t

n

e

m

u

c

o

d

l

i

a

n

g

i

r

o

e

h

t

l

o

r

t

n

o

c

o

t

.

t

p

e

D

e

t

a

D

THERMAL PRINTER

FTP-628MCL101#50

PRODUCT SPECIFICATION

(Corresponds to RoHS)

e

m

a

N

FTP-628MCL101#50 SPECIFICATION

02 07.03.05 M.Tsuchiya

Rev.

Design

Date

06.01.14 Y,Takabatake

Design

Inspection

Inspect.

For Vdd=3v (p17,22,24,36change) Y.Mori

i

g

n

w

a

r

D

.

o

N

Submit to

Changes made

Approv.

Y.Mori

FUJITSU COMPONENT LIMITED

1

e

g

a

P

36

�

t

n

e

m

u

c

o

d

l

i

a

n

g

i

r

o

e

h

t

l

o

r

t

n

o

c

o

t

.

t

p

e

D

e

t

a

D

- Table of Contents -

1. Guideline for product recycling

2. Product design, warnings and cautions for using the product

2-1. Handling the printer

2-2. Casing design

2-3. Paper to be used

2-4. Cleaning

2-5. Maintenance

2-6. Storing

2-7. Others

2-8. The figures of the platen retainer and the paper insertion area

3. Specifications

3-1. Application

3-2. Overview

3-3. Structure

3-4. Standard specifications

3-5. Outer dimensions and installing position

3-6. Connector (flexible) specifications

3-7. Thermal head specifications

3-8. Stepping motor specifications

3-9. Sensor specifications

4. Product model plate

5. Packing

6. Pre-printing specifications

7. Revision history table

e

m

a

N

FTP-628MCL101#50 SPECIFICATION

Date

Design

Rev.

Design

Inspection

Inspect.

Changes made

Approv.

FUJITSU COMPONENT LIMITED

2

e

g

a

P

36

i

g

n

w

a

r

D

.

o

N

Submit to

�

t

n

e

m

u

c

o

d

l

i

a

n

g

i

r

o

e

h

t

l

o

r

t

n

o

c

o

t

.

t

p

e

D

e

t

a

D

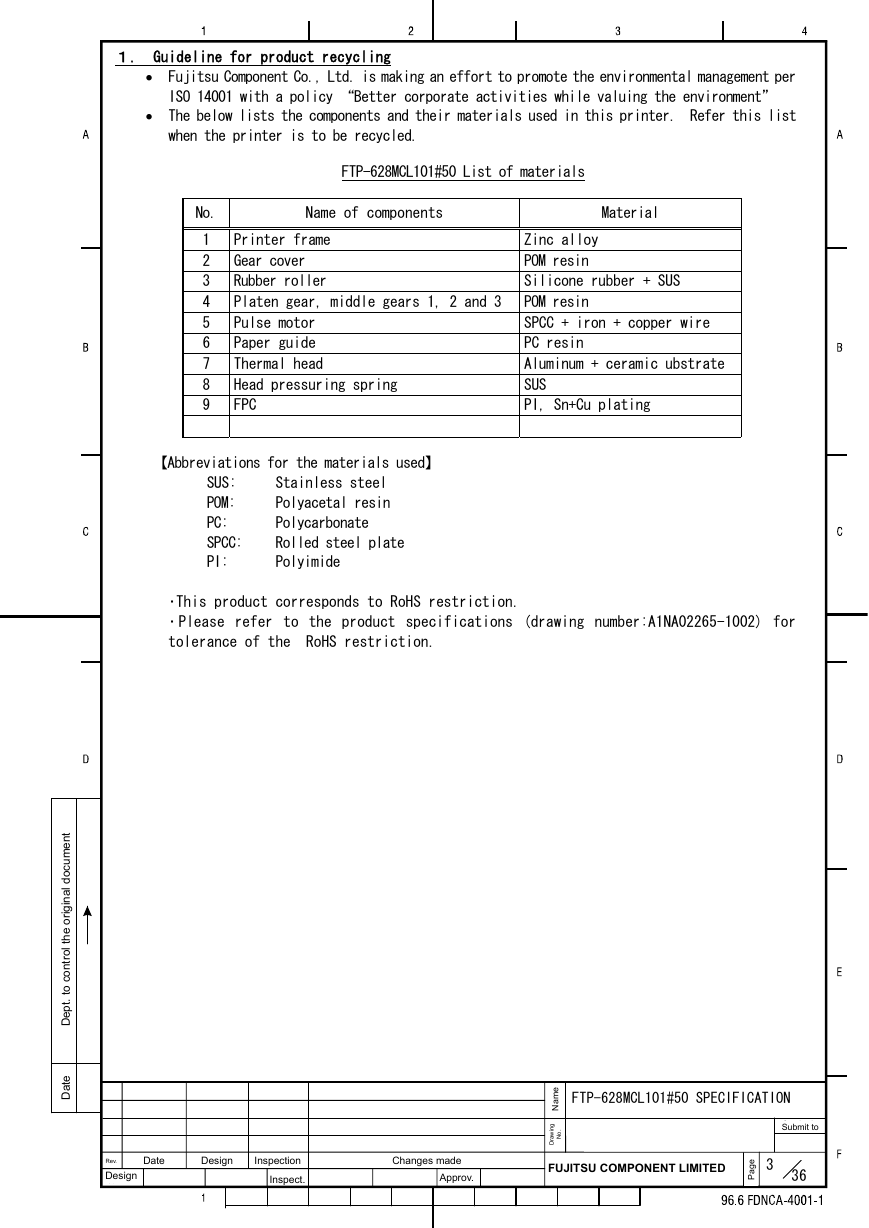

1. Guideline for product recycling

• Fujitsu Component Co., Ltd. is making an effort to promote the environmental management per

ISO 14001 with a policy “Better corporate activities while valuing the environment”

• The below lists the components and their materials used in this printer. Refer this list

when the printer is to be recycled.

FTP-628MCL101#50 List of materials

No.

Name of components

Material

1

2

3

4

5

6

7

8

9

Printer frame

Gear cover

Rubber roller

Platen gear, middle gears 1, 2 and 3

Pulse motor

Paper guide

Thermal head

Head pressuring spring

FPC

Zinc alloy

POM resin

Silicone rubber + SUS

POM resin

SPCC + iron + copper wire

PC resin

Aluminum + ceramic ubstrate

SUS

PI, Sn+Cu plating

【Abbreviations for the materials used】

SUS:

POM:

PC:

SPCC:

PI:

Stainless steel

Polyacetal resin

Polycarbonate

Rolled steel plate

Polyimide

・This product corresponds to RoHS restriction.

・ Please refer to the product specifications (drawing number:A1NA02265-1002) for

tolerance of the RoHS restriction.

e

m

a

N

FTP-628MCL101#50 SPECIFICATION

Date

Design

Rev.

Design

Inspection

Inspect.

Changes made

Approv.

FUJITSU COMPONENT LIMITED

3

e

g

a

P

36

i

g

n

w

a

r

D

.

o

N

Submit to

�

t

n

e

m

u

c

o

d

l

i

a

n

g

i

r

o

e

h

t

l

o

r

t

n

o

c

o

t

.

t

p

e

D

e

t

a

D

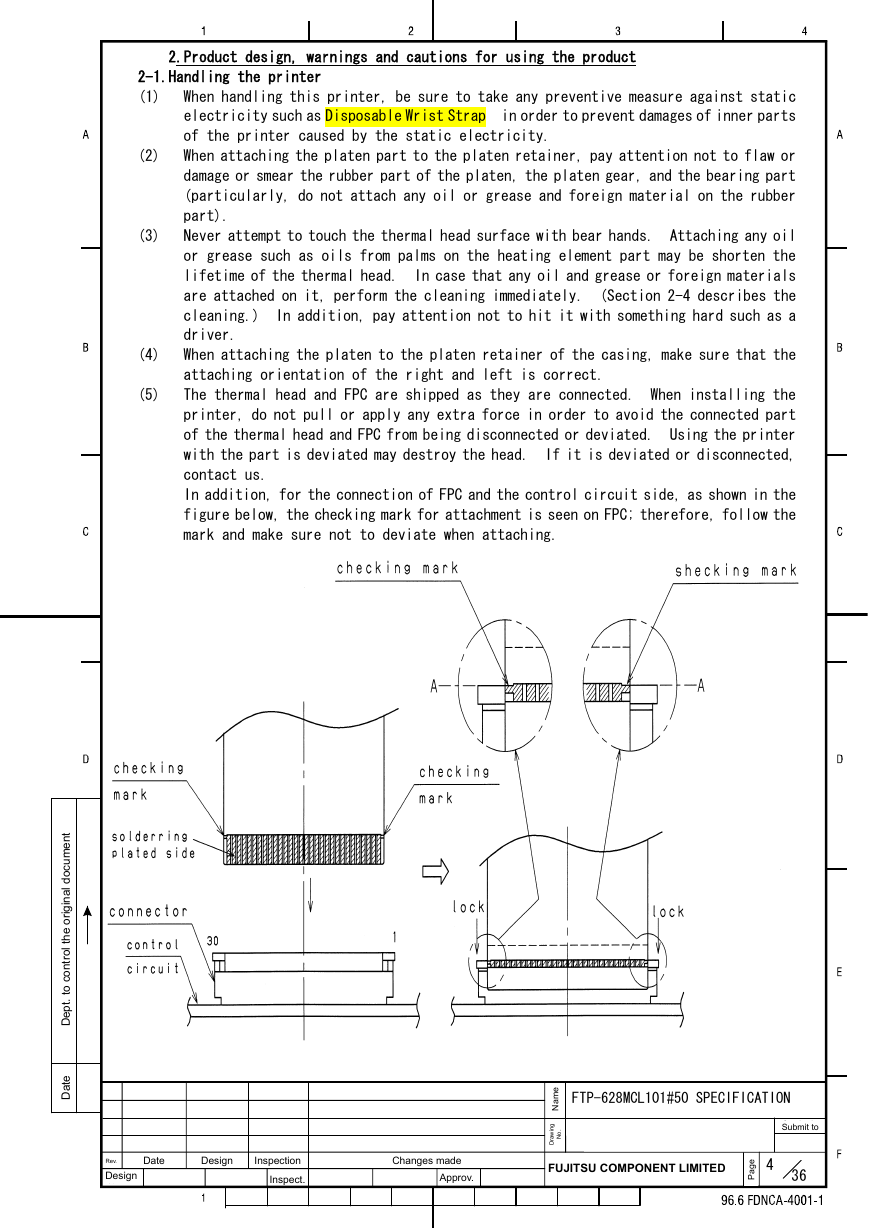

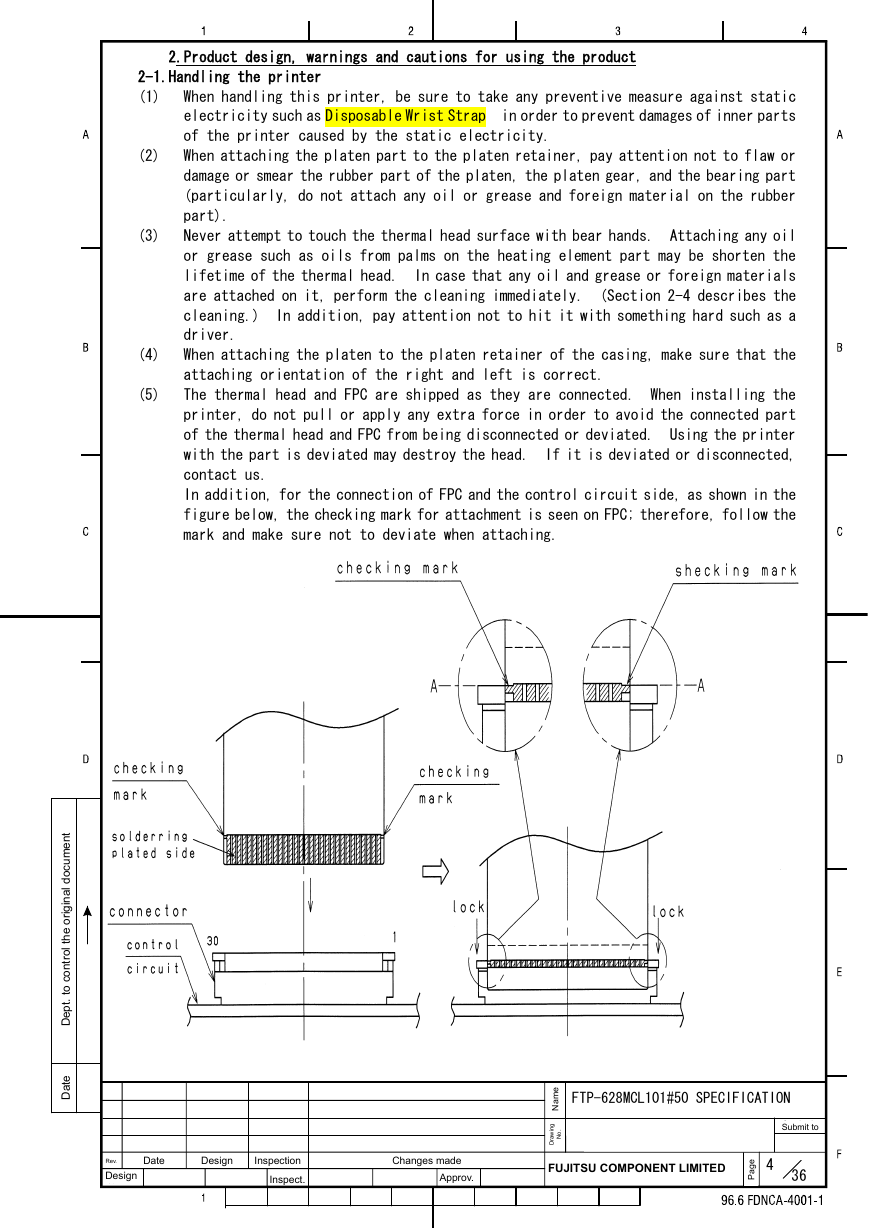

2.Product design, warnings and cautions for using the product

(5)

(4)

(3)

(2)

2-1.Handling the printer

(1) When handling this printer, be sure to take any preventive measure against static

electricity such as Disposable Wrist Strap in order to prevent damages of inner parts

of the printer caused by the static electricity.

When attaching the platen part to the platen retainer, pay attention not to flaw or

damage or smear the rubber part of the platen, the platen gear, and the bearing part

(particularly, do not attach any oil or grease and foreign material on the rubber

part).

Never attempt to touch the thermal head surface with bear hands. Attaching any oil

or grease such as oils from palms on the heating element part may be shorten the

lifetime of the thermal head. In case that any oil and grease or foreign materials

are attached on it, perform the cleaning immediately. (Section 2-4 describes the

cleaning.) In addition, pay attention not to hit it with something hard such as a

driver.

When attaching the platen to the platen retainer of the casing, make sure that the

attaching orientation of the right and left is correct.

The thermal head and FPC are shipped as they are connected. When installing the

printer, do not pull or apply any extra force in order to avoid the connected part

of the thermal head and FPC from being disconnected or deviated. Using the printer

with the part is deviated may destroy the head. If it is deviated or disconnected,

contact us.

In addition, for the connection of FPC and the control circuit side, as shown in the

figure below, the checking mark for attachment is seen on FPC; therefore, follow the

mark and make sure not to deviate when attaching.

e

m

a

N

FTP-628MCL101#50 SPECIFICATION

Date

Design

Rev.

Design

Inspection

Inspect.

Changes made

Approv.

FUJITSU COMPONENT LIMITED

4

e

g

a

P

36

i

g

n

w

a

r

D

.

o

N

Submit to

�

t

n

e

m

u

c

o

d

l

i

a

n

g

i

r

o

e

h

t

l

o

r

t

n

o

c

o

t

.

t

p

e

D

e

t

a

D

(6)

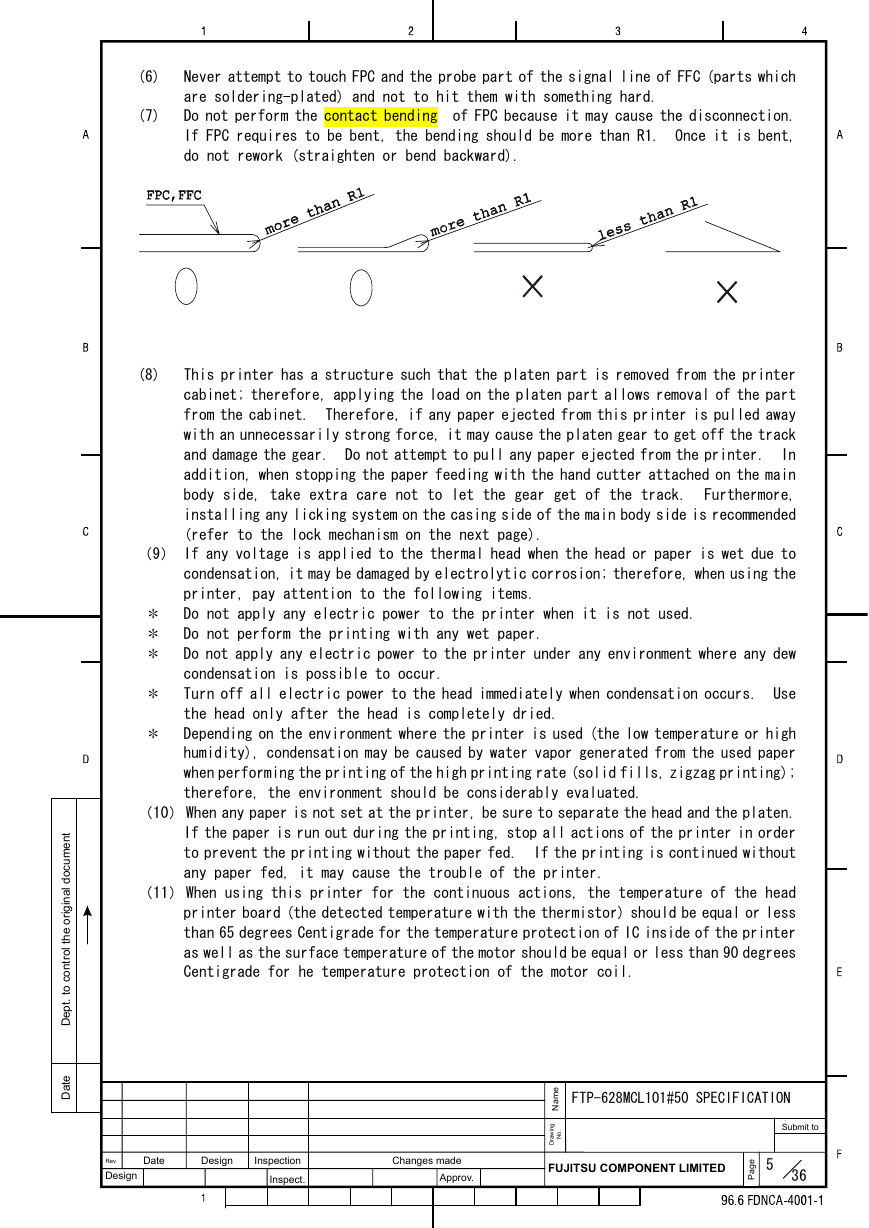

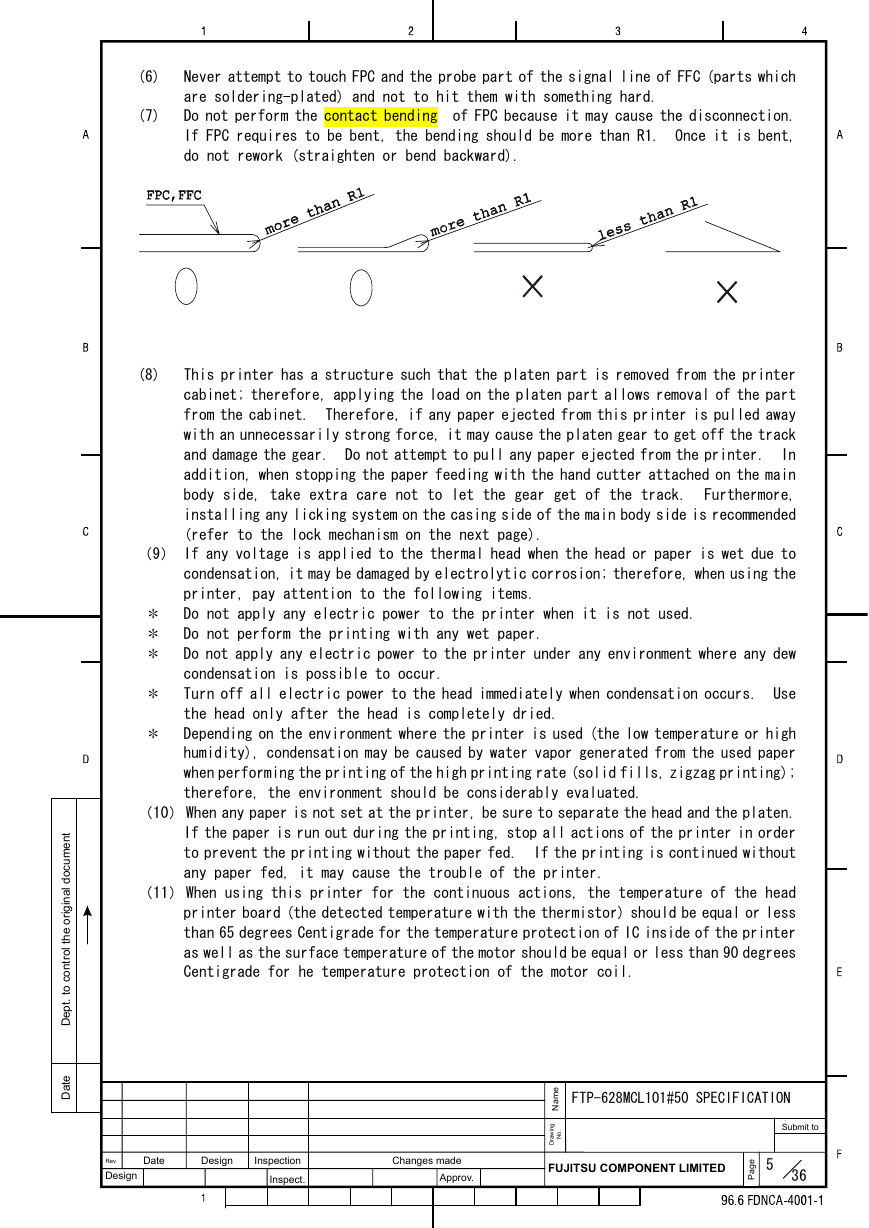

(7)

Never attempt to touch FPC and the probe part of the signal line of FFC (parts which

are soldering-plated) and not to hit them with something hard.

Do not perform the contact bending of FPC because it may cause the disconnection.

If FPC requires to be bent, the bending should be more than R1. Once it is bent,

do not rework (straighten or bend backward).

(8)

This printer has a structure such that the platen part is removed from the printer

cabinet; therefore, applying the load on the platen part allows removal of the part

from the cabinet. Therefore, if any paper ejected from this printer is pulled away

with an unnecessarily strong force, it may cause the platen gear to get off the track

and damage the gear. Do not attempt to pull any paper ejected from the printer. In

addition, when stopping the paper feeding with the hand cutter attached on the main

body side, take extra care not to let the gear get of the track. Furthermore,

installing any licking system on the casing side of the main body side is recommended

(refer to the lock mechanism on the next page).

*

*

*

(9) If any voltage is applied to the thermal head when the head or paper is wet due to

condensation, it may be damaged by electrolytic corrosion; therefore, when using the

printer, pay attention to the following items.

Do not apply any electric power to the printer when it is not used.

Do not perform the printing with any wet paper.

Do not apply any electric power to the printer under any environment where any dew

condensation is possible to occur.

Turn off all electric power to the head immediately when condensation occurs. Use

the head only after the head is completely dried.

Depending on the environment where the printer is used (the low temperature or high

humidity), condensation may be caused by water vapor generated from the used paper

when performing the printing of the high printing rate (solid fills, zigzag printing);

therefore, the environment should be considerably evaluated.

*

*

(10) When any paper is not set at the printer, be sure to separate the head and the platen.

If the paper is run out during the printing, stop all actions of the printer in order

to prevent the printing without the paper fed. If the printing is continued without

any paper fed, it may cause the trouble of the printer.

(11) When using this printer for the continuous actions, the temperature of the head

printer board (the detected temperature with the thermistor) should be equal or less

than 65 degrees Centigrade for the temperature protection of IC inside of the printer

as well as the surface temperature of the motor should be equal or less than 90 degrees

Centigrade for he temperature protection of the motor coil.

e

m

a

N

FTP-628MCL101#50 SPECIFICATION

Date

Design

Rev.

Design

Inspection

Inspect.

Changes made

Approv.

FUJITSU COMPONENT LIMITED

5

e

g

a

P

36

i

g

n

w

a

r

D

.

o

N

Submit to

�

t

n

e

m

u

c

o

d

l

i

a

n

g

i

r

o

e

h

t

l

o

r

t

n

o

c

o

t

.

t

p

e

D

e

t

a

D

(12) Never attempt to any back feeding action of the paper.

(13) This printer is using the infrared photo-sensor for paper-end detection and mark

detection. For this reason, if it is used in a strong light like sunlight, a sensor

may incorrect-operate. When you use it in such an environment, please evaluate enough.

And if needed, please cope with it to prevent from such light.

(14) When a printer is used near a mobile terminal or a radio, there is a possibility that

the obstacle occurs by the electromagnetic radiation noise. When using a printer in

such an environment, please evaluate enough. And if needed, please cope with it with

a shield or grounding reinforcement etc.

2-2.Casing design

□Platen retainer

(1) Refer to Attached Paper, Section 2-8 "The figures of the platen retainer and the paper

insertion area" for attachment of the platen part. If it is used with any different

size from the recommended ones, it may cause uneven printing, unfavorable removal

of the platen, and troubles such as damages due to the lack of the strength; therefore,

be sure to conform with the recommendation. The recommended dimension of the

retainer is in a range where the angle is 11°±0.5° and the size of the X-direction

is 50-200 mm.

(2) Cover the platen gear part so that it is not exposed. The platen has some play against

the retainer part; therefore, the gap between the platen gear and the cover should

have sufficiently play.

(3) Materials of the platen retainer should have high strength and high impact-resistance

as the ones for the platen retainer (equivalent to PC or PC+ABS).

(4) Avoid removing the platen from the platen retainer as much as possible after having

attached it to the platen retainer.

(5) Please install the cover on the case side so that neither garbage nor the foreign

body may enter the PLATEN open and close detection switch of the printer in the gear

box as much as possible. When garbage and the foreign body, etc. enter, it causes

the breakdown.

e

m

a

N

FTP-628MCL101#50 SPECIFICATION

Date

Design

Rev.

Design

Inspection

Inspect.

Changes made

Approv.

FUJITSU COMPONENT LIMITED

6

e

g

a

P

36

i

g

n

w

a

r

D

.

o

N

Submit to

�

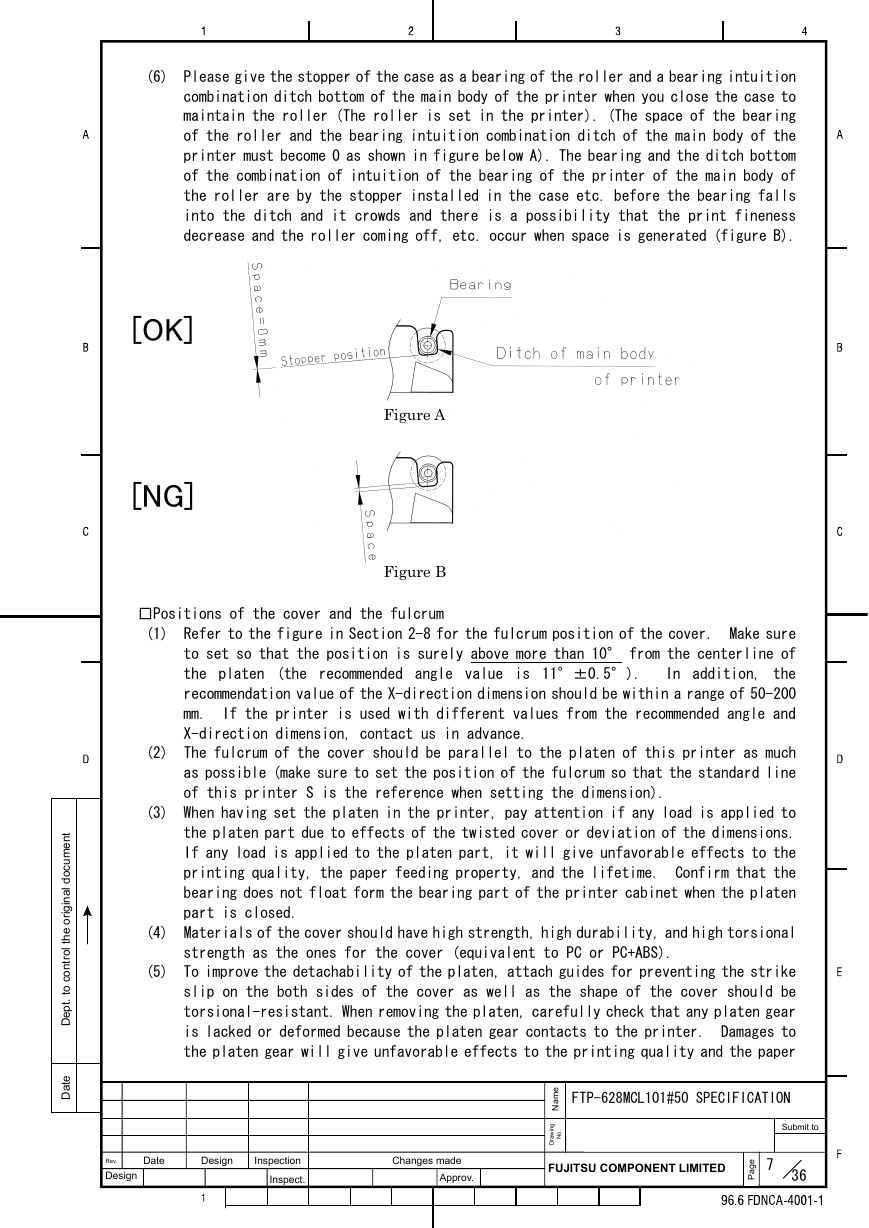

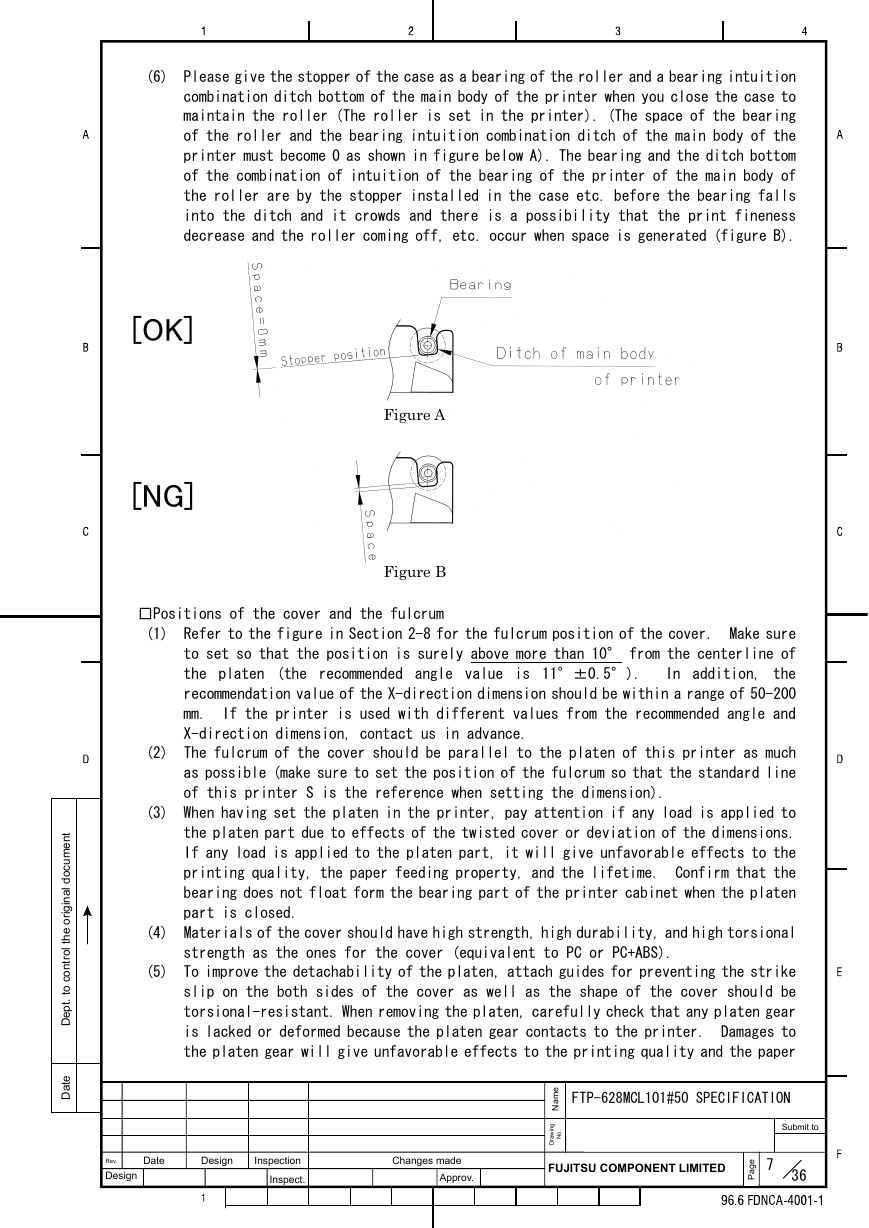

(6) Please give the stopper of the case as a bearing of the roller and a bearing intuition

combination ditch bottom of the main body of the printer when you close the case to

maintain the roller (The roller is set in the printer). (The space of the bearing

of the roller and the bearing intuition combination ditch of the main body of the

printer must become 0 as shown in figure below A). The bearing and the ditch bottom

of the combination of intuition of the bearing of the printer of the main body of

the roller are by the stopper installed in the case etc. before the bearing falls

into the ditch and it crowds and there is a possibility that the print fineness

decrease and the roller coming off, etc. occur when space is generated (figure B).

[OK]

[NG]

Figure A

Figure B

□Positions of the cover and the fulcrum

(1) Refer to the figure in Section 2-8 for the fulcrum position of the cover. Make sure

to set so that the position is surely above more than 10° from the centerline of

the platen (the recommended angle value is 11°±0.5°). In addition, the

recommendation value of the X-direction dimension should be within a range of 50-200

mm. If the printer is used with different values from the recommended angle and

X-direction dimension, contact us in advance.

(2) The fulcrum of the cover should be parallel to the platen of this printer as much

as possible (make sure to set the position of the fulcrum so that the standard line

of this printer S is the reference when setting the dimension).

(3) When having set the platen in the printer, pay attention if any load is applied to

the platen part due to effects of the twisted cover or deviation of the dimensions.

If any load is applied to the platen part, it will give unfavorable effects to the

printing quality, the paper feeding property, and the lifetime. Confirm that the

bearing does not float form the bearing part of the printer cabinet when the platen

part is closed.

(4) Materials of the cover should have high strength, high durability, and high torsional

strength as the ones for the cover (equivalent to PC or PC+ABS).

(5) To improve the detachability of the platen, attach guides for preventing the strike

slip on the both sides of the cover as well as the shape of the cover should be

torsional-resistant. When removing the platen, carefully check that any platen gear

is lacked or deformed because the platen gear contacts to the printer. Damages to

the platen gear will give unfavorable effects to the printing quality and the paper

e

m

a

N

FTP-628MCL101#50 SPECIFICATION

t

n

e

m

u

c

o

d

l

i

a

n

g

i

r

o

e

h

t

l

o

r

t

n

o

c

o

t

.

t

p

e

D

e

t

a

D

Date

Design

Rev.

Design

Inspection

Inspect.

Changes made

Approv.

FUJITSU COMPONENT LIMITED

7

e

g

a

P

36

i

g

n

w

a

r

D

.

o

N

Submit to

�

t

n

e

m

u

c

o

d

l

i

a

n

g

i

r

o

e

h

t

l

o

r

t

n

o

c

o

t

.

t

p

e

D

e

t

a

D

feeding property.

(6) The paper feeding motor (a pulse motor) of the printer and the thermal head may have

the hot temperature, depending on the running time. When designing the casing,

consider the heat radiation property. Be sure to design the casing so that no one

is allowed to directly touch with bear hands such as adopting a cover structure, etc.

□Lock mechanism of the casing

(1) The platen retainer part of this printer provides an easy retaining (locking)

mechanism (the printer as a single unit can perform the printing action), which

comprises of the pressure of the head and the shape of the bearing part of the sideboard.

However, if the following items are considered, the lock mechanism is recommended

to mount on the casing side.

(2) When using with a portable terminal, the casing may be opened and the rolled paper

inside may jump out when it is dropped or moved (particularly, while it is being

carried).

(3) Depending on the attaching orientation of the printer, loads of the cover or the

rolled paper may work to directions to which the platen is removed. Due to that,

the platen gear may get off the track or the platen may be detached during the printing.

(4) When cutting the paper ejected from the printer with a manual cutter or depending

on the pulling direction of the paper, the platen gear may get off the track or the

platen may be detached (when locking, minimize the play of the platen as much as

possible).

□Installing the printer

(1) When installing the printer, fix the edge part with a hook at one place and fix the

rear part with screws of M2 at two places. Flatness of the installing surface of

the printer should be within equal or less than 0.1mm. It is recommended that the

printer is connected to the main body FG with screws of M2 at two places (refer to

the figure of the installation dimension). Pay attention not to apply any extra force

to the printer main body and FPC since any of such force will give unfavorable effects

to the printing quality, paper traveling property (meandering, running short of the

paper, and the paper jam), and life time.

(2) When installing the printer, install it so that the printer and the rolled paper

should be parallel as much as possible. When designing the casing, it should be

designed so that the printer and the holder part of the roller paper are located at

the place shown in the Fig (6) in Section 2-8. The roller paper should be ejected

smoothly so that the paper does not hit anything such as the cover. If the above

is not conformed, troubles such as meandering of the printing paper, the running short

of the paper, and the paper jam may occur.

(3) The paper detection sensor is provided on the main body side of the printer; therefore,

be sure to design the paper holder so that the printing paper surely contact to the

sensor (refer to Section 2-8). If the printing paper floats on the sensor equal or

greater than 0.7mm, the sensor may determines the paper is not fed; therefore, attach

paper holding guides on the casing side for preventing the paper from floating. In

addition, when the roller paper is close to the end and the last part of it comes

to the paper opening paper of the printer, the paper jam may occur at the opening.

This paper holding guide works as the preventive measure of this paper jam; therefore,

adding this guide to the casing is recommended.

(4) When plugging in and out FPC to the connector of the control side, be sure that all

power is turned off before doing that.

e

m

a

N

FTP-628MCL101#50 SPECIFICATION

Date

Design

Rev.

Design

Inspection

Inspect.

Changes made

Approv.

FUJITSU COMPONENT LIMITED

8

e

g

a

P

36

i

g

n

w

a

r

D

.

o

N

Submit to

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc