Manipulator is now used as a industrial robots in use, the control objectives often appear often in industrial automation. Industrial automation technology has gradually matured, as mature a technology line has been rapid development in industrial automation as aseparate subject. Manipulator application began to filter into welding, logistics, mechanical processing, and other industries. Especially at high or very low temperatures, full of poisonous gases, high radiation case, robot in similar circumstances showed great use also brings great convenience to the staff. Precisely because of this robot to get people's attention began to be a high degree of development. Labor rates, working conditions, labor intensive aspects of promoting development. Both at home and abroad to develop the PLC (programmable logic controller) is in various special circumstances and under special conditions set for mechanical devices. Now turned on the development of the microelectronics automatic control

technology and the rapid development of the trains, the success of PLC hardware software and simulation control win big and successful development, now continues to develop as a factory automation standards. Because robots are good development of the technology makes a good optimization of productive capital, and robot shows this unique advantages, such as: has good compatibility, wide availability, hardware is complete, and programming that can be mastered in a short time, so in the context of industrial PLC applications became ubiquitous. Manipulator in many developed country agriculture and industry has been applied, such as the use of mechanical harvesting large areas of farmland, repeated operations on the high-speed line that uses a robotic arm, and so on. Today, the high level of automation combined with restrictions on the manipulator development level is slightly lower than the international. The design is mainly arm welding machine by PLC Automation control. This

of design let designers on in school by learn of has a must of consolidation, understand has some usually didn't opportunities awareness in world range within some leading level of know ledge has has must awareness, hope designers can in yihou of design in the can success of using in this design in the proceeds of experience 1.2 manipulator in both at home and abroad of research profile automation mechanical arm research began Yu 20th century medium-term, after years with with computer and automation technology of development, Makes mechanical arm on the Grand stage of industrial automation and shine, gradually became an industrial evaluation standards, and its importance can be seen. Now original robotic arm spent most of mass production and use on the production line, which is programmed robotic arm. As the first generation of manipulator position control systems main features, although not back several generations that can detect the external environment, but can still

successfully complete likewelding, painting, delivery as well as for materials simple movements. Second generation mechanical arms are equipped with sensors and manipulators have the environment there is a certain amount of "sense", when the mechanical arm is to use the program as a basis. Difference is that the robot begand

2009 年一级建造师建筑工程考试真题及答案

一、单项选择题(共 20 题,每题的备选项中,只有一个最符合题意)

1.《网壳结构技术规程》(JGJ——2003)规定,单块双曲抛物线面壳体的矢量可取二个

对角支撑点之间距离的(

)。

A. 1/8-1/6

C. 1/6-1/4

2. 下列关于抹灰工程的说法符合《建筑装修工程质量验收规范》(GB——2001)规定的

B. 1/7-1/5

D. 1/4-1/2

是(

)。

A. 当抹灰总厚度大于 25cm 时,应采取加强措施

B. 不同材料基体交接处表面的抹灰,采用加强网防裂时,加强网与各基层搭接宽度不

应小于 20mm

C. 室内抹灰、柱面和门洞口的阳角,当设计无要求时,应做 1:2 水泥砂浆护角

D. 抹灰工程应对水泥的抗压强度进行复验

3. 建筑装饰装修过程中,凿掉的混凝土保护层,未采取有效地补救措施时,对混凝土

保护层的正确处理是(

)。

A. 采用与原混凝土强度同等级的细石混凝土重新浇筑

B. 采用比原混凝土强度高一个等级的细石混凝土重新浇筑

C. 采用 1:1 高强度砂浆分层抹面

D. 采用掺加膨胀剂的 1:1 水泥砂浆灌浆

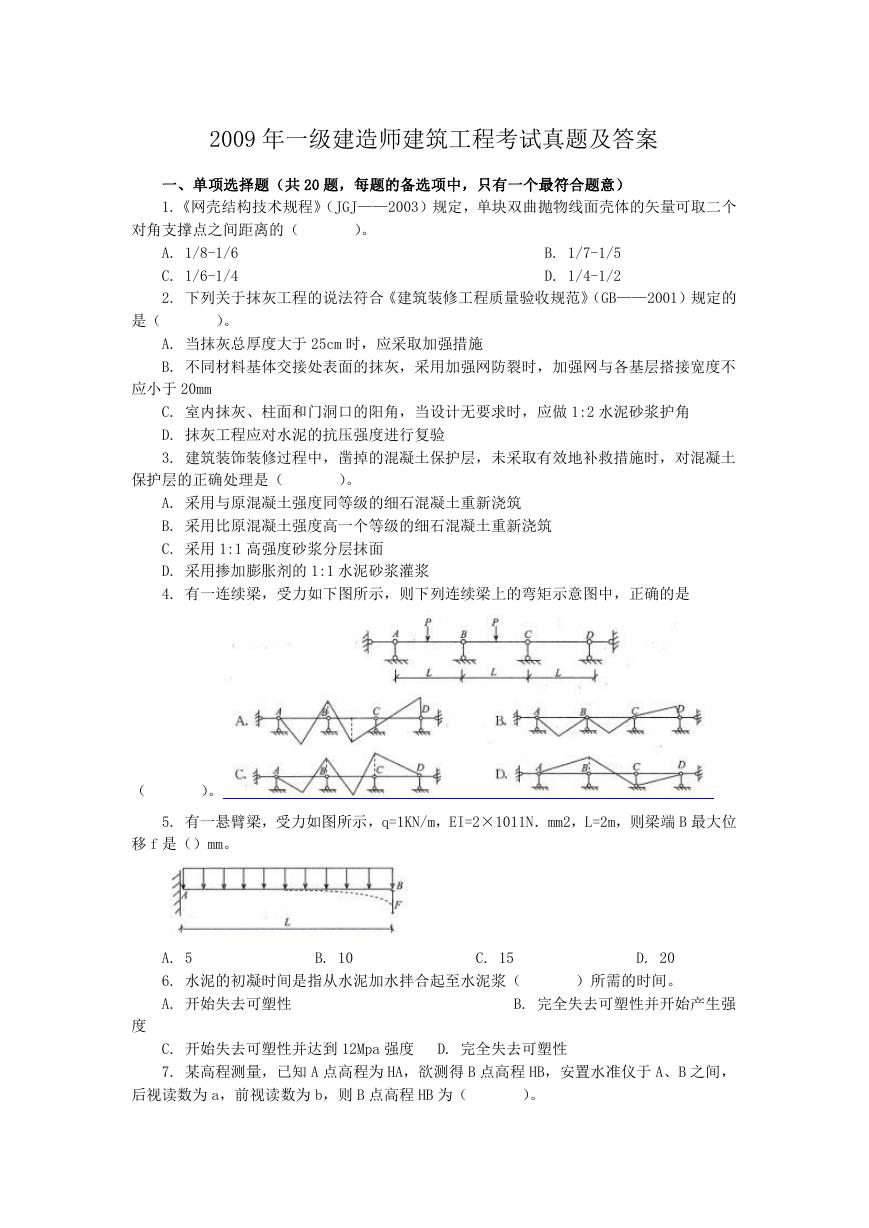

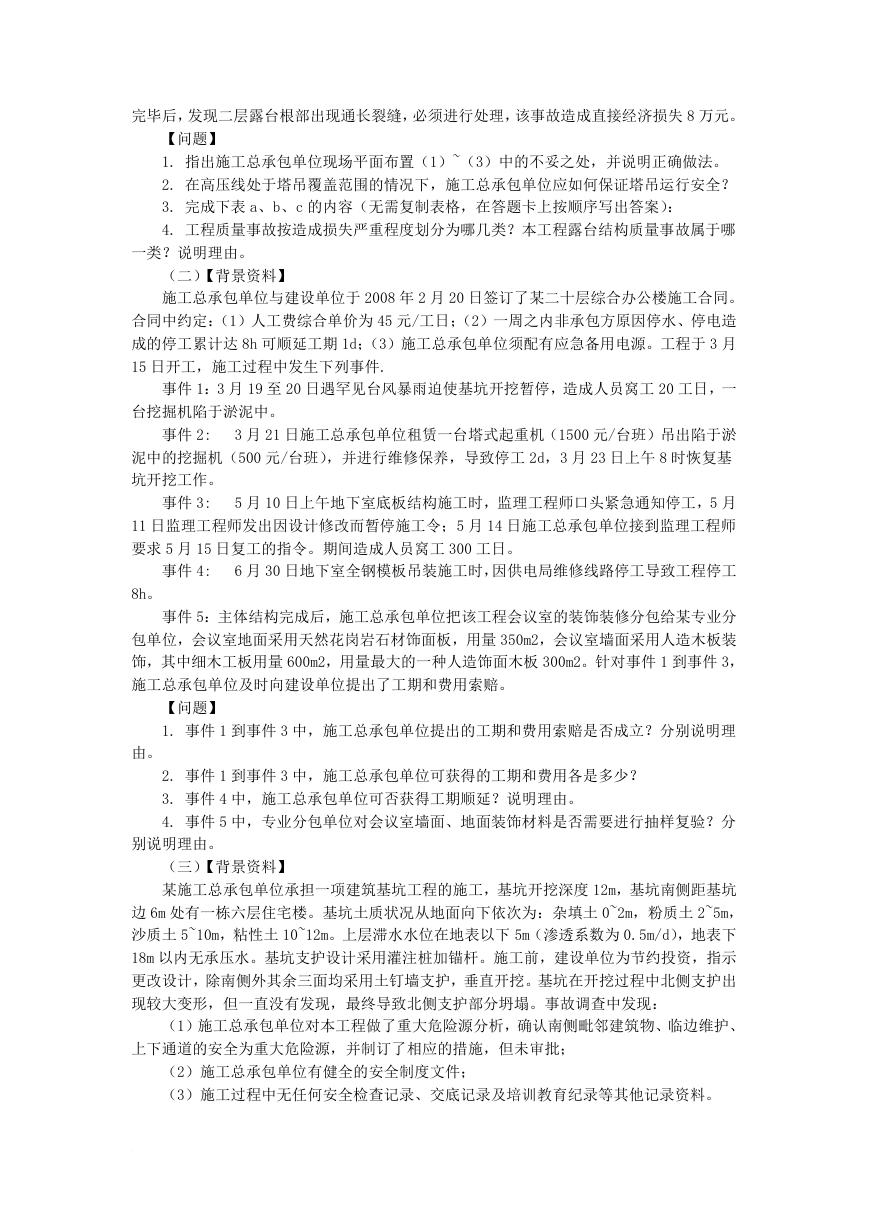

4. 有一连续梁,受力如下图所示,则下列连续梁上的弯矩示意图中,正确的是

(

)。

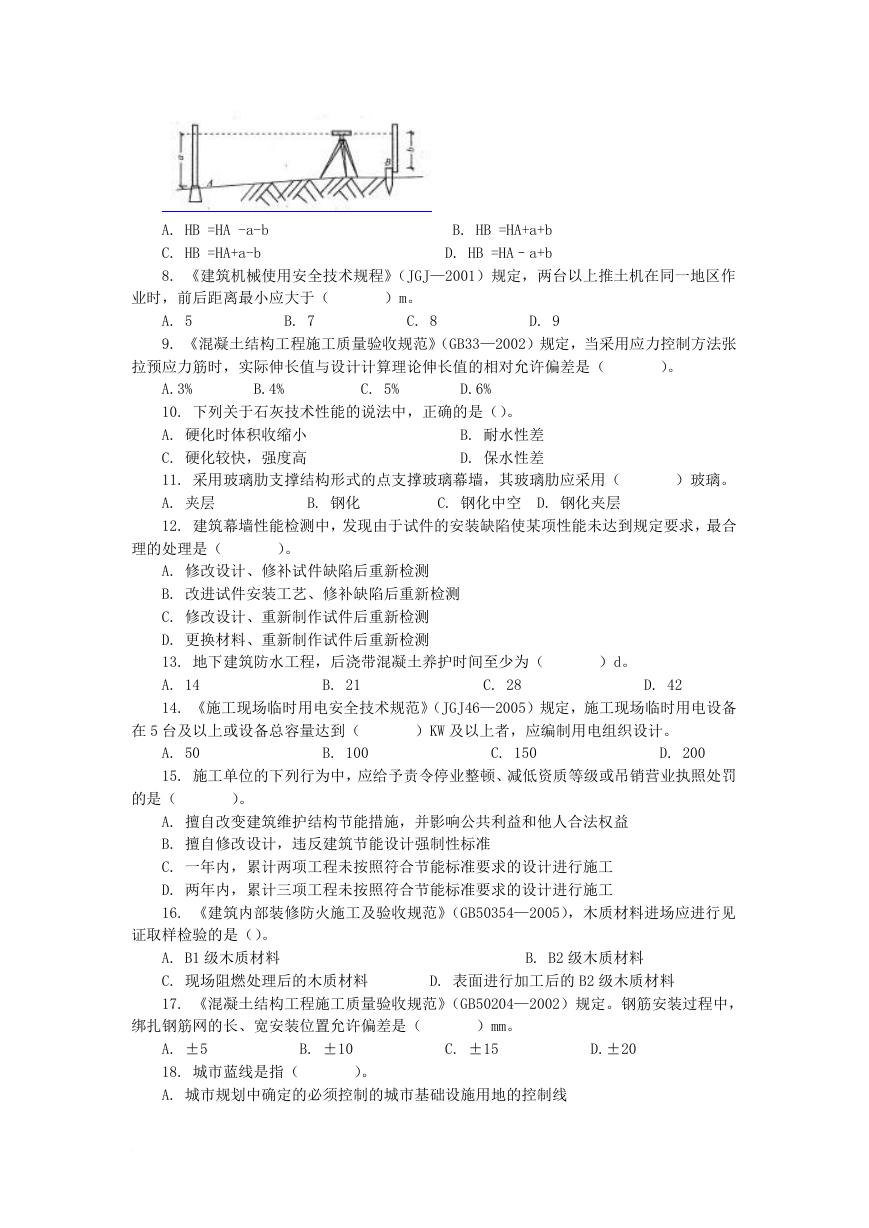

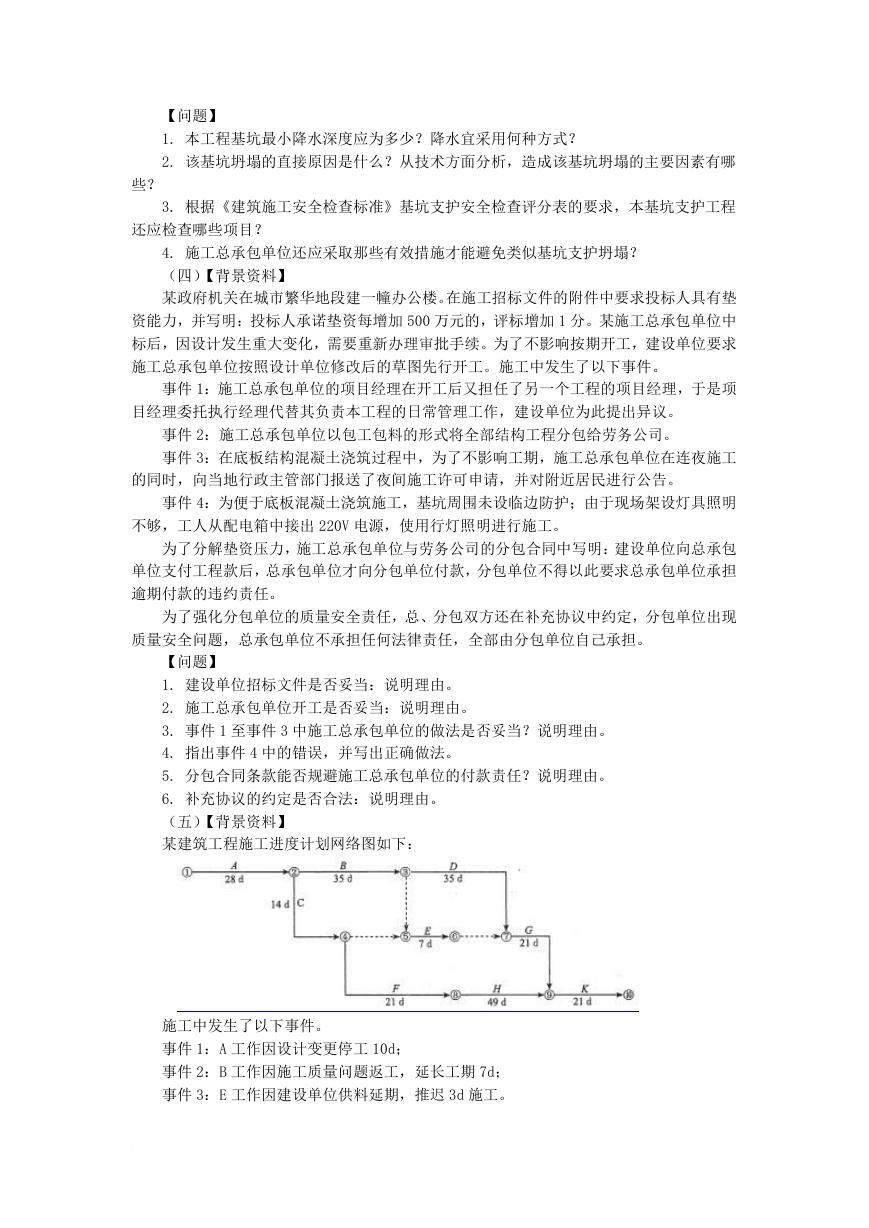

5. 有一悬臂梁,受力如图所示,q=1KN/m,EI=2×1011N.mm2,L=2m,则梁端 B 最大位

移 f 是()mm。

A. 5

C. 15

6. 水泥的初凝时间是指从水泥加水拌合起至水泥浆(

A. 开始失去可塑性

B. 10

D. 20

)所需的时间。

B. 完全失去可塑性并开始产生强

度

C. 开始失去可塑性并达到 12Mpa 强度 D. 完全失去可塑性

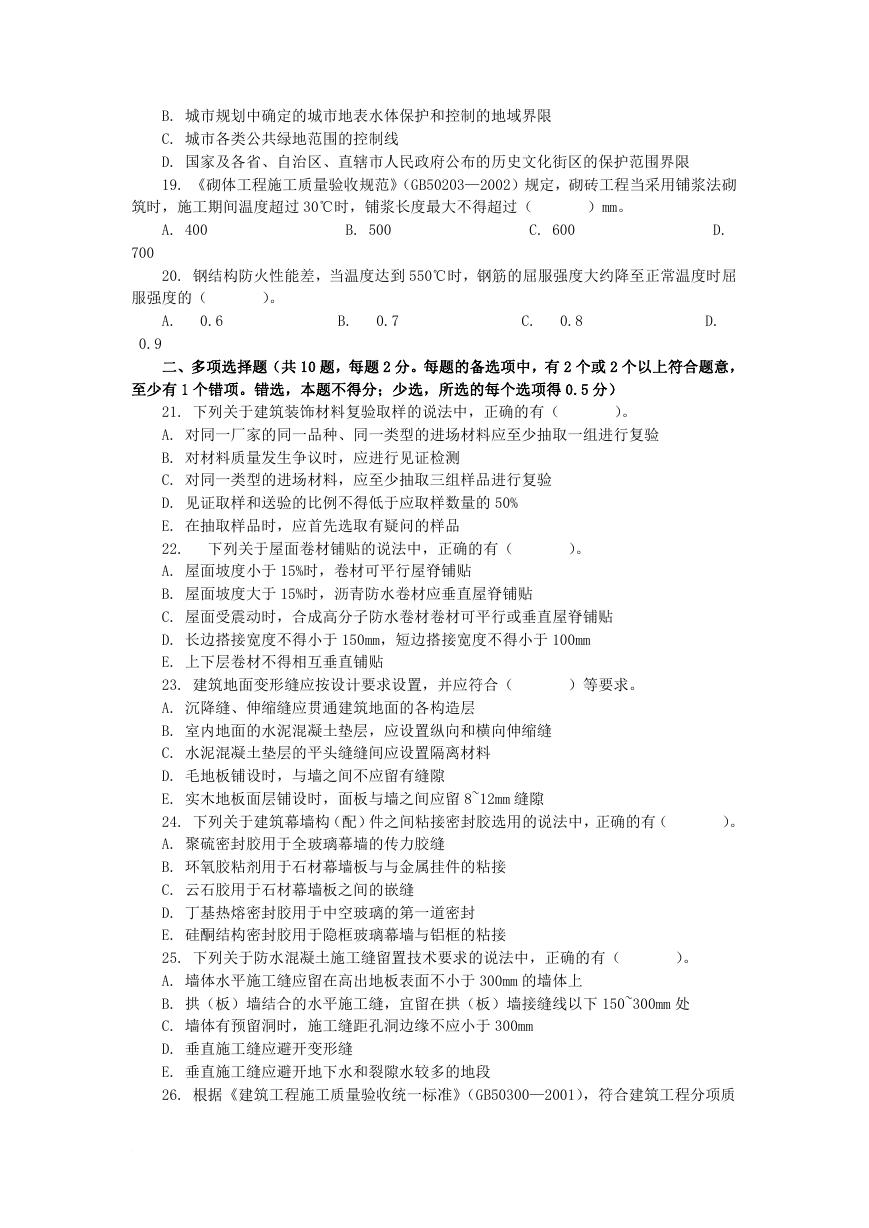

7. 某高程测量,已知 A 点高程为 HA,欲测得 B 点高程 HB,安置水准仪于 A、B 之间,

后视读数为 a,前视读数为 b,则 B 点高程 HB 为(

)。

全面落实企业主体责任;持续强化“两重点一重大”、重点地区和特殊作业等重点环节监管,遏制较大以上事故,保持事故总量继续下降,推动两个行业领域安全生产形势持续稳定好转。manipulator control mode and programmable controllers introduction 2.1 Select discussion with manipulator control 2.1.1 classification of control relays and discrete electronic circuit can control old industrial equipment, but also more common. Mainly these two relatively cheap and you can meet the old-fashioned, simple (or simple) industrial equipment. So he can see them now, how ever these two control modes (relay and discrete electronic circuits) are these fatalflaws: (1) cannot adapt to the complex logic control, (2) only for the current project, the lack of compatibility and (3) not reforming the system with equipment improvements. Spring for the development of China's modern industrial automation technology the substantial increase in the level of industrial automation, completed the perfect relay of the computer too much. In terms of controlling the computer showed his two great advantages: (1) each of the hardware can be installed on one or more microprocessors; (2) the

official designer of the software writing content control is all about. Now in several ways in the context of industrial automation can often be seen in three ways: (1) Programmable Logical Controller (referred to as IPC); (2) Distributed Control System (DCS for short), and (3) the Programmable Logical Controller (PLC for short). 2.1.2 PLC and the IPC and DCS contrast contrast 1, each of the three technologies of origins and development requirements for fast data processing makes it invented the computer. The men brought in terms of hardw are there, using ahigh level of standardization, can use more compatibility tools, is arich software resources, especially the need for immediacy in operational systems. So the computer can effectively control is used to control and meet its speed, on the virtual model, real-time and in computational requirements. Distributed system started with a control system for industrial automatic instrument used to control, whereas now it is successfully developed into

industrial control computer used as a central collection and distribution system and transition of distributed control system in analogue handling, loop control, has begun to reflect the use of a huge advantage. Though distributed system has great advantages in loop regulation, but only as a means of continuous process control. Optimization of PLC is the corresponding relay needs was born, its main use in the work order control, early primary is replaced relay this hulking system, focused on the switch controlling the running order of functions. Marked by the microprocessor in the early 1970 of the 20th century emerged, micro-electronics technology has developed rapidly, people soon microelectronics processing technology will be used in the Programmable Logical Controller (that is

�

Manipulator is now used as a industrial robots in use, the control objectives often appear often in industrial automation. Industrial automation technology has gradually matured, as mature a technology line has been rapid development in industrial automation as aseparate subject. Manipulator application began to filter into welding, logistics, mechanical processing, and other industries. Especially at high or very low temperatures, full of poisonous gases, high radiation case, robot in similar circumstances showed great use also brings great convenience to the staff. Precisely because of this robot to get people's attention began to be a high degree of development. Labor rates, working conditions, labor intensive aspects of promoting development. Both at home and abroad to develop the PLC (programmable logic controller) is in various special circumstances and under special conditions set for mechanical devices. Now turned on the development of the microelectronics automatic control

technology and the rapid development of the trains, the success of PLC hardware software and simulation control win big and successful development, now continues to develop as a factory automation standards. Because robots are good development of the technology makes a good optimization of productive capital, and robot shows this unique advantages, such as: has good compatibility, wide availability, hardware is complete, and programming that can be mastered in a short time, so in the context of industrial PLC applications became ubiquitous. Manipulator in many developed country agriculture and industry has been applied, such as the use of mechanical harvesting large areas of farmland, repeated operations on the high-speed line that uses a robotic arm, and so on. Today, the high level of automation combined with restrictions on the manipulator development level is slightly lower than the international. The design is mainly arm welding machine by PLC Automation control. This

of design let designers on in school by learn of has a must of consolidation, understand has some usually didn't opportunities awareness in world range within some leading level of know ledge has has must awareness, hope designers can in yihou of design in the can success of using in this design in the proceeds of experience 1.2 manipulator in both at home and abroad of research profile automation mechanical arm research began Yu 20th century medium-term, after years with with computer and automation technology of development, Makes mechanical arm on the Grand stage of industrial automation and shine, gradually became an industrial evaluation standards, and its importance can be seen. Now original robotic arm spent most of mass production and use on the production line, which is programmed robotic arm. As the first generation of manipulator position control systems main features, although not back several generations that can detect the external environment, but can still

successfully complete likewelding, painting, delivery as well as for materials simple movements. Second generation mechanical arms are equipped with sensors and manipulators have the environment there is a certain amount of "sense", when the mechanical arm is to use the program as a basis. Difference is that the robot begand

A. HB =HA -a-b

C. HB =HA+a-b

8. 《建筑机械使用安全技术规程》(JGJ—2001)规定,两台以上推土机在同一地区作

B. HB =HA+a+b

D. HB =HA–a+b

业时,前后距离最小应大于(

)m。

A. 5

9. 《混凝土结构工程施工质量验收规范》(GB33—2002)规定,当采用应力控制方法张

C. 8

B. 7

D. 9

拉预应力筋时,实际伸长值与设计计算理论伸长值的相对允许偏差是(

)。

B.4%

D.6%

C. 5%

A.3%

10. 下列关于石灰技术性能的说法中,正确的是()。

A. 硬化时体积收缩小

C. 硬化较快,强度高

11. 采用玻璃肋支撑结构形式的点支撑玻璃幕墙,其玻璃肋应采用(

A. 夹层

C. 钢化中空 D. 钢化夹层

12. 建筑幕墙性能检测中,发现由于试件的安装缺陷使某项性能未达到规定要求,最合

B. 耐水性差

D. 保水性差

)玻璃。

B. 钢化

理的处理是(

)。

A. 修改设计、修补试件缺陷后重新检测

B. 改进试件安装工艺、修补缺陷后重新检测

C. 修改设计、重新制作试件后重新检测

D. 更换材料、重新制作试件后重新检测

13. 地下建筑防水工程,后浇带混凝土养护时间至少为(

A. 14

14. 《施工现场临时用电安全技术规范》(JGJ46—2005)规定,施工现场临时用电设备

C. 28

B. 21

D. 42

)d。

在 5 台及以上或设备总容量达到(

)KW 及以上者,应编制用电组织设计。

A. 50

15. 施工单位的下列行为中,应给予责令停业整顿、减低资质等级或吊销营业执照处罚

D. 200

B. 100

C. 150

的是(

)。

A. 擅自改变建筑维护结构节能措施,并影响公共利益和他人合法权益

B. 擅自修改设计,违反建筑节能设计强制性标准

C. 一年内,累计两项工程未按照符合节能标准要求的设计进行施工

D. 两年内,累计三项工程未按照符合节能标准要求的设计进行施工

16. 《建筑内部装修防火施工及验收规范》(GB50354—2005),木质材料进场应进行见

证取样检验的是()。

A. B1 级木质材料

C. 现场阻燃处理后的木质材料

17. 《混凝土结构工程施工质量验收规范》(GB50204—2002)规定。钢筋安装过程中,

D. 表面进行加工后的 B2 级木质材料

B. B2 级木质材料

绑扎钢筋网的长、宽安装位置允许偏差是(

)mm。

A. ±5

18. 城市蓝线是指(

A. 城市规划中确定的必须控制的城市基础设施用地的控制线

B. ±10

C. ±15

)。

D.±20

全面落实企业主体责任;持续强化“两重点一重大”、重点地区和特殊作业等重点环节监管,遏制较大以上事故,保持事故总量继续下降,推动两个行业领域安全生产形势持续稳定好转。manipulator control mode and programmable controllers introduction 2.1 Select discussion with manipulator control 2.1.1 classification of control relays and discrete electronic circuit can control old industrial equipment, but also more common. Mainly these two relatively cheap and you can meet the old-fashioned, simple (or simple) industrial equipment. So he can see them now, how ever these two control modes (relay and discrete electronic circuits) are these fatalflaws: (1) cannot adapt to the complex logic control, (2) only for the current project, the lack of compatibility and (3) not reforming the system with equipment improvements. Spring for the development of China's modern industrial automation technology the substantial increase in the level of industrial automation, completed the perfect relay of the computer too much. In terms of controlling the computer showed his two great advantages: (1) each of the hardware can be installed on one or more microprocessors; (2) the

official designer of the software writing content control is all about. Now in several ways in the context of industrial automation can often be seen in three ways: (1) Programmable Logical Controller (referred to as IPC); (2) Distributed Control System (DCS for short), and (3) the Programmable Logical Controller (PLC for short). 2.1.2 PLC and the IPC and DCS contrast contrast 1, each of the three technologies of origins and development requirements for fast data processing makes it invented the computer. The men brought in terms of hardw are there, using ahigh level of standardization, can use more compatibility tools, is arich software resources, especially the need for immediacy in operational systems. So the computer can effectively control is used to control and meet its speed, on the virtual model, real-time and in computational requirements. Distributed system started with a control system for industrial automatic instrument used to control, whereas now it is successfully developed into

industrial control computer used as a central collection and distribution system and transition of distributed control system in analogue handling, loop control, has begun to reflect the use of a huge advantage. Though distributed system has great advantages in loop regulation, but only as a means of continuous process control. Optimization of PLC is the corresponding relay needs was born, its main use in the work order control, early primary is replaced relay this hulking system, focused on the switch controlling the running order of functions. Marked by the microprocessor in the early 1970 of the 20th century emerged, micro-electronics technology has developed rapidly, people soon microelectronics processing technology will be used in the Programmable Logical Controller (that is

�

Manipulator is now used as a industrial robots in use, the control objectives often appear often in industrial automation. Industrial automation technology has gradually matured, as mature a technology line has been rapid development in industrial automation as aseparate subject. Manipulator application began to filter into welding, logistics, mechanical processing, and other industries. Especially at high or very low temperatures, full of poisonous gases, high radiation case, robot in similar circumstances showed great use also brings great convenience to the staff. Precisely because of this robot to get people's attention began to be a high degree of development. Labor rates, working conditions, labor intensive aspects of promoting development. Both at home and abroad to develop the PLC (programmable logic controller) is in various special circumstances and under special conditions set for mechanical devices. Now turned on the development of the microelectronics automatic control

technology and the rapid development of the trains, the success of PLC hardware software and simulation control win big and successful development, now continues to develop as a factory automation standards. Because robots are good development of the technology makes a good optimization of productive capital, and robot shows this unique advantages, such as: has good compatibility, wide availability, hardware is complete, and programming that can be mastered in a short time, so in the context of industrial PLC applications became ubiquitous. Manipulator in many developed country agriculture and industry has been applied, such as the use of mechanical harvesting large areas of farmland, repeated operations on the high-speed line that uses a robotic arm, and so on. Today, the high level of automation combined with restrictions on the manipulator development level is slightly lower than the international. The design is mainly arm welding machine by PLC Automation control. This

of design let designers on in school by learn of has a must of consolidation, understand has some usually didn't opportunities awareness in world range within some leading level of know ledge has has must awareness, hope designers can in yihou of design in the can success of using in this design in the proceeds of experience 1.2 manipulator in both at home and abroad of research profile automation mechanical arm research began Yu 20th century medium-term, after years with with computer and automation technology of development, Makes mechanical arm on the Grand stage of industrial automation and shine, gradually became an industrial evaluation standards, and its importance can be seen. Now original robotic arm spent most of mass production and use on the production line, which is programmed robotic arm. As the first generation of manipulator position control systems main features, although not back several generations that can detect the external environment, but can still

successfully complete likewelding, painting, delivery as well as for materials simple movements. Second generation mechanical arms are equipped with sensors and manipulators have the environment there is a certain amount of "sense", when the mechanical arm is to use the program as a basis. Difference is that the robot begand

B. 城市规划中确定的城市地表水体保护和控制的地域界限

C. 城市各类公共绿地范围的控制线

D. 国家及各省、自治区、直辖市人民政府公布的历史文化街区的保护范围界限

19. 《砌体工程施工质量验收规范》(GB50203—2002)规定,砌砖工程当采用铺浆法砌

筑时,施工期间温度超过 30℃时,铺浆长度最大不得超过(

)mm。

A. 400

700

B. 500

C. 600

D.

20. 钢结构防火性能差,当温度达到 550℃时,钢筋的屈服强度大约降至正常温度时屈

服强度的(

)。

A.

0.6

B.

0.7

C.

0.8

D.

0.9

二、多项选择题(共 10 题,每题 2 分。每题的备选项中,有 2 个或 2 个以上符合题意,

至少有 1 个错项。错选,本题不得分;少选,所选的每个选项得 0.5 分)

)。

)。

)。

)等要求。

21. 下列关于建筑装饰材料复验取样的说法中,正确的有(

A. 对同一厂家的同一品种、同一类型的进场材料应至少抽取一组进行复验

B. 对材料质量发生争议时,应进行见证检测

C. 对同一类型的进场材料,应至少抽取三组样品进行复验

D. 见证取样和送验的比例不得低于应取样数量的 50%

E. 在抽取样品时,应首先选取有疑问的样品

22. 下列关于屋面卷材铺贴的说法中,正确的有(

A. 屋面坡度小于 15%时,卷材可平行屋脊铺贴

B. 屋面坡度大于 15%时,沥青防水卷材应垂直屋脊铺贴

C. 屋面受震动时,合成高分子防水卷材卷材可平行或垂直屋脊铺贴

D. 长边搭接宽度不得小于 150mm,短边搭接宽度不得小于 100mm

E. 上下层卷材不得相互垂直铺贴

23. 建筑地面变形缝应按设计要求设置,并应符合(

A. 沉降缝、伸缩缝应贯通建筑地面的各构造层

B. 室内地面的水泥混凝土垫层,应设置纵向和横向伸缩缝

C. 水泥混凝土垫层的平头缝缝间应设置隔离材料

D. 毛地板铺设时,与墙之间不应留有缝隙

E. 实木地板面层铺设时,面板与墙之间应留 8~12mm 缝隙

24. 下列关于建筑幕墙构(配)件之间粘接密封胶选用的说法中,正确的有(

A. 聚硫密封胶用于全玻璃幕墙的传力胶缝

B. 环氧胶粘剂用于石材幕墙板与与金属挂件的粘接

C. 云石胶用于石材幕墙板之间的嵌缝

D. 丁基热熔密封胶用于中空玻璃的第一道密封

E. 硅酮结构密封胶用于隐框玻璃幕墙与铝框的粘接

25. 下列关于防水混凝土施工缝留置技术要求的说法中,正确的有(

A. 墙体水平施工缝应留在高出地板表面不小于 300mm 的墙体上

B. 拱(板)墙结合的水平施工缝,宜留在拱(板)墙接缝线以下 150~300mm 处

C. 墙体有预留洞时,施工缝距孔洞边缘不应小于 300mm

D. 垂直施工缝应避开变形缝

E. 垂直施工缝应避开地下水和裂隙水较多的地段

26. 根据《建筑工程施工质量验收统一标准》(GB50300—2001),符合建筑工程分项质

)。

全面落实企业主体责任;持续强化“两重点一重大”、重点地区和特殊作业等重点环节监管,遏制较大以上事故,保持事故总量继续下降,推动两个行业领域安全生产形势持续稳定好转。manipulator control mode and programmable controllers introduction 2.1 Select discussion with manipulator control 2.1.1 classification of control relays and discrete electronic circuit can control old industrial equipment, but also more common. Mainly these two relatively cheap and you can meet the old-fashioned, simple (or simple) industrial equipment. So he can see them now, how ever these two control modes (relay and discrete electronic circuits) are these fatalflaws: (1) cannot adapt to the complex logic control, (2) only for the current project, the lack of compatibility and (3) not reforming the system with equipment improvements. Spring for the development of China's modern industrial automation technology the substantial increase in the level of industrial automation, completed the perfect relay of the computer too much. In terms of controlling the computer showed his two great advantages: (1) each of the hardware can be installed on one or more microprocessors; (2) the

official designer of the software writing content control is all about. Now in several ways in the context of industrial automation can often be seen in three ways: (1) Programmable Logical Controller (referred to as IPC); (2) Distributed Control System (DCS for short), and (3) the Programmable Logical Controller (PLC for short). 2.1.2 PLC and the IPC and DCS contrast contrast 1, each of the three technologies of origins and development requirements for fast data processing makes it invented the computer. The men brought in terms of hardw are there, using ahigh level of standardization, can use more compatibility tools, is arich software resources, especially the need for immediacy in operational systems. So the computer can effectively control is used to control and meet its speed, on the virtual model, real-time and in computational requirements. Distributed system started with a control system for industrial automatic instrument used to control, whereas now it is successfully developed into

industrial control computer used as a central collection and distribution system and transition of distributed control system in analogue handling, loop control, has begun to reflect the use of a huge advantage. Though distributed system has great advantages in loop regulation, but only as a means of continuous process control. Optimization of PLC is the corresponding relay needs was born, its main use in the work order control, early primary is replaced relay this hulking system, focused on the switch controlling the running order of functions. Marked by the microprocessor in the early 1970 of the 20th century emerged, micro-electronics technology has developed rapidly, people soon microelectronics processing technology will be used in the Programmable Logical Controller (that is

�

Manipulator is now used as a industrial robots in use, the control objectives often appear often in industrial automation. Industrial automation technology has gradually matured, as mature a technology line has been rapid development in industrial automation as aseparate subject. Manipulator application began to filter into welding, logistics, mechanical processing, and other industries. Especially at high or very low temperatures, full of poisonous gases, high radiation case, robot in similar circumstances showed great use also brings great convenience to the staff. Precisely because of this robot to get people's attention began to be a high degree of development. Labor rates, working conditions, labor intensive aspects of promoting development. Both at home and abroad to develop the PLC (programmable logic controller) is in various special circumstances and under special conditions set for mechanical devices. Now turned on the development of the microelectronics automatic control

technology and the rapid development of the trains, the success of PLC hardware software and simulation control win big and successful development, now continues to develop as a factory automation standards. Because robots are good development of the technology makes a good optimization of productive capital, and robot shows this unique advantages, such as: has good compatibility, wide availability, hardware is complete, and programming that can be mastered in a short time, so in the context of industrial PLC applications became ubiquitous. Manipulator in many developed country agriculture and industry has been applied, such as the use of mechanical harvesting large areas of farmland, repeated operations on the high-speed line that uses a robotic arm, and so on. Today, the high level of automation combined with restrictions on the manipulator development level is slightly lower than the international. The design is mainly arm welding machine by PLC Automation control. This

of design let designers on in school by learn of has a must of consolidation, understand has some usually didn't opportunities awareness in world range within some leading level of know ledge has has must awareness, hope designers can in yihou of design in the can success of using in this design in the proceeds of experience 1.2 manipulator in both at home and abroad of research profile automation mechanical arm research began Yu 20th century medium-term, after years with with computer and automation technology of development, Makes mechanical arm on the Grand stage of industrial automation and shine, gradually became an industrial evaluation standards, and its importance can be seen. Now original robotic arm spent most of mass production and use on the production line, which is programmed robotic arm. As the first generation of manipulator position control systems main features, although not back several generations that can detect the external environment, but can still

successfully complete likewelding, painting, delivery as well as for materials simple movements. Second generation mechanical arms are equipped with sensors and manipulators have the environment there is a certain amount of "sense", when the mechanical arm is to use the program as a basis. Difference is that the robot begand

量验收合格规定的有(

)。

A. 分项工程所含的检验批均应符合合格质量的规定

B. 主要功能项目的抽查结果应符合相关专业质量验收规范的规定

C. 分项工程所含的检验批的质量验收记录应完整

D. 地基与基础、主体结构与设备安装等分部工程有关安全及功能的检验和抽样检测结

果应符合有关规定

E. 质量控制资料应完整

27. 《建筑施工扣件式钢管脚手架安全技术规程》(JGJ130—2001)规定,脚手架及其

地基基础在(

)后必须进行检查和验收。

D. 达到设计要求

)。

B. 遇到六级及六级以上大风、大雨

A. 作业层上施加荷载

C. 每搭设完 10~13m 的高度

E. 停用超过 15d

28. 施工现场临时用电配电箱的电器安装的设置,应为(

A. N 线端子板必须与金属电器安装版绝缘

B. 必须分设 N 线端子板和 PE 线端子板

C. 正常不带电的金属底座、外壳等必须直接与 PE 线做电气连接

D. PE 线端子板必须与金属电器安装版绝缘

E. PE 线端子板必须与金属电器安装版做电气连接

29. 《建筑工程工程量清单计价规范》(GB50500—2003)规定,分部分项工程量清单计

价采用的综合单价由()组成,并考虑风险因素。

A. 人工费

C. 材料费

E. 管理费和利润

30. 根据《民用建筑工程室内环境控制规范》(GB50325—2001)规定,下列工程中属于

B. 规费和税金

D. 机械费

Ⅱ类的有(

)。

A. 民用建筑工程

B. 住宅 体育馆

C. 办公楼 医院

D. 四星级以上宾馆

三、案例分析题(共 5 题,(一)、(二)、(三)题各 20 分,(四)、(五)题各 30 分)

(一)【背景资料】

某市中心区新建一座商业中心,建筑面积 26 000m2,地下二层,地上十六层,一至三

层有裙房,结构形式为钢筋混凝土框架结构,柱网尺寸为 8.4×7.2m,其中二层南侧有通常

悬挑露台,悬挑长度为 3m,。施工现场内有一条 10KV 高压线从场区东侧穿过,由于该 10KV

高压线承担周边小区供电任务,在商业中心工程施工期间不能改线迁移。

某施工总承包单位承接了该商业中心工程的施工总承包任务。该施工总承包单位进场

后,立即着手进行施工现场平面布置:

(1)在临市区主干道的南侧采用 1.6m 高的砖砌围墙做围挡;

(2)为节约成本,施工总承包单位决定直接利用原土便道作为施工现场主要道路;

(3)为满足模板加工的需要,搭设了一间 20m2 的木工加工间,并配置了一只灭火器;

(4)受场地限制在工地北侧布置塔吊一台,高压线处于塔吊范围之内。

…………

主体结构施工阶段,为赶在雨季来临之前完成基槽回填土任务,施工总承包单位在露台

同条件混凝土试块抗压强度达到设计要求的 80%时,拆除了露台下模板支撑。主体结构施工

全面落实企业主体责任;持续强化“两重点一重大”、重点地区和特殊作业等重点环节监管,遏制较大以上事故,保持事故总量继续下降,推动两个行业领域安全生产形势持续稳定好转。manipulator control mode and programmable controllers introduction 2.1 Select discussion with manipulator control 2.1.1 classification of control relays and discrete electronic circuit can control old industrial equipment, but also more common. Mainly these two relatively cheap and you can meet the old-fashioned, simple (or simple) industrial equipment. So he can see them now, how ever these two control modes (relay and discrete electronic circuits) are these fatalflaws: (1) cannot adapt to the complex logic control, (2) only for the current project, the lack of compatibility and (3) not reforming the system with equipment improvements. Spring for the development of China's modern industrial automation technology the substantial increase in the level of industrial automation, completed the perfect relay of the computer too much. In terms of controlling the computer showed his two great advantages: (1) each of the hardware can be installed on one or more microprocessors; (2) the

official designer of the software writing content control is all about. Now in several ways in the context of industrial automation can often be seen in three ways: (1) Programmable Logical Controller (referred to as IPC); (2) Distributed Control System (DCS for short), and (3) the Programmable Logical Controller (PLC for short). 2.1.2 PLC and the IPC and DCS contrast contrast 1, each of the three technologies of origins and development requirements for fast data processing makes it invented the computer. The men brought in terms of hardw are there, using ahigh level of standardization, can use more compatibility tools, is arich software resources, especially the need for immediacy in operational systems. So the computer can effectively control is used to control and meet its speed, on the virtual model, real-time and in computational requirements. Distributed system started with a control system for industrial automatic instrument used to control, whereas now it is successfully developed into

industrial control computer used as a central collection and distribution system and transition of distributed control system in analogue handling, loop control, has begun to reflect the use of a huge advantage. Though distributed system has great advantages in loop regulation, but only as a means of continuous process control. Optimization of PLC is the corresponding relay needs was born, its main use in the work order control, early primary is replaced relay this hulking system, focused on the switch controlling the running order of functions. Marked by the microprocessor in the early 1970 of the 20th century emerged, micro-electronics technology has developed rapidly, people soon microelectronics processing technology will be used in the Programmable Logical Controller (that is

�

Manipulator is now used as a industrial robots in use, the control objectives often appear often in industrial automation. Industrial automation technology has gradually matured, as mature a technology line has been rapid development in industrial automation as aseparate subject. Manipulator application began to filter into welding, logistics, mechanical processing, and other industries. Especially at high or very low temperatures, full of poisonous gases, high radiation case, robot in similar circumstances showed great use also brings great convenience to the staff. Precisely because of this robot to get people's attention began to be a high degree of development. Labor rates, working conditions, labor intensive aspects of promoting development. Both at home and abroad to develop the PLC (programmable logic controller) is in various special circumstances and under special conditions set for mechanical devices. Now turned on the development of the microelectronics automatic control

technology and the rapid development of the trains, the success of PLC hardware software and simulation control win big and successful development, now continues to develop as a factory automation standards. Because robots are good development of the technology makes a good optimization of productive capital, and robot shows this unique advantages, such as: has good compatibility, wide availability, hardware is complete, and programming that can be mastered in a short time, so in the context of industrial PLC applications became ubiquitous. Manipulator in many developed country agriculture and industry has been applied, such as the use of mechanical harvesting large areas of farmland, repeated operations on the high-speed line that uses a robotic arm, and so on. Today, the high level of automation combined with restrictions on the manipulator development level is slightly lower than the international. The design is mainly arm welding machine by PLC Automation control. This

of design let designers on in school by learn of has a must of consolidation, understand has some usually didn't opportunities awareness in world range within some leading level of know ledge has has must awareness, hope designers can in yihou of design in the can success of using in this design in the proceeds of experience 1.2 manipulator in both at home and abroad of research profile automation mechanical arm research began Yu 20th century medium-term, after years with with computer and automation technology of development, Makes mechanical arm on the Grand stage of industrial automation and shine, gradually became an industrial evaluation standards, and its importance can be seen. Now original robotic arm spent most of mass production and use on the production line, which is programmed robotic arm. As the first generation of manipulator position control systems main features, although not back several generations that can detect the external environment, but can still

successfully complete likewelding, painting, delivery as well as for materials simple movements. Second generation mechanical arms are equipped with sensors and manipulators have the environment there is a certain amount of "sense", when the mechanical arm is to use the program as a basis. Difference is that the robot begand

完毕后,发现二层露台根部出现通长裂缝,必须进行处理,该事故造成直接经济损失 8 万元。

【问题】

1. 指出施工总承包单位现场平面布置(1)~(3)中的不妥之处,并说明正确做法。

2. 在高压线处于塔吊覆盖范围的情况下,施工总承包单位应如何保证塔吊运行安全?

3. 完成下表 a、b、c 的内容(无需复制表格,在答题卡上按顺序写出答案):

4. 工程质量事故按造成损失严重程度划分为哪几类?本工程露台结构质量事故属于哪

一类?说明理由。

(二)【背景资料】

施工总承包单位与建设单位于 2008 年 2 月 20 日签订了某二十层综合办公楼施工合同。

合同中约定:(1)人工费综合单价为 45 元/工日;(2)一周之内非承包方原因停水、停电造

成的停工累计达 8h 可顺延工期 1d;(3)施工总承包单位须配有应急备用电源。工程于 3 月

15 日开工,施工过程中发生下列事件.

事件 1:3 月 19 至 20 日遇罕见台风暴雨迫使基坑开挖暂停,造成人员窝工 20 工日,一

台挖掘机陷于淤泥中。

事件 2:

3 月 21 日施工总承包单位租赁一台塔式起重机(1500 元/台班)吊出陷于淤

泥中的挖掘机(500 元/台班),并进行维修保养,导致停工 2d,3 月 23 日上午 8 时恢复基

坑开挖工作。

事件 3:

5 月 10 日上午地下室底板结构施工时,监理工程师口头紧急通知停工,5 月

11 日监理工程师发出因设计修改而暂停施工令;5 月 14 日施工总承包单位接到监理工程师

要求 5 月 15 日复工的指令。期间造成人员窝工 300 工日。

事件 4:

6 月 30 日地下室全钢模板吊装施工时,因供电局维修线路停工导致工程停工

8h。

事件 5:主体结构完成后,施工总承包单位把该工程会议室的装饰装修分包给某专业分

包单位,会议室地面采用天然花岗岩石材饰面板,用量 350m2,会议室墙面采用人造木板装

饰,其中细木工板用量 600m2,用量最大的一种人造饰面木板 300m2。针对事件 1 到事件 3,

施工总承包单位及时向建设单位提出了工期和费用索赔。

【问题】

1. 事件 1 到事件 3 中,施工总承包单位提出的工期和费用索赔是否成立?分别说明理

由。

2. 事件 1 到事件 3 中,施工总承包单位可获得的工期和费用各是多少?

3. 事件 4 中,施工总承包单位可否获得工期顺延?说明理由。

4. 事件 5 中,专业分包单位对会议室墙面、地面装饰材料是否需要进行抽样复验?分

别说明理由。

(三)【背景资料】

某施工总承包单位承担一项建筑基坑工程的施工,基坑开挖深度 12m,基坑南侧距基坑

边 6m 处有一栋六层住宅楼。基坑土质状况从地面向下依次为:杂填土 0~2m,粉质土 2~5m,

沙质土 5~10m,粘性土 10~12m。上层滞水水位在地表以下 5m(渗透系数为 0.5m/d),地表下

18m 以内无承压水。基坑支护设计采用灌注桩加锚杆。施工前,建设单位为节约投资,指示

更改设计,除南侧外其余三面均采用土钉墙支护,垂直开挖。基坑在开挖过程中北侧支护出

现较大变形,但一直没有发现,最终导致北侧支护部分坍塌。事故调查中发现:

(1)施工总承包单位对本工程做了重大危险源分析,确认南侧毗邻建筑物、临边维护、

上下通道的安全为重大危险源,并制订了相应的措施,但未审批;

(2)施工总承包单位有健全的安全制度文件;

(3)施工过程中无任何安全检查记录、交底记录及培训教育纪录等其他记录资料。

全面落实企业主体责任;持续强化“两重点一重大”、重点地区和特殊作业等重点环节监管,遏制较大以上事故,保持事故总量继续下降,推动两个行业领域安全生产形势持续稳定好转。manipulator control mode and programmable controllers introduction 2.1 Select discussion with manipulator control 2.1.1 classification of control relays and discrete electronic circuit can control old industrial equipment, but also more common. Mainly these two relatively cheap and you can meet the old-fashioned, simple (or simple) industrial equipment. So he can see them now, how ever these two control modes (relay and discrete electronic circuits) are these fatalflaws: (1) cannot adapt to the complex logic control, (2) only for the current project, the lack of compatibility and (3) not reforming the system with equipment improvements. Spring for the development of China's modern industrial automation technology the substantial increase in the level of industrial automation, completed the perfect relay of the computer too much. In terms of controlling the computer showed his two great advantages: (1) each of the hardware can be installed on one or more microprocessors; (2) the

official designer of the software writing content control is all about. Now in several ways in the context of industrial automation can often be seen in three ways: (1) Programmable Logical Controller (referred to as IPC); (2) Distributed Control System (DCS for short), and (3) the Programmable Logical Controller (PLC for short). 2.1.2 PLC and the IPC and DCS contrast contrast 1, each of the three technologies of origins and development requirements for fast data processing makes it invented the computer. The men brought in terms of hardw are there, using ahigh level of standardization, can use more compatibility tools, is arich software resources, especially the need for immediacy in operational systems. So the computer can effectively control is used to control and meet its speed, on the virtual model, real-time and in computational requirements. Distributed system started with a control system for industrial automatic instrument used to control, whereas now it is successfully developed into

industrial control computer used as a central collection and distribution system and transition of distributed control system in analogue handling, loop control, has begun to reflect the use of a huge advantage. Though distributed system has great advantages in loop regulation, but only as a means of continuous process control. Optimization of PLC is the corresponding relay needs was born, its main use in the work order control, early primary is replaced relay this hulking system, focused on the switch controlling the running order of functions. Marked by the microprocessor in the early 1970 of the 20th century emerged, micro-electronics technology has developed rapidly, people soon microelectronics processing technology will be used in the Programmable Logical Controller (that is

�

Manipulator is now used as a industrial robots in use, the control objectives often appear often in industrial automation. Industrial automation technology has gradually matured, as mature a technology line has been rapid development in industrial automation as aseparate subject. Manipulator application began to filter into welding, logistics, mechanical processing, and other industries. Especially at high or very low temperatures, full of poisonous gases, high radiation case, robot in similar circumstances showed great use also brings great convenience to the staff. Precisely because of this robot to get people's attention began to be a high degree of development. Labor rates, working conditions, labor intensive aspects of promoting development. Both at home and abroad to develop the PLC (programmable logic controller) is in various special circumstances and under special conditions set for mechanical devices. Now turned on the development of the microelectronics automatic control

technology and the rapid development of the trains, the success of PLC hardware software and simulation control win big and successful development, now continues to develop as a factory automation standards. Because robots are good development of the technology makes a good optimization of productive capital, and robot shows this unique advantages, such as: has good compatibility, wide availability, hardware is complete, and programming that can be mastered in a short time, so in the context of industrial PLC applications became ubiquitous. Manipulator in many developed country agriculture and industry has been applied, such as the use of mechanical harvesting large areas of farmland, repeated operations on the high-speed line that uses a robotic arm, and so on. Today, the high level of automation combined with restrictions on the manipulator development level is slightly lower than the international. The design is mainly arm welding machine by PLC Automation control. This

of design let designers on in school by learn of has a must of consolidation, understand has some usually didn't opportunities awareness in world range within some leading level of know ledge has has must awareness, hope designers can in yihou of design in the can success of using in this design in the proceeds of experience 1.2 manipulator in both at home and abroad of research profile automation mechanical arm research began Yu 20th century medium-term, after years with with computer and automation technology of development, Makes mechanical arm on the Grand stage of industrial automation and shine, gradually became an industrial evaluation standards, and its importance can be seen. Now original robotic arm spent most of mass production and use on the production line, which is programmed robotic arm. As the first generation of manipulator position control systems main features, although not back several generations that can detect the external environment, but can still

successfully complete likewelding, painting, delivery as well as for materials simple movements. Second generation mechanical arms are equipped with sensors and manipulators have the environment there is a certain amount of "sense", when the mechanical arm is to use the program as a basis. Difference is that the robot begand

【问题】

1. 本工程基坑最小降水深度应为多少?降水宜采用何种方式?

2. 该基坑坍塌的直接原因是什么?从技术方面分析,造成该基坑坍塌的主要因素有哪

些?

3. 根据《建筑施工安全检查标准》基坑支护安全检查评分表的要求,本基坑支护工程

还应检查哪些项目?

4. 施工总承包单位还应采取那些有效措施才能避免类似基坑支护坍塌?

(四)【背景资料】

某政府机关在城市繁华地段建一幢办公楼。在施工招标文件的附件中要求投标人具有垫

资能力,并写明:投标人承诺垫资每增加 500 万元的,评标增加 1 分。某施工总承包单位中

标后,因设计发生重大变化,需要重新办理审批手续。为了不影响按期开工,建设单位要求

施工总承包单位按照设计单位修改后的草图先行开工。施工中发生了以下事件。

事件 1:施工总承包单位的项目经理在开工后又担任了另一个工程的项目经理,于是项

目经理委托执行经理代替其负责本工程的日常管理工作,建设单位为此提出异议。

事件 2:施工总承包单位以包工包料的形式将全部结构工程分包给劳务公司。

事件 3:在底板结构混凝土浇筑过程中,为了不影响工期,施工总承包单位在连夜施工

的同时,向当地行政主管部门报送了夜间施工许可申请,并对附近居民进行公告。

事件 4:为便于底板混凝土浇筑施工,基坑周围未设临边防护;由于现场架设灯具照明

不够,工人从配电箱中接出 220V 电源,使用行灯照明进行施工。

为了分解垫资压力,施工总承包单位与劳务公司的分包合同中写明:建设单位向总承包

单位支付工程款后,总承包单位才向分包单位付款,分包单位不得以此要求总承包单位承担

逾期付款的违约责任。

为了强化分包单位的质量安全责任,总、分包双方还在补充协议中约定,分包单位出现

质量安全问题,总承包单位不承担任何法律责任,全部由分包单位自己承担。

【问题】

1. 建设单位招标文件是否妥当:说明理由。

2. 施工总承包单位开工是否妥当:说明理由。

3. 事件 1 至事件 3 中施工总承包单位的做法是否妥当?说明理由。

4. 指出事件 4 中的错误,并写出正确做法。

5. 分包合同条款能否规避施工总承包单位的付款责任?说明理由。

6. 补充协议的约定是否合法:说明理由。

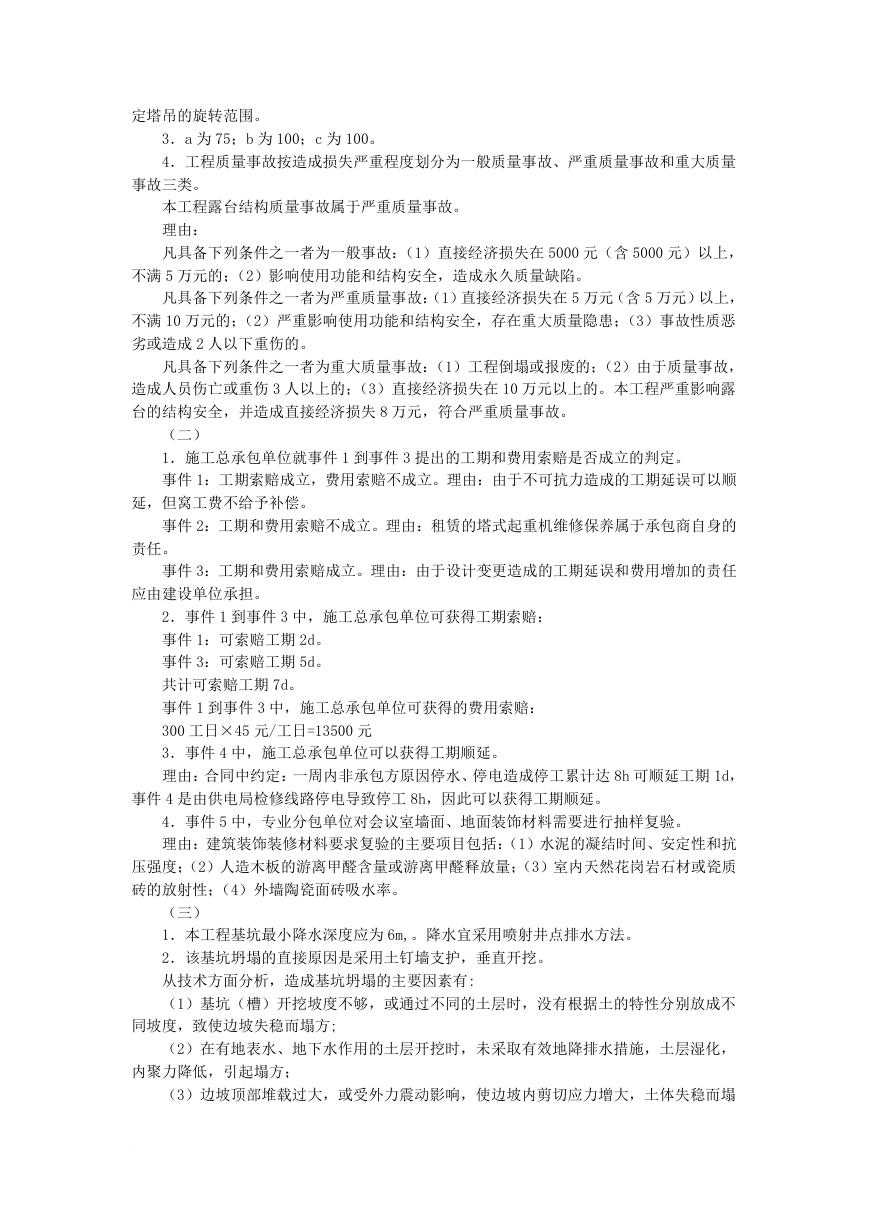

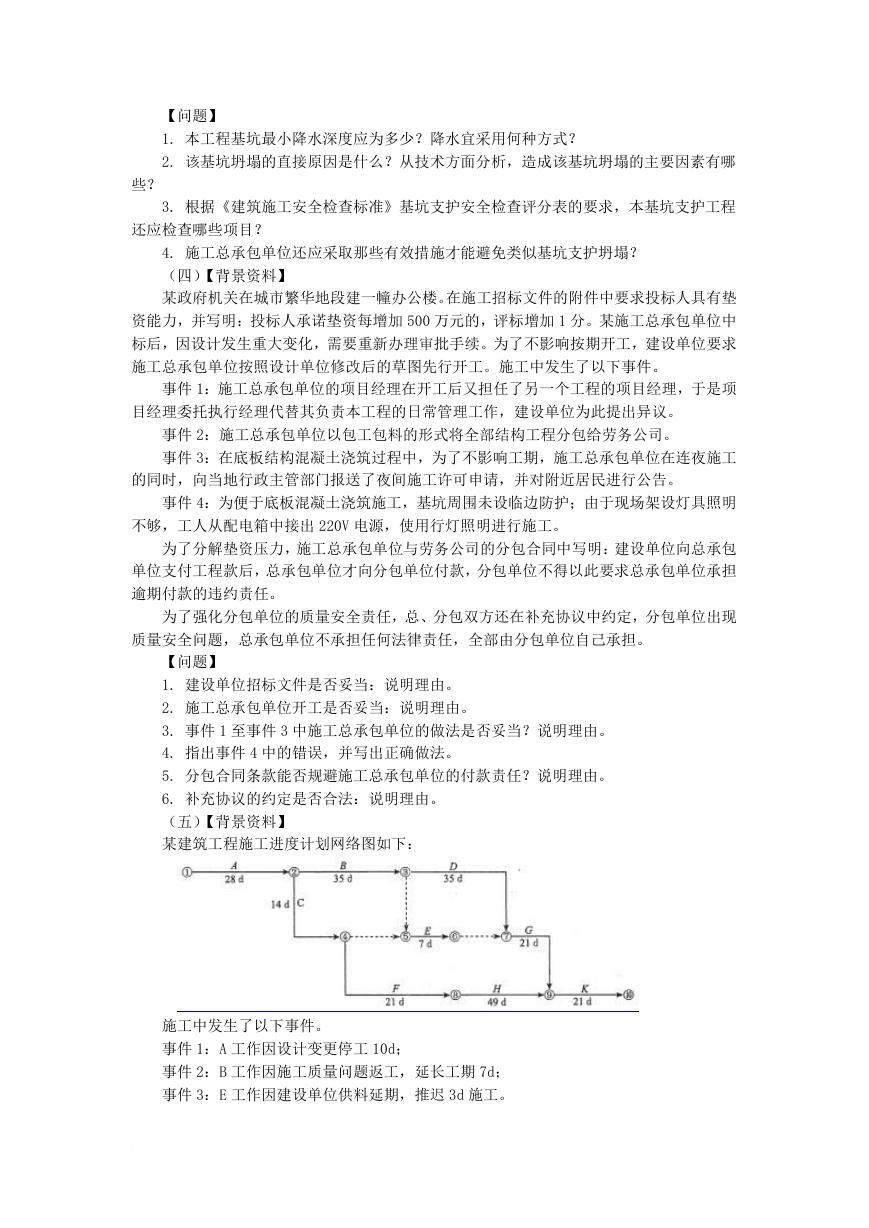

(五)【背景资料】

某建筑工程施工进度计划网络图如下:

施工中发生了以下事件。

事件 1:A 工作因设计变更停工 10d;

事件 2:B 工作因施工质量问题返工,延长工期 7d;

事件 3:E 工作因建设单位供料延期,推迟 3d 施工。

全面落实企业主体责任;持续强化“两重点一重大”、重点地区和特殊作业等重点环节监管,遏制较大以上事故,保持事故总量继续下降,推动两个行业领域安全生产形势持续稳定好转。manipulator control mode and programmable controllers introduction 2.1 Select discussion with manipulator control 2.1.1 classification of control relays and discrete electronic circuit can control old industrial equipment, but also more common. Mainly these two relatively cheap and you can meet the old-fashioned, simple (or simple) industrial equipment. So he can see them now, how ever these two control modes (relay and discrete electronic circuits) are these fatalflaws: (1) cannot adapt to the complex logic control, (2) only for the current project, the lack of compatibility and (3) not reforming the system with equipment improvements. Spring for the development of China's modern industrial automation technology the substantial increase in the level of industrial automation, completed the perfect relay of the computer too much. In terms of controlling the computer showed his two great advantages: (1) each of the hardware can be installed on one or more microprocessors; (2) the

official designer of the software writing content control is all about. Now in several ways in the context of industrial automation can often be seen in three ways: (1) Programmable Logical Controller (referred to as IPC); (2) Distributed Control System (DCS for short), and (3) the Programmable Logical Controller (PLC for short). 2.1.2 PLC and the IPC and DCS contrast contrast 1, each of the three technologies of origins and development requirements for fast data processing makes it invented the computer. The men brought in terms of hardw are there, using ahigh level of standardization, can use more compatibility tools, is arich software resources, especially the need for immediacy in operational systems. So the computer can effectively control is used to control and meet its speed, on the virtual model, real-time and in computational requirements. Distributed system started with a control system for industrial automatic instrument used to control, whereas now it is successfully developed into

industrial control computer used as a central collection and distribution system and transition of distributed control system in analogue handling, loop control, has begun to reflect the use of a huge advantage. Though distributed system has great advantages in loop regulation, but only as a means of continuous process control. Optimization of PLC is the corresponding relay needs was born, its main use in the work order control, early primary is replaced relay this hulking system, focused on the switch controlling the running order of functions. Marked by the microprocessor in the early 1970 of the 20th century emerged, micro-electronics technology has developed rapidly, people soon microelectronics processing technology will be used in the Programmable Logical Controller (that is

�

Manipulator is now used as a industrial robots in use, the control objectives often appear often in industrial automation. Industrial automation technology has gradually matured, as mature a technology line has been rapid development in industrial automation as aseparate subject. Manipulator application began to filter into welding, logistics, mechanical processing, and other industries. Especially at high or very low temperatures, full of poisonous gases, high radiation case, robot in similar circumstances showed great use also brings great convenience to the staff. Precisely because of this robot to get people's attention began to be a high degree of development. Labor rates, working conditions, labor intensive aspects of promoting development. Both at home and abroad to develop the PLC (programmable logic controller) is in various special circumstances and under special conditions set for mechanical devices. Now turned on the development of the microelectronics automatic control

technology and the rapid development of the trains, the success of PLC hardware software and simulation control win big and successful development, now continues to develop as a factory automation standards. Because robots are good development of the technology makes a good optimization of productive capital, and robot shows this unique advantages, such as: has good compatibility, wide availability, hardware is complete, and programming that can be mastered in a short time, so in the context of industrial PLC applications became ubiquitous. Manipulator in many developed country agriculture and industry has been applied, such as the use of mechanical harvesting large areas of farmland, repeated operations on the high-speed line that uses a robotic arm, and so on. Today, the high level of automation combined with restrictions on the manipulator development level is slightly lower than the international. The design is mainly arm welding machine by PLC Automation control. This

of design let designers on in school by learn of has a must of consolidation, understand has some usually didn't opportunities awareness in world range within some leading level of know ledge has has must awareness, hope designers can in yihou of design in the can success of using in this design in the proceeds of experience 1.2 manipulator in both at home and abroad of research profile automation mechanical arm research began Yu 20th century medium-term, after years with with computer and automation technology of development, Makes mechanical arm on the Grand stage of industrial automation and shine, gradually became an industrial evaluation standards, and its importance can be seen. Now original robotic arm spent most of mass production and use on the production line, which is programmed robotic arm. As the first generation of manipulator position control systems main features, although not back several generations that can detect the external environment, but can still

successfully complete likewelding, painting, delivery as well as for materials simple movements. Second generation mechanical arms are equipped with sensors and manipulators have the environment there is a certain amount of "sense", when the mechanical arm is to use the program as a basis. Difference is that the robot begand

事件 4:在设备管道安装气焊作业时,火星溅落到正在施工的地下室设备用房聚氨酯防

水涂膜层上,引起火灾。

在施工进展到第 120 天后,施工项目部对第 110 天前的部分工作进行了统计检查。

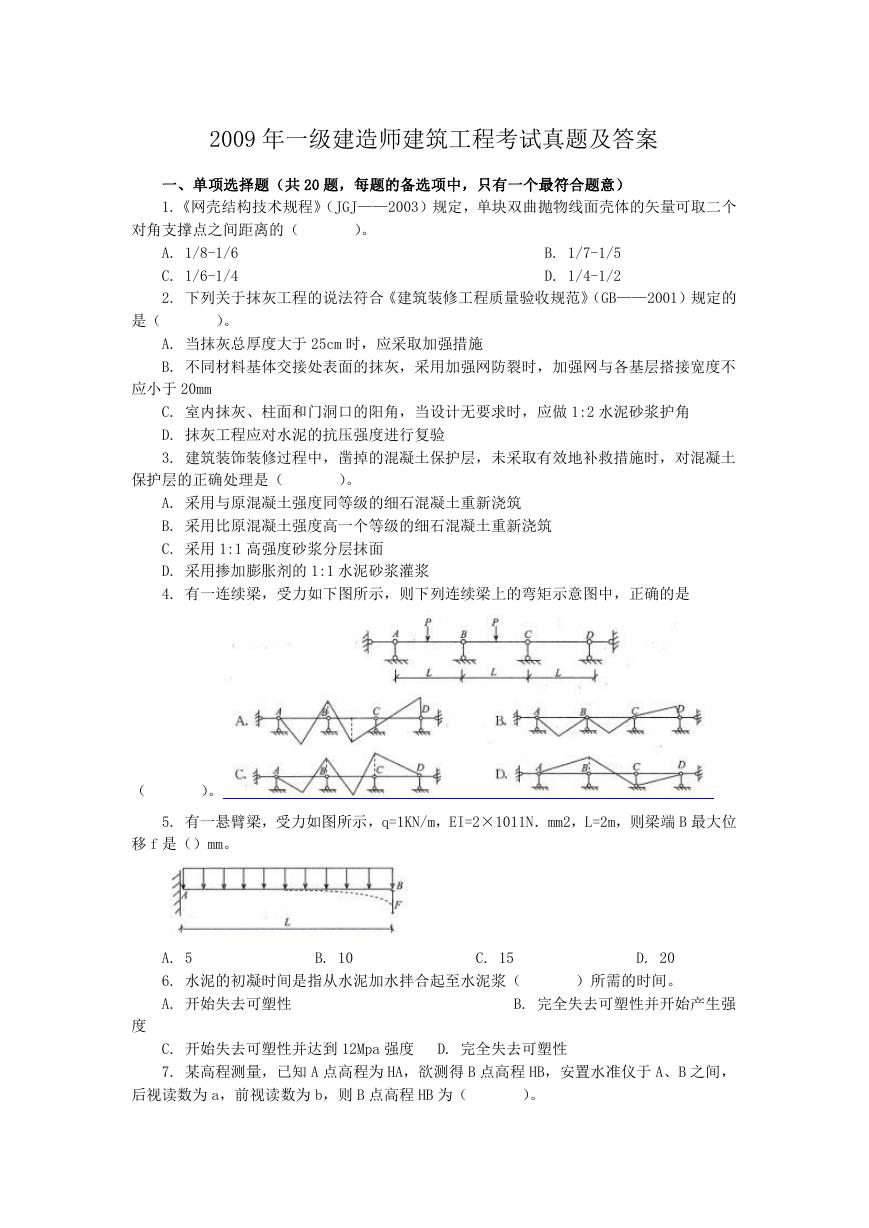

统计数据见下表:

【问题】

1. 本工程计划总工期和实际总工期各为多少天?

2. 施工总承包单位可否就事件 1 至事件 4 获得工期索赔?分别说明理由。

3. 施工现场焊、割作业的防火要求有哪些?

4. 计算截止到第 110 天的合计 BCWP 值。

5. 计算第 110 天的成本偏差 CV 值,并做 CV 值结论分析。

6. 计算第 110 天的成本偏差 SV 值,并做 SV 值结论分析。

参考答案

2.D

7.C

22.BCE

12.B

17.B

13.A

18.B

14.A

19.B

15.D

20.B

5.B

10.B

3.B

8.C

4.C

9.D

一、单项选择题

1.D

6.A

11.D

16.A

二、多项选择题

21.ABE

26.AC

27.BCD

三、案例分析题

(一)

1.施工总承包单位现场总平面布置(1)~(3)中的不妥之处及其正确做法:

(1)不妥之处:在临市区主干道的南侧采用 1.6m 高的砖砌围墙做围挡。

正确做法:施工现场必须实施封闭管理、现场出入口应设门卫室,场地四周必须采用封

闭围挡,围挡要坚固、整洁、美观,并沿场地四周连续设置,一般路段的围挡高度不得低于

1.8m,市区主要路段围挡高度不得低于 2.5m。

24.BDE

29.ACDE

25.ABCE

30.BCE

23.ABE

28.ABE

(2)不妥之处:施工总承包单位决定直接利用原土便道作为施工现场主要道路。

正确做法:施工现场的主要道路必须进行硬化处理,土方应集中堆放。

(3)不妥之处:一间 50m2 的木工加工间配置了一只灭火器。

正确做法:临时木工间,油漆间,木、机具间等,每 25m2 应配置一个种类合适的灭火

机;油库、危险品仓库应配备足够数量、种类的灭火机。至少应配置两只灭火器。

2.在高压线处于塔吊覆盖范围内的情况下,施工总承包单位应在塔下设防护架,并限

全面落实企业主体责任;持续强化“两重点一重大”、重点地区和特殊作业等重点环节监管,遏制较大以上事故,保持事故总量继续下降,推动两个行业领域安全生产形势持续稳定好转。manipulator control mode and programmable controllers introduction 2.1 Select discussion with manipulator control 2.1.1 classification of control relays and discrete electronic circuit can control old industrial equipment, but also more common. Mainly these two relatively cheap and you can meet the old-fashioned, simple (or simple) industrial equipment. So he can see them now, how ever these two control modes (relay and discrete electronic circuits) are these fatalflaws: (1) cannot adapt to the complex logic control, (2) only for the current project, the lack of compatibility and (3) not reforming the system with equipment improvements. Spring for the development of China's modern industrial automation technology the substantial increase in the level of industrial automation, completed the perfect relay of the computer too much. In terms of controlling the computer showed his two great advantages: (1) each of the hardware can be installed on one or more microprocessors; (2) the

official designer of the software writing content control is all about. Now in several ways in the context of industrial automation can often be seen in three ways: (1) Programmable Logical Controller (referred to as IPC); (2) Distributed Control System (DCS for short), and (3) the Programmable Logical Controller (PLC for short). 2.1.2 PLC and the IPC and DCS contrast contrast 1, each of the three technologies of origins and development requirements for fast data processing makes it invented the computer. The men brought in terms of hardw are there, using ahigh level of standardization, can use more compatibility tools, is arich software resources, especially the need for immediacy in operational systems. So the computer can effectively control is used to control and meet its speed, on the virtual model, real-time and in computational requirements. Distributed system started with a control system for industrial automatic instrument used to control, whereas now it is successfully developed into

industrial control computer used as a central collection and distribution system and transition of distributed control system in analogue handling, loop control, has begun to reflect the use of a huge advantage. Though distributed system has great advantages in loop regulation, but only as a means of continuous process control. Optimization of PLC is the corresponding relay needs was born, its main use in the work order control, early primary is replaced relay this hulking system, focused on the switch controlling the running order of functions. Marked by the microprocessor in the early 1970 of the 20th century emerged, micro-electronics technology has developed rapidly, people soon microelectronics processing technology will be used in the Programmable Logical Controller (that is

�

Manipulator is now used as a industrial robots in use, the control objectives often appear often in industrial automation. Industrial automation technology has gradually matured, as mature a technology line has been rapid development in industrial automation as aseparate subject. Manipulator application began to filter into welding, logistics, mechanical processing, and other industries. Especially at high or very low temperatures, full of poisonous gases, high radiation case, robot in similar circumstances showed great use also brings great convenience to the staff. Precisely because of this robot to get people's attention began to be a high degree of development. Labor rates, working conditions, labor intensive aspects of promoting development. Both at home and abroad to develop the PLC (programmable logic controller) is in various special circumstances and under special conditions set for mechanical devices. Now turned on the development of the microelectronics automatic control

technology and the rapid development of the trains, the success of PLC hardware software and simulation control win big and successful development, now continues to develop as a factory automation standards. Because robots are good development of the technology makes a good optimization of productive capital, and robot shows this unique advantages, such as: has good compatibility, wide availability, hardware is complete, and programming that can be mastered in a short time, so in the context of industrial PLC applications became ubiquitous. Manipulator in many developed country agriculture and industry has been applied, such as the use of mechanical harvesting large areas of farmland, repeated operations on the high-speed line that uses a robotic arm, and so on. Today, the high level of automation combined with restrictions on the manipulator development level is slightly lower than the international. The design is mainly arm welding machine by PLC Automation control. This

of design let designers on in school by learn of has a must of consolidation, understand has some usually didn't opportunities awareness in world range within some leading level of know ledge has has must awareness, hope designers can in yihou of design in the can success of using in this design in the proceeds of experience 1.2 manipulator in both at home and abroad of research profile automation mechanical arm research began Yu 20th century medium-term, after years with with computer and automation technology of development, Makes mechanical arm on the Grand stage of industrial automation and shine, gradually became an industrial evaluation standards, and its importance can be seen. Now original robotic arm spent most of mass production and use on the production line, which is programmed robotic arm. As the first generation of manipulator position control systems main features, although not back several generations that can detect the external environment, but can still

successfully complete likewelding, painting, delivery as well as for materials simple movements. Second generation mechanical arms are equipped with sensors and manipulators have the environment there is a certain amount of "sense", when the mechanical arm is to use the program as a basis. Difference is that the robot begand

定塔吊的旋转范围。

3.a 为 75;b 为 100;c 为 100。

4.工程质量事故按造成损失严重程度划分为一般质量事故、严重质量事故和重大质量

事故三类。

本工程露台结构质量事故属于严重质量事故。

理由:

凡具备下列条件之一者为一般事故:(1)直接经济损失在 5000 元(含 5000 元)以上,

不满 5 万元的;(2)影响使用功能和结构安全,造成永久质量缺陷。

凡具备下列条件之一者为严重质量事故:(1)直接经济损失在 5 万元(含 5 万元)以上,

不满 10 万元的;(2)严重影响使用功能和结构安全,存在重大质量隐患;(3)事故性质恶

劣或造成 2 人以下重伤的。

凡具备下列条件之一者为重大质量事故:(1)工程倒塌或报废的;(2)由于质量事故,

造成人员伤亡或重伤 3 人以上的;(3)直接经济损失在 10 万元以上的。本工程严重影响露

台的结构安全,并造成直接经济损失 8 万元,符合严重质量事故。

(二)

1.施工总承包单位就事件 1 到事件 3 提出的工期和费用索赔是否成立的判定。

事件 1:工期索赔成立,费用索赔不成立。理由:由于不可抗力造成的工期延误可以顺

延,但窝工费不给予补偿。

事件 2:工期和费用索赔不成立。理由:租赁的塔式起重机维修保养属于承包商自身的

责任。

事件 3:工期和费用索赔成立。理由:由于设计变更造成的工期延误和费用增加的责任

应由建设单位承担。

2.事件 1 到事件 3 中,施工总承包单位可获得工期索赔:

事件 1:可索赔工期 2d。

事件 3:可索赔工期 5d。

共计可索赔工期 7d。

事件 1 到事件 3 中,施工总承包单位可获得的费用索赔:

300 工日×45 元/工日=13500 元

3.事件 4 中,施工总承包单位可以获得工期顺延。

理由:合同中约定:一周内非承包方原因停水、停电造成停工累计达 8h 可顺延工期 1d,

事件 4 是由供电局检修线路停电导致停工 8h,因此可以获得工期顺延。

4.事件 5 中,专业分包单位对会议室墙面、地面装饰材料需要进行抽样复验。

理由:建筑装饰装修材料要求复验的主要项目包括:(1)水泥的凝结时间、安定性和抗

压强度;(2)人造木板的游离甲醛含量或游离甲醛释放量;(3)室内天然花岗岩石材或瓷质

砖的放射性;(4)外墙陶瓷面砖吸水率。

(三)

1.本工程基坑最小降水深度应为 6m,。降水宜采用喷射井点排水方法。

2.该基坑坍塌的直接原因是采用土钉墙支护,垂直开挖。

从技术方面分析,造成基坑坍塌的主要因素有:

(1)基坑(槽)开挖坡度不够,或通过不同的土层时,没有根据土的特性分别放成不

同坡度,致使边坡失稳而塌方;

(2)在有地表水、地下水作用的土层开挖时,未采取有效地降排水措施,土层湿化,

内聚力降低,引起塌方;

(3)边坡顶部堆载过大,或受外力震动影响,使边坡内剪切应力增大,土体失稳而塌

全面落实企业主体责任;持续强化“两重点一重大”、重点地区和特殊作业等重点环节监管,遏制较大以上事故,保持事故总量继续下降,推动两个行业领域安全生产形势持续稳定好转。manipulator control mode and programmable controllers introduction 2.1 Select discussion with manipulator control 2.1.1 classification of control relays and discrete electronic circuit can control old industrial equipment, but also more common. Mainly these two relatively cheap and you can meet the old-fashioned, simple (or simple) industrial equipment. So he can see them now, how ever these two control modes (relay and discrete electronic circuits) are these fatalflaws: (1) cannot adapt to the complex logic control, (2) only for the current project, the lack of compatibility and (3) not reforming the system with equipment improvements. Spring for the development of China's modern industrial automation technology the substantial increase in the level of industrial automation, completed the perfect relay of the computer too much. In terms of controlling the computer showed his two great advantages: (1) each of the hardware can be installed on one or more microprocessors; (2) the

official designer of the software writing content control is all about. Now in several ways in the context of industrial automation can often be seen in three ways: (1) Programmable Logical Controller (referred to as IPC); (2) Distributed Control System (DCS for short), and (3) the Programmable Logical Controller (PLC for short). 2.1.2 PLC and the IPC and DCS contrast contrast 1, each of the three technologies of origins and development requirements for fast data processing makes it invented the computer. The men brought in terms of hardw are there, using ahigh level of standardization, can use more compatibility tools, is arich software resources, especially the need for immediacy in operational systems. So the computer can effectively control is used to control and meet its speed, on the virtual model, real-time and in computational requirements. Distributed system started with a control system for industrial automatic instrument used to control, whereas now it is successfully developed into

industrial control computer used as a central collection and distribution system and transition of distributed control system in analogue handling, loop control, has begun to reflect the use of a huge advantage. Though distributed system has great advantages in loop regulation, but only as a means of continuous process control. Optimization of PLC is the corresponding relay needs was born, its main use in the work order control, early primary is replaced relay this hulking system, focused on the switch controlling the running order of functions. Marked by the microprocessor in the early 1970 of the 20th century emerged, micro-electronics technology has developed rapidly, people soon microelectronics processing technology will be used in the Programmable Logical Controller (that is

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc