基于 DSP 的直流电机调速系统的设计

�

摘要

随着科学技术的迅速发展,直流电机调速系统的方法获得了极大的提高。由于数

字控制具有较好的控制性能和较强的抗干扰性,所以成为直流电机的主要控制方式。

本文主要研究基于 DSP 的直流电机调速控制系统的设计。针对实际的条件和要求,

建立了以 DSP 控制器为核心的直流电机调速系统,给出了系统的整体方案;整个系

统根据调速原理的方法,采用 TI 公司的 TMS320LF2407A DSP 芯片为控制芯片,利

用 H 型电路对直流电机的调速进行控制,通过光电传感器对直流电动机的转速进行

测定。通过对设计的 DSP 调速控制器的研究及测试,最终实现了该控制平台稳定运

行和预期的功能,能够实现电机的测速调速和显示功能。

关键词:直流电动机,DSP ,调速

Abstract

With the rapid development of science and technology, the method of DC motor speed

control system has been greatly improved. As digital control has good control performance

and strong anti-interference, it becomes the main control mode of DC motor. This paper

mainly studies the design of DC motor speed control system based on DSP. According to

the actual conditions and requirements, the DC motor speed control system with DSP

controller as the core is established, and the overall scheme of the system is given.

According to the principle of speed regulation method,

the whole system adopts

TMS320LF2407A DSP chip of TI company as control chip, using H circuit to control dc

motor speed control, as measured by photoelectric sensor for DC motor speed. Through the

study and test of the designed DSP speed controller, the stable operation and expected

function of the control platform are finally realized, and the speed measurement and

display function of the motor can be realized.

Keywords: DC Motor, DSP, Speed Regulation

2

�

目 录

摘要 ·······································································································2

第一章 绪论 ···························································································· 5

1.1 引言 ·································································································5

1.2 国内外现状 ························································································ 5

1.3 发展趋势 ··························································································· 5

第二章 设计内容及意义 ·············································································6

2.1 本课题的设计内容 ··············································································· 6

2.2 选题意义 ··························································································· 7

第三章 直流调速原理 ················································································7

3.1 调速方法 ··························································································· 7

3.1.1 直流电动机调速方法 ··········································································7

3.1.2 PWM 调速控制原理 ············································································9

3.2 测速方法 ··························································································13

3.3 本章小结 ··························································································14

第四章 DSP 控制器介绍 ··········································································· 14

4.1 DSP 芯片发展及结构 ··········································································· 14

4.1.1 DSP 芯片发展 ··················································································14

4.1.2 DSP 芯片结构原理 ············································································15

4.2 控制器 TMS320LF2407A 介绍 ·······························································17

4.2.1 控制器 TMS320LF2407A 特点 ···························································· 17

4.2.2 设计用到的模块 ·············································································· 18

4.3 DSP 开发 ·························································································· 20

4.3.1 DSP 开发所需硬件资源 ······································································20

4.3.2 DSP 软件开发 ··················································································20

4.4 本章小结 ··························································································21

第五章 硬件设计 ···················································································· 21

5.1 系统总体方案 ····················································································22

5.2 DSP 供电电源设计 ·············································································· 22

5.3 JTAG 接口电路设计 ············································································ 23

3

�

5.4 直流电动机 PWM 调速测速电路设计 ······················································24

5.4.1 直流电动机 PWM 调速电路设计 ························································· 24

5.4.2 转速采集电路设计 ··········································································· 25

5.5 本章小结 ··························································································26

第六章 软件设计 ···················································································· 27

6.1 程序设计 ··························································································27

6.2 本章小结 ···························································································28

第七章 结论 ···························································································28

7.1 调试结果 ··························································································28

7.2 总结 ································································································29

参考文献 ······························································································· 30

4

�

第一章 绪论

1.1 引言

近几年来,电动机作为最主要的机电能量转换装置,其应用范围已遍及国民经济

的各个领域和人们的日常生活。过去电动机的调速控制不太灵敏,随着计算机、微电

子技术的发展以及新型电力电子功率器件的不断涌现,电动机的控制策略发生了极大

的变化。传统的模拟控制方法正逐渐被以微控制器为核心的数字控制所取代[1]。

1.2 国内外现状

20 世纪 70 年代以来,利用单片机作为控制器开始在电机控制系统中被广泛使用,

如 Intel8031/8051、AT89C51、AT89C52[2]等。在单片机控制系统中,单片机作为系统

控制的核心,主要用来完成一些算法,同时还要处理一些输入,输出、显示任务等,

单片机的使用使电动机控制系统的性能得到了很大提高。利用专用芯片内部具有的电

动机专用硬件控制机制,用来快速产生用于电动机功率电子电路的控制信号。这些系

统将单片机和专用芯片优势互补,使得系统即可以满足实时性的要求,又具有用户可

编程的灵活性,从而迅速成为主流的电动机控制系统设计方法。

为了使电机控制系统既能适应一般的应用场合,又能满足一些高精度、高性能的

控制要求。许多公司推出了面向运动控制系统、电动机控制的控制器。例如:TI 公

司的 TMS320x24xx 系列 DSP 控制器,它把一个 16 位定点 DSP 核和用于控制的外设、

大容量的片上存储器集成在单一芯片上,为电动机控制系统注入了新活力。此系列

DSP 控制器的内部 DSP 核具有用于控制的片上外设,使得它们从硬件机制上可以较

好地满足任意电动机控制系统的要求。

1.3 发展趋势

电动机的数字控制技术的发展依赖于微电子技术、电力电子技术、传感器技术、

自动控制技术;特别是微控制器技术,现代控制技术是以微控制器为核心的技术,由

此构成的控制系统成为当今工业控制的主流系统。这种系统已取代常规的模拟检测、

调节、显示、记录等仪器设备和很大部分操作的人工职能,使受控对象的动态过程按

规定方式和技术运行,以完成各种控制、操作管理等任务[3]。近几年来,嵌入式系统

在通信、工业、仪器等领域的广泛应用,现代控制技术已深入各行业的诸多领域。进

入 90 年代以来,由于计算机技术的飞速发展,推动数控技术更快的更新换代。世界

5

�

上许多数控系统生产厂家利用 PC 机丰富的软硬件资源开发开放式体系结构的新一代

数控系统。开放式体系结构使数控系统有更好的通用性、柔性、适应性、扩展性,并

向智能化、网络化方向大大发展。

电动机的数字控制系统的发展趋势可以表现在以下几个方面。

(1)性能上高速、高精、高效化。速度、精度和效率是工业制造技术的关键性能

指标。由于采用了高速 CPU 芯片、RISC 芯片、多 CPU 控制系统以及带高分辨率绝

对式检测元件的数字伺服系统,同时采取了改善电机动态、静态特性等有效措施,电

机的高速高精高效化已大大提高。

(2)控制实时智能化。早期的实时系统通常针对相对简单的理想环境,其作用是

如何调度任务,以确保任务在规定期限内完成。而人工智能则试图用计算模型实现人

类的各种智能行为。科学技术发展到今天,实时系统和人工智能相互结合,人工智能

正向着具有实时响应的、更现实的领域发展,而实时系统也朝着具有智能行为的、更

加复杂的应用发展,由此产生了实时智能控制这一新的领域。

(3)系统集成化、模块化、网络化。采用高度集成化 CPU、RISC 芯片和大规模可

编程集成电路 FPGA、CPLD 以及专用集成电路 ASIC 芯片,可提高数控系统的集成

度和软硬件运行速度;硬件模块化易于实现数控系统的集成化和标准化;电机联网可

进行远程控制和无人化操作;利用计算机组成总线式、模块化、开放式、嵌入式结构。

第二章 设计内容及意义

2.1 本课题的设计内容

本课题主要完成以下五方面工作:

1.硬件设计,设计硬件电路,实现键盘输入命令控制,使直流电动机停止和以不

同速度前进或后退,并将实时速度和正反状态显示在 LCD 上;

2.软件设计,编写程序,实现硬件功能;

3.绘制电路原理图;

4.制作样机;

5.系统各功能模块设计结束以后,将系统进行调试,实现不了功能的地方进行修

改以便完成系统的综合效果。

6

�

2.2 选题意义

一个多世纪以来,电动机作为机电能量转换装置,一直在现代化生产和生活中发

挥着十分重要的作用。无论是工农业生产、交通运输、国防、航空航天、医疗卫生、

商务与办公设备,还是日常生活中的家用电器,都大量地使用着各种各样的电机。据

资料统计,现在有 90%以上的动力源来自于电动机,我国生产的电能大约有 60%用

于电动机,电动机与人们的生活息息相关,密不可分[4]。

电动机主要类型有同步电动机、异步电动机与直流电动机三种。其中,直流电动

机在八十年代以前一直处于调速传动领域的主导地位,这主要源于其完美的转矩控制

特性,即通过调节电枢电压和励磁电流就可以任意调节其转速和转矩。

本毕业设计基于 TI 公司的 TMS320LF2407 控制器,对直流电动机进行调速测速

的控制系统,进行了设计研究,制作了一个小型的直流电动机调速装置,虽然实际应

用中较难用到这么小的直流电动机调速装置,但万变不离其宗,实际应用中的直流电

动机调速装置大致原理与本设计相差无几,因此本设计有着很强的理论和指导意义。

第三章 直流调速原理

在现代化工业生产中,生产机械都不停地运转着,几乎无处不使用电力传动装置。

由于各种不同的生产机械运动规律不一样,对传动装置性能的要求也不一样。为了提

高产品质量,增加产量,提高生产效率,越来越多的生产机械要求能实现转速调节与

相应的自动化控制,并且对电力传动装置的拖动性能要求也越来越高。本章分析了直

流调速系统原理,通过分析可以明确硬件总体设计以及软件实现的功能。

3.1 调速方法

3.1.1 直流电动机调速方法

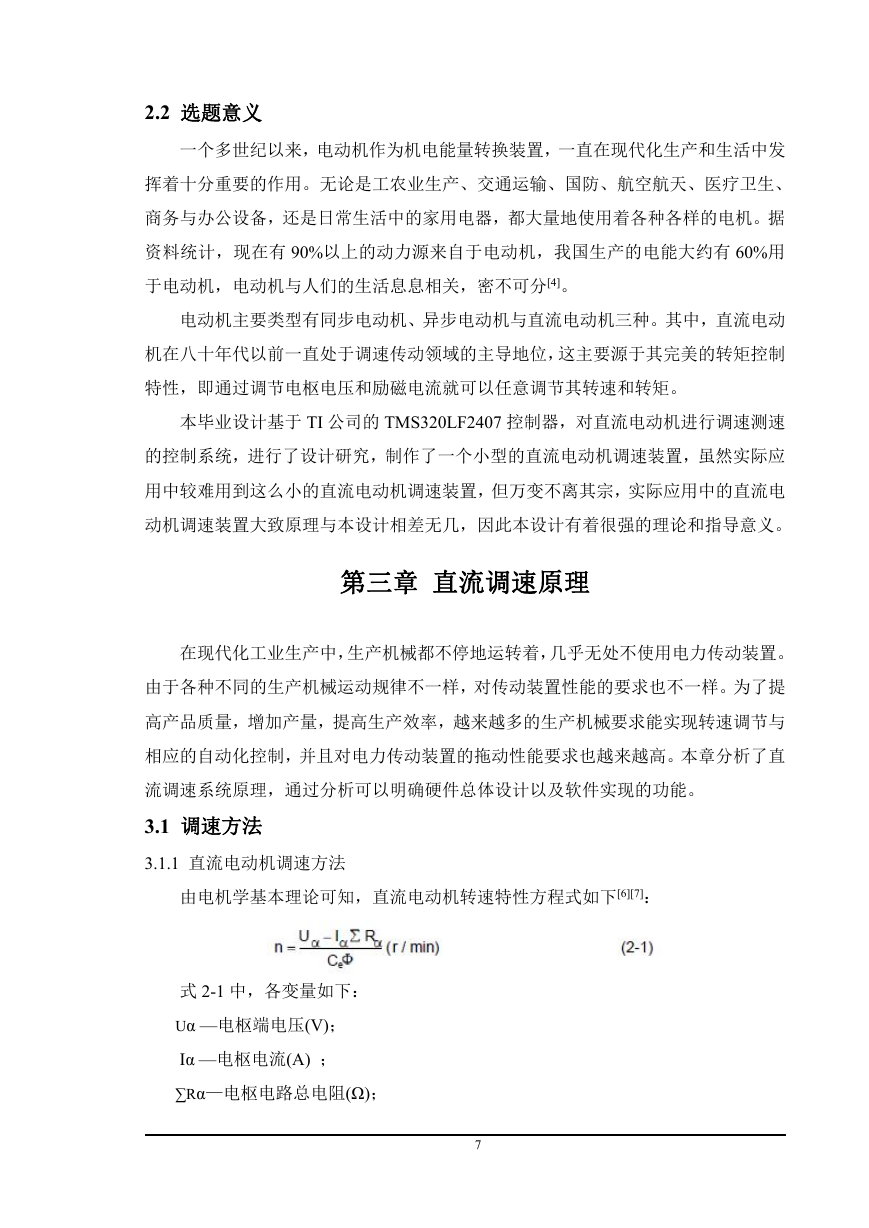

由电机学基本理论可知,直流电动机转速特性方程式如下[6][7]:

式 2-1 中,各变量如下:

Uα —电枢端电压(V);

Iα —电枢电流(A) ;

∑Rα—电枢电路总电阻(Ω);

7

�

Φ—每极磁通量(Wb);

Ce—与电机有关的常数。

从上式可以看出,直流电机转速 n 的控制方法有三种:

(1)改变电枢电路电阻值 R,在电动机电枢外串电阻进行调速。这种方法只能进行

有级调速,平滑性差、机械特性软、效率低;

(2)改变电机主磁通Φ。这种方法只能减弱磁通,使电动机从额定转速向上变速,

属恒功率调速方法,动态响应较馒,虽能无级平滑调速,但调速范围小;

(3)调节电枢电压 U,从而改变转速。属恒转矩调速方法,动态响应快,适用于

要求大范围无级平滑调速的系统。

在这几种方法中,改变电阻只能有级调速,而且缺点很多,目前很少采用;减弱

磁通虽然能够平滑调速,但调速范围不大,往往只是配合调压方案,在基速(额转速)

以上作小范围的弱磁升速。因此,自动控制的直流调速系统往往以变压调速为主。改

变电枢电压主要有三种方式:旋转变流机组、静止变流装置(晶闸管变流装置)、

PWM(脉宽调制)变换器(或称直流斩波器)。

(1)旋转变流机组用交流电动机和直流发电机组成机组以获得可调直流电压,简

称 G.M 系统。G.M 系统具有很好的调速性能,但系统复杂、体积大、效率低、运行

噪音、维护不方便。

(2)采用晶闸管变流装置供电的直流调速系统简称 V-M 系统,通过改变晶闸管触

发控制角 a,进而改变整流电压 Ud 的大小,达到调节直流电动机转速的目的。V-M

系统在调速性能、可靠性、经济性上具有一定的优越性,但操作不是太方便,所以现

在使用更多的是下面介绍的 PWM(脉宽调制)。

(3)PWM( 脉宽调制)变换器又称直流斩波器,是利用功率开关器件通断实现控,

调节通断时间比例,将固定的直流电源电压变成平均值可调的直流电压,亦称 DC-DC

变换器。PWM(脉宽调制)变换器不仅在调速性能、可靠性、经济性上都具有优越性,

而且控制起来非常方便, 实用性很强, 因此成为直流调速系统的主要形式。

本次设计主要就是通过 DSP 芯片 TMS320LF2407A 中的 PWM 口,对其编写程

序产生 PWM 波来输出控制电机的平均电压来对电机进行调速,需要对直流电动机搭

建 H 型电桥驱动电路才能实现 PWM 调速,下面将详细介绍直流电动机 PWM 调速原

理。

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc