TÜV SÜD

TÜV SÜD

TÜV SÜD

2003

2010

1

2012

4

TÜV

TÜV SÜD

TÜV SÜD

ISO26262

ECU

(ISO26262)

(IEC61508) (

IEC61508

TÜV

2013

2012

2012

2011

2010

2010

TÜV SÜD

:TP12010172)

ISO26262

Slide 2

TÜV SÜD

1

TÜV

2

3

ISO 26262

4

5

TÜV SÜD ISO 26262

TÜV

1866

1

6

TÜV (Technischer Überwachungs-Verein)

(Technical Inspection Association)

TÜV SÜD

TÜV SÜD

Slide 4

�

TÜV SÜD

TÜV SÜD

1

150

800

1,700

17,200

150

800

2011

17

17200

TÜV SÜD

TÜV SÜD

TÜV SÜD

40

2,000

20000

TÜV SÜD

Slide 5

TÜV SÜD

TÜV SÜD

TÜV SÜD Automotive Services / TÜV SÜD

TÜV SÜD Automotive provides end-to-end solutions for:

TÜV SÜD

Slide 6

Original Equipment Manufacturers (OEMs) /

Automotive Suppliers /

/

TÜV SÜD

TÜV SÜD

Slide 7

TÜV SÜD

Slide 8

Consultancy

Supplier audits

Vehicle & component testing

Management System auditing & certification

Homologation & Type approvals

Quality conformity

Training

Functional Safety

Consultancy

Supplier audits

Component testing

Management System auditing & certification

Quality conformity

Training

Functional Safety

�

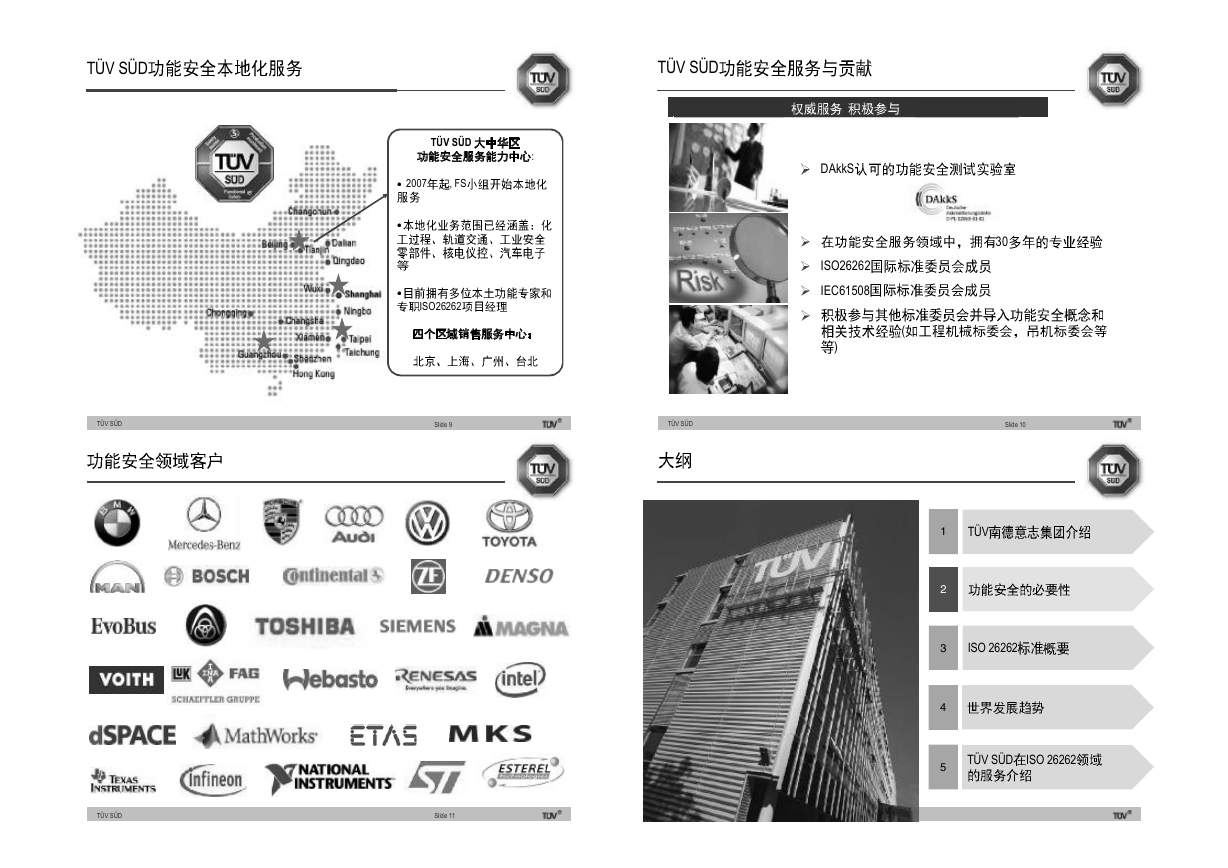

TÜV SÜD

TÜV SÜD

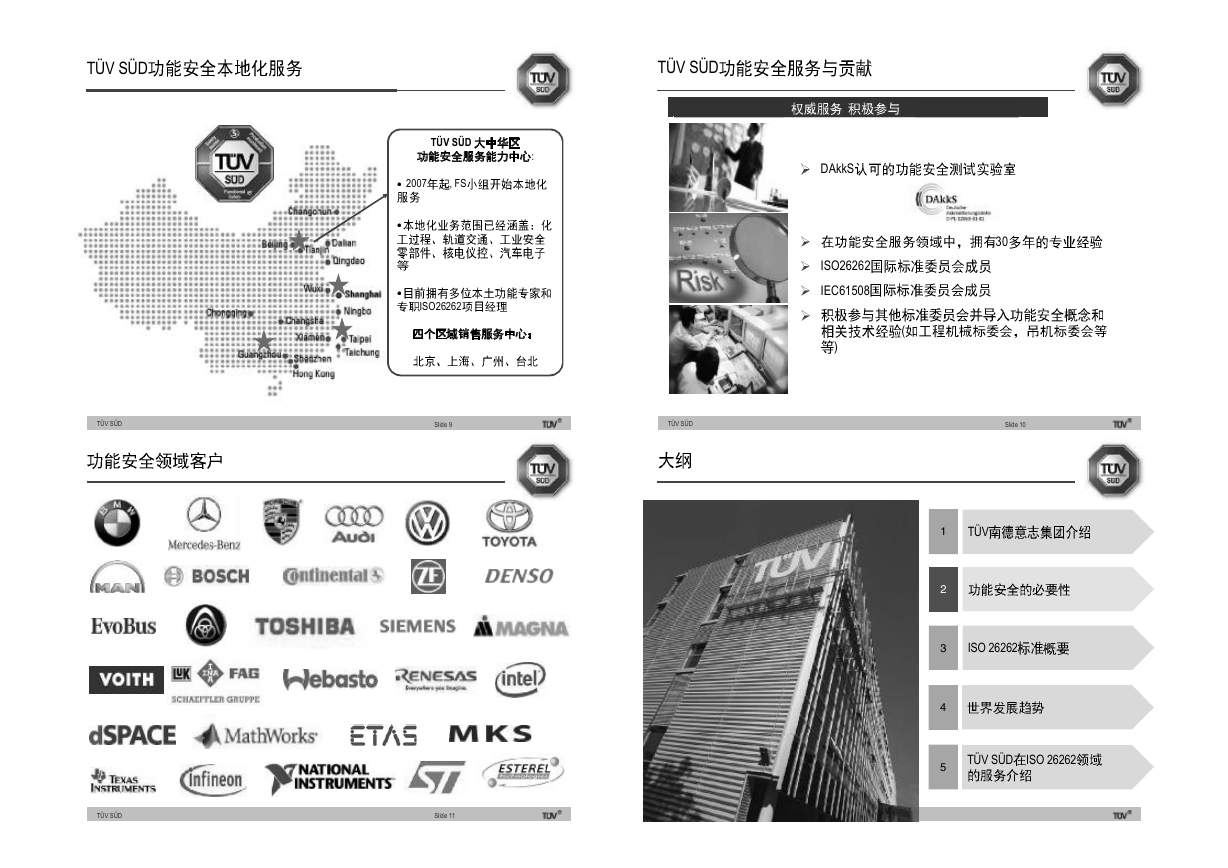

:

TÜV SÜD

, FS

2007

ISO26262

TÜV SÜD

Slide 9

TÜV SÜD

DAkkS

ISO26262

IEC61508

(

)

30

Slide 10

1

TÜV

TÜV SÜD

Slide 11

TÜV SÜD

4

5

TÜV SÜD ISO 26262

2

3

ISO 26262

�

(

)

TÜV SÜD

Slide 13

TÜV SÜD

Slide 14

TÜV SÜD

Slide 15

2011

2010

2010

2009

Source: GSI Darmstadt

TÜV SÜD

25,792

408/2.0L

300,000

540,000

10,000

Slide 16

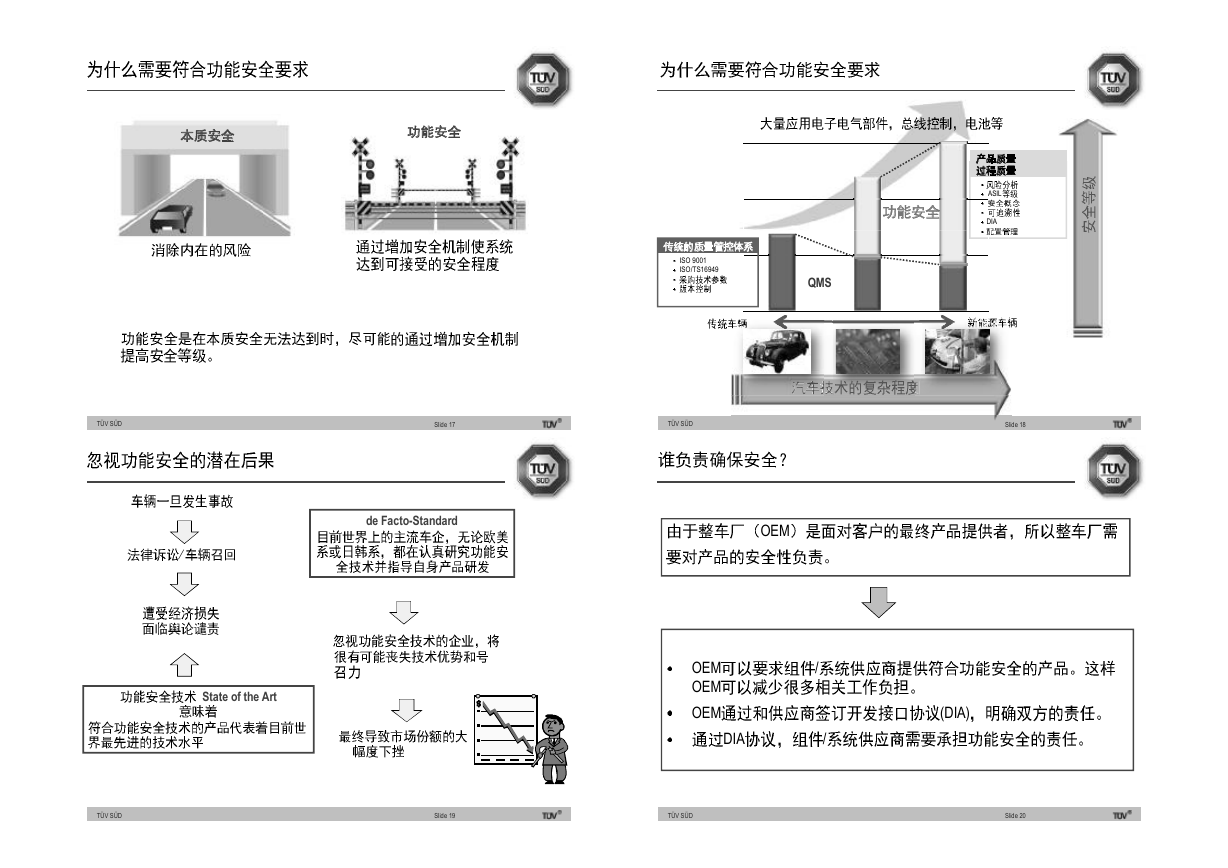

�

State of the Art

TÜV SÜD

/

ISO 9001

ISO/TS16949

QMS

Slide 17

TÜV SÜD

de Facto-Standard

OEM

/

/

OEM

OEM

OEM

DIA

Slide 18

ASIL

DIA

(DIA)

TÜV SÜD

Slide 19

TÜV SÜD

Slide 20

�

OEM

ASIL

DIA

OEM

OEM

/

ISO26262

Slide 21

2011

11

TÜV SÜD

ISO26262

ISO26262

ISO26262

ISO26262

ISO26262

TÜV SÜD

1

TÜV

2

3

ISO 26262

4

5

TÜV SÜD ISO 26262

TÜV SÜD

ISO26262

2-5 Overall Functional Safety Management

1. Vocabulary

2. Management of Functional Safety

2-6 Safety Management during Item Development

2-7 Safety Management after release of Production

3. Concept Phase

3-5 Item Definition

4-5 Initiation of system development

4. System Design Phase

4-11 Release for Production

7. Production and Operation

3-6 Initiation of Safety Life Cycle

4-6 Specification Technical Safety Requirement

4-10 Functional Safety Assessment

7-5 Production

3-7 Hazard Analysis / Risk Assess

4-7 System Design

3-8 Functional Safety Concept

4-9 Safety Validation

4-8 Item Integration and Testing

7-6 Operation, Services Maintenance and

repair

and decommissioning

5. Hardware Development

5. Hardware Development

5-5 Initiation of Hardware Development

5-6 Specification of Hardware Safety Req

5-7 Hardware Design

5-8 Hardware Architectural Metrics

5-9 Random Hardware Failure Evaluation

5-10 Hardware Integration and Testing

6. Software Development

6. Software Development

6-5 Initiation of Software Development

6-6 Specification of Software Safety Req

6-7 Software Architecture Design

6-8 Software Unit Design

6-9 Software Unit Testing

6-10 Software Integration Testing

6-11 Verification of Software Safety Req

3.5

ASIL A

D

8-5 Interface with Distributed Development

8-6 Specification and management of Safety requirements

8-7 Configuration Management

8-8 Change Management

8-9 Verification

9-5 Requirement decomposition with respect to ASIL requirement

9-6 Criteria for coexistence of elements

Slide 23

TÜV SÜD

8. Support Process

8-10 Documentation

8-11 Software tool qualification

8-12 Software component qualification

8-13 Hardware component qualification

8-14 Proven in use argument

9. ASIL oriented Safety analysis

9-7 Analysis of dependent failure

9-8 Safety Analysis

10. ISO 26262 Guideline

�

ISO26262

1.

2.

Functional Safety Management

Part 2

Safety Product Development

Concept development phase (Part 3)

System development phase (Part 4)

H/W & S/W (Part5,6)

Actual product development

3.

Production and Operation (Part 7)

TÜV SÜD

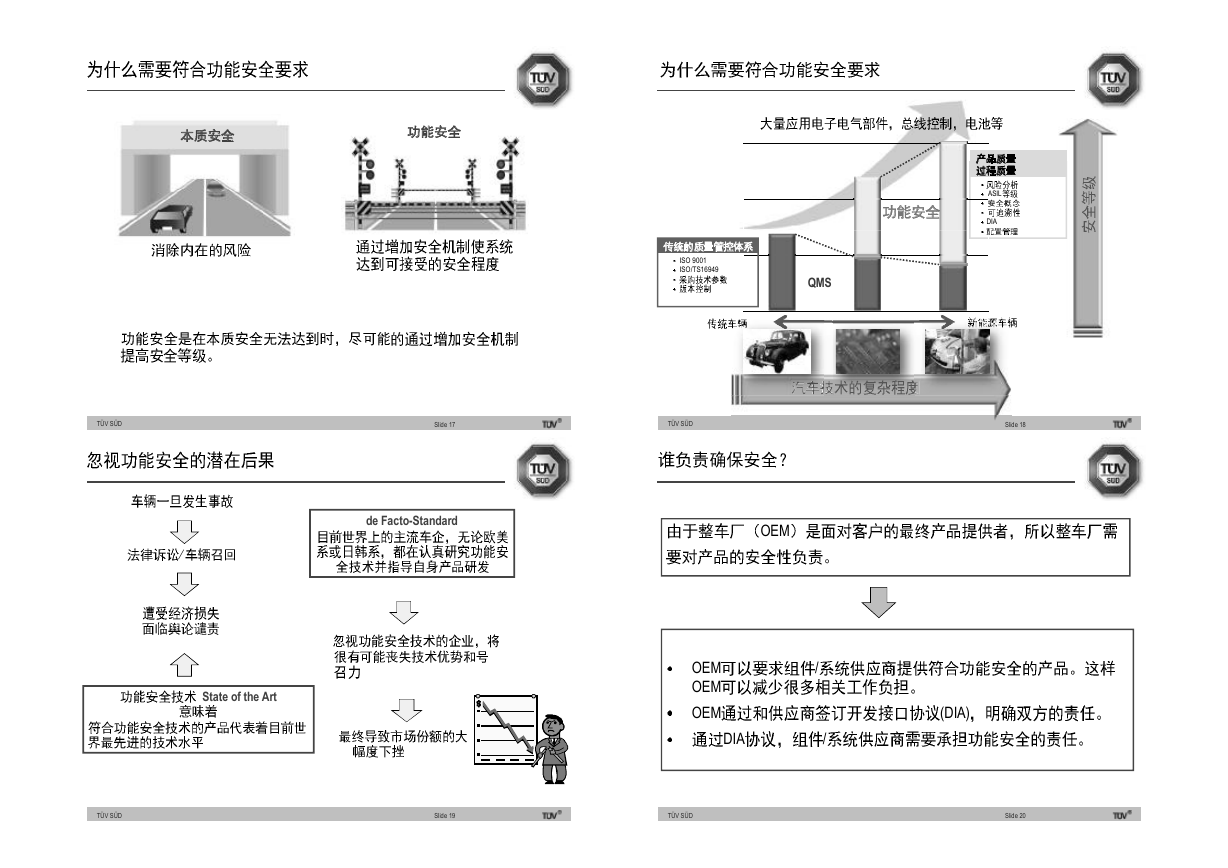

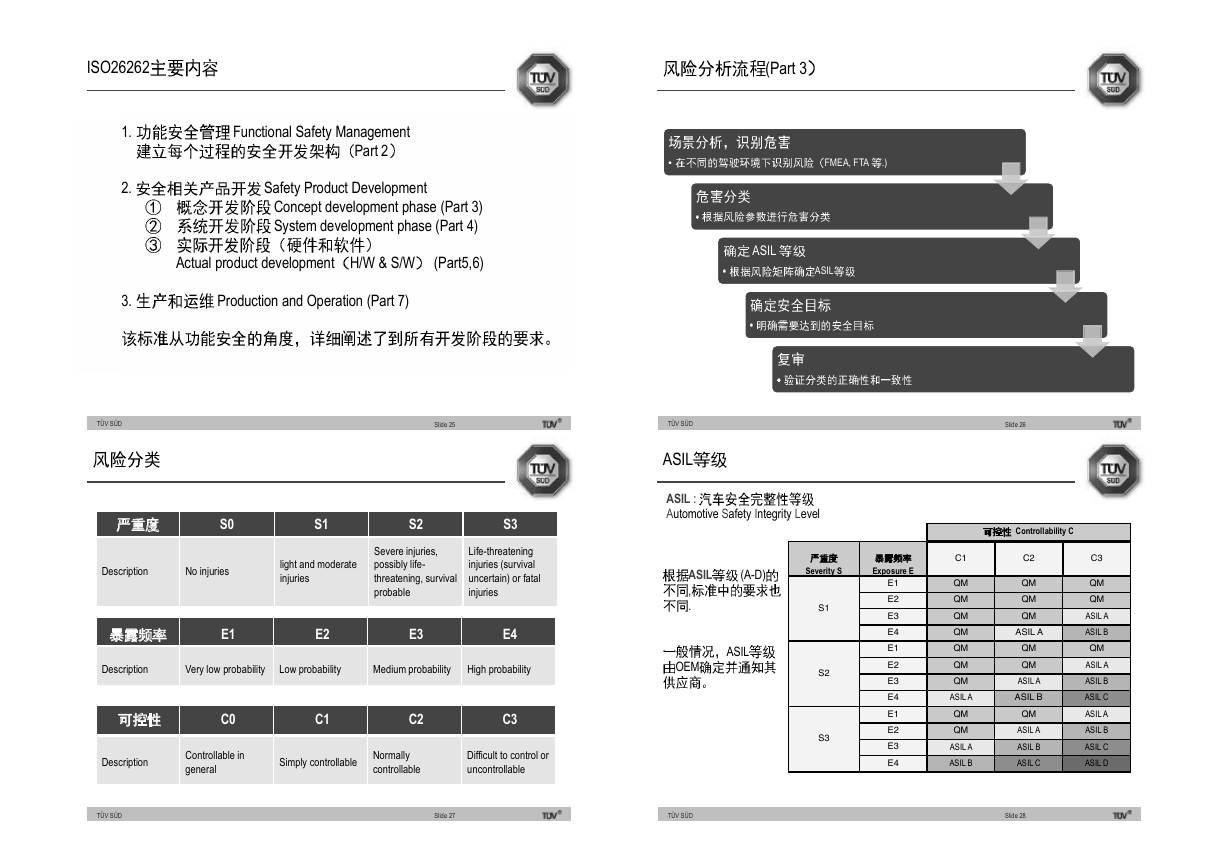

S0

Description

No injuries

Slide 25

S1

light and moderate

injuries

S2

S3

Severe injuries,

possibly life-

threatening, survival

probable

Life-threatening

injuries (survival

uncertain) or fatal

injuries

E1

E2

E3

E4

Description

Very low probability Low probability

Medium probability High probability

C0

C1

C2

C3

Description

Controllable in

general

Simply controllable

Normally

controllable

Difficult to control or

uncontrollable

TÜV SÜD

Slide 27

TÜV SÜD

Slide 28

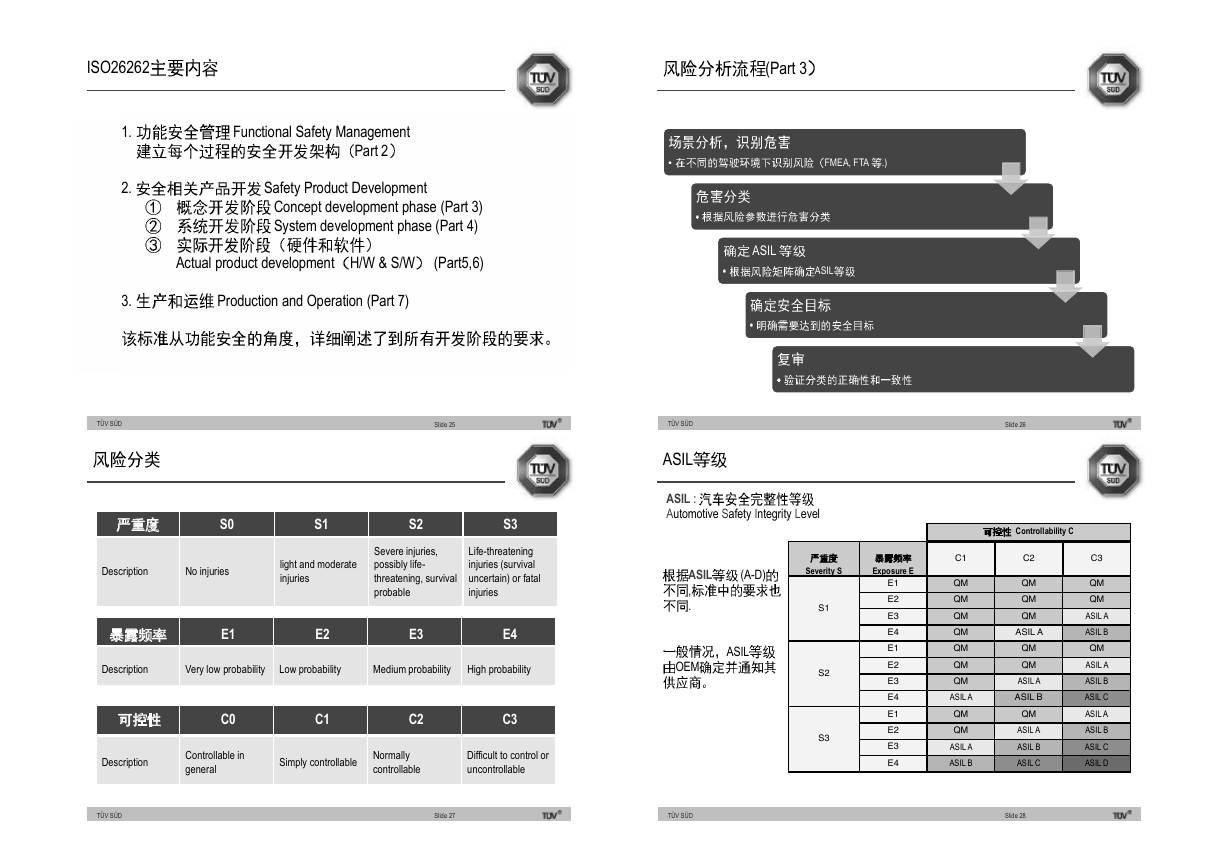

(Part 3

FMEA, FTA

.)

ASIL

ASIL

TÜV SÜD

ASIL

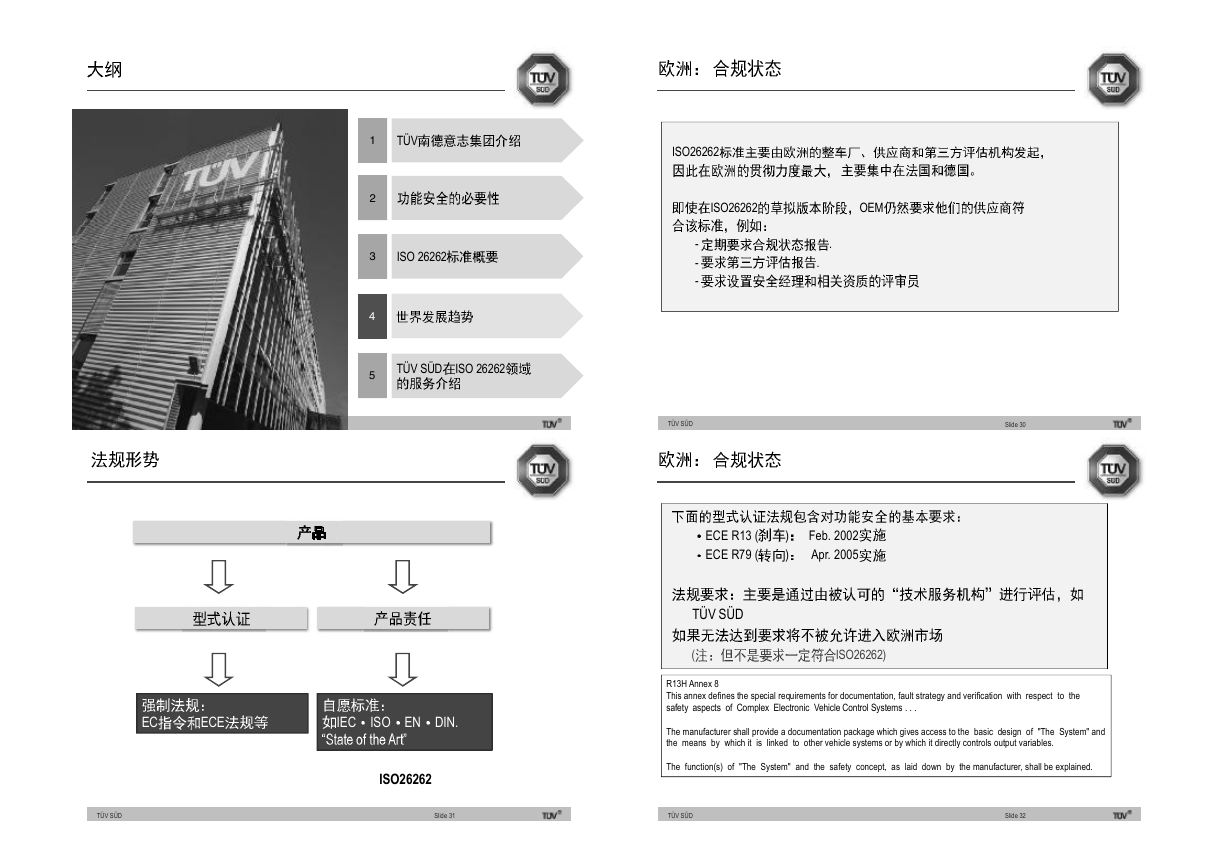

ASIL :

Automotive Safety Integrity Level

(A-D)

Severity S

ASIL

,

.

ASIL

OEM

S1

S2

S3

Slide 26

Controllability C

C2

QM

QM

QM

ASIL A

QM

QM

ASIL A

ASIL B

QM

ASIL A

ASIL B

ASIL C

C3

QM

QM

ASIL A

ASIL B

QM

ASIL A

ASIL B

ASIL C

ASIL A

ASIL B

ASIL C

ASIL D

Exposure E

E1

E2

E3

E4

E1

E2

E3

E4

E1

E2

E3

E4

C1

QM

QM

QM

QM

QM

QM

QM

ASIL A

QM

QM

ASIL A

ASIL B

�

TÜV SÜD

1

TÜV

2

3

ISO 26262

TÜV SÜD ISO 26262

4

5

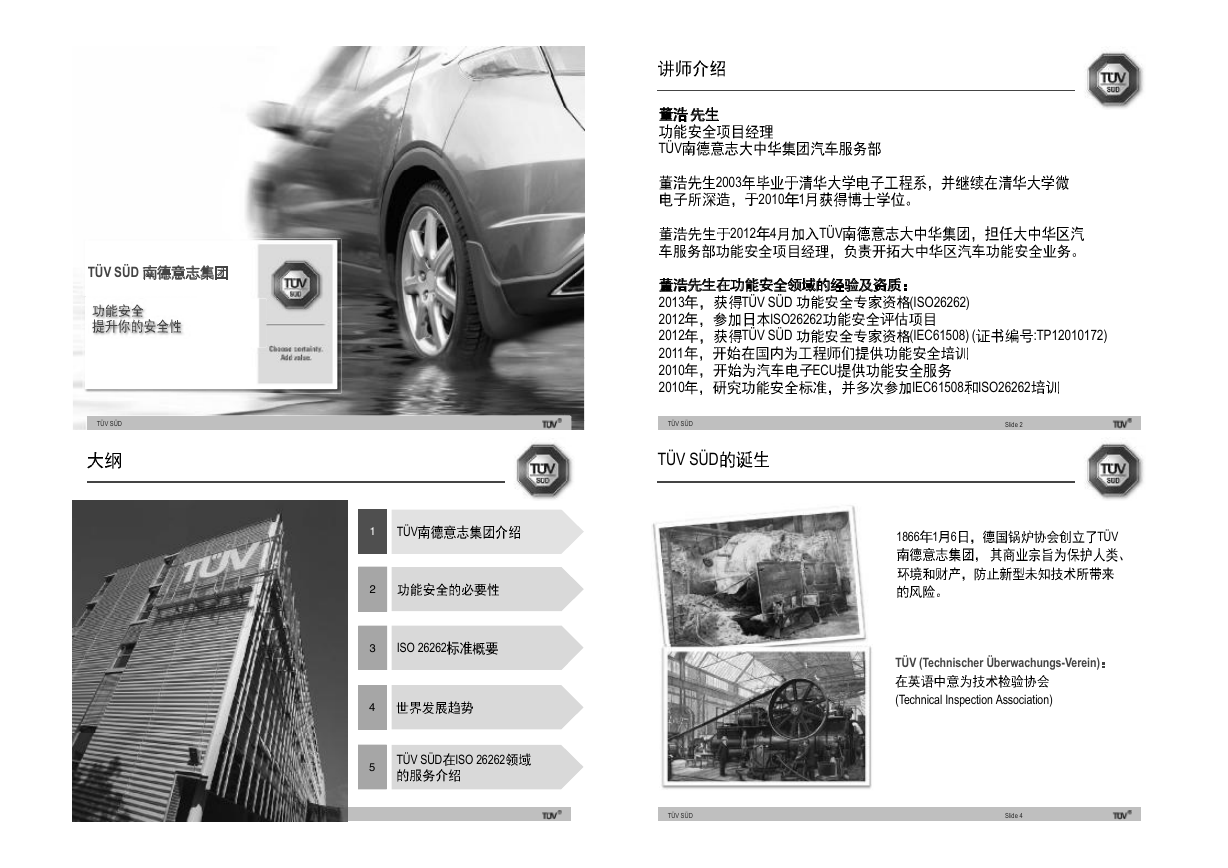

EC

ECE

IEC ISO EN DIN.

ISO26262

OEM

.

.

ISO26262

ISO26262

-

-

-

TÜV SÜD

Slide 30

ECE R13 (

ECE R79 (

)

)

Feb. 2002

Apr. 2005

TÜV SÜD

(

ISO26262)

R13H Annex 8

This annex defines the special requirements for documentation, fault strategy and verification with respect to the

safety aspects of Complex Electronic Vehicle Control Systems . . .

The manufacturer shall provide a documentation package which gives access to the basic design of "The System" and

the means by which it is linked to other vehicle systems or by which it directly controls output variables.

The function(s) of "The System" and the safety concept, as laid down by the manufacturer, shall be explained.

TÜV SÜD

Slide 31

TÜV SÜD

Slide 32

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc