Computer Organization and Architecture

Course Design

The Report of the parallel output controller

(POC)

School of Information Science and Engineering

Southeast University

March 2013

1

�

Contents

1. Purpose--------------------------------------------------

2. Tasks-----------------------------------------------------

3. The overall connection-------------------------------

4. Design description-------------------------------------

5. Simulation result-------------------------------------

6. Conclusion and discussion---------------------------

7. Appendix---------------------------------------------

2

�

1. Purpose

The purpose of this project is to design and simulate a parallel output controller

(POC)which acts an interface between system bus and printer. The Altera’s Maxplus

II EDA tool is recommended and provided for simulation. Please refer to William

Stallings.“Computer Organization and Architecture, Designing for Performance”,

P.65~75; P.185~190.

2. Tasks

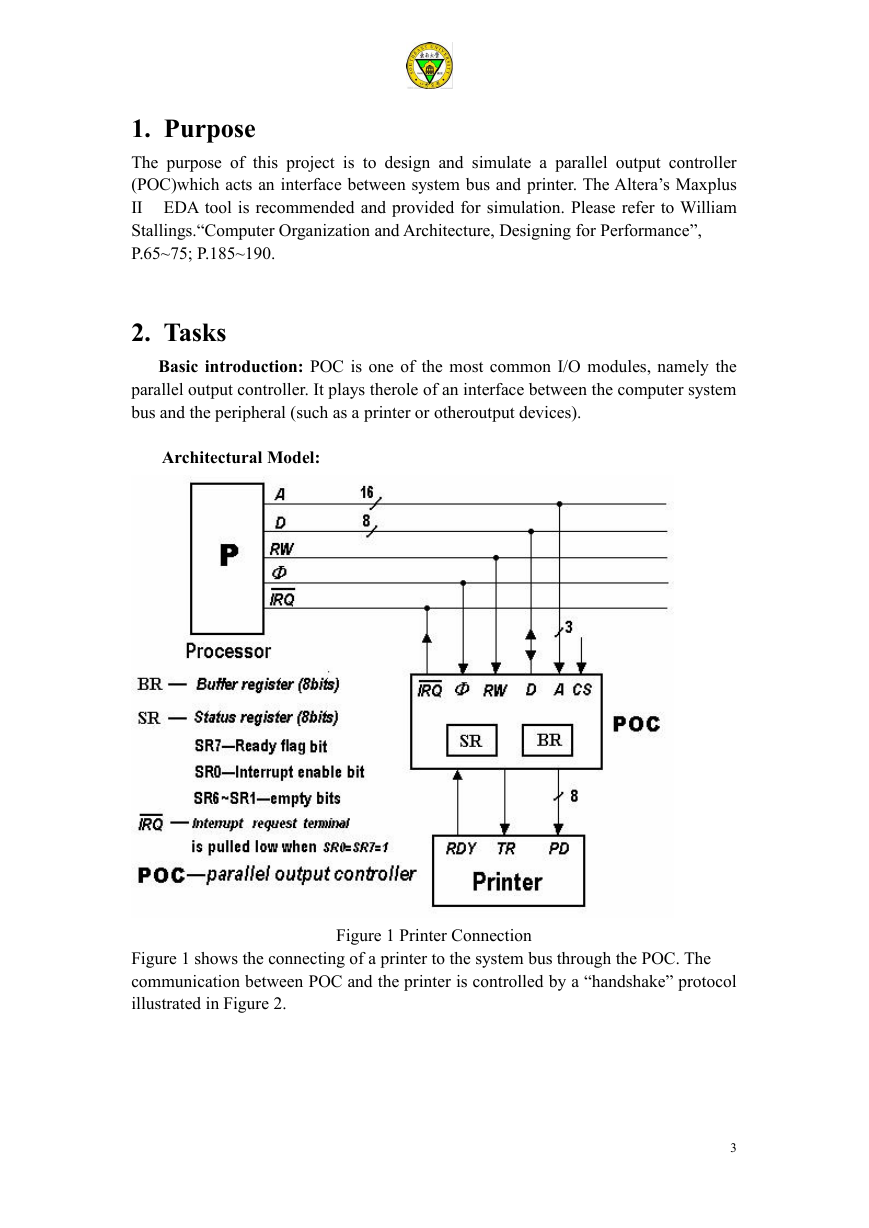

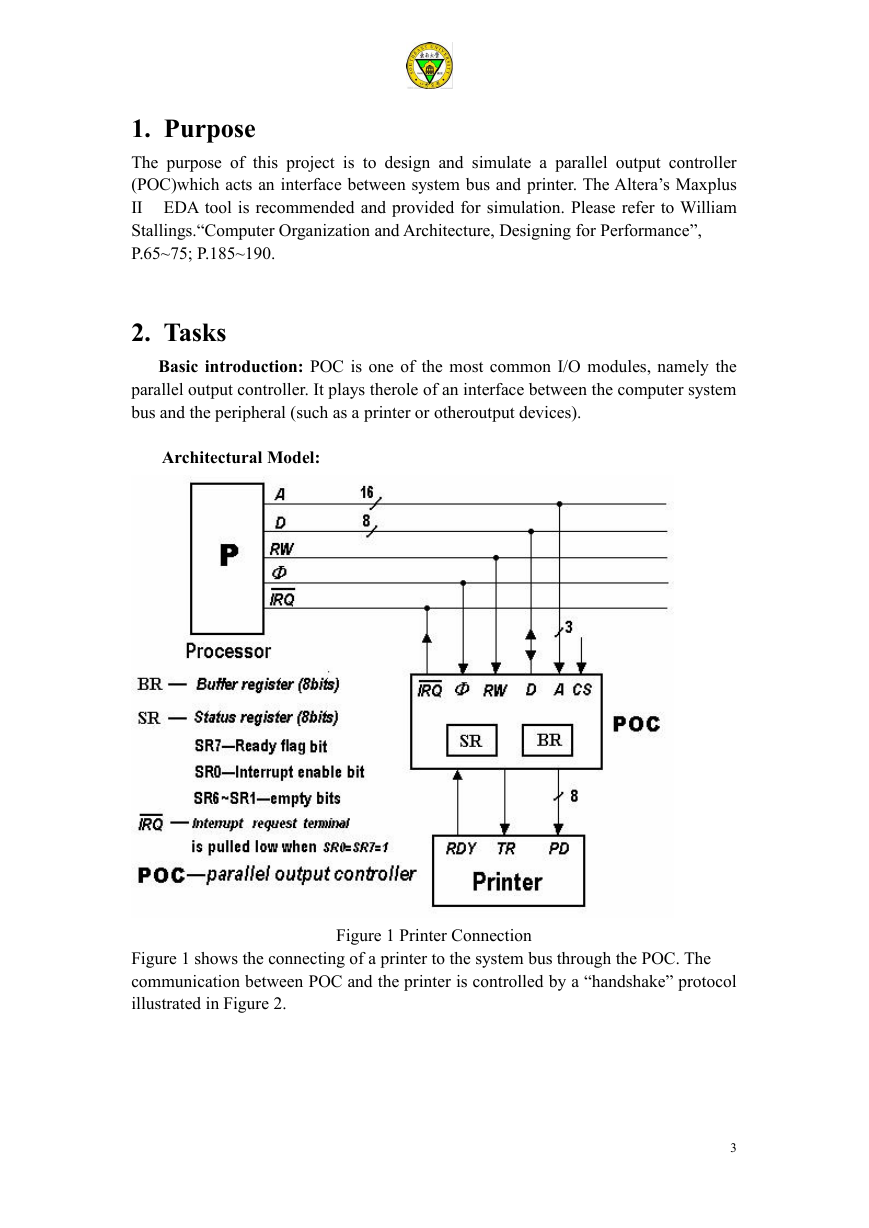

Basic introduction: POC is one of the most common I/O modules, namely the

parallel output controller. It plays therole of an interface between the computer system

bus and the peripheral (such as a printer or otheroutput devices).

Architectural Model:

Figure 1 Printer Connection

Figure 1 shows the connecting of a printer to the system bus through the POC. The

communication between POC and the printer is controlled by a “handshake” protocol

illustrated in Figure 2.

3

�

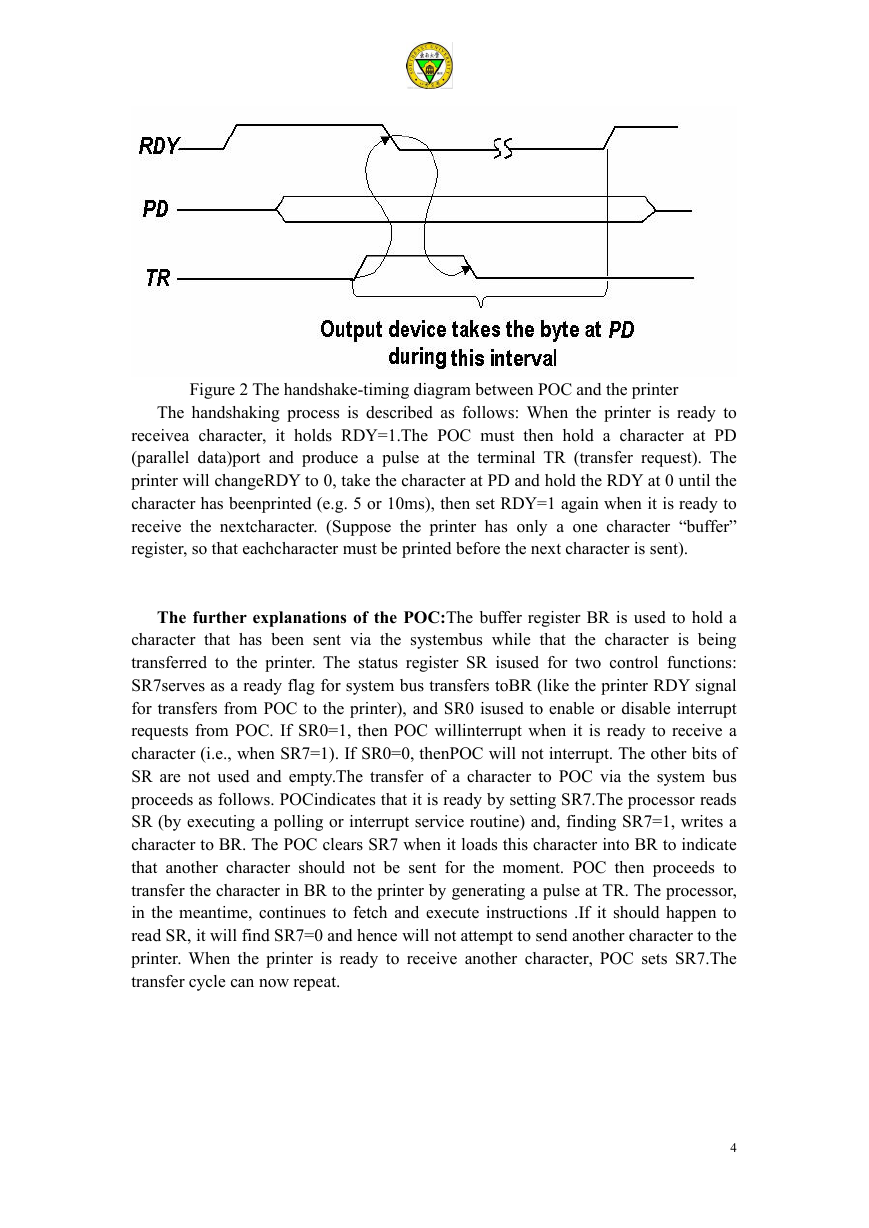

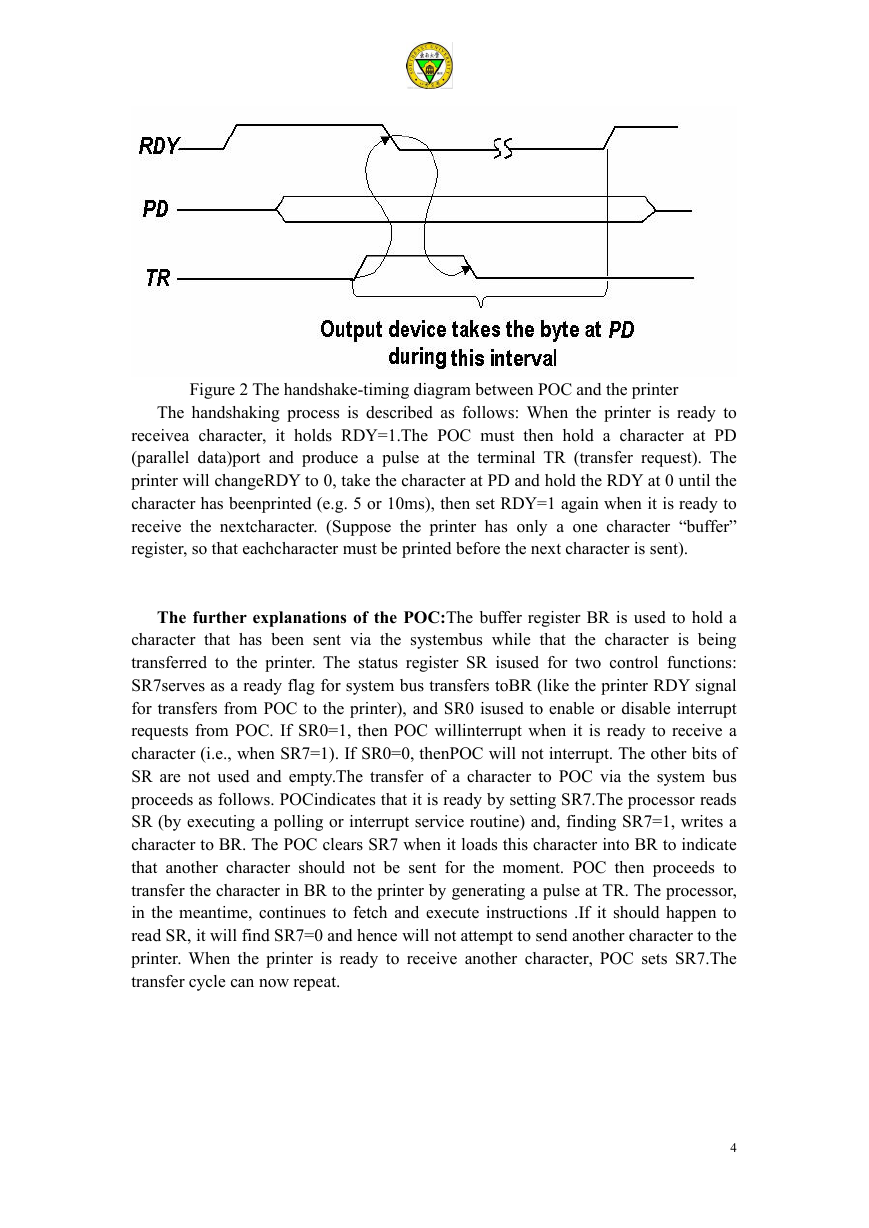

Figure 2 The handshake-timing diagram between POC and the printer

The handshaking process is described as follows: When the printer is ready to

receivea character, it holds RDY=1.The POC must then hold a character at PD

(parallel data)port and produce a pulse at the terminal TR (transfer request). The

printer will changeRDY to 0, take the character at PD and hold the RDY at 0 until the

character has beenprinted (e.g. 5 or 10ms), then set RDY=1 again when it is ready to

receive the nextcharacter. (Suppose the printer has only a one character “buffer”

register, so that eachcharacter must be printed before the next character is sent).

The further explanations of the POC:The buffer register BR is used to hold a

character that has been sent via the systembus while that the character is being

transferred to the printer. The status register SR isused for two control functions:

SR7serves as a ready flag for system bus transfers toBR (like the printer RDY signal

for transfers from POC to the printer), and SR0 isused to enable or disable interrupt

requests from POC. If SR0=1, then POC willinterrupt when it is ready to receive a

character (i.e., when SR7=1). If SR0=0, thenPOC will not interrupt. The other bits of

SR are not used and empty.The transfer of a character to POC via the system bus

proceeds as follows. POCindicates that it is ready by setting SR7.The processor reads

SR (by executing a polling or interrupt service routine) and, finding SR7=1, writes a

character to BR. The POC clears SR7 when it loads this character into BR to indicate

that another character should not be sent for the moment. POC then proceeds to

transfer the character in BR to the printer by generating a pulse at TR. The processor,

in the meantime, continues to fetch and execute instructions .If it should happen to

read SR, it will find SR7=0 and hence will not attempt to send another character to the

printer. When the printer is ready to receive another character, POC sets SR7.The

transfer cycle can now repeat.

4

�

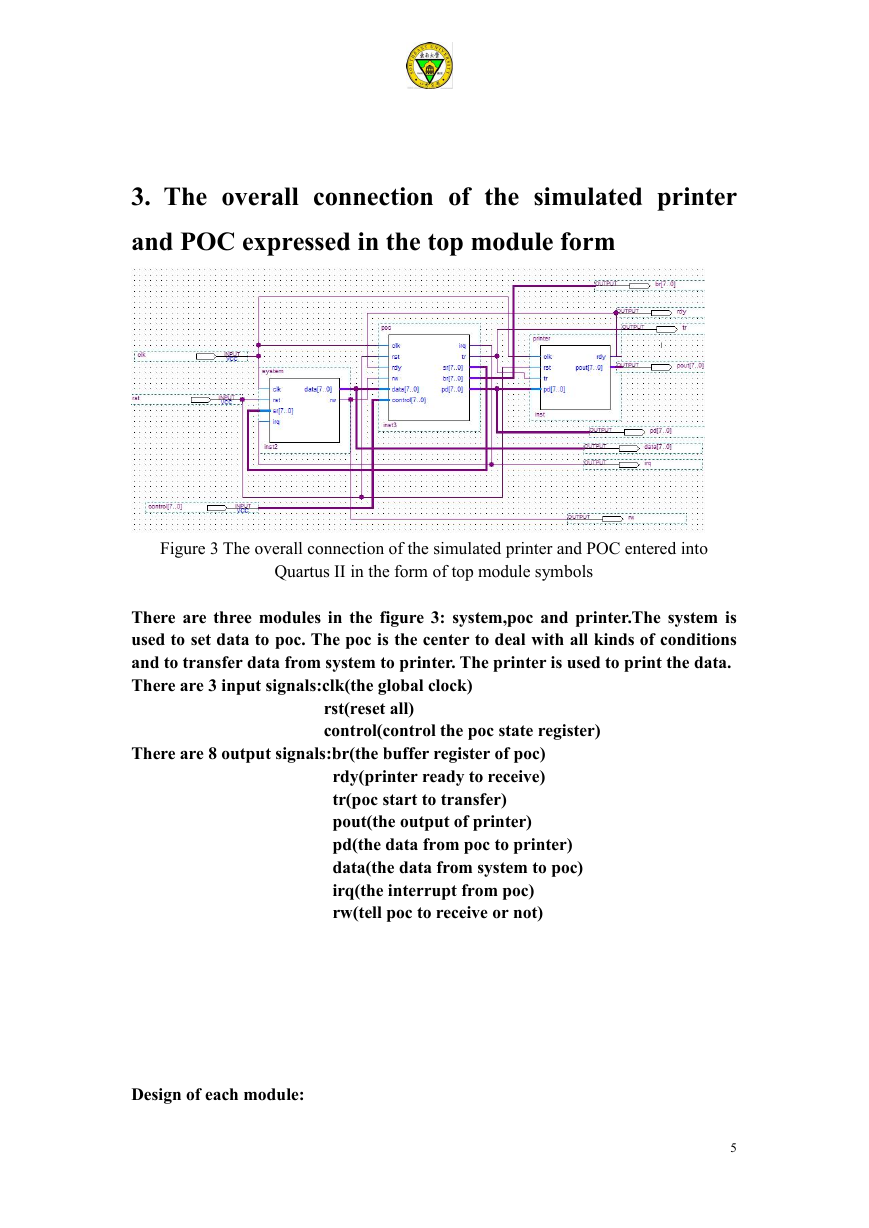

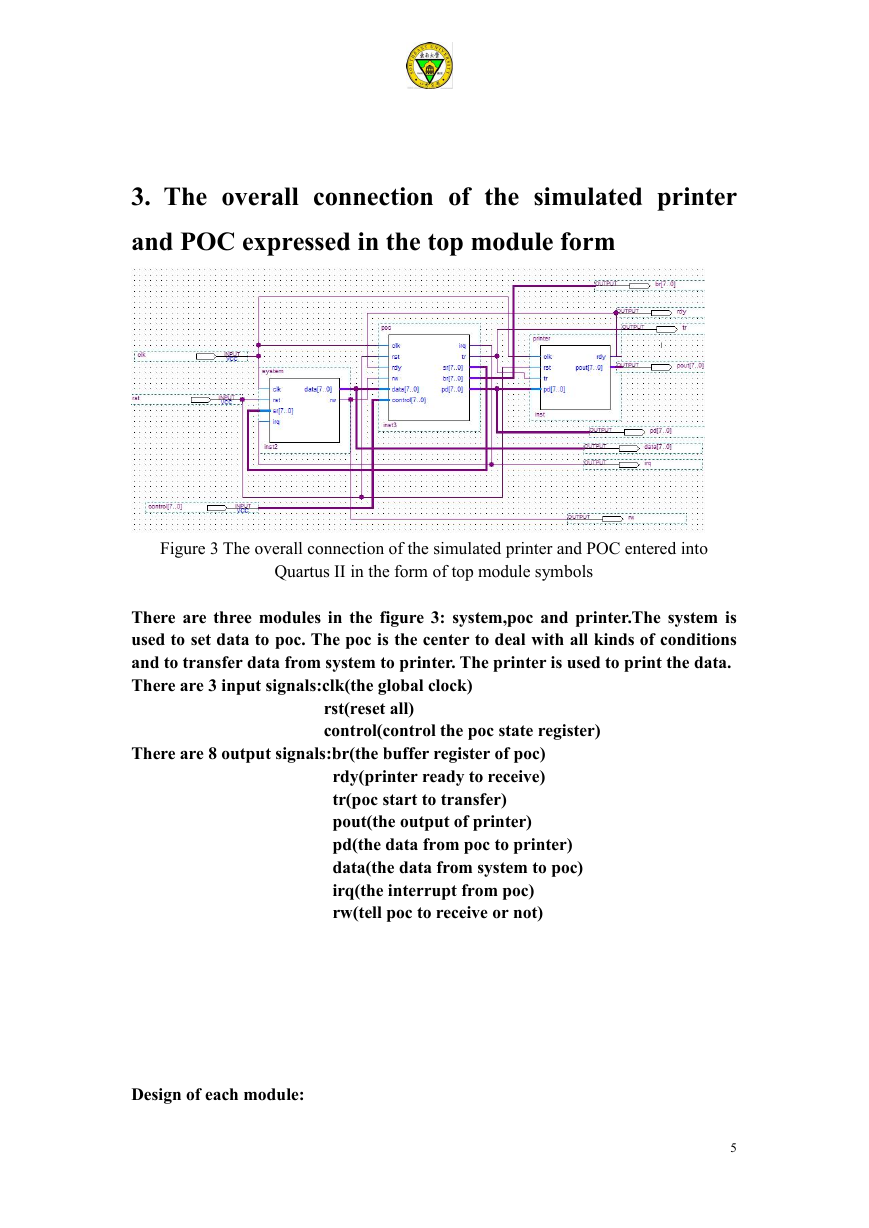

3. The overall connection of the simulated printer

and POC expressed in the top module form

Figure 3 The overall connection of the simulated printer and POC entered into

Quartus II in the form of top module symbols

There are three modules in the figure 3: system,poc and printer.The system is

used to set data to poc. The poc is the center to deal with all kinds of conditions

and to transfer data from system to printer. The printer is used to print the data.

There are 3 input signals:clk(the global clock)

rst(reset all)

control(control the poc state register)

There are 8 output signals:br(the buffer register of poc)

rdy(printer ready to receive)

tr(poc start to transfer)

pout(the output of printer)

pd(the data from poc to printer)

data(the data from system to poc)

irq(the interrupt from poc)

rw(tell poc to receive or not)

Design of each module:

5

�

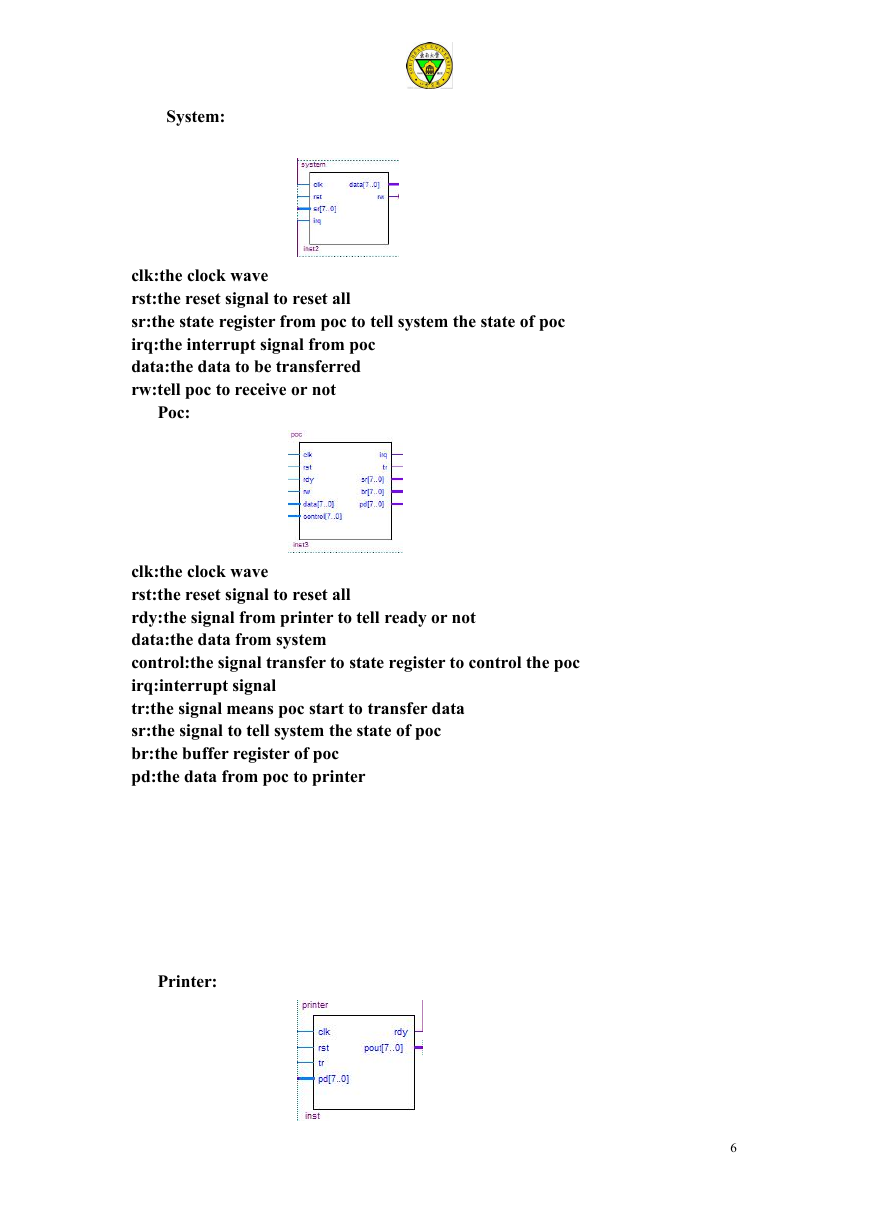

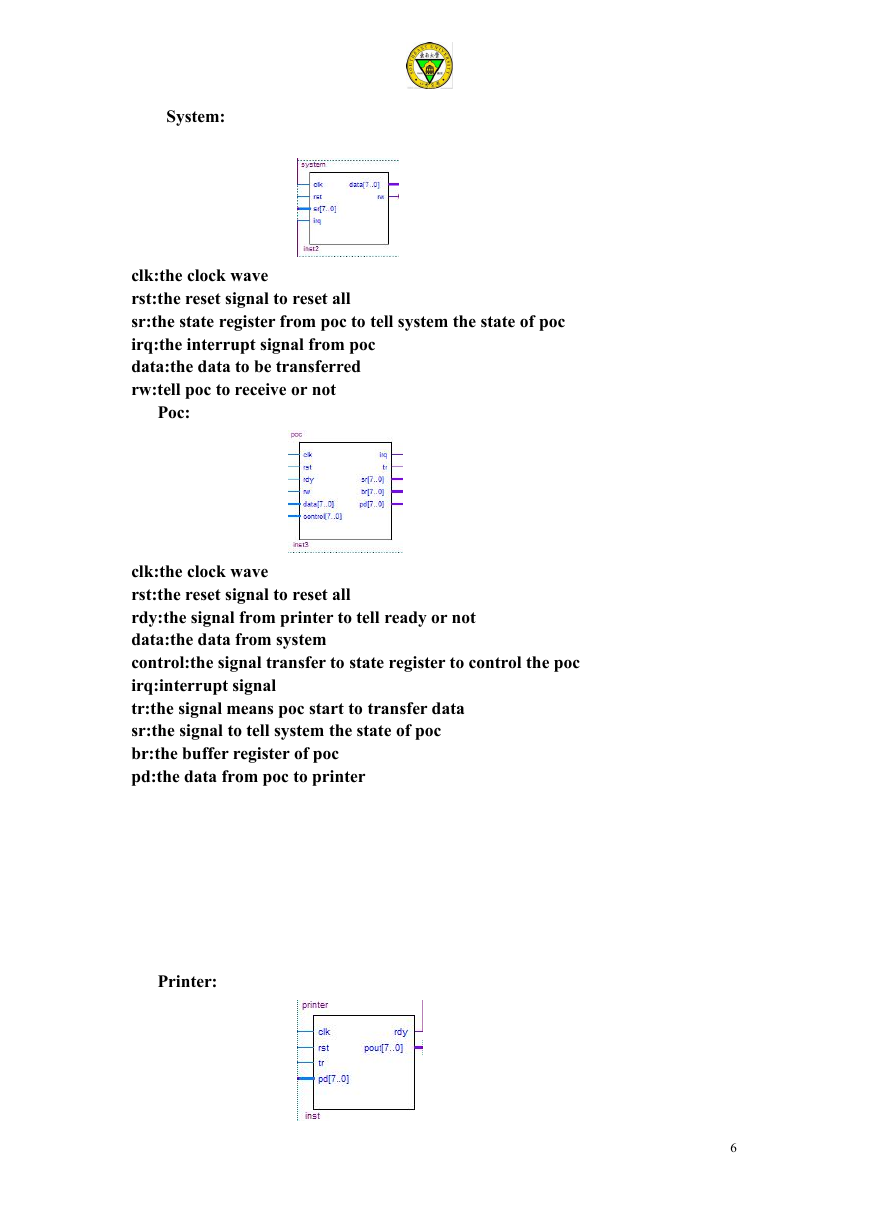

System:

clk:the clock wave

rst:the reset signal to reset all

sr:the state register from poc to tell system the state of poc

irq:the interrupt signal from poc

data:the data to be transferred

rw:tell poc to receive or not

Poc:

clk:the clock wave

rst:the reset signal to reset all

rdy:the signal from printer to tell ready or not

data:the data from system

control:the signal transfer to state register to control the poc

irq:interrupt signal

tr:the signal means poc start to transfer data

sr:the signal to tell system the state of poc

br:the buffer register of poc

pd:the data from poc to printer

Printer:

6

�

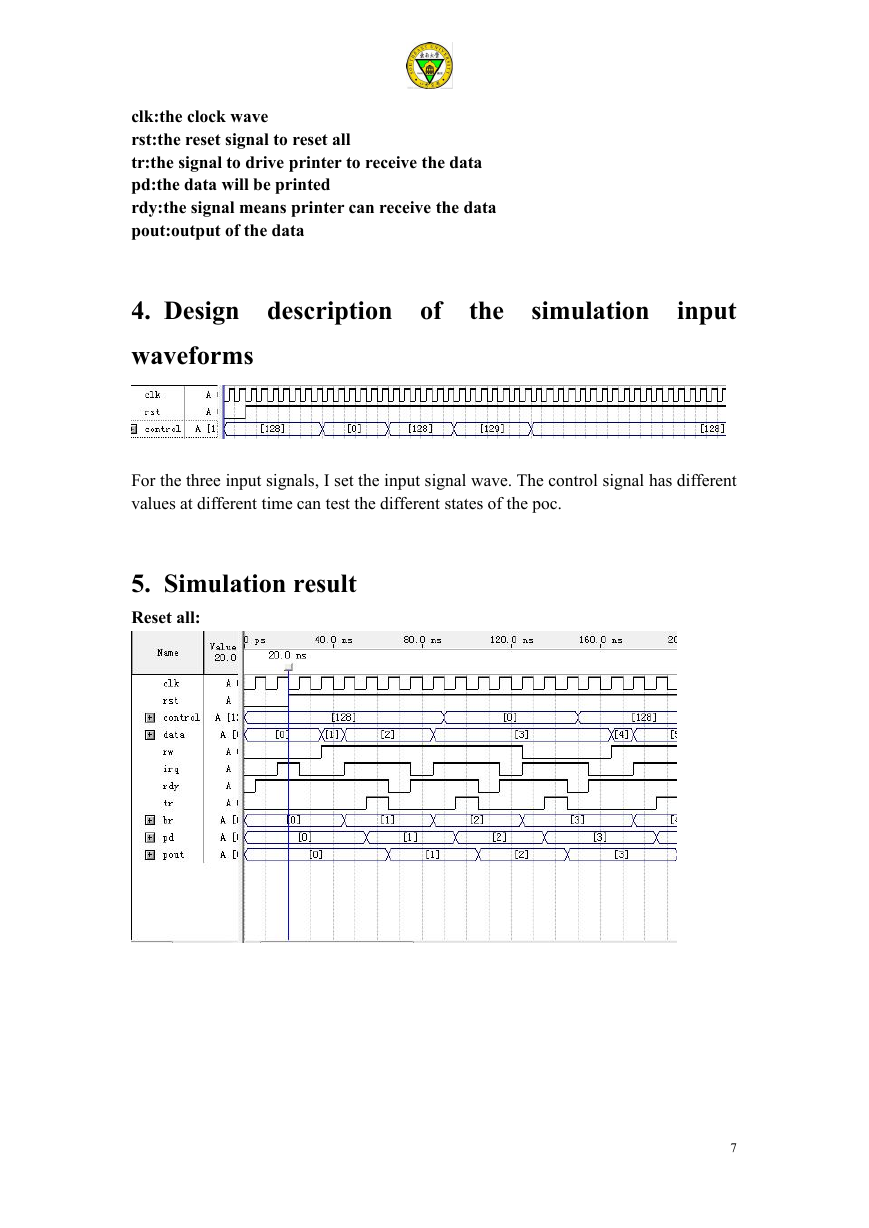

clk:the clock wave

rst:the reset signal to reset all

tr:the signal to drive printer to receive the data

pd:the data will be printed

rdy:the signal means printer can receive the data

pout:output of the data

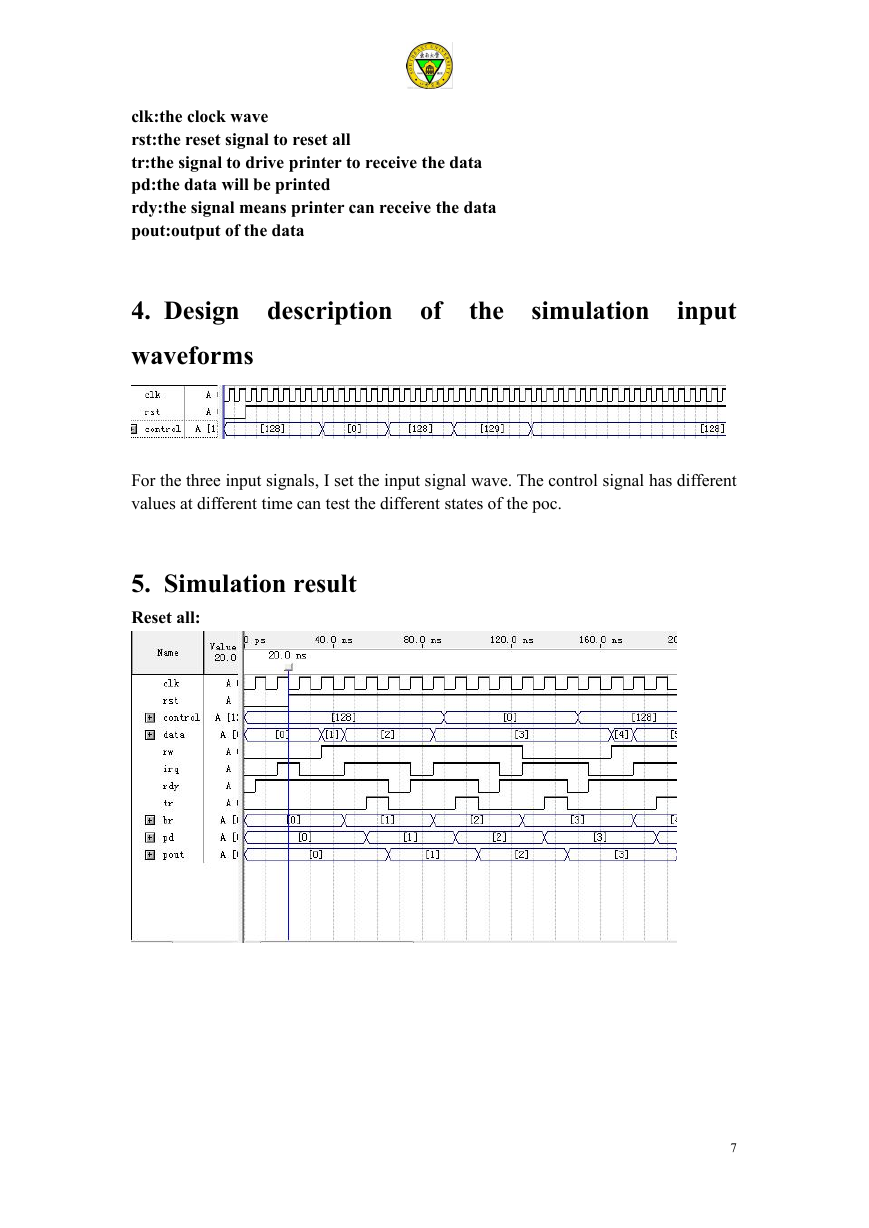

4. Design description of

waveforms

the

simulation input

For the three input signals, I set the input signal wave. The control signal has different

values at different time can test the different states of the poc.

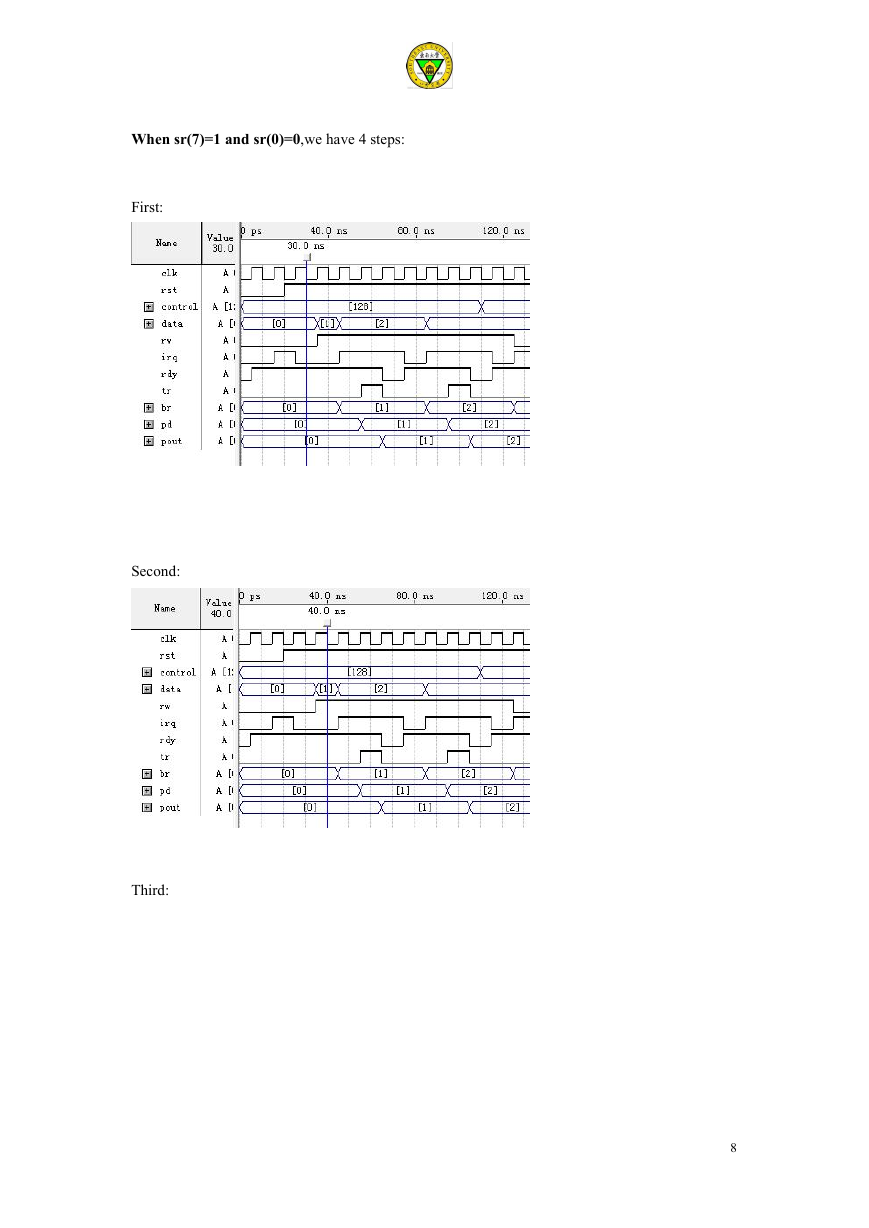

5. Simulation result

Reset all:

7

�

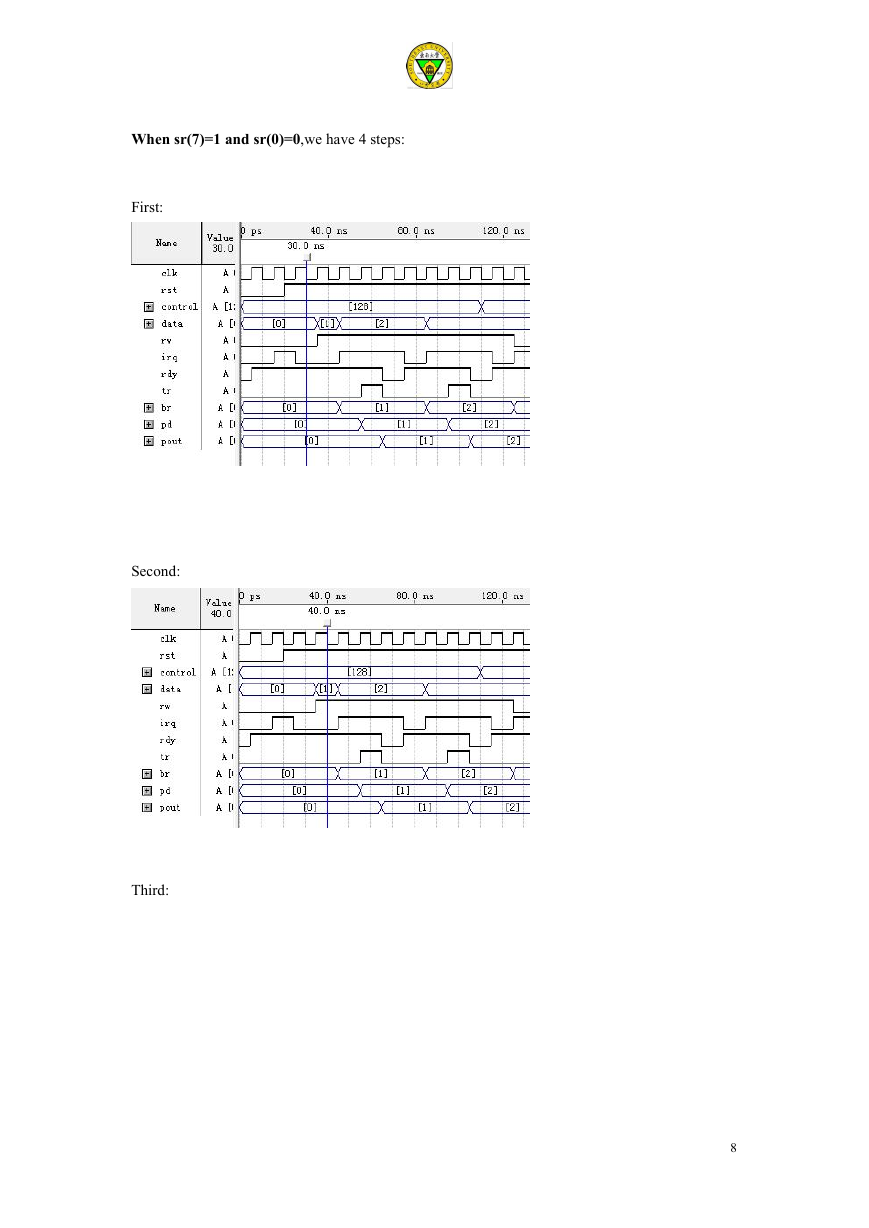

When sr(7)=1 and sr(0)=0,we have 4 steps:

First:

Second:

Third:

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc