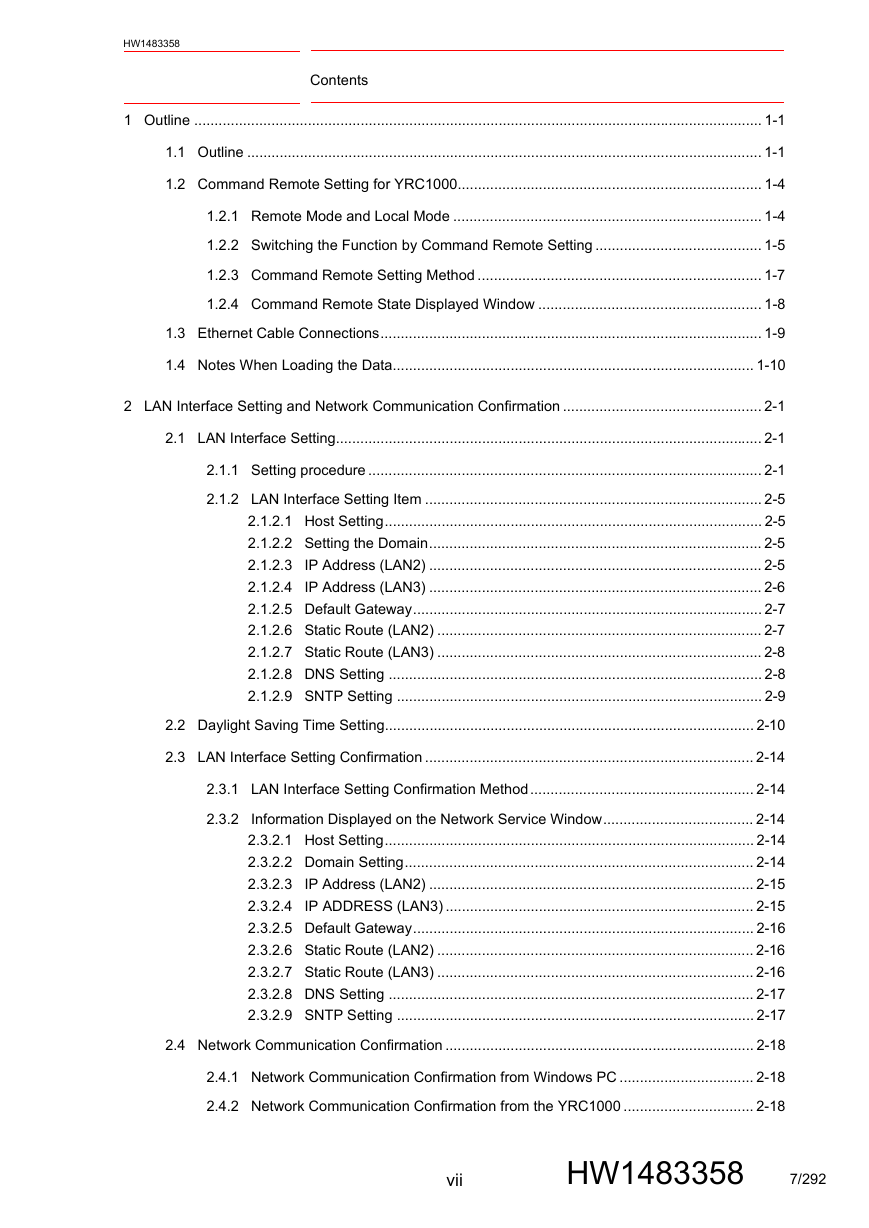

1 Outline

1.1 Outline

1.2 Command Remote Setting for YRC1000

1.2.1 Remote Mode and Local Mode

1.2.2 Switching the Function by Command Remote Setting

1.2.3 Command Remote Setting Method

1.2.4 Command Remote State Displayed Window

1.3 Ethernet Cable Connections

1.4 Notes When Loading the Data

2 LAN Interface Setting and Network Communication Confirmation

2.1 LAN Interface Setting

2.1.1 Setting procedure

2.1.2 LAN Interface Setting Item

2.1.2.1 Host Setting

2.1.2.2 Setting the Domain

2.1.2.3 IP Address (LAN2)

2.1.2.4 IP Address (LAN3)

2.1.2.5 Default Gateway

2.1.2.6 Static Route (LAN2)

2.1.2.7 Static Route (LAN3)

2.1.2.8 DNS Setting

2.1.2.9 SNTP Setting

2.2 Daylight Saving Time Setting

2.3 LAN Interface Setting Confirmation

2.3.1 LAN Interface Setting Confirmation Method

2.3.2 Information Displayed on the Network Service Window

2.3.2.1 Host Setting

2.3.2.2 Domain Setting

2.3.2.3 IP Address (LAN2)

2.3.2.4 IP ADDRESS (LAN3)

2.3.2.5 Default Gateway

2.3.2.6 Static Route (LAN2)

2.3.2.7 Static Route (LAN3)

2.3.2.8 DNS Setting

2.3.2.9 SNTP Setting

2.4 Network Communication Confirmation

2.4.1 Network Communication Confirmation from Windows PC

2.4.2 Network Communication Confirmation from the YRC1000

3 High-Speed Ethernet Server Function

3.1 Outline

3.1.1 System Configuration

3.1.2 Communication Target

3.1.3 Restriction

3.2 Setting

3.2.1 Basic Setting

3.2.2 Batch Data Back-up Function Setting

3.2.3 Command Remote Setting

3.3 Communication Method

3.3.1 Packet Format

3.3.2 Transmission Procedure

3.3.2.1 Robot Control/Status Reading

3.3.2.2 Robot Control/Data Writing to Register

3.3.2.3 File Control (File Saving)

3.3.2.4 File Control (File Loading)

3.3.2.5 File Control (File List)

3.3.2.6 File Control (Deleting of file)

3.3.3 Robot Control Command

3.3.3.1 Alarm Data Reading Command

3.3.3.2 Alarm History Reading Command

3.3.3.3 Status Information Reading Command

3.3.3.4 Executing Job Information Reading Command

3.3.3.5 Axis Configuration Information Reading Command

3.3.3.6 Robot Position Data Reading Command

3.3.3.7 Position Error Reading Command

3.3.3.8 Torque Data Reading Data

3.3.3.9 I/O Data Reading / Writing Command

3.3.3.10 Register Data Reading / Writing Command

3.3.3.11 Byte Variable (B) Reading / Writing Command

3.3.3.12 Integer Type Variable (I) Reading / Writing Command

3.3.3.13 Double Precision Integer Type Variable (D) Reading / Writing Command

3.3.3.14 Real Type Variable (R) Reading / Writing Command

3.3.3.15 16 Byte Character Type Variable (S) Reading Writing Command

3.3.3.16 Robot Position Type Variable (P) Reading / Writing Command

3.3.3.17 Base Position Type Variable (BP) Reading / Writing Command

3.3.3.18 External Axis Type Variable (EX) Reading / Writing Command

3.3.3.19 Alarm Reset / Error Cancel Command

3.3.3.20 Hold / Servo On/off Command

3.3.3.21 Step / Cycle / Auto Switching Command

3.3.3.22 Character String Display Command To The Programming Pendant

3.3.3.23 Start-up (Job Start) Command

3.3.3.24 Job Select Command

3.3.3.25 Management Time Acquiring Command

3.3.3.26 System Information Acquiring Command

3.3.3.27 Plural I/O Data Reading / Writing Command

3.3.3.28 Plural Register Data Reading / Writing Command

3.3.3.29 Plural Byte Type Variable (B) Reading / Writing Command

3.3.3.30 Plural Integer Type Variable (I) Reading / Writing Command

3.3.3.31 Plural Double Precision Integer Type Variable (D) Reading / Writing Command

3.3.3.32 Plural Real Type Variable (R) Reading / Writing Command

3.3.3.33 Plural 16 Byte Character Type Variable (S) Reading / Writing Command

3.3.3.34 Plural Robot Position Type Variable (P) Reading / Writing Command

3.3.3.35 Plural Base Position Type Variable (BP) Reading / Writing Command

3.3.3.36 Plural Station Type Variable (EX) Reading / Writing Command

3.3.3.37 Alarm Data Reading Command (for Applying the Sub Code Character String)

3.3.3.38 Alarm History Reading Command (for Applying the Sub Code Character String)

3.3.3.39 Move instruction command (Type Cartesian Coordinate)

3.3.3.40 Move Instruction Command (Type Pulse)

3.3.3.41 32 Byte Character Type Variable (S) Reading Writing Command

3.3.3.42 Plural 32 Byte Character Type Variable (S) Reading / Writing Command

3.3.4 File Control Command

3.3.4.1 File Deleting Command

3.3.4.2 File Loading Command

3.3.4.3 File Saving Command

3.3.4.4 File List Acquiring Command

3.3.4.5 File Saving Command (Batch Data Backup)

3.4 Response Code

3.4.1 Status Code

3.4.2 Added Status Code

3.5 Troubleshooting

3.5.1 Network Communication Confirmation

3.5.2 Communication Setting Confirmation for Firewall and Security Software

3.5.3 Error Log Confirmation of High-speed Ethernet Server Communication

4 FTP Server Function

4.1 Outline

4.1.1 System Configuration

4.1.2 Communication Target

4.1.3 Function Mode

4.1.4 CMOS Saving Function via FTP

4.1.5 Restriction

4.2 Setting

4.2.1 Enabling Setting for the FTP Function

4.2.2 Enabling the CMOS Saving Function via FTP

4.2.3 Command Remote Setting

4.3 Specification

4.3.1 Account

4.4 Communication Method

4.4.1 Example of Communication Procedure in Normal Operation Mode (When Using the Windows 7 Command Prompt)

4.4.2 Example of Communication Procedure in Expand Mode (When Using FileZilla)

4.4.3 Saving CMOS Data by Using CMOS Saving Function via FTP

4.5 Troubleshooting

4.5.1 Network Communication Confirmation

4.5.2 Confirming the Communication Setting for Firewall and Security Software

4.5.3 Confirming the Function Mode

5 DCI Function

5.1 Outline

5.1.1 System Configuration

5.1.2 Communication Target

5.2 Setting

5.2.1 Communication Target Setting

5.2.2 Command Remote OFF Setting

5.3 Preparation at the YRC1000 Side

5.3.1 Command for Job Transmission

5.3.1.1 LOADJ

5.3.1.2 SAVEJ

5.3.1.3 DELETEJ

5.3.1.4 SWAIT

5.3.2 Command for Variable Transmission

5.3.2.1 LOADV

5.3.2.2 SAVEV

5.3.3 Registering DCI Command

5.3.4 Concurrent Task from Multiple Job

5.3.5 DCI Parallel Execution

5.3.5.1 Parallel Execution Using NWAIT

5.3.5.2 Parallel Execution Using PSTART (Optional)

5.3.6 Axis Data Transmission Format

5.4 Preparation at the PC Side

5.5 Executing the DCI Function

5.6 Alarm Code

5.7 Troubleshooting

5.7.1 Network Communication Confirmation

5.7.2 Communication Setting Confirmation for Firewall and Security Software

5.7.3 Confirming the Operation of the PC-side Application

5.7.4 Confirming That the Remote Setting is OFF

6 FTP Client Function

6.1 Outline

6.1.1 System Configuration

6.1.2 Communication Target

6.1.3 Restriction

6.2 Preparation at the PC Side

6.3 YRC1000-side Setting and Operation

6.3.1 Enabling Setting for the FTP Function

6.3.2 Setting for the FTP Connection Condition

6.3.3 Selecting the FTP Function

6.3.4 Save

6.3.4.1 Saving a Job

6.3.4.2 Saving Files Except for Job

6.3.5 Load

6.3.5.1 Loading a Job

6.3.5.2 Loading File Except for Job

6.3.6 Verification

6.3.6.1 Verifying a Job

6.3.6.2 Verifying File Except for Job

6.3.7 Selecting Job and Data File

6.4 Troubleshooting

6.4.1 Network Communication Confirmation

6.4.2 Communication Setting Confirmation for Firewall and Security Software

6.4.3 Confirming the FTP Server Operation

6.4.4 Confirming That the Remote Setting is OFF

7 Internal Data Browsing Function by Using a Web Browser

7.1 Outline

7.1.1 System Configuration

7.1.2 Communication Target

7.1.3 Restriction

7.2 Setting Method

7.2.1 Function Setting

7.2.2 Command Remote Setting

7.3 Transmission Procedure Example

7.4 Troubleshooting

7.4.1 Network Communication Confirmation

7.4.2 Communication Setting Confirmation for Firewall and Security Software

8 Ethernet Server Function

8.1 Outline

8.1.1 System Configuration

8.1.2 Communication Target

8.1.3 General Information for When Using the Ethernet Server Function

8.1.4 Restriction

8.2 Setting

8.2.1 Function Setting

8.2.2 Command Remote Setting

8.3 Communication Method

8.3.1 Transmission procedure

8.3.1.1 Socket Connection

8.3.1.2 START Request

8.3.1.3 Response to START Request

8.3.1.4 Command

8.3.1.5 Response to Command

8.3.1.6 Command Data

8.3.1.7 Answer

8.3.1.8 Closing of a Socket

8.3.2 Command Detail

8.3.2.1 Status Read Function

8.3.2.2 System Control Function

8.3.2.3 I/O Read/Write Function

8.3.3 Transmission Example

8.3.3.1 Read-Out of Status for Mode, Cycle, etc

8.3.3.2 Read-Out of I/O Signals for the YRC1000

8.3.3.3 Write-In of I/O Signals for the YRC1000

8.3.3.4 Continuous Execution of Multiple Command

8.4 Troubleshooting

8.4.1 Network Communication Confirmation

8.4.2 Communication Setting Confirmation for Firewall and Security Software

8.4.3 Confirming the connection of the Ethernet Server Function

9 Host Control Function

9.1 Outline

9.1.1 System Configuration

9.1.2 Communication Target

9.1.3 General Information When Using the Host Control Function

9.1.4 Restriction

9.2 Setting

9.2.1 Command Remote Setting

9.3 Transmission Procedure

9.3.1 File Data Transmission Function

9.3.2 Manipulator Control Function

9.4 Troubleshooting

9.4.1 Network Communication Confirmation

9.4.2 Communication Setting Confirmation of Firewall and Security Software

10 Standalone Function

10.1 Outline

10.1.1 System Configuration

10.1.2 Communication Target

10.2 Setting

10.2.1 Communication Target Setting

10.2.2 Command Remote to OFF Setting

10.3 Preparation at the PC Side

10.4 Executing the Standalone Function

10.4.1 Selecting the Standalone Function

10.4.2 Save

10.4.2.1 Save Job

10.4.2.2 Save a File Other Than Job

10.4.3 Load

10.4.3.1 Load the Job

10.4.3.2 Load a File Other Than Job

10.4.4 Verification

10.4.4.1 Verifying the Job

10.4.4.2 Verifying the File Other Than the Job

10.4.5 Selection Mode of the Job

10.4.5.1 Single Selection Mode

10.4.5.2 Related Selection Mode

10.4.5.3 Switching the Selection Mode

10.4.6 Selecting a Job or Data File

10.4.6.1 Individual Selection

10.4.6.2 SELECT ALL

10.5 Troubleshooting

10.5.1 Network Communication Confirmation

10.5.2 Communication Setting Confirmation for Firewall and Security Software

10.5.3 Confirming the Operation of the PC-side Application

10.5.4 Confirming That the Remote Setting is OFF

11 Related Information

11.1 General Information About the Host Control System Function

11.1.1 List of Interlock for Command of Host Control Function

11.1.2 Command that Handle Axis Data

11.1.3 Response to MOV-type Command

11.1.4 Command for Multi-control Group and Independent Control Function

11.1.4.1 Command for Multi-control Group

11.1.4.2 Command for Independent Control Function

11.1.5 Interpreter Message

11.1.6 Alarm Code

11.2 Related Parameter

11.3 Communication Specification

11.4 Recommended Cable and Switching Hub

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc