IEEE TRANSACTIONS ON HUMAN-MACHINE SYSTEMS, VOL. 46, NO. 5, OCTOBER 2016

761

iLeg—A Lower Limb Rehabilitation Robot: A Proof of Concept

Feng Zhang, Zeng-Guang Hou, Long Cheng, Weiqun Wang, Yixiong Chen, Jin Hu, Liang Peng, and Hongbo Wang

Abstract—In this paper, a robot, namely iLeg, is designed for the pur-

pose of rehabilitation of patients with hemiplegia or paraplegia. The iLeg

is composed of one reclining seat and two leg orthoses, and each leg ortho-

sis has three degrees of freedom, which correspond to the hip, knee, and

ankle. Based on this robotic system, two controllers, i.e., passive training

controller and active training controller, are proposed. The former takes ad-

vantage of the proportional-integral control method to solve the trajectory

tracking problem, and the latter employs the surface electromyography sig-

nals to achieve active training. Two simplified impedance controllers, i.e.,

damping-type velocity controller and spring-type position controller, are

designed for active training. A perceptron neural network detects move-

ment intentions. The performance of the controllers was investigated with

one able-bodied male. The results showed that the leg orthosis tracked the

predefined trajectory based on the passive training controller, with the er-

ror rates of 0.45%, 0.44%, and 0.27%, respectively, for the hip, knee,

and ankle. The active training controller whose loop rate is 6.67 Hz can

move the leg orthosis smoothly, and the average recognition error of the

perceptron neural network is less than 5%.

Index

electromyography

(EMG),

Terms—Active

training,

rehabilitation robot, spinal cord injury (SCI).

I. INTRODUCTION

S TROKE and spinal cord injury (SCI) often lead to long-

term limb dysfunctions, especially hemiplegia and para-

plegia. To improve neurorehabilitation and motor recovery, and

to avoid disuse atrophy of the lower limbs, repetitive and inten-

sive rehabilitation exercises with the disabled limbs are indis-

pensable. Traditional rehabilitation exercises that are conducted

manually with the help of therapists are not only labor intensive,

but also very costly. Rehabilitation bikes are often used in China

to help stroke or SCI patients do treadmill training, which has a

positive role on activities of daily living in convalescent stroke

patients [1]. The lower limb rehabilitation robot (LLRR) could

provide a more flexible alternative to rehabilitation bikes.

Manuscript received December 17, 2014; revised April 25, 2015, October

21, 2015, and January 10, 2016; accepted April 8, 2016. Date of publica-

tion July 7, 2016; date of current version September 14, 2016. This work

was supported in part by the National Natural Science Foundation of China

under Grant 61225017, Grant 61403378, Grant 61422310, Grant 61421004,

and Grant 61533016, and by the Strategic Priority Research Program of the

Chinese Academy of Sciences under Grant XDB02080000. This paper was rec-

ommended by Associate Editor J. L. Contreras-Vidal. (Corresponding author:

Zeng-Guang Hou.)

F. Zhang, Z.-G. Hou, L. Cheng, W. Wang, Y. Chen, J. Hu, and L. Peng are

with the State Key Laboratory of Management and Control for Complex Sys-

tems, Institute of Automation, Chinese Academy of Sciences, Beijing 100190,

China (e-mail: feng.zhang@ia.ac.cn; zengguang.hou@ia.ac.cn; long.cheng@

ia.ac.cn; weiqun.wang@ia.ac.cn; yixiong.chen@ia.ac.cn;

jin.hu@ia.ac.cn;

liang.peng@ia.ac.cn).

H. Wang is with the School of Mechanical Engineering, Yanshan University,

Qinhuangdao 066004, China (e-mail: hongbo_w@ysu.edu.cn).

Color versions of one or more of the figures in this paper are available online

at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/THMS.2016.2562510

The LLRRs can be categorized into three types according to

their driving mechanisms and locomotor training styles. The first

one is the sitting/lying type that features a reclining seat and two

leg orthoses, e.g., MotionMaker [2]. It can be used for single-

and multiple-joint rehabilitation. The second one is the stand-

ing/walking type that usually comprises a step-posture control

system and a body weight support system, e.g., Lokomat [3],

LOPES [4], LokoHelp [5], ReoAmbulator [6], Gait Trainer [7],

HapticWalker [8], and WalkTrainer [9]. This type of LLRR as-

sists walking movements of gait-impaired patients and combines

intensive functional locomotion therapy with patient assessment

and feedback tools. The third one is the wearable exoskeleton

type that can be worn by the patient and assists him/her to stand

or walk, e.g., Ekso [10], Rex [11], Robot Suit HAL [12], and

ReWalk [13]. The effectiveness of LLRR is still an open topic

in the current literature. While some studies show their effec-

tiveness [3], [15], [16], other studies suggest that robotics are

not superior to traditional physical therapy [14].

The sitting/lying-type LLRR could provide a useful alterna-

tive to rehabilitation bikes, as it can help patients do not only

passive treadmill training, but also other types of training, such

as active training or functional electrical stimulation (FES). For

example, the MotionMakerTM takes advantage of FES to mimic

natural exercise during the rehabilitation [16].

Voluntary or active motor training has been proven more

beneficial than passive motor training in eliciting performance

improvements and cortical reorganization [17]; thus, an LLRR

that can help patients accomplish not only passive training, but

also active training would be more helpful. Electromyography

(EMG) that contains rich information of muscle activity and

voluntary intention can be used for this purpose. For example,

Leonard et al. developed a novel EMG-driven hand exoskeleton

for bilateral rehabilitation of grasping in stroke, and the EMG

signals from the nonparetic hand were used to estimate the

grasping force and then replicated as robotic assistance for the

paretic hand by means of the hand-exoskeleton [18]. Studies

also suggest that substantial motor control information can be

extracted from paretic muscles of stroke survivors by EMG

signals [19].

In this study, we introduce a novel sitting/lying-type LLRR,

namely iLeg. iLeg is intended for handicapped and hemiplegic

patients, and its main functions are training and rehabilitation

of articular mobility and movement coordination, as well as

muscular strength. The purpose of developing iLeg is to re-

place rehabilitation bikes and provide more rehabilitation train-

ing methods. Two rehabilitation training control methods, i.e.,

passive training and active training, are proposed. Two sim-

plified impedance control methods, i.e., spring-type position

control and damping-type velocity control based on EMG sig-

nals, are implemented to control the robot’s motion. Finally,

2168-2291 © 2016 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission.

See http://www.ieee.org/publications standards/publications/rights/index.html for more information.

�

762

IEEE TRANSACTIONS ON HUMAN-MACHINE SYSTEMS, VOL. 46, NO. 5, OCTOBER 2016

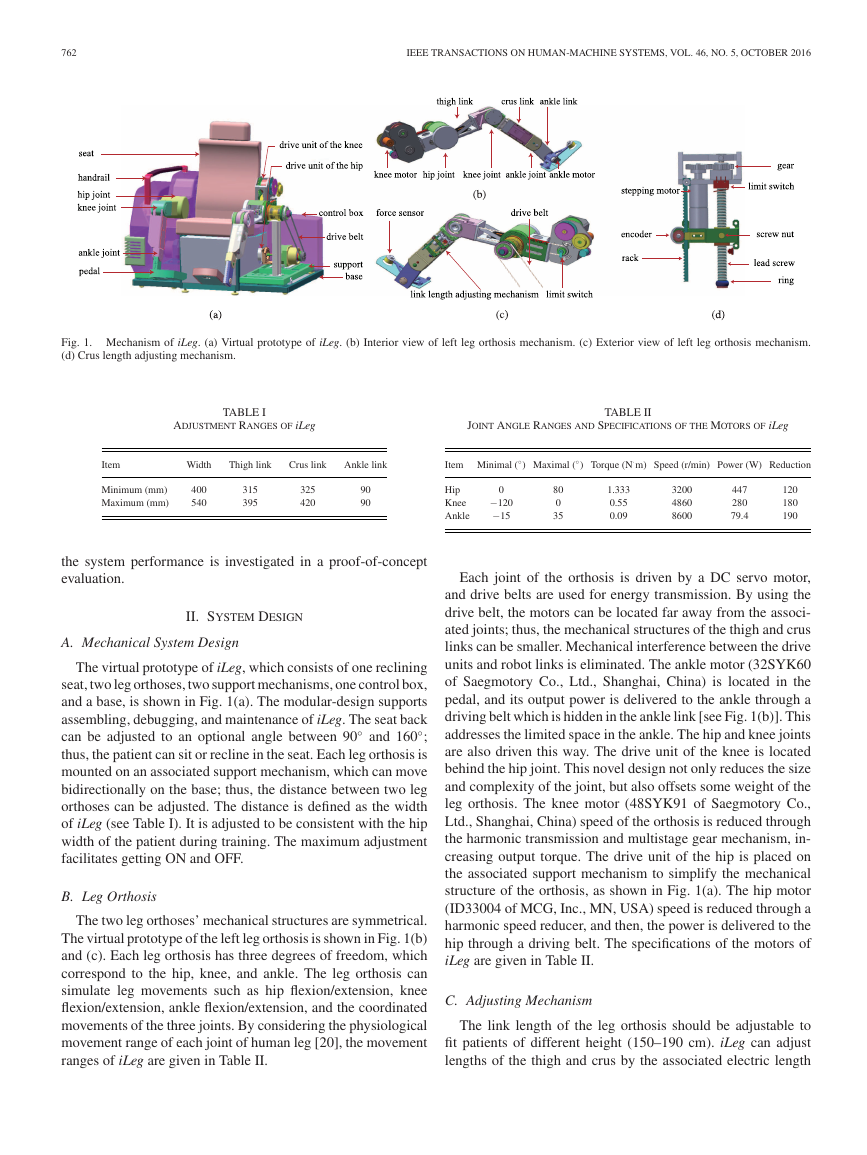

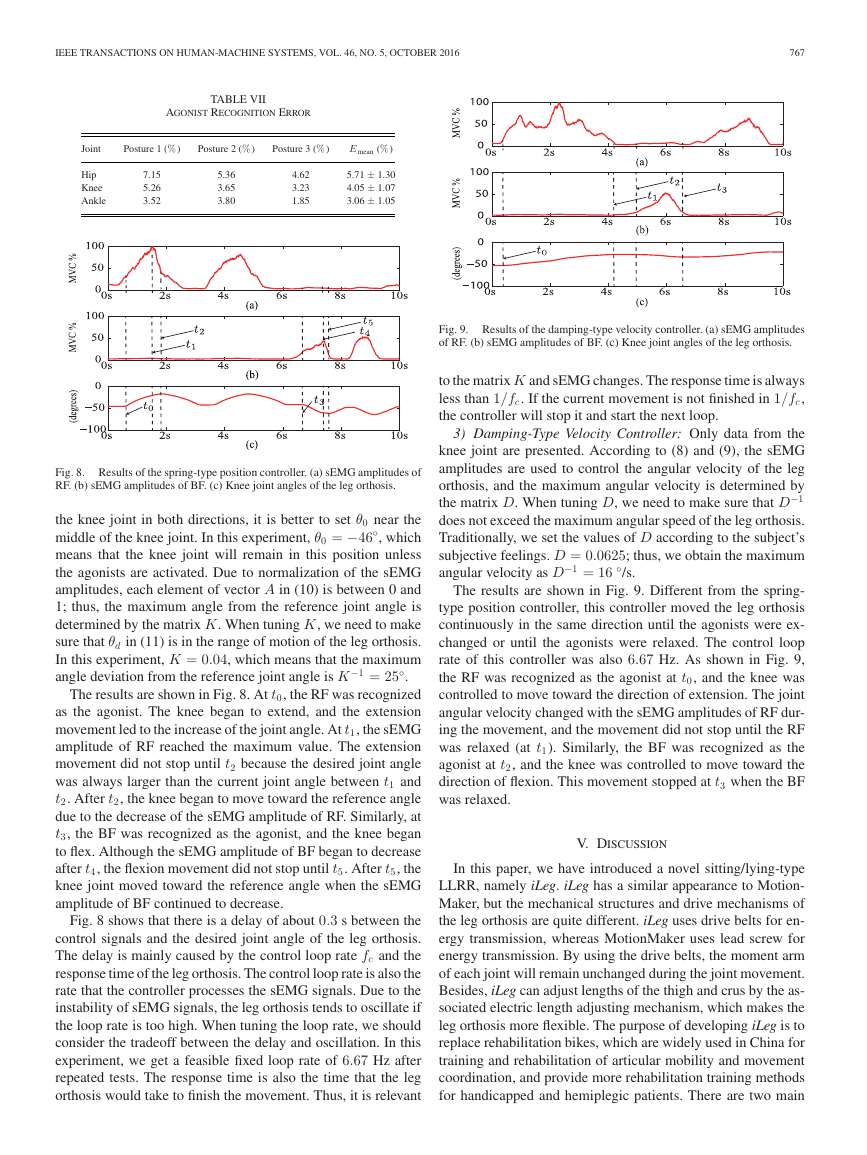

Fig. 1. Mechanism of iLeg. (a) Virtual prototype of iLeg. (b) Interior view of left leg orthosis mechanism. (c) Exterior view of left leg orthosis mechanism.

(d) Crus length adjusting mechanism.

TABLE I

ADJUSTMENT RANGES OF iLeg

JOINT ANGLE RANGES AND SPECIFICATIONS OF THE MOTORS OF iLeg

TABLE II

Item

Width

Thigh link

Crus link

Ankle link

◦

Item Minimal (

◦

) Maximal (

·

) Torque (N

m) Speed (r/min) Power (W) Reduction

Minimum (mm)

Maximum (mm)

400

540

315

395

325

420

90

90

Hip

Knee

Ankle

0

−120

−15

80

0

35

1.333

0.55

0.09

3200

4860

8600

447

280

79.4

120

180

190

the system performance is investigated in a proof-of-concept

evaluation.

II. SYSTEM DESIGN

A. Mechanical System Design

The virtual prototype of iLeg, which consists of one reclining

seat, two leg orthoses, two support mechanisms, one control box,

and a base, is shown in Fig. 1(a). The modular-design supports

assembling, debugging, and maintenance of iLeg. The seat back

◦

and 160

;

can be adjusted to an optional angle between 90

thus, the patient can sit or recline in the seat. Each leg orthosis is

mounted on an associated support mechanism, which can move

bidirectionally on the base; thus, the distance between two leg

orthoses can be adjusted. The distance is defined as the width

of iLeg (see Table I). It is adjusted to be consistent with the hip

width of the patient during training. The maximum adjustment

facilitates getting ON and OFF.

◦

B. Leg Orthosis

The two leg orthoses’ mechanical structures are symmetrical.

The virtual prototype of the left leg orthosis is shown in Fig. 1(b)

and (c). Each leg orthosis has three degrees of freedom, which

correspond to the hip, knee, and ankle. The leg orthosis can

simulate leg movements such as hip flexion/extension, knee

flexion/extension, ankle flexion/extension, and the coordinated

movements of the three joints. By considering the physiological

movement range of each joint of human leg [20], the movement

ranges of iLeg are given in Table II.

Each joint of the orthosis is driven by a DC servo motor,

and drive belts are used for energy transmission. By using the

drive belt, the motors can be located far away from the associ-

ated joints; thus, the mechanical structures of the thigh and crus

links can be smaller. Mechanical interference between the drive

units and robot links is eliminated. The ankle motor (32SYK60

of Saegmotory Co., Ltd., Shanghai, China) is located in the

pedal, and its output power is delivered to the ankle through a

driving belt which is hidden in the ankle link [see Fig. 1(b)]. This

addresses the limited space in the ankle. The hip and knee joints

are also driven this way. The drive unit of the knee is located

behind the hip joint. This novel design not only reduces the size

and complexity of the joint, but also offsets some weight of the

leg orthosis. The knee motor (48SYK91 of Saegmotory Co.,

Ltd., Shanghai, China) speed of the orthosis is reduced through

the harmonic transmission and multistage gear mechanism, in-

creasing output torque. The drive unit of the hip is placed on

the associated support mechanism to simplify the mechanical

structure of the orthosis, as shown in Fig. 1(a). The hip motor

(ID33004 of MCG, Inc., MN, USA) speed is reduced through a

harmonic speed reducer, and then, the power is delivered to the

hip through a driving belt. The specifications of the motors of

iLeg are given in Table II.

C. Adjusting Mechanism

The link length of the leg orthosis should be adjustable to

fit patients of different height (150–190 cm). iLeg can adjust

lengths of the thigh and crus by the associated electric length

�

IEEE TRANSACTIONS ON HUMAN-MACHINE SYSTEMS, VOL. 46, NO. 5, OCTOBER 2016

763

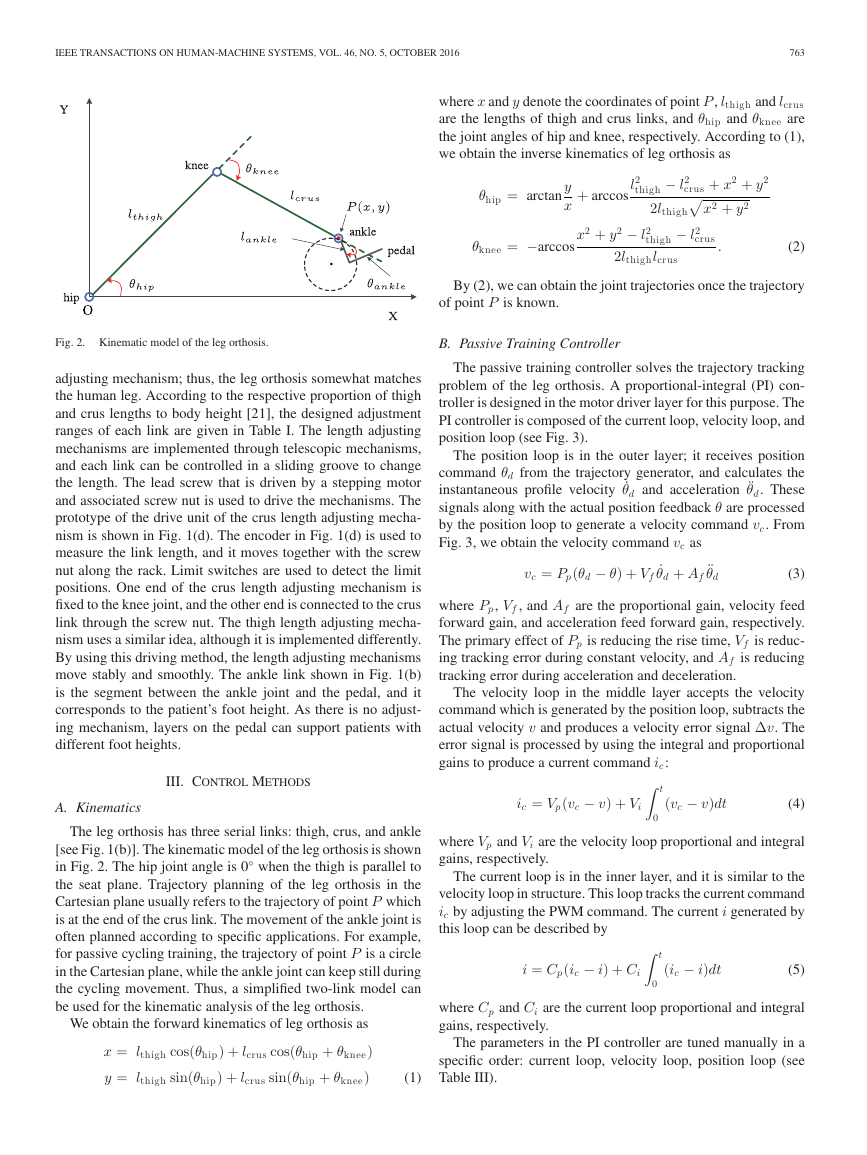

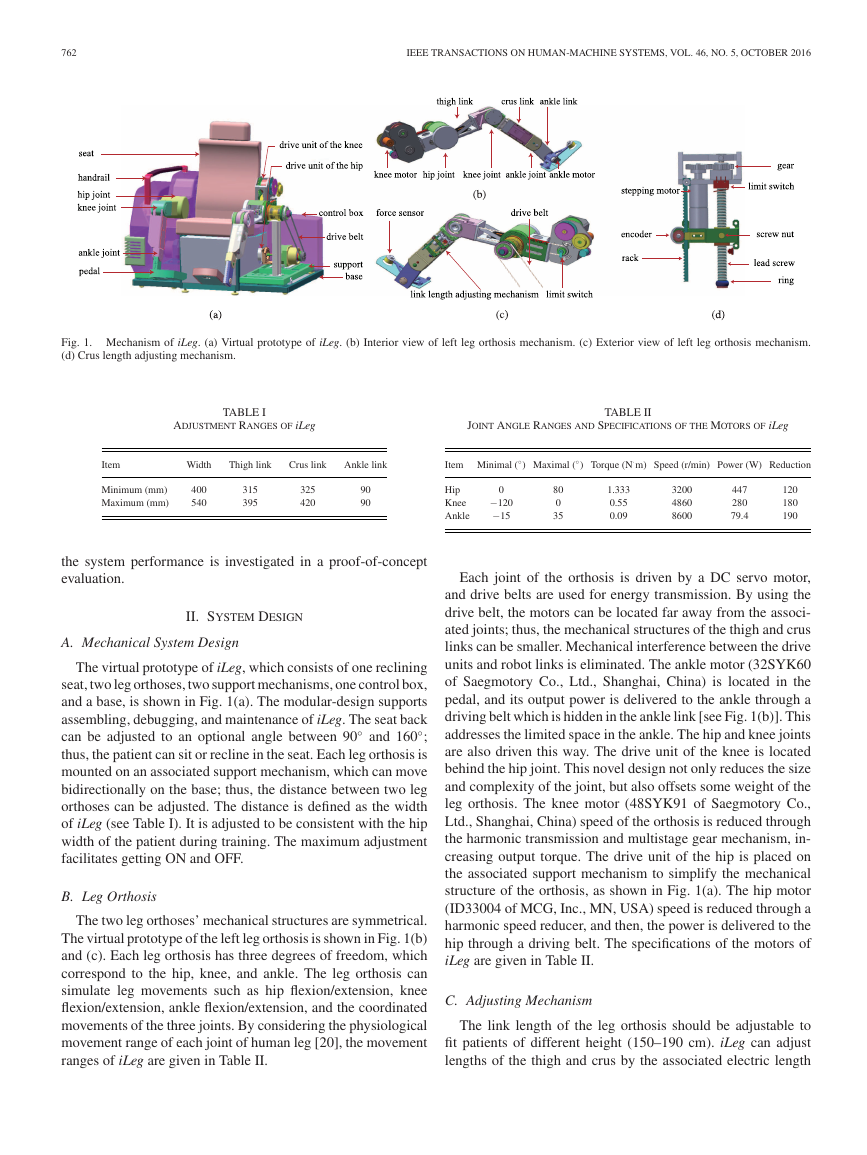

where x and y denote the coordinates of point P , lthigh and lcrus

are the lengths of thigh and crus links, and θhip and θknee are

the joint angles of hip and knee, respectively. According to (1),

we obtain the inverse kinematics of leg orthosis as

θhip = arctan

y

x

θknee = −arccos

l2

thigh

+ arccos

x2 + y2 − l2

thigh

2lthigh lcrus

− l2

crus + x2 + y2

2lthigh

− l2

x2 + y2

crus

.

(2)

Fig. 2. Kinematic model of the leg orthosis.

B. Passive Training Controller

By (2), we can obtain the joint trajectories once the trajectory

of point P is known.

adjusting mechanism; thus, the leg orthosis somewhat matches

the human leg. According to the respective proportion of thigh

and crus lengths to body height [21], the designed adjustment

ranges of each link are given in Table I. The length adjusting

mechanisms are implemented through telescopic mechanisms,

and each link can be controlled in a sliding groove to change

the length. The lead screw that is driven by a stepping motor

and associated screw nut is used to drive the mechanisms. The

prototype of the drive unit of the crus length adjusting mecha-

nism is shown in Fig. 1(d). The encoder in Fig. 1(d) is used to

measure the link length, and it moves together with the screw

nut along the rack. Limit switches are used to detect the limit

positions. One end of the crus length adjusting mechanism is

fixed to the knee joint, and the other end is connected to the crus

link through the screw nut. The thigh length adjusting mecha-

nism uses a similar idea, although it is implemented differently.

By using this driving method, the length adjusting mechanisms

move stably and smoothly. The ankle link shown in Fig. 1(b)

is the segment between the ankle joint and the pedal, and it

corresponds to the patient’s foot height. As there is no adjust-

ing mechanism, layers on the pedal can support patients with

different foot heights.

III. CONTROL METHODS

A. Kinematics

The leg orthosis has three serial links: thigh, crus, and ankle

[see Fig. 1(b)]. The kinematic model of the leg orthosis is shown

◦

when the thigh is parallel to

in Fig. 2. The hip joint angle is 0

the seat plane. Trajectory planning of the leg orthosis in the

Cartesian plane usually refers to the trajectory of point P which

is at the end of the crus link. The movement of the ankle joint is

often planned according to specific applications. For example,

for passive cycling training, the trajectory of point P is a circle

in the Cartesian plane, while the ankle joint can keep still during

the cycling movement. Thus, a simplified two-link model can

be used for the kinematic analysis of the leg orthosis.

We obtain the forward kinematics of leg orthosis as

x = lthigh cos(θhip) + lcrus cos(θhip + θknee)

y = lthigh sin(θhip) + lcrus sin(θhip + θknee)

(1)

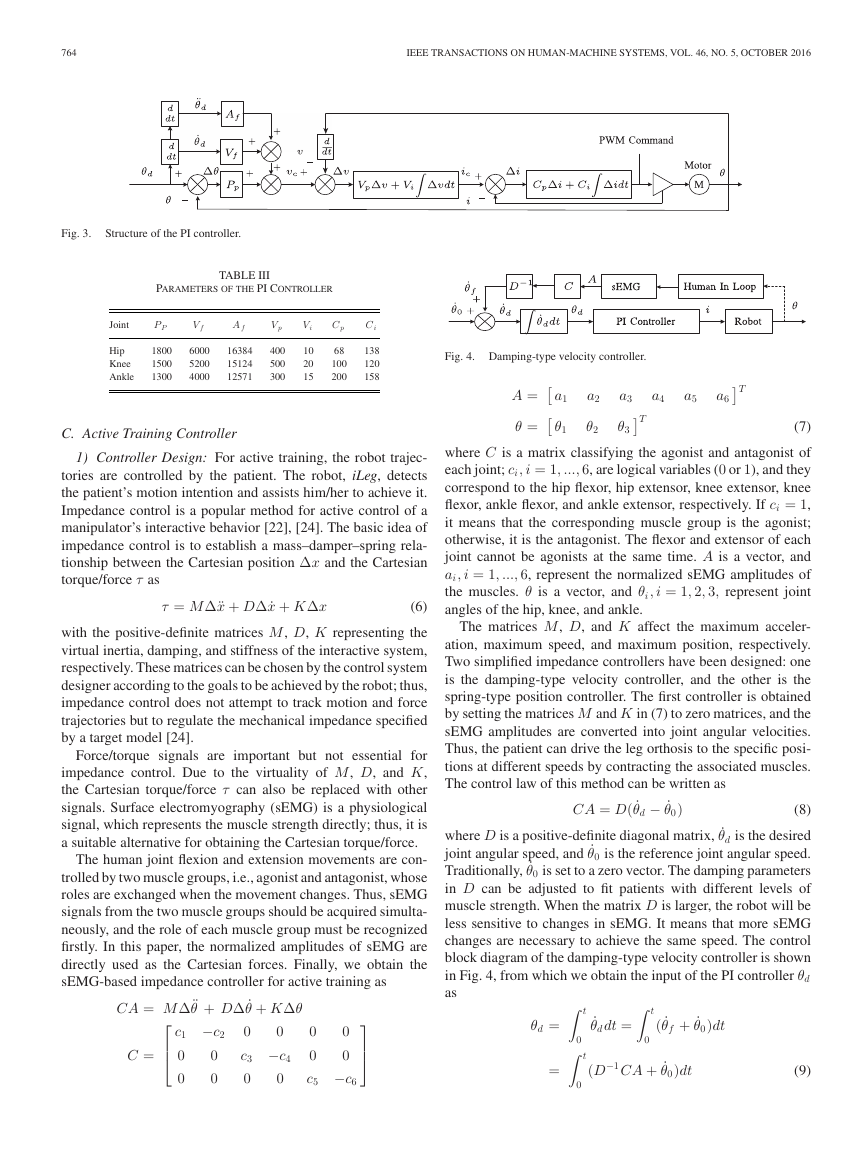

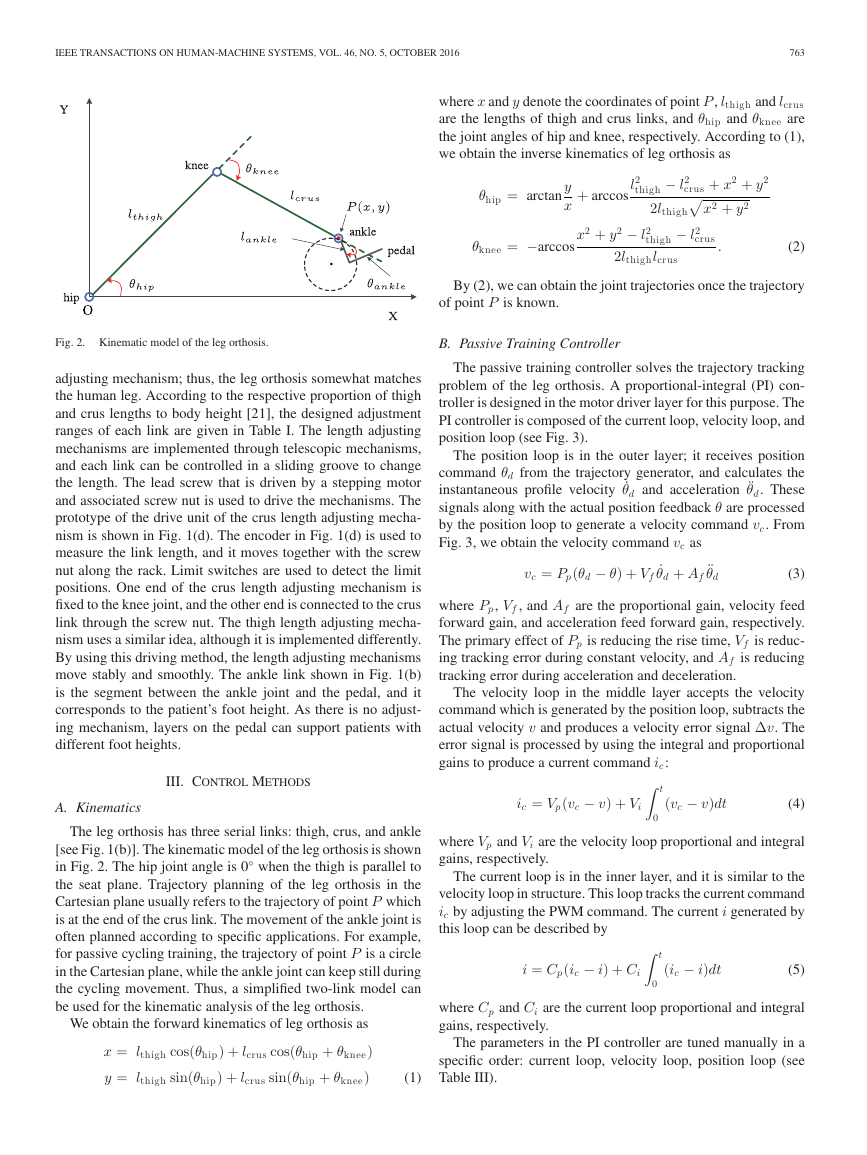

The passive training controller solves the trajectory tracking

problem of the leg orthosis. A proportional-integral (PI) con-

troller is designed in the motor driver layer for this purpose. The

PI controller is composed of the current loop, velocity loop, and

position loop (see Fig. 3).

The position loop is in the outer layer; it receives position

command θd from the trajectory generator, and calculates the

instantaneous profile velocity ˙θd and acceleration ¨θd. These

signals along with the actual position feedback θ are processed

by the position loop to generate a velocity command vc. From

Fig. 3, we obtain the velocity command vc as

˙θd + Af

vc = Pp(θd − θ) + Vf

¨θd

(3)

where Pp, Vf , and Af are the proportional gain, velocity feed

forward gain, and acceleration feed forward gain, respectively.

The primary effect of Pp is reducing the rise time, Vf is reduc-

ing tracking error during constant velocity, and Af is reducing

tracking error during acceleration and deceleration.

The velocity loop in the middle layer accepts the velocity

command which is generated by the position loop, subtracts the

actual velocity v and produces a velocity error signal Δv. The

error signal is processed by using the integral and proportional

gains to produce a current command ic:

ic = Vp(vc − v) + Vi

t

(vc − v)dt

(4)

0

where Vp and Vi are the velocity loop proportional and integral

gains, respectively.

The current loop is in the inner layer, and it is similar to the

velocity loop in structure. This loop tracks the current command

ic by adjusting the PWM command. The current i generated by

this loop can be described by

i = Cp(ic − i) + Ci

0

t

(ic − i)dt

(5)

where Cp and Ci are the current loop proportional and integral

gains, respectively.

The parameters in the PI controller are tuned manually in a

specific order: current loop, velocity loop, position loop (see

Table III).

�

764

IEEE TRANSACTIONS ON HUMAN-MACHINE SYSTEMS, VOL. 46, NO. 5, OCTOBER 2016

Fig. 3.

Structure of the PI controller.

TABLE III

PARAMETERS OF THE PI CONTROLLER

Joint

Hip

Knee

Ankle

P P

V f

A f

1800

1500

1300

6000

5200

4000

16384

15124

12571

V p

400

500

300

V i

10

20

15

C p

C i

68

100

200

138

120

158

C. Active Training Controller

1) Controller Design: For active training, the robot trajec-

tories are controlled by the patient. The robot, iLeg, detects

the patient’s motion intention and assists him/her to achieve it.

Impedance control is a popular method for active control of a

manipulator’s interactive behavior [22], [24]. The basic idea of

impedance control is to establish a mass–damper–spring rela-

tionship between the Cartesian position Δx and the Cartesian

torque/force τ as

τ = MΔ¨x + DΔ ˙x + KΔx

(6)

with the positive-definite matrices M, D, K representing the

virtual inertia, damping, and stiffness of the interactive system,

respectively. These matrices can be chosen by the control system

designer according to the goals to be achieved by the robot; thus,

impedance control does not attempt to track motion and force

trajectories but to regulate the mechanical impedance specified

by a target model [24].

Force/torque signals are important but not essential for

impedance control. Due to the virtuality of M, D, and K,

the Cartesian torque/force τ can also be replaced with other

signals. Surface electromyography (sEMG) is a physiological

signal, which represents the muscle strength directly; thus, it is

a suitable alternative for obtaining the Cartesian torque/force.

The human joint flexion and extension movements are con-

trolled by two muscle groups, i.e., agonist and antagonist, whose

roles are exchanged when the movement changes. Thus, sEMG

signals from the two muscle groups should be acquired simulta-

neously, and the role of each muscle group must be recognized

firstly. In this paper, the normalized amplitudes of sEMG are

directly used as the Cartesian forces. Finally, we obtain the

sEMG-based impedance controller for active training as

CA = MΔ¨θ + DΔ ˙θ + KΔθ

⎡

⎢

⎣

c1 −c2

0

0

0

0

C =

0

0

c3 −c4

0

0

0

0

0

0

c5 −c6

⎤

⎥

⎦

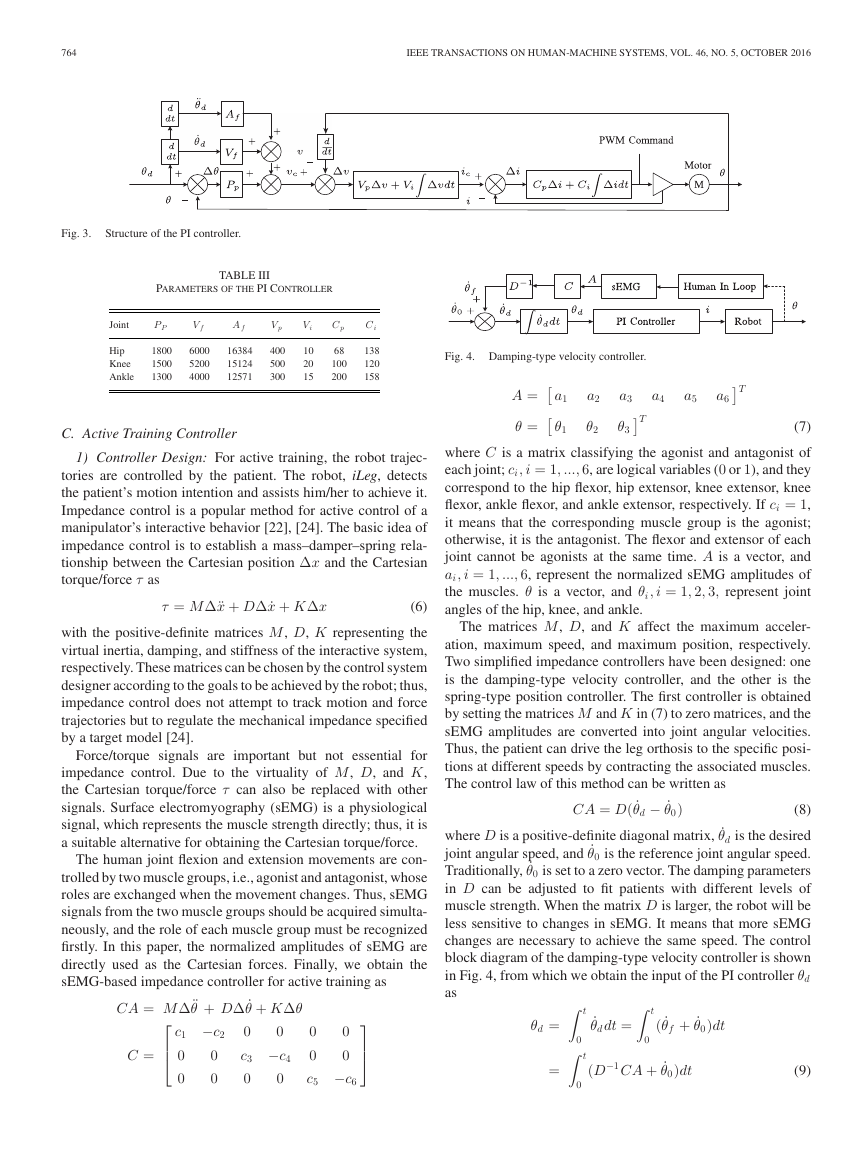

Fig. 4. Damping-type velocity controller.

a1

θ1

A =

θ =

a2

θ2

a3

θ3

T

T

a4

a5

a6

(7)

where C is a matrix classifying the agonist and antagonist of

each joint; ci, i = 1, ..., 6, are logical variables (0 or 1), and they

correspond to the hip flexor, hip extensor, knee extensor, knee

flexor, ankle flexor, and ankle extensor, respectively. If ci = 1,

it means that the corresponding muscle group is the agonist;

otherwise, it is the antagonist. The flexor and extensor of each

joint cannot be agonists at the same time. A is a vector, and

ai, i = 1, ..., 6, represent the normalized sEMG amplitudes of

the muscles. θ is a vector, and θi, i = 1, 2, 3, represent joint

angles of the hip, knee, and ankle.

The matrices M, D, and K affect the maximum acceler-

ation, maximum speed, and maximum position, respectively.

Two simplified impedance controllers have been designed: one

is the damping-type velocity controller, and the other is the

spring-type position controller. The first controller is obtained

by setting the matrices M and K in (7) to zero matrices, and the

sEMG amplitudes are converted into joint angular velocities.

Thus, the patient can drive the leg orthosis to the specific posi-

tions at different speeds by contracting the associated muscles.

The control law of this method can be written as

CA = D( ˙θd − ˙θ0)

(8)

where D is a positive-definite diagonal matrix, ˙θd is the desired

joint angular speed, and ˙θ0 is the reference joint angular speed.

Traditionally, ˙θ0 is set to a zero vector. The damping parameters

in D can be adjusted to fit patients with different levels of

muscle strength. When the matrix D is larger, the robot will be

less sensitive to changes in sEMG. It means that more sEMG

changes are necessary to achieve the same speed. The control

block diagram of the damping-type velocity controller is shown

in Fig. 4, from which we obtain the input of the PI controller θd

as

t

t

θd =

=

0

0

˙θd dt =

0

t

( ˙θf + ˙θ0)dt

−1CA + ˙θ0)dt

(D

(9)

�

IEEE TRANSACTIONS ON HUMAN-MACHINE SYSTEMS, VOL. 46, NO. 5, OCTOBER 2016

765

Fig. 5.

Spring-type position controller.

gi = g(yi) = g

⎝

Each perceptron has three inputs: sEMG amplitudes of the

corresponding flexor and extensor, and the threshold value

bi, i = 1, 2, 3. The output of each perceptron can be written

as

⎛

2i

j=2i−1

⎞

wj aj + bi

⎠

⎛

⎝sgn

⎛

⎝

2i

j=2i−1

⎞

⎠ + 1

⎞

⎠

wj aj + bi

=

1

2

1,

0,

yi > 0

yi ≤ 0,

=

(12)

The following two linear functions f1(·) and f2(·) are used

to obtain the outputs of the network:

i = 1, 2, 3.

Fig. 6.

Structure of the neural network.

where ˙θf is the speed command generated by the sEMG signals.

Similarly, the second controller is obtained by setting the

matrices M and D in (7) to zero matrices, and the sEMG ampli-

tudes are converted into joint angles. There is a reference angle

for each joint. The orthosis deviates from the reference angle

when the subject contracts the relevant muscles, and the orthosis

moves back to the reference angle when the relevant muscles

are relaxed. The leg orthosis works like a spring, and the control

law of this method can be written as

CA = K(θd − θ0)

(10)

where K is a positive-definite diagonal matrix, θd is the desired

joint angle, and θ0 is the reference joint angle. The stiffness

parameters in K can be adjusted to fit patients with different

levels of muscle strength. Similarly, when the matrix K is larger,

the robot will be less sensitive to changes in sEMG. It means

that more sEMG changes are necessary to achieve the same

difference between θd and θ0. The control block diagram of the

spring-type position controller is shown in Fig. 5. According to

Fig. 5 and (10), we obtain the input of the PI controller θd as

θd = θf + θ0 = K

−1CA + θ0

(11)

where θf is the error between θd and θ0, which is generated by

the sEMG signals.

The patient is in loop of the controllers, and he/she can control

the position or velocity of the leg orthosis voluntarily by con-

tracting the agonists (see Figs. 4 and 5). Both controllers can

motivate the patient to actively participate in the rehabilitation

by setting appropriate training goals.

2) Agonist Recognition: Since the movements of the leg or-

thosis are controlled by sEMG from the agonists, the agonist

recognition, namely computation of the matrix C in (7)–(11)

must be completed first. Considering the independence of the

joint movements, a neural network (see Fig. 6) that consists of

three perceptrons with the same structure is designed for the

agonist recognition.

f1(x) = x,

f2(x) = 1 − x,

x = 0, 1

x = 0, 1.

(13)

IV. PROOF-OF-CONCEPT PROTOTYPE EVALUATION

A proof-of-conceptual prototype evaluation was conducted

with an able-bodied 30-year-old 175-cm-tall male. The study

was approved by the Institutional Review Board of China Re-

habilitation Center (Beijing, China). The experiments include

passive training and active training, and all were conducted un-

der the guidance of physician.

A. Passive Training

The purpose of passive training evaluation is to test the trajec-

tory tracking performance of the PI controller. Because cycling

training can dramatically improve aerobic capacity and func-

tional performance of stroke patients [25], [26], the leg orthosis

is controlled to follow a predefined cycling movement in this

experiment.

For cycling movement, the trajectory of point P (x, y), shown

in Fig. 2, is a circle, which can be described as

x = xc + r cos (ωt)

y = yc + r sin (ωt)

(14)

with (xc, yc) the center’s coordinates, r the radius, and ω the

◦

between

angular velocity. There is a phase difference of 180

two leg orthoses.

By substituting (14) into (2), we can obtain trajectories of

the hip and knee joints. The trajectory of ankle joint is planned

as that of the hip, except that the amplitude is reduced by half.

Such planning can result in the ankle flexion when the ankle

approaches the hip, and ankle extension when the ankle leaves

the hip.

The thigh and crus links lengths were adjusted to the subject’s

height, in this case, lthigh = 48 cm, lcrus = 42 cm. In this ex-

periment, (xc , yc) = (65, 0) cm, r = 15 cm, and ω = −0.5 π/s.

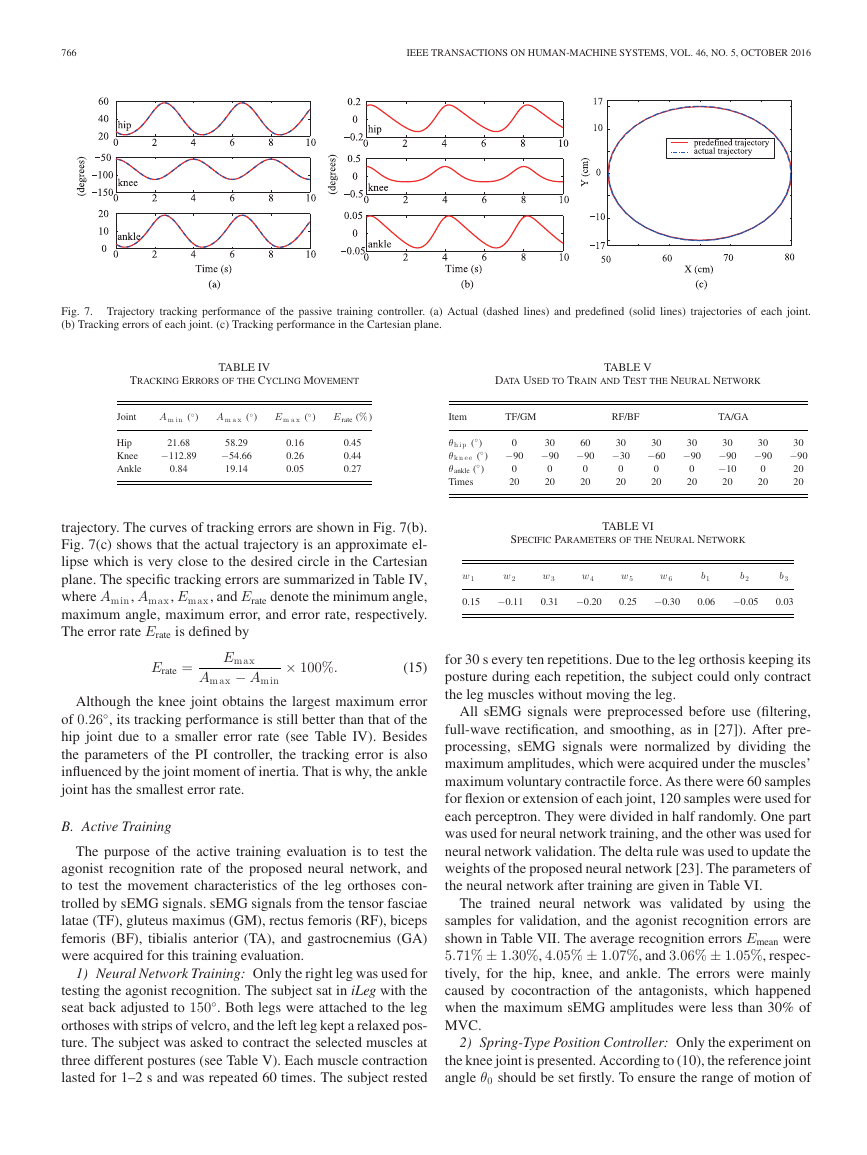

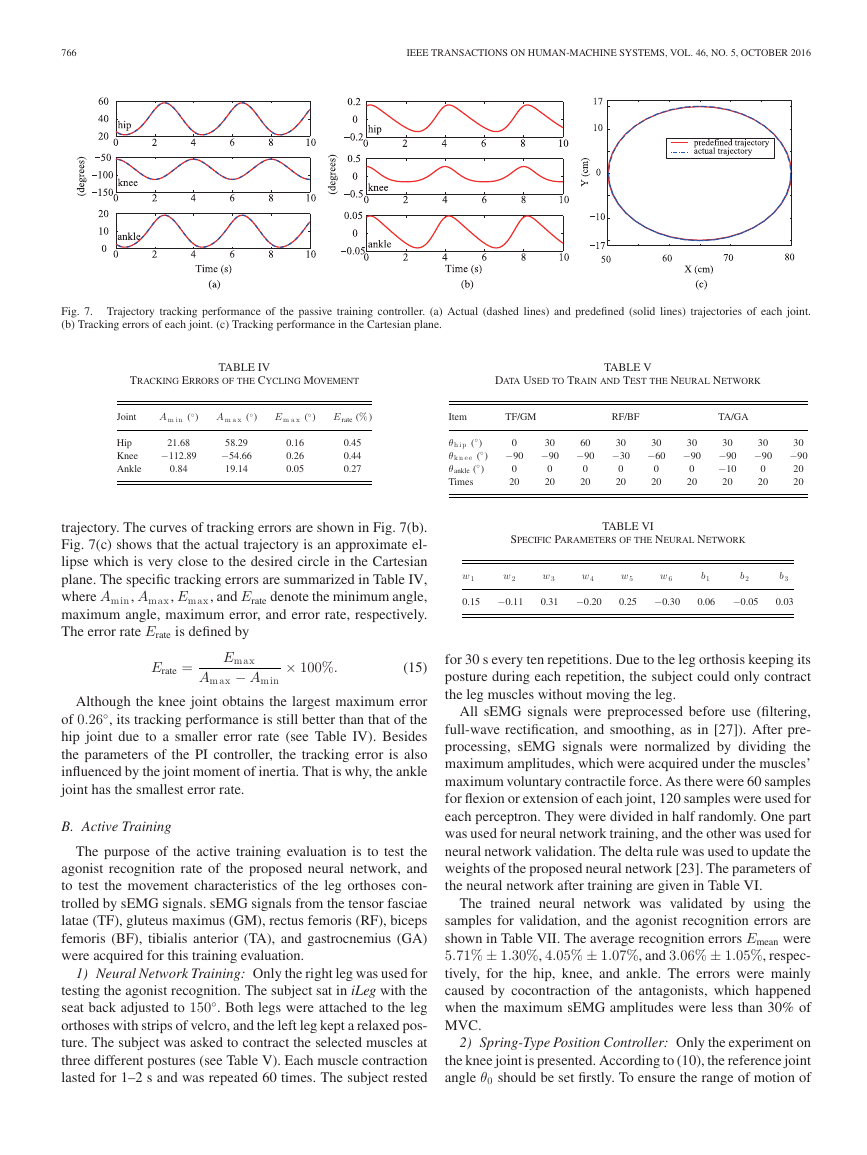

Trajectory tracking performance is summarized in Fig. 7. The

predefined and actual trajectories of each joint are shown in

Fig. 7(a); each joint moves smoothly and follows the predefined

�

766

IEEE TRANSACTIONS ON HUMAN-MACHINE SYSTEMS, VOL. 46, NO. 5, OCTOBER 2016

Fig. 7. Trajectory tracking performance of the passive training controller. (a) Actual (dashed lines) and predefined (solid lines) trajectories of each joint.

(b) Tracking errors of each joint. (c) Tracking performance in the Cartesian plane.

TRACKING ERRORS OF THE CYCLING MOVEMENT

DATA USED TO TRAIN AND TEST THE NEURAL NETWORK

TABLE IV

TABLE V

Joint

Hip

Knee

Ankle

◦

A m i n (

)

◦

A m a x (

)

◦

E m a x (

)

E rate (%)

21.68

−112.89

0.84

58.29

−54.66

19.14

0.16

0.26

0.05

0.45

0.44

0.27

Item

TF/GM

RF/BF

TA/GA

◦

)

θh i p (

◦

θk n e e (

◦

θankle (

Times

)

)

0

−90

0

20

30

−90

0

20

60

−90

0

20

30

−30

0

20

30

−60

0

20

30

−90

0

20

30

−90

−10

20

30

−90

0

20

30

−90

20

20

trajectory. The curves of tracking errors are shown in Fig. 7(b).

Fig. 7(c) shows that the actual trajectory is an approximate el-

lipse which is very close to the desired circle in the Cartesian

plane. The specific tracking errors are summarized in Table IV,

where Amin, Amax, Emax, and Erate denote the minimum angle,

maximum angle, maximum error, and error rate, respectively.

The error rate Erate is defined by

Erate =

Emax

Amax − Amin

× 100%.

(15)

Although the knee joint obtains the largest maximum error

of 0.26◦

, its tracking performance is still better than that of the

hip joint due to a smaller error rate (see Table IV). Besides

the parameters of the PI controller, the tracking error is also

influenced by the joint moment of inertia. That is why, the ankle

joint has the smallest error rate.

B. Active Training

The purpose of the active training evaluation is to test the

agonist recognition rate of the proposed neural network, and

to test the movement characteristics of the leg orthoses con-

trolled by sEMG signals. sEMG signals from the tensor fasciae

latae (TF), gluteus maximus (GM), rectus femoris (RF), biceps

femoris (BF), tibialis anterior (TA), and gastrocnemius (GA)

were acquired for this training evaluation.

1) Neural Network Training: Only the right leg was used for

testing the agonist recognition. The subject sat in iLeg with the

seat back adjusted to 150◦

. Both legs were attached to the leg

orthoses with strips of velcro, and the left leg kept a relaxed pos-

ture. The subject was asked to contract the selected muscles at

three different postures (see Table V). Each muscle contraction

lasted for 1–2 s and was repeated 60 times. The subject rested

SPECIFIC PARAMETERS OF THE NEURAL NETWORK

TABLE VI

w 1

0.15

w 2

−0.11

w 3

0.31

w 4

−0.20

w 5

0.25

w 6

−0.30

b1

0.06

b2

−0.05

b3

0.03

for 30 s every ten repetitions. Due to the leg orthosis keeping its

posture during each repetition, the subject could only contract

the leg muscles without moving the leg.

All sEMG signals were preprocessed before use (filtering,

full-wave rectification, and smoothing, as in [27]). After pre-

processing, sEMG signals were normalized by dividing the

maximum amplitudes, which were acquired under the muscles’

maximum voluntary contractile force. As there were 60 samples

for flexion or extension of each joint, 120 samples were used for

each perceptron. They were divided in half randomly. One part

was used for neural network training, and the other was used for

neural network validation. The delta rule was used to update the

weights of the proposed neural network [23]. The parameters of

the neural network after training are given in Table VI.

The trained neural network was validated by using the

samples for validation, and the agonist recognition errors are

shown in Table VII. The average recognition errors Emean were

5.71% ± 1.30%, 4.05% ± 1.07%, and 3.06% ± 1.05%, respec-

tively, for the hip, knee, and ankle. The errors were mainly

caused by cocontraction of the antagonists, which happened

when the maximum sEMG amplitudes were less than 30% of

MVC.

2) Spring-Type Position Controller: Only the experiment on

the knee joint is presented. According to (10), the reference joint

angle θ0 should be set firstly. To ensure the range of motion of

�

IEEE TRANSACTIONS ON HUMAN-MACHINE SYSTEMS, VOL. 46, NO. 5, OCTOBER 2016

767

TABLE VII

AGONIST RECOGNITION ERROR

Joint

Posture 1 (%)

Posture 2 (%)

Posture 3 (%)

Hip

Knee

Ankle

7.15

5.26

3.52

5.36

3.65

3.80

4.62

3.23

1.85

E mean (%)

5.71 ± 1.30

4.05 ± 1.07

3.06 ± 1.05

Fig. 9. Results of the damping-type velocity controller. (a) sEMG amplitudes

of RF. (b) sEMG amplitudes of BF. (c) Knee joint angles of the leg orthosis.

to the matrix K and sEMG changes. The response time is always

less than 1/fc. If the current movement is not finished in 1/fc,

the controller will stop it and start the next loop.

Fig. 8. Results of the spring-type position controller. (a) sEMG amplitudes of

RF. (b) sEMG amplitudes of BF. (c) Knee joint angles of the leg orthosis.

the knee joint in both directions, it is better to set θ0 near the

middle of the knee joint. In this experiment, θ0 = −46◦

, which

means that the knee joint will remain in this position unless

the agonists are activated. Due to normalization of the sEMG

amplitudes, each element of vector A in (10) is between 0 and

1; thus, the maximum angle from the reference joint angle is

determined by the matrix K. When tuning K, we need to make

sure that θd in (11) is in the range of motion of the leg orthosis.

In this experiment, K = 0.04, which means that the maximum

angle deviation from the reference joint angle is K

−1 = 25◦

.

The results are shown in Fig. 8. At t0, the RF was recognized

as the agonist. The knee began to extend, and the extension

movement led to the increase of the joint angle. At t1, the sEMG

amplitude of RF reached the maximum value. The extension

movement did not stop until t2 because the desired joint angle

was always larger than the current joint angle between t1 and

t2. After t2, the knee began to move toward the reference angle

due to the decrease of the sEMG amplitude of RF. Similarly, at

t3, the BF was recognized as the agonist, and the knee began

to flex. Although the sEMG amplitude of BF began to decrease

after t4, the flexion movement did not stop until t5. After t5, the

knee joint moved toward the reference angle when the sEMG

amplitude of BF continued to decrease.

Fig. 8 shows that there is a delay of about 0.3 s between the

control signals and the desired joint angle of the leg orthosis.

The delay is mainly caused by the control loop rate fc and the

response time of the leg orthosis. The control loop rate is also the

rate that the controller processes the sEMG signals. Due to the

instability of sEMG signals, the leg orthosis tends to oscillate if

the loop rate is too high. When tuning the loop rate, we should

consider the tradeoff between the delay and oscillation. In this

experiment, we get a feasible fixed loop rate of 6.67 Hz after

repeated tests. The response time is also the time that the leg

orthosis would take to finish the movement. Thus, it is relevant

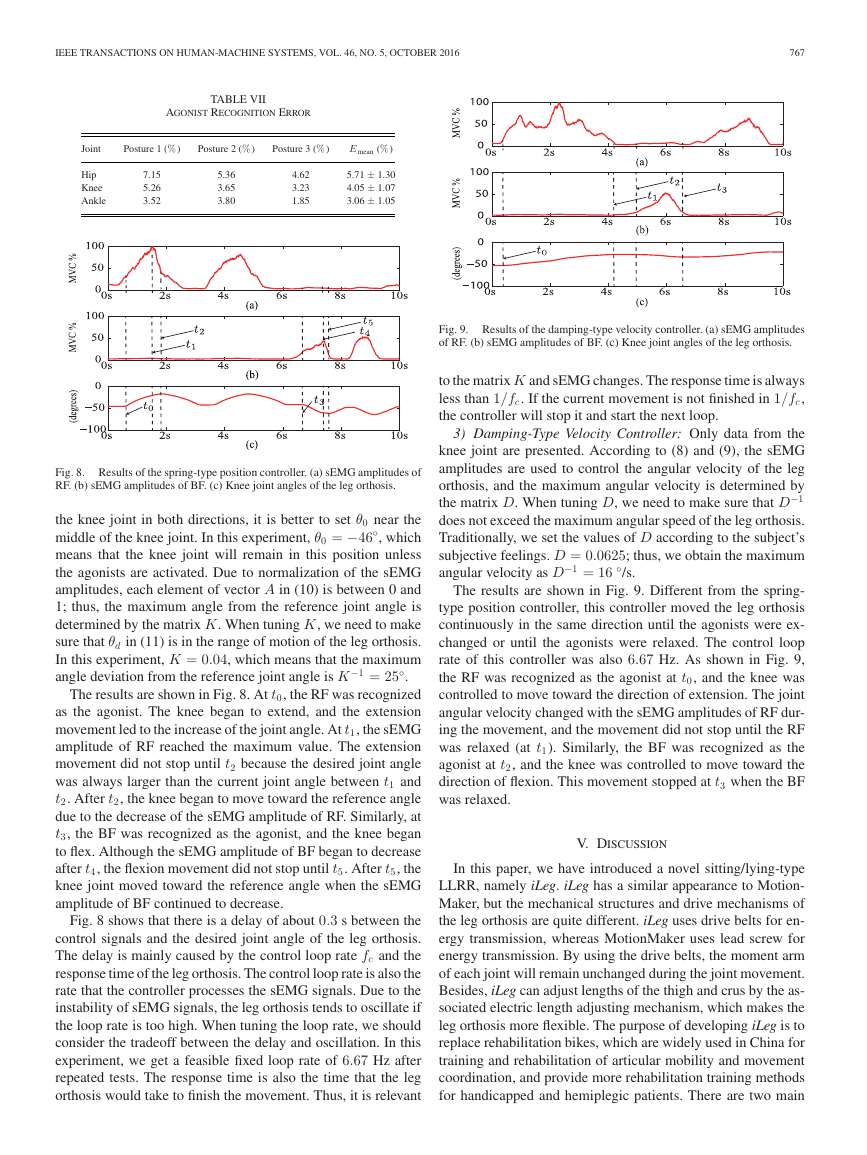

3) Damping-Type Velocity Controller: Only data from the

knee joint are presented. According to (8) and (9), the sEMG

amplitudes are used to control the angular velocity of the leg

orthosis, and the maximum angular velocity is determined by

−1

the matrix D. When tuning D, we need to make sure that D

does not exceed the maximum angular speed of the leg orthosis.

Traditionally, we set the values of D according to the subject’s

subjective feelings. D = 0.0625; thus, we obtain the maximum

angular velocity as D

−1 = 16 ◦

/s.

The results are shown in Fig. 9. Different from the spring-

type position controller, this controller moved the leg orthosis

continuously in the same direction until the agonists were ex-

changed or until the agonists were relaxed. The control loop

rate of this controller was also 6.67 Hz. As shown in Fig. 9,

the RF was recognized as the agonist at t0, and the knee was

controlled to move toward the direction of extension. The joint

angular velocity changed with the sEMG amplitudes of RF dur-

ing the movement, and the movement did not stop until the RF

was relaxed (at t1). Similarly, the BF was recognized as the

agonist at t2, and the knee was controlled to move toward the

direction of flexion. This movement stopped at t3 when the BF

was relaxed.

V. DISCUSSION

In this paper, we have introduced a novel sitting/lying-type

LLRR, namely iLeg. iLeg has a similar appearance to Motion-

Maker, but the mechanical structures and drive mechanisms of

the leg orthosis are quite different. iLeg uses drive belts for en-

ergy transmission, whereas MotionMaker uses lead screw for

energy transmission. By using the drive belts, the moment arm

of each joint will remain unchanged during the joint movement.

Besides, iLeg can adjust lengths of the thigh and crus by the as-

sociated electric length adjusting mechanism, which makes the

leg orthosis more flexible. The purpose of developing iLeg is to

replace rehabilitation bikes, which are widely used in China for

training and rehabilitation of articular mobility and movement

coordination, and provide more rehabilitation training methods

for handicapped and hemiplegic patients. There are two main

�

768

IEEE TRANSACTIONS ON HUMAN-MACHINE SYSTEMS, VOL. 46, NO. 5, OCTOBER 2016

differences between iLeg and the current popular LLRRs. One

is the novel mechanism design, and the other is the passive and

active training control methods. Thus, iLeg has not only all the

functions of a rehabilitation bike, but also can provide sEMG-

based active rehabilitation training methods. Because China has

the largest population in the world, iLeg is expected to be widely

used in China.

Compared with the standing/walking-type LLRRs, such as

the Lokomat or LOPES, the training trajectories of iLeg are

more diverse, such as cycling movement. This novel system

may help patients perform uniarticular training, which provides

convenience for targeted joint rehabilitation, such as foot drop.

The sEMG-based impedance controllers detect not only the

subject’s movement intention, but also voluntary participation,

which may encourage a patient to move his/her legs. Compared

to existing techniques, the active training controllers proposed

in this paper do not need the user to remember the relationship

between the muscle contraction and the motion. Moreover, since

the position or velocity of the leg orthosis is determined by the

sEMG amplitudes, the user may try his/her best to contract

the muscles to generate strong sEMG amplitudes during each

rehabilitation session. Such voluntary participation could make

the rehabilitation training more effective.

Muscle spasm should be considered seriously during active

rehabilitation. The sEMG should be treated as abnormal signal

when muscle spasm happens, and the controllers should stop

iLeg immediately to avoid secondary damage to the subject.

Although studies have suggested that substantial motor control

information can be extracted from paretic muscles of stroke

survivors by EMG signals [19], there are still many challenges

when impaired subjects try and use iLeg. People with stroke

and SCI typically are weak and have relatively small EMG

amplitudes and abnormal muscle coordination patterns that may

make it difficult for them to control iLeg. To deal with these

challenges, we should focus on two aspects. One is choosing the

appropriate EMG signals that can describe the motion intention

of patients, and the other is improving the motion intention

recognition algorithm. In our future work, we will focus on the

clinical validation of this system.

ACKNOWLEDGMENT

The authors are grateful to Dr. Y. Hong, J. Zhang, and Z. Lu with the

China Rehabilitation Research Center, Beijing, China, for providing

suggestions.

REFERENCES

[1] G. Yan, H. Shen, X. Zhao, Q. Wei, Y. Kang, Z. Jia, L. Song, and M. Huang,

“Effects of treadmill training on ADL of convalescent stroke patients,”

Chin. J. Rehabil., vol. 22, no. 3, pp. 163–164, 2007.

[2] C. Schmitt, P. M´etrailler, A. Al-Khodairy, R. Brodard, J. Fournier,

M. Bouri, and R. Clavel, “The Motion MakerTM: A rehabilitation system

combining an orthosis with closed-loop electrical muscle stimulation,” in

Proc. 8th Vienna Int. Workshop Funct. Elect. Stimul., Vienna, Austria,

2004, pp. 117–120.

[3] M. A. Maestro, A. E. Ruz, R. M. Casado-Lopez, A. M. Gonzalez,

G. P. Mateos, E. G. Valdizan, and J. L. Martin, “Lokomat robotic-assisted

versus overground training within 3 to 6 months of incomplete spinal

cord lesion: Randomized controlled trial,” Neuralrehabil. Neural Repair,

vol. 26, no. 9, pp. 1058–1063, 2012.

[4] J. F. Veneman, R. Kruidhof, E. E. G. Hekman, R. Ekkelenkamp, E. H.

F. van Asseldonk, and H. van der Kooij, “Design and evaluation of the

LOPES exoskeleton robot for interactive gait rehabilitation,” IEEE Trans.

Neural Syst. Rehabil. Eng., vol. 15, no. 3, pp. 379–386, Sep. 2007.

[5] S. Freivogel, J. Mehrholz, T. Husak-Sotomayor, and D. Schmalohr, “Gait

training with the newly developed ‘LokoHelp’-system is feasible for non-

ambulatory patients after stroke, spinal cord and brain injury: A feasibility

study, Brain Injury, vol. 22, nos. 7/8, pp. 625–632, 2008.

[6] G. R. West, “Powered gait orthosis and method of utilizing same,” Patent

6 689 075, 2004.

[7] S. Hesse, C. Werner, D. Uhlenbrock, S. Frankenberg, A. Bardeleben, and

B. Brandl-Hesse, “An electromechanical gait trainer for restoration of gait

in hemiparetic stroke patients: Preliminary results,” Neurorehabil. Neural

Repair, vol. 15, no. 1, pp. 39–50, 2001.

[8] H. Schmidt, “HapticWalker—A novel haptic device for walking simula-

tion,” in Proc. EuroHaptics, Munich Germany, 2004, pp. 66–70.

[9] Y. Stauffer, Y. Allemand, M. Bouri, J. Fournier, R. Clavel, P. Metrailler,

R. Brodard, and F. Reynard, “The WalkTrainer—A new generation of

walking reeducation device combining orthoses and muscle stimulation,”

IEEE Trans. Neural Syst. Rehabil. Eng., vol. 17, no. 1, pp. 38–45, Feb.

2009.

[10] E. Strickland, “Good-bye, wheelchair,” IEEE Spectr., vol. 49, no. 1,

pp. 30–32, Jan. 2012.

[11] Rex Bionics REX web site, 2014. [Online]. Available: http://www.

rexbionics.com

[12] A. Tsukahara, R. Kawanishi, Y. Hasegawa, and Y. Sankai, “Sit-to-stand

and stand-to-sit transfer support for complete paraplegic patients with

robot suit HAL,” Adv. Robot., vol. 24, no. 11, pp. 1615–1638, 2010.

[13] Argo Medical Technologies ReWalk web site, 2014. [Online]. Available:

http://www.argomedtec.com

[14] B. H. Dobkin and P. W. Duncan, “Should body weight-supported treadmill

training and robotic-assistive steppers for locomotor training trot back to

the starting gate?” Neurorehabil. Neural Repair, vol. 26, no. 4, pp. 308–

317, 2012.

[15] S. Freivoqel, D. Schmalohr, and J. Mehrholz, “Improved walking ability

and reduced therapeutic stress with an electromechanical gait device,” J.

Rehabil. Med., vol. 41, no. 9, pp. 734–739, 2009.

[16] P. Metrailler

et al., “Improvement of rehabilitation possibilities with

the MotionMakerTM,” in Proc. 1st IEEE/RAS-EMBS Int. Conf. Biomed.

Robot. Biomechatron., 2006, pp. 359–364.

[17] M. Lotze, C. Braun, N. Birbaumer, S. Anders, and L. G. Cohen, “Mo-

tor learning elicited by voluntary drive,” Brain, vol. 126, pp. 866–872,

2003.

[18] D. Leonardis et al., “An EMG-controlled robotic hand exoskeleton for

bilateral rehabilitation,” IEEE Trans. Haptics, vol. 8, no. 2, pp. 140–151,

Apr.–Jun. 2015.

[19] X. Zhang and P. Zhou, “High-density myoelectric pattern recogni-

tion toward improved stroke rehabilitation,” IEEE Trans. Biomed. Eng.,

vol. 59, no. 6, pp. 1649–1657, Jun. 2012.

[20] A. Roaas and G. B. J. Andersson, “Normal range of motion of the hip, knee

and ankle joints in male subjects, 30–40 years of age,” Acta Orthopaedica

Scandinavica, vol. 53, pp. 205–208, 1982

[21] Y-C. Lin, M-J. J. Wang, and E. M. Wang, “The comparisons of anthropo-

metric characteristics among four peoples in East Asia,” Appl. Ergonom.,

vol. 35, no. 2, pp. 173–178, 2004.

[22] N. Hogan, “Impedance control: An approach to manipulation: Parts I-III,”

J. Dyn. Syst. Meas. Control, vol. 107, no. 1, pp. 1–24, 1985.

[23] B. Widrow and M. E. Hoff, “Adaptive switching circuits,” in Proc. IRE

WESCON Convention Rec., 1960, pp. 96–104.

[24] C. C. Cheah and D. Wang, “Learning impedance control for robotic ma-

nipulators,” IEEE Trans. Robot. Autom., vol. 14, no. 3, pp. 452–465, Jun.

1998.

[25] K. L. Michal, “The influence of early cycling training on balance in

stroke patients at the subacute stage: Results of a preliminary trial,” Clin.

Rehabil., vol. 20, no. 5, pp. 398–405, 2006.

[26] W. J. Thomas, J. M. Beltman, P. Elich, P. A. Koppe, H. Konijnenbelt,

A. de Haan, and K. H. Gerrits, “Effects of electric stimulation-assisted

cycling training in people with chronic stroke,” Arch. Phys. Med. Rehabil.,

vol. 89, no. 3, pp. 463–469, 2008.

[27] F. Zhang, P. Li, Z.-G. Hou, Z. Lu, Y. Chen, Q. Li, and M. Tan, “sEMG-

based continuous estimation of joint angles of human legs by using

BP neural network,” Neurocomputing, vol. 78, no. 1, pp. 139–148,

2012.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc