< Dual-In-Line Package Intelligent Power Module >

PSS25SA2FT

INSULATED TYPE

TRANSFER MOLDING TYPE

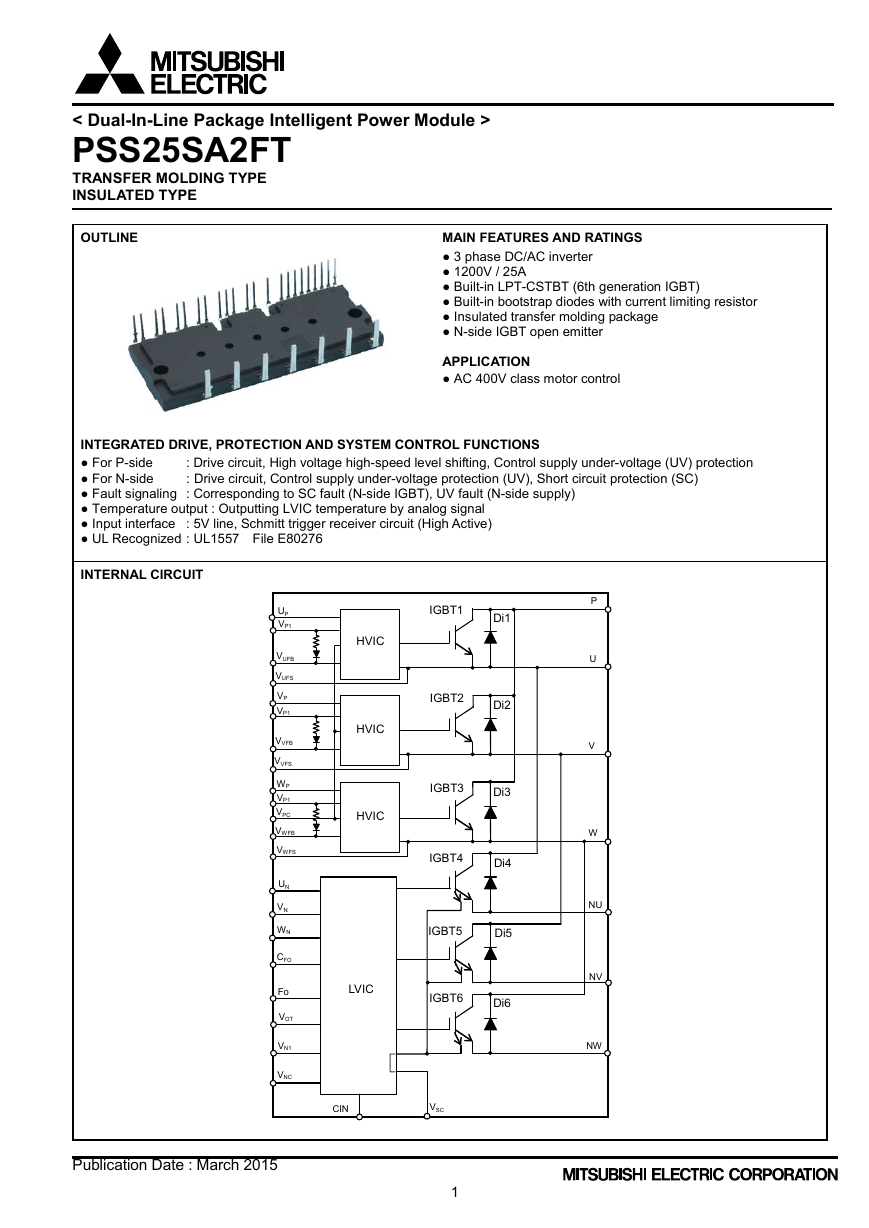

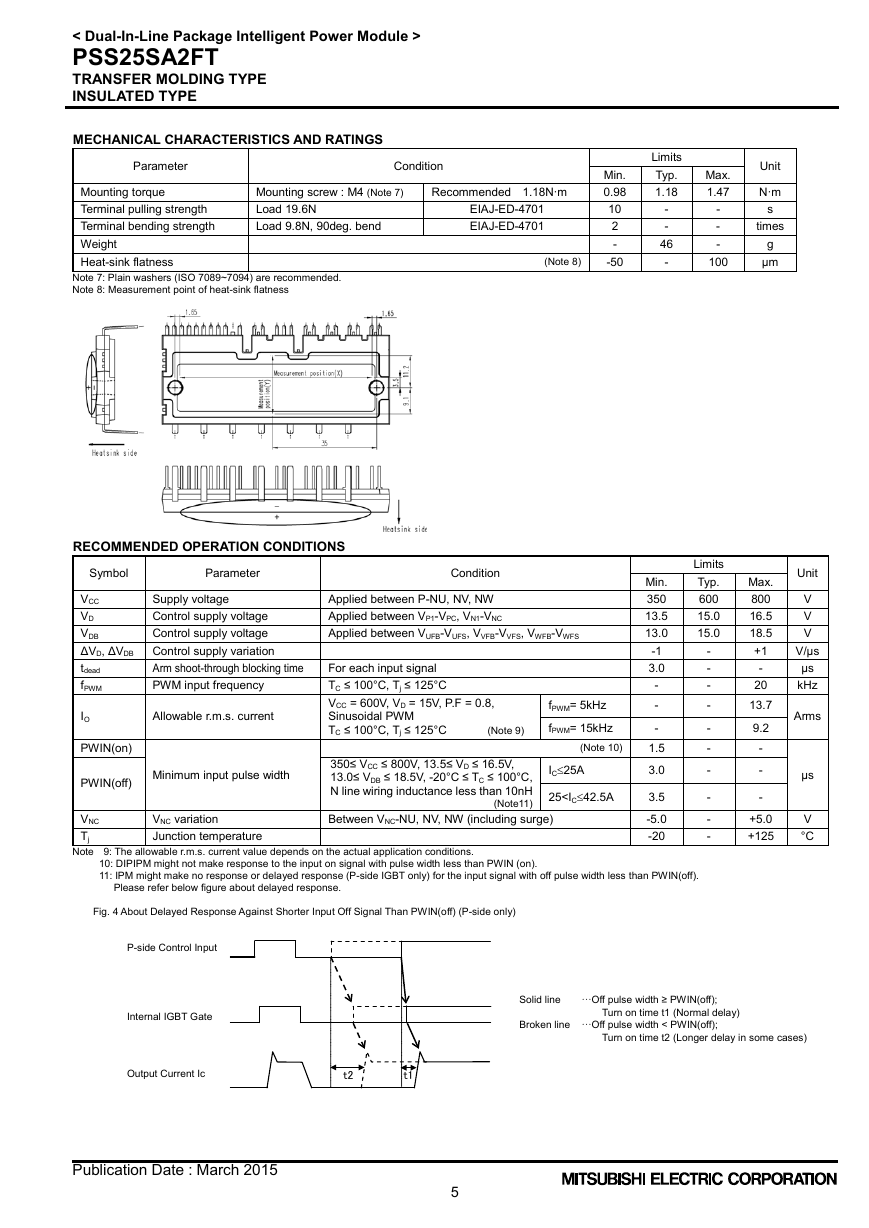

OUTLINE

MAIN FEATURES AND RATINGS

● 3 phase DC/AC inverter

● 1200V / 25A

● Built-in LPT-CSTBT (6th generation IGBT)

● Built-in bootstrap diodes with current limiting resistor

● Insulated transfer molding package

● N-side IGBT open emitter

APPLICATION

● AC 400V class motor control

: Drive circuit, High voltage high-speed level shifting, Control supply under-voltage (UV) protection

: Drive circuit, Control supply under-voltage protection (UV), Short circuit protection (SC)

INTEGRATED DRIVE, PROTECTION AND SYSTEM CONTROL FUNCTIONS

● For P-side

● For N-side

● Fault signaling : Corresponding to SC fault (N-side IGBT), UV fault (N-side supply)

● Temperature output : Outputting LVIC temperature by analog signal

● Input interface : 5V line, Schmitt trigger receiver circuit (High Active)

● UL Recognized : UL1557 File E80276

INTERNAL CIRCUIT

HVIC

HVIC

HVIC

IGBT1

Di1

IGBT2

Di2

IGBT3

Di3

IGBT4

Di4

IGBT5

Di5

LVIC

IGBT6

Di6

UP

VP1

VUFB

VUFS

VP

VP1

VVFB

VVFS

WP

VP1

VPC

VWFB

VWFS

UN

VN

WN

CFO

Fo

VOT

VN1

VNC

P

U

V

W

NU

NV

NW

Publication Date : March 2015

CIN

VSC

1

�

< Dual-In-Line Package Intelligent Power Module >

PSS25SA2FT

TRANSFER MOLDING TYPE

INSULATED TYPE

MAXIMUM RATINGS (Tj = 25°C, unless otherwise noted)

INVERTER PART

Parameter

Supply voltage

Supply voltage (surge)

Collector-emitter voltage

Each IGBT collector current

Each IGBT collector current (peak)

Collector dissipation

Junction temperature

Symbol

VCC

VCC(surge)

VCES

±IC

±ICP

PC

Tj

Note 1: Pulse width and period are limited due to junction temperature.

CONTROL (PROTECTION) PART

Parameter

Control supply voltage

Control supply voltage

Input voltage

Fault output supply voltage

Fault output current

Current sensing input voltage

Symbol

VD

VDB

VIN

VFO

IFO

VSC

Condition

Applied between P-NU,NV,NW

Applied between P-NU,NV,NW

TC= 25°C (Note 1)

TC= 25°C, up to 1ms

TC= 25°C, per 1 chip

Ratings

900

1000

1200

25

50

103

-30~+150

Condition

Applied between VP1-VPC, VN1-VNC

Applied between VUFB-VUFS, VVFB-VVFS, VWFB-VWFS

Applied between UP, VP, WP-VPC, UN, VN, WN-VNC

Applied between FO-VNC

Sink current at FO terminal

Applied between CIN-VNC

Unit

V

V

V

A

A

W

°C

Unit

V

V

V

V

mA

V

Unit

V

°C

°C

Vrms

Ratings

20

20

-0.5~VD+0.5

-0.5~VD+0.5

5

-0.5~VD+0.5

Ratings

800

-30~+100

-40~+125

2500

TOTAL SYSTEM

Parameter

Symbol

VCC(PROT) Self protection supply voltage limit

(Short circuit protection capability)

Module case operation temperature

TC

Storage temperature

Tstg

Viso

Isolation voltage

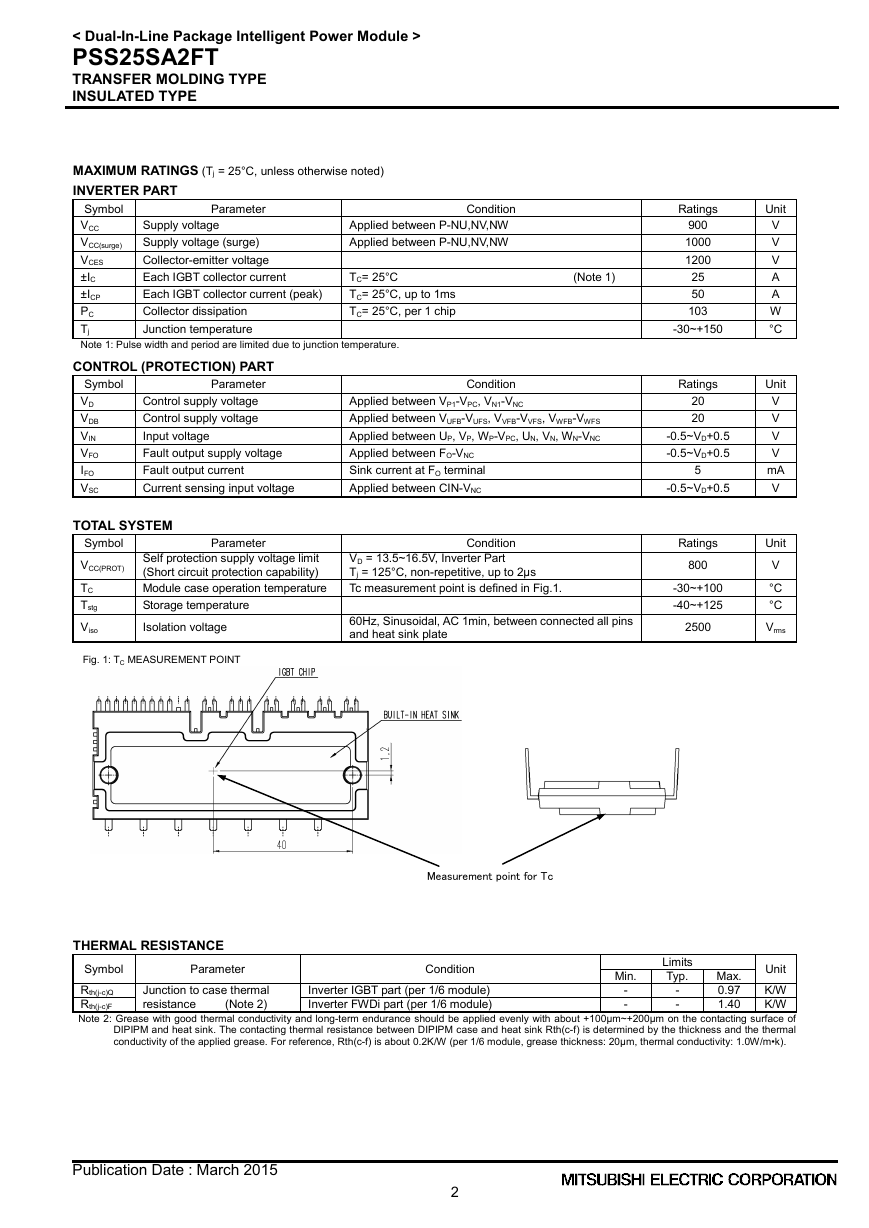

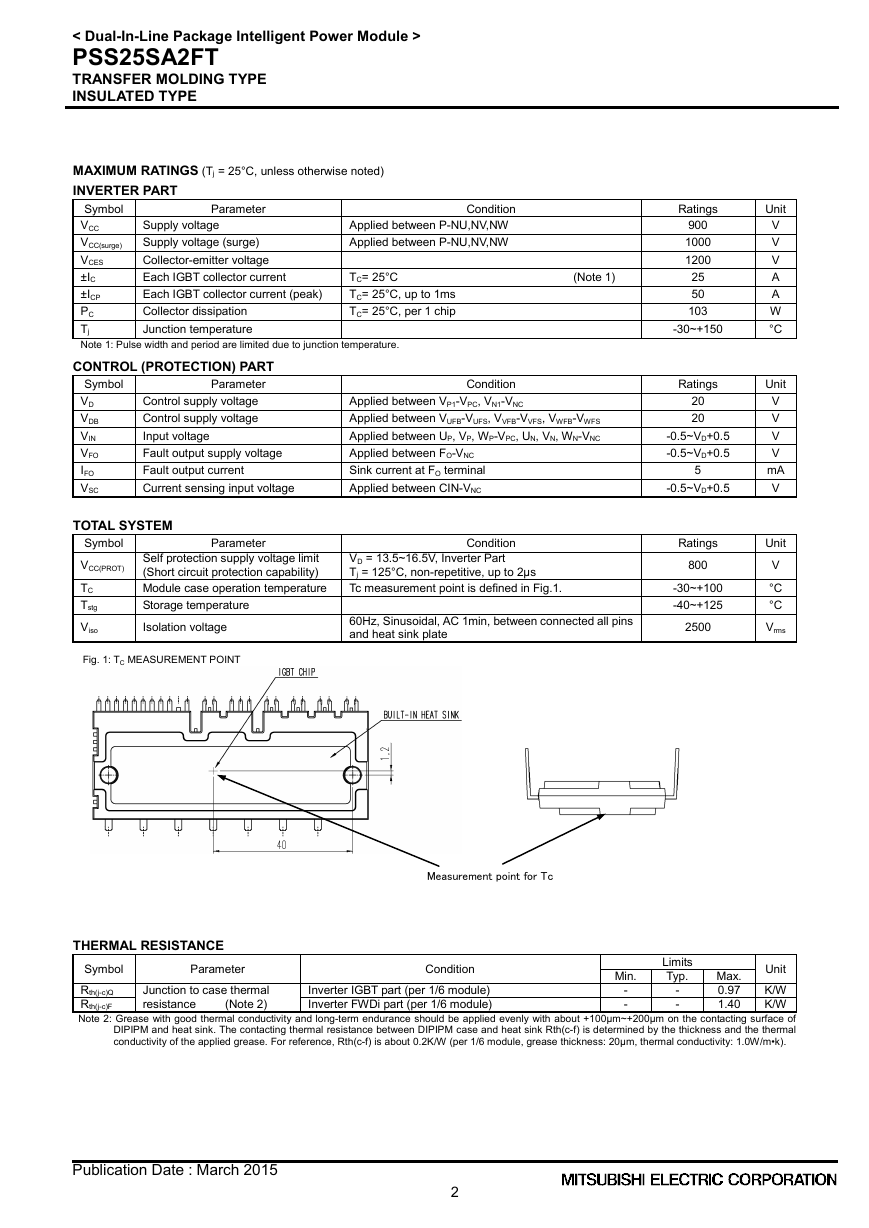

Fig. 1: TC MEASUREMENT POINT

Condition

VD = 13.5~16.5V, Inverter Part

Tj = 125°C, non-repetitive, up to 2μs

Tc measurement point is defined in Fig.1.

60Hz, Sinusoidal, AC 1min, between connected all pins

and heat sink plate

THERMAL RESISTANCE

Measurement point for Tc

Parameter

Condition

Symbol

Rth(j-c)Q

Rth(j-c)F

Note 2: Grease with good thermal conductivity and long-term endurance should be applied evenly with about +100μm~+200μm on the contacting surface of

DIPIPM and heat sink. The contacting thermal resistance between DIPIPM case and heat sink Rth(c-f) is determined by the thickness and the thermal

conductivity of the applied grease. For reference, Rth(c-f) is about 0.2K/W (per 1/6 module, grease thickness: 20μm, thermal conductivity: 1.0W/m•k).

Inverter IGBT part (per 1/6 module)

Inverter FWDi part (per 1/6 module)

Junction to case thermal

resistance (Note 2)

Unit

K/W

K/W

Max.

0.97

1.40

Min.

-

-

Limits

Typ.

-

-

Publication Date : March 2015

2

�

< Dual-In-Line Package Intelligent Power Module >

PSS25SA2FT

TRANSFER MOLDING TYPE

INSULATED TYPE

ELECTRICAL CHARACTERISTICS (Tj = 25°C, unless otherwise noted)

INVERTER PART

Symbol

Parameter

Condition

VCE(sat)

VEC

ton

tC(on)

toff

tC(off)

trr

ICES

Collector-emitter saturation

voltage

FWDi forward voltage

VD=VDB = 15V, VIN= 5V, IC= 25A

VIN= 0V, -IC= 25A

Tj= 25°C

Tj= 125°C

Switching times

VCC= 600V, VD= VDB= 15V

IC= 25A, Tj= 125°C, VIN= 0↔5V

Inductive Load (upper-lower arm)

Collector-emitter cut-off

current

VCE=VCES

Tj= 25°C

Tj= 125°C

CONTROL (PROTECTION) PART

Symbol

Parameter

ID

IDB

ISC

Circuit current

Short circuit trip level

Condition

VD=15V, VIN=0V

VD=15V, VIN=5V

VDB=15V, VIN=0V

VDB=15V, VIN=5V

Total of VP1-VPC, VN1-VNC

Each part of VUFB-VUFS,

VVFB-VVFS, VWFB-VWFS

-30°C≤Tj≤125°C, Rs=75Ω (±1%),

Not connecting outer shunt resistors to

NU,NV,NW terminals

Limits

Typ.

1.50

1.70

2.20

1.90

0.50

2.60

0.50

0.50

-

-

Min.

-

-

-

1.10

-

-

-

-

-

-

Limits

Typ.

Min.

-

-

-

-

(Note 3)

42.5

-

-

-

-

-

Unit

V

V

μs

μs

μs

μs

μs

mA

Unit

mA

Max.

2.20

2.40

2.80

2.60

0.80

3.60

0.90

-

1

10

Max.

5.60

5.60

1.10

1.10

-

A

Tj ≤125°C

Tj ≤125°C

Fault output voltage

Trip level

Reset level

Trip level

Reset level

P-side Control supply

under-voltage

protection(UV)

N-side Control supply

under-voltage

protection(UV)

UVDBt

UVDBr

UVDt

UVDr

VFOH

VFOL

tFO

IIN

Vth(on)

Vth(off)

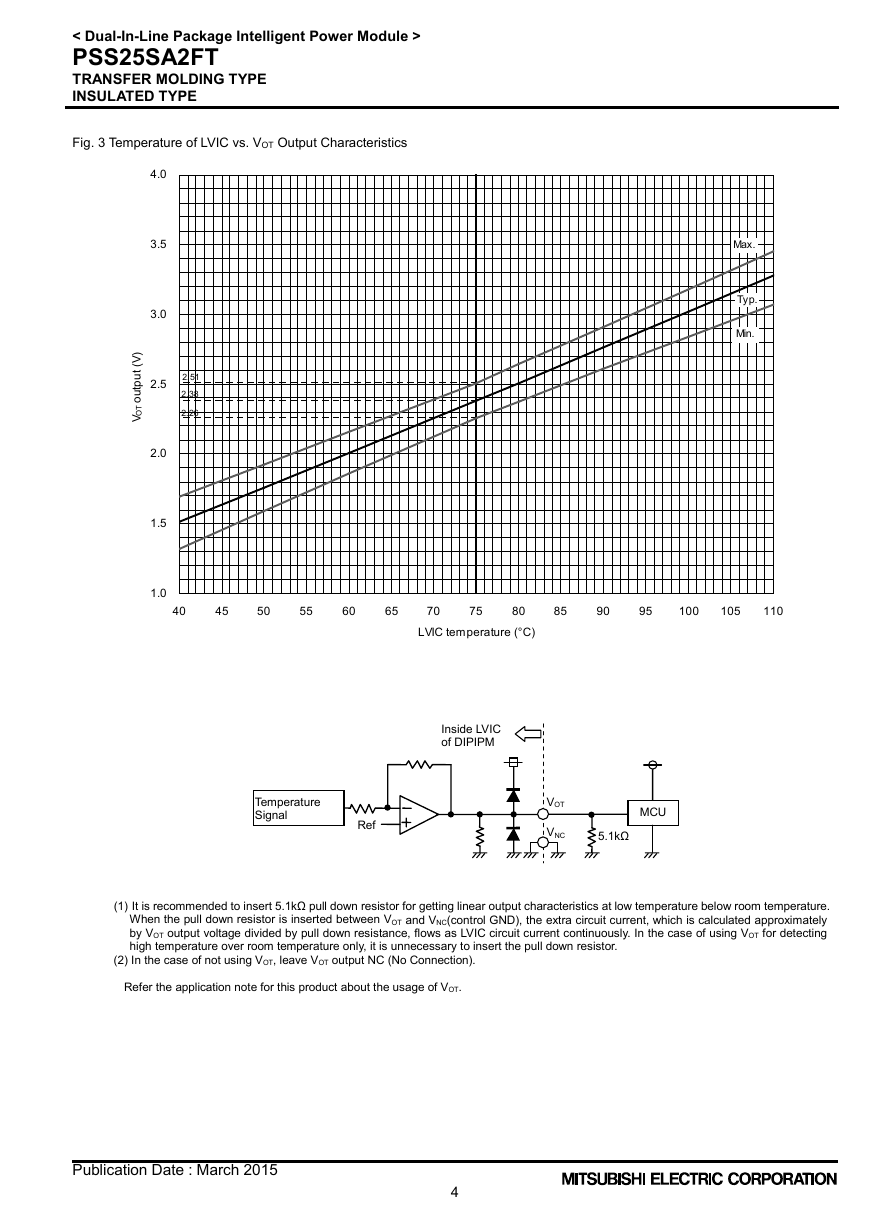

VOT

VF

R

Note 3: Short circuit protection detects sense current divided from main current at N-side IGBT and works for N-side IGBT only. In the case that outer shunt resistor is

Fault output pulse width

Input current

ON threshold voltage

OFF threshold voltage

Temperature output

Bootstrap Di forward voltage

Built-in limiting resistance

VSC = 0V, FO terminal pulled up to 5V by 10kΩ

VSC = 1V, IFO = 1mA

CFO=22nF

VIN = 5V

LVIC temperature = 75°C

IF=10mA including voltage drop by limiting resistor

Included in bootstrap Di

-

-

-

-

-

-

2.4

1.00

10.0

10.5

10.3

10.8

4.9

-

1.6

0.70

-

0.8

2.26

0.5

16

Applied between UP, VP, WP, UN, VN, WN-VNC

V

V

V

V

V

V

ms

mA

(Note 5)

(Note 6)

12.0

12.5

12.5

13.0

-

-

0.95

1.50

3.5

-

2.51

1.3

24

-

-

2.38

0.9

20

inserted into main current path, protection current level ISC changes. For details, please refer the application note for this DIPIPM.

Note 4: Fault signal is output when short circuit or N-side control supply under-voltage protection works. The fault output pulse-width tFO depends on the capacitance of

V

V

V

Ω

(Note 4)

CFO. (CFO (typ.) = tFO x 9.1 x 10-6) [F])

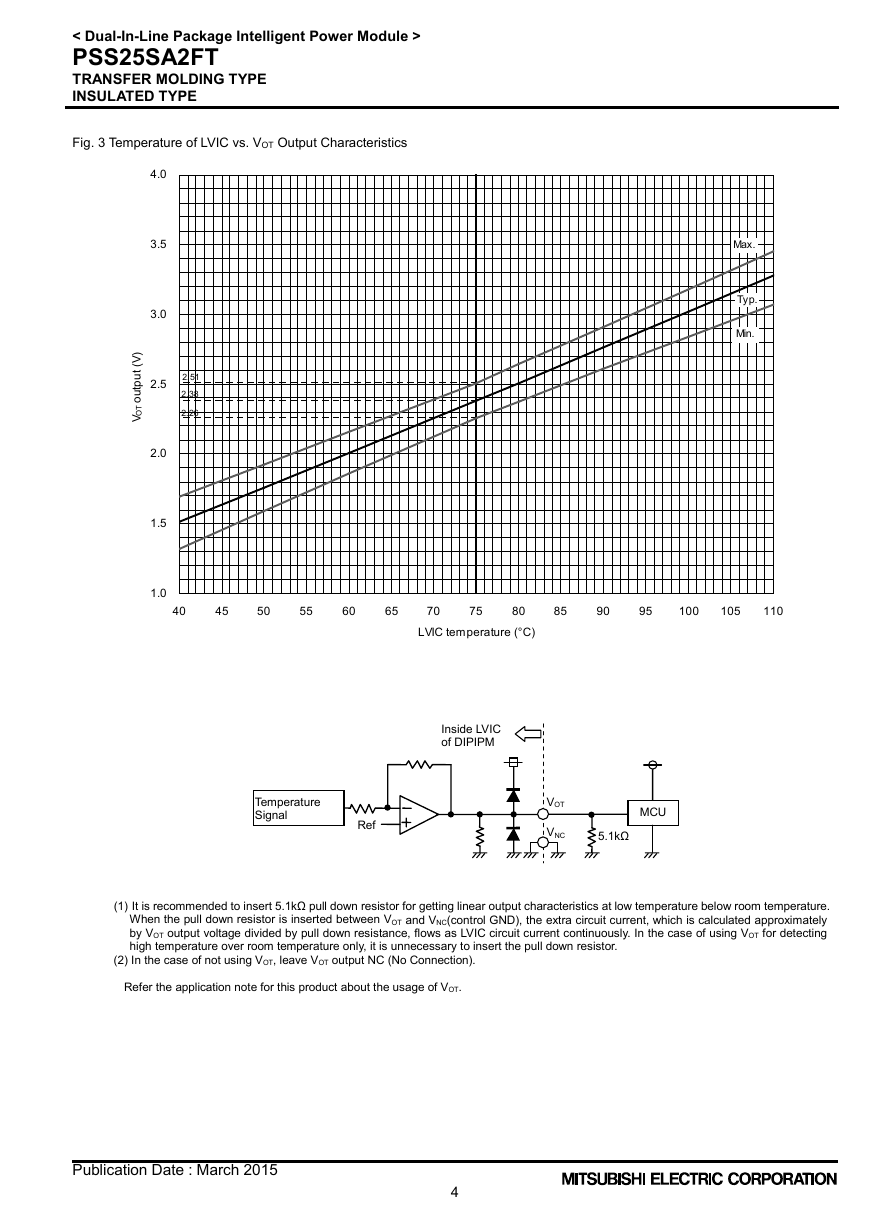

Note 5: DIPIPM doesn't shut down IGBTs and output fault signal automatically when temperature rises excessively. When temperature exceeds the protective level that

user defined, controller (MCU) should stop immediately. Temperature of LVIC vs. VOT output characteristics is described in Fig.3

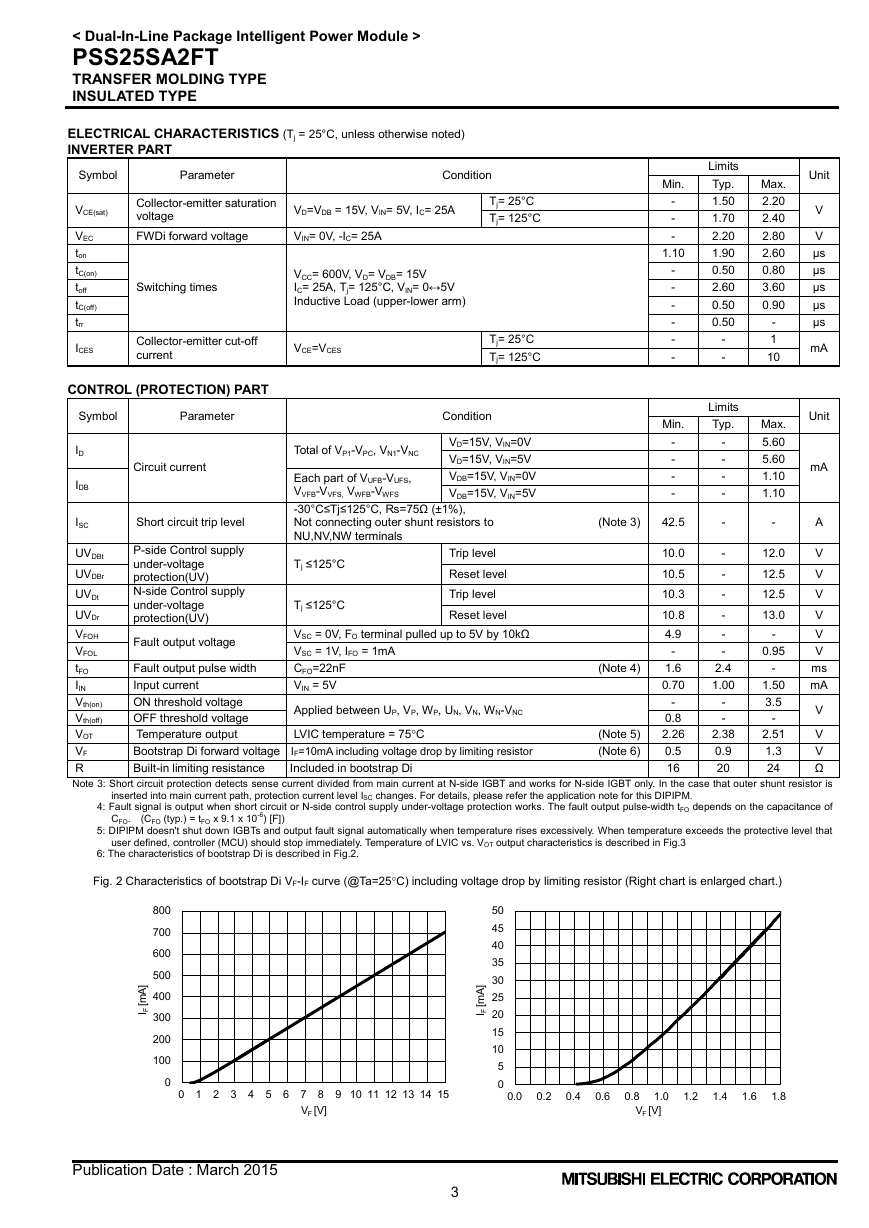

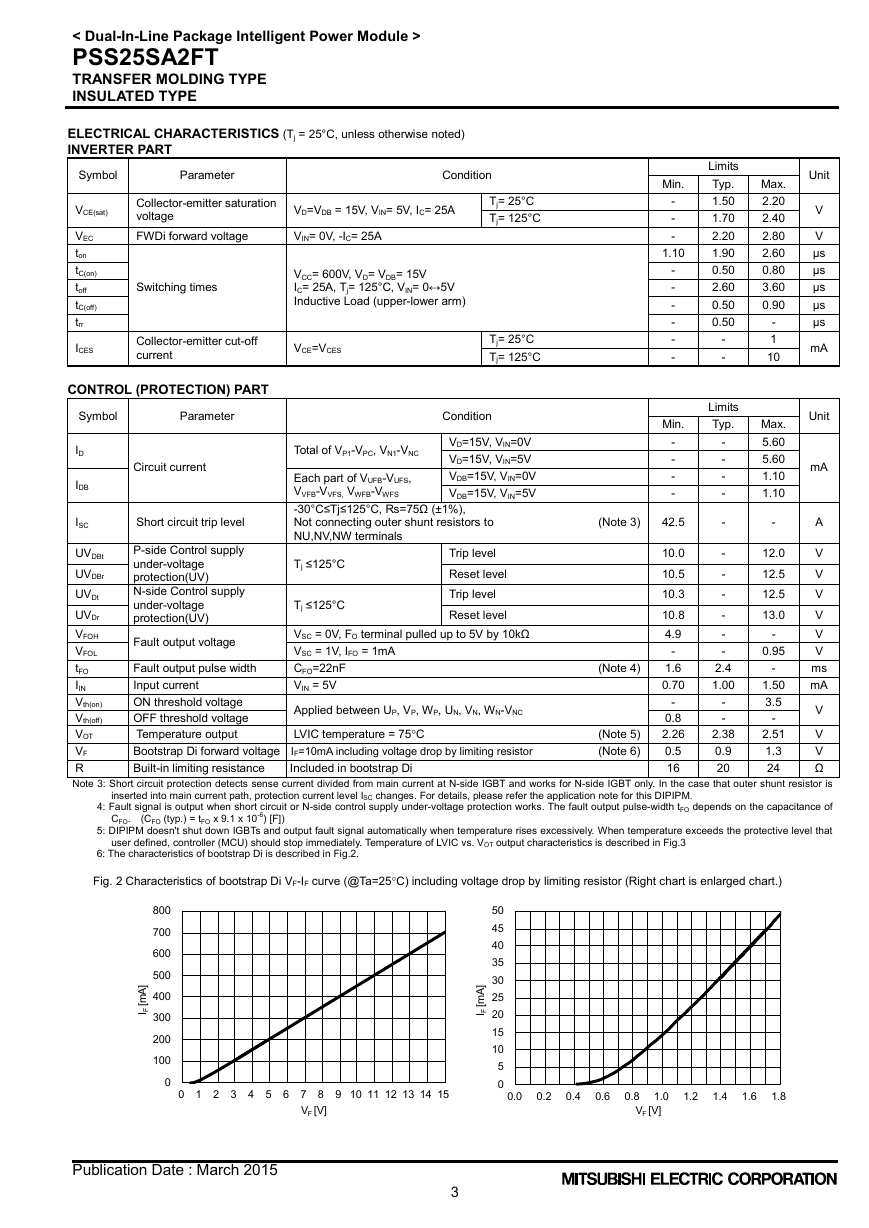

Note 6: The characteristics of bootstrap Di is described in Fig.2.

Fig. 2 Characteristics of bootstrap Di VF-IF curve (@Ta=25°C) including voltage drop by limiting resistor (Right chart is enlarged chart.)

]

A

m

[

F

I

800

700

600

500

400

300

200

100

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

VF [V]

Publication Date : March 2015

3

]

A

m

[

F

I

50

45

40

35

30

25

20

15

10

5

0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

VF [V]

�

< Dual-In-Line Package Intelligent Power Module >

PSS25SA2FT

TRANSFER MOLDING TYPE

INSULATED TYPE

Fig. 3 Temperature of LVIC vs. VOT Output Characteristics

_

)

V

(

t

t

u

p

u

o

T

O

V

4.0

3.5

3.0

2.5

2.0

1.5

1.0

2.51

2.38

2.26

Max.

Typ.

Min.

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

LVIC temperature (°C)

Inside LVIC

of DIPIPM

Temperature

Signal

Ref

VOT

VNC

MCU

5.1kΩ

(1) It is recommended to insert 5.1kΩ pull down resistor for getting linear output characteristics at low temperature below room temperature.

When the pull down resistor is inserted between VOT and VNC(control GND), the extra circuit current, which is calculated approximately

by VOT output voltage divided by pull down resistance, flows as LVIC circuit current continuously. In the case of using VOT for detecting

high temperature over room temperature only, it is unnecessary to insert the pull down resistor.

(2) In the case of not using VOT, leave VOT output NC (No Connection).

Refer the application note for this product about the usage of VOT.

Publication Date : March 2015

4

�

< Dual-In-Line Package Intelligent Power Module >

PSS25SA2FT

TRANSFER MOLDING TYPE

INSULATED TYPE

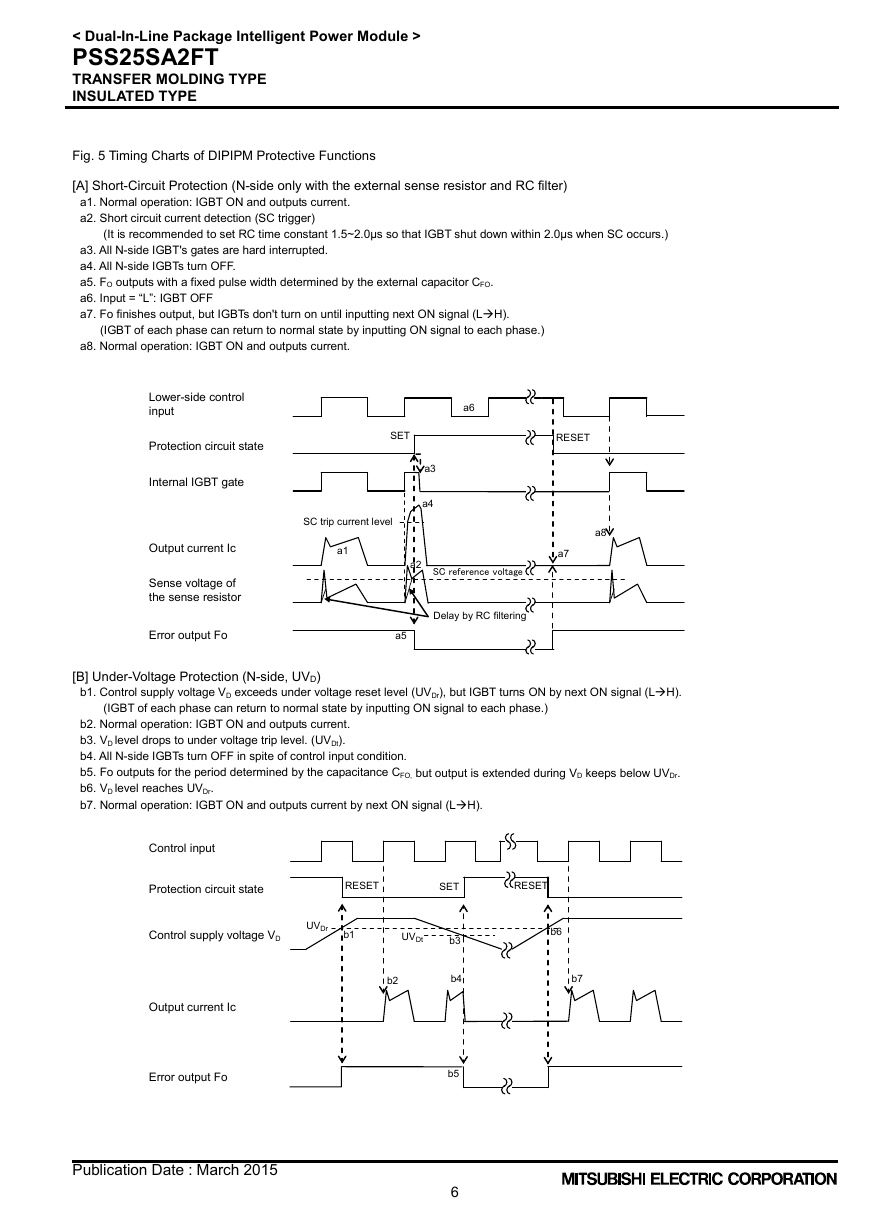

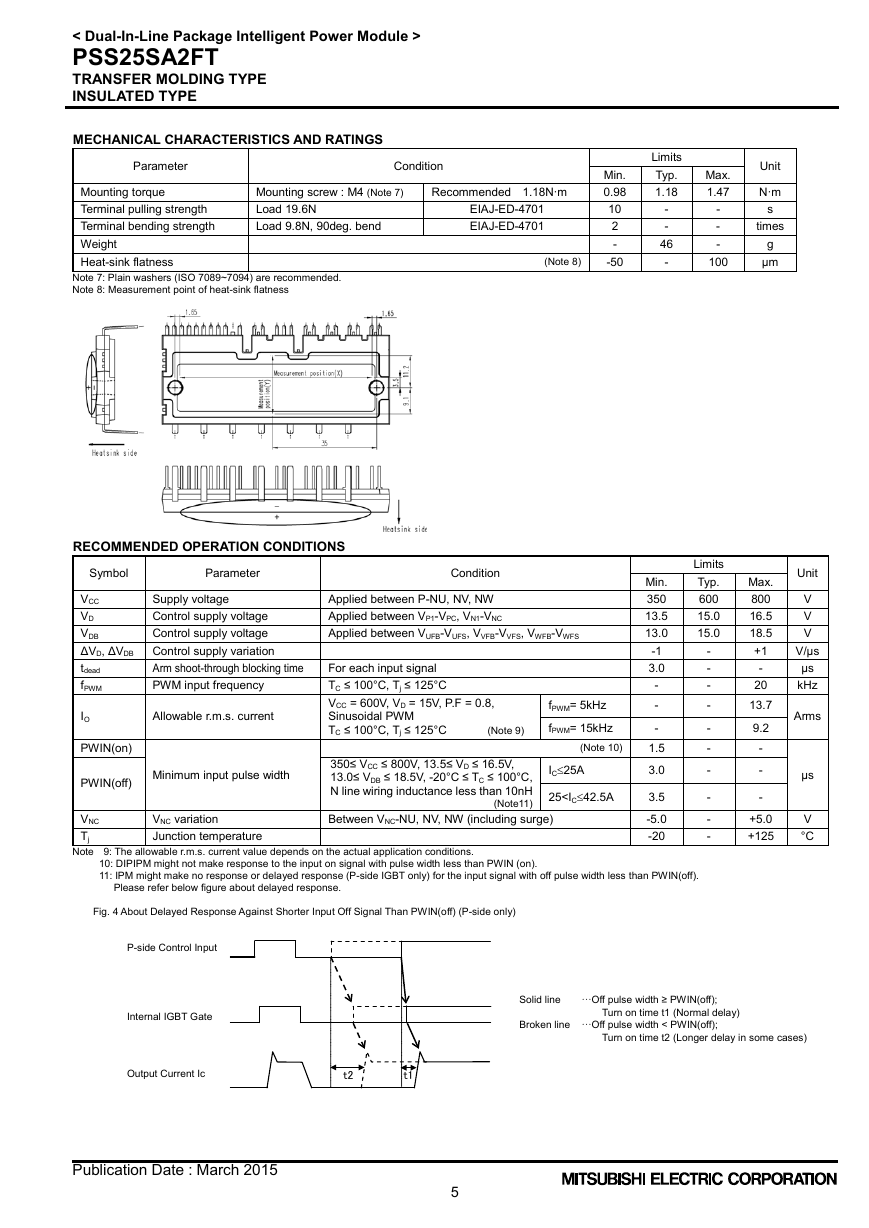

MECHANICAL CHARACTERISTICS AND RATINGS

Parameter

Mounting torque

Terminal pulling strength

Terminal bending strength

Weight

Heat-sink flatness

Condition

Mounting screw : M4 (Note 7)

Load 19.6N

Load 9.8N, 90deg. bend

Recommended 1.18N·m

EIAJ-ED-4701

EIAJ-ED-4701

(Note 8)

Limits

Typ.

1.18

-

-

46

-

Min.

0.98

10

2

-

-50

Max.

1.47

-

-

-

100

Unit

N·m

s

times

g

μm

Note 7: Plain washers (ISO 7089~7094) are recommended.

Note 8: Measurement point of heat-sink flatness

RECOMMENDED OPERATION CONDITIONS

Symbol

Parameter

Condition

VCC

Supply voltage

VD

Control supply voltage

VDB

Control supply voltage

ΔVD, ΔVDB Control supply variation

tdead

fPWM

Arm shoot-through blocking time

PWM input frequency

IO

Allowable r.m.s. current

PWIN(on)

PWIN(off)

Minimum input pulse width

Applied between P-NU, NV, NW

Applied between VP1-VPC, VN1-VNC

Applied between VUFB-VUFS, VVFB-VVFS, VWFB-VWFS

For each input signal

TC ≤ 100°C, Tj ≤ 125°C

VCC = 600V, VD = 15V, P.F = 0.8,

Sinusoidal PWM

TC ≤ 100°C, Tj ≤ 125°C (Note 9)

350≤ VCC ≤ 800V, 13.5≤ VD ≤ 16.5V,

13.0≤ VDB ≤ 18.5V, -20°C ≤ TC ≤ 100°C,

N line wiring inductance less than 10nH

(Note11)

IC≤25A

fPWM= 5kHz

fPWM= 15kHz

(Note 10)

25

< Dual-In-Line Package Intelligent Power Module >

PSS25SA2FT

TRANSFER MOLDING TYPE

INSULATED TYPE

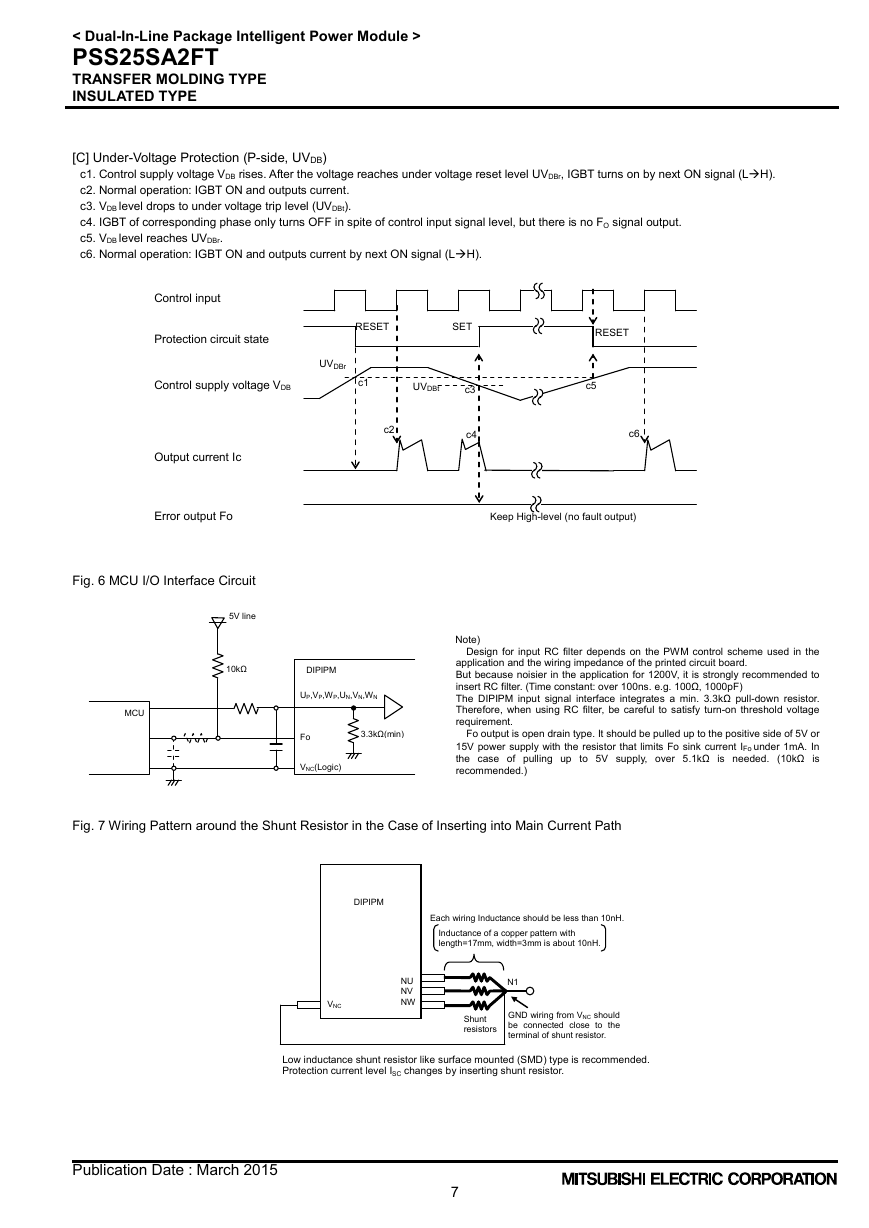

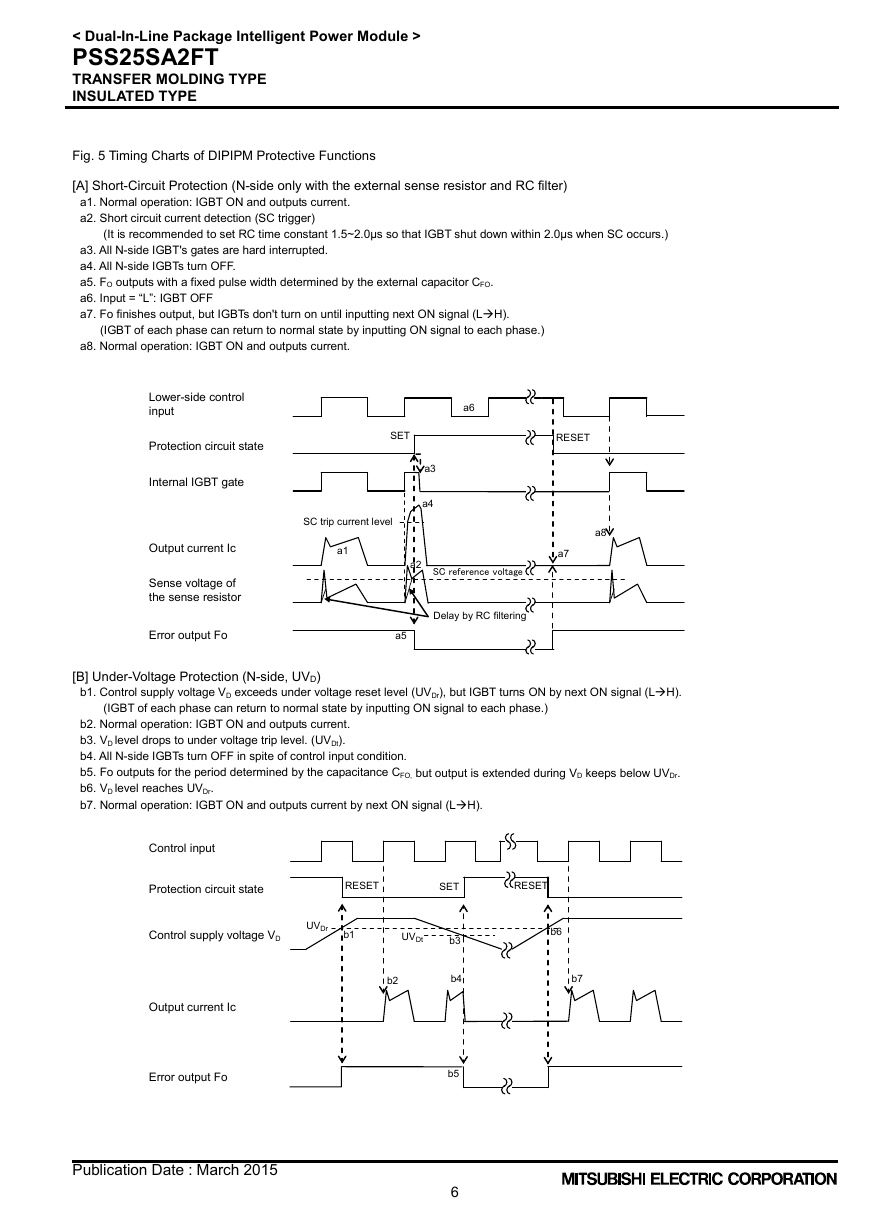

Fig. 5 Timing Charts of DIPIPM Protective Functions

[A] Short-Circuit Protection (N-side only with the external sense resistor and RC filter)

a1. Normal operation: IGBT ON and outputs current.

a2. Short circuit current detection (SC trigger)

(It is recommended to set RC time constant 1.5~2.0μs so that IGBT shut down within 2.0μs when SC occurs.)

a3. All N-side IGBT's gates are hard interrupted.

a4. All N-side IGBTs turn OFF.

a5. FO outputs with a fixed pulse width determined by the external capacitor CFO.

a6. Input = “L”: IGBT OFF

a7. Fo finishes output, but IGBTs don't turn on until inputting next ON signal (LH).

(IGBT of each phase can return to normal state by inputting ON signal to each phase.)

a8. Normal operation: IGBT ON and outputs current.

a6

Internal IGBT gate

SET

RESET

Protection circuit state

Lower-side control

input

[B] Under-Voltage Protection (N-side, UVD)

b1. Control supply voltage VD exceeds under voltage reset level (UVDr), but IGBT turns ON by next ON signal (LH).

Sense voltage of

the sense resistor

a2

SC reference voltage

a8

a7

Output current Ic

a1

Error output Fo

a5

a3

a4

SC trip current level

Delay by RC filtering

(IGBT of each phase can return to normal state by inputting ON signal to each phase.)

b2. Normal operation: IGBT ON and outputs current.

b3. VD level drops to under voltage trip level. (UVDt).

b4. All N-side IGBTs turn OFF in spite of control input condition.

b5. Fo outputs for the period determined by the capacitance CFO, but output is extended during VD keeps below UVDr.

b6. VD level reaches UVDr.

b7. Normal operation: IGBT ON and outputs current by next ON signal (LH).

Control input

Protection circuit state

RESET

SET

RESET

Control supply voltage VD

UVDr

b1

UVDt

b2

Output current Ic

Error output Fo

b6

b7

b3

b4

b5

6

Publication Date : March 2015

�

< Dual-In-Line Package Intelligent Power Module >

PSS25SA2FT

TRANSFER MOLDING TYPE

INSULATED TYPE

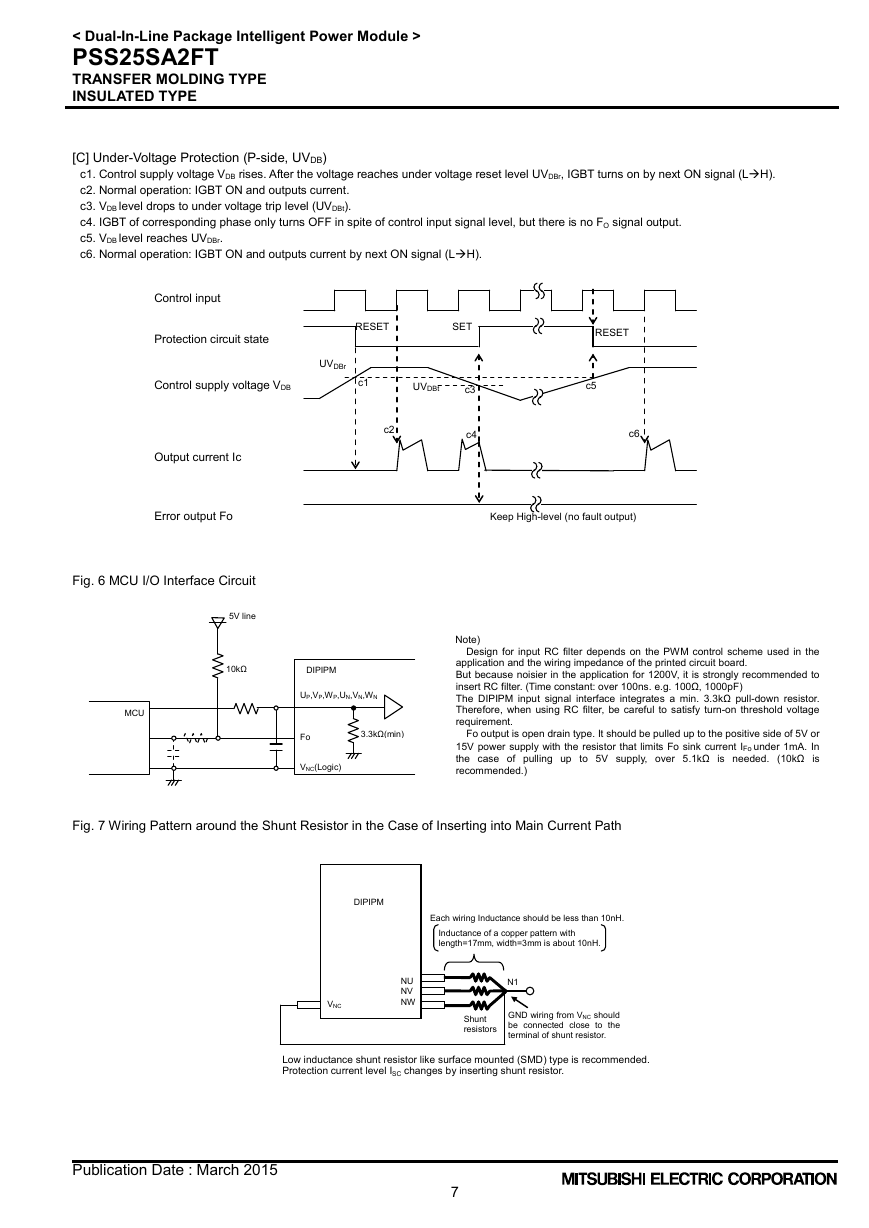

[C] Under-Voltage Protection (P-side, UVDB)

c1. Control supply voltage VDB rises. After the voltage reaches under voltage reset level UVDBr, IGBT turns on by next ON signal (LH).

c2. Normal operation: IGBT ON and outputs current.

c3. VDB level drops to under voltage trip level (UVDBt).

c4. IGBT of corresponding phase only turns OFF in spite of control input signal level, but there is no FO signal output.

c5. VDB level reaches UVDBr.

c6. Normal operation: IGBT ON and outputs current by next ON signal (LH).

RESET

c6

Keep High-level (no fault output)

5V line

Control input

Error output Fo

UVDBt

c3

c5

c2

c4

UVDBr

c1

RESET

SET

Output current Ic

Protection circuit state

Control supply voltage VDB

Fig. 6 MCU I/O Interface Circuit

Fig. 7 Wiring Pattern around the Shunt Resistor in the Case of Inserting into Main Current Path

Inductance of a copper pattern with

length=17mm, width=3mm is about 10nH.

GND wiring from VNC should

be connected close to the

terminal of shunt resistor.

Fo

3.3kΩ(min)

10kΩ

DIPIPM

NU

NV

NW

VNC

N1

Shunt

resistors

DIPIPM

Each wiring Inductance should be less than 10nH.

UP,VP,WP,UN,VN,WN

VNC(Logic)

MCU

Note)

Design for input RC filter depends on the PWM control scheme used in the

application and the wiring impedance of the printed circuit board.

But because noisier in the application for 1200V, it is strongly recommended to

insert RC filter. (Time constant: over 100ns. e.g. 100Ω, 1000pF)

The DIPIPM input signal interface integrates a min. 3.3kΩ pull-down resistor.

Therefore, when using RC filter, be careful to satisfy turn-on threshold voltage

requirement.

Fo output is open drain type. It should be pulled up to the positive side of 5V or

15V power supply with the resistor that limits Fo sink current IFo under 1mA. In

the case of pulling up to 5V supply, over 5.1kΩ is needed. (10kΩ is

recommended.)

Low inductance shunt resistor like surface mounted (SMD) type is recommended.

Protection current level ISC changes by inserting shunt resistor.

Publication Date : March 2015

7

�

< Dual-In-Line Package Intelligent Power Module >

PSS25SA2FT

TRANSFER MOLDING TYPE

INSULATED TYPE

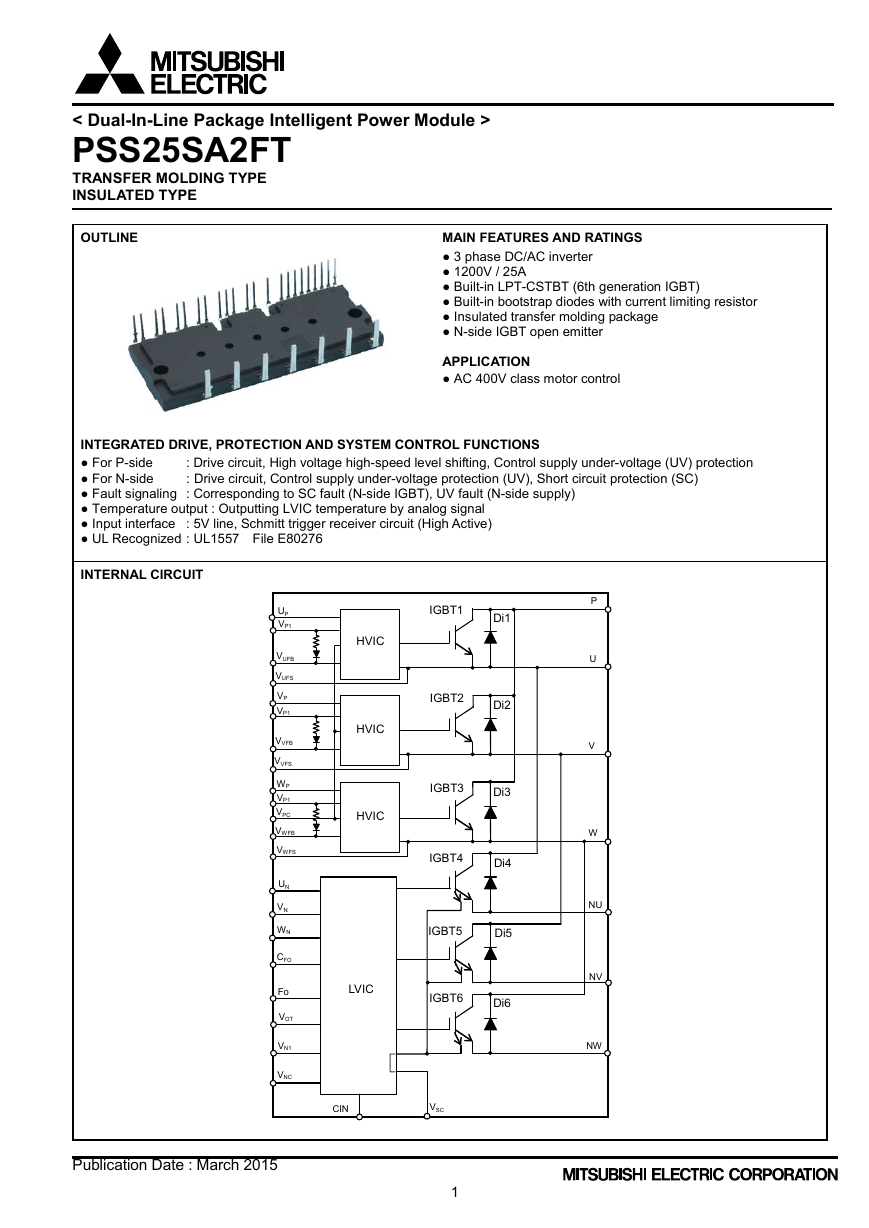

Fig. 8 Example of Application Circuit

M

C

U

HVIC

HVIC

HVIC

LVIC

R3

C5

C2

+

C1 D1 C2

R3

C5

C2

+

C1 D1 C2

R3

C5

C2

+

C1 D1 C2

R3

C5

R3

C5

R3

C5

5V

R2

15V

VD

+

D1

C1

C2

UP(1)

VP1(3)

VUFB(4)

VUFS(6)

VP(7)

VP1(9)

VVFB(10)

VVFS(12)

WP(13)

VP1(14)

VPC(15)

VWFB(16)

VWFS(18)

UN(27)

VN(28)

WN(29)

CFO(25)

Fo(26)

VOT(23)

VN1(21)

VNC(22)

CIN(24)

C4

B

R1

IGBT1

Di1

IGBT2

Di2

IGBT3

Di3

IGBT4

Di4

IGBT5

Di5

IGBT6

Di6

VSC(19)

D

Sense

resistor

A

P(40)

U(39)

V(38)

M

W(37)

NU (36)

NV (35)

NW(34)

C

+

C3

Note

1 :If control GND and power GND are patterned by common wiring, it may cause malfunction by fluctuation of power GND level. It is recommended to connect

Control GND wiring

Power GND wiring

N1

control GND and power GND at only a N1 point at which NU, NV, NW are connected to power GND line.

2 :It is recommended to insert a Zener diode D1 (24V/1W) between each pair of control supply terminals to prevent surge destruction.

3 :To prevent surge destruction, the wiring between the smoothing capacitor and the P, N1 terminals should be as short as possible. Generally inserting a

0.1μ~0.22μF snubber capacitor C3 between the P-N1 terminals is recommended.

4 :R1, C4 of RC filter for preventing protection circuit malfunction is recommended to select tight tolerance, temp-compensated type. The time constant R1C4

should be set so that SC current is shut down within 2μs. (1.5μs~2μs is general value.) SC interrupting time might vary with the wiring pattern, so the enough

evaluation on the real system is recommended. If R1 is too small, it may leads to delay of protection. So R1 should be min. 10 times larger resistance than Rs.

(100 times is recommended.)

5 :To prevent erroneous operation, the wiring of A, B, C should be as short as possible.

6 :For sense resistor, the variation within 1%(including temperature characteristics), low inductance type is recommended. And the over 0.03W is recommended,

8 :All capacitors should be mounted as close to the terminals of the DIPIPM as possible. (C1: good temperature, frequency characteristic electrolytic type, and

C2: 0.01μ~2.0μF, good temperature, frequency and DC bias characteristic ceramic type are recommended.)

9 :Input drive is High-active type. There is a min. 3.3kΩ pull-down resistor in the input circuit of IC. To prevent malfunction, the wiring of each input should be as

short as possible. And it is recommended to insert RC filter (e.g. R3=100Ω and C5=1000pF) and confirm the input signal level to meet the turn-on and turn-off

threshold voltage. Thanks to HVIC inside the module, direct coupling to MCU without any opto-coupler or transformer isolation is possible.

10 :Fo output is open drain type. Fo output will be max 0.95V(@IFO=1mA,25℃), so it should be pulled up to MCU or control power supply (e.g. 5V,15V) by a

resistor that makes IFo up to 1mA. (In the case of pulled up to 5V, 10kΩ is recommended.)

11 :Error signal output width (tFo) can be set by the capacitor connected to CFO terminal. CFO(typ.) = tFo x 9.1 x 10-6 (F)

12 :If high frequency noise superimposed to the control supply line, IC malfunction might happen and cause erroneous operation. To avoid such problem, voltage

ripple of control supply line should meet dV/dt ≤+/-1V/μs, Vripple≤2Vp-p.

13 :For DIPIPM, it isn't recommended to drive same load by parallel connection with other phase IGBT or other DIPIPM.

7 :To prevent erroneous SC protection, the wiring from VSC terminal to CIN filter should be divided at the point D that is close to the terminal of sense resistor.

but it is necessary to evaluate in your real system finally.

And the wiring should be patterned as short as possible.

Publication Date : March 2015

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc