ARTICLE IN PRESS

Reliability Engineering and System Safety ] (]]]]) ]]]–]]]

Contents lists available at ScienceDirect

Reliability Engineering and System Safety

journal homepage: www.elsevier.com/locate/ress

Dynamic fault tree analysis using Monte Carlo simulation in probabilistic

safety assessment

K. Durga Rao a,�, V. Gopika a, V.V.S. Sanyasi Rao a, H.S. Kushwaha a, A.K. Verma b, A. Srividya b

a Bhabha Atomic Research Centre, Mumbai, India

b Indian Institute of Technology Bombay, Mumbai, India

a r t i c l e i n f o

a b s t r a c t

Article history:

Received 21 July 2007

Received in revised form

22 September 2008

Accepted 24 September 2008

Keywords:

Dynamic fault trees

Markov models

Monte Carlo simulation

Probabilistic safety assessment

Reactor regulation system

Traditional fault tree (FT) analysis is widely used for reliability and safety assessment of complex and

critical engineering systems. The behavior of components of complex systems and their interactions

such as sequence- and functional-dependent failures, spares and dynamic redundancy management,

and priority of failure events cannot be adequately captured by traditional FTs. Dynamic fault tree (DFT)

extend traditional FT by defining additional gates called dynamic gates to model these complex

interactions. Markov models are used in solving dynamic gates. However, state space becomes too large

for calculation with Markov models when the number of gate inputs increases. In addition, Markov

model is applicable for only exponential failure and repair distributions. Modeling test and maintenance

information on spare components is also very difficult. To address these difficulties, Monte Carlo

simulation-based approach is used in this work to solve dynamic gates. The approach is first applied to a

problem available in the literature which is having non-repairable components. The obtained results are

in good agreement with those in literature. The approach is later applied to a simplified scheme of

electrical power supply system of nuclear power plant (NPP), which is a complex repairable system

having tested and maintained spares. The results obtained using this approach are in good agreement

with those obtained using analytical approach. In addition to point estimates of reliability measures,

failure time, and repair time distributions are also obtained from simulation. Finally a case study on

reactor regulation system (RRS) of NPP is carried out to demonstrate the application of simulation-

based DFT approach to large-scale problems.

& 2008 Elsevier Ltd. All rights reserved.

1.

Introduction

Fault tree (FT) analysis has gained wide spread acceptance for

the quantitative reliability and safety analysis. FT is graphical

representation of various combinations of basic failures that lead

to the occurrence of undesirable top event. Starting with the top

event all possible ways for this event to occur are systematically

deduced. The methodology is based on three assumptions: (i)

events are binary events, (ii) events are statistically independent,

and (iii) relationship between events are represented by means of

logical Boolean gates (AND, OR, and Voting). The analysis is

carried out

in two steps: a qualitative step in which the

logical expression of the top event is derived in terms of

prime implicants (the minimal cut-sets); a quantitative step in

which on the basis of the probabilities assigned to the failure

events of the basic components, the probability of occurrence of

the top event is calculated.

� Corresponding author.

E-mail address: durga_k_rao@yahoo.com (K. Durga Rao).

0951-8320/$ - see front matter & 2008 Elsevier Ltd. All rights reserved.

doi:10.1016/j.ress.2008.09.007

The traditional static fault trees with AND, OR, and Voting

gates cannot capture the dynamic behavior of system failure

mechanisms such as sequence-dependent events, spares and

dynamic redundancy management, and priorities of

failure

events.

In order to overcome this difficulty, the concept of

dynamic FTs is introduced by adding sequential notion to the

traditional FT approach. System failures can then depend on

component failure order as well as combination [1]. This is done

by introducing dynamic gates into FTs. With the help of dynamic

gates, system sequence-dependent

failure behavior can be

specified using dynamic FTs that are compact and easily under-

stood. The modeling power of dynamic FTs has gained the

attention of many reliability engineers working on safety critical

systems [2].

Several researchers [1–3] proposed methods to solve dynamic

FTs. Dugan et al. [1,4,5], has shown through a process known as

modularization, it is possible to identify the independent sub-

trees with dynamic gates and to use different Markov model for

each of them. It was applied to computer-based fault tolerant

systems successfully. But, with the increase in the number of basic

elements, there is problem state space explosion. To reduce state

space and minimize the computational

time, an improved

Please cite this article as: Durga Rao K, et al. Dynamic fault tree analysis using Monte Carlo simulation in probabilistic safety

assessment. Reliab Eng Syst Safety (2008), doi:10.1016/j.ress.2008.09.007

�

ARTICLE IN PRESS

2

K. Durga Rao et al. / Reliability Engineering and System Safety ] (]]]]) ]]]–]]]

decomposition scheme where the dynamic sub-tree can be

further modularized (if there exist some independent sub-trees

in it) is proposed by Huang and Chang [6]. Amari et al. [2],

proposed a numerical integration technique for solving dynamic

gates. Though, this method is solving the state-space problem, it

cannot be easily applied for repairable systems. Bobbio et al. [3,7],

proposed Bayesian network-based method to further reduce the

problem of solving dynamic FTs with state-space approach.

Keeping the importance of sophisticated modeling for engineering

systems in dynamic environment, several researches [8–11]

contributed significantly to the development and application of

dynamic FTs.

However, state-space approach for solving dynamic gates

becomes too large for calculation with Markov models when the

number of gate input increases. This is the case especially with

probabilistic safety assessment (PSA) of nuclear power plant (NPP)

where there is large number of cut sets. In addition, Markov

model is applicable for exponential failure and repair distributions

and also modeling test, maintenance information on spare

components is difficult. Many of the methods to solve dynamic

FTs are problem specific and it may be difficult to generalize for all

the scenarios. In order to address some of these limitations of the

above-mentioned methods, Monte Carlo simulation approach is

attempted here to implement dynamic gates. Scenarios which

may often be difficult to solve with analytical solutions are easily

tackled with the Monte Carlo simulation approach. Monte Carlo

simulation-based reliability approach, due to its inherent cap-

ability in simulating the actual process and random behavior of

the system, can eliminate uncertainty in reliability modeling

[12,13]. A software tool, Dynamic Reliability with SIMulation

(DRSIM) is developed to do comprehensive dynamic FT analysis.

Two reliability problems are solved with the tool and found that

results are exactly matching with the analytical approaches. After

validation of the approach, it is extended to a case study on RRS

of NPP.

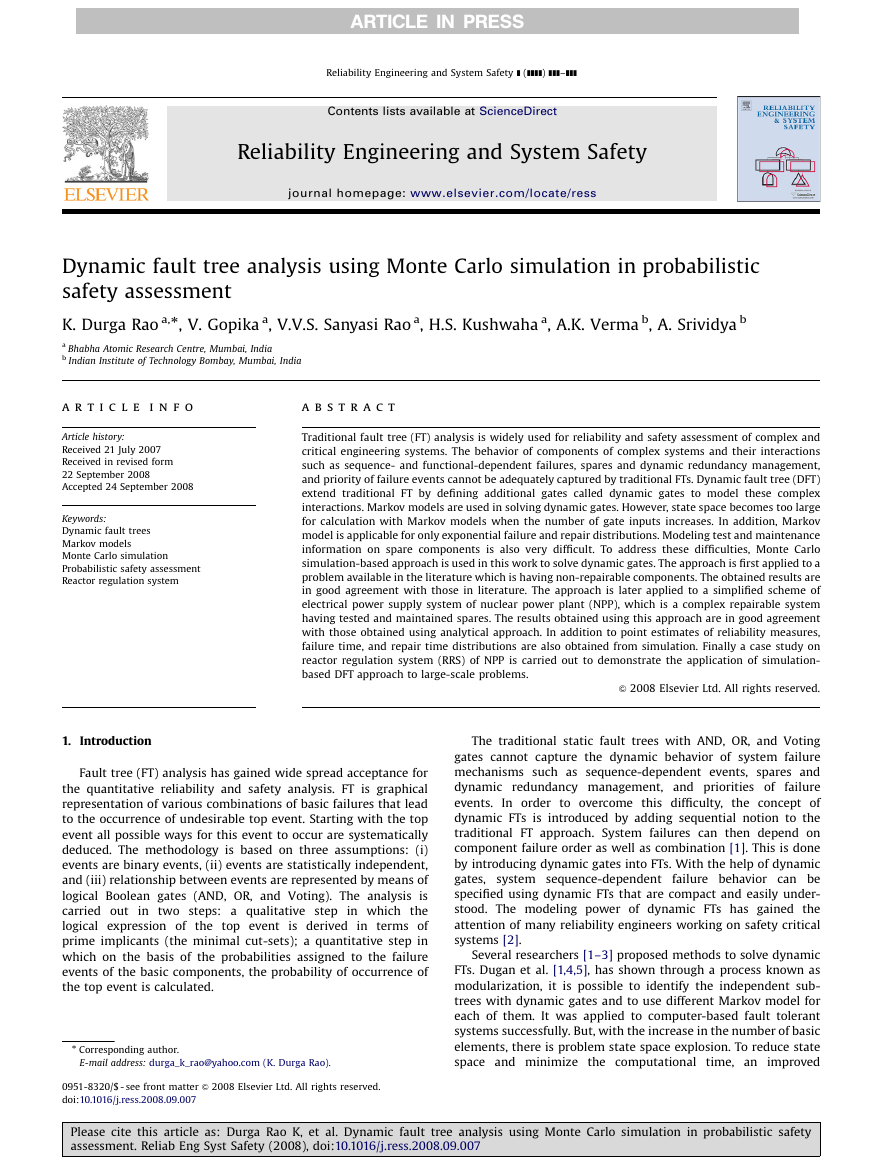

2. Dynamic fault tree analysis: dynamic gates

Dynamic fault trees (DFTs) introduces four basic (dynamic)

gates: the priority AND (PAND), the sequence enforcing (SEQ), the

standby or spare (SPARE), and the functional dependency (FDEP)

[1]. They are discussed here briefly.

The PAND gate reaches a failure state if all of its input

components have failed in a pre-assigned order (from left to right

in graphical notation). A SEQ gate forces its inputs to fail in a

particular order: when a SEQ gate is found in a DFT, it never

happens that the failure sequence takes place in different orders.

While the SEQ gate allows the events to occur only in a pre-

assigned order and states that a different failure sequence can

never take place, the PAND gate does not force such a strong

assumption: it simply detects the failure order and fails just in one

case (in Fig. 1—PAND: failure occurs if A fails before B, but B may

fail before A without producing a failure in G).

SPARE gates are dynamic gates modeling one or more principal

components that can be substituted by one or more backups

(spares), with the same functionality (Fig. 1). The SPARE gate fails

when the number of operational powered spares and/or principal

components is less than the minimum required. Spares can fail

even while they are dormant, but the failure rate of an unpowered

spare is lower than the failure rate of the corresponding powered

one. More precisely, l being the failure rate of a powered spare,

the failure rate of the unpowered spare is al, where 0pap1 is the

dormancy factor. Spares are more properly called ‘‘hot’’ if a ¼ 1

and ‘‘cold’’ if a ¼ 0.

In the FDEP gate (Fig. 1), there will be one trigger-input (either

a basic event or the output of another gate in the tree) and one or

more dependent events. The dependent events are functionally

dependent on the trigger event. When the trigger event occurs,

the dependent basic events are forced to occur. In the Markov-

chain generation, when a state is generated in which the trigger

event is satisfied, all the associated dependent events are marked

as having occurred. The separate occurrence of any of the

dependent basic events has no effect on the trigger event.

3. Monte Carlo simulation-based approach for dynamic gates

Monte Carlo simulation is a very valuable method which is

widely used in the solution of real engineering problems in many

fields. Lately the utilization of this method is growing for the

assessment of availability of complex systems and the monetary

value of plant operations and maintenances [12–15]. The com-

plexity of the modern engineering systems besides the need for

realistic considerations when modeling their availability/reliabil-

ity renders analytical methods very difficult to be used. Analyses

that involve repairable systems with multiple additional events

and/or other maintainability information are very difficult to solve

analytically (dynamic FTs through state space, numerical integra-

tion, Bayesian network approaches). Dynamic FT through simula-

tion approach can incorporate these complexities and can give

wide range of output parameters.

Simulation technique estimates the reliability indices by

simulating the actual process and random behavior of the system

in a computer model in order to create a realistic lifetime scenario

of the system. This method treats the problem as a series of real

experiments conducted in a simulated time. It estimates the

probability and other indices by counting the number of times an

event occurs in simulated time. The required information for the

analysis is: probability density functions (PDF) for time to failure

and repair of all basic components with the parameter values;

maintenance policies; interval and duration of tests and pre-

ventive maintenance.

Components are simulated for a specified mission time for

depicting the duration of available (up) and unavailable (down)

states. Up and down states will come alternatively, as these states

are changing with time they are called state time diagrams. Down

state can be due to unexpected failure and its recovery will

G

G

G

G

PAND

SEQ

SPARE

FDEP

T

A

B

A

B

C

A

S1

S2

A

B C

Fig. 1. Dynamic gates.

Please cite this article as: Durga Rao K, et al. Dynamic fault tree analysis using Monte Carlo simulation in probabilistic safety

assessment. Reliab Eng Syst Safety (2008), doi:10.1016/j.ress.2008.09.007

�

ARTICLE IN PRESS

K. Durga Rao et al. / Reliability Engineering and System Safety ] (]]]]) ]]]–]]]

3

depend upon the time taken for repair action. Duration of the

state is random for both up and down states. It will depend upon

PDF of time to failure and time to repair, respectively.

3.1. Evaluation of time to failure or time to repair for state

time diagrams

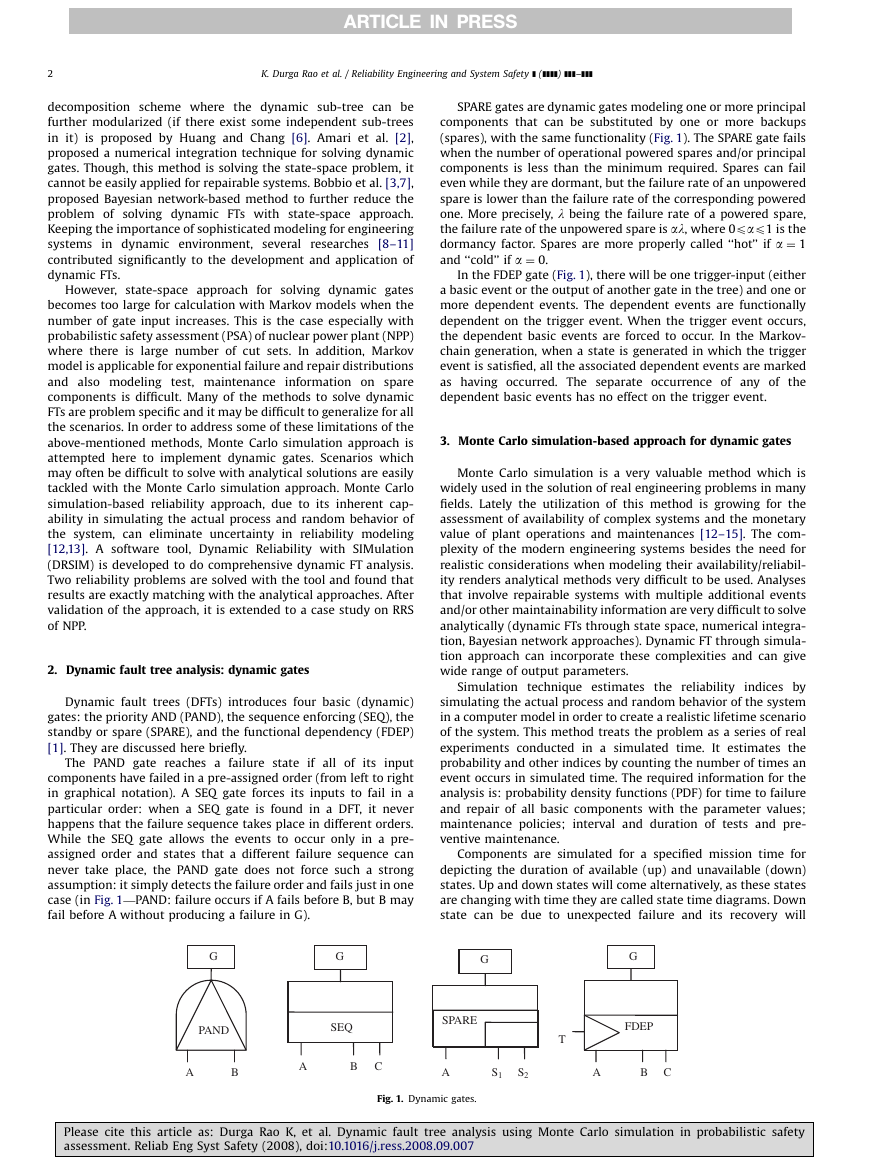

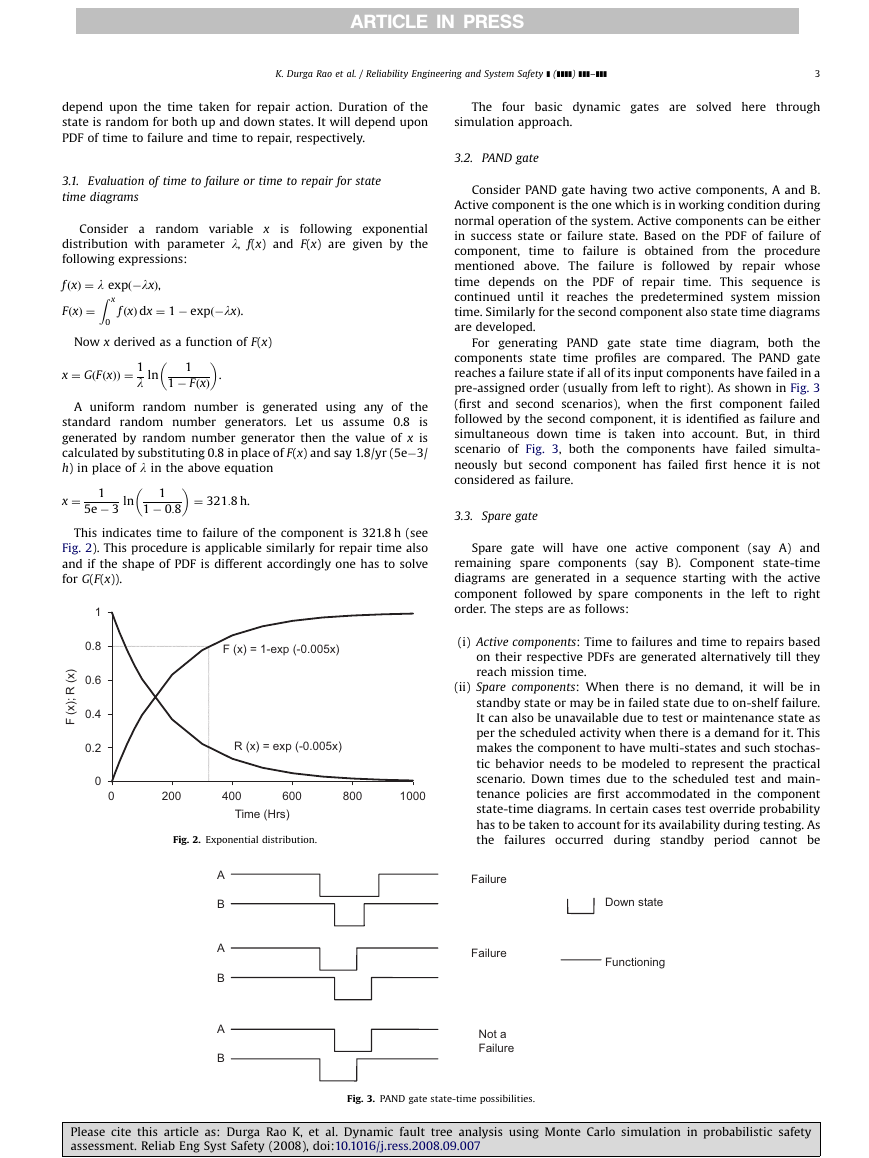

Consider a random variable x is following exponential

distribution with parameter l, f(x) and F(x) are given by the

following expressions:

fðxÞ ¼ l expð�lxÞ,

FðxÞ ¼

fðxÞ dx ¼ 1 � expð�lxÞ.

Z

x

0

Now x derived as a function of F(x)

�

�

x ¼ GðFðxÞÞ ¼ 1

l ln

1

1 � FðxÞ

.

A uniform random number is generated using any of the

standard random number generators. Let us assume 0.8 is

generated by random number generator then the value of x is

calculated by substituting 0.8 in place of F(x) and say 1.8/yr (5e�3/

h) in place of l in the above equation

�

�

x ¼ 1

5e � 3

ln

1

1 � 0:8

¼ 321:8 h.

This indicates time to failure of the component is 321.8 h (see

Fig. 2). This procedure is applicable similarly for repair time also

and if the shape of PDF is different accordingly one has to solve

for G(F(x)).

1

0.8

0.6

0.4

0.2

)

x

(

R

;

)

x

(

F

0

0

F (x) = 1-exp (-0.005x)

R (x) = exp (-0.005x)

200

400

600

Time (Hrs)

800

1000

Fig. 2. Exponential distribution.

A

B

A

B

A

B

The four basic dynamic gates are solved here through

simulation approach.

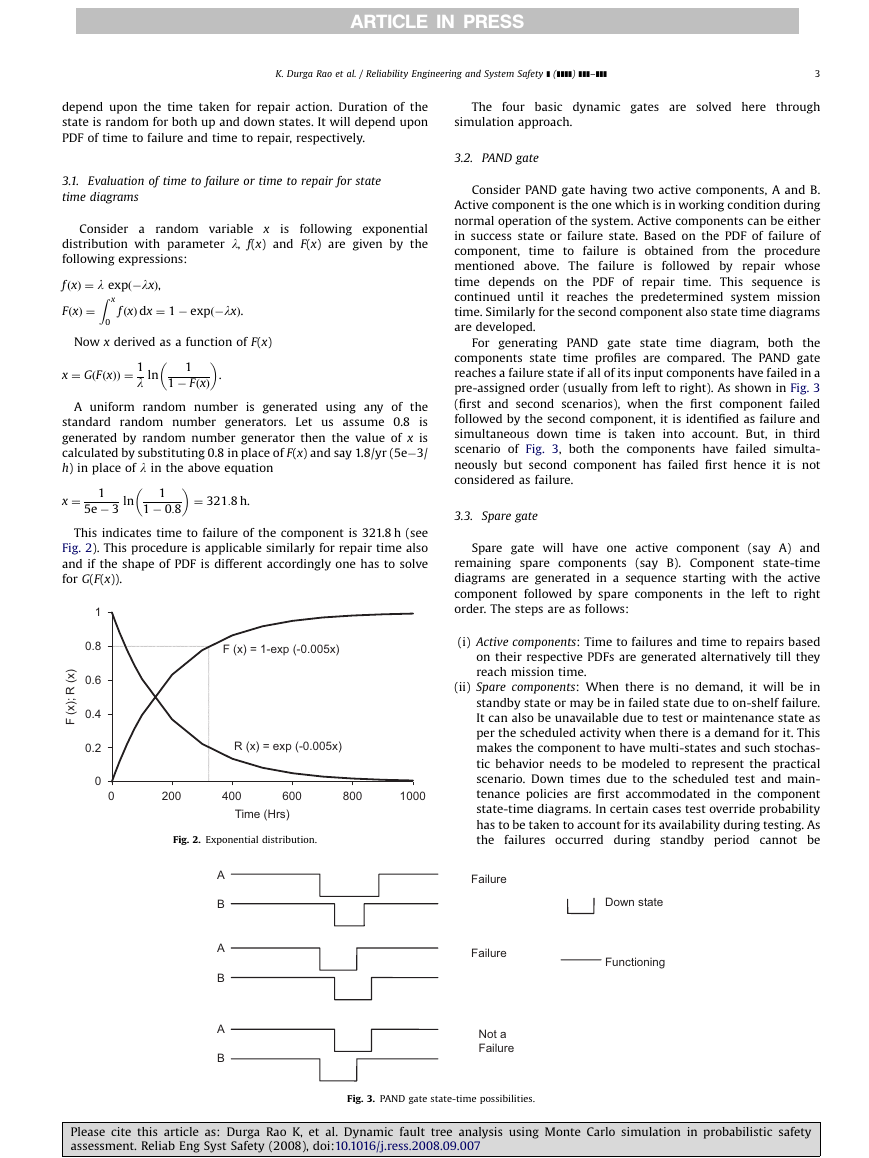

3.2. PAND gate

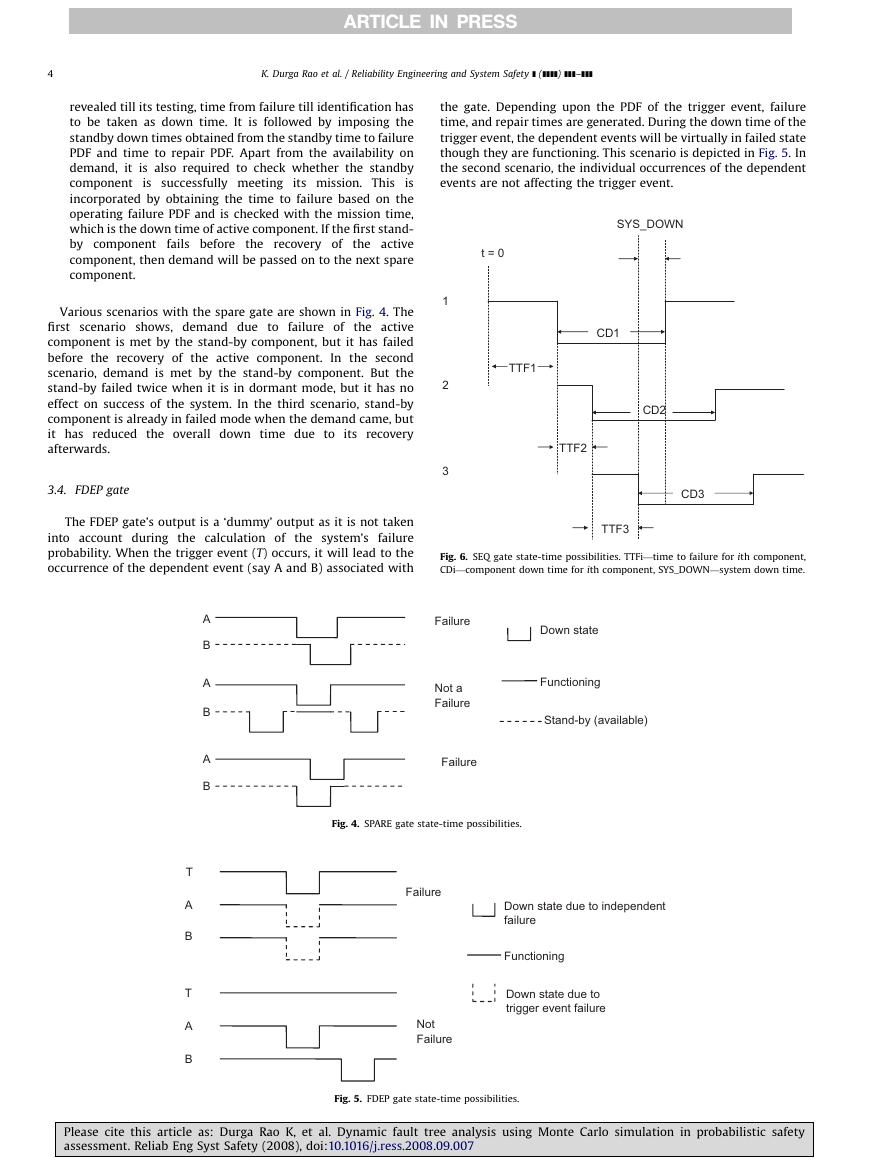

Consider PAND gate having two active components, A and B.

Active component is the one which is in working condition during

normal operation of the system. Active components can be either

in success state or failure state. Based on the PDF of failure of

component, time to failure is obtained from the procedure

mentioned above. The failure is followed by repair whose

time depends on the PDF of repair time. This sequence is

continued until it reaches the predetermined system mission

time. Similarly for the second component also state time diagrams

are developed.

For generating PAND gate state time diagram, both the

components state time profiles are compared. The PAND gate

reaches a failure state if all of its input components have failed in a

pre-assigned order (usually from left to right). As shown in Fig. 3

(first and second scenarios), when the first component failed

followed by the second component, it is identified as failure and

simultaneous down time is taken into account. But, in third

scenario of Fig. 3, both the components have failed simulta-

neously but second component has failed first hence it is not

considered as failure.

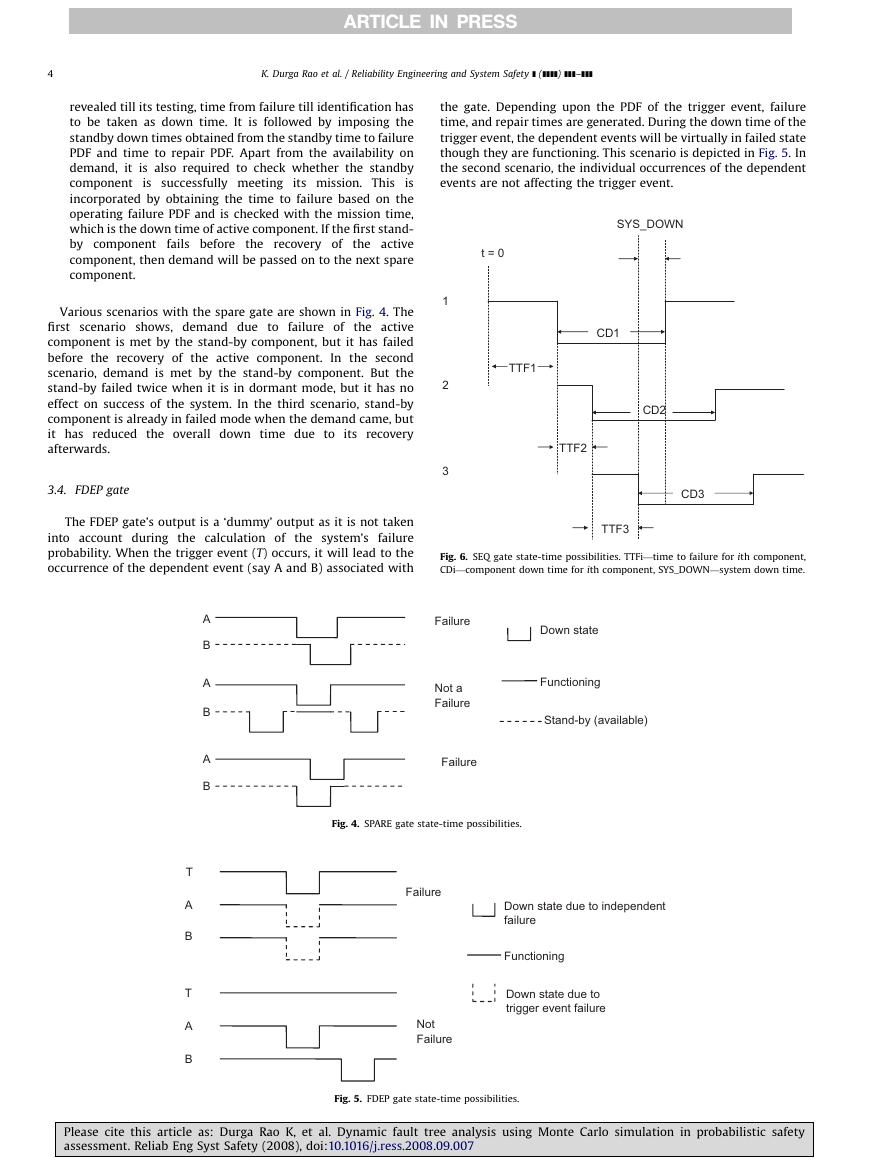

3.3. Spare gate

Spare gate will have one active component (say A) and

remaining spare components (say B). Component state-time

diagrams are generated in a sequence starting with the active

component followed by spare components in the left to right

order. The steps are as follows:

(i) Active components: Time to failures and time to repairs based

on their respective PDFs are generated alternatively till they

reach mission time.

(ii) Spare components: When there is no demand, it will be in

standby state or may be in failed state due to on-shelf failure.

It can also be unavailable due to test or maintenance state as

per the scheduled activity when there is a demand for it. This

makes the component to have multi-states and such stochas-

tic behavior needs to be modeled to represent the practical

scenario. Down times due to the scheduled test and main-

tenance policies are first accommodated in the component

state-time diagrams. In certain cases test override probability

has to be taken to account for its availability during testing. As

the failures occurred during standby period cannot be

Down state

Functioning

Failure

Failure

Not a

Failure

Please cite this article as: Durga Rao K, et al. Dynamic fault tree analysis using Monte Carlo simulation in probabilistic safety

assessment. Reliab Eng Syst Safety (2008), doi:10.1016/j.ress.2008.09.007

Fig. 3. PAND gate state-time possibilities.

�

ARTICLE IN PRESS

4

K. Durga Rao et al. / Reliability Engineering and System Safety ] (]]]]) ]]]–]]]

revealed till its testing, time from failure till identification has

to be taken as down time. It is followed by imposing the

standby down times obtained from the standby time to failure

PDF and time to repair PDF. Apart from the availability on

demand, it is also required to check whether the standby

component

is successfully meeting its mission. This is

incorporated by obtaining the time to failure based on the

operating failure PDF and is checked with the mission time,

which is the down time of active component. If the first stand-

by component

the active

component, then demand will be passed on to the next spare

component.

fails before the recovery of

Various scenarios with the spare gate are shown in Fig. 4. The

first scenario shows, demand due to failure of

the active

component is met by the stand-by component, but it has failed

before the recovery of the active component.

In the second

scenario, demand is met by the stand-by component. But the

stand-by failed twice when it is in dormant mode, but it has no

effect on success of the system. In the third scenario, stand-by

component is already in failed mode when the demand came, but

it has reduced the overall down time due to its recovery

afterwards.

3.4. FDEP gate

The FDEP gate’s output is a ‘dummy’ output as it is not taken

into account during the calculation of the system’s failure

probability. When the trigger event (T) occurs, it will lead to the

occurrence of the dependent event (say A and B) associated with

the gate. Depending upon the PDF of the trigger event, failure

time, and repair times are generated. During the down time of the

trigger event, the dependent events will be virtually in failed state

though they are functioning. This scenario is depicted in Fig. 5. In

the second scenario, the individual occurrences of the dependent

events are not affecting the trigger event.

SYS_DOWN

t = 0

1

2

3

CD1

TTF1

CD2

TTF2

CD3

TTF3

Fig. 6. SEQ gate state-time possibilities. TTFi—time to failure for ith component,

CDi—component down time for ith component, SYS_DOWN—system down time.

A

B

A

B

A

B

T

A

B

T

A

B

Failure

Not a

Failure

Failure

Down state

Functioning

Stand-by (available)

Fig. 4. SPARE gate state-time possibilities.

Failure

Down state due to independent

failure

Functioning

Down state due to

trigger event failure

Not

Failure

Please cite this article as: Durga Rao K, et al. Dynamic fault tree analysis using Monte Carlo simulation in probabilistic safety

assessment. Reliab Eng Syst Safety (2008), doi:10.1016/j.ress.2008.09.007

Fig. 5. FDEP gate state-time possibilities.

�

ARTICLE IN PRESS

K. Durga Rao et al. / Reliability Engineering and System Safety ] (]]]]) ]]]–]]]

5

3.5. SEQ gate

It is similar to PAND gate but occurrence of events are forced to

take place in a particular fashion. Failure of first component forces

the other components to follow. No component can fail prior to

the first component. Consider a three input SEQ gate having

repairable components. The following steps are involved with

Monte Carlo simulation approach.

1. Component state time profile is generated for first component

based upon its failure and repair rate. Down time of first

component

the second component.

Similarly the down time of second component is mission time

for the third component.

is mission time for

2. When first component fails, operation of the second compo-

nent starts. Failure instance of the first component is taken as

t ¼ 0 for second component. Time to failure (TTF2) and time to

Table 1

Failure data for the basic events

Gate

AND

OR

Failure rate of basic events

1.1e�2

1.1e�3

1.2e�2

1.2e�3

1.3e�2

1.3e�3

1.4e�2

1.4e�3

1.5e�2

1.5e�3

repair/component down time (CD2) is generated for second

component.

3. When second component fails, operation of the third compo-

nent starts. Failure instance of the second component is taken

as t ¼ 0 for third component. Time to failure (TTF3) and time to

repair/component down time (CD3) is generated for third

component.

4. The common period in which all the components are down is

considered as the down time of the SEQ gate.

5. The process is repeated for all the down states of the first

component (Fig. 6).

4. Validation with examples

4.1. Example 1—DFT problem from Ref. [2]

Consider a PAND gate with AND and OR gates as inputs (see

Table 1 and Fig. 7). Amari et al. [2] suggested an approach based

on the numerical integration technique to solve this problem and

compared it with Markov-model approach. For mission time

1000 h, the top event probability is 3.6e�1, and overall computa-

tion time is less than 1.0e�2 s. State-space approach generated

162 states and computation time is 25 s. However, both the

methods need lot of time for the development of analytical

expression and multiple states, respectively. Once the analytical

Top Event

PAND

Gate 2:

Static AND

Gate 3: OR

Event 1

Event 5

Event 6

Event 10

...

...

Fig. 7. Fault tree having dynamic gate (PAND).

)

x

(

f

0.12

0.1

0.08

0.06

0.04

0.02

0

)

x

(

F

1

0.8

0.6

0.4

0.2

0

0

200 400 600 800 1000 1200

failure time (x)

0

200 400 600 800 1000 1200

failure time(x)

Please cite this article as: Durga Rao K, et al. Dynamic fault tree analysis using Monte Carlo simulation in probabilistic safety

assessment. Reliab Eng Syst Safety (2008), doi:10.1016/j.ress.2008.09.007

Fig. 8. Failure time distributions.

�

ARTICLE IN PRESS

6

K. Durga Rao et al. / Reliability Engineering and System Safety ] (]]]]) ]]]–]]]

expression is developed, calculation is straightforward. However,

the former method is limited for non-repairable basic events only.

The disadvantage with the later method is number of states in the

Markov model which increases exponentially as the number of

basic events increase. Solution to this problem has been obtained

with the simulation approach as explained in the previous section.

Simulation is carried out for 10,000 iterations with a mission time

of 1000 h. The top event probability is obtained same as Amari

et al. [2] method. Apart from the mean value of failure probability,

randomness in the failure time is characterized by the probability

distribution as shown in Fig. 8. Mean time to failure is obtained as

290.1 h with simulation approach.

4.2. Example 2—simplified electrical (AC) power supply system of

typical NPP

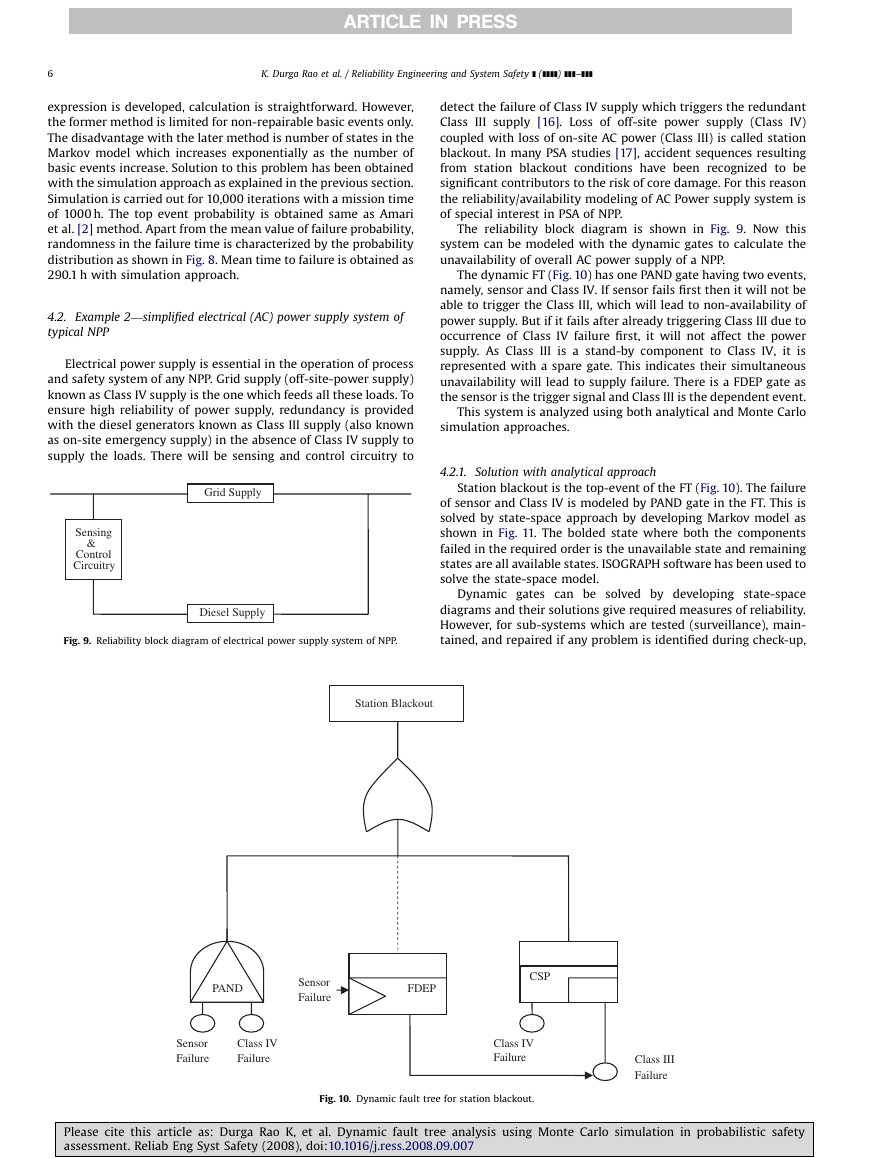

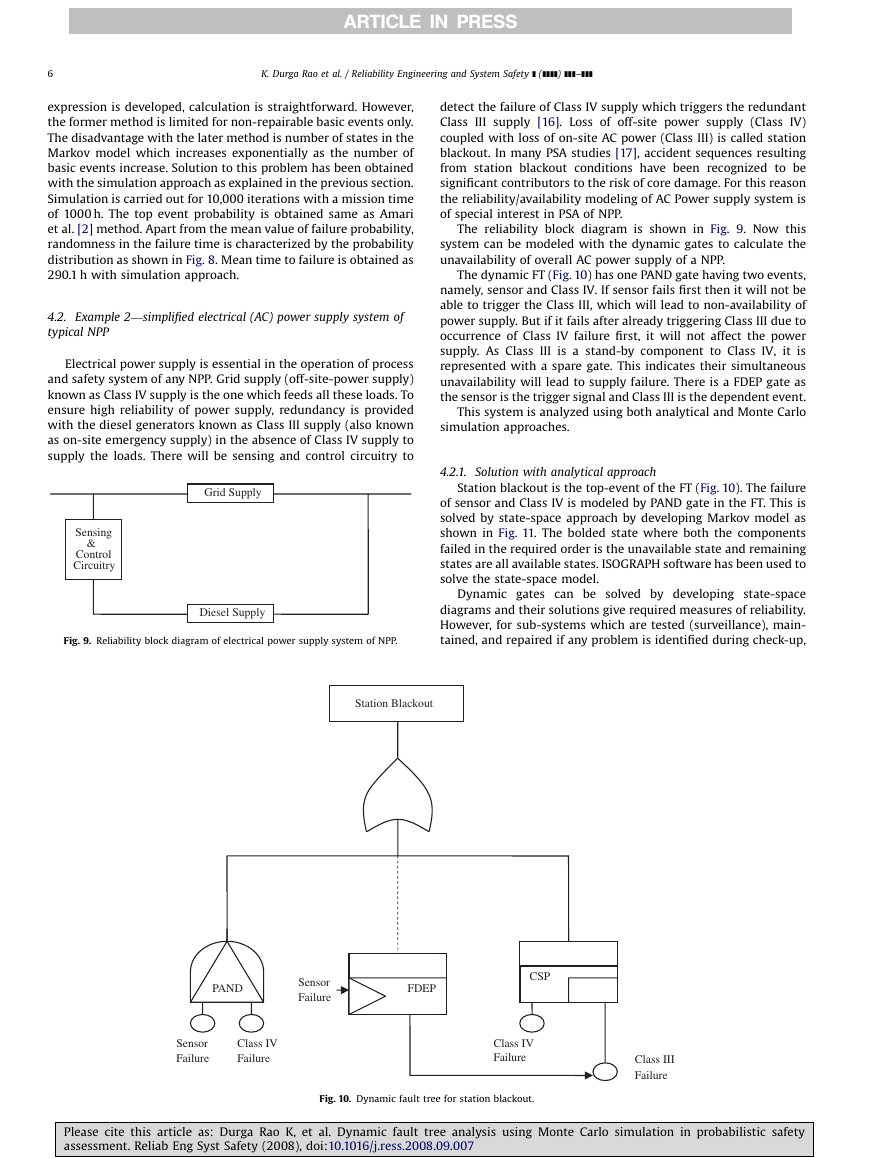

Electrical power supply is essential in the operation of process

and safety system of any NPP. Grid supply (off-site-power supply)

known as Class IV supply is the one which feeds all these loads. To

ensure high reliability of power supply, redundancy is provided

with the diesel generators known as Class III supply (also known

as on-site emergency supply) in the absence of Class IV supply to

supply the loads. There will be sensing and control circuitry to

Sensing

&

Control

Circuitry

Grid Supply

Diesel Supply

Fig. 9. Reliability block diagram of electrical power supply system of NPP.

Station Blackout

detect the failure of Class IV supply which triggers the redundant

Class III supply [16]. Loss of off-site power supply (Class IV)

coupled with loss of on-site AC power (Class III) is called station

blackout. In many PSA studies [17], accident sequences resulting

from station blackout conditions have been recognized to be

significant contributors to the risk of core damage. For this reason

the reliability/availability modeling of AC Power supply system is

of special interest in PSA of NPP.

The reliability block diagram is shown in Fig. 9. Now this

system can be modeled with the dynamic gates to calculate the

unavailability of overall AC power supply of a NPP.

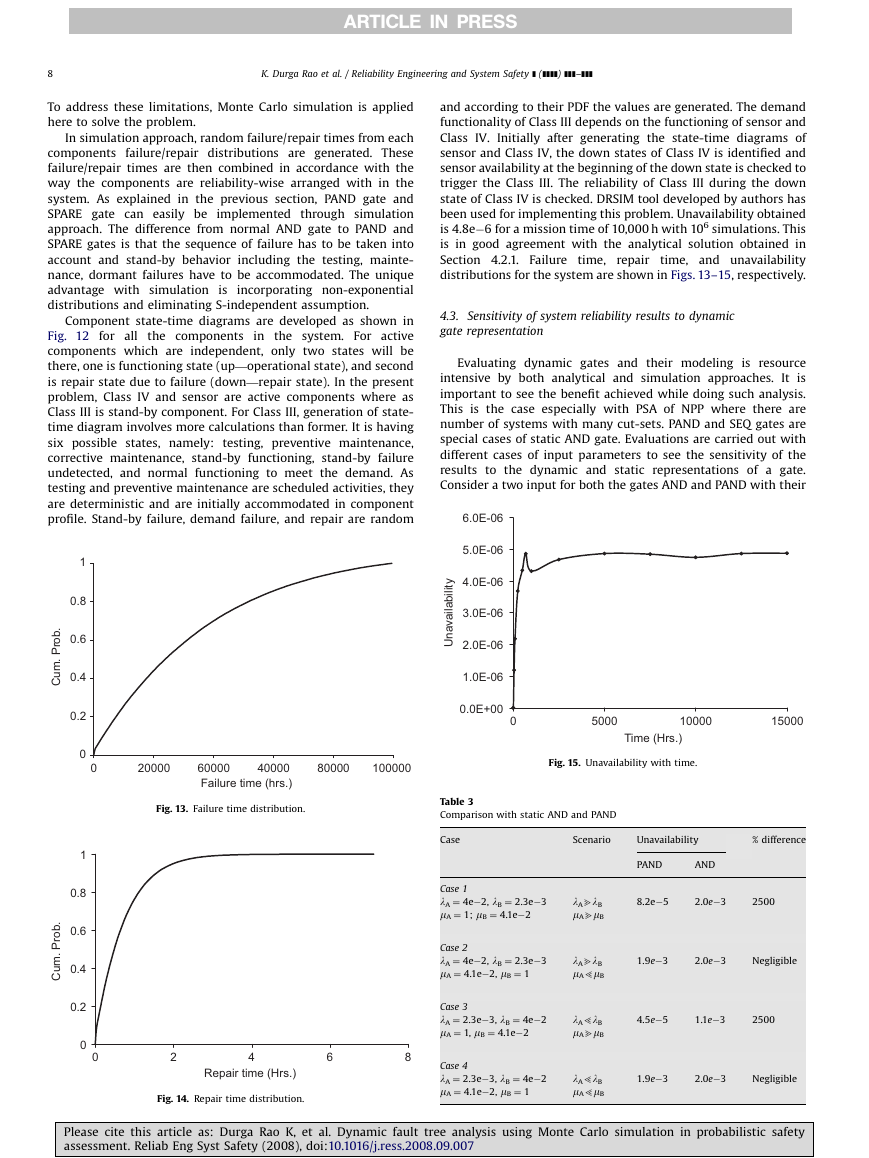

The dynamic FT (Fig. 10) has one PAND gate having two events,

namely, sensor and Class IV. If sensor fails first then it will not be

able to trigger the Class III, which will lead to non-availability of

power supply. But if it fails after already triggering Class III due to

occurrence of Class IV failure first, it will not affect the power

supply. As Class III is a stand-by component to Class IV, it is

represented with a spare gate. This indicates their simultaneous

unavailability will lead to supply failure. There is a FDEP gate as

the sensor is the trigger signal and Class III is the dependent event.

This system is analyzed using both analytical and Monte Carlo

simulation approaches.

4.2.1. Solution with analytical approach

Station blackout is the top-event of the FT (Fig. 10). The failure

of sensor and Class IV is modeled by PAND gate in the FT. This is

solved by state-space approach by developing Markov model as

shown in Fig. 11. The bolded state where both the components

failed in the required order is the unavailable state and remaining

states are all available states. ISOGRAPH software has been used to

solve the state-space model.

Dynamic gates can be solved by developing state-space

diagrams and their solutions give required measures of reliability.

However, for sub-systems which are tested (surveillance), main-

tained, and repaired if any problem is identified during check-up,

PAND

Sensor

Failure

FDEP

Sensor

Failure

Class IV

Failure

CSP

Class IV

Failure

Class III

Failure

Fig. 10. Dynamic fault tree for station blackout.

Please cite this article as: Durga Rao K, et al. Dynamic fault tree analysis using Monte Carlo simulation in probabilistic safety

assessment. Reliab Eng Syst Safety (2008), doi:10.1016/j.ress.2008.09.007

�

ARTICLE IN PRESS

K. Durga Rao et al. / Reliability Engineering and System Safety ] (]]]]) ]]]–]]]

7

SENSOR (A)

CLASS IV (B)

λA

μB

A – Dn

B – Up

μA

λB

A – Up

B – Dn

Failed state

A – Dn

B – Dn

μA

μB

A – Dn

B – Dn

λB

μB

λA

μA

Fig. 11. Markov (state-space) diagram for PAND gate having sensor and Class IV as inputs.

Table 2

Component failure and maintenance information

Component

Failure rate (h)

Repair rate (h)

Test period (h)

Test time (h)

Maint. period (h)

Maint. time (h)

Class IV

Sensor

Class III

2.3e�4

1.0e�4

5.3e�4

2.6

2.5e�1

8.7e�2

–

–

168

–

–

8.3e�2

–

–

2160

–

–

8

Class IV

Class III

Sensor

System

Stand-by (available)

Functioning

Down state

Fig. 12. State-time diagrams for Class IV, sensor, Class III and overall system.

cannot be modeled by state-space diagrams. Though, there is a

school of thought that initial state probabilities can be given as

per the maintenance and demand information, this is often

debatable. A simplified time averaged unavailability expression is

suggested in IAEA P-4 [18] for stand-by subsystems having

exponential failure/repair characteristics. The same is applied

here to solve stand-by (SPARE) gate. If Q is the unavailability of

stand-by component, it is expressed by the following equation:

�

þ ½f mT m þ ½lT r,

Q ¼ 1 � 1 � e�lT

lT

�

h i

þ t

T

where l is failure rate, T is test interval, t is test duration, fm is

frequency of preventive maintenance, Tm is duration of main-

tenance, and Tr is repair time. It is sum of contribution from

failures, test outage, maintenance outage and repair outage. In

order to obtain the unavailability of stand-by gate, unavailability

of Class IV is multiplied with the unavailability (Q) of stand-by

component Class III.

Input parameter values used in the analysis are shown in

Table 2 [19]. The sum of the both the values (PAND and SPARE)

give the unavailability of station blackout scenario which is

obtained as 4.8e�6.

4.2.2. Solution with Monte Carlo simulation

As one can see Markov model for a two-component dynamic

gate is having 5 states with 10 transitions, thus state space

becomes unmanageable as the number of components increases.

In case of stand-by components, the time-averaged analytical

expression for unavailability is only valid for exponential cases.

Please cite this article as: Durga Rao K, et al. Dynamic fault tree analysis using Monte Carlo simulation in probabilistic safety

assessment. Reliab Eng Syst Safety (2008), doi:10.1016/j.ress.2008.09.007

�

ARTICLE IN PRESS

8

K. Durga Rao et al. / Reliability Engineering and System Safety ] (]]]]) ]]]–]]]

To address these limitations, Monte Carlo simulation is applied

here to solve the problem.

In simulation approach, random failure/repair times from each

components failure/repair distributions are generated. These

failure/repair times are then combined in accordance with the

way the components are reliability-wise arranged with in the

system. As explained in the previous section, PAND gate and

SPARE gate can easily be implemented through simulation

approach. The difference from normal AND gate to PAND and

SPARE gates is that the sequence of failure has to be taken into

account and stand-by behavior including the testing, mainte-

nance, dormant failures have to be accommodated. The unique

advantage with simulation is incorporating non-exponential

distributions and eliminating S-independent assumption.

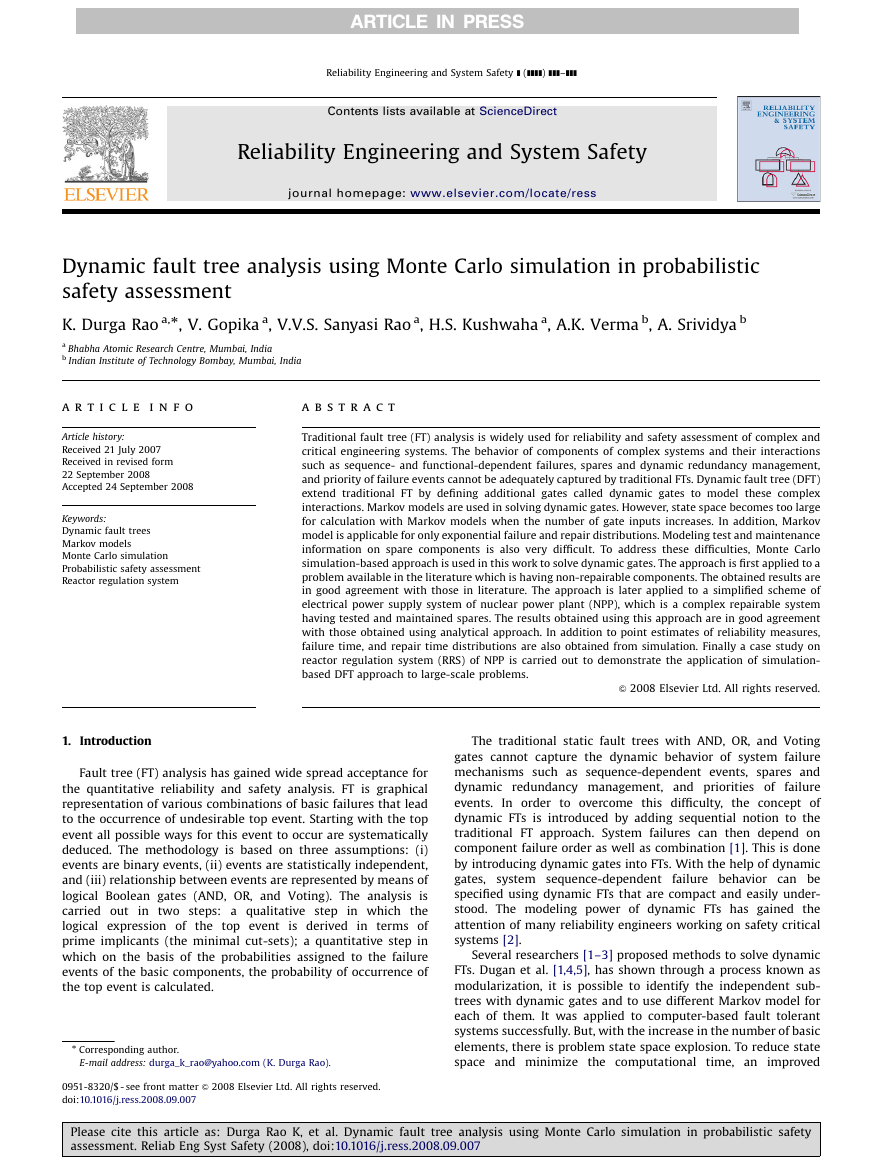

Component state-time diagrams are developed as shown in

the components in the system. For active

Fig. 12 for all

components which are independent, only two states will be

there, one is functioning state (up—operational state), and second

is repair state due to failure (down—repair state). In the present

problem, Class IV and sensor are active components where as

Class III is stand-by component. For Class III, generation of state-

time diagram involves more calculations than former. It is having

six possible states, namely: testing, preventive maintenance,

corrective maintenance, stand-by functioning, stand-by failure

undetected, and normal functioning to meet the demand. As

testing and preventive maintenance are scheduled activities, they

are deterministic and are initially accommodated in component

profile. Stand-by failure, demand failure, and repair are random

and according to their PDF the values are generated. The demand

functionality of Class III depends on the functioning of sensor and

Class IV. Initially after generating the state-time diagrams of

sensor and Class IV, the down states of Class IV is identified and

sensor availability at the beginning of the down state is checked to

trigger the Class III. The reliability of Class III during the down

state of Class IV is checked. DRSIM tool developed by authors has

been used for implementing this problem. Unavailability obtained

is 4.8e�6 for a mission time of 10,000 h with 106 simulations. This

is in good agreement with the analytical solution obtained in

Section 4.2.1. Failure time,

time, and unavailability

distributions for the system are shown in Figs. 13–15, respectively.

repair

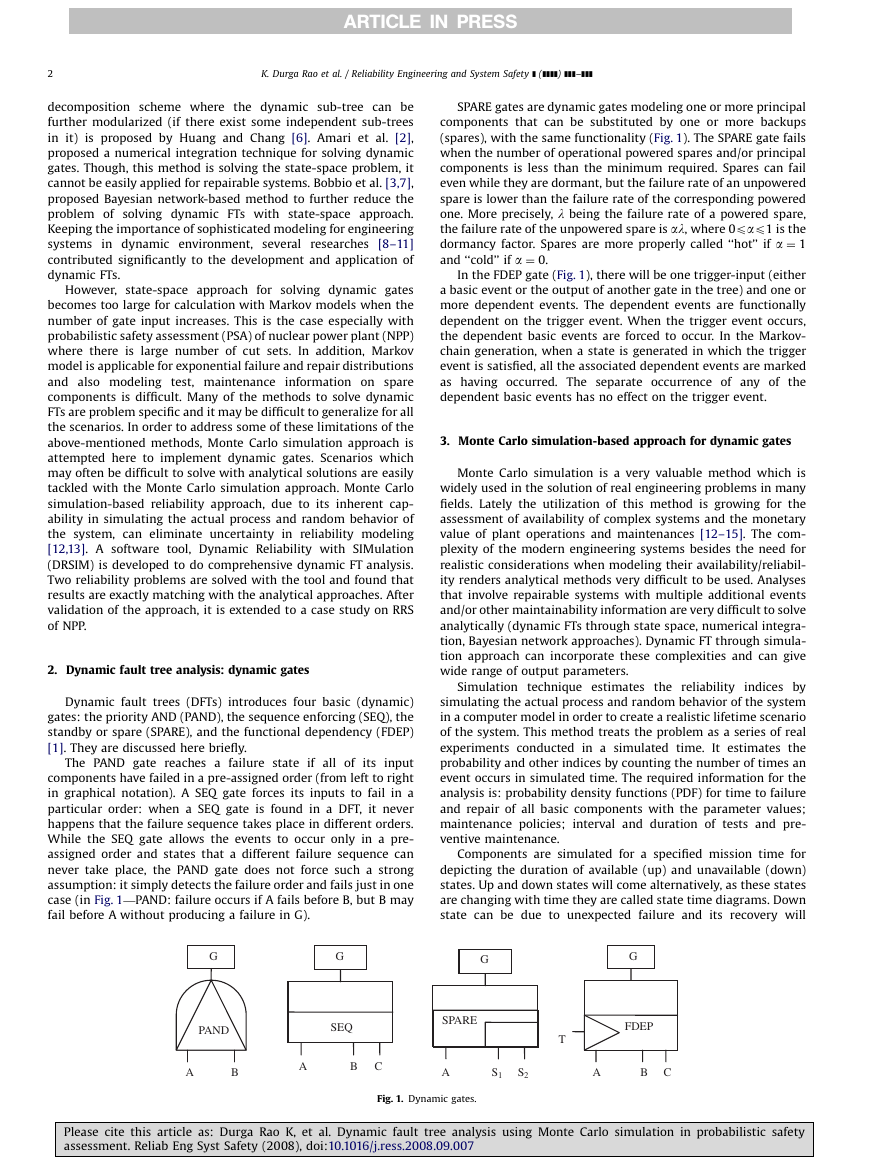

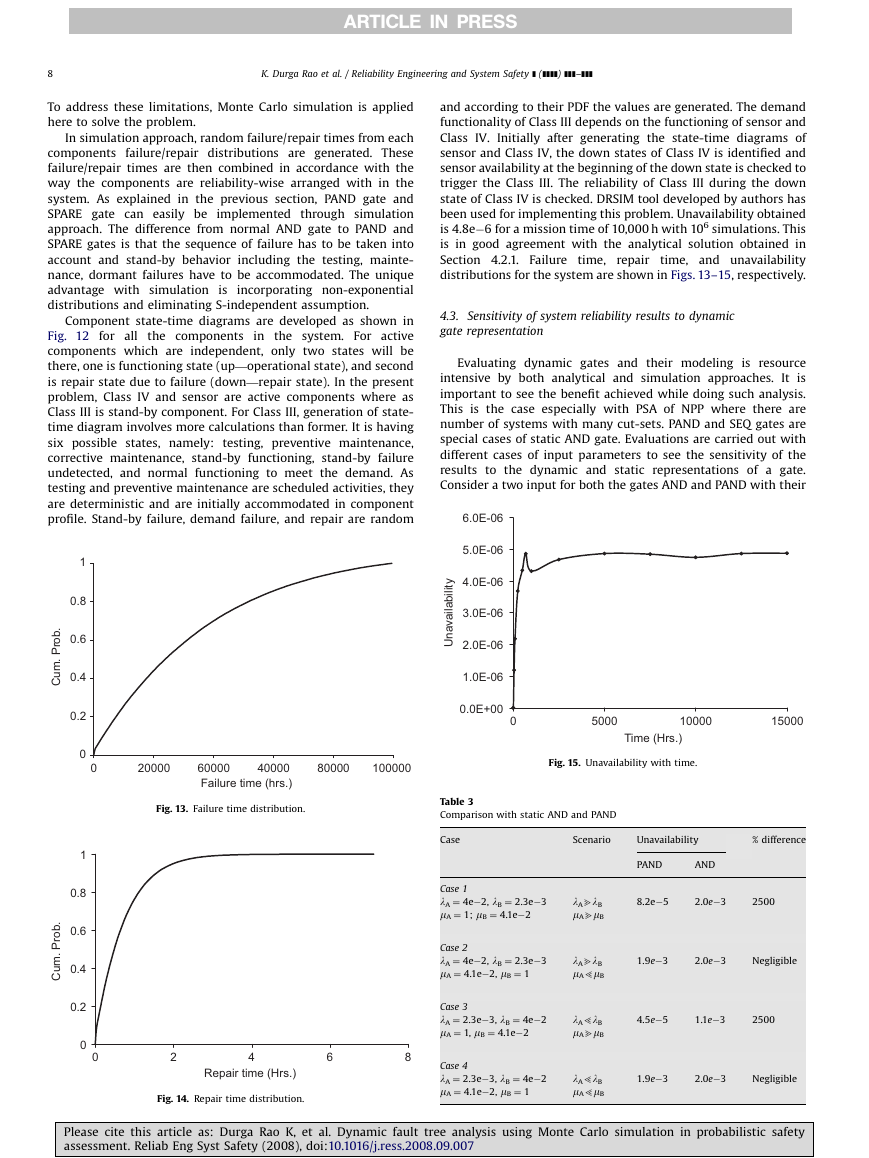

4.3. Sensitivity of system reliability results to dynamic

gate representation

Evaluating dynamic gates and their modeling is resource

intensive by both analytical and simulation approaches. It is

important to see the benefit achieved while doing such analysis.

This is the case especially with PSA of NPP where there are

number of systems with many cut-sets. PAND and SEQ gates are

special cases of static AND gate. Evaluations are carried out with

different cases of input parameters to see the sensitivity of the

results to the dynamic and static representations of a gate.

Consider a two input for both the gates AND and PAND with their

6.0E-06

5.0E-06

4.0E-06

3.0E-06

2.0E-06

1.0E-06

y

t

i

l

i

b

a

l

i

a

v

a

n

U

0.0E+00

0

5000

10000

15000

Time (Hrs.)

Fig. 15. Unavailability with time.

.

b

o

r

P

.

m

u

C

.

b

o

r

P

.

m

u

C

1

0.8

0.6

0.4

0.2

0

0

1

0.8

0.6

0.4

0.2

0

0

20000

60000

40000

Failure time (hrs.)

80000

100000

Fig. 13. Failure time distribution.

Table 3

Comparison with static AND and PAND

Case

Scenario

Unavailability

% difference

Case 1

lA ¼ 4e�2, lB ¼ 2.3e�3

mA ¼ 1; mB ¼ 4.1e�2

Case 2

lA ¼ 4e�2, lB ¼ 2.3e�3

mA ¼ 4.1e�2, mB ¼ 1

Case 3

lA ¼ 2.3e�3, lB ¼ 4e�2

mA ¼ 1, mB ¼ 4.1e�2

Case 4

lA ¼ 2.3e�3, lB ¼ 4e�2

mA ¼ 4.1e�2, mB ¼ 1

lAblB

mAbmB

lAblB

mA5mB

lA5lB

mAbmB

lA5lB

mA5mB

PAND

AND

8.2e�5

2.0e�3

2500

1.9e�3

2.0e�3

Negligible

4.5e�5

1.1e�3

2500

1.9e�3

2.0e�3

Negligible

2

4

6

8

Repair time (Hrs.)

Fig. 14. Repair time distribution.

Please cite this article as: Durga Rao K, et al. Dynamic fault tree analysis using Monte Carlo simulation in probabilistic safety

assessment. Reliab Eng Syst Safety (2008), doi:10.1016/j.ress.2008.09.007

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc