Software Spotlight

ECC Options for Improving NAND Device Reliability

ECC Options for Improving NAND Flash Memory Reliability

A Micron Software Engineer Highlights Hardware and Software ECC Solutions

By Marina Mariano

Micron Software Engineer

NAND Flash memory devices cover a wide range of applications that go beyond traditional

storage in USB flash devices, memory cards, and solid state drives. NAND is being used

more and more as support for server solutions, networking products, embedded systems,

and so forth. These segments require a high level of reliability that is in contrast with the

technology shrinking, which can be a source of data corruption in memory storage.

In addition to increasing densities and decreasing device sizes, Micron creates products that

are more reliable than traditional NAND devices, thanks to a wide range of solutions that

can be adapted to a variety of markets. The needs of embedded systems, in conjunction

with our standards for excellence, have made it possible to design products aimed at a

stable level of performance and reliability throughout their lifespan.

To achieve the challenging level of reliability required by markets like embedded devices

and mobile phones, Micron protects data integrity with the adoption of error correction code

(ECC) in a broad variety of memory solutions. ECC was initially used in RAM, but now adds

reliability to NAND devices. This article discusses some of the ECC solutions available.

Using ECC to Improve NAND Data Integrity

In this article, we discuss NAND Flash memory devices that use one of two memory cell

technologies. The first is single-level cell (SLC) NAND in which each cell contains one bit,

which can be a 0 or 1. The second is multilevel cell (MLC) NAND, which provides the ability

to store two bits in each cell (or more in some cases). The voltage threshold determines the

content of each cell, representing one of four possible values for the two bits.

SLC NAND provides better data endurance compared to the same density MLC NAND

because of the accuracy required for recognizing the four different thresholds. Both SLC and

MLC NAND require an ECC algorithm to ensure data integrity. However, the data in MLC

NAND needs a significantly more sophisticated correction scheme to obtain the same level

of integrity.

PDF: 09005aef848aca27/Source: 09005aef848aca46

Rev. C, 01/12

© 2012 Micron Technology, Inc. Micron and the Micron logo are trademarks of Micron Technology, Inc. All other trademarks are the

property of their respective owners. All information is provided on an “AS IS” basis, without warranties of any kind.

�

Software Spotlight

ECC Options for Improving NAND Device Reliability

Figure 1. ECC Bit Correction Requirements Trend for SLC and MLC NAND

ECC Algorithms for NAND

General definitions in ECC algorithms provide for both error detection and error correction.

Error detection techniques enable the detection of errors, while error correction provides the

ability to reconstruct the original data. The general idea behind detection and correction

code is to introduce a redundancy to the data message, enabling the algorithm to check

whether the stored data is correct. NAND devices provide an additional storage area (called

the spare area) to add further information to the contents of a page. Typically, management

data such as ECC redundancy code is stored in the spare area in NAND.

Introducing a redundancy means setting the distance between valid words of the message,

which is the significant part of the user data. For example, a distance up to 4 bits ensures

that a 1-bit error and a 2-bit error can be distinguished from each other so that message

contents can be recovered when up to 4-bit errors occur.

Among the ECC code types, linear codes are the most common because of their algebraic

structure. They are easier to describe, encode, and decode than nonlinear codes.

The most widely adopted code for 1-bit ECC is the Hamming code, which detects and

corrects data corruption during operation on SLC NAND devices with geometry of 70nm and

above. The Hamming algorithm is an industry-accepted method for error detection and

correction in many NAND-based applications. It can detect 2-bit errors and correct up to 1

bit.

As previously stated, MLC and SLC NAND with high levels of shrink geometry require a

more complex correction code. One family of cyclic codes is known as BCH codes. The

binary BCH codes were discovered around 1960 by Hocquenghem and independently by

Bose and Ray-Chaudhuri, whose names make up the algorithm’s acronym. Around the time

BCH codes first appeared in literature, Reed and Solomon published a work describing a

PDF: 09005aef848aca27/Source: 09005aef848aca46

Rev. C, 01/12

© 2012 Micron Technology, Inc. Micron and the Micron logo are trademarks of Micron Technology, Inc. All other trademarks are the

property of their respective owners. All information is provided on an “AS IS” basis, without warranties of any kind.

�

Software Spotlight

ECC Options for Improving NAND Device Reliability

subclass of these codes. Because of their error-correction capabilities, Reed-Solomon

codes can be used to improve the general reliability of MLC NAND, compact discs, and

other data storage equipment.

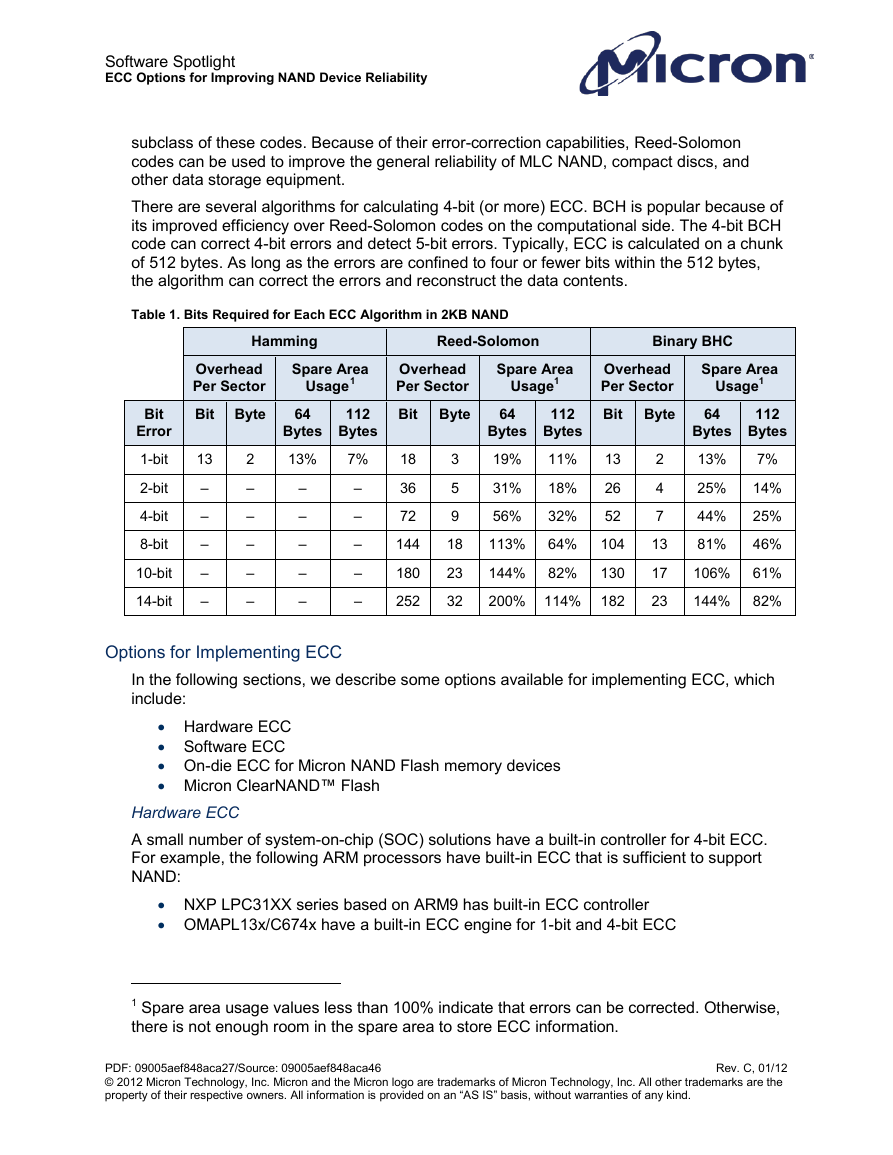

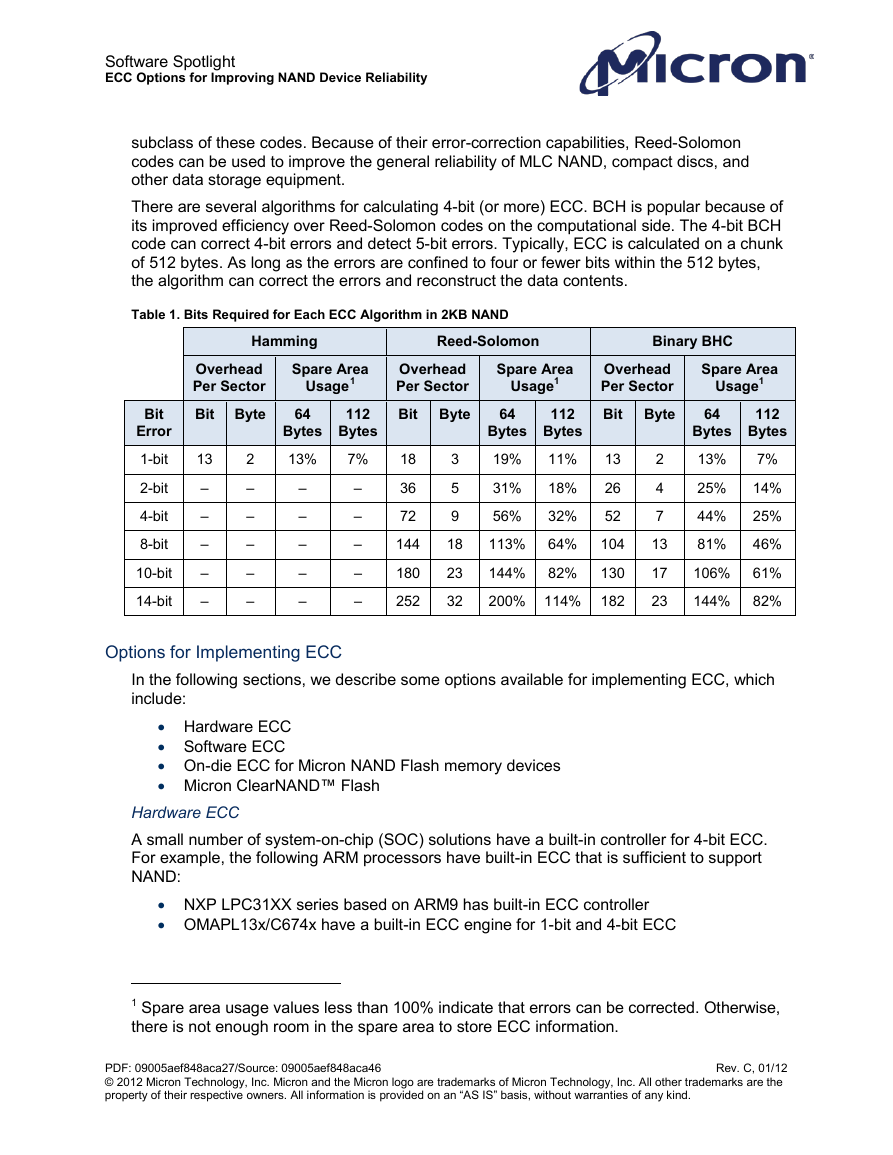

There are several algorithms for calculating 4-bit (or more) ECC. BCH is popular because of

its improved efficiency over Reed-Solomon codes on the computational side. The 4-bit BCH

code can correct 4-bit errors and detect 5-bit errors. Typically, ECC is calculated on a chunk

of 512 bytes. As long as the errors are confined to four or fewer bits within the 512 bytes,

the algorithm can correct the errors and reconstruct the data contents.

Table 1. Bits Required for Each ECC Algorithm in 2KB NAND

Bit

Error

1-bit

2-bit

4-bit

8-bit

10-bit

14-bit

Hamming

Reed-Solomon

Binary BHC

Overhead

Per Sector

Bit Byte

13

–

–

–

–

–

2

–

–

–

–

–

Spare Area

Usage1

64

Bytes

13%

–

–

–

–

–

112

Bytes

7%

–

–

–

–

–

Overhead

Per Sector

Bit Byte

18

36

72

144

180

252

3

5

9

18

23

32

Spare Area

Usage1

64

Overhead

Per Sector

Bit Byte

112

Bytes

11%

18%

32%

64%

82%

Bytes

13

19%

26

31%

52

56%

104

113%

144%

130

200% 114% 182

2

4

7

13

17

23

Spare Area

Usage1

64

Bytes

13%

25%

44%

81%

106%

144%

112

Bytes

7%

14%

25%

46%

61%

82%

Options for Implementing ECC

In the following sections, we describe some options available for implementing ECC, which

include:

Hardware ECC

Software ECC

On-die ECC for Micron NAND Flash memory devices

Micron ClearNAND™ Flash

Hardware ECC

A small number of system-on-chip (SOC) solutions have a built-in controller for 4-bit ECC.

For example, the following ARM processors have built-in ECC that is sufficient to support

NAND:

NXP LPC31XX series based on ARM9 has built-in ECC controller

OMAPL13x/C674x have a built-in ECC engine for 1-bit and 4-bit ECC

1 Spare area usage values less than 100% indicate that errors can be corrected. Otherwise,

there is not enough room in the spare area to store ECC information.

PDF: 09005aef848aca27/Source: 09005aef848aca46

Rev. C, 01/12

© 2012 Micron Technology, Inc. Micron and the Micron logo are trademarks of Micron Technology, Inc. All other trademarks are the

property of their respective owners. All information is provided on an “AS IS” basis, without warranties of any kind.

�

Software Spotlight

ECC Options for Improving NAND Device Reliability

The OMAP35x, AM35x, and AM/DM37x devices do not support 4-bit or 8-bit correction in

hardware. However, they do support 1-bit, 4-bit (excluding the OMAP35x), and 8-bit

hardware detection. It is important to note that using NAND that requires 8-bit ECC with 4-bit

hardware ECC could have negative consequences, including boot failure.

Software ECC

In the absence of hardware dedicated to calculating ECC, we have implemented a

Hamming code for 1-bit ECC and a multibit ECC encoder/decoder for NAND in software.

The library we provide to implement BCH ECC calculates the ECC on 512 bytes for NAND

sectors that consist of a 512-byte data area and a 16-byte spare area, totaling 528 bytes per

sector. A binary N-error-correcting BCH code is implemented to ensure data integrity (N

represents the number of bits that can be corrected). Inputs and outputs to or from the

encoder/decoder are in the byte format. Data is read out in two hex words per byte and the

information length of the BCH code must be a multiple of four. Even though the BCH

algorithm is designed for optimizing the implementation provided in software, 4-bit BCH

requires many microprocessor cycles to perform data computation.

ECC correction can be implemented in software for errors that are 2 bits and greater, and

optimized software can have good performance. However, the algorithm has a high

computational complexity and requires a large amount of RAM, which should be taken into

account when the code is implemented on embedded systems with limited resources.

On-Die ECC for Micron NAND Devices

Our MT29FxGxxAxxDAxx NAND is an example of a Micron device that provides built-in

ECC, which is tailored to ensure the highest level of reliability for each device. This device

includes a built-in 4-bit ECC internal controller. Although the adoption of a hardware

controller implies better READ speed performance when compared to an on-die ECC

implementation, the adoption of on-die ECC ensures smoother integration, and it is nearly

effortless for the user to replace existing memory devices. This means that

MT29FxGxxAxxDAxx devices can replace memory devices with 1-bit hardware support or

no hardware ECC support with only minor changes to the system. Enabling internal on-die

ECC ensures a high level of endurance for all types of Micron NAND family devices,

providing the user with a reliable memory solution.

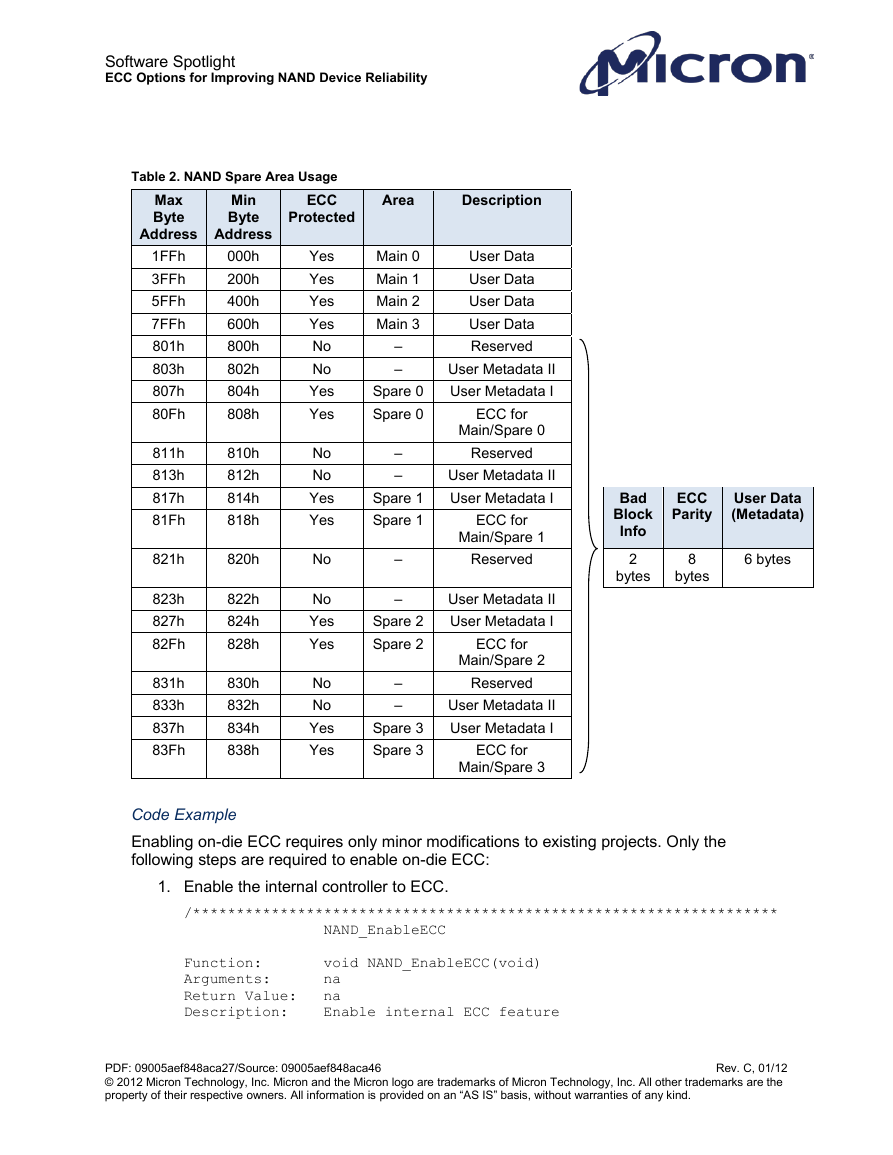

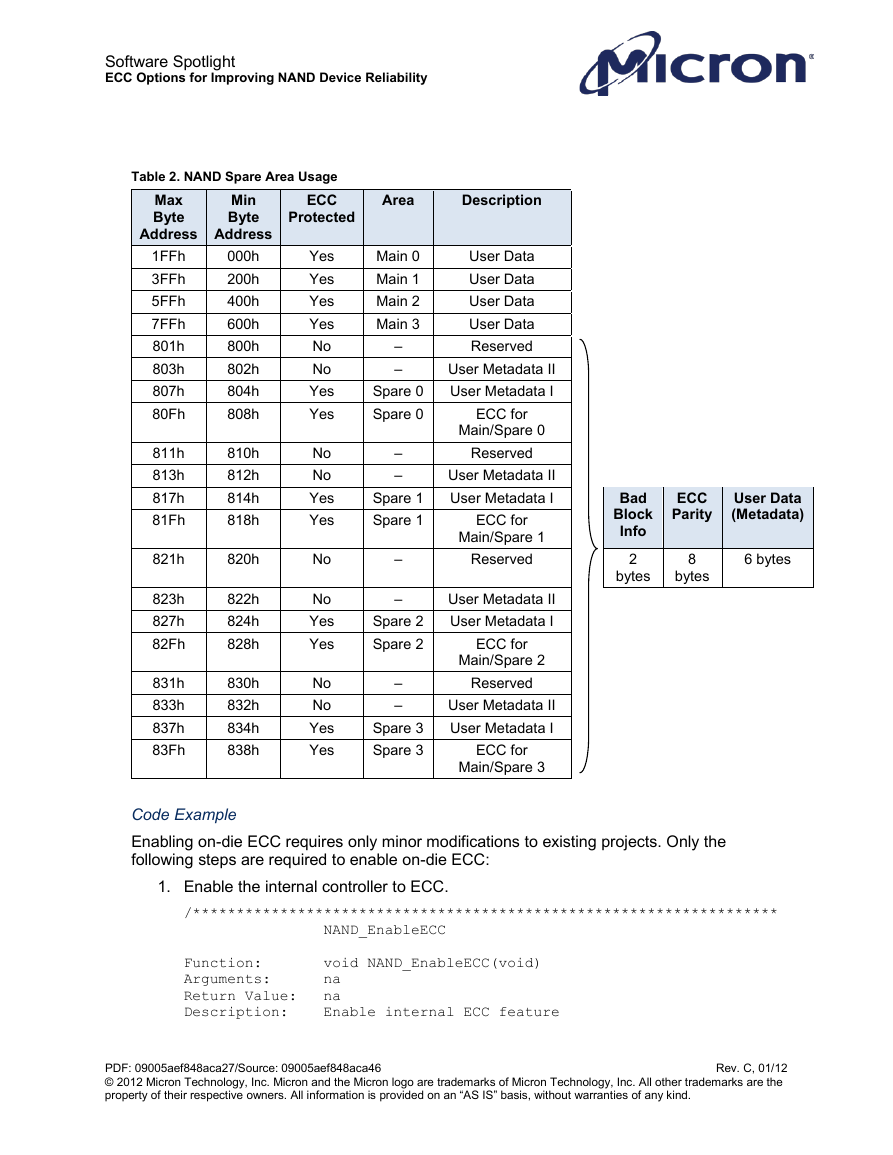

Internal ECC enables 5-bit error detection and ensures 4-bit error correction. The on-die

ECC implements a BCH error correction code, and as a result, the number of partial page

programs cannot exceed four. Otherwise, the algorithm does not calculate the correction

code properly. During the busy time of the PROGRAM operation, the internal ECC

generates and stores the parity bit. Then, during a READ operation the on-die controller

checks for the presence of errors. When an error larger than four bits occurs, which cannot

be corrected, the engine signals the event and sets the least significant bit of the status

register. Results are unpredictable for errors that are 6 bits and greater. Table 2 illustrates

the usage of the NAND spare area with the limitation that a small part of the spare area is

not protected by ECC and the ECC user area must be included in the writing of four partial

pages.

PDF: 09005aef848aca27/Source: 09005aef848aca46

Rev. C, 01/12

© 2012 Micron Technology, Inc. Micron and the Micron logo are trademarks of Micron Technology, Inc. All other trademarks are the

property of their respective owners. All information is provided on an “AS IS” basis, without warranties of any kind.

�

Software Spotlight

ECC Options for Improving NAND Device Reliability

Table 2. NAND Spare Area Usage

ECC

Protected

Max

Byte

Min

Byte

Address

Address

1FFh

3FFh

5FFh

7FFh

801h

803h

807h

80Fh

811h

813h

817h

81Fh

821h

823h

827h

82Fh

831h

833h

837h

83Fh

000h

200h

400h

600h

800h

802h

804h

808h

810h

812h

814h

818h

820h

822h

824h

828h

830h

832h

834h

838h

Yes

Yes

Yes

Yes

No

No

Yes

Yes

No

No

Yes

Yes

No

No

Yes

Yes

No

No

Yes

Yes

Area

Description

Main 0

Main 1

Main 2

Main 3

–

–

Spare 0

Spare 0

–

–

Spare 1

Spare 1

–

–

Spare 2

Spare 2

–

–

Spare 3

Spare 3

User Data

User Data

User Data

User Data

Reserved

User Metadata II

User Metadata I

ECC for

Main/Spare 0

Reserved

User Metadata II

User Metadata I

ECC for

Main/Spare 1

Reserved

User Metadata II

User Metadata I

ECC for

Main/Spare 2

Reserved

User Metadata II

User Metadata I

ECC for

Main/Spare 3

Bad

Block

Info

2

bytes

ECC

Parity

User Data

(Metadata)

8

bytes

6 bytes

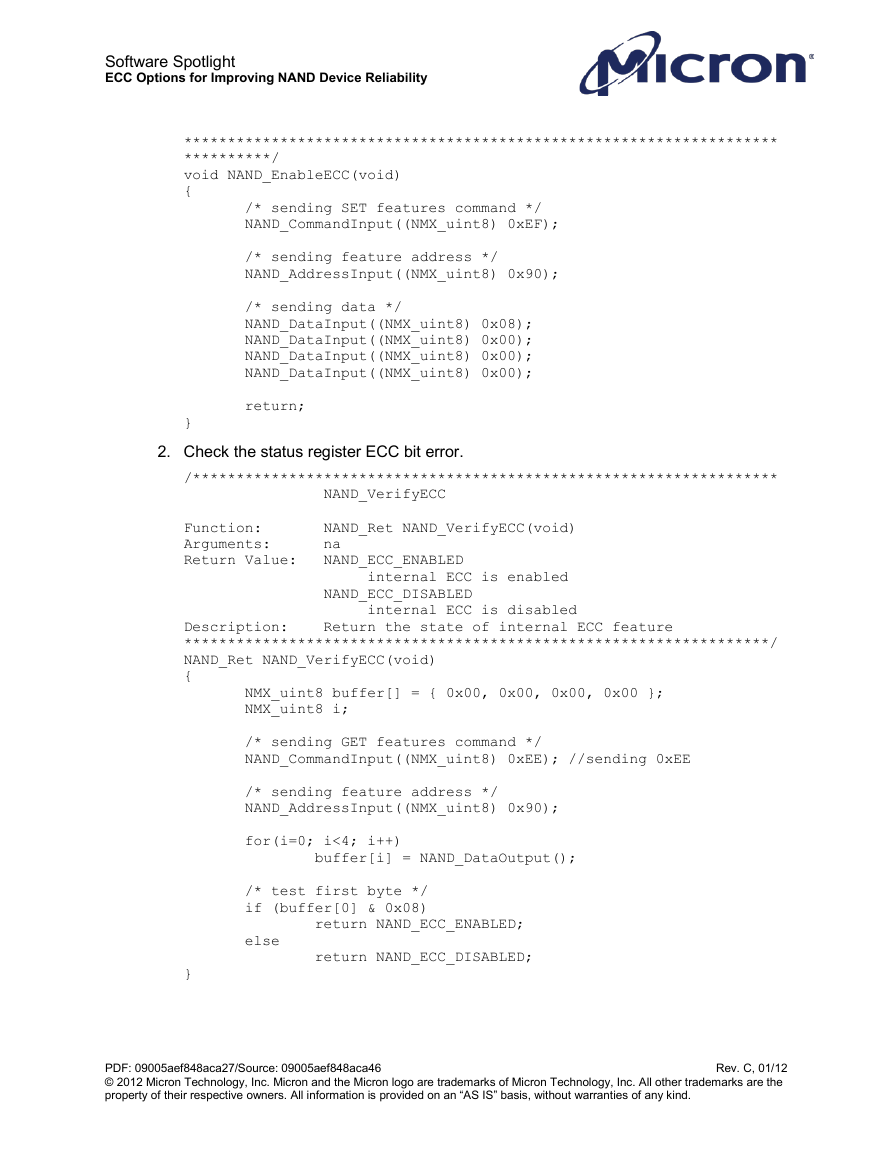

Code Example

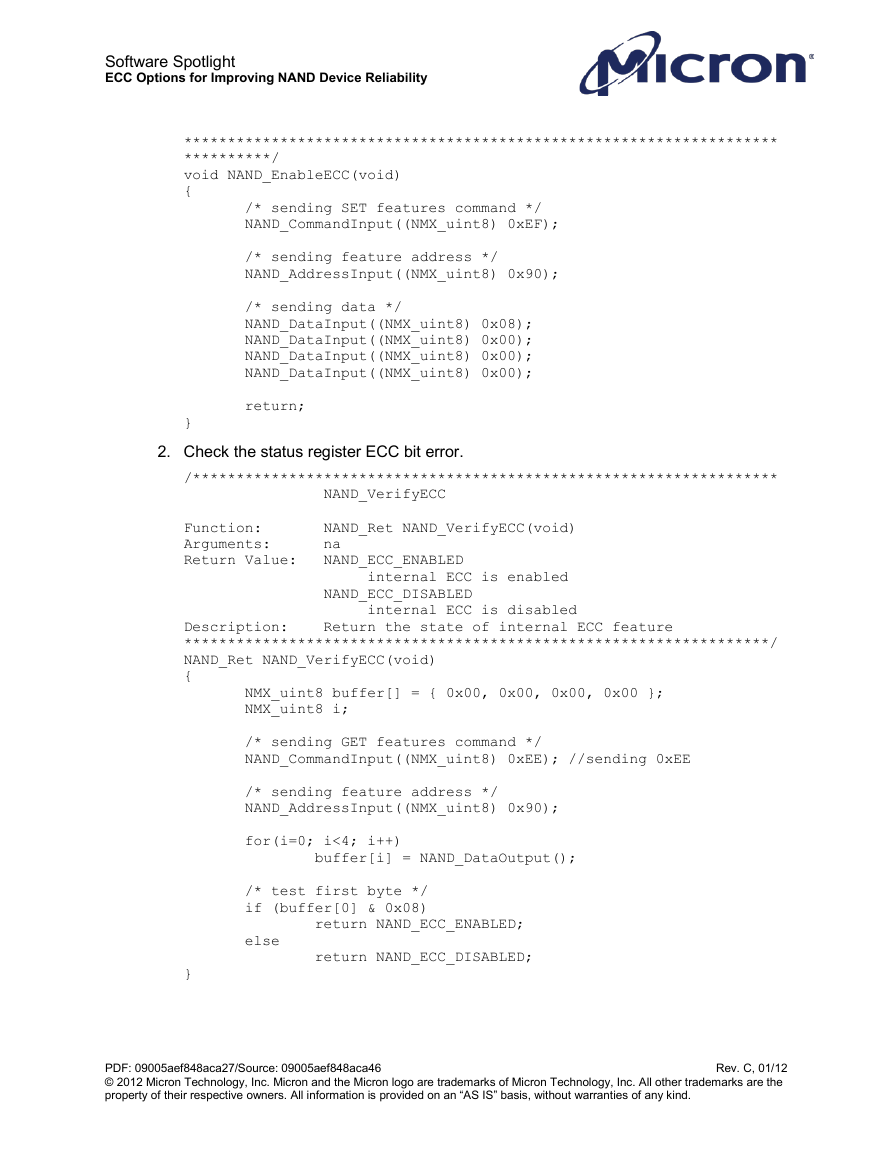

Enabling on-die ECC requires only minor modifications to existing projects. Only the

following steps are required to enable on-die ECC:

1. Enable the internal controller to ECC.

/*******************************************************************

NAND_EnableECC

Function: void NAND_EnableECC(void)

Arguments: na

Return Value: na

Description: Enable internal ECC feature

PDF: 09005aef848aca27/Source: 09005aef848aca46

Rev. C, 01/12

© 2012 Micron Technology, Inc. Micron and the Micron logo are trademarks of Micron Technology, Inc. All other trademarks are the

property of their respective owners. All information is provided on an “AS IS” basis, without warranties of any kind.

�

Software Spotlight

ECC Options for Improving NAND Device Reliability

********************************************************************

**********/

void NAND_EnableECC(void)

{

/* sending SET features command */

NAND_CommandInput((NMX_uint8) 0xEF);

/* sending feature address */

NAND_AddressInput((NMX_uint8) 0x90);

/* sending data */

NAND_DataInput((NMX_uint8) 0x08);

NAND_DataInput((NMX_uint8) 0x00);

NAND_DataInput((NMX_uint8) 0x00);

NAND_DataInput((NMX_uint8) 0x00);

return;

}

2. Check the status register ECC bit error.

/*******************************************************************

NAND_VerifyECC

Function: NAND_Ret NAND_VerifyECC(void)

Arguments: na

Return Value: NAND_ECC_ENABLED

internal ECC is enabled

NAND_ECC_DISABLED

internal ECC is disabled

Description: Return the state of internal ECC feature

*******************************************************************/

NAND_Ret NAND_VerifyECC(void)

{

NMX_uint8 buffer[] = { 0x00, 0x00, 0x00, 0x00 };

NMX_uint8 i;

/* sending GET features command */

NAND_CommandInput((NMX_uint8) 0xEE); //sending 0xEE

/* sending feature address */

NAND_AddressInput((NMX_uint8) 0x90);

for(i=0; i<4; i++)

buffer[i] = NAND_DataOutput();

/* test first byte */

if (buffer[0] & 0x08)

return NAND_ECC_ENABLED;

else

return NAND_ECC_DISABLED;

}

PDF: 09005aef848aca27/Source: 09005aef848aca46

Rev. C, 01/12

© 2012 Micron Technology, Inc. Micron and the Micron logo are trademarks of Micron Technology, Inc. All other trademarks are the

property of their respective owners. All information is provided on an “AS IS” basis, without warranties of any kind.

�

Software Spotlight

ECC Options for Improving NAND Device Reliability

ClearNAND Flash

ClearNAND Flash is our response to industry demands for a higher capacity solution that

also addresses existing ECC concerns. While we have been aggressively shrinking our

technology processes to meet those demands, we also recognize that process shrinks have

a direct effect on NAND performance and endurance and make error correction increasingly

difficult to manage. The adoption of an integrated solution for calculating ECC makes it

possible for users to develop one solution that can be easily migrated to future applications.

Our ClearNAND solution offers excellent performance in terms of throughput. For specific

applications, an effective Flash translation layer (FTL) solution should be adopted to

maximize the lifespan of the cells, even if this solution impacts overall performance.

Conclusion

As lithographies shrink, both SLC and MLC NAND increasingly require the use of ECC

algorithms to insure data integrity. Solutions include hardware, software, on-die, and

ClearNAND Flash. At Micron, we’ve developed a variety of ECC solutions for protecting data

integrity in a wide variety of applications. This means that we have the right NAND device

and ECC solution for every design. Micron’s NAND portfolio provides comprehensive, cost-

competitive memory products for computing, networking, mobile, and embedded

applications. For more information on our NAND and ECC solutions, contact your Micron

representative.”

References

TN-29-08: Hamming Codes for NAND Flash Memory Devices

TN-29-62: Software Device Drivers for Large Page Micron NAND Flash Memory

About the Author

Marina Mariano is a Micron software engineer responsible for

developing, debugging, and supporting software device drivers for

NAND, NOR, and phase change memory (PCM). She has been

instrumental in the development of low-level drivers for Micron.

PDF: 09005aef848aca27/Source: 09005aef848aca46

Rev. C, 01/12

© 2012 Micron Technology, Inc. Micron and the Micron logo are trademarks of Micron Technology, Inc. All other trademarks are the

property of their respective owners. All information is provided on an “AS IS” basis, without warranties of any kind.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc