ADCNC

Function Reference Manual

2.0

Wei-Li Chuang

MAPS-Embedded System Section

1

�

Revision sheet:

Rev Date

Author

Description

2.0

2014.10.14

Weili

Release ADCNC function reference manual

MAPS-Embedded System Section

2

�

1. Introduction

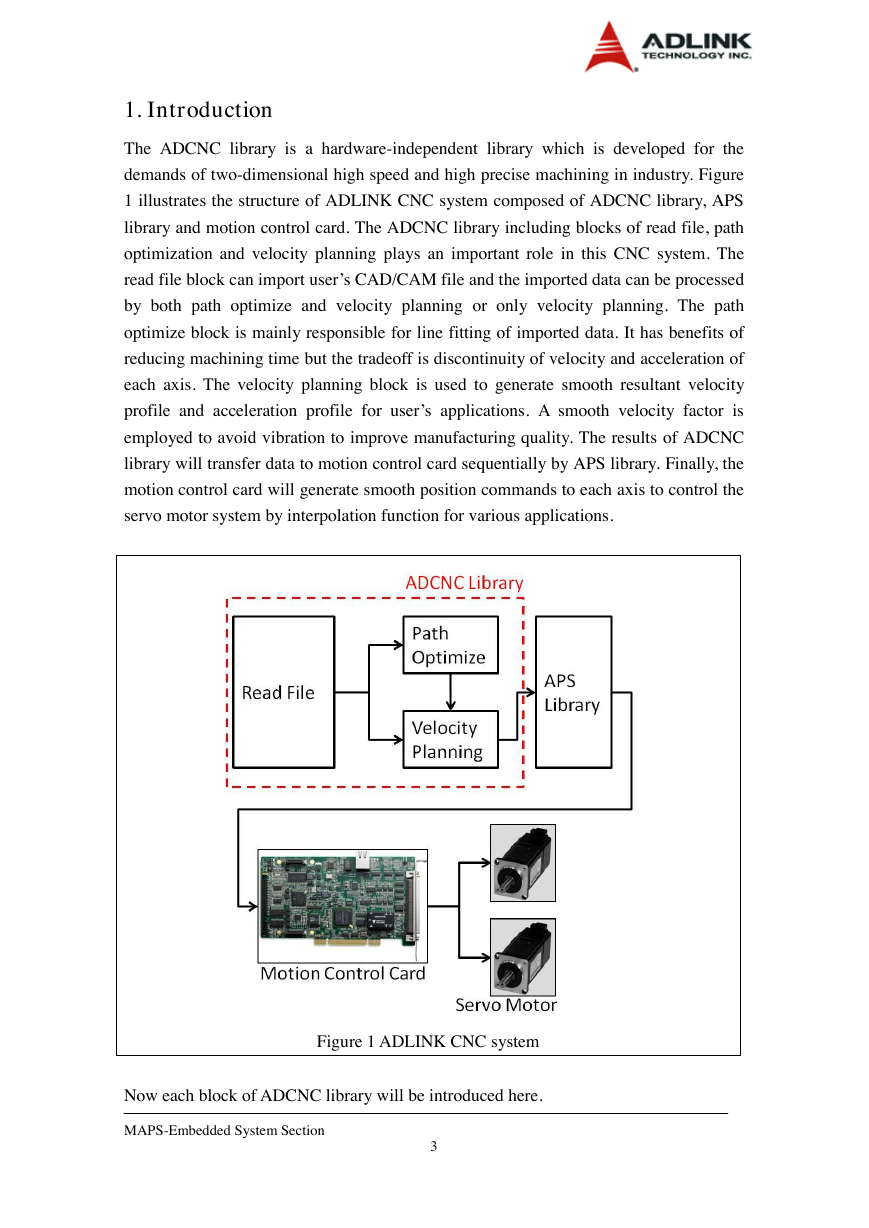

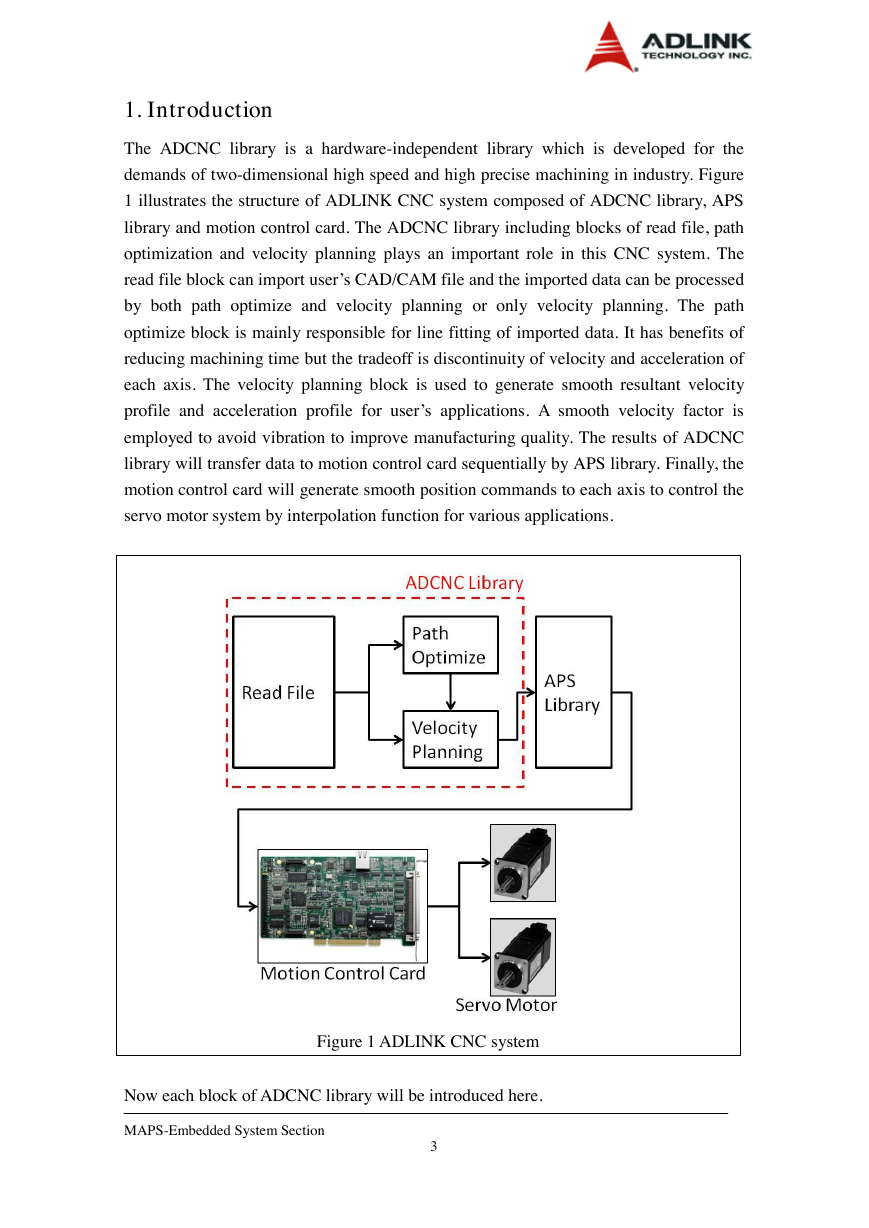

The ADCNC library is a hardware-independent library which is developed for the

demands of two-dimensional high speed and high precise machining in industry. Figure

1 illustrates the structure of ADLINK CNC system composed of ADCNC library, APS

library and motion control card. The ADCNC library including blocks of read file, path

optimization and velocity planning plays an important role in this CNC system. The

read file block can import user’s CAD/CAM file and the imported data can be processed

by both path optimize and velocity planning or only velocity planning. The path

optimize block is mainly responsible for line fitting of imported data. It has benefits of

reducing machining time but the tradeoff is discontinuity of velocity and acceleration of

each axis. The velocity planning block is used to generate smooth resultant velocity

profile and acceleration profile for user’s applications. A smooth velocity factor is

employed to avoid vibration to improve manufacturing quality. The results of ADCNC

library will transfer data to motion control card sequentially by APS library. Finally, the

motion control card will generate smooth position commands to each axis to control the

servo motor system by interpolation function for various applications.

Figure 1 ADLINK CNC system

Now each block of ADCNC library will be introduced here.

MAPS-Embedded System Section

3

�

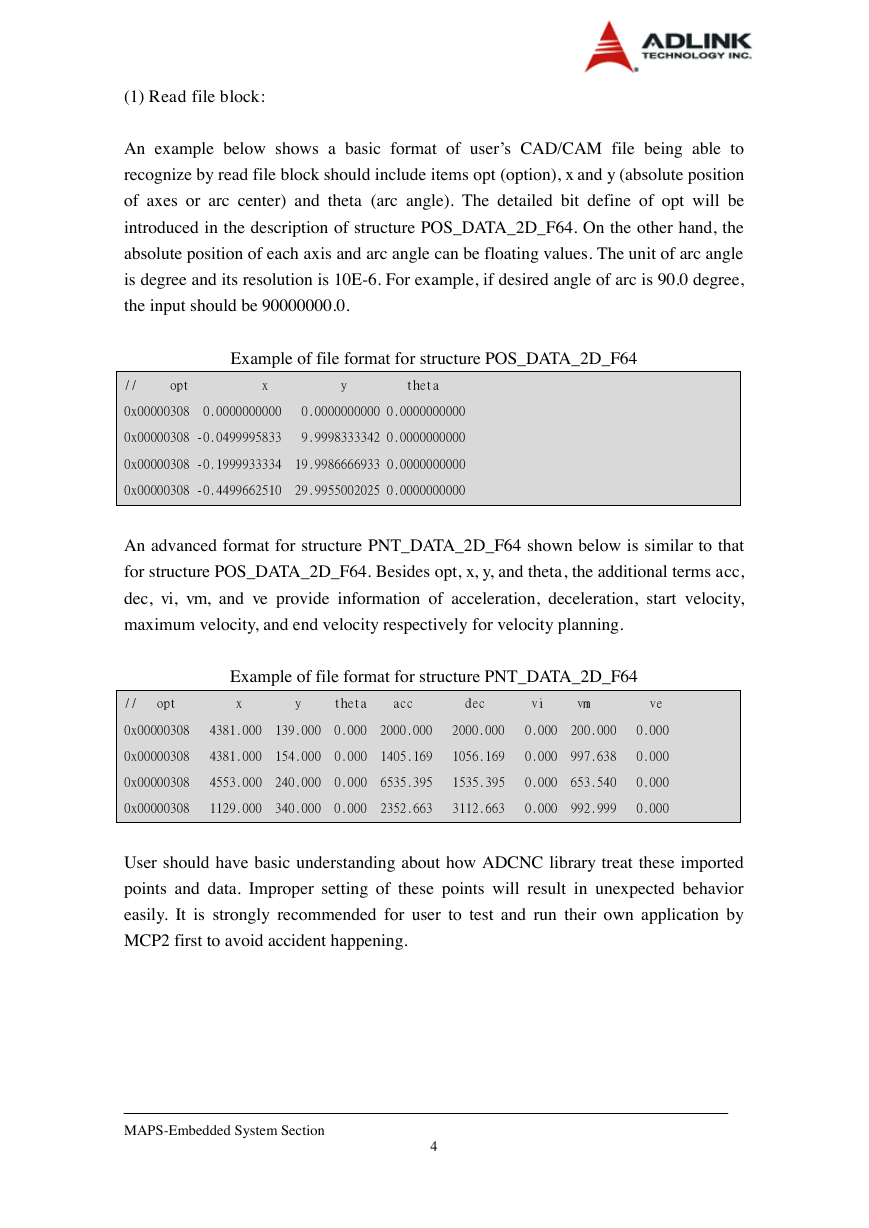

(1) Read file block:

An example below shows a basic format of user’s CAD/CAM file being able to

recognize by read file block should include items opt (option), x and y (absolute position

of axes or arc center) and theta (arc angle). The detailed bit define of opt will be

introduced in the description of structure POS_DATA_2D_F64. On the other hand, the

absolute position of each axis and arc angle can be floating values. The unit of arc angle

is degree and its resolution is 10E-6. For example, if desired angle of arc is 90.0 degree,

the input should be 90000000.0.

Example of file format for structure POS_DATA_2D_F64

// opt x y theta

0x00000308 0.0000000000 0.0000000000 0.0000000000

0x00000308 -0.0499995833 9.9998333342 0.0000000000

0x00000308 -0.1999933334 19.9986666933 0.0000000000

0x00000308 -0.4499662510 29.9955002025 0.0000000000

An advanced format for structure PNT_DATA_2D_F64 shown below is similar to that

for structure POS_DATA_2D_F64. Besides opt, x, y, and theta, the additional terms acc,

dec, vi, vm, and ve provide information of acceleration, deceleration, start velocity,

maximum velocity, and end velocity respectively for velocity planning.

Example of file format for structure PNT_DATA_2D_F64

// opt x y theta acc dec vi vm ve

0x00000308 4381.000 139.000 0.000 2000.000 2000.000 0.000 200.000 0.000

0x00000308 4381.000 154.000 0.000 1405.169 1056.169 0.000 997.638 0.000

0x00000308 4553.000 240.000 0.000 6535.395 1535.395 0.000 653.540 0.000

0x00000308 1129.000 340.000 0.000 2352.663 3112.663 0.000 992.999 0.000

User should have basic understanding about how ADCNC library treat these imported

points and data. Improper setting of these points will result in unexpected behavior

easily. It is strongly recommended for user to test and run their own application by

MCP2 first to avoid accident happening.

MAPS-Embedded System Section

4

�

(2) Path optimize block:

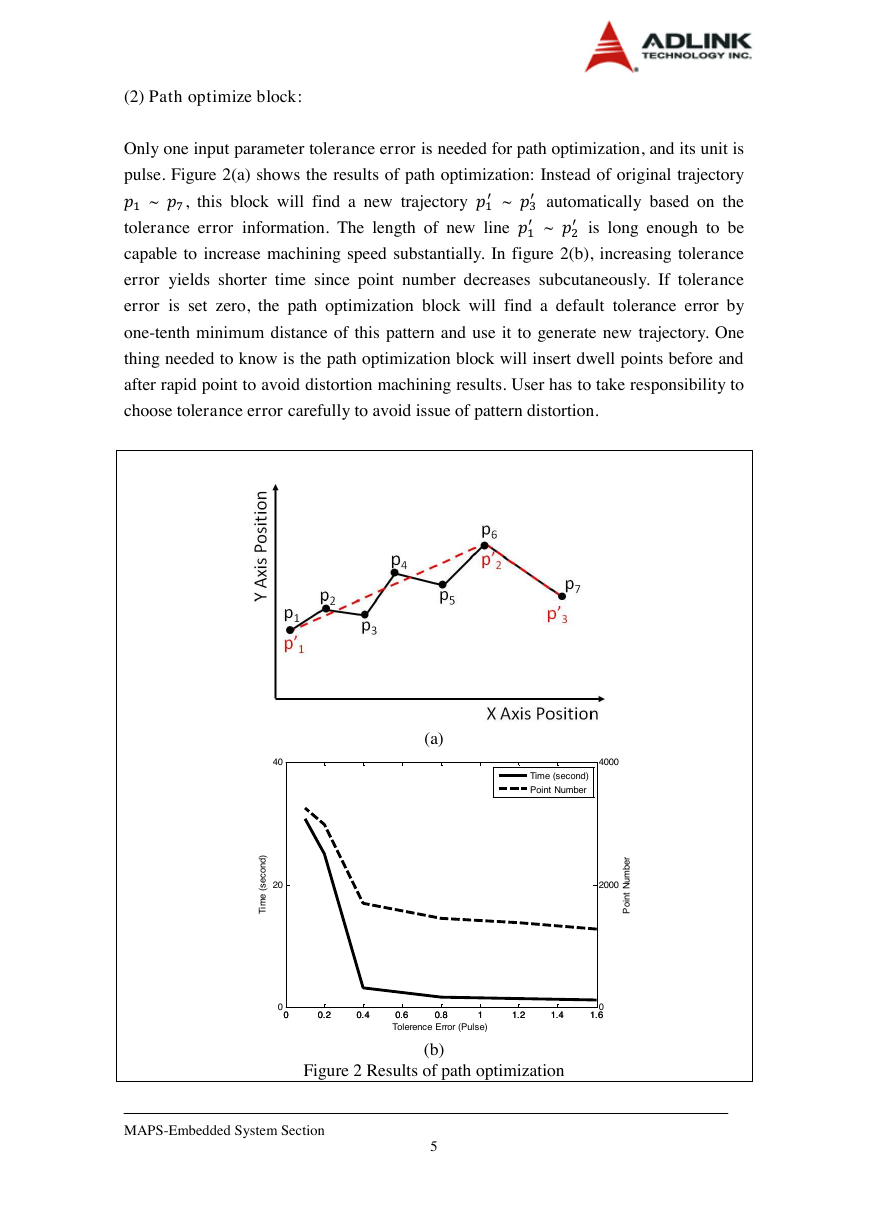

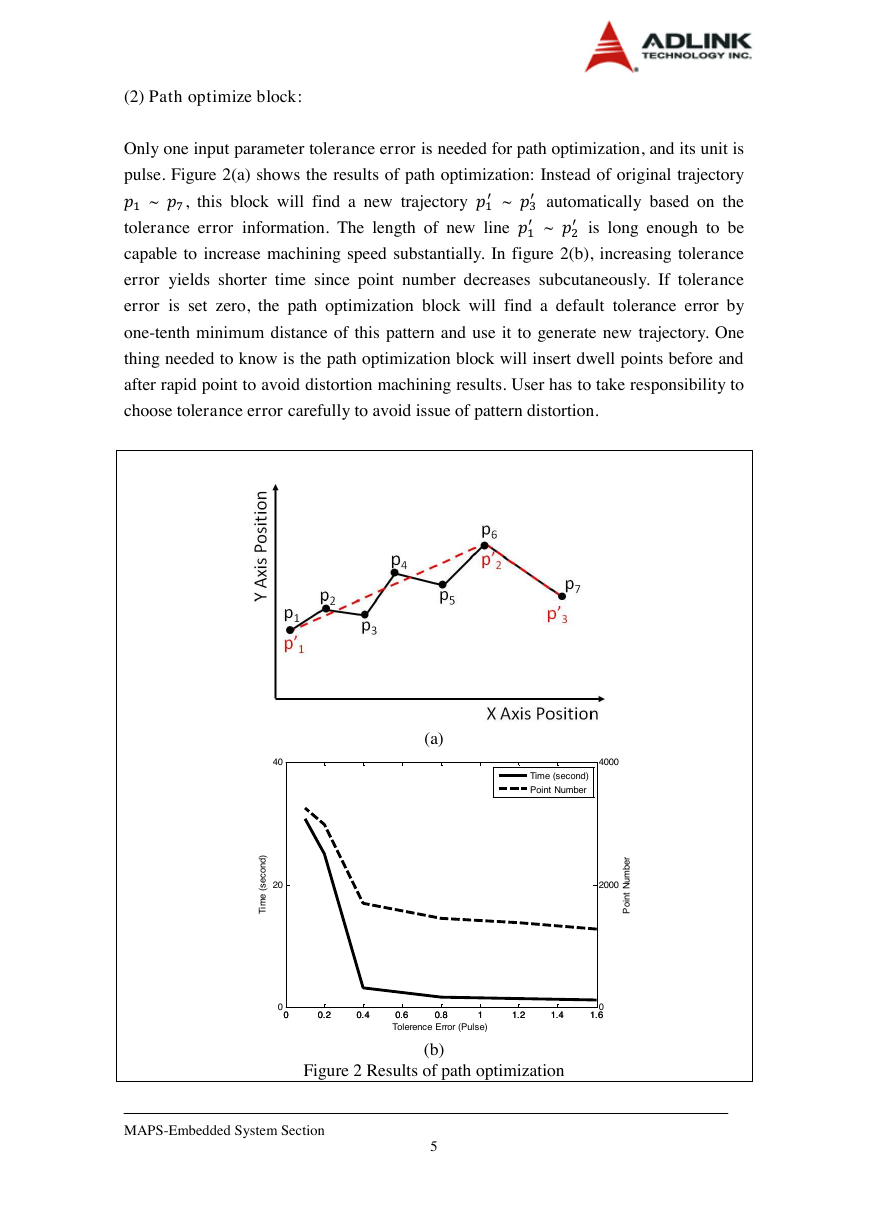

Only one input parameter tolerance error is needed for path optimization, and its unit is

pulse. Figure 2(a) shows the results of path optimization: Instead of original trajectory

automatically based on the

~

~ , this block will find a new trajectory

~

is long enough to be

tolerance error information. The length of new line

capable to increase machining speed substantially. In figure 2(b), increasing tolerance

error yields shorter time since point number decreases subcutaneously. If tolerance

error is set zero, the path optimization block will find a default tolerance error by

one-tenth minimum distance of this pattern and use it to generate new trajectory. One

thing needed to know is the path optimization block will insert dwell points before and

after rapid point to avoid distortion machining results. User has to take responsibility to

choose tolerance error carefully to avoid issue of pattern distortion.

(a)

(b)

Figure 2 Results of path optimization

MAPS-Embedded System Section

5

00.20.40.60.811.21.41.602040Time (second)Tolerence Error (Pulse) 00.20.40.60.811.21.41.6020004000Point NumberTime (second)Point Number�

(3) Velocity planning block

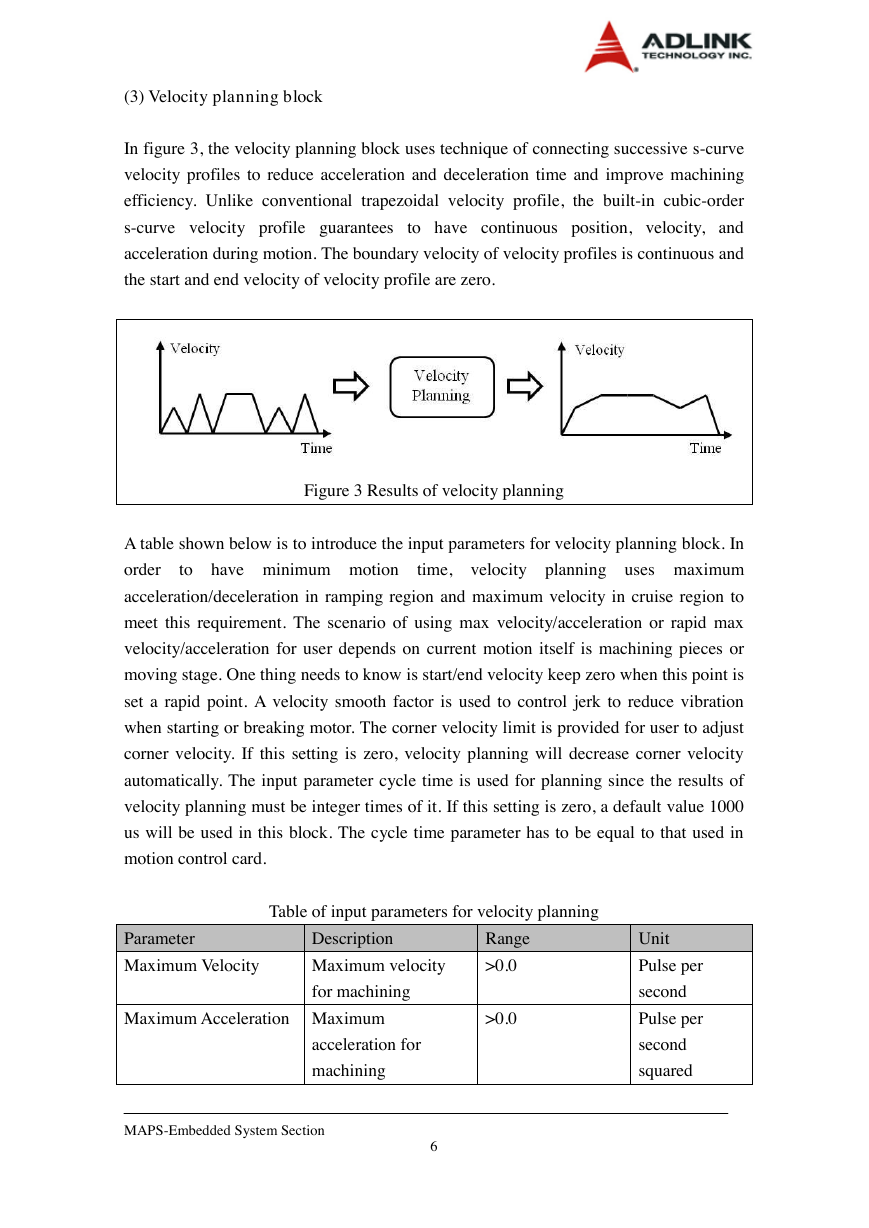

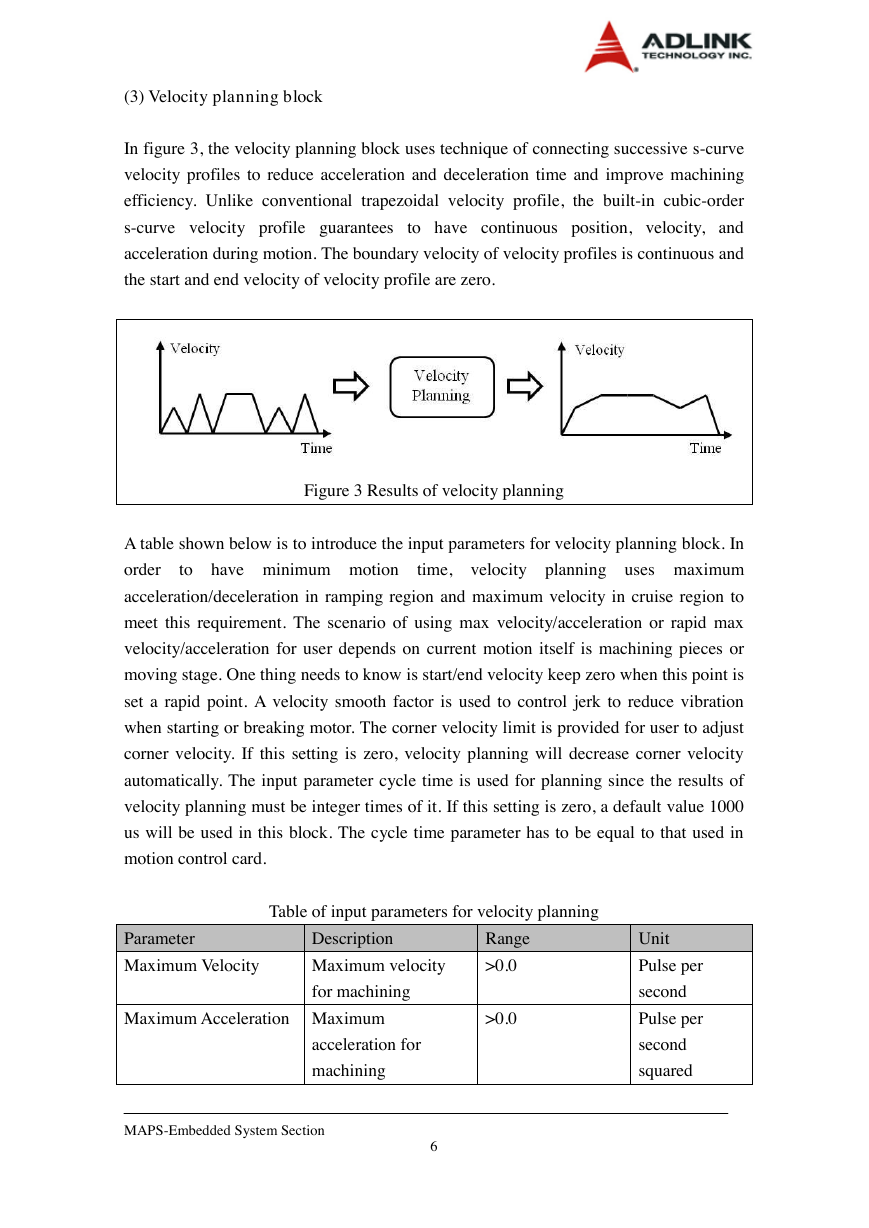

In figure 3, the velocity planning block uses technique of connecting successive s-curve

velocity profiles to reduce acceleration and deceleration time and improve machining

efficiency. Unlike conventional trapezoidal velocity profile, the built-in cubic-order

s-curve velocity profile guarantees to have continuous position, velocity, and

acceleration during motion. The boundary velocity of velocity profiles is continuous and

the start and end velocity of velocity profile are zero.

Figure 3 Results of velocity planning

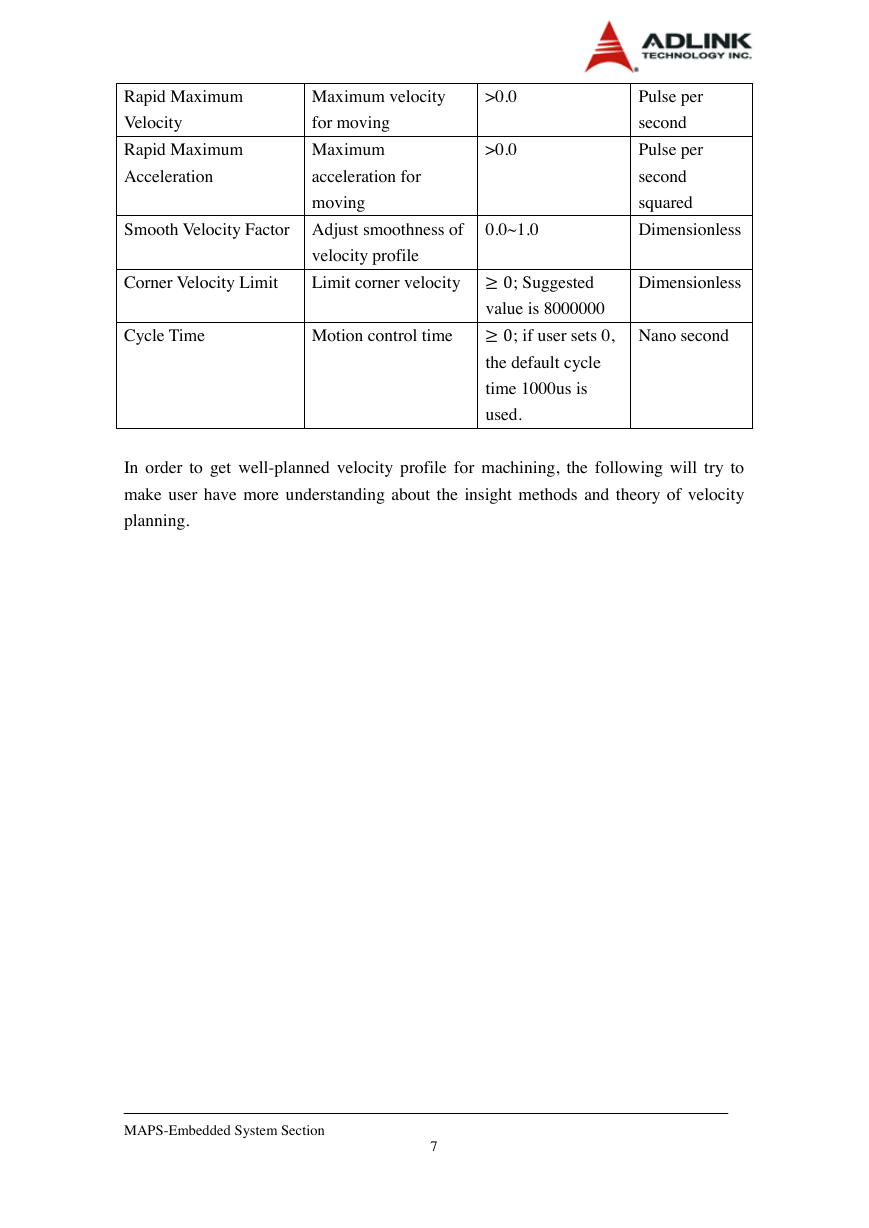

A table shown below is to introduce the input parameters for velocity planning block. In

order

to have minimum motion

time, velocity planning uses maximum

acceleration/deceleration in ramping region and maximum velocity in cruise region to

meet this requirement. The scenario of using max velocity/acceleration or rapid max

velocity/acceleration for user depends on current motion itself is machining pieces or

moving stage. One thing needs to know is start/end velocity keep zero when this point is

set a rapid point. A velocity smooth factor is used to control jerk to reduce vibration

when starting or breaking motor. The corner velocity limit is provided for user to adjust

corner velocity. If this setting is zero, velocity planning will decrease corner velocity

automatically. The input parameter cycle time is used for planning since the results of

velocity planning must be integer times of it. If this setting is zero, a default value 1000

us will be used in this block. The cycle time parameter has to be equal to that used in

motion control card.

Table of input parameters for velocity planning

Parameter

Description

Range

Maximum Velocity

Maximum velocity

>0.0

Maximum Acceleration Maximum

>0.0

for machining

acceleration for

machining

MAPS-Embedded System Section

6

Unit

Pulse per

second

Pulse per

second

squared

�

Rapid Maximum

Maximum velocity

>0.0

Velocity

Rapid Maximum

for moving

Maximum

Acceleration

acceleration for

>0.0

moving

Pulse per

second

Pulse per

second

squared

Smooth Velocity Factor Adjust smoothness of

0.0~1.0

Dimensionless

velocity profile

Corner Velocity Limit

Limit corner velocity ; Suggested

Dimensionless

Cycle Time

Motion control time

; if user sets 0,

Nano second

value is 8000000

the default cycle

time 1000us is

used.

In order to get well-planned velocity profile for machining, the following will try to

make user have more understanding about the insight methods and theory of velocity

planning.

MAPS-Embedded System Section

7

�

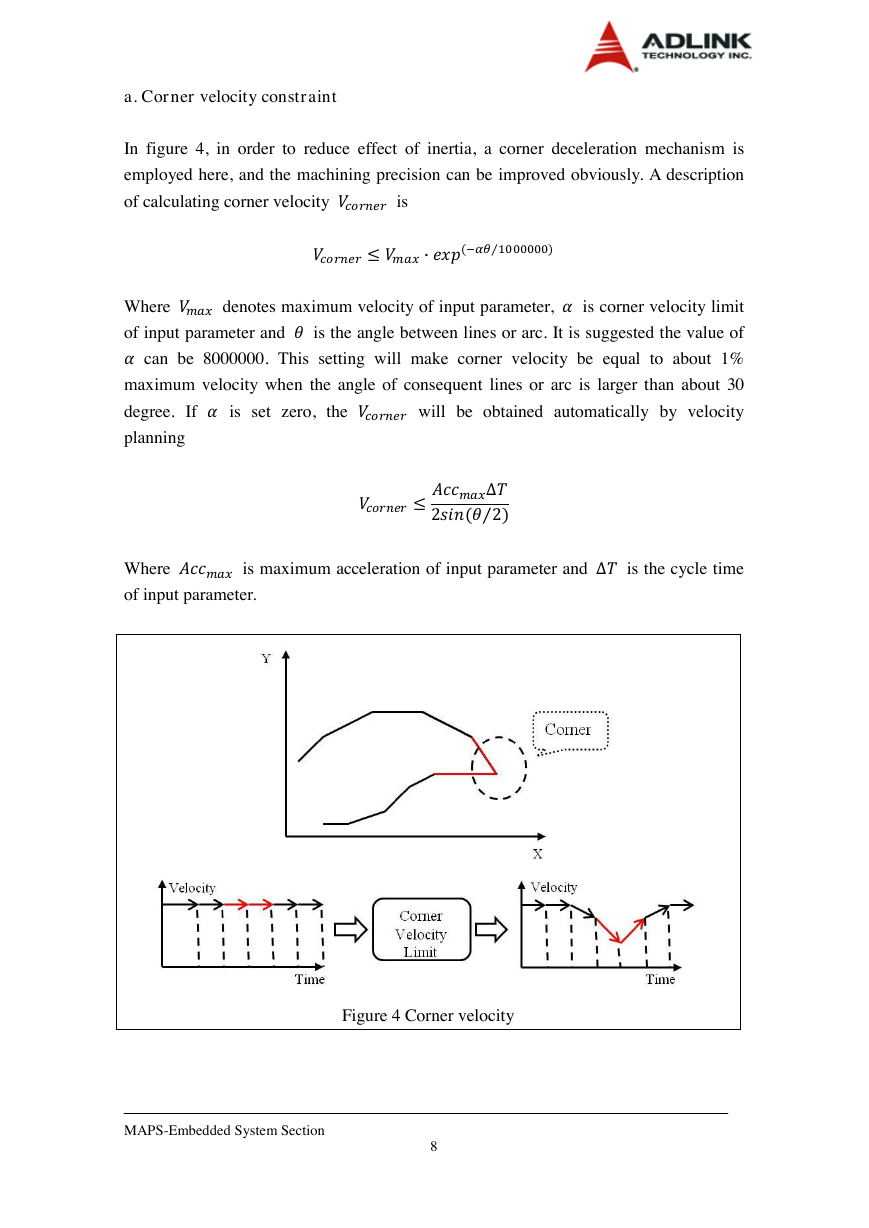

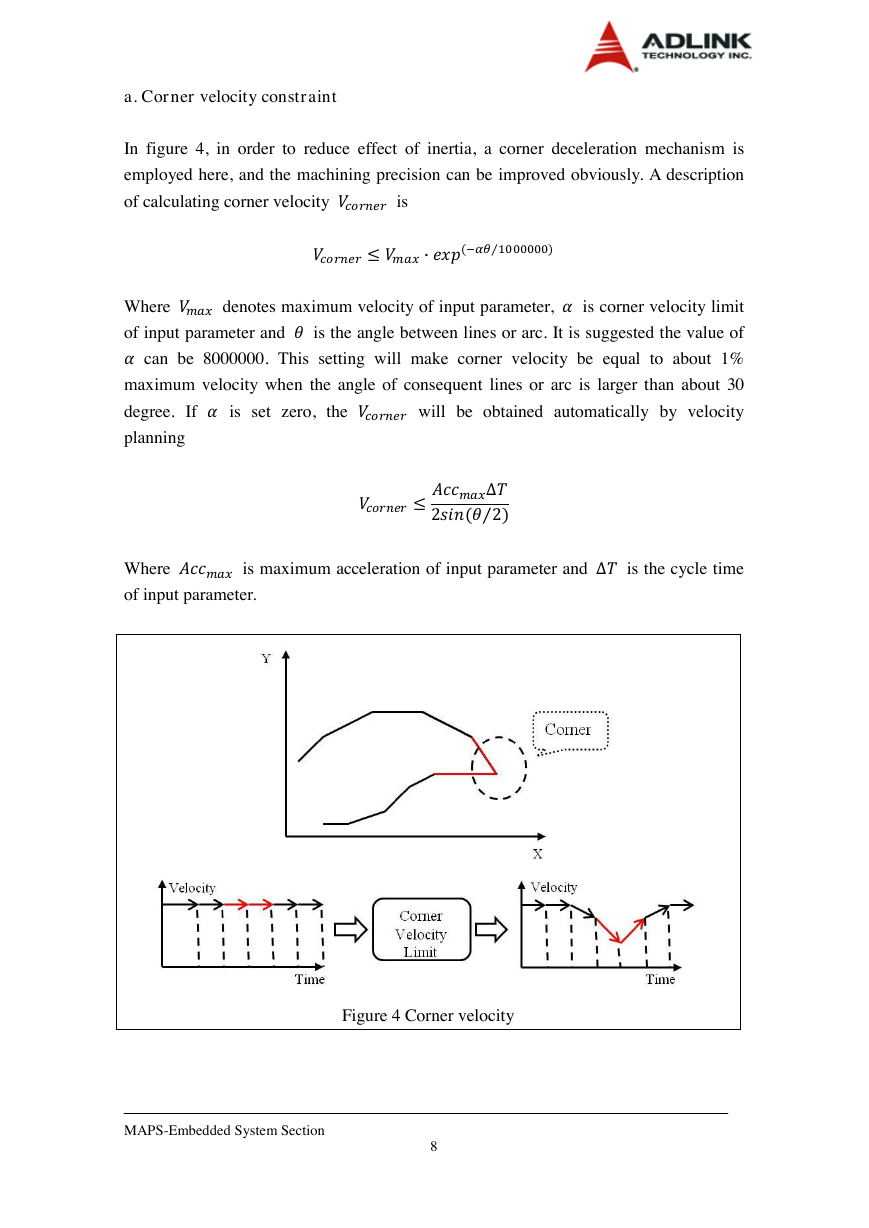

a. Corner velocity constraint

In figure 4, in order to reduce effect of inertia, a corner deceleration mechanism is

employed here, and the machining precision can be improved obviously. A description

of calculating corner velocity is

Where denotes maximum velocity of input parameter, is corner velocity limit

of input parameter and is the angle between lines or arc. It is suggested the value of

can be 8000000. This setting will make corner velocity be equal to about 1%

maximum velocity when the angle of consequent lines or arc is larger than about 30

degree. If is set zero, the will be obtained automatically by velocity

planning

Where is maximum acceleration of input parameter and is the cycle time

of input parameter.

Figure 4 Corner velocity

MAPS-Embedded System Section

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc