ICS 29.020

备案号:CEC 400^2010

Q / GDW 1827 — 2010

Q/GDW

国 家 电 网 公 司 企 业 标 准

Q / GDW 1827 — 2012

三相智能电能表技术规范

Technical specification for polyphase smart electricity meters

××××-××-××发布

××××-××-××实施

国家电网公司 发 布

�

�

Q / GDW 1827— 2012

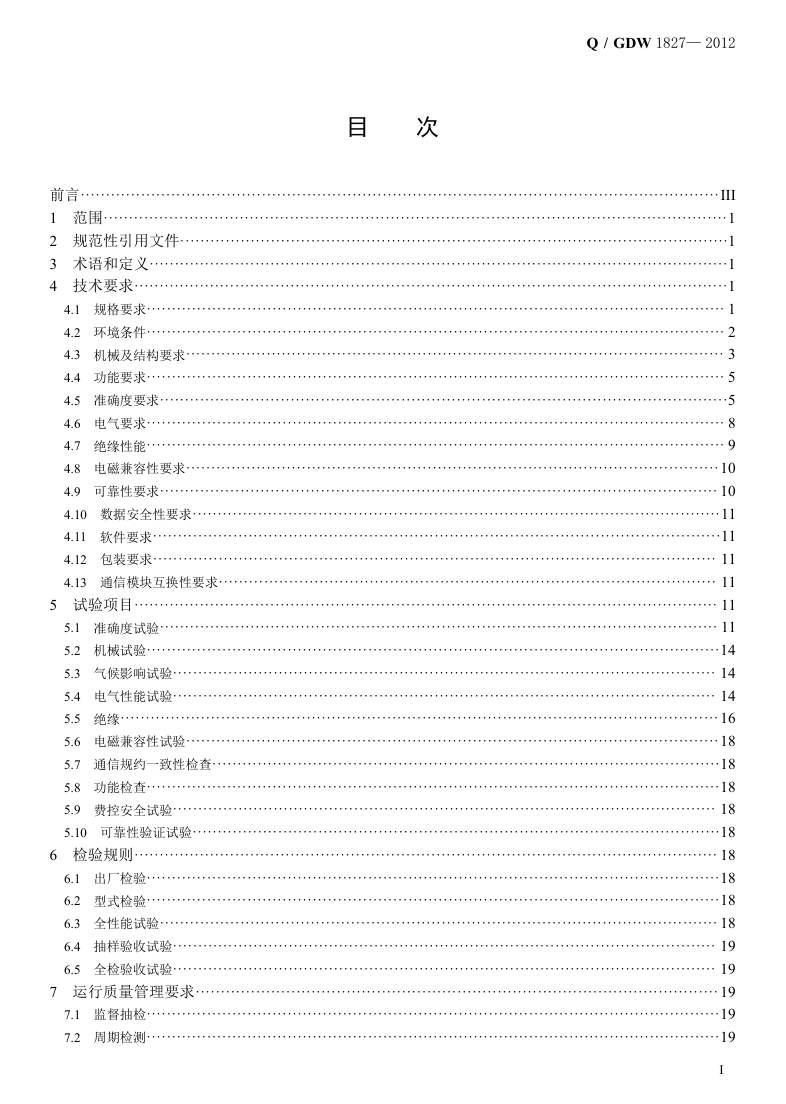

目 次

前言·······························································································································III

1 范围····························································································································1

2 规范性引用文件·············································································································1

3 术语和定义···················································································································1

4 技术要求······················································································································1

4.1 规格要求··················································································································· 1

4.2 环境条件··················································································································· 2

4.3 机械及结构要求··········································································································· 3

4.4 功能要求··················································································································· 5

4.5 准确度要求·················································································································5

4.6 电气要求··················································································································· 8

4.7 绝缘性能··················································································································· 9

4.8 电磁兼容性要求··········································································································10

4.9 可靠性要求··············································································································· 10

4.10 数据安全性要求·········································································································11

4.11 软件要求·················································································································11

4.12 包装要求················································································································ 11

4.13 通信模块互换性要求··································································································· 11

5 试验项目···················································································································· 11

5.1 准确度试验··············································································································· 11

5.2 机械试验··················································································································14

5.3 气候影响试验············································································································ 14

5.4 电气性能试验············································································································ 14

5.5 绝缘·······················································································································16

5.6 电磁兼容性试验··········································································································18

5.7 通信规约一致性检查·····································································································18

5.8 功能检查··················································································································18

5.9 费控安全试验············································································································ 18

5.10 可靠性验证试验·········································································································18

6 检验规则···················································································································· 18

6.1 出厂检验··················································································································18

6.2 型式检验··················································································································18

6.3 全性能试验··············································································································· 18

6.4 抽样验收试验············································································································ 19

6.5 全检验收试验············································································································ 19

7 运行质量管理要求········································································································ 19

7.1 监督抽检··················································································································19

7.2 周期检测··················································································································19

I

�

Q / GDW 1827 — 2012

7.3 故障统计分析············································································································ 19

7.4 技术服务要求············································································································ 19

附录 A(资料性附录) 智能电能表电压、电流规格对照表······················································· 21

附录 B(资料性附录) 试验项目明细表················································································23

编制说明·························································································································25

II

�

Q / GDW 1827— 2012

前

言

本标准是根据国家电网科[2012]66 号文件《关于下达 2012 年度国家电网公司技术标准制修订计

划的通知》要求,对 Q/GDW 357—2009~Q/GDW 363—2009 进行的第一次修订。

本标准规定了三相智能电能表的规格、适应环境、机械性能、电气性能、抗干扰及可靠性等方面的

技术要求和试验项目,规定了电能表的检验规则和运行质量管理要求。

本标准与 Q/GDW 357—2009~Q/GDW 363—2009 相比,主要变化如下:

——三相智能电能表技术规范由原来的 7 个精简为 1 个;

——删除与三相智能电能表型式规范和智能电能表功能规范重复描述的内容;

——增加通信模块接口带载能力、电流回路阻抗、通信模块互换性、恒定磁场防护性能、工频磁场

防潜动性能、高温极限工作影响的技术要求和试验项目;

——细化部分试验项目的检测方法;

——调整标准所列试验项目的合格评判标准;

——调整抽样验收试验的试验项目;

——明确负荷开关在不同应用环境下的技术要求。

本标准实施后代替 Q/GDW 357—2009~Q/GDW 363—2009。

本标准与《智能电能表功能规范》、《三相智能电能表型式规范》、《智能电能表信息交换安全认证技

术规范》共同成为三相智能电能表设计、制造、管理、维护的技术依据。

本标准由国家电网公司营销部提出并负责解释。

本标准由国家电网公司科技部归口。

本标准起草单位:中国电力科学研究院、冀北电力有限公司、北京市电力公司、河南省电力公司、

天津市电力公司、山东省电力集团公司。

本标准主要起草人:姜洪浪、章欣、杜蜀薇、杜新纲、彭楚宁、徐英辉、郜波、林繁涛、崔星毅、

周晖、李亦非、秦楠、张卫欣、代燕杰。

本标准首次公布。

III

�

�

Q / GDW 1827— 2012

三相智能电能表技术规范

1 范围

本标准规定了三相智能电能表(以下简称“电能表”)的规格、适应环境、机械性能、电气性能、

抗干扰及可靠性等方面的技术要求和试验项目,规定了电能表的检验规则和运行质量管理要求。

本标准适用于国家电网公司系统内电能表的设计、制造、采购及验收。

2 规范性引用文件

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注日期的版本适用于本文件。

凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

GB 4208—2008 外壳防护等级(IP 代码)

GB/T 13384—2008 机电产品包装通用技术条件

GB/T 17215.211—2006 交流电测量设备 通用要求 试验和试验条件 第 11 部分:测量设备

GB/T 17215.301—2007 多功能电能表 特殊要求

GB/T 17215.321—2008 交流电测量设备 特殊要求 第 21 部分 静止式有功电能表(1 级和 2 级)

GB/T 17215.322—2008 交流电测量设备 特殊要求 第 22 部分 静止式有功电能表(0.2S 级和

0.5S 级)

GB/T 17215.323—2008 交流电测量设备 特殊要求 第 23 部分 静止式无功电能表(2 级和 3 级)

DL/T 645—2007 多功能电能表通信协议

DL/T 830—2002 静止式单相交流有功电能表使用导则

JJG 596 电子式电能表

Q/GDW 206 电能表抽样技术规范

Q/GDW 1354—2012 智能电能表功能规范

Q/GDW 1356—2012 三相智能电能表型式规范

Q/GDW 1365—2012 智能电能表信息交换安全认证技术规范

3 术语和定义

Q/GDW 1354—2012《智能电能表功能规范》界定的术语和定义适用于本文件。

4 技术要求

4.1 规格要求

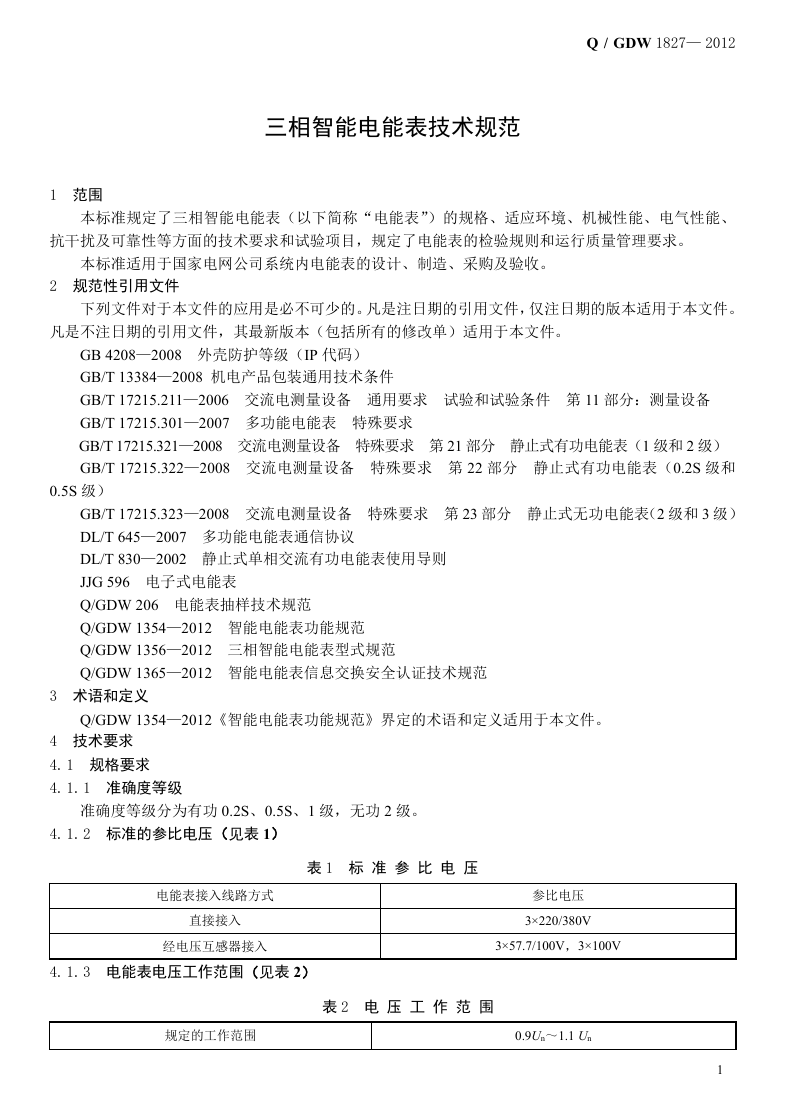

4.1.1 准确度等级

准确度等级分为有功 0.2S、0.5S、1 级,无功 2 级。

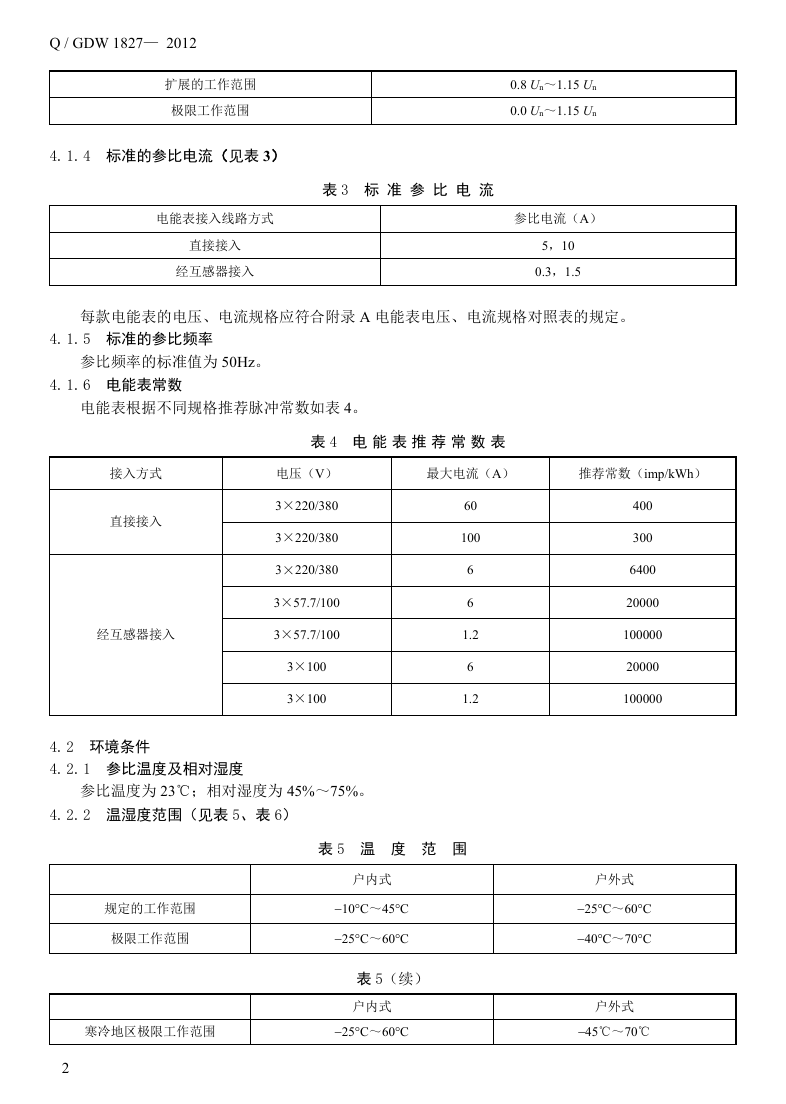

4.1.2 标准的参比电压(见表 1)

表 1 标 准 参 比 电 压

电能表接入线路方式

直接接入

经电压互感器接入

4.1.3 电能表电压工作范围(见表 2)

参比电压

3×220/380V

3×57.7/100V,3×100V

表 2 电 压 工 作 范 围

规定的工作范围

0.9Un~1.1 Un

1

�

Q / GDW 1827— 2012

扩展的工作范围

极限工作范围

4.1.4 标准的参比电流(见表 3)

电能表接入线路方式

直接接入

经互感器接入

表 3 标 准 参 比 电 流

0.8 Un~1.15 Un

0.0 Un~1.15 Un

参比电流(A)

5,10

0.3,1.5

每款电能表的电压、电流规格应符合附录 A 电能表电压、电流规格对照表的规定。

4.1.5 标准的参比频率

参比频率的标准值为 50Hz。

4.1.6 电能表常数

电能表根据不同规格推荐脉冲常数如表 4。

表 4 电 能 表 推 荐 常 数 表

接入方式

直接接入

经互感器接入

电压(V)

3×220/380

3×220/380

3×220/380

3×57.7/100

3×57.7/100

3×100

3×100

4.2 环境条件

4.2.1 参比温度及相对湿度

参比温度为 23℃;相对湿度为 45%~75%。

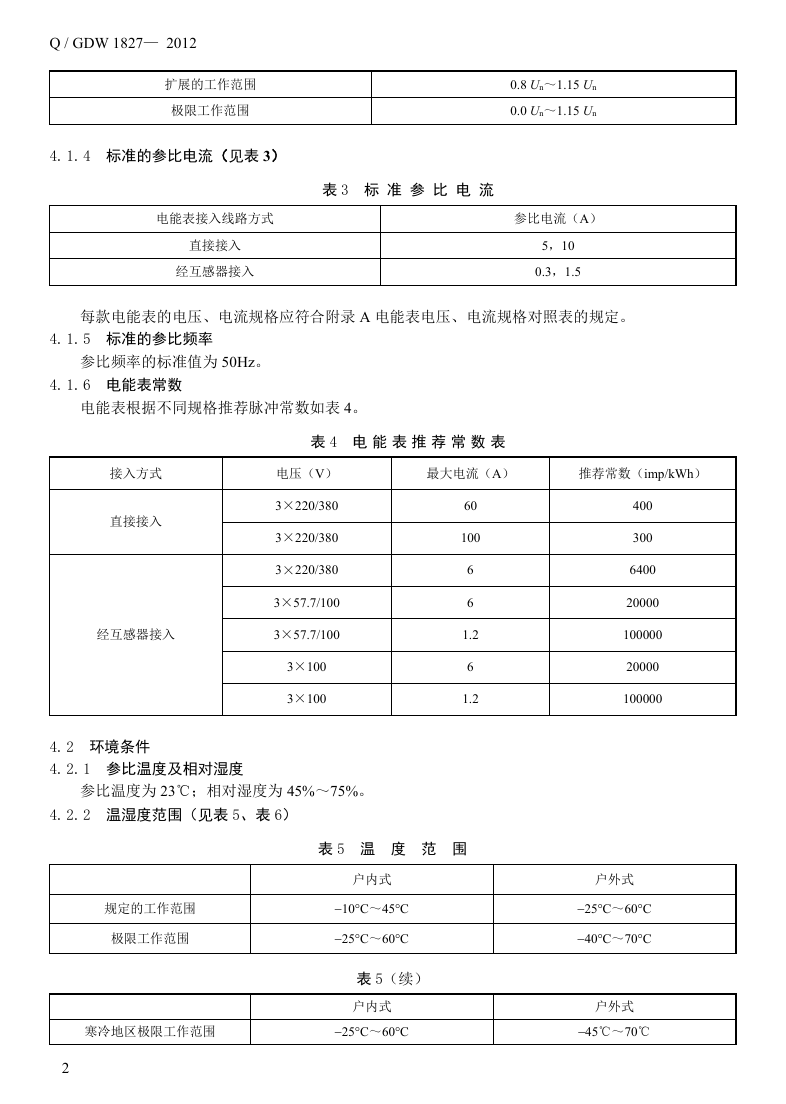

4.2.2 温湿度范围(见表 5、表 6)

最大电流(A)

推荐常数(imp/kWh)

60

100

6

6

1.2

6

1.2

400

300

6400

20000

100000

20000

100000

表 5 温 度 范 围

户内式

10C~45C

25C~60C

表 5(续)

户内式

25C~60C

户外式

25C~60C

40C~70C

户外式

45℃~70℃

规定的工作范围

极限工作范围

寒冷地区极限工作范围

2

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc