Engineering Structures 24 (2002) 1383–1396

www.elsevier.com/locate/engstruct

Path-dependent cyclic stress–strain relationship of reinforcing bar

including buckling

Rajesh Prasad Dhakal a,∗, Koichi Maekawa b

a Protective Technology Research Centre, School of Civil and Environmental Engineering, Nanyang Technological University, 50 Nanyang

b Department of Civil Engineering, The University of Tokyo, Hongo 7-3-1, Bunkyo-Ku, Tokyo 113-8656, Japan

Avenue, Singapore 639798

Received 25 January 2002; received in revised form 13 May 2002; accepted 21 May 2002

Abstract

In this paper, the formulation and verification of a cyclic stress–strain relationship of reinforcing bars are presented. The tension

envelope comprises an elastic range, a yield plateau and a hardening zone. The compression envelope also includes a linear elastic

range followed by a non-linear buckling model. The cyclic loops follow Giuffre–Menegotto–Pinto equations with some modifications

to account for the effect of buckling. A complete path-dependent cyclic constitutive model is then obtained by combining the

equations representing the two monotonic envelopes and the cyclic loops. Comparison with bare bar test results shows that the

proposed model could reasonably predict the cyclic behaviour of reinforcing bars including the post-buckling loops. 2002 Elsevier

Science Ltd. All rights reserved.

Keywords: Buckling; Reinforcing bar; Envelope; Cyclic loop; Path-dependent; Stress–strain relationship

1. Introduction

Although

As the performance-based design method is gaining

popularity, the reliable assessment of seismic perform-

ance has emerged as a vital step in seismic design. With

the advancement in computing facilities that can easily

handle complicated and large-scale mathematical oper-

ations, computational models with wider scope and

greater accuracy are being developed regardless of their

complexity.

on

member/component models can provide global structural

behaviour, constitutive models of constituent material

are needed to evaluate local response and also to assess

damage. An important constituent of reinforced concrete

(RC) members is the reinforcement, which has a domi-

nant contribution in the overall seismic response. Rein-

forcing bars inside RC structures experience a wide

range of strain variations when subjected to seismic exci-

tation. Apart from experiencing large tensile and com-

analysis

based

∗ Corresponding author. Tel.: +65-6790-4150; fax: +65-6791-0046.

E-mail address: cdhakal@ntu.edu.sg (R.P. Dhakal).

pressive strains, these bars also undergo random strain

reversals from different strain levels. As the post-elastic

response of reinforcing bars depends on strain history, a

reliable path-dependent cyclic stress–strain relationship

that can cover all possible strain paths is deemed neces-

sary for evaluating structural seismic performance ana-

lytically.

Some cyclic constitutive models for reinforcing bars

have been proposed recently. However, many of them

do not incorporate the effect of buckling [1–3]. Hence,

these models are applicable either to thick bars that are

unlikely to buckle within a reasonable compressive

strain range or to loading cases where strain does not

reach high values in compression. As buckling of rein-

forcing bars in RC members is not uncommon during

seismic excitations, proper consideration of buckling is

necessary for seismic performance evaluation, and mod-

els that ignore buckling are hence not ideal for use in

seismic analysis of RC structures. Buckling-induced

instability of reinforcing bars inside RC members has

been extensively studied in the past [4–9]. Some of these

studies also discussed the average compressive response

of reinforcing bars including buckling, but none came

up with a complete cyclic model. The authors are aware

0141-0296/02/$ - see front matter 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 1 4 1 - 02 96 ( 0 2 ) 0 0 08 0- 9

�

1384

R.P. Dhakal, K. Maekawa / Engineering Structures 24 (2002) 1383–1396

of a few cyclic models [10–12] that are reported to

include the effect of buckling.

the most

Rodriguez et al. [12] conducted monotonic and cyclic

tests on deformed steel bars. Based on test results of

several specimens, they proposed equations to locate

onset of buckling during monotonic and cyclic loadings.

They also proposed a cyclic constitutive model, which

is basically the same as that proposed by Mander et al.

[1] for cases without buckling with an additional rec-

ommendation to curtail the model at the onset of buck-

ling. Nevertheless, this model is silent on the post-buck-

ling response of reinforcing bars. Direct measurement of

steel stress inside RC columns [10] and cyclic tests on

bare bars [11] have shown that reinforcing bars can carry

significant tensile stress even after the initiation of buck-

ling, although the compressive stress-carrying capacity

decreases. One of

informative studies on

reinforcement buckling is that conducted by Suda et al.

[10], in which they monitored the stress carried by rein-

forcing bars

inside RC columns with a specially

designed stress sensor. With the help of these special

test results and some assumptions, they came up with a

cyclic stress–strain relationship of

reinforcing bars

including buckling. However, this relationship suggests

a common post-buckling behaviour for all bars regard-

less of their geometrical and mechanical properties. This

does not seem logical, as past studies [6,7,13] have

shown that the buckling initiation point and the post-

buckling response are sensitive to the bar length to bar

diameter ratio (i.e.

the slenderness ratio) and yield

strength of the bar. In another genuine effort, Monti and

Nuti [11] conducted monotonic and cyclic tests on some

normal-strength deformed steel bars, and concluded that

buckling takes place in bars only with slenderness ratio

greater than 5. Based on the test results, they proposed

equations to relate average compressive response with

the slenderness ratio. They also theoretically derived

equations for cyclic loops based on different hardening

rules for cases with and without buckling, and modified

an existing cyclic model [14] to represent results of the

tests that included buckling. However, the equations pro-

posed and the constants included were derived to fit the

test results of normal-strength bars (fy ⫽ 480 MPa) with

slenderness ratio equal

to 5, 8 and 11 only. Conse-

quently, these equations cannot be general as they cover

only a narrow range of geometrical properties and do

not take into account the effect of yield strength and

bar types.

This paper presents a path-dependent cyclic model for

reinforcing bars that overcomes the aforementioned

shortcomings. The model proposed here fulfils the fol-

lowing requirements: (1) it takes into account the effect

of geometrical and mechanical properties of the bar on

its post-buckling response, and is applicable to bars with

any material properties and any type of hardening mech-

anism; (2) it is of s ⫽ f(e) type, which offers significant

in any non-linear finite element

advantages

(FE)

computation based on kinematic approximations, as in

displacement-controlled FE analysis; (3) it is fully path-

dependent and covers all possible strain paths; and (4)

it is simple in formulation and is based on material para-

meters that are readily available, making it easy to

implement/encode into any FE analysis program.

2. Uniaxial monotonic curves

Manufacturers of reinforcing bars usually provide

mechanical properties that partly or completely define

the uniaxial tensile behaviour of their products. Never-

theless, values of these parameters in compression are

seldom specified,

thus implicitly compelling one to

assume that these properties are isotropic and are equal

in tension and compression. This is true when we talk

about the point-wise stress–strain relationships because

the point-wise relationships are not influenced by the

change in overall geometry [2]. On the other hand, aver-

age tensile and compressive behaviours are not necessar-

ily the same, as a geometrical non-linearity exists in

compression [13] due to lateral deformation of reinforc-

ing bars; referred to as buckling hereafter. As monotonic

compression test results [1,11] suggest that the average

compressive stress–strain curves of

reinforcing bar

samples with slenderness ratio small enough to avoid

premature buckling are very close to the corresponding

tension envelopes, it is assumed in this study that the

average compressive and tensile envelopes are similar in

the absence of buckling.

2.1. Tension envelope

Accurate representation of

the tension envelope

becomes indispensable to ensure the accuracy of the

complete cyclic model because both the compression

envelope and cyclic loops are influenced by the tension

envelope. Note that specifying only yield strength,

Young modulus and breaking strength does not com-

pletely describe the tensile response of a bar. To trace

the post-yielding tensile response until breaking, it is

necessary to specify the range of the yield plateau, the

nature of strain-hardening, the hardening stiffness, and

the breaking strain. The authors are of the view that it

is not appropriate to extrapolate the hardening behaviour

of a bar based on its elastic properties. Tensile properties

of deformed bars reported in Refs. [8,11,15,16] manifest

that the hardening behaviours of bars with different yield

strength and manufactured in different parts of the globe

are significantly different from one another. As the hard-

ening behaviour of deformed bars becomes more brittle

with increase in yield strength, normalizing the post-

yield tension parameters with respect to the yield stress

and yield strain cannot be justified. In order to generate

�

R.P. Dhakal, K. Maekawa / Engineering Structures 24 (2002) 1383–1396

1385

a universal cyclic model that can be used for bars with

any type of hardening behaviour, the complete tension

envelope is used as an input.

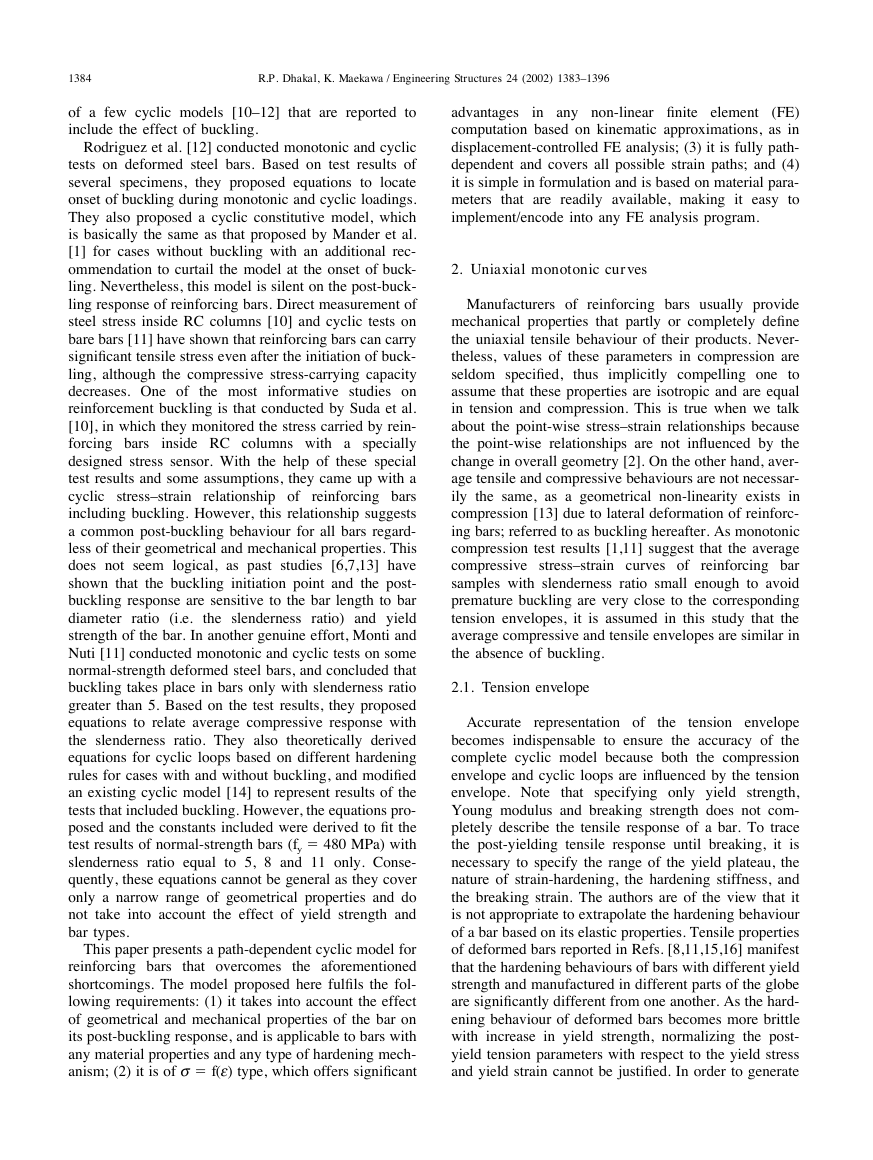

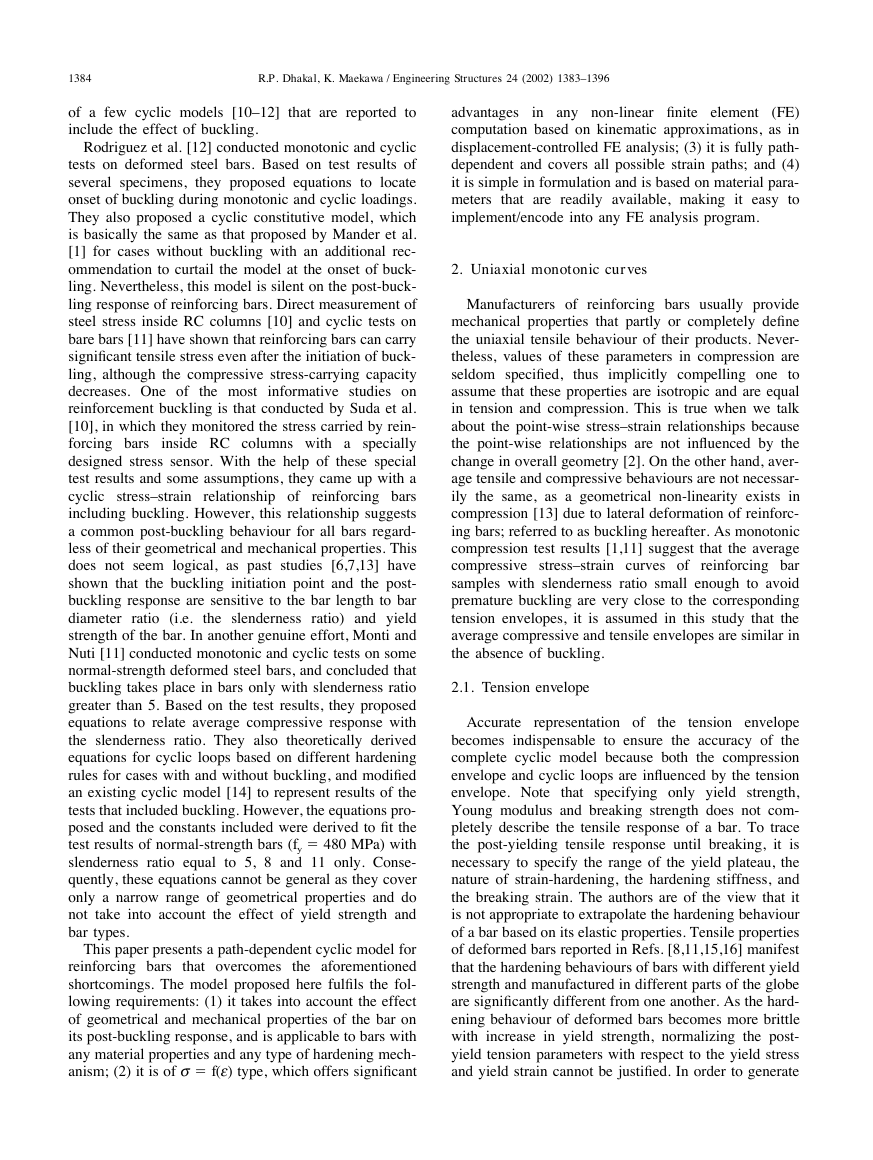

Regardless of the manufacturer and yield strength, the

tension envelope of all bars can be represented qualitat-

ively as shown in Fig. 1(a). The tension envelope con-

sists of four parts: an elastic branch (O–Y), a yield pla-

teau (Y–H), a strain-hardening zone (H–U) and the post-

ultimate descending branch (U–F). Although a closer

look inside the yield plateau is reported to reveal small

stress undulations [2], it is represented here as a straight

line with the stress equal to the yield strength for sim-

plicity. As the final post-ultimate descending branch is

of less significance in RC structural analysis, the tension

envelope only up to the ultimate stress point is usually

considered. The tension envelop until the strain-harden-

ing point esh can be represented by the following uniaxial

stress–strain (sst–est) relationships:

sst ⫽ Esest for estⱕey

and

sst ⫽ fy for ey ⬍ estⱕesh.

(2)

In Eqs. (1) and (2), Es, fy, ey and esh are Young’s

modulus, yield strength, yield strain and strain at the

starting point of hardening, respectively. Mander et al.

[1] proposed the following equations to idealize the non-

linear strain-hardening branch:

(1)

for esh ⬍ estⱕeu

冊P

sst ⫽ fu ⫹ (fy⫺fu)冉eu⫺est

P ⫽ Esh冉eu⫺esh

冊.

eu⫺esh

and

fu⫺fy

(3)

(4)

Here, fu and eu are respectively the stress and strain

at the ultimate point, and P is a parameter that describes

the shape of the hardening curve. P can be calculated as

shown in Eq. (4), where Esh is the tangential stiffness of

the hardening curve at the starting point. Note that P

equal to zero (i.e. Esh ⫽ 0) represents an elasto-plastic

bar, and P equal to 1 [i.e. Esh ⫽ (fu–fy) / (eu⫺esh)] rep-

resents a bar with linear strain-hardening behaviour.

Although the coordinates of the strain-hardening point

and the ultimate point can be located in an envelope, it

is not easy to measure Esh correctly. To avoid the uncer-

tainty involved in estimating Esh, Rodriguez et al. [12]

proposed the following equation that utilizes the coordi-

nates of any point (esh1, fsh1) in the strain-hardening zone

to evaluate P:

冊

log冉fu⫺fsh1

冊.

log冉eu⫺esh1

fu⫺fy

eu⫺esh

P ⫽

(5)

If the correct value of initial hardening stiffness Esh

is not known, the authors also prefer to use Eq. (5) as

it provides better control over the shape of the strain-

hardening curve. If an intermediate point is selected

properly, a bilinear approximation as shown in Fig. 1(b)

can also closely represent the hardening curve. However,

the selection of the intermediate point (esh1, fsh1) is diffi-

cult, when only the extreme points of the strain-harden-

ing curve are supplied and the nature of the hardening

curve in between is not known. In such cases, it is rec-

ommended to assume esh1 ⫽ [0.5(esh ⫹ eu)] and fsh1 ⫽

[fy ⫹ 0.75(fu–fy)].

2.2. Compression envelope

As mentioned earlier,

the average compressive

response within a control volume including the effect of

buckling is different from the tensile one, although the

point-wise stress–strain relationships in tension and

compression are the same regardless of buckling. In the

past, a few average compressive stress–strain relation-

ships including buckling have been proposed [11,12] to

satisfy the results of the tests, which were conducted

within a small range of slenderness ratio. Because of

the

different material properties used in these tests,

Fig. 1. Schematic representation of monotonic tension envelope.

�

1386

R.P. Dhakal, K. Maekawa / Engineering Structures 24 (2002) 1383–1396

empirical relationships derived differ considerably from

one another. Although the equations proposed could pre-

dict the effect of slenderness ratio in the tested range,

they do not account for the effect of other parameters

such as yield strength that was not varied in the tests. As

a general model has to cover conditions that are hardly

reproduced in the tests,

the experiments planned for

obtaining widely applicable constitutive models should

consist of test specimens that systematically cover a

wide range of geometrical as well as mechanical proper-

ties. Experiments consisting of a few specimens with

random properties are, of course, informative, and better

suited to verify proposed models rather than to generate

new models based on them.

In order to generate data for model formulation, the

authors conducted an analytical parametric study based

on the fibre technique [14], where the elements were

intentionally chosen to be of small length to ensure that

the behaviour within an element is unaffected by global

geometrical alterations. Hence, use of the tension envel-

ope to represent the compressive stress–strain relation-

ship of fibres in each element regardless of the extent of

buckling is justified. To reproduce actual test conditions,

rotation and displacement at the two extreme nodes were

restrained, and an axial downward displacement was

applied gradually at the topmost node. Of course, the

analytical tool was verified experimentally [13] before

conducting the extensive parametric study. Length L,

diameter D and yield strength fy of the bar were ident-

ified to govern the axial load–displacement relationship,

and these three parameters were varied within wide

ranges to investigate their effect on the average com-

pressive response.

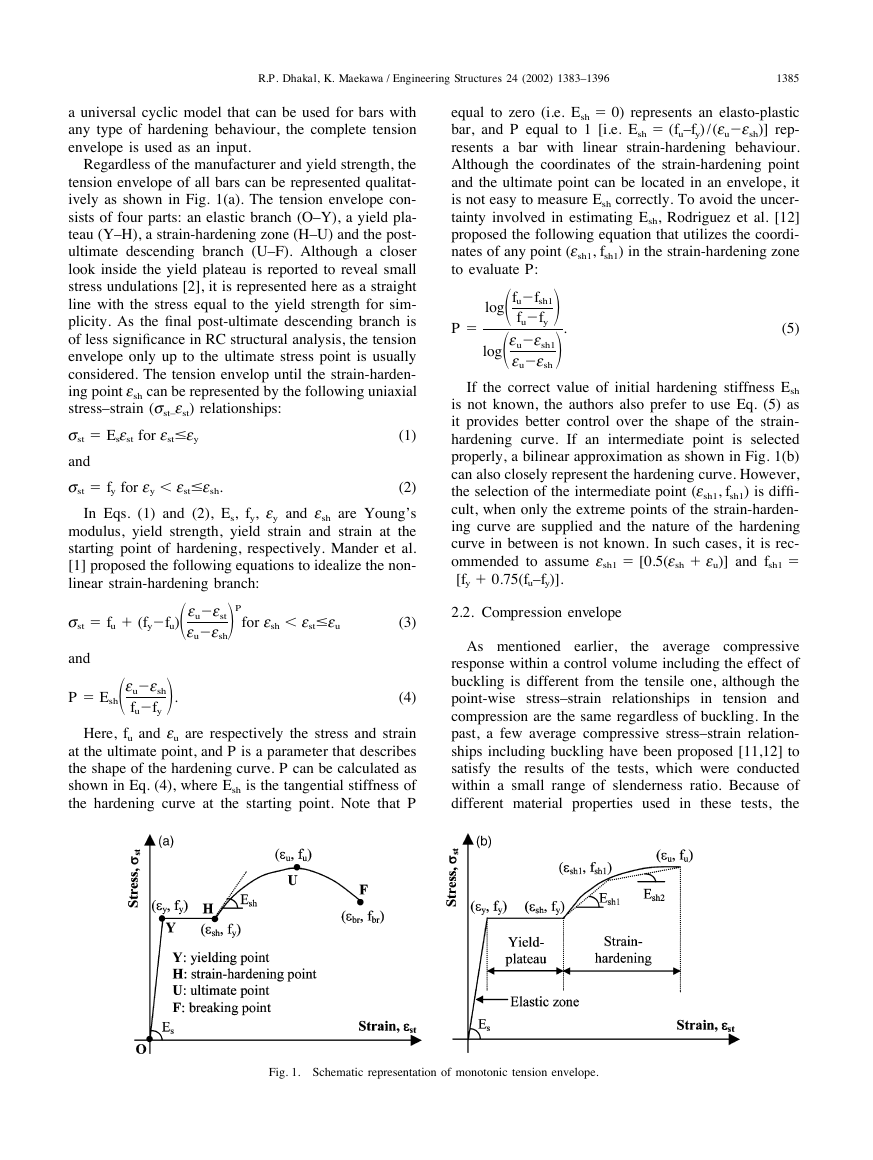

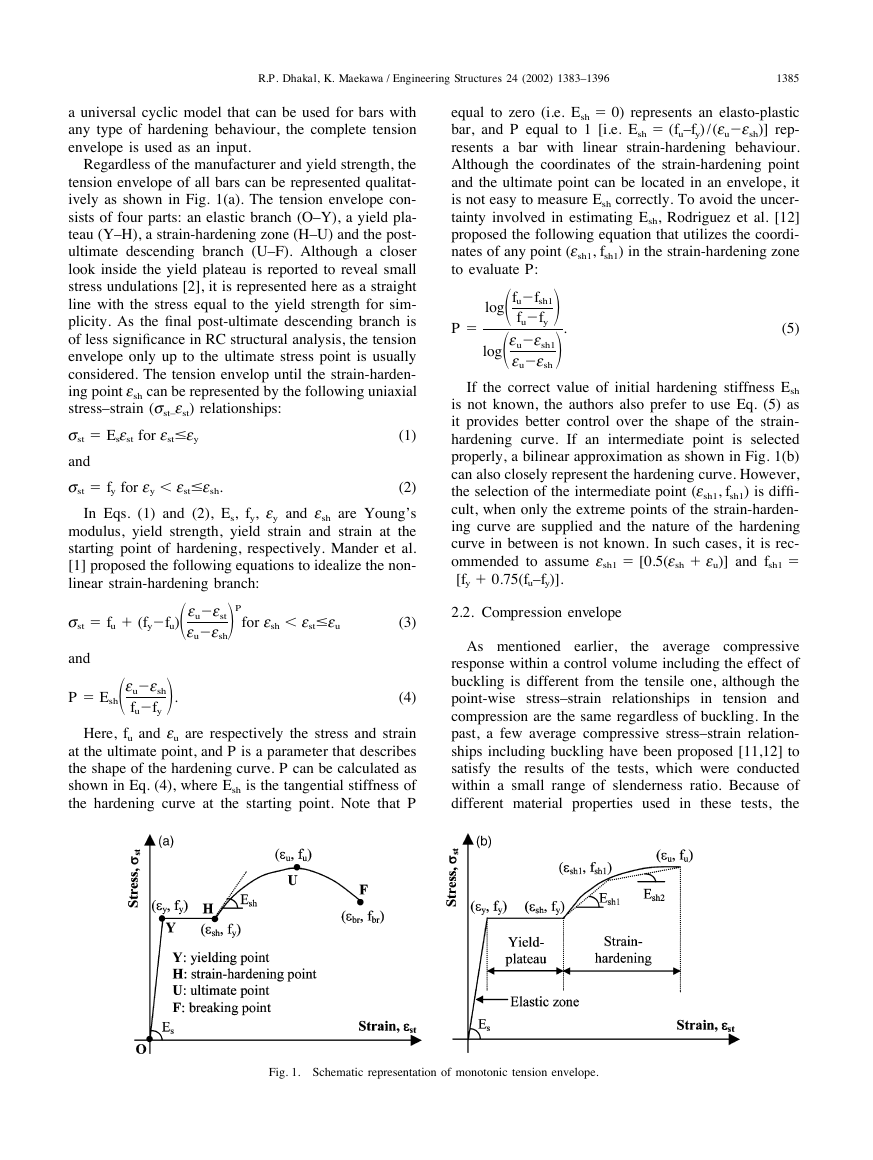

Detailed discussions on the analytical method and the

results are beyond the scope of this paper, and have been

reported in another paper [13]. A typical result of the

parametric study for an elastic–perfectly plastic bar is

illustrated in Fig. 2. The comparative normalized aver-

age stress–strain curves for slenderness ratios of 5 and

10 and yield strengths ranging from 100 MPa to 1600

MPa are presented in Fig. 2(a) and (b), respectively. The

results suggest that the critical slenderness ratio below

which the effect of buckling is negligible depends also

on yield strength of the reinforcing bar. Interestingly,

two pairs of special cases [(i) fy ⫽ 100 MPa, L/ D ⫽

10 and fy ⫽ 400 MPa, L/ D ⫽ 5;

fy ⫽

400 MPa, L/ D ⫽ 10 and fy ⫽ 1600 MPa, L / D ⫽ 5],

compared in Fig. 2(c), showed similar average responses

for the two cases in each pair, suggesting that the nor-

malized average compressive response depends only on

L/ D√fy. The variation of normalized compressive stress

with L / D√fy is shown in Fig. 2(d). As the value of

L/ D√fy increases,

the buckling-induced stress degra-

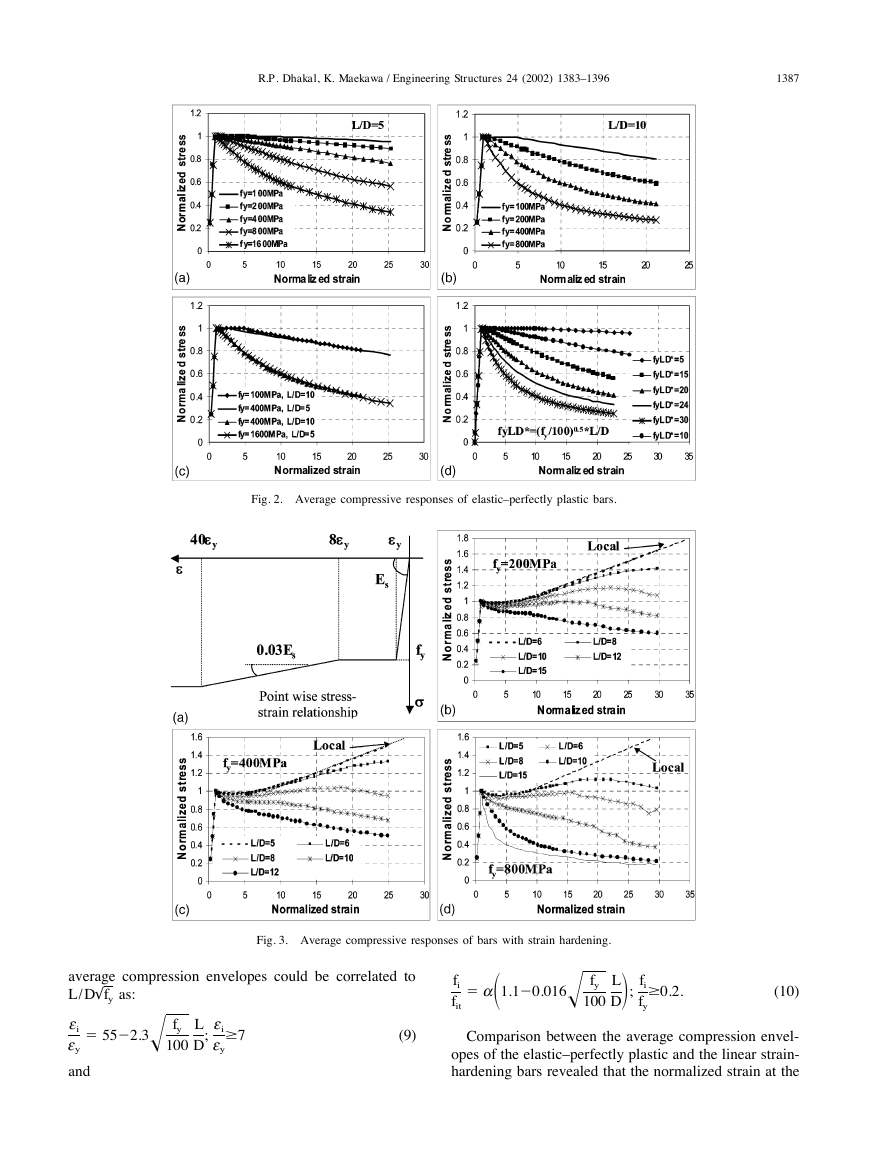

dation becomes more severe. Next, similar parametric

study was conducted for reinforcing bars with a linear

and (ii)

strain-hardening behaviour as shown in Fig. 3(a). The

normalized compressive stress–strain curves for these

bars with slenderness ratios ranging from 5 to 15 for

yield strengths equal to 200, 400 and 800 MPa are shown

in Fig. 3(b)–(d), respectively. In this case too, the aver-

age compressive response was found to depend uniquely

on L / D√fy, irrespective of separate values of L, D and

fy. The past studies could not unearth this unique inter-

relationship, which is the backbone of the model pro-

posed in this paper.

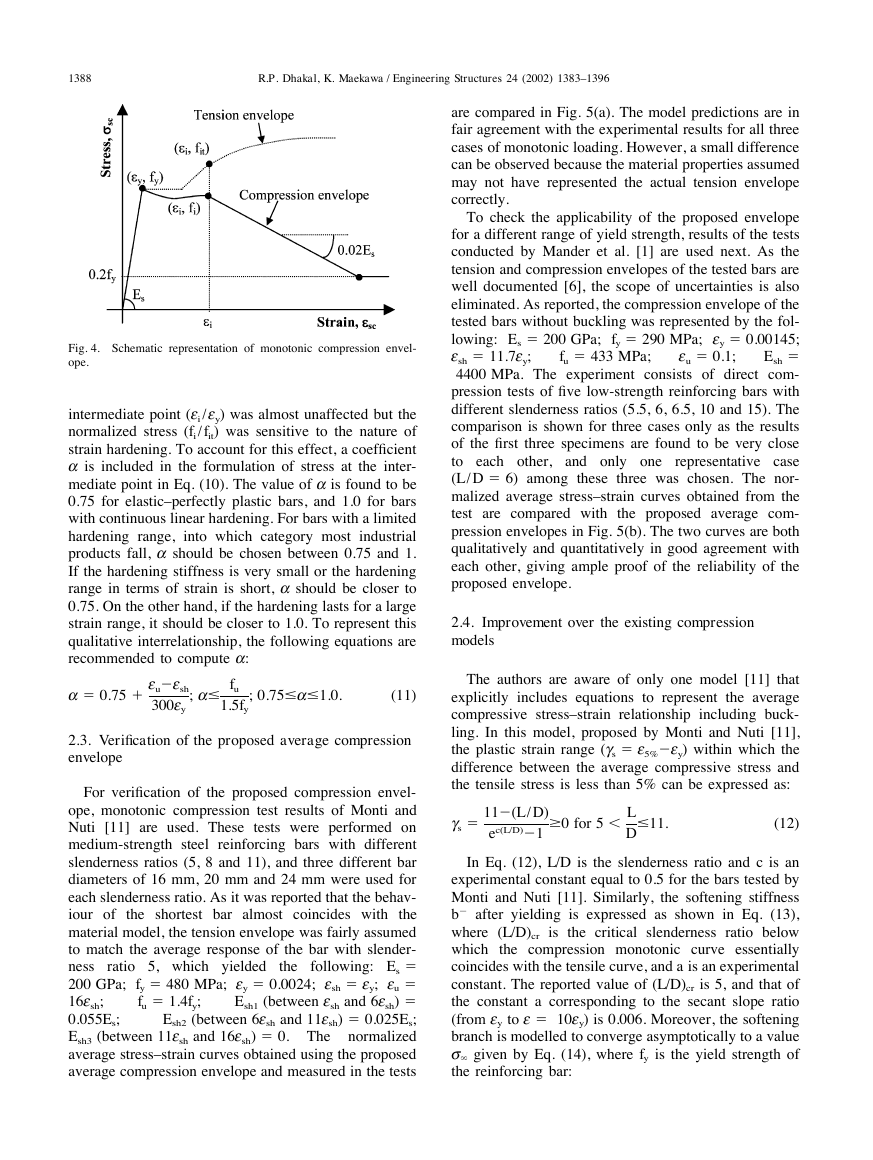

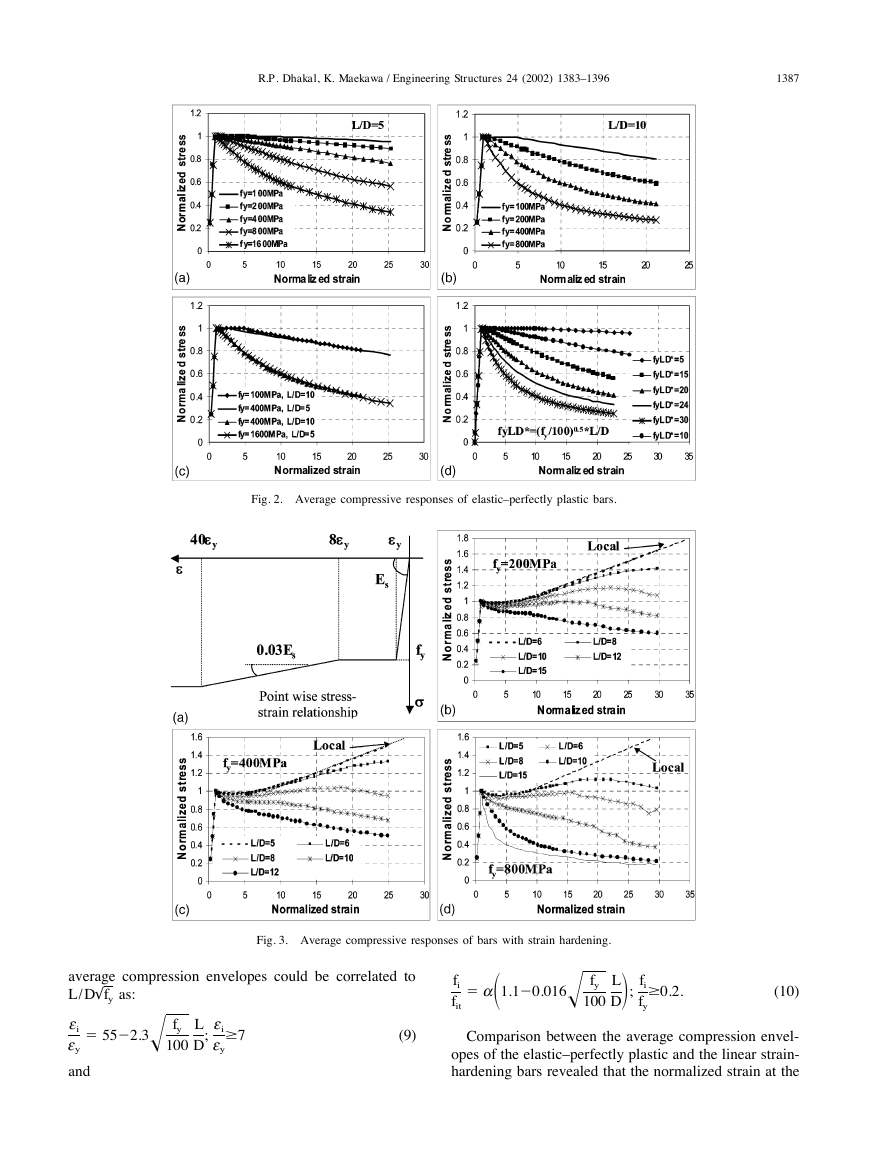

Through this analytical parametric study, various facts

regarding the average behaviour of reinforcing bars in

compression are revealed. Some of them are: (1) the

average compressive stress–strain relationship can be

described completely by L / D√fy; (2) the average com-

pression envelope lies below the tension envelope when

plotted together; (3) the trend of average compressive

stress degradation depends on the value of L/ D√fy and

also on the tension envelope; (4) regardless of L/ D√fy,

the compressive stress degradation rate in the later stage

is nearly constant with a negative slope approximately

equal to 0.02Es; and (5) the average compressive stress

becomes constant after it becomes equal to 20% of the

yield strength. Guided by these unique interrelationships,

an

stress–strain

relationship is proposed, the general layout of which is

sketched in Fig. 4. Note that the compressive stresses

and strains specified in Fig. 4 and used in the equations

to follow are absolute, and their signs should be changed

before merging with

and

unloading/reloading loops to form a complete cyclic

model. An intermediate point (ei, fi) is established, after

which a constant negative stiffness equal to 0.02Es is

applied until the average compressive stress becomes

equal to 0.2fy. To represent the aforementioned mech-

anisms, the following compressive stress–strain (ssc–esc)

relationships are proposed:

ssc ⫽ Esesc for escⱕey,

average monotonic

compressive

envelope

tension

the

(6)

⫽ 1⫺冉1⫺fi

冊冉esc⫺ey

冊 for ey ⬍ escⱕei

fit

(7)

ei⫺ey

ssc

st

and

ssc ⫽ fi⫺0.02Es(esc⫺ei); sscⱖ0.2fy for esc ⬎ ei.

(8)

Here, st and fit are the stresses in the tension envelope

corresponding to esc (current strain) and ei (strain at the

intermediate point), respectively. To make the model

applicable to bars with all types of material model, the

compressive stress ssc at and before the intermediate

point is normalized with respect to st. This normaliz-

ation technique also renders the shape of the average

compression envelope before this intermediate point

look like the tension envelope; a characteristic that was

observed distinctly in all analytical results. The coordi-

nates of intermediate points in the analytically generated

�

R.P. Dhakal, K. Maekawa / Engineering Structures 24 (2002) 1383–1396

1387

Fig. 2. Average compressive responses of elastic–perfectly plastic bars.

Fig. 3. Average compressive responses of bars with strain hardening.

average compression envelopes could be correlated to

L/ D√fy as:

⫽ 55⫺2.3冪 fy

ei

ey

and

ei

ey

100

L

D

;

ⱖ7

(9)

fi

fit

⫽ a冉1.1⫺0.016冪 fy

100

冊;

fi

fy

ⱖ0.2.

(10)

L

D

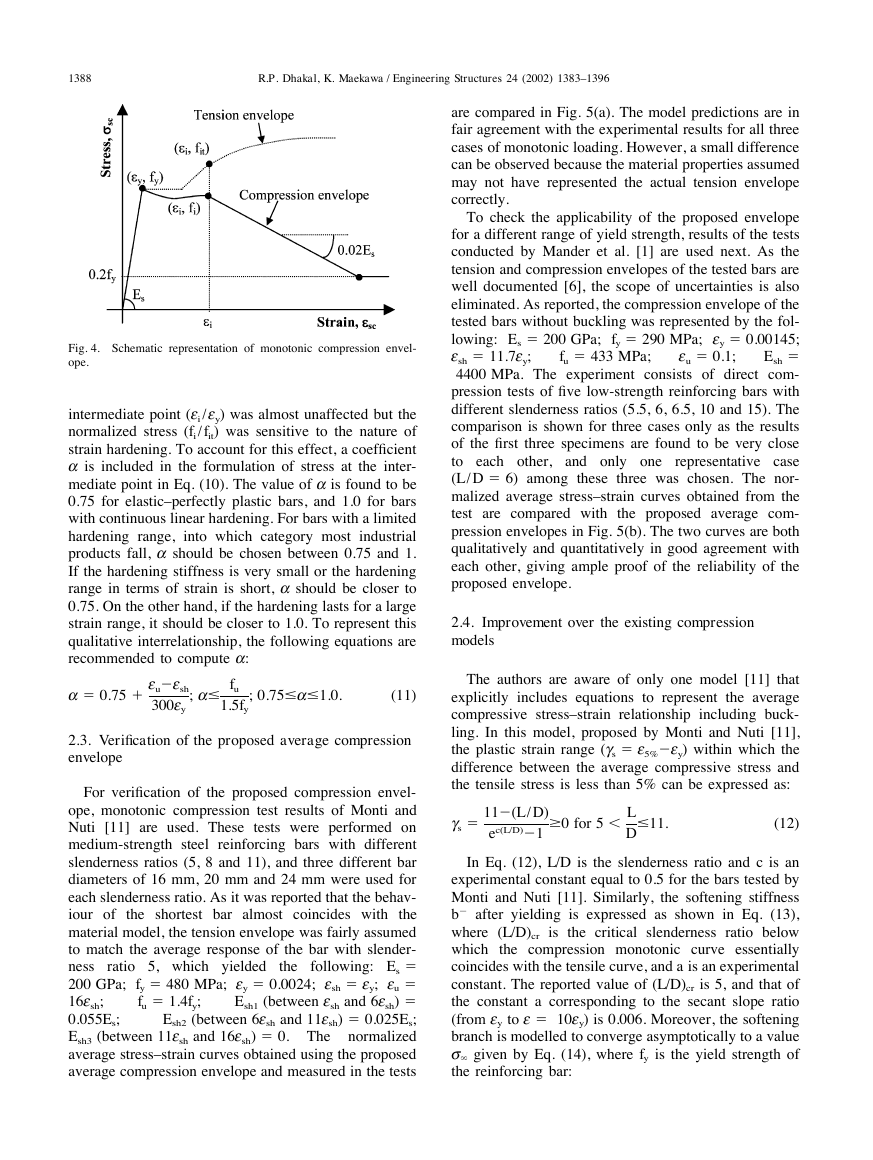

Comparison between the average compression envel-

opes of the elastic–perfectly plastic and the linear strain-

hardening bars revealed that the normalized strain at the

�

1388

R.P. Dhakal, K. Maekawa / Engineering Structures 24 (2002) 1383–1396

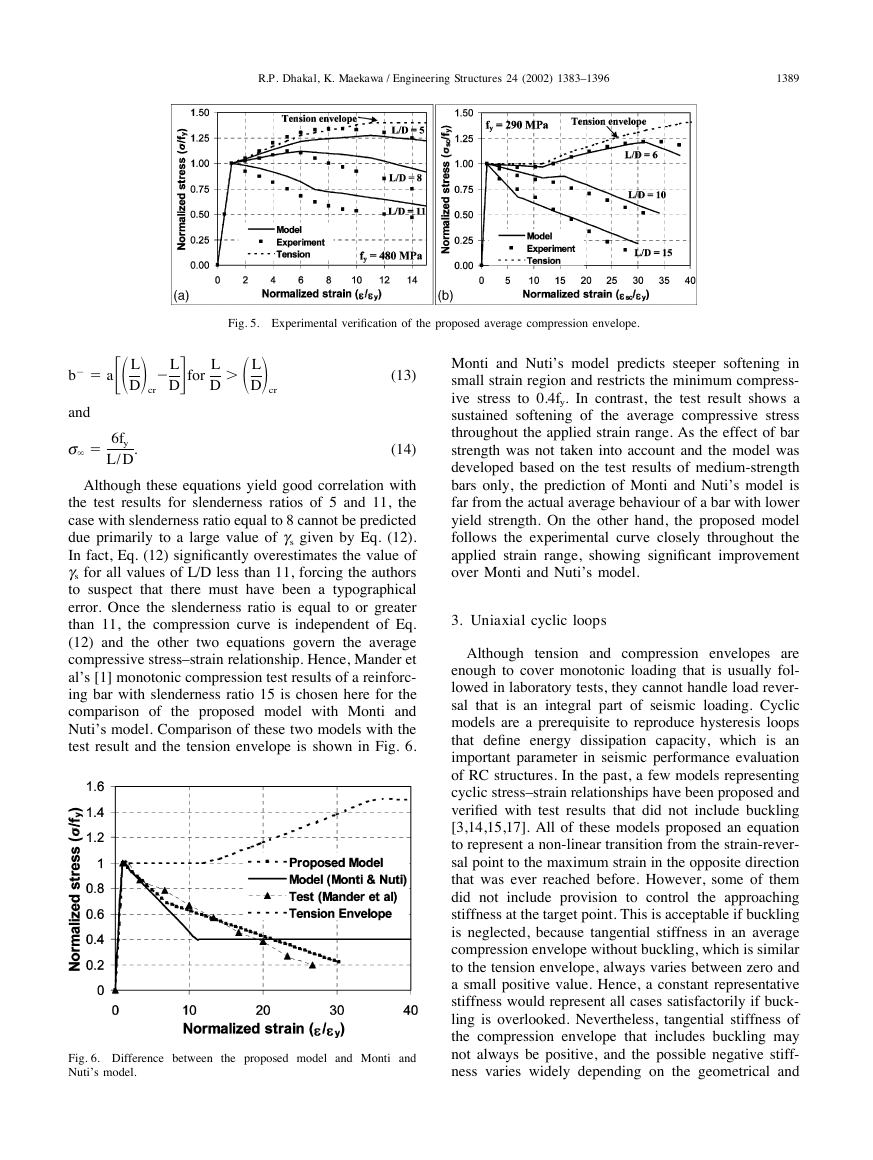

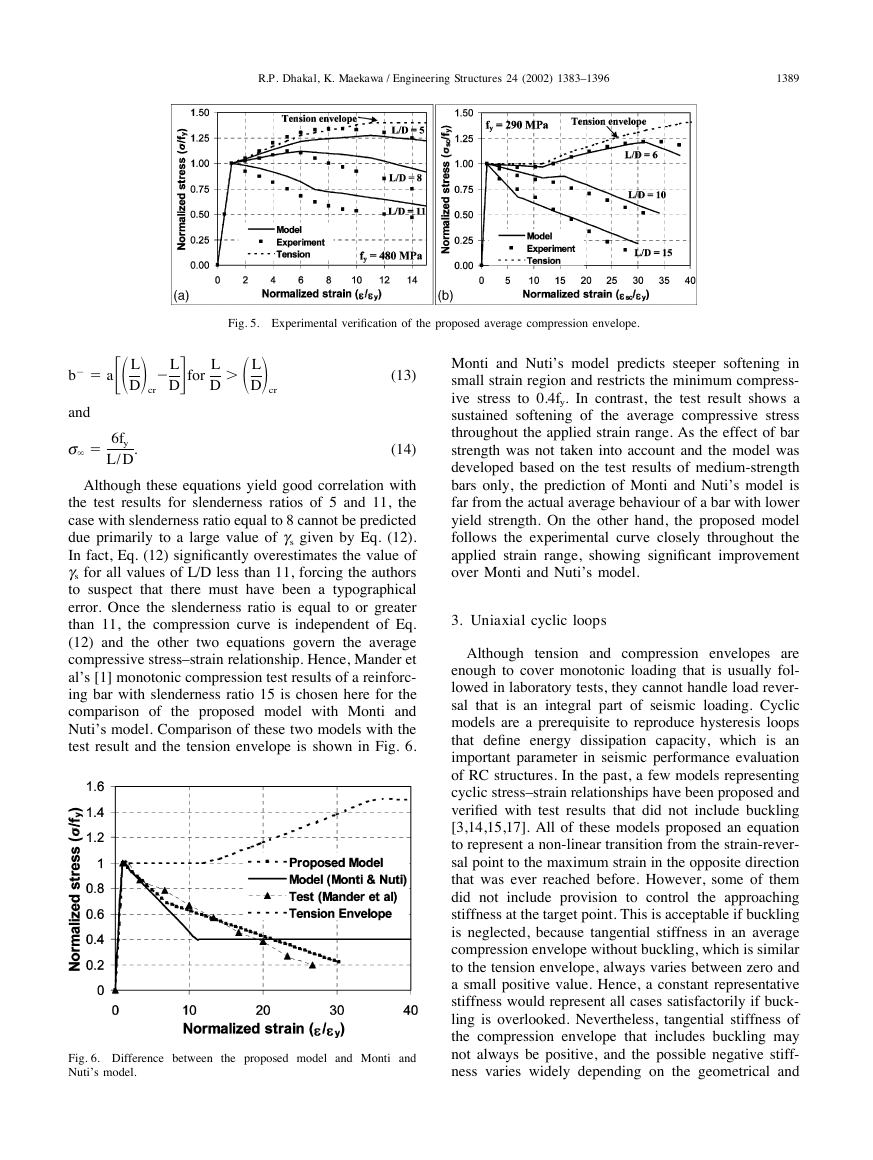

are compared in Fig. 5(a). The model predictions are in

fair agreement with the experimental results for all three

cases of monotonic loading. However, a small difference

can be observed because the material properties assumed

may not have represented the actual tension envelope

correctly.

eu ⫽ 0.1;

fu ⫽ 433 MPa;

To check the applicability of the proposed envelope

for a different range of yield strength, results of the tests

conducted by Mander et al. [1] are used next. As the

tension and compression envelopes of the tested bars are

well documented [6], the scope of uncertainties is also

eliminated. As reported, the compression envelope of the

tested bars without buckling was represented by the fol-

lowing: Es ⫽ 200 GPa;

fy ⫽ 290 MPa; ey ⫽ 0.00145;

esh ⫽ 11.7ey;

Esh ⫽

4400 MPa. The experiment consists of direct com-

pression tests of five low-strength reinforcing bars with

different slenderness ratios (5.5, 6, 6.5, 10 and 15). The

comparison is shown for three cases only as the results

of the first three specimens are found to be very close

to each other, and only one representative case

(L / D ⫽ 6) among these three was chosen. The nor-

malized average stress–strain curves obtained from the

test are compared with the proposed average com-

pression envelopes in Fig. 5(b). The two curves are both

qualitatively and quantitatively in good agreement with

each other, giving ample proof of the reliability of the

proposed envelope.

2.4. Improvement over the existing compression

models

The authors are aware of only one model [11] that

explicitly includes equations to represent the average

compressive stress–strain relationship including buck-

ling. In this model, proposed by Monti and Nuti [11],

the plastic strain range (gs ⫽ e5%⫺ey) within which the

difference between the average compressive stress and

the tensile stress is less than 5% can be expressed as:

gs ⫽ 11⫺(L / D)

ec(L/D)⫺1

ⱖ0 for 5 ⬍ L

D

ⱕ11.

(12)

In Eq. (12), L/D is the slenderness ratio and c is an

experimental constant equal to 0.5 for the bars tested by

Monti and Nuti [11]. Similarly, the softening stiffness

b⫺ after yielding is expressed as shown in Eq. (13),

is the critical slenderness ratio below

where (L/D)cr

which the compression monotonic curve essentially

coincides with the tensile curve, and a is an experimental

constant. The reported value of (L/D)cr is 5, and that of

the constant a corresponding to the secant slope ratio

(from ey to e ⫽ 10ey) is 0.006. Moreover, the softening

branch is modelled to converge asymptotically to a value

s⬁ given by Eq. (14), where fy is the yield strength of

the reinforcing bar:

Fig. 4. Schematic representation of monotonic compression envel-

ope.

intermediate point (ei /ey) was almost unaffected but the

normalized stress (fi/ fit) was sensitive to the nature of

strain hardening. To account for this effect, a coefficient

a is included in the formulation of stress at the inter-

mediate point in Eq. (10). The value of a is found to be

0.75 for elastic–perfectly plastic bars, and 1.0 for bars

with continuous linear hardening. For bars with a limited

hardening range, into which category most industrial

products fall, a should be chosen between 0.75 and 1.

If the hardening stiffness is very small or the hardening

range in terms of strain is short, a should be closer to

0.75. On the other hand, if the hardening lasts for a large

strain range, it should be closer to 1.0. To represent this

qualitative interrelationship, the following equations are

recommended to compute a:

a ⫽ 0.75 ⫹ eu⫺esh

; aⱕ fu

300ey

1.5fy

; 0.75ⱕaⱕ1.0.

(11)

2.3. Verification of the proposed average compression

envelope

For verification of the proposed compression envel-

ope, monotonic compression test results of Monti and

Nuti [11] are used. These tests were performed on

medium-strength steel reinforcing bars with different

slenderness ratios (5, 8 and 11), and three different bar

diameters of 16 mm, 20 mm and 24 mm were used for

each slenderness ratio. As it was reported that the behav-

iour of

the shortest bar almost coincides with the

material model, the tension envelope was fairly assumed

to match the average response of the bar with slender-

ratio 5, which yielded the following: Es ⫽

ness

fy ⫽ 480 MPa; ey ⫽ 0.0024; esh ⫽ ey; eu ⫽

200 GPa;

fu ⫽ 1.4fy;

Esh1 (between esh and 6esh) ⫽

16esh;

Esh2 (between 6esh and 11esh) ⫽ 0.025Es;

0.055Es;

Esh3 (between 11esh and 16esh) ⫽ 0. The

normalized

average stress–strain curves obtained using the proposed

average compression envelope and measured in the tests

�

R.P. Dhakal, K. Maekawa / Engineering Structures 24 (2002) 1383–1396

1389

Fig. 5. Experimental verification of the proposed average compression envelope.

⬎冉L

冊

D

cr

冊

⫺L

D

cr

册for

L

D

b⫺ ⫽ a冋冉L

D

and

s⬁ ⫽ 6fy

L/ D

.

(13)

(14)

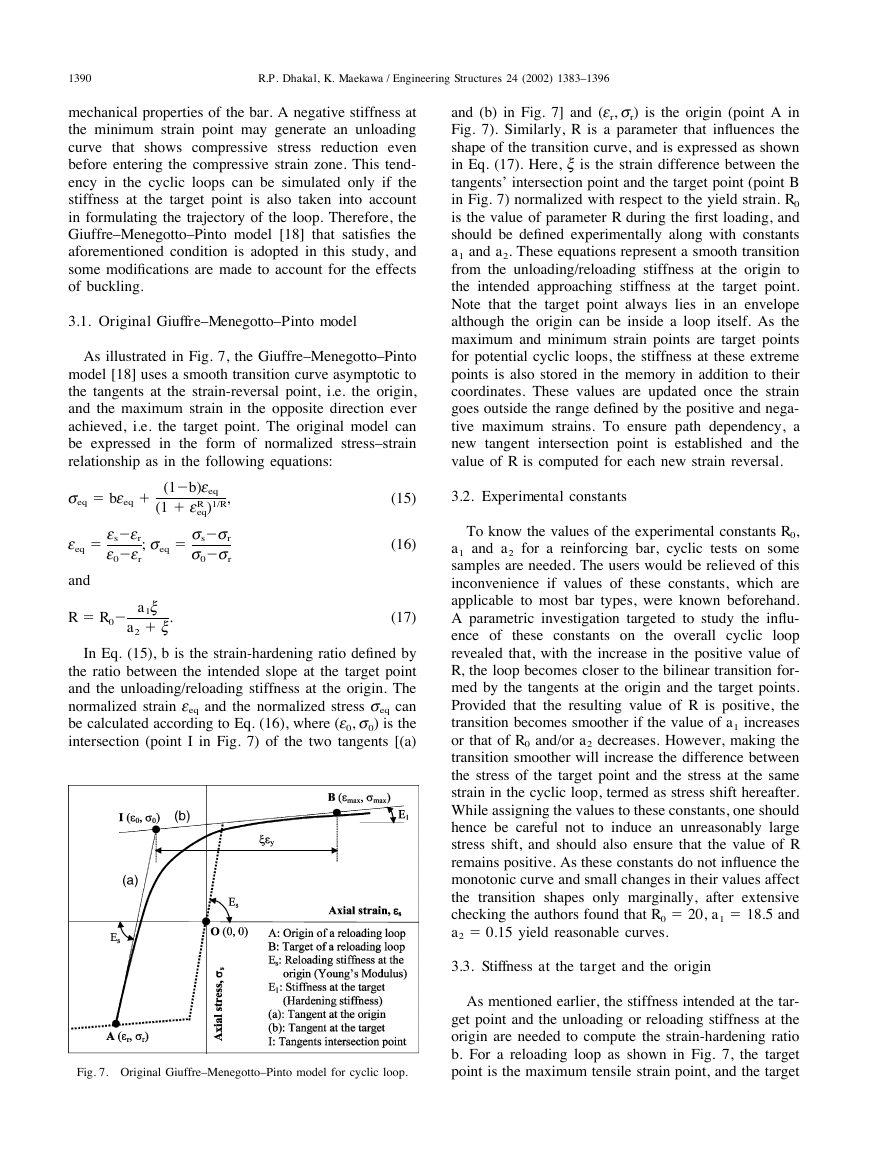

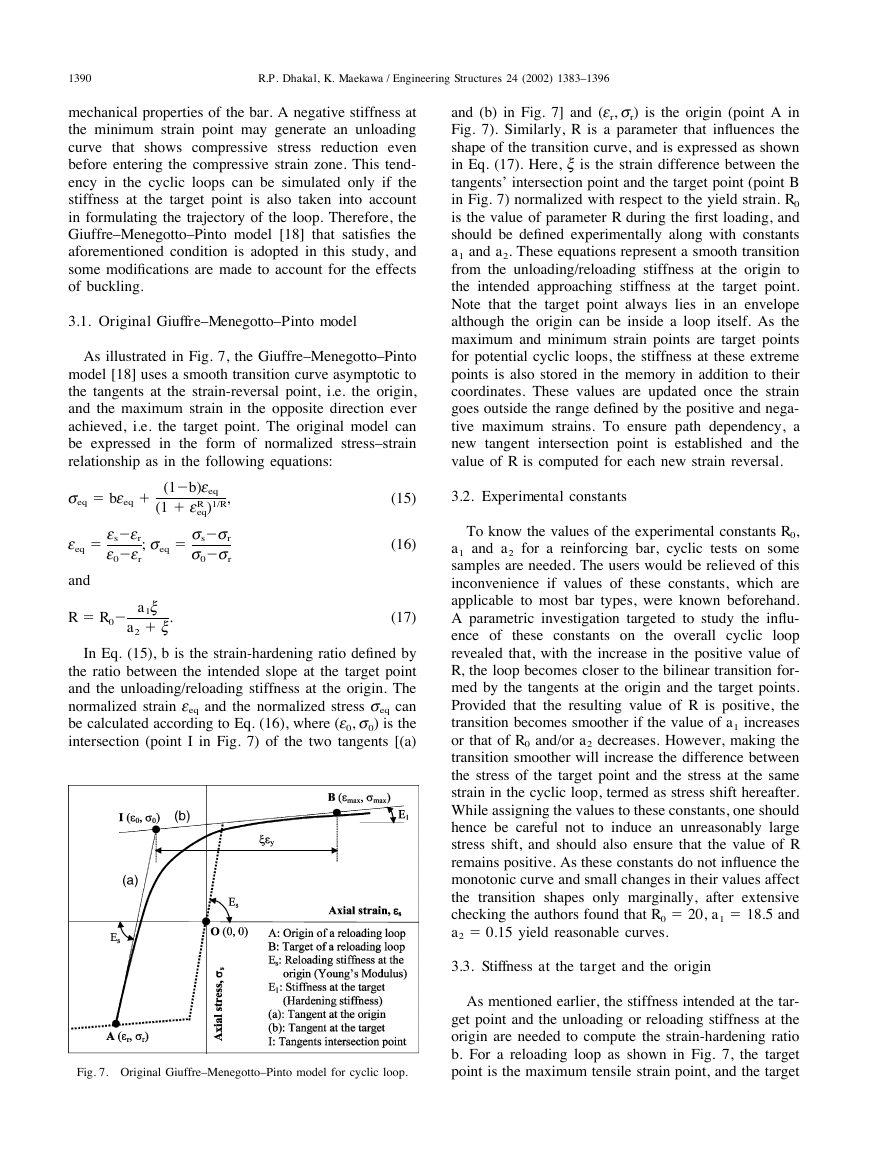

Although these equations yield good correlation with

the test results for slenderness ratios of 5 and 11, the

case with slenderness ratio equal to 8 cannot be predicted

due primarily to a large value of gs given by Eq. (12).

In fact, Eq. (12) significantly overestimates the value of

gs for all values of L/D less than 11, forcing the authors

to suspect that there must have been a typographical

error. Once the slenderness ratio is equal to or greater

than 11, the compression curve is independent of Eq.

(12) and the other two equations govern the average

compressive stress–strain relationship. Hence, Mander et

al’s [1] monotonic compression test results of a reinforc-

ing bar with slenderness ratio 15 is chosen here for the

comparison of the proposed model with Monti and

Nuti’s model. Comparison of these two models with the

test result and the tension envelope is shown in Fig. 6.

Fig. 6. Difference between the proposed model and Monti and

Nuti’s model.

Monti and Nuti’s model predicts steeper softening in

small strain region and restricts the minimum compress-

ive stress to 0.4fy. In contrast, the test result shows a

sustained softening of the average compressive stress

throughout the applied strain range. As the effect of bar

strength was not taken into account and the model was

developed based on the test results of medium-strength

bars only, the prediction of Monti and Nuti’s model is

far from the actual average behaviour of a bar with lower

yield strength. On the other hand, the proposed model

follows the experimental curve closely throughout the

applied strain range, showing significant improvement

over Monti and Nuti’s model.

3. Uniaxial cyclic loops

Although tension and compression envelopes are

enough to cover monotonic loading that is usually fol-

lowed in laboratory tests, they cannot handle load rever-

sal that is an integral part of seismic loading. Cyclic

models are a prerequisite to reproduce hysteresis loops

that define energy dissipation capacity, which is an

important parameter in seismic performance evaluation

of RC structures. In the past, a few models representing

cyclic stress–strain relationships have been proposed and

verified with test results that did not include buckling

[3,14,15,17]. All of these models proposed an equation

to represent a non-linear transition from the strain-rever-

sal point to the maximum strain in the opposite direction

that was ever reached before. However, some of them

did not include provision to control the approaching

stiffness at the target point. This is acceptable if buckling

is neglected, because tangential stiffness in an average

compression envelope without buckling, which is similar

to the tension envelope, always varies between zero and

a small positive value. Hence, a constant representative

stiffness would represent all cases satisfactorily if buck-

ling is overlooked. Nevertheless, tangential stiffness of

the compression envelope that includes buckling may

not always be positive, and the possible negative stiff-

ness varies widely depending on the geometrical and

�

1390

R.P. Dhakal, K. Maekawa / Engineering Structures 24 (2002) 1383–1396

mechanical properties of the bar. A negative stiffness at

the minimum strain point may generate an unloading

curve that shows compressive stress reduction even

before entering the compressive strain zone. This tend-

ency in the cyclic loops can be simulated only if the

stiffness at the target point is also taken into account

in formulating the trajectory of the loop. Therefore, the

Giuffre–Menegotto–Pinto model [18] that satisfies the

aforementioned condition is adopted in this study, and

some modifications are made to account for the effects

of buckling.

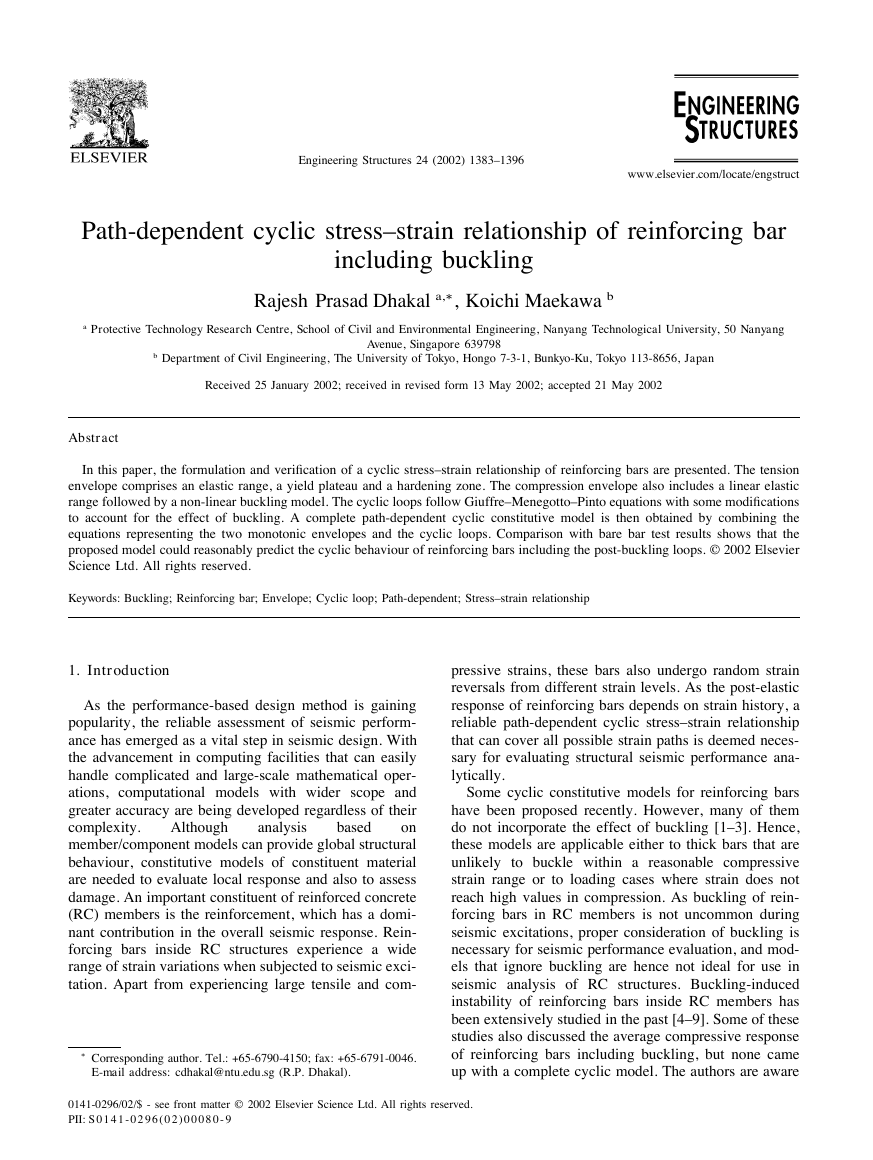

3.1. Original Giuffre–Menegotto–Pinto model

As illustrated in Fig. 7, the Giuffre–Menegotto–Pinto

model [18] uses a smooth transition curve asymptotic to

the tangents at the strain-reversal point, i.e. the origin,

and the maximum strain in the opposite direction ever

achieved, i.e. the target point. The original model can

be expressed in the form of normalized stress–strain

relationship as in the following equations:

seq ⫽ beeq ⫹ (1⫺b)eeq

eq)1/R,

(1 ⫹ eR

; seq ⫽ ss⫺sr

s0⫺sr

eeq ⫽ es⫺er

e0⫺er

(15)

(16)

and

R ⫽ R0⫺ a1x

a2 ⫹ x

.

(17)

In Eq. (15), b is the strain-hardening ratio defined by

the ratio between the intended slope at the target point

and the unloading/reloading stiffness at the origin. The

normalized strain eeq and the normalized stress seq can

be calculated according to Eq. (16), where (e0, s0) is the

intersection (point I in Fig. 7) of the two tangents [(a)

Fig. 7. Original Giuffre–Menegotto–Pinto model for cyclic loop.

and (b) in Fig. 7] and (er, sr) is the origin (point A in

Fig. 7). Similarly, R is a parameter that influences the

shape of the transition curve, and is expressed as shown

in Eq. (17). Here, x is the strain difference between the

tangents’ intersection point and the target point (point B

in Fig. 7) normalized with respect to the yield strain. R0

is the value of parameter R during the first loading, and

should be defined experimentally along with constants

a1 and a2. These equations represent a smooth transition

from the unloading/reloading stiffness at the origin to

the intended approaching stiffness at the target point.

Note that the target point always lies in an envelope

although the origin can be inside a loop itself. As the

maximum and minimum strain points are target points

for potential cyclic loops, the stiffness at these extreme

points is also stored in the memory in addition to their

coordinates. These values are updated once the strain

goes outside the range defined by the positive and nega-

tive maximum strains. To ensure path dependency, a

new tangent intersection point is established and the

value of R is computed for each new strain reversal.

3.2. Experimental constants

To know the values of the experimental constants R0,

a1 and a2 for a reinforcing bar, cyclic tests on some

samples are needed. The users would be relieved of this

inconvenience if values of these constants, which are

applicable to most bar types, were known beforehand.

A parametric investigation targeted to study the influ-

ence of these constants on the overall cyclic loop

revealed that, with the increase in the positive value of

R, the loop becomes closer to the bilinear transition for-

med by the tangents at the origin and the target points.

Provided that the resulting value of R is positive, the

transition becomes smoother if the value of a1 increases

or that of R0 and/or a2 decreases. However, making the

transition smoother will increase the difference between

the stress of the target point and the stress at the same

strain in the cyclic loop, termed as stress shift hereafter.

While assigning the values to these constants, one should

hence be careful not to induce an unreasonably large

stress shift, and should also ensure that the value of R

remains positive. As these constants do not influence the

monotonic curve and small changes in their values affect

the transition shapes only marginally, after extensive

checking the authors found that R0 ⫽ 20, a1 ⫽ 18.5 and

a2 ⫽ 0.15 yield reasonable curves.

3.3. Stiffness at the target and the origin

As mentioned earlier, the stiffness intended at the tar-

get point and the unloading or reloading stiffness at the

origin are needed to compute the strain-hardening ratio

b. For a reloading loop as shown in Fig. 7, the target

point is the maximum tensile strain point, and the target

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc