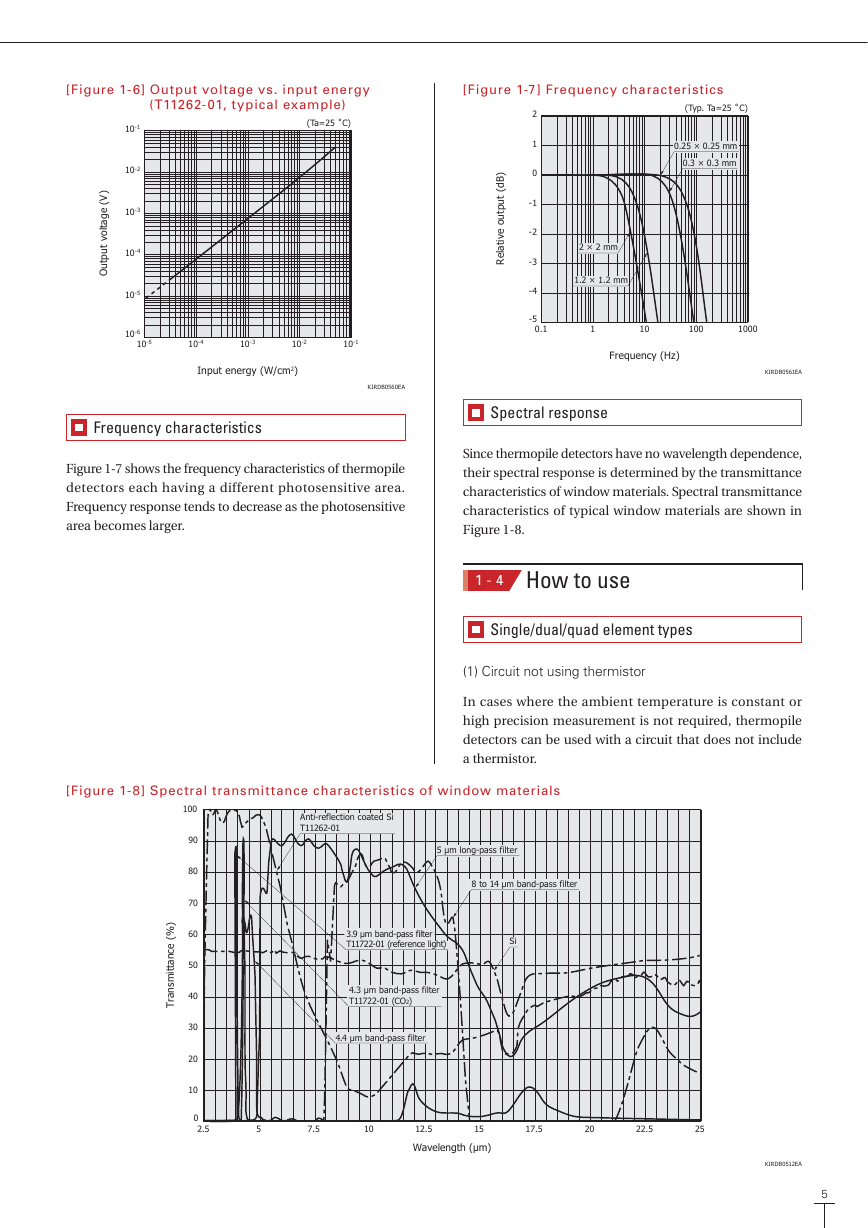

Figure 1-6 shows an example of the relation between the

input energy and output voltage. Thermopile detector

output voltage is proportional to the input energy.

To manufacture linear and area arrays, the gap between

each element must be made narrow in order to reduce

non-sensitive areas. To do this, the portion directly under

each photosensitive area is selectively bored by surface

processing technology so that the photosensitive area

becomes a thin membrane-like structure. CMOS process

technology is utilized to lay out the signal processing

circuits on the same chip where the thermopile section is

formed.

[Figure 1-3] Cross-sectional view

(linear and area arrays)

Thermocouple

Cold junction

Hot

junction

Infrared

absorption film

Isolation

layer

Etching

hole

Metal

wiring

Substrate

Thermopile section

Thermopile section

Signal processing

circuit

KIRDC0107EA

1 - 3

Characteristics

Sensitivity

Thermopile sensitivity (Rv) is determined by the number

of thermocouples as expressed by equation (1).

η n α

Rv = [V/W] ……… (1)

G 1 + ω2τ2

η : emissivity

n : number of thermocouples

α : Seebeck coefficient

G : thermal conductivity

ω : angular frequency

τ : thermal time constant

Noise

Thermal noise called Johnson noise in the element

resistance is predominant in thermopile detector noise.

Noise (VN) is expressed by equation (2).

VN = 4k T Rd Δf [V rms] ……… (2)

k : Boltzmann’s constant

T : absolute temperature

Rd : element resistance

Δf : bandwidth

4

�

[Figure 1-6] Output voltage vs. input energy

(T11262-01, typical example)

(Ta=25 ˚C)

10-1

10-2

10-3

10-4

10-5

)

V

(

e

g

a

t

l

o

v

t

u

p

t

u

O

10-6

10-5

10-4

10-3

10-2

10-1

Input energy (W/cm2)

KIRDB0560EA

[Figure 1-7] Frequency characteristics

)

B

d

(

t

u

p

t

u

o

e

v

l

i

t

a

e

R

2

1

0

-1

-2

-3

-4

-5

0.1

(Typ. Ta=25 ˚C)

0.25 × 0.25 mm

0.3 × 0.3 mm

2 × 2 mm

1.2 × 1.2 mm

1

10

100

1000

Frequency (Hz)

KIRDB0561EA

Frequency characteristics

Spectral response

Figure 1-7 shows the frequency characteristics of thermopile

detectors each having a different photosensitive area.

Frequency response tends to decrease as the photosensitive

area becomes larger.

Since thermopile detectors have no wavelength dependence,

their spectral response is determined by the transmittance

characteristics of window materials. Spectral transmittance

characteristics of typical window materials are shown in

Figure 1-8.

1 - 4

How to use

Single/dual/quad element types

(1) Circuit not using thermistor

In cases where the ambient temperature is constant or

high precision measurement is not required, thermopile

detectors can be used with a circuit that does not include

a thermistor.

[Figure 1-8] Spectral transmittance characteristics of window materials

)

%

(

e

c

n

a

t

t

i

m

s

n

a

r

T

100

90

80

70

60

50

40

30

20

10

0

2.5

Anti-reflection coated Si

T11262-01

5 μm long-pass filter

8 to 14 μm band-pass filter

3.9 μm band-pass filter

T11722-01 (reference light)

Si

4.3 μm band-pass filter

T11722-01 (CO2)

4.4 μm band-pass filter

5

7.5

10

12.5

15

17.5

20

22.5

25

Wavelength (μm)

KIRDB0512EA

5

�

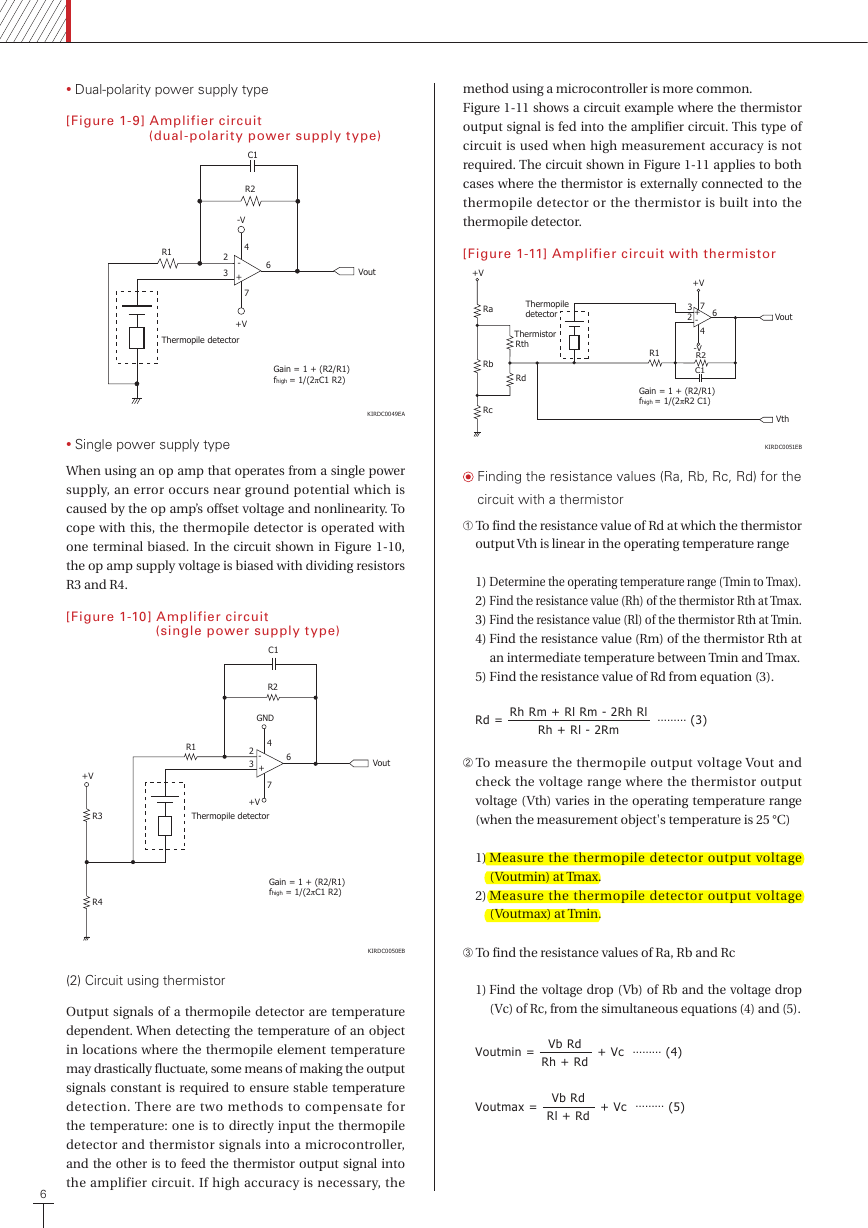

Dual-polarity power supply type

[Figure 1-9] Amplifier circuit

(dual-polarity power supply type)

method using a microcontroller is more common.

Figure 1-11 shows a circuit example where the thermistor

output signal is fed into the amplifier circuit. This type of

circuit is used when high measurement accuracy is not

required. The circuit shown in Figure 1-11 applies to both

cases where the thermistor is externally connected to the

thermopile detector or the thermistor is built into the

thermopile detector.

[Figure 1-11] Amplifier circuit with thermistor

Vout

+V

Thermopile

detector

Thermistor

Rth

Rd

Ra

Rb

Rc

6

Vout

+V

3

2

7

+

-

4

-V

R2

C1

R1

Gain = 1 + (R2/R1)

fhigh = 1/(2πR2 C1)

Vth

KIRDC0051EB

Finding the resistance values (Ra, Rb, Rc, Rd) for the

circuit with a thermistor

To find the resistance value of Rd at which the thermistor

output Vth is linear in the operating temperature range

1) Determine the operating temperature range (Tmin to Tmax).

2) Find the resistance value (Rh) of the thermistor Rth at Tmax.

3) Find the resistance value (Rl) of the thermistor Rth at Tmin.

4) Find the resistance value (Rm) of the thermistor Rth at

an intermediate temperature between Tmin and Tmax.

5) Find the resistance value of Rd from equation (3).

Rh Rm + Rl Rm - 2Rh Rl

Rd = ……… (3)

Rh + Rl - 2Rm

To measure the thermopile output voltage Vout and

check the voltage range where the thermistor output

voltage (Vth) varies in the operating temperature range

(when the measurement object's temperature is 25 °C)

1) Measure the thermopile detector output voltage

(Voutmin) at Tmax.

2) Measure the thermopile detector output voltage

(Voutmax) at Tmin.

C1

R2

6

-V

2

3

-

+

4

7

+V

R1

Thermopile detector

Gain = 1 + (R2/R1)

fhigh = 1/(2πC1 R2)

KIRDC0049EA

Single power supply type

When using an op amp that operates from a single power

supply, an error occurs near ground potential which is

caused by the op amp’s offset voltage and nonlinearity. To

cope with this, the thermopile detector is operated with

one terminal biased. In the circuit shown in Figure 1-10,

the op amp supply voltage is biased with dividing resistors

R3 and R4.

[Figure 1-10] Amplifier circuit

(single power supply type)

C1

R2

GND

4

7

2

3

-

+

+V

R1

Thermopile detector

6

Vout

Gain = 1 + (R2/R1)

fhigh = 1/(2πC1 R2)

+V

R3

R4

KIRDC0050EB

To find the resistance values of Ra, Rb and Rc

(2) Circuit using thermistor

Output signals of a thermopile detector are temperature

dependent. When detecting the temperature of an object

in locations where the thermopile element temperature

may drastically fluctuate, some means of making the output

signals constant is required to ensure stable temperature

detection. There are two methods to compensate for

the temperature: one is to directly input the thermopile

detector and thermistor signals into a microcontroller,

and the other is to feed the thermistor output signal into

the amplifier circuit. If high accuracy is necessary, the

6

1) Find the voltage drop (Vb) of Rb and the voltage drop

(Vc) of Rc, from the simultaneous equations (4) and (5).

Voutmin = + Vc ……… (4)

Vb Rd

Rh + Rd

Voutmax = + Vc ……… (5)

Vb Rd

Rl + Rd

�

2) Find the voltage drop (Va) of Ra.

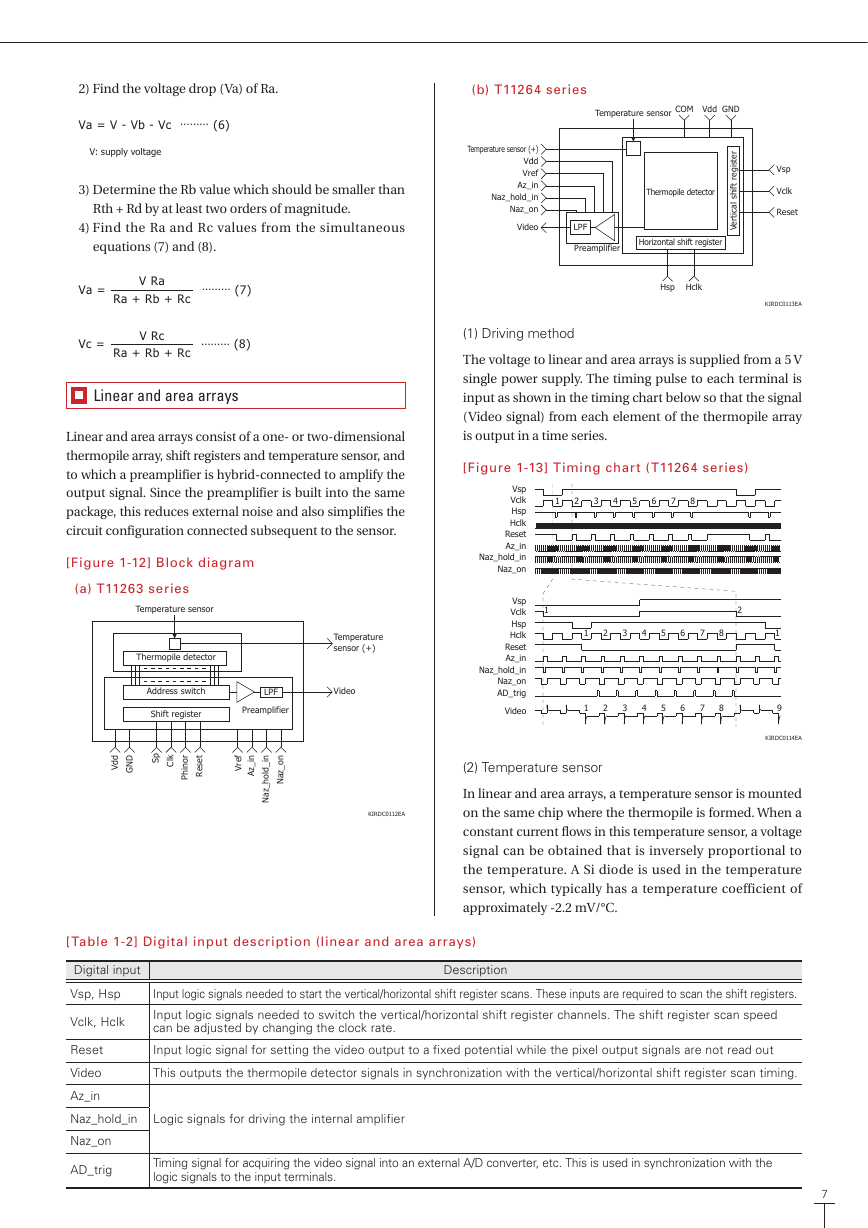

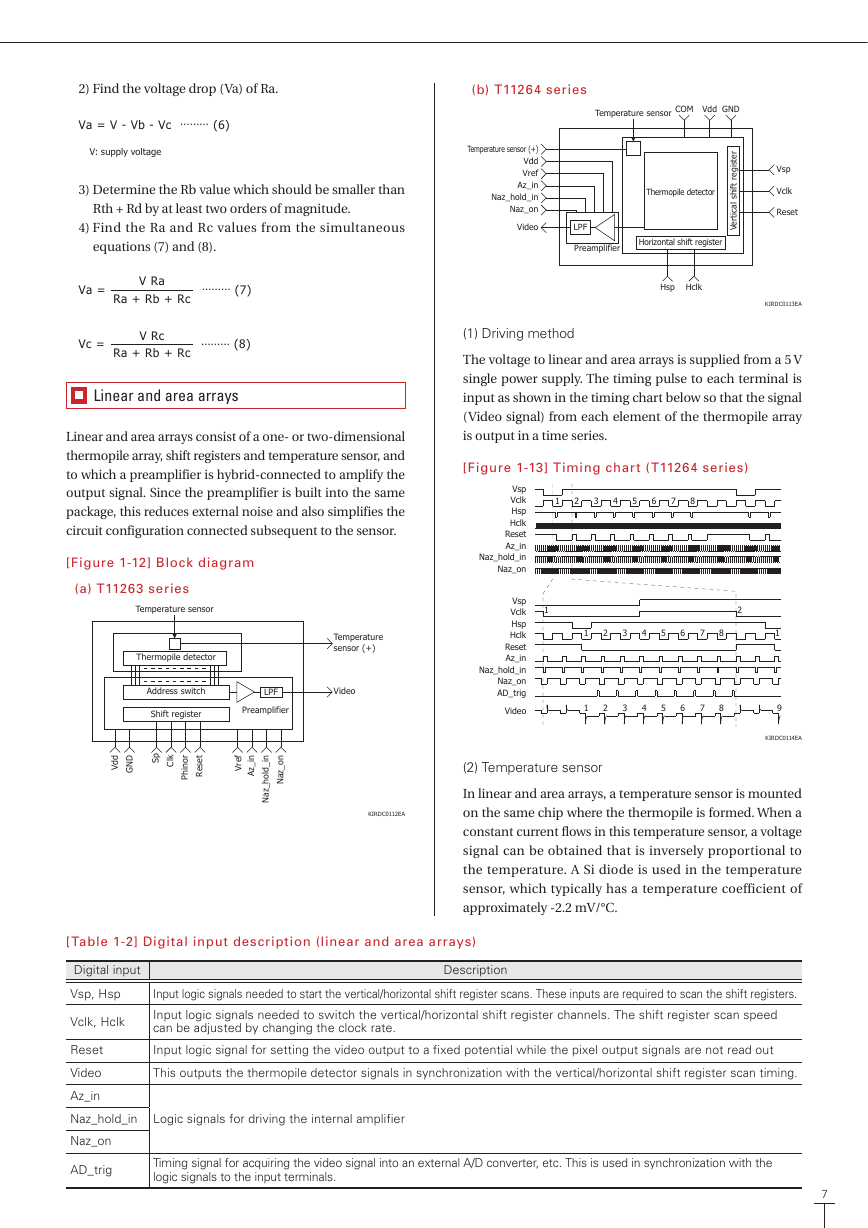

(b) T11264 series

Va = V - Vb - Vc ……… (6)

V: supply voltage

3) Determine the Rb value which should be smaller than

Rth + Rd by at least two orders of magnitude.

Temperature sensor (+)

Vdd

Vref

Az_in

Naz_hold_in

Naz_on

4) Find the Ra and Rc values from the simultaneous

Video

LPF

Temperature sensor

COM

Vdd

GND

Thermopile detector

r

e

t

s

i

g

e

r

t

f

i

h

s

l

a

c

i

t

r

e

V

Vsp

Vclk

Reset

equations (7) and (8).

Preamplifier

Horizontal shift register

Va = ……… (7)

V Ra

Ra + Rb + Rc

V Rc

Vc = ……… (8)

Ra + Rb + Rc

Linear and area arrays

Linear and area arrays consist of a one- or two-dimensional

thermopile array, shift registers and temperature sensor, and

to which a preamplifier is hybrid-connected to amplify the

output signal. Since the preamplifier is built into the same

package, this reduces external noise and also simplifies the

circuit configuration connected subsequent to the sensor.

[Figure 1-12] Block diagram

(a) T11263 series

Temperature sensor

Thermopile detector

Temperature

sensor (+)

Address switch

LPF

Video

Shift register

Preamplifier

Hsp Hclk

KIRDC0113EA

(1) Driving method

The voltage to linear and area arrays is supplied from a 5 V

single power supply. The timing pulse to each terminal is

input as shown in the timing chart below so that the signal

(Video signal) from each element of the thermopile array

is output in a time series.

[Figure 1-13] Timing chart (T11264 series)

Vsp

Vclk

Hsp

Hclk

Reset

Az_in

Naz_hold_in

Naz_on

Vsp

Vclk

Hsp

Hclk

Reset

Az_in

Naz_hold_in

Naz_on

AD_trig

Video

1

2

3

4

5

6

7

8

1

2

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

9

KIRDC0114EA

d

d

V

p

D S

N

G

l

k

C

r

o

n

h

P

i

t

e

s

e

R

f

e

r

V

i

n

_

z

A

i

l

n

_

d

o

h

_

z

a

N

n

o

_

z

a

N

(2) Temperature sensor

KIRDC0112EA

In linear and area arrays, a temperature sensor is mounted

on the same chip where the thermopile is formed. When a

constant current flows in this temperature sensor, a voltage

signal can be obtained that is inversely proportional to

the temperature. A Si diode is used in the temperature

sensor, which typically has a temperature coefficient of

approximately -2.2 mV/°C.

[Table 1-2] Digital input description (linear and area arrays)

Digital input

Vsp, Hsp

Vclk, Hclk

Reset

Video

Az_in

Description

Input logic signals needed to start the vertical/horizontal shift register scans. These inputs are required to scan the shift registers.

Input logic signals needed to switch the vertical/horizontal shift register channels. The shift register scan speed

can be adjusted by changing the clock rate.

Input logic signal for setting the video output to a fixed potential while the pixel output signals are not read out

This outputs the thermopile detector signals in synchronization with the vertical/horizontal shift register scan timing.

Naz_hold_in

Logic signals for driving the internal amplifier

Naz_on

AD_trig

Timing signal for acquiring the video signal into an external A/D converter, etc. This is used in synchronization with the

logic signals to the input terminals.

7

�

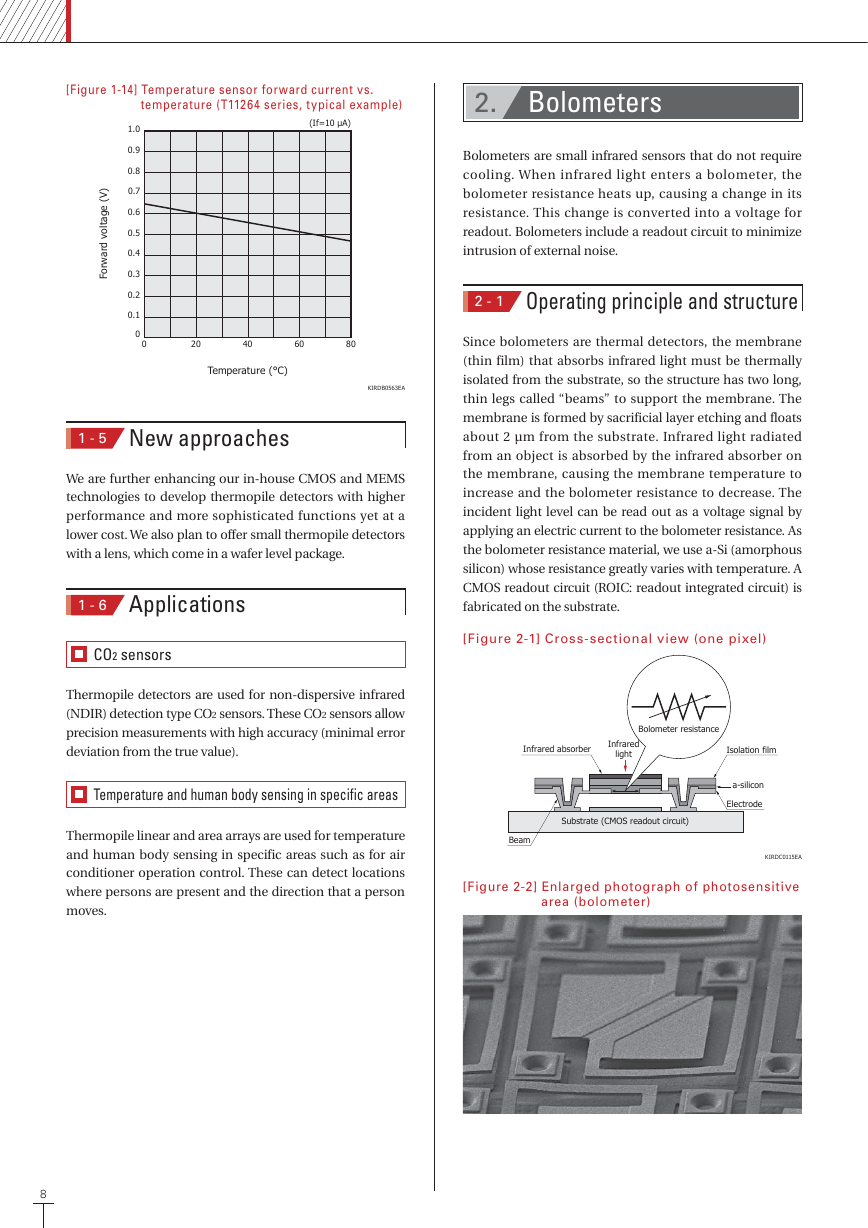

[Figure 1-14] Temperature sensor forward current vs.

temperature (T11264 series, typical example)

)

V

(

e

g

a

t

l

o

v

d

r

a

w

r

o

F

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

0

(If=10 μA)

20

40

60

80

Temperature (°C)

KIRDB0563EA

1 - 5

New approaches

We are further enhancing our in-house CMOS and MEMS

technologies to develop thermopile detectors with higher

performance and more sophisticated functions yet at a

lower cost. We also plan to offer small thermopile detectors

with a lens, which come in a wafer level package.

1 - 6

Applications

CO2 sensors

Thermopile detectors are used for non-dispersive infrared

(NDIR) detection type CO2 sensors. These CO2 sensors allow

precision measurements with high accuracy (minimal error

deviation from the true value).

Temperature and human body sensing in specific areas

Thermopile linear and area arrays are used for temperature

and human body sensing in specific areas such as for air

conditioner operation control. These can detect locations

where persons are present and the direction that a person

moves.

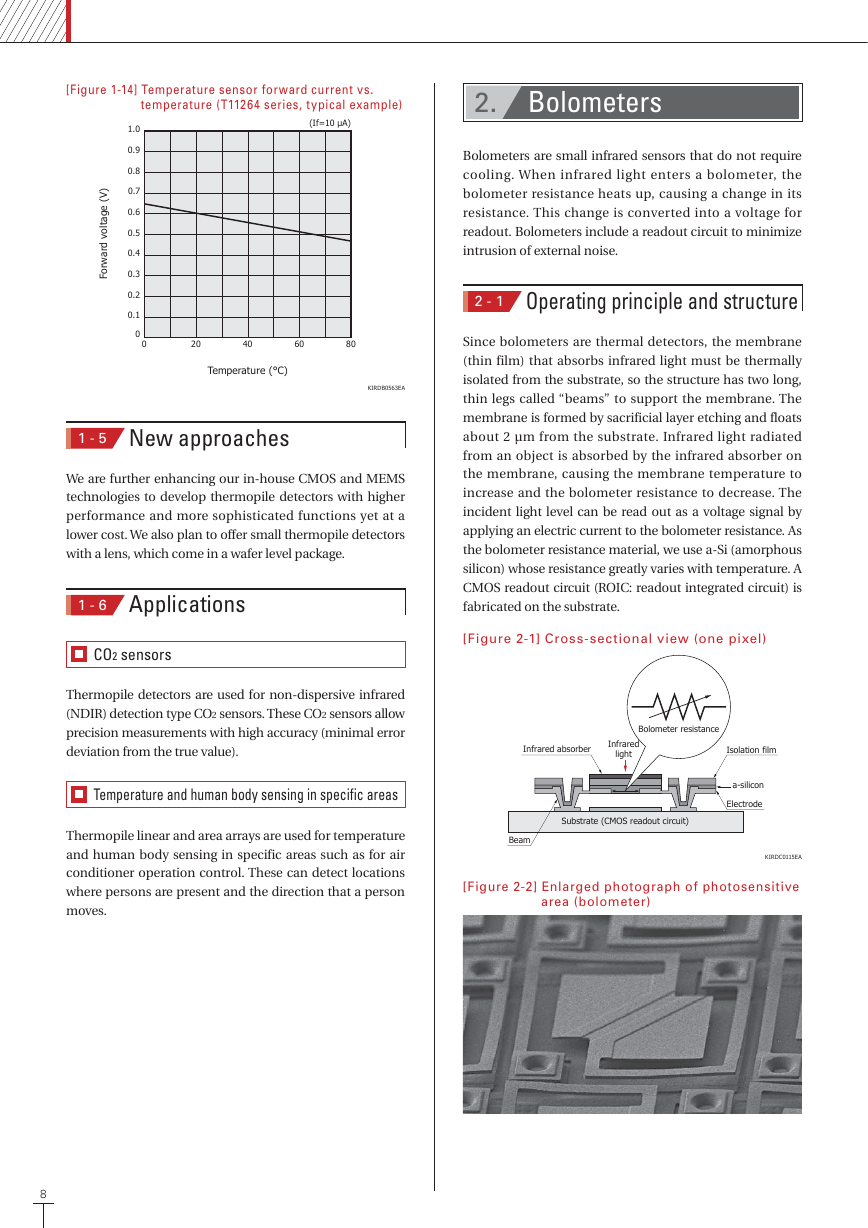

2.

Bolometers

Bolometers are small infrared sensors that do not require

cooling. When infrared light enters a bolometer, the

bolometer resistance heats up, causing a change in its

resistance. This change is converted into a voltage for

readout. Bolometers include a readout circuit to minimize

intrusion of external noise.

2 - 1

Operating principle and structure

Since bolometers are thermal detectors, the membrane

(thin film) that absorbs infrared light must be thermally

isolated from the substrate, so the structure has two long,

thin legs called “beams” to support the membrane. The

membrane is formed by sacrificial layer etching and floats

about 2 µm from the substrate. Infrared light radiated

from an object is absorbed by the infrared absorber on

the membrane, causing the membrane temperature to

increase and the bolometer resistance to decrease. The

incident light level can be read out as a voltage signal by

applying an electric current to the bolometer resistance. As

the bolometer resistance material, we use a-Si (amorphous

silicon) whose resistance greatly varies with temperature. A

CMOS readout circuit (ROIC: readout integrated circuit) is

fabricated on the substrate.

[Figure 2-1] Cross-sectional view (one pixel)

Bolometer resistance

Infrared absorber

Infrared

light

Substrate (CMOS readout circuit)

Beam

Isolation film

a-silicon

Electrode

KIRDC0115EA

[Figure 2-2] Enlarged photograph of photosensitive

area (bolometer)

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc