Understanding And Using

PMBus™ Data Formats

Robert V. White

bob.white@ieee.org

Daniel Durant

dan.durant@artesyn.com

Artesyn Technologies

1401 West 122nd Avenue, Suite 180

Westminster, Colorado 80234, USA

and

supply

Abstract—The Power Management Bus (PMBus™) in an open

standard protocol for power system management that was

introduced in 2005. The reception has been enthusiastic with

adoption by both power

semiconductor

manufacturers. A key part of the specification, which took more

than 250 person-hours to define, is the formats for sending and

receiving data to and from a PMBus device. One format, called

the Literal Format, exchanges data in user friendly units like

volts and amperes. This format uses a floating-point like format

with an eleven bit signed mantissa and a five bit signed exponent.

The Literal Format minimizes the burden on the host or master

device at the expense of greater complexity in the PMBus device.

The Direct Format provides an alternative that minimizes or

eliminates the computation in the PMBus device at the expense of

more bus communication and being more computation intensive

for the host or master device. This paper explores both formats,

showing examples of how data is exchanged with PMBus devices.

Particular attention is paid to the Direct Format, including a

rigorous derivation of the equations needed to define the

coefficients of the equation used by the host to encode and decode

information exchanged with PMBus devices.

I.

INTRODUCTION

for

language

configuring,

The PMBus™ is an open standard protocol for power

system management. It defines both the transport (how to get

the bits and bytes to and from a PMBus device) and a

command

controlling and

monitoring PMBus devices [1][2]. The PMBus can be used to

configure, control and monitor a wide variety of power

converters and other devices. One of the goals of the PMBus

Specification Working Group was to create a standard that

could be used with isolated dc-dc converters, point-of-load

converters, microprocessor powering VRMs and offline ac-dc

power supplies.

The wide range of voltages, current and temperatures in

these devices was a major problem for the Working Group. It

was important to find the fewest possible data formats that

could represent values over six orders of magnitude and with

resolution requirements for some applications as tight as

0.025%.

II. CONVENTIONS

Before proceeding with the discussion, it will be helpful to

establish the conventions used in this paper, which are the

same as those used in the PMBus specifications.

First, all PMBus commands are in all capital letters. An

example: VOUT_COMMAND.

MSB always means “most significant bit” and LSB always

means “least significant bit.” In any diagram of a byte or

bytes, the LSB will always be on the right and the MSB will

always be to the left.

Numbers are generally presumed decimal unless otherwise

indicated or obvious from context. For example, the string

1101001101 is assumed to be binary. Binary numbers are

indicted by a suffix of the letter “b” (Example: 11000b).

Explicitly decimal numbers have a suffix of “d” (Example:

100d for the decimal value one hundred.).

III. PMBUS COMMANDS

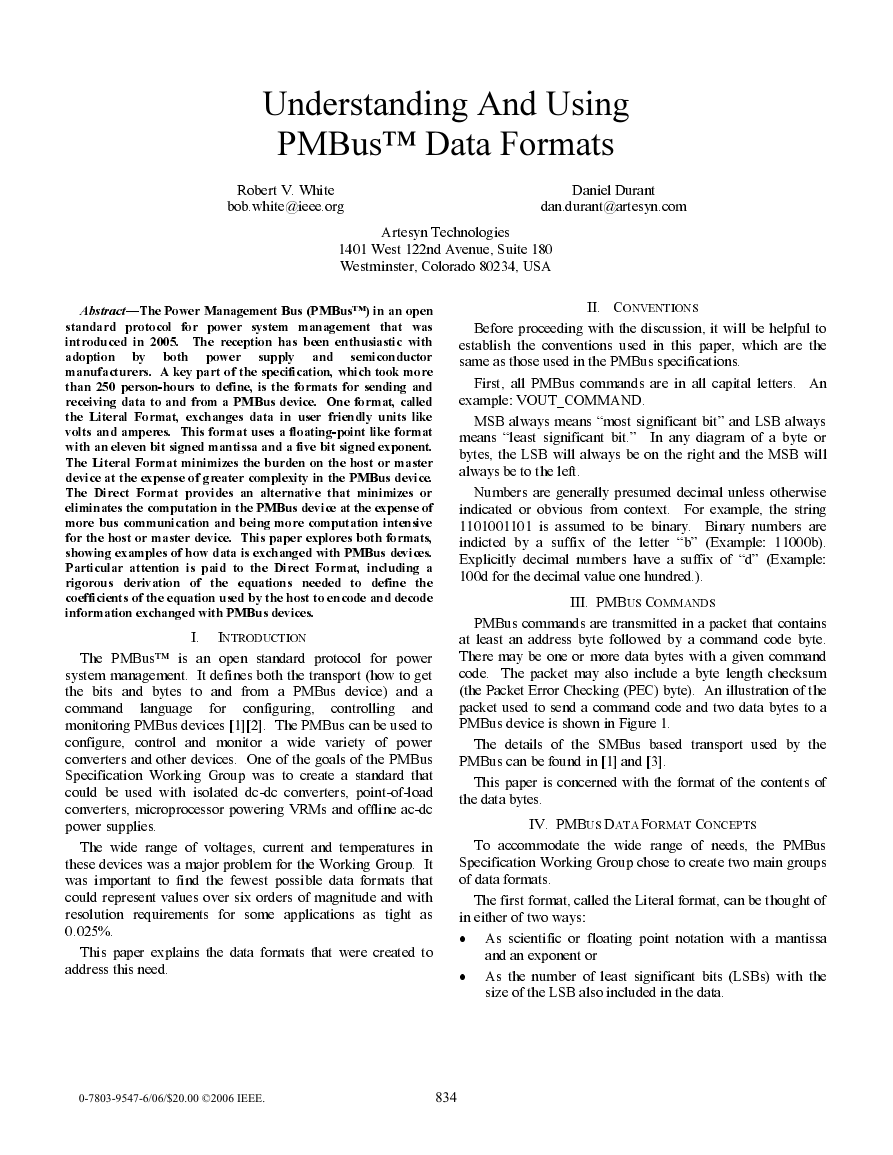

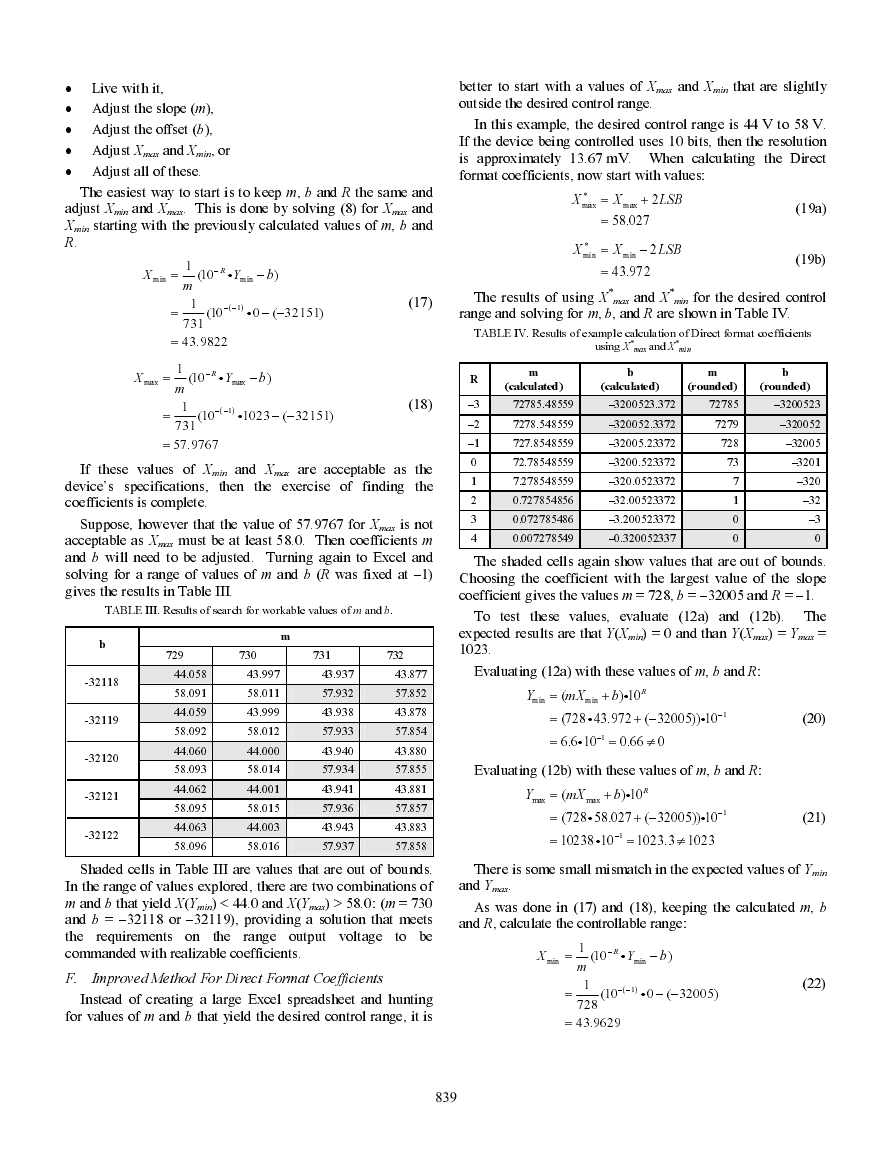

PMBus commands are transmitted in a packet that contains

at least an address byte followed by a command code byte.

There may be one or more data bytes with a given command

code. The packet may also include a byte length checksum

(the Packet Error Checking (PEC) byte). An illustration of the

packet used to send a command code and two data bytes to a

PMBus device is shown in Figure 1.

The details of the SMBus based transport used by the

PMBus can be found in [1] and [3].

This paper is concerned with the format of the contents of

the data bytes.

IV. PMBUS DATA FORMAT CONCEPTS

To accommodate the wide range of needs, the PMBus

Specification Working Group chose to create two main groups

of data formats.

The first format, called the Literal format, can be thought of

in either of two ways:

•

As scientific or floating point notation with a mantissa

This paper explains the data formats that were created to

and an exponent or

address this need.

•

As the number of least significant bits (LSBs) with the

size of the LSB also included in the data.

0-7803-9547-6/06/$20.00 ©2006 IEEE.

834

�

Address Byte

Command Code

S 7 6 5 4 3 2 1

W

r

A 7 6 5 4 3 2 1 0 A

Data Byte Low

Data Byte High

7 6 5 4 3 2 1 0 A 7 6 5 4 3 2 1 0 A

Optional PEC Byte

7 6 5 4 3 2 1 0

A

P

S

A

START Condition

From Host To Device

Acknowledge (ACK)

From Device To Host

W

r

P

Read/Write Bit

Set For Write (0)

STOP Condition

From Host To Device

Figure 1. PMBus Packet Construction

The Literal format allows the host to send values that are

independent of the PMBus device implementation, such as 3.3

to command an output voltage.

The other format is the Direct format. Direct format data

can be thought of as “raw” and in the native format of the

PMBus device. For example, the output voltage is not

commanded by sending a value such as 3.3 but a binary value

corresponding to a value between the minimum and maximum

rated output voltages.

The Literal and Direct formats are explained in depth

below.

The Working Group also created variations of each format

depending on whether or not the data was related to setting the

output voltage (or a related parameter such as the output

overvoltage fault limit) or not. The data formats for the output

voltage related commands were given the ability to command

a much smaller resolution. In addition, there is a mode for

output voltage related commands that sends the manufacturer

specified VID code for specified microprocessors.

This gives a total of five different ways that data can be

formatted for a PMBus device. The Working Group struggled

with this more than any other topic and decided this was the

minimum possible to cover all the desired applications and the

needs of those applications.

V. SETTING THE OUTPUT VOLTAGE

The output voltage of a PMBus device is set in two steps.

The first step uses the VOUT_MODE command to tell the

device the format of the output voltage related commands that

will be used to send commands to the device. This is usually

only done once or as needed. PMBus devices may also be

manufactured so that they accept output voltage and output

voltage related commands in one or a fixed subset of the

possible VOUT_MODE values.

The second command, VOUT_COMMAND, sends the

actual value. The data bytes for VOUT_COMMAND are a

sixteen bit unsigned binary integer. The output voltage

command instructs the device to set the voltage between the

positive and negative output terminals. Whether these

terminals are connected to ground to make a positive voltage

output, connected to make a negative voltage output, or left

flowing do not matter when commanding the output voltage.

More information on setting the output voltage and output

voltage related parameters can be found in Part II of the

PMBus Specification [2][4].

VI. GENERAL PURPOSE LITERAL FORMAT

The general purpose Literal format [2][4], as mentioned

above, can be thought of as a floating point number. The

mantissa, Y, is an eleven bit two’s complement binary integer.

The exponent, N, is a five bit two’s complement binary

integer. The value to be transmitted over the bus, X is

represented as:

X = Y · 2N

(1)

The combination of an eleven bit signed mantissa and a five

bit signed exponent allows for a wide range of values with

excellent resolution. The range of the values that can be

represented using the PMBus general purpose Literal format is

shown in Table I.

TABLE I. Range of values for Literal format data

Maximum Positive

Minimum Value

Maximum Negative

33.52 × 106

(1023 × 215)

±15.26 × 10–6

(±1 × 2-16)

–33.55 × 106

(–1024 × 215)

Another way of thinking of the Literal format is as a

combination of the number of LSBs (Y) and the size of the

LSB (2N). For example, if N = –10, 2N = 977 × 10–6, or about

1 mV/bit. The value of 3.3 could then be thought of as 3,379

LSBs, where each LSB = 2–10.

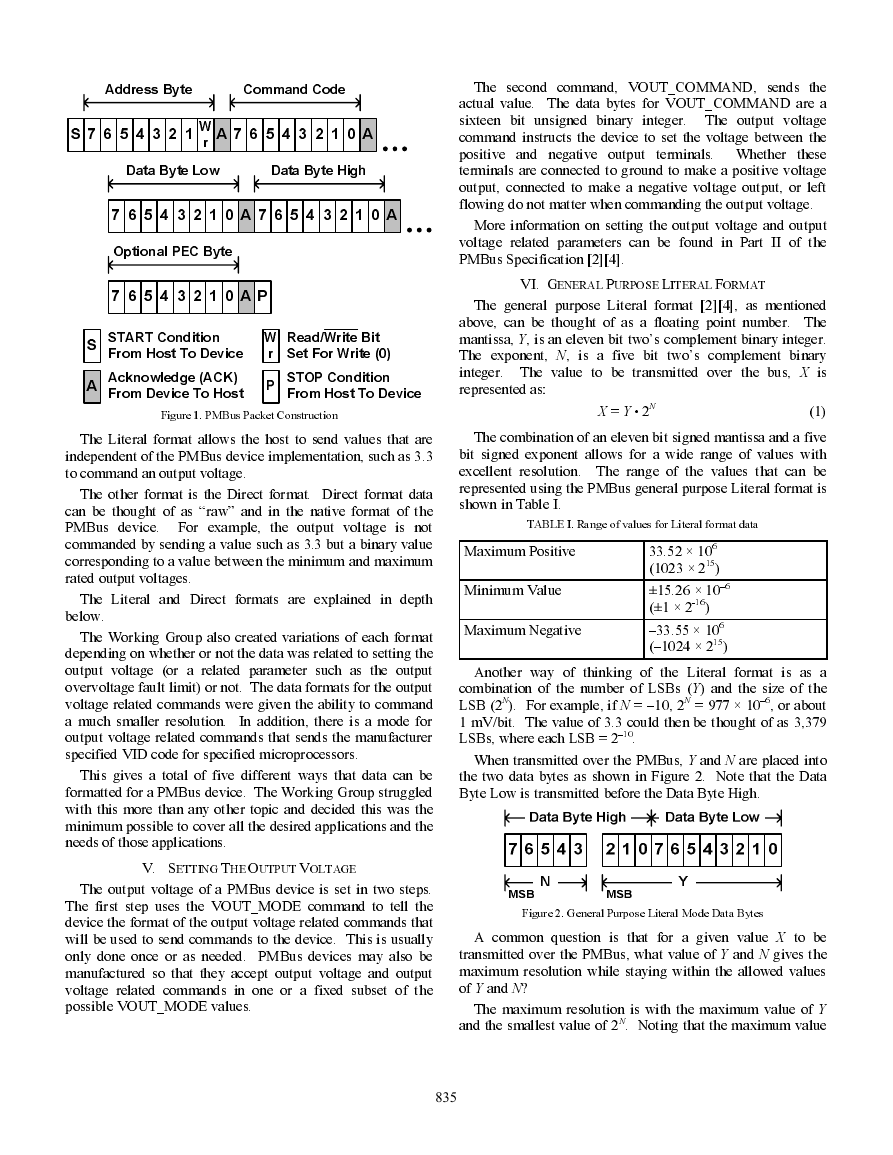

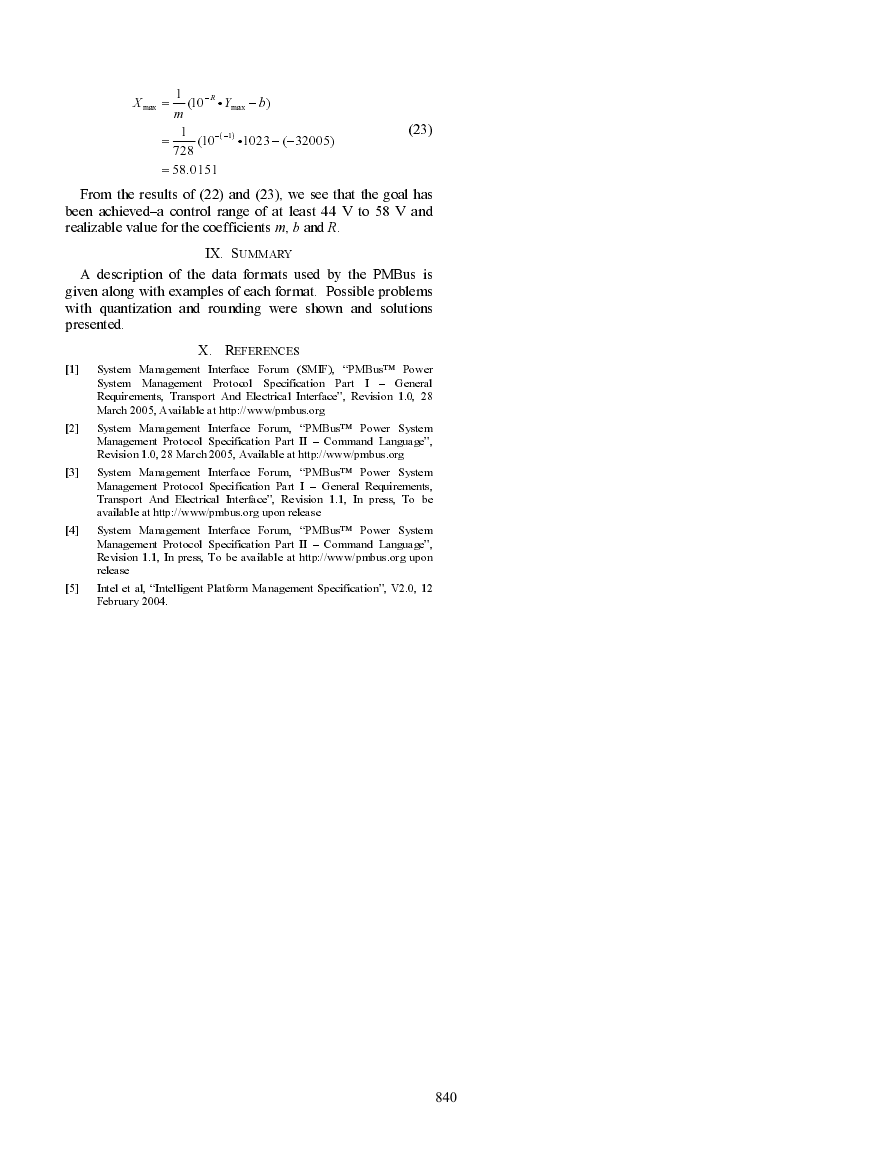

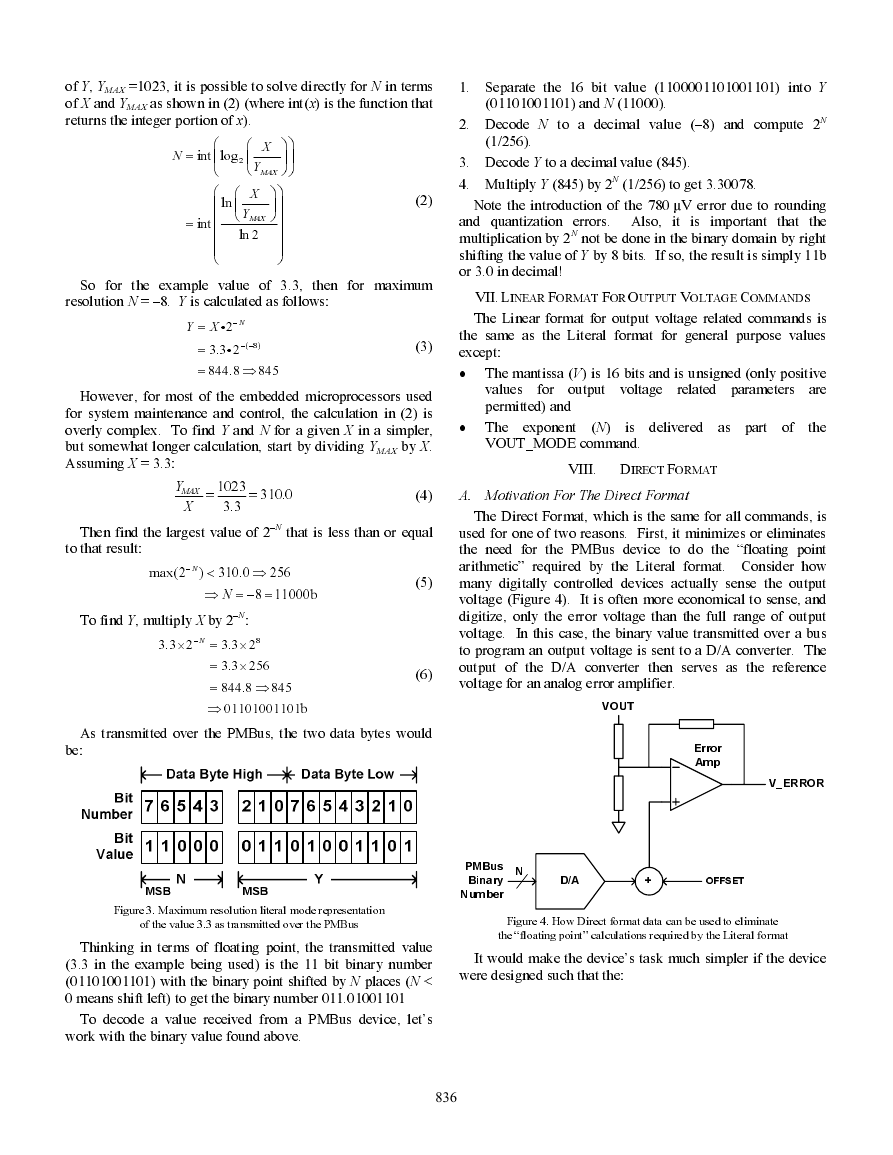

When transmitted over the PMBus, Y and N are placed into

the two data bytes as shown in Figure 2. Note that the Data

Byte Low is transmitted before the Data Byte High.

Figure 2. General Purpose Literal Mode Data Bytes

A common question is that for a given value X to be

transmitted over the PMBus, what value of Y and N gives the

maximum resolution while staying within the allowed values

of Y and N?

The maximum resolution is with the maximum value of Y

and the smallest value of 2N. Noting that the maximum value

835

�

of Y, YMAX =1023, it is possible to solve directly for N in terms

of X and YMAX as shown in (2) (where int(x) is the function that

returns the integer portion of x).

1. Separate the 16 bit value (1100001101001101) into Y

(01101001101) and N (11000).

2. Decode N to a decimal value (–8) and compute 2N

N

=

int

=

int

⎛

⎜

⎝

⎛

⎜

⎜

⎜

⎜

⎜

⎝

log

2

⎛

⎜

⎝

X

Y

MAX

⎞

⎟

⎠

⎞

⎟

⎠

ln

X

⎛

⎜

⎝

ln 2

Y

MAX

⎞

⎟

⎠

⎞

⎟

⎟

⎟

⎟

⎟

⎠

(2)

So for the example value of 3.3, then for maximum

resolution N = –8. Y is calculated as follows:

(1/256).

3. Decode Y to a decimal value (845).

4. Multiply Y (845) by 2N (1/256) to get 3.30078.

Note the introduction of the 780 µV error due to rounding

and quantization errors. Also, it is important that the

multiplication by 2N not be done in the binary domain by right

shifting the value of Y by 8 bits. If so, the result is simply 11b

or 3.0 in decimal!

VII. LINEAR FORMAT FOR OUTPUT VOLTAGE COMMANDS

Y

=

X −

2

i

N

=

3.3 2

i

− −

( 8)

=

844.8

⇒

845

However, for most of the embedded microprocessors used

for system maintenance and control, the calculation in (2) is

overly complex. To find Y and N for a given X in a simpler,

but somewhat longer calculation, start by dividing YMAX by X.

Assuming X = 3.3:

Then find the largest value of 2–N that is less than or equal

to that result:

max(2 ) 310.0

<

−

N

⇒

256

⇒ = − =

N

8 11000b

To find Y, multiply X by 2–N:

3.3 2

×

N−

8

3.3 2

×

=

=

3.3 256

×

=

844.8

⇒

845

⇒

01101001101b

(5)

(6)

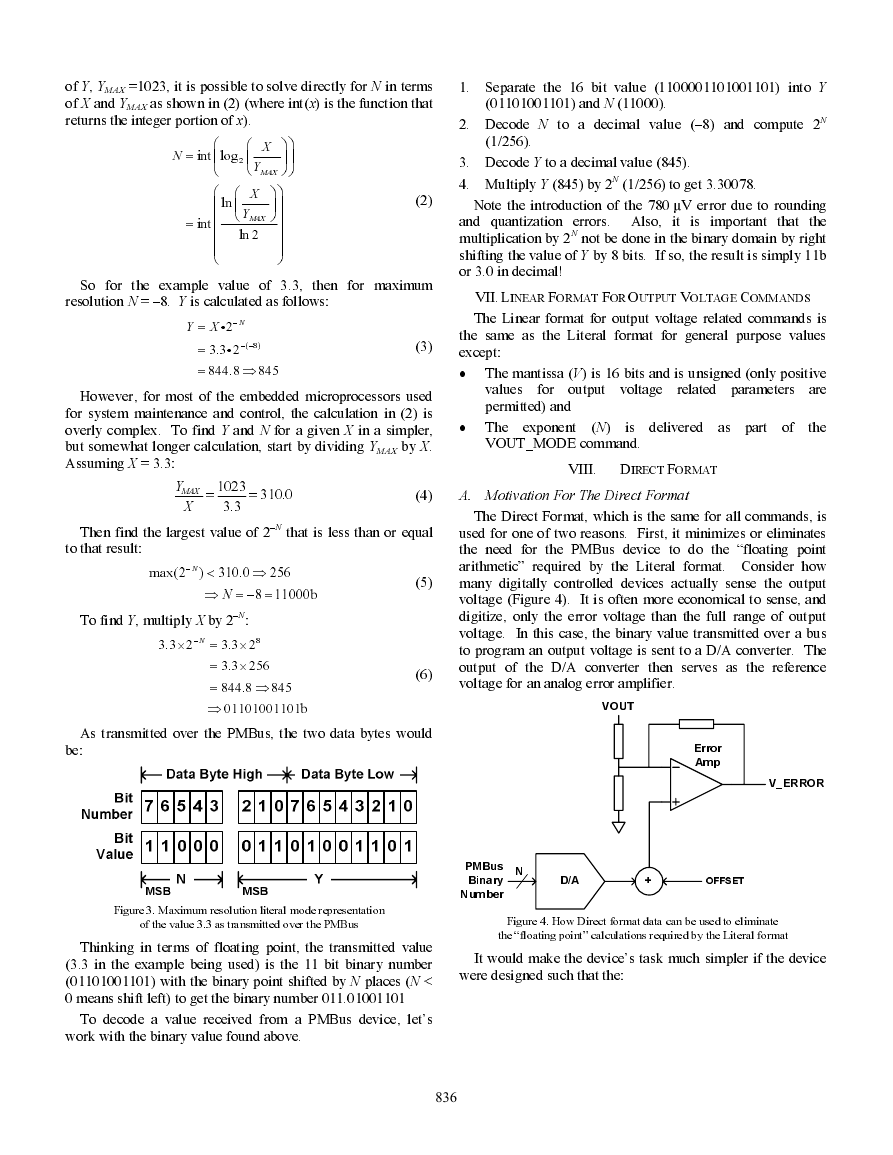

As transmitted over the PMBus, the two data bytes would

be:

Y

MAX

=

1023

X

3.3

=

310.0

(4)

A. Motivation For The Direct Format

The Linear format for output voltage related commands is

the same as the Literal format for general purpose values

except:

(3)

•

The mantissa (V) is 16 bits and is unsigned (only positive

related parameters are

for output voltage

values

permitted) and

•

The exponent

(N)

is delivered as part of

the

VOUT_MODE command.

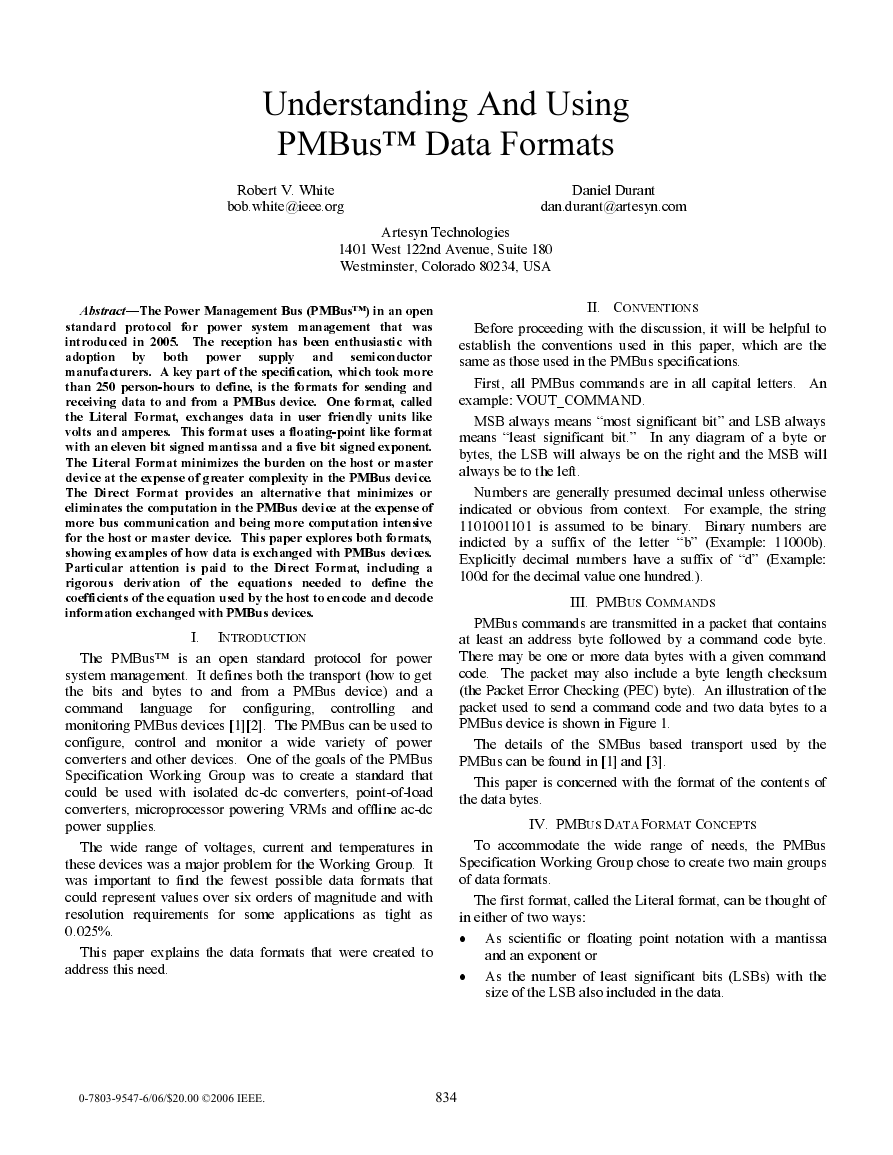

VIII. DIRECT FORMAT

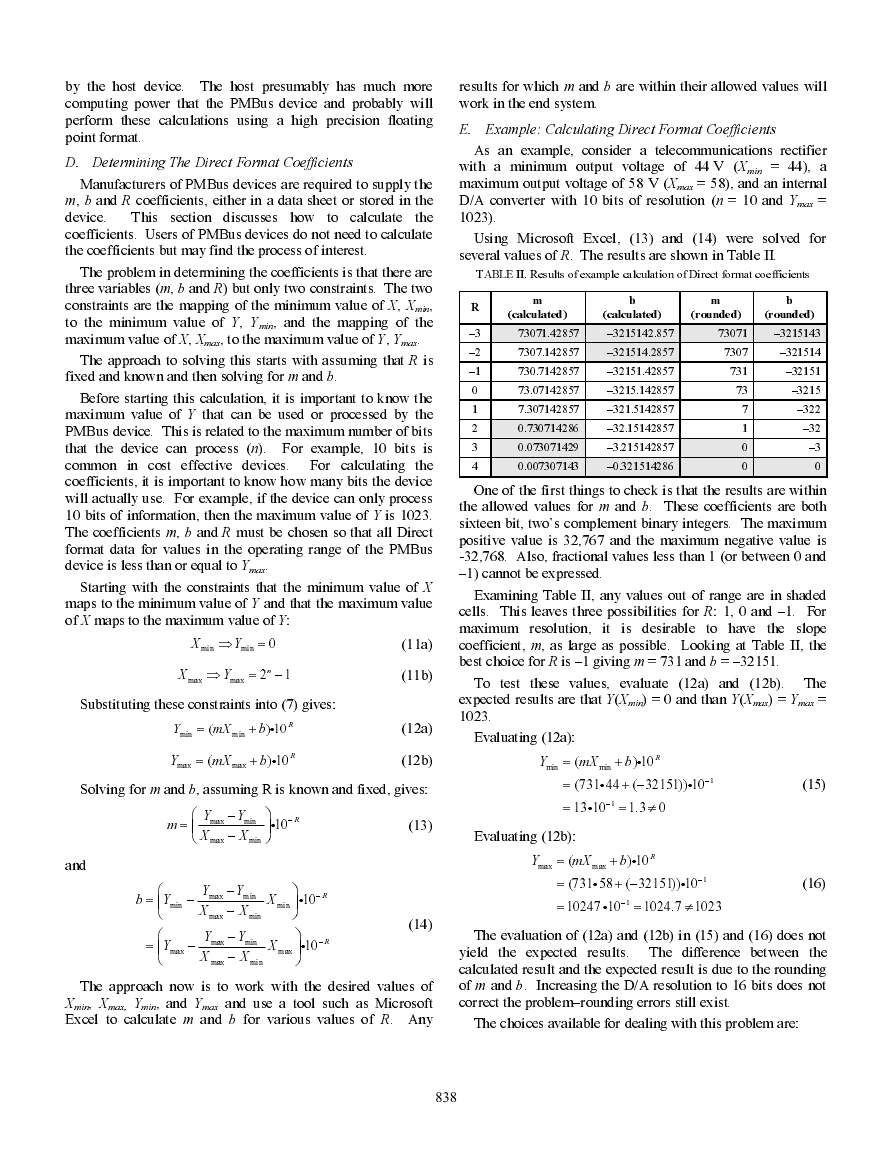

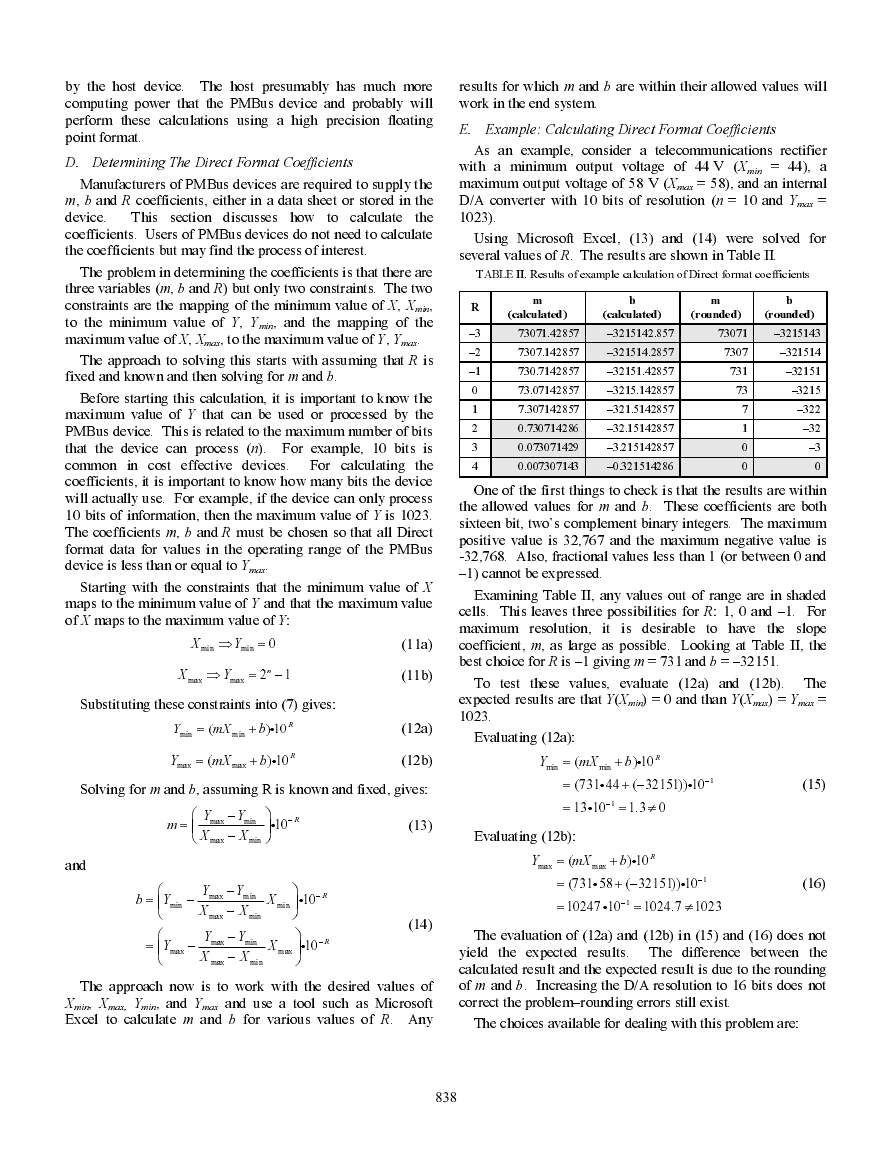

The Direct Format, which is the same for all commands, is

used for one of two reasons. First, it minimizes or eliminates

the need for the PMBus device to do the “floating point

arithmetic” required by the Literal format. Consider how

many digitally controlled devices actually sense the output

voltage (Figure 4). It is often more economical to sense, and

digitize, only the error voltage than the full range of output

voltage. In this case, the binary value transmitted over a bus

to program an output voltage is sent to a D/A converter. The

output of the D/A converter then serves as the reference

voltage for an analog error amplifier.

VOUT

Error

Amp

V_ERROR

PMBus

Binary

Number

N

D/A

+

OFFSET

Figure 3. Maximum resolution literal mode representation

of the value 3.3 as transmitted over the PMBus

Thinking in terms of floating point, the transmitted value

(3.3 in the example being used) is the 11 bit binary number

(01101001101) with the binary point shifted by N places (N <

0 means shift left) to get the binary number 011.01001101

To decode a value received from a PMBus device, let’s

work with the binary value found above.

Figure 4. How Direct format data can be used to eliminate

the “floating point” calculations required by the Literal format

It would make the device’s task much simpler if the device

were designed such that the:

836

�

•

Minimum value transmitted over the bus (Ymin) set the

C. Using Direct Format Data

device output to its minimum rated output value, and the

•

Maximum value transmitted over the bus (Ymax) set the

device output to its maximum rated output value.

interest

is when

Another case of

the range being

commanded, such as a device’s output voltage, has a

substantial offset from zero. For example, rectifiers used in

telecommunications applications

typically have output

voltages that can be varied from about 44 Vdc to 58 Vdc.

Another requirement is that the output voltage be controlled

with a resolution in the range of 10-20 mV. And often, to

minimize cost, the D/A converters used for controlling the

output voltage have a resolution of only 10 bits.

However, to control the output voltage from 0 V to 58 V

with a resolution of even 20 mV requires at least 12 bits of

resolution (and 10 mV requires at least 13 bits). However, the

range from 44 V to 58 V can be controlled with a 10 bit D/A

with a resolution of 13.4 mV–which is good enough for most

applications.

This is made possible by the Direct format. In the Direct

format, the host sends a value of 0 over the bus to command

the output to 44 V and the maximum binary value the device

can use (such as 1023 for a device that has a 10 bit D/A) to

command the output to 58 V.

B.

Direct Format Equations

The Direct Mode actually uses an equation to define the

encoding of information sent to a PMBus device [2][4]. This

equation based encoding was inspired by the format used in

the Intelligent Peripheral Management Interface specification

[5].

The equation used to encode data being sent across the

PMBus is:

Where:

Y mX b+ i

=(

) 10 R

(7)

•

•

•

•

•

X

is the value to be encoded,

m, the slope coefficient, is a 16 bit two’s complement

integer,

b, the offset coefficient, is a 16 bit two’s complement

integer,

R, the scaling coefficient is an 8 bit two’s complement

integer, and

Y, the value transmitted over the bus, is a 16 bit two’s

complement integer.

To decode values received from a PMBus transmission, the

inverse of (7) is used:

X

=

1

m

R

−

(10

−i

Y b

)

(8)

The coefficients of the equation, m, b and R, are supplied by

the PMBus device manufacturer. They can be made available

from a data sheet or retrieved from the device itself with the

COEFFICIENTS command [2][4].

837

Before a host or master can send or retrieve Direct format

data from a PMBus device, it must have the m, b and R

coefficients used in (7) and (8). These values may either be

programmed into the host from values supplied in a data sheet

or they may be retrieved from the PMBus device using the

COEFFICIENTS command.

The details of using the

COEFFICIENTS command are given in [2] and [4].

Two examples will illustrate the use of Direct format data

for sending and receiving data from a PMBus device. In the

first example, the host is to send a command to a PMBus

device to set the output voltage to 3.30 V. In the second

example, the host will read back the actual output voltage

from the same device.

The cycle to send the command for the output voltage starts

with requesting the m, b and R coefficients for

the

VOUT_COMMAND command from the PMBus device.

Suppose the device returns the values m = 3615, b = –2892

and R = –1. The host uses (7) to calculate the value to be sent

over the bus (Y) using the desired output voltage of 3.3 for X.

Y mX b

+

=(

R

) 10

i

=

(3615 3.3 ( 2892)) 10

+ −

i

i

=

903.75

⇒

904

−

1

(9)

The decimal value of 904 is converted to a 16 bit unsigned

binary integer and sent over the bus to the PMBus device.

Now suppose that the host wants to know the actual output

voltage of the device whose output it just commanded to

3.3 V. The VOUT_COMMAND commands the nominal

output voltage setpoint of the PMBus device. However, there

are many factors that cause the actual output voltage to be

different from the VOUT_COMAND values. These factors

include tolerances within the PMBus, the effect of commands

that adjust the output voltage (such as VOUT_TRIM), and the

effect of current sharing circuits.

The PMBus specification provides the READ_VOUT

command that instructs the PMBus device to return the actual,

measured value of the output voltage. When using Direct

format data, the host starts the process of requesting the actual

output voltage by requesting from the PMBus device the m, b

and R coefficients for the READ_VOUT command. Suppose

the device returns the values m = 10240, b = 0 and R = –1.

The host then sends the PMBus device a READ_VOUT

command. Suppose the device returned the value 3364d. The

host then uses (8) to calculate the output voltage:

X

=

1

m

−

R

(10

Y b

−

i

)

1

=

=

10240

3.285

− −

( 1)

(10

i

3364 0)

−

(10)

From this calculation, the device’s actual, measured output

voltage is reported as 3.285 V.

It is important to note that the calculations (9) and (10) are

not done in the PMBus device. These calculations are made

�

by the host device. The host presumably has much more

computing power that the PMBus device and probably will

perform these calculations using a high precision floating

point format.

D. Determining The Direct Format Coefficients

Manufacturers of PMBus devices are required to supply the

m, b and R coefficients, either in a data sheet or stored in the

device.

the

coefficients. Users of PMBus devices do not need to calculate

the coefficients but may find the process of interest.

This section discusses how

to calculate

The problem in determining the coefficients is that there are

three variables (m, b and R) but only two constraints. The two

constraints are the mapping of the minimum value of X, Xmin,

to the minimum value of Y, Ymin, and the mapping of the

maximum value of X, Xmax, to the maximum value of Y, Ymax.

The approach to solving this starts with assuming that R is

fixed and known and then solving for m and b.

Before starting this calculation, it is important to know the

maximum value of Y that can be used or processed by the

PMBus device. This is related to the maximum number of bits

that the device can process (n). For example, 10 bits is

common in cost effective devices. For calculating the

coefficients, it is important to know how many bits the device

will actually use. For example, if the device can only process

10 bits of information, then the maximum value of Y is 1023.

The coefficients m, b and R must be chosen so that all Direct

format data for values in the operating range of the PMBus

device is less than or equal to Ymax.

Starting with the constraints that the minimum value of X

maps to the minimum value of Y and that the maximum value

of X maps to the maximum value of Y:

X

min

Y⇒ =

0

min

X

max

Y⇒ =

max

2

1n

−

Substituting these constraints into (7) gives:

Y

min

=

mX

(

min

+ i

) 10R

b

Y

max

=

mX

(

max

+ i

) 10 R

b

(11a)

(11b)

(12a)

(12b)

Solving for m and b, assuming R is known and fixed, gives:

m

⎛

= ⎜

⎝

Y

max

X

max

−

−

Y

min

X

min

and

−

10 R

i

⎞

⎟

⎠

b

=

=

⎛

⎜

⎝

⎛

⎜

⎝

Y

min

−

Y

max

−

Y

max

X

max

Y

max

X

max

−

−

−

−

Y

min

X

min

Y

min

X

min

X

min

X

max

⎞

⎟

⎠

⎞

⎟

⎠

(13)

(14)

−

R

10

i

−

R

10

i

The approach now is to work with the desired values of

Xmin, Xmax

, Ymin, and Ymax and use a tool such as Microsoft

Excel to calculate m and b for various values of R. Any

838

results for which m and b are within their allowed values will

work in the end system.

E. Example: Calculating Direct Format Coefficients

As an example, consider a telecommunications rectifier

with a minimum output voltage of 44 V (Xmin = 44), a

maximum output voltage of 58 V (Xmax = 58), and an internal

D/A converter with 10 bits of resolution (n = 10 and Ymax =

1023).

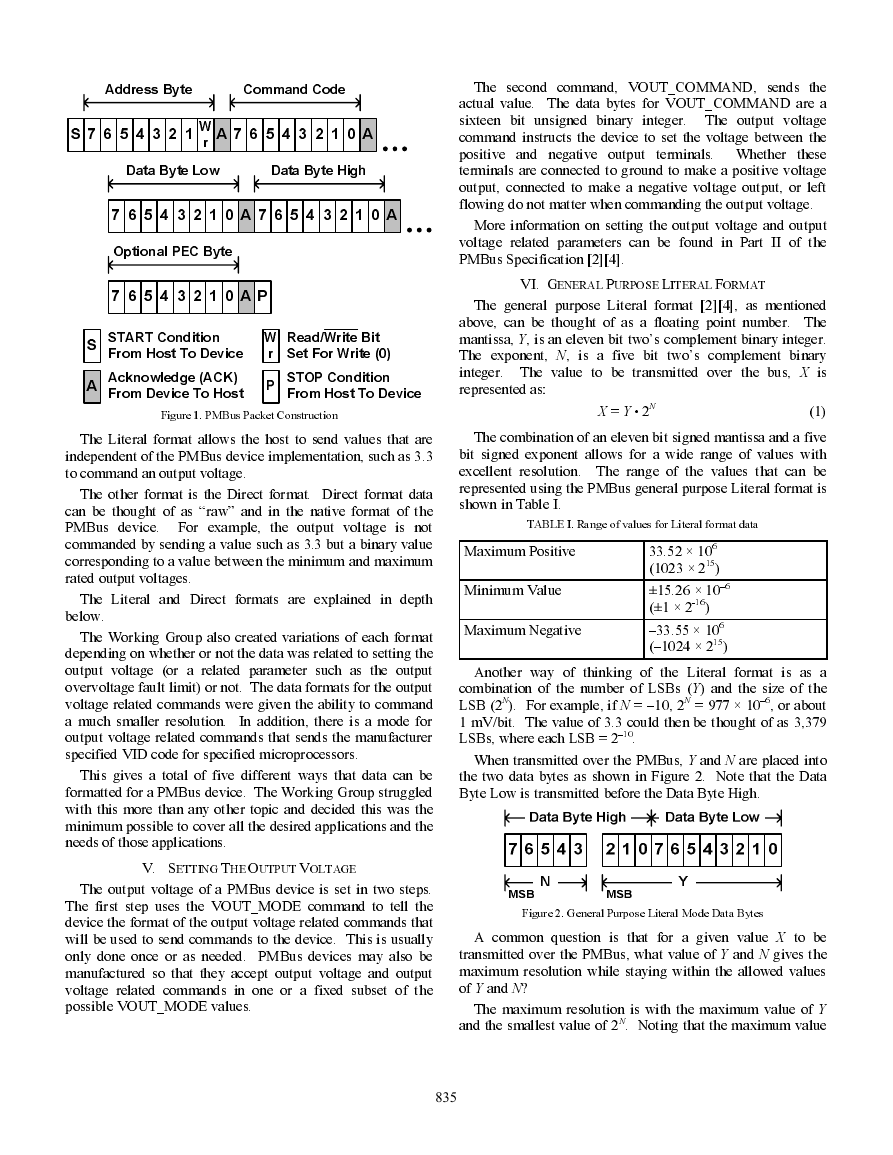

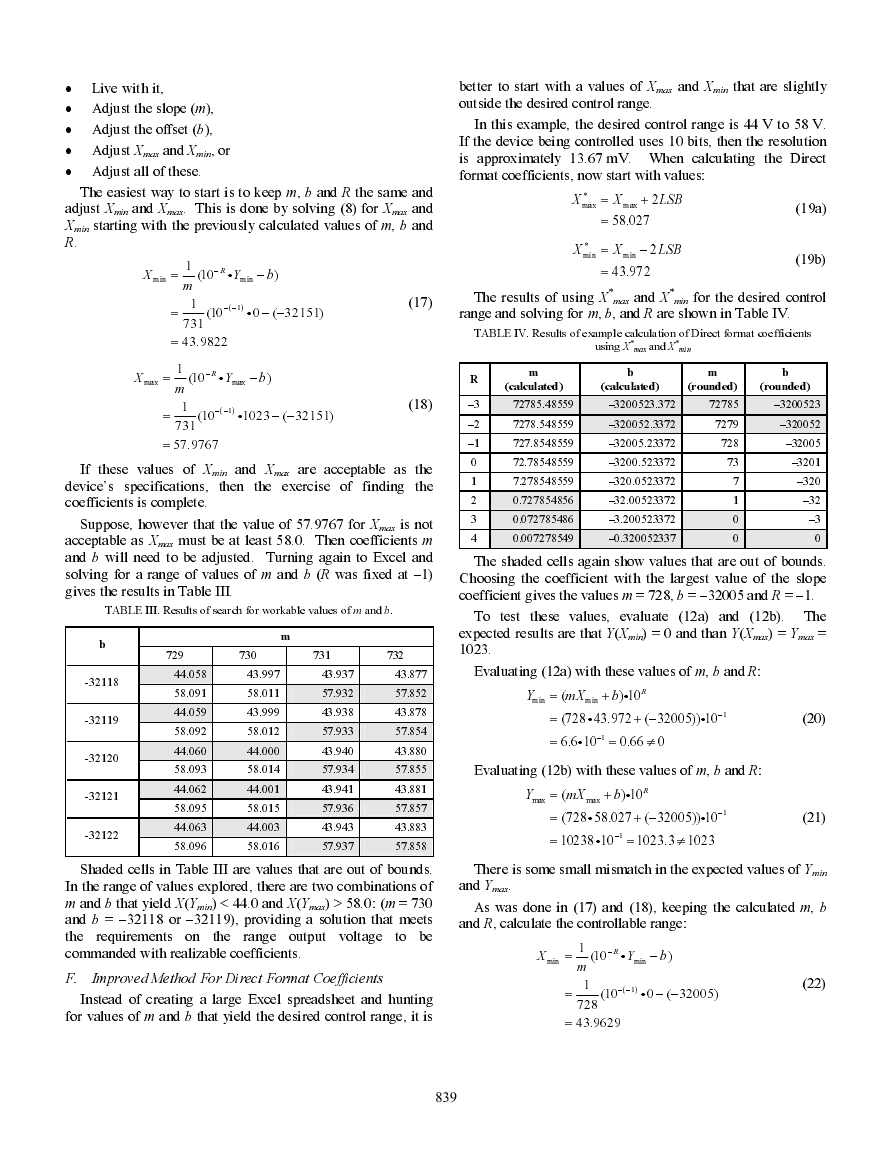

Using Microsoft Excel, (13) and (14) were solved for

several values of R. The results are shown in Table II.

TABLE II. Results of example calculation of Direct format coefficients

R

–3

–2

–1

0

1

2

3

4

m

b

m

b

(calculated)

(calculated)

(rounded)

(rounded)

73071.42857

–3215142.857

73071

–3215143

7307.142857

–321514.2857

7307

–321514

730.7142857

–32151.42857

73.07142857

–3215.142857

7.307142857

–321.5142857

0.730714286

–32.15142857

0.073071429

–3.215142857

0.007307143

–0.321514286

731

73

7

1

0

0

–32151

–3215

–322

–32

–3

0

One of the first things to check is that the results are within

the allowed values for m and b. These coefficients are both

sixteen bit, two’s complement binary integers. The maximum

positive value is 32,767 and the maximum negative value is

-32,768. Also, fractional values less than 1 (or between 0 and

–1) cannot be expressed.

Examining Table II, any values out of range are in shaded

cells. This leaves three possibilities for R: 1, 0 and –1. For

maximum resolution, it is desirable to have the slope

coefficient, m, as large as possible. Looking at Table II, the

best choice for R is –1 giving m = 731 and b = –32151.

To test these values, evaluate (12a) and (12b). The

expected results are that Y(Xmin) = 0 and than Y(Xmax) = Ymax =

1023.

Evaluating (12a):

Y

min

=

mX

(

min

+

b

) 10

i

R

=

=

(731 44 ( 32151)) 10

+ −

i

i

1

−

13 10

i

=

1.3 0

≠

1

−

(15)

Evaluating (12b):

Y

max

=

mX

(

max

+

b

) 10

i

R

=

(731 58 ( 32151)) 10

+ −

i

i

1

−

(16)

=

10247 10

i

−

1

=

1024.7 1023

≠

The evaluation of (12a) and (12b) in (15) and (16) does not

yield the expected results. The difference between the

calculated result and the expected result is due to the rounding

of m and b. Increasing the D/A resolution to 16 bits does not

correct the problem–rounding errors still exist.

The choices available for dealing with this problem are:

�

•

Live with it,

•

Adjust the slope (m),

•

Adjust the offset (b),

•

Adjust Xmax and Xmin, or

•

Adjust all of these.

The easiest way to start is to keep m, b and R the same and

adjust Xmin and Xmax. This is done by solving (8) for Xmax and

Xmin starting with the previously calculated values of m, b and

R.

X

=

min

1

m

−

R

i

(10

Y

min

−

b

)

1

− −

( 1)

(10

=

=

731

43.9822

i

0 ( 32151)

− −

better to start with a values of Xmax and Xmin that are slightly

outside the desired control range.

In this example, the desired control range is 44 V to 58 V.

If the device being controlled uses 10 bits, then the resolution

is approximately 13.67 mV. When calculating the Direct

format coefficients, now start with values:

X

*

max

=

X

max

+

2

LSB

=

58.027

X

*

min

=

X

min

−

2

LSB

=

43.972

(19a)

(19b)

(17)

The results of using X

*

*

max and X

min for the desired control

range and solving for m, b, and R

are shown in Table IV.

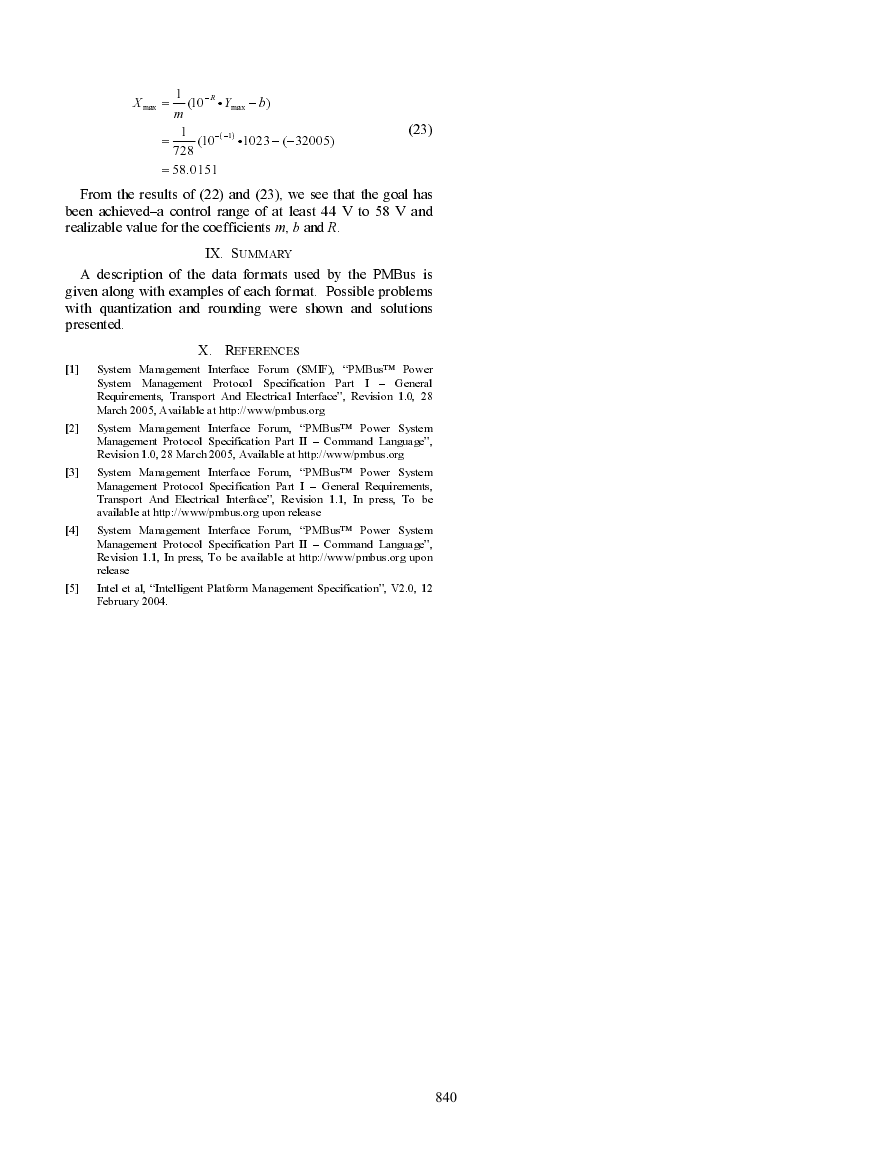

TABLE IV. Results of example calculation of Direct format coefficients

*

*

using X

min

max and X

X

=

max

1

m

−

R

i

(10

Y

max

−

b

)

1

− −

( 1)

(10

=

=

731

57.9767

i

1023 ( 32151)

− −

(18)

If these values of Xmin and Xmax are acceptable as the

device’s specifications, then the exercise of finding the

coefficients is complete.

Suppose, however that the value of 57.9767 for Xmax is not

acceptable as Xmax must be at least 58.0. Then coefficients m

and b will need to be adjusted. Turning again to Excel and

solving for a range of values of m and b (R was fixed at –1)

gives the results in Table III.

TABLE III. Results of search for workable values of m and b.

729

730

731

732

m

R

–3

–2

–1

0

1

2

3

4

m

b

m

b

(calculated)

(calculated)

(rounded)

(rounded)

72785.48559

–3200523.372

72785

–3200523

7278.548559

–320052.3372

7279

–320052

727.8548559

–32005.23372

72.78548559

–3200.523372

7.278548559

–320.0523372

0.727854856

–32.00523372

0.072785486

–3.200523372

0.007278549

–0.320052337

728

73

7

1

0

0

–32005

–3201

–320

–32

–3

0

The shaded cells again show values that are out of bounds.

Choosing the coefficient with the largest value of the slope

coefficient gives the values m = 728, b = –32005 and R = –1.

To test these values, evaluate (12a) and (12b). The

expected results are that Y(Xmin) = 0 and than Y(Xmax) = Ymax =

1023.

44.058

43.997

43.937

43.877

Evaluating (12a) with these values of m, b and R:

58.091

58.011

57.932

57.852

44.059

43.999

43.938

43.878

58.092

58.012

57.933

57.854

44.060

44.000

43.940

43.880

Y

min

=

mX

(

min

+

b

) 10

i

R

=

(728 43.972 ( 32005)) 10

+ −

i

i

=

6.6 10

i

1

−

=

0.66 0

≠

1

−

58.093

58.014

57.934

57.855

Evaluating (12b) with these values of m, b and R:

44.062

44.001

43.941

43.881

58.095

58.015

57.936

57.857

44.063

44.003

43.943

43.883

58.096

58.016

57.937

57.858

Y

max

=

mX

(

max

+

b

) 10

i

R

=

(728 58.027 ( 32005)) 10

+ −

i

i

=

10238 10

i

1

−

=

1023.3 1023

≠

−

1

(20)

(21)

b

-32118

-32119

-32120

-32121

-32122

Shaded cells in Table III are values that are out of bounds.

In the range of values explored, there are two combinations of

m and b that yield X(Ymin) < 44.0 and X(Ymax) > 58.0: (m = 730

and b = –32118 or –32119), providing a solution that meets

the requirements on

to be

commanded with realizable coefficients.

the range output voltage

F. Improved Method For Direct Format Coefficients

Instead of creating a large Excel spreadsheet and hunting

for values of m and b that yield the desired control range, it is

839

There is some small mismatch in the expected values of Ymin

and Ymax.

As was done in (17) and (18), keeping the calculated m, b

and R, calculate the controllable range:

X

=

min

1

m

−

R

i

(10

Y

min

−

b

)

1

− −

( 1)

(10

=

=

728

43.9629

i

0 ( 32005)

− −

(22)

�

X

=

max

1

m

−

R

i

(10

Y

max

−

b

)

1

− −

( 1)

(10

=

=

728

58.0151

i

1023 ( 32005)

− −

(23)

From the results of (22) and (23), we see that the goal has

been achieved–a control range of at least 44 V to 58 V and

realizable value for the coefficients m, b and R.

IX. SUMMARY

A description of the data formats used by the PMBus is

given along with examples of each format. Possible problems

with quantization and rounding were shown and solutions

presented.

X. REFERENCES

[1]

[2]

[3]

[4]

System Management Interface Forum (SMIF), “PMBus™ Power

System Management Protocol Specification Part I – General

Requirements, Transport And Electrical Interface”, Revision 1.0, 28

March 2005, Available at http://www/pmbus.org

System Management Interface Forum, “PMBus™ Power System

Management Protocol Specification Part II – Command Language”,

Revision 1.0, 28 March 2005, Available at http://www/pmbus.org

System Management Interface Forum, “PMBus™ Power System

Management Protocol Specification Part I – General Requirements,

Transport And Electrical Interface”, Revision 1.1, In press, To be

available at http://www/pmbus.org upon release

System Management Interface Forum, “PMBus™ Power System

Management Protocol Specification Part II – Command Language”,

Revision 1.1, In press, To be available at http://www/pmbus.org upon

release

[5]

Intel et al, “Intelligent Platform Management Specification”, V2.0, 12

February 2004.

840

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc