Cover

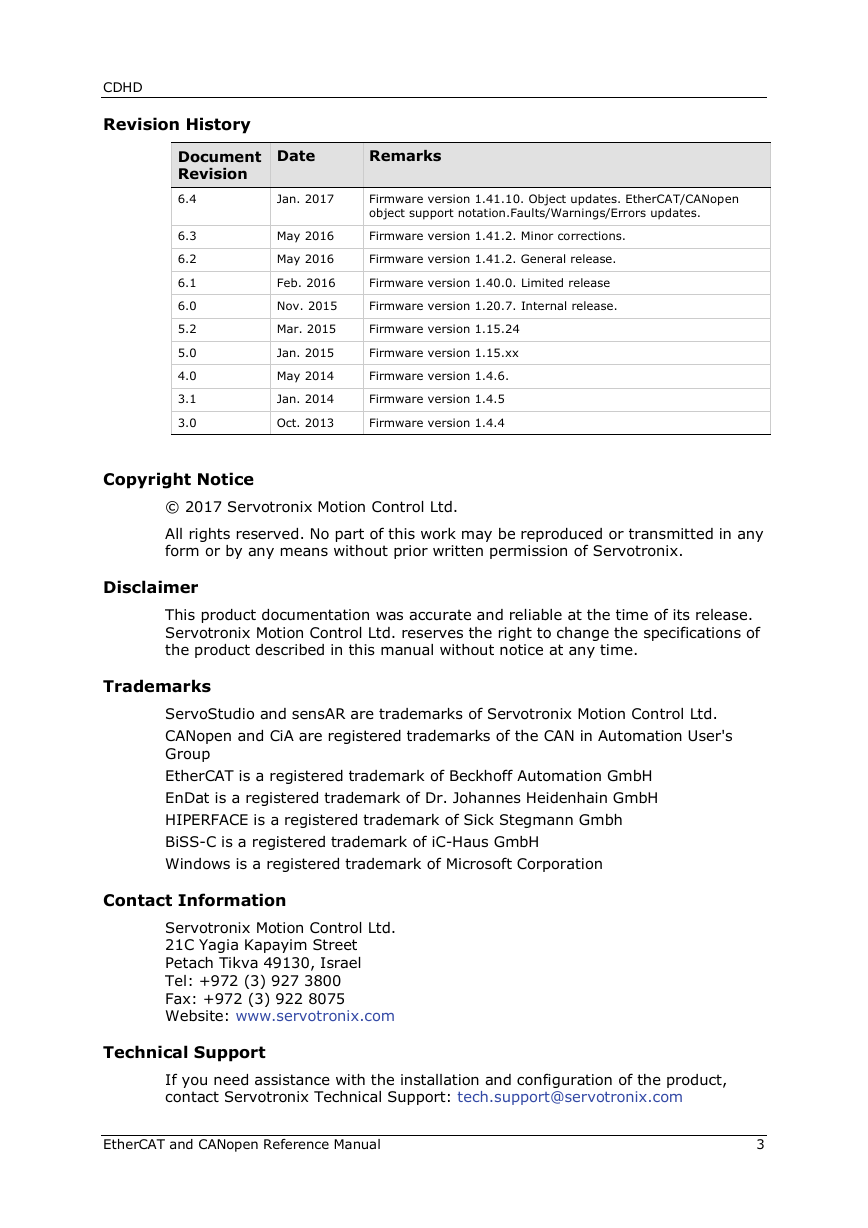

Revision History

Copyright Notice

Disclaimer

Trademarks

Contact Information

Technical Support

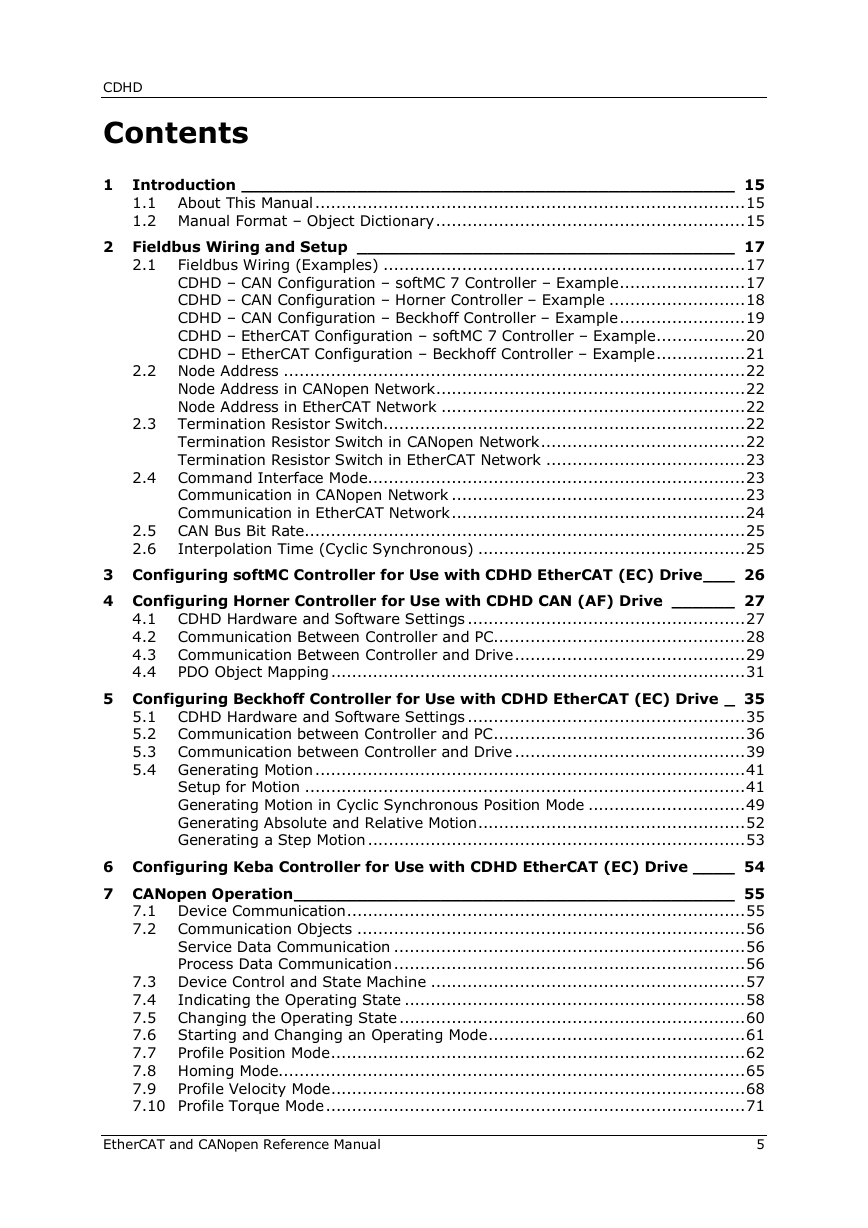

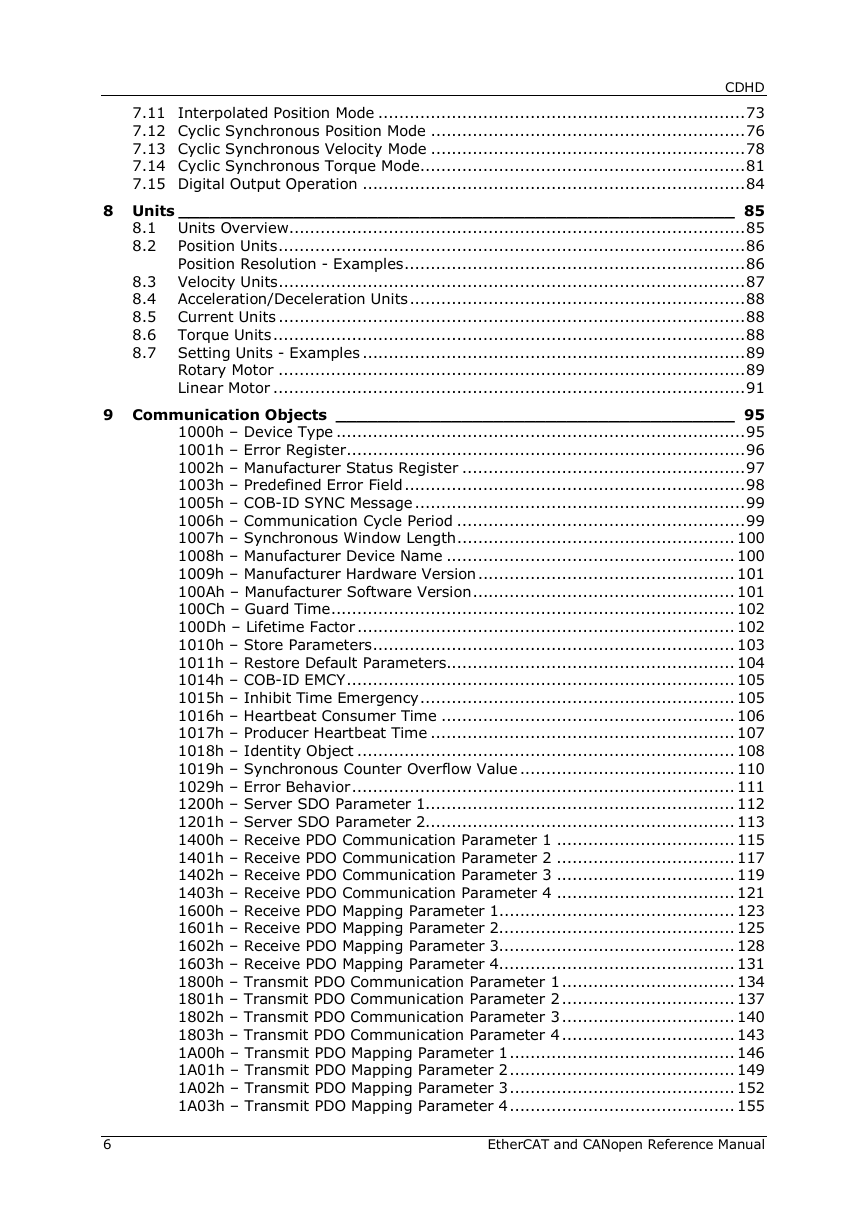

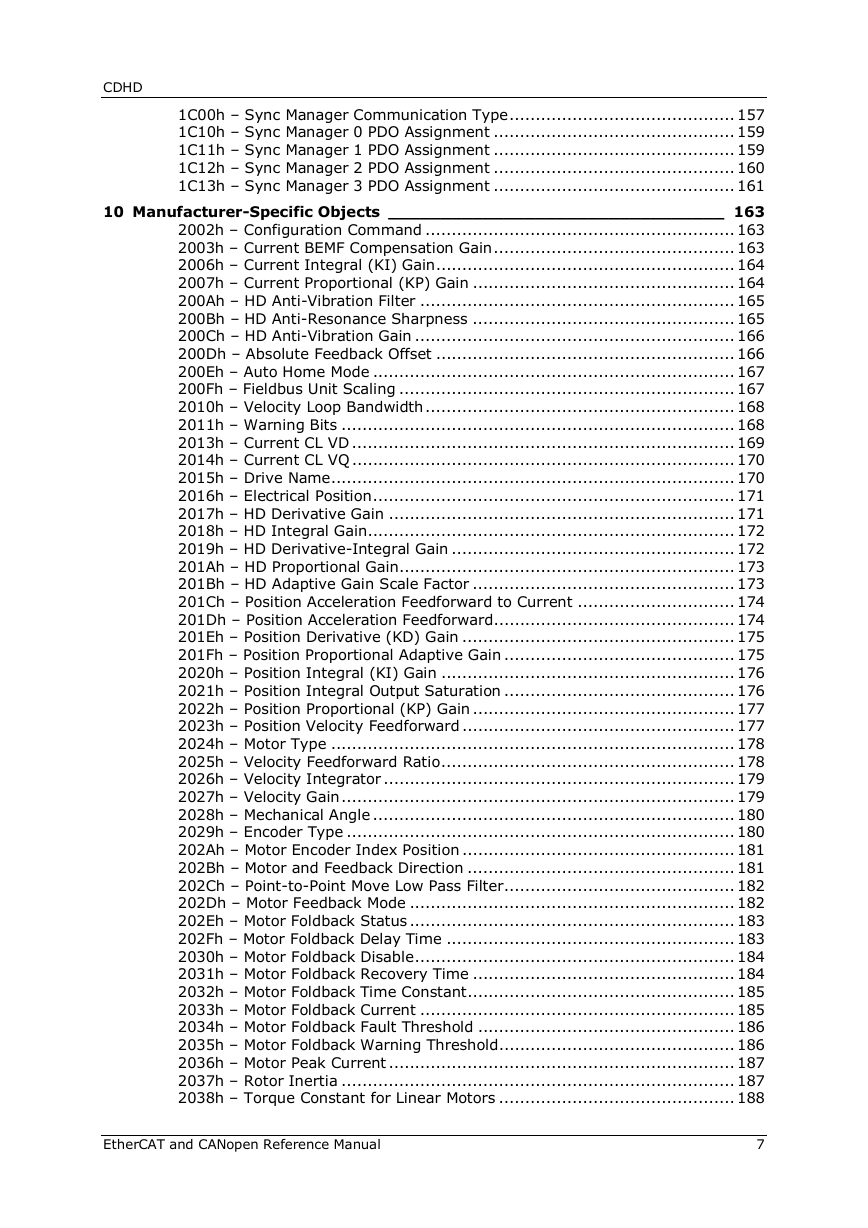

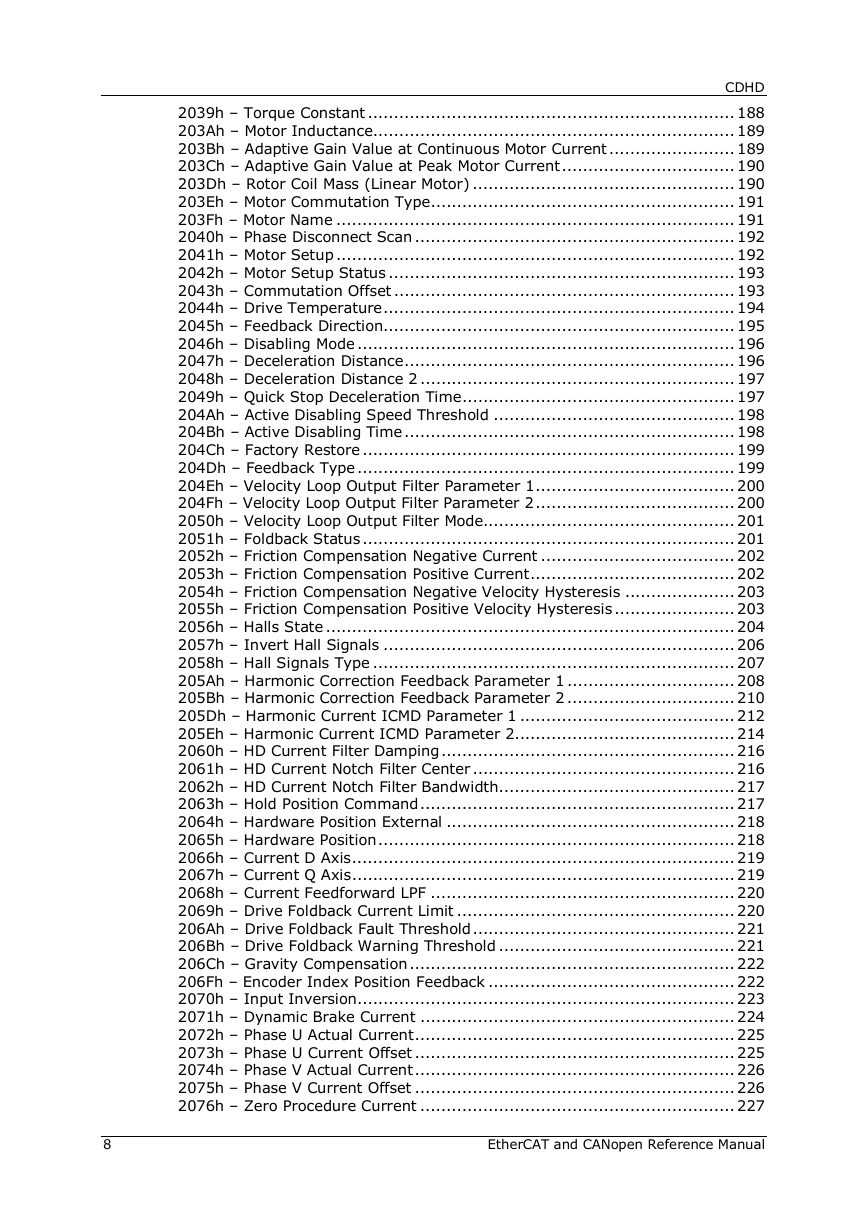

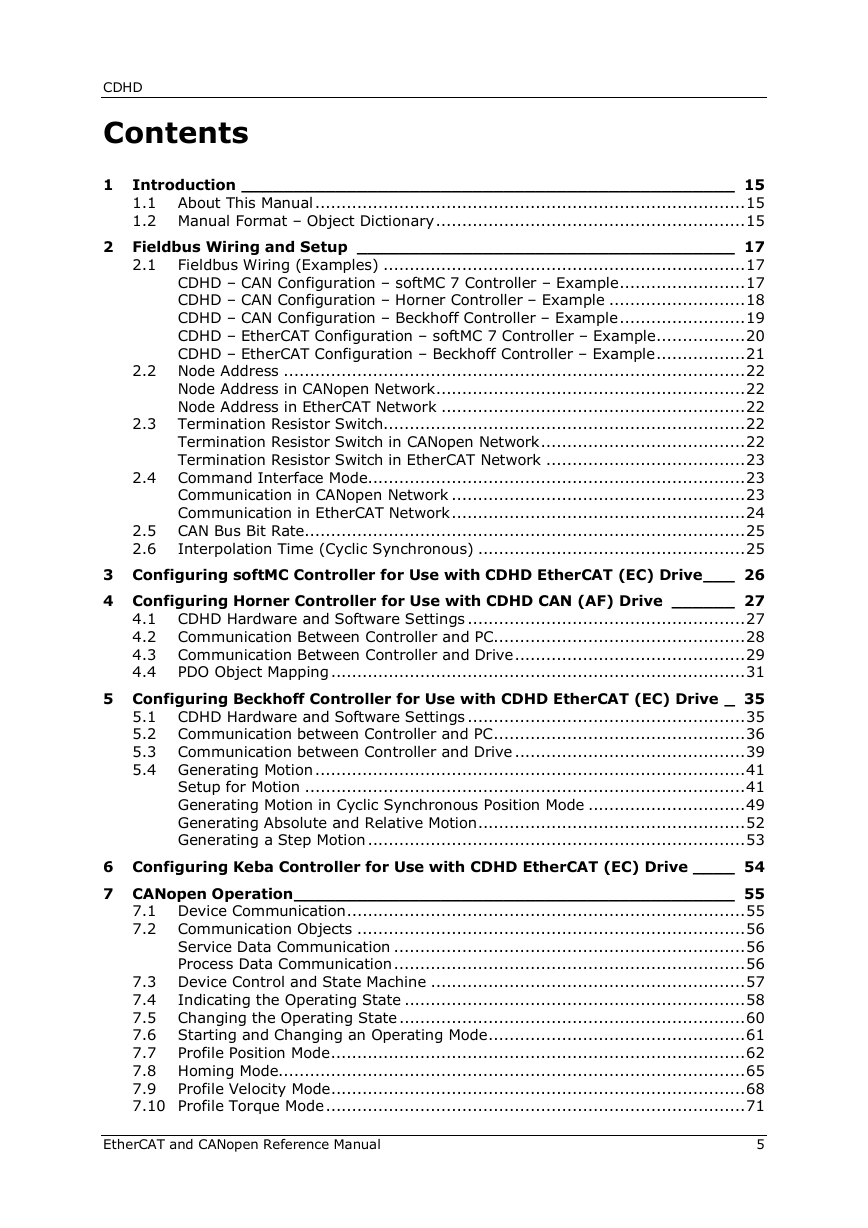

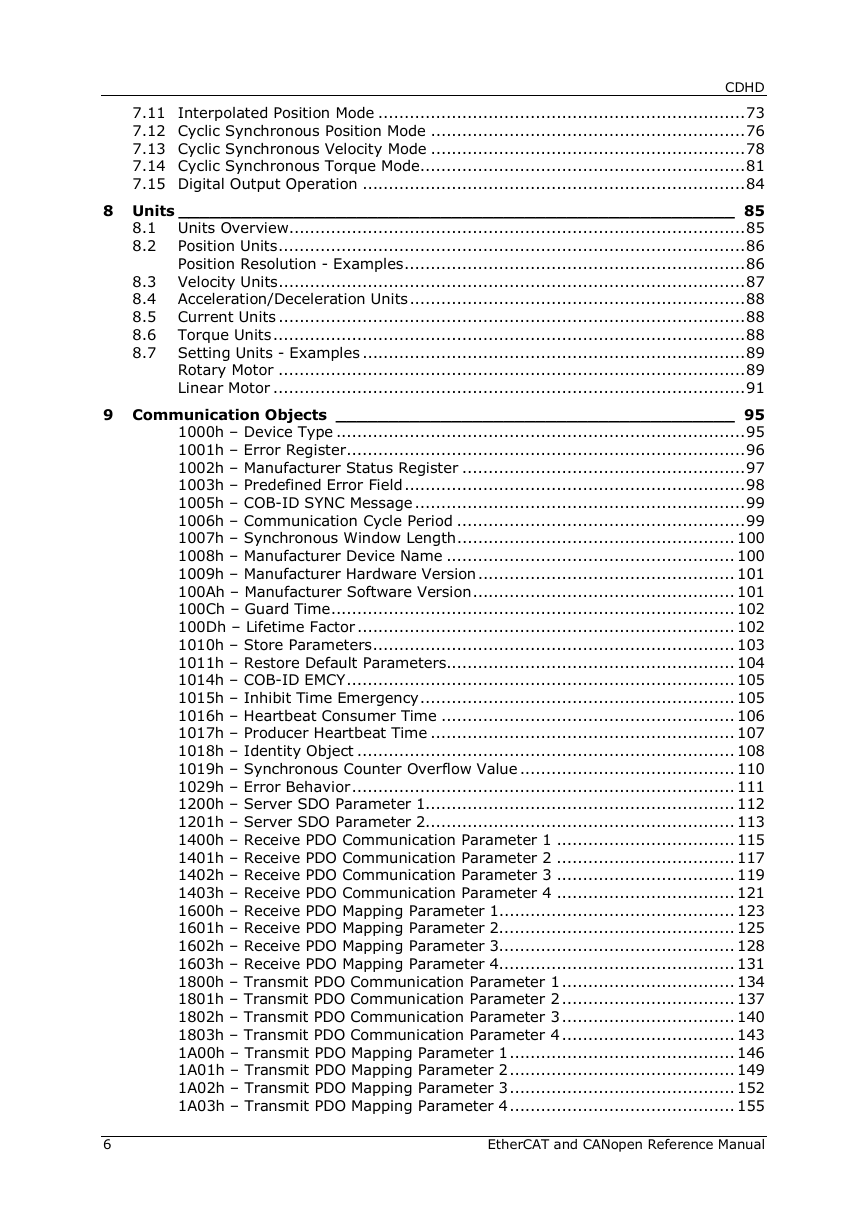

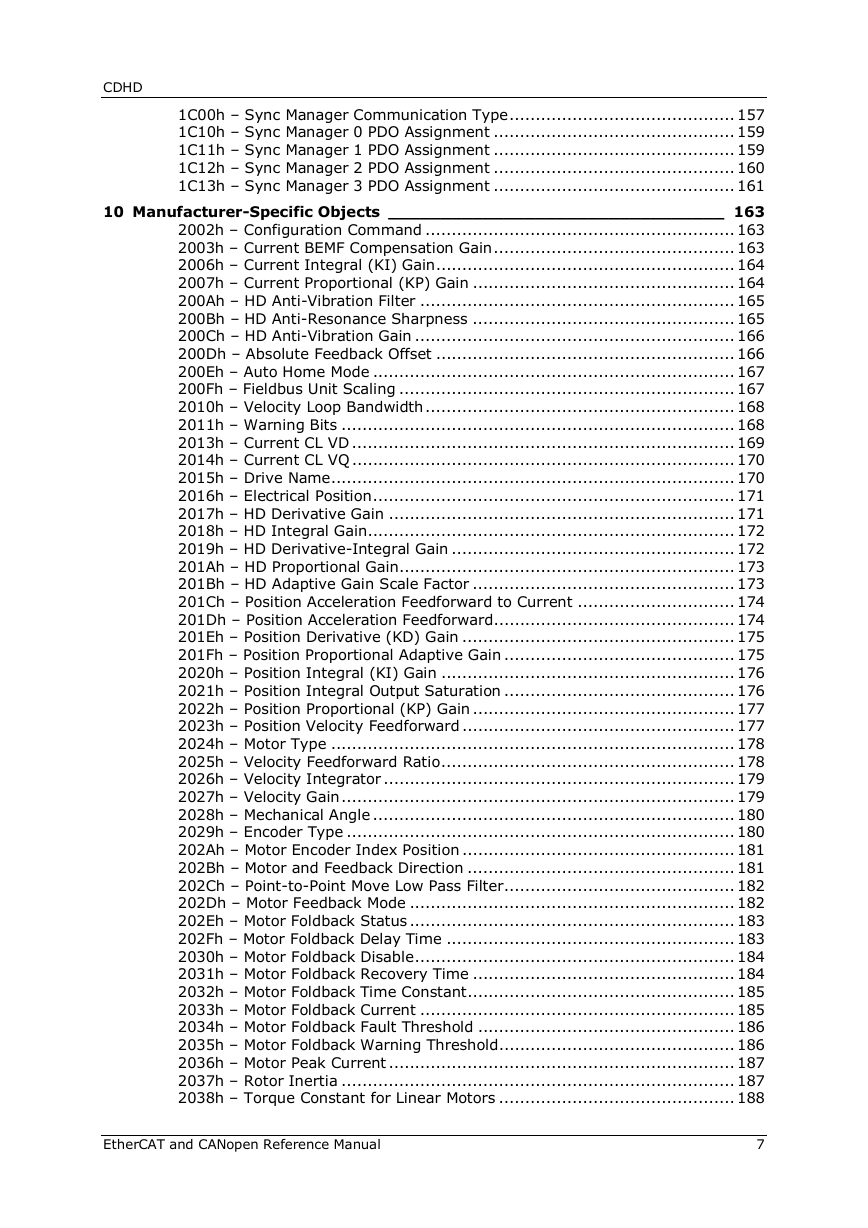

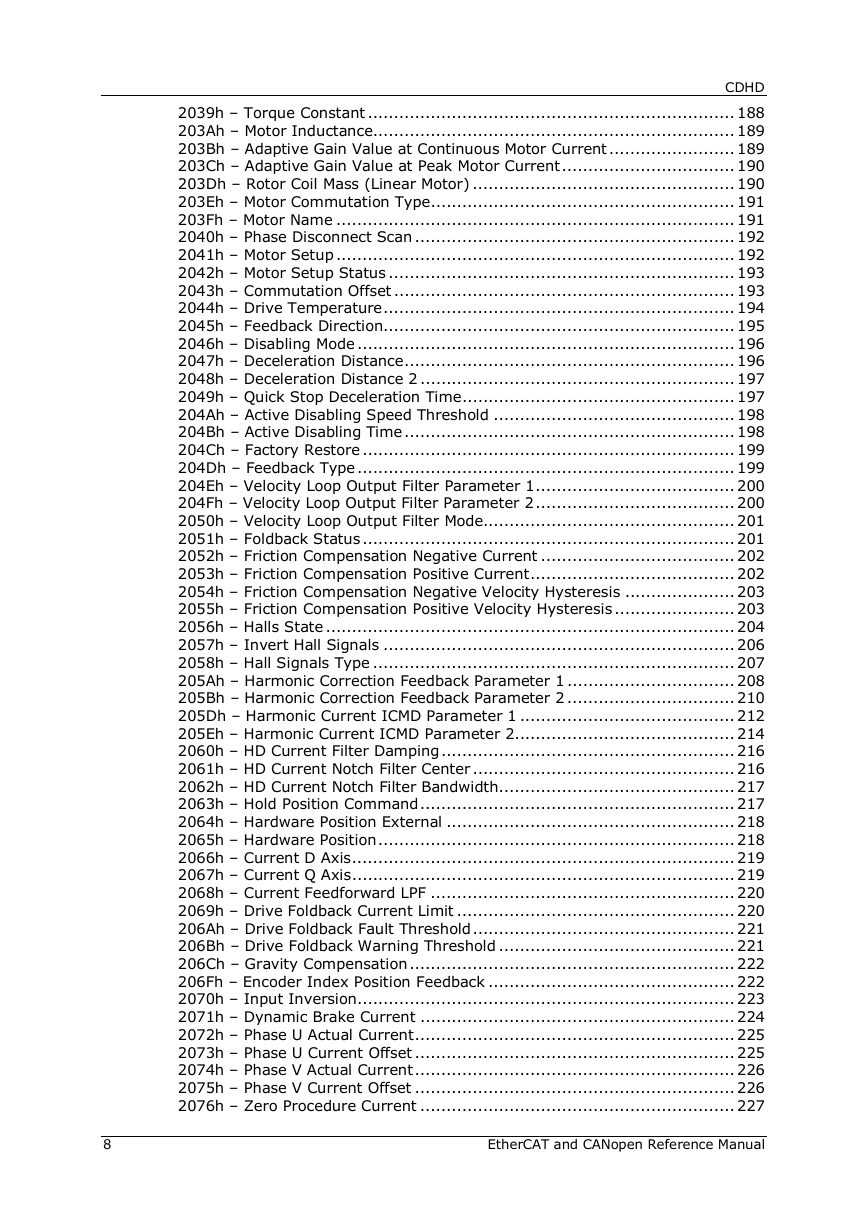

Contents

1 Introduction

1.1 About This Manual

1.2 Manual Format – Object Dictionary

2 Fieldbus Wiring and Setup

2.1 Fieldbus Wiring (Examples)

CDHD – CAN Configuration – softMC 7 Controller – Example

CDHD – CAN Configuration – Horner Controller – Example

CDHD – CAN Configuration – Beckhoff Controller – Example

CDHD – EtherCAT Configuration – softMC 7 Controller – Example

CDHD – EtherCAT Configuration – Beckhoff Controller – Example

2.2 Node Address

Node Address in CANopen Network

Node Address in EtherCAT Network

2.3 Termination Resistor Switch

Termination Resistor Switch in CANopen Network

Termination Resistor Switch in EtherCAT Network

2.4 Command Interface Mode

Communication in CANopen Network

Communication in EtherCAT Network

2.5 CAN Bus Bit Rate

2.6 Interpolation Time (Cyclic Synchronous)

3 Configuring softMC Controller for Use with CDHD EtherCAT (EC) Drive

4 Configuring Horner Controller for Use with CDHD CAN (AF) Drive

4.1 CDHD Hardware and Software Settings

4.2 Communication Between Controller and PC

4.3 Communication Between Controller and Drive

4.4 PDO Object Mapping

5 Configuring Beckhoff Controller for Use with CDHD EtherCAT (EC) Drive

5.1 CDHD Hardware and Software Settings

5.2 Communication between Controller and PC

5.3 Communication between Controller and Drive

5.4 Generating Motion

Setup for Motion

Generating Motion in Cyclic Synchronous Position Mode

Generating Absolute and Relative Motion

Generating a Step Motion

6 Configuring Keba Controller for Use with CDHD EtherCAT (EC) Drive

7 CANopen Operation

7.1 Device Communication

7.2 Communication Objects

Service Data Communication

Process Data Communication

7.3 Device Control and State Machine

7.4 Indicating the Operating State

7.5 Changing the Operating State

7.6 Starting and Changing an Operating Mode

7.7 Profile Position Mode

Example: Profile Position

7.8 Homing Mode

Example: Homing

7.9 Profile Velocity Mode

Example: Profile Velocity

7.10 Profile Torque Mode

Example: Profile Torque

7.11 Interpolated Position Mode

Example: Interpolated Position Profile

7.12 Cyclic Synchronous Position Mode

Example: Cyclic Synchronous Position Profile

7.13 Cyclic Synchronous Velocity Mode

Example: Cyclic Synchronous Velocity

7.14 Cyclic Synchronous Torque Mode

Example: Cyclic Synchronous Torque

7.15 Digital Output Operation

8 Units

8.1 Units Overview

8.2 Position Units

Position Resolution - Examples

8.3 Velocity Units

8.4 Acceleration/Deceleration Units

8.5 Current Units

8.6 Torque Units

8.7 Setting Units - Examples

Rotary Motor

Setting Units to Represent Revolutions

Setting Units to Represent Degrees

Setting Units to Represent Feedback Counts

Linear Motor

Setting Units to Represent Motor Pitch

Setting Units to Represent Millimeters

Setting Units to Represent Feedback Counts

9 Communication Objects

1000h – Device Type

1001h – Error Register

1002h – Manufacturer Status Register

1003h – Predefined Error Field

1005h – COBID SYNC Message

1006h – Communication Cycle Period

1007h – Synchronous Window Length

1008h – Manufacturer Device Name

1009h – Manufacturer Hardware Version

100Ah – Manufacturer Software Version

100Ch – Guard Time

100Dh – Lifetime Factor

1010h – Store Parameters

1011h – Restore Default Parameters

1014h – COBID EMCY

1015h – Inhibit Time Emergency

1016h – Heartbeat Consumer Time

1017h – Producer Heartbeat Time

1018h – Identity Object

1019h – Synchronous Counter Overflow Value

1029h – Error Behavior

1200h – Server SDO Parameter 1

1201h – Server SDO Parameter 2

1400h – Receive PDO Communication Parameter 1

1401h – Receive PDO Communication Parameter 2

1402h – Receive PDO Communication Parameter 3

1403h – Receive PDO Communication Parameter 4

1600h – Receive PDO Mapping Parameter 1

1601h – Receive PDO Mapping Parameter 2

1602h – Receive PDO Mapping Parameter 3

1603h – Receive PDO Mapping Parameter 4

1800h – Transmit PDO Communication Parameter 1

1801h – Transmit PDO Communication Parameter 2

1802h – Transmit PDO Communication Parameter 3

1803h – Transmit PDO Communication Parameter 4

1A00h – Transmit PDO Mapping Parameter 1

1A01h – Transmit PDO Mapping Parameter 2

1A02h – Transmit PDO Mapping Parameter 3

1A03h – Transmit PDO Mapping Parameter 4

1C00h – Sync Manager Communication Type

1C10h – Sync Manager 0 PDO Assignment

1C11h – Sync Manager 1 PDO Assignment

1C12h – Sync Manager 2 PDO Assignment

1C13h – Sync Manager 3 PDO Assignment

10 ManufacturerSpecific Objects

2002h – Configuration Command

2003h – Current BEMF Compensation Gain

2006h – Current Integral (KI) Gain

2007h – Current Proportional (KP) Gain

200Ah – HD AntiVibration Filter

200Bh – HD AntiResonance Sharpness

200Ch – HD AntiVibration Gain

200Dh – Absolute Feedback Offset

200Eh – Auto Home Mode

200Fh – Fieldbus Unit Scaling

2010h – Velocity Loop Bandwidth

2011h – Warning Bits

2013h – Current CL VD

2014h – Current CL VQ

2015h – Drive Name

2016h – Electrical Position

2017h – HD Derivative Gain

2018h – HD Integral Gain

2019h – HD DerivativeIntegral Gain

201Ah – HD Proportional Gain

201Bh – HD Adaptive Gain Scale Factor

201Ch – Position Acceleration Feedforward to Current

201Dh – Position Acceleration Feedforward

201Eh – Position Derivative (KD) Gain

201Fh – Position Proportional Adaptive Gain

2020h – Position Integral (KI) Gain

2021h – Position Integral Output Saturation

2022h – Position Proportional (KP) Gain

2023h – Position Velocity Feedforward

2024h – Motor Type

2025h – Velocity Feedforward Ratio

2026h – Velocity Integrator

2027h – Velocity Gain

2028h – Mechanical Angle

2029h – Encoder Type

202Ah – Motor Encoder Index Position

202Bh – Motor and Feedback Direction

202Ch – Point-to-Point Move Low Pass Filter

202Dh – Motor Feedback Mode

202Eh – Motor Foldback Status

202Fh – Motor Foldback Delay Time

2030h – Motor Foldback Disable

2031h – Motor Foldback Recovery Time

2032h – Motor Foldback Time Constant

2033h – Motor Foldback Current

2034h – Motor Foldback Fault Threshold

2035h – Motor Foldback Warning Threshold

2036h – Motor Peak Current

2037h – Rotor Inertia

2038h – Torque Constant for Linear Motors

2039h – Torque Constant

203Ah – Motor Inductance

203Bh – Adaptive Gain Value at Continuous Motor Current

203Ch – Adaptive Gain Value at Peak Motor Current

203Dh – Rotor Coil Mass (Linear Motor)

203Eh – Motor Commutation Type

203Fh – Motor Name

2040h – Phase Disconnect Scan

2041h – Motor Setup

2042h – Motor Setup Status

2043h – Commutation Offset

2044h – Drive Temperature

2045h – Feedback Direction

2046h – Disabling Mode

2047h – Deceleration Distance

2048h – Deceleration Distance 2

2049h – Quick Stop Deceleration Time

204Ah – Active Disabling Speed Threshold

204Bh – Active Disabling Time

204Ch – Factory Restore

204Dh – Feedback Type

204Eh – Velocity Loop Output Filter Parameter 1

204Fh – Velocity Loop Output Filter Parameter 2

2050h – Velocity Loop Output Filter Mode

2051h – Foldback Status

2052h – Friction Compensation Negative Current

2053h – Friction Compensation Positive Current

2054h – Friction Compensation Negative Velocity Hysteresis

2055h – Friction Compensation Positive Velocity Hysteresis

2056h – Halls State

2057h – Invert Hall Signals

2058h – Hall Signals Type

205Ah – Harmonic Correction Feedback Parameter 1

205Bh – Harmonic Correction Feedback Parameter 2

205Dh – Harmonic Current ICMD Parameter 1

205Eh – Harmonic Current ICMD Parameter 2

2060h – HD Current Filter Damping

2061h – HD Current Notch Filter Center

2062h – HD Current Notch Filter Bandwidth

2063h – Hold Position Command

2064h – Hardware Position External

2065h – Hardware Position

2066h – Current D Axis

2067h – Current Q Axis

2068h – Current Feedforward LPF

2069h – Drive Foldback Current Limit

206Ah – Drive Foldback Fault Threshold

206Bh – Drive Foldback Warning Threshold

206Ch – Gravity Compensation

206Fh – Encoder Index Position Feedback

2070h – Input Inversion

2071h – Dynamic Brake Current

2072h – Phase U Actual Current

2073h – Phase U Current Offset

2074h – Phase V Actual Current

2075h – Phase V Current Offset

2076h – Zero Procedure Current

2077h – Position Integral Input Saturation

2078h – Negative Limit Switch Status

2079h – Positive Limit Switch Status

207Ah – Load to Motor Inertia Ratio

207Bh – Drive Peak Current

207Ch – Drive Continuous Current

207Dh – Motor Pitch

207Eh – Motor Poles

207Fh – Motor Resistance

2080h – Motor Resolver Poles

2081h – Motor Rated Torque

2082h – Current KCFF Gain

2083h – Torque Commutation Angle Advance at Motor Continuous Current

2084h – Torque Commutation Angle Advance at Motor Peak Current

2085h – Velocity Commutation Angle Advance at Motor Maximum Speed

2086h – Velocity Commutation Angle Advance at Motor Maximum Speed/2

2087h – HD Spring Filter

2088h – PFB Backup

2089h – PFB Backup Mode

208Ah – HD Maximum Adaptive Gain

208Bh – HD Current Filter – Second Notch Filter Bandwidth

208Ch – HD Current Filter – Second Notch Filter Center

208Dh – Emergency or Controlled Stop Current Limit

208Eh – Position Command

208Fh – HD Flexibility Compensation

2090h – Home Status

2091h – HD Spring Deceleration Ratio

2095h – Position Feedback Offset

2096h – HD Anti Vibration Filter

2097h – HD Anti Vibration Filter 2

2099h – Current Level 1 for Digital Output Definition

209Ah – Current Level 2 for Digital Output Definition

209Bh – Output Inversion

209Ch – Output Mode

209Dh – Position Level 1 for Digital Output Definition

209Eh – Position Level 2 for Digital Output Definition

209Fh – Velocity Level 1 for Digital Output Definition

20A0h – Velocity Level 2 for Digital Output Definition

20A1h – OverVoltage Threshold

20A2h – Software Enable Status

20A3h – Position Loop Position Error

20A4h – Phase Find Command

20A5h – Forced Electrical Position

20A6h – Phase Find Gain

20A7h – Phase Find Current

20A8h – Phase Find Mode

20A9h – Phase Find Status

20AAh – Phase Find Duration

20ABh – Position Loop Controller Mode

20ACh – Software Position Limit Mode

20ADh – PRB Generator Frequency

20AEh – PRB Generator Mode

20AFh – PRB Generator Configuration

20B0h – PTP Generator Target Error

20B1h – PTP Generator Velocity Command

20B2h – PWM Frequency

20B3h – Gear Mode

20B5h – Position Error in Position Flag

20B6h – Machine Hardware Position External (DSP)

20B8h – Fault Relay Status

20B9h – Fault Relay Mode

20BAh – Remote Hardware Enable Status

20BBh – Resolver Amplitude Range

20BCh – Resolver Conversion Bandwidth

20BDh – Save/Load Status

20BEh – Sine/Cosine Calibration Command

20BFh – Sine/Cosine Calibration Mode

20C0h – Sine/Cosine Calibration Status

20C1h – Sine/Cosine Calibration Parameters

20C2h – Synchronization Mode

20C3h – Tracking Factor

20C4h – Motor OverTemperature

20C5h – Motor OverTemperature Clear Fault Level

20C6h – Motor OverTemperature Mode

20C7h – Motor Temperature

20C8h – Motor OverTemperature Time

20C9h – Motor OverTemperature Fault Level

20CAh – Motor OverTemperature Type

20CBh – Tamagawa MultiTurn Reset

20CCh – Run Time

20CDh – UnderVoltage Mode

20CEh – UnderVoltage Recovery Mode

20CFh – UnderVoltage Threshold

20D0h – UnderVoltage Time

20D1h – Bus Voltage (DC)

20D3h – Velocity Error

20D4h – Velocity Loop Controller

20D5h – Velocity Design Structure

20D6h – Velocity Filter Mode

20D7h – Drive Version

20D8h – Velocity Loop Output Filter

20D9h – Velocity Loop Input Filter

20DAh – Advanced Pole Placement H Polynomial

20DBh – Advanced Pole Placement R Polynomial

20DCh – Wake No Shake Status

20DDh – Display Warnings

20DEh – External Encoder Resolution

20DFh – Zeroing Command

20E0h – Input Mode

20E1h – Rotary Address Switch

20E2h – Test 7Segment Display

20E3h – Encoder Simulation Mode

20E4h – Encoder Simulation Resolution

20E5h – Encoder Simulation Index Position

20E6h – Record Done Indicator

20E7h – Get Recorded Data

20E8h – Trigger Recording

20E9h – Stop Recording

20EAh – Record

20EBh – Recording Status

20ECh – Ready to Record

20EEh – Drive and Motor Maximum Velocity

20EFh – Dead Time Compensation Minimal Level

20F0h – Drive and Motor Maximum Current

20F2h – Analog Input 1

20F3h – Analog Input 1 Deadband

20F4h – Analog Input 1 Current Scaling

20F5h – Analog Input 1 Low Pass Filter

20F6h – Analog Input 1 Offset

20F7h – Analog Input 1 Velocity Scaling

20F8h – Analog Input 1 Zeroing

20F9h – Analog Input 2

20FAh – Analog Input 2 Deadband

20FBh – Analog Input 2 Current Scaling

20FCh – Analog Input 2 Low Pass Filter

20FDh – Analog Input 2 Offset

20FFh – Analog Input 2 Zeroing

2100h – Analog Input 2 Mode

2103h – Homing Command

2104h – Current Level for Homing on Hard Stop

2106h – Current Loop Compatibility Mode

2108h – Point-to-Point Move Average

2109h – Point-to-Point Move Smoothing Mode

210Bh – Load to Motor Inertia Ratio for Anti-Vibration Only

210Ch – HD Anti-Resonance Filter Divider

210Dh – HD Current Filter Low Pass Filter Rise Time

2113h – Drive Ready

2114h – Drive Status

2115h – Step Command

2116h – Position Motion Ended

2117h – Units Linear Acc/Dec

2118h – Units Linear Position

2119h – Units Linear Velocity

211Ah – Units Rotary Acc/Dec

211Bh – Units Rotary Position

211Ch – Units Rotary Velocity

211Dh – Velocity Filter Pole Frequency

211Eh – Gear

2120h – Gear Acceleration Threshold

2121h – Gear Filter Acceleration Feedforward

2122h – Gear Filter Mode

2123h – Gear Filter Depth

2124h – Gear Filter Velocity and Acceleration Depth

2125h – Gear Filter Velocity Feedforward

2126h – Gear Ratio Multiplier

2127h – Gearing Input Interpolation Mode

2128h – Gear Following Limits Mode

2129h – Gear Ratio Divider

212Ah – Drive Info

212Bh – Torque Window

212Ch – Block Control Word

212Dh – HD Anti-Vibration Sharpness2

212Eh – HD KIDV Gain

212Fh – HD KPI Gain

2130h – Torque Slope Enable

2131h – Touch Probe Event Counter

2133h – Analog Output

2134h – Analog Output Command

2135h – Analog Output Current Scaling

2136h – Analog Output Limit

2137h – Analog Output Mode

2138h – Analog Output Velocity Scaling

2139h – Secondary Feedback Mode

213Ah – Secondary Feedback Type

213Bh – Secondary Feedback Scaling Numerator

213Ch – Secondary Feedback Scaling Denominator

213Dh – Secondary Feedback Unit Numerator

213Eh – Secondary Feedback Unit Denominator

213Fh – Secondary Feedback Offset

2140h – Secondary Feedback Position Actual Value

2141h – Secondary Feedback Velocity Actual Value

2142h – Primary Position Actual Value

2143h – Primary Velocity Actual Value

2144h – Secondary Feedback Position Error Max

2145h – Secondary Feedback Position Error Threshold

2146h – Secondary Feedback Position Error Time

2147h – Probe Data Rise

2148h – Probe Data Fall

2149h – Probe Variable Select

214Ah – Software Position Limit Hysteresis Value

214Bh – Probe Level Period

214Ch – SensAR Info

214Eh – Modulo Mode

214Fh – Modulo Limits

2150h – Counts Per Revolution

2151h – Start SFB Voltage Correction Calibration

2152h – SFB Voltage Correct Number of Sectors

2153h – SFB Slow Movement Lower Voltage

2154h – SFB Slow Movement Upper Voltage

2155h – Voltage Correction Number of Sectors for Analog Input 2

2156h – Voltage Correction Result for Analog Input 2

2157h – SFB Manual Calibration Process Activation

2158h – Digital Outputs After Fault

2159h – Heartbeat Tolerance

215Ah – Sankyo Multi-Turn Reset

215Bh – Voltage State

215Ch – Voltage Non-Volatile State

215Dh – Voltage Backlash Position

215Eh – Voltage Correction Current Limit

215Fh – Voltage Fast Speed

2160h – Voltage Slow Speed

2161h – Secondary Feedback Position Actual Value - User Units

2162h – Secondary Feedback Offset - User Units

2163h – Secondary Feedback Position Error Max - User Units

2164h – Secondary Feedback Position Error Threshold - User Units

2165h – Secondary Feedback Position Command - User Units

2166h – Secondary Feedback Position Error - User Units

2167h – Secondary Feedback Voltage Dwell Time

2168h – Secondary Feedback Position Error

2169h – Voltage Correction Array

216Ah – Voltage Correction Array 2

216Bh – Probe 2 Level Period for Stabilization

216Ch – CANopen Manufacturer-Specific SDO Abort Code

216Dh – Analog Input 2 User Command

216Eh – Analog Input 2 User Denominator

216Fh – Analog Input 2 User Numerator

2170h – Analog Input 2 User Offset

2171h – Secondary Feedback Voltage Correction 1

2172h – Secondary Feedback Voltage Correction 2

2173h – Motor Pitch High Resolution

2176h – BiSS-C Fields

2179h – Halls Only Communication

217Ah – Debug Position Command

217Bh – Zero Motor Phase Degree

217Ch – Reference Offset Value

217Dh – Hardware Version

217Eh – Machine Hardware Position External (FPGA)

11 Standard Servo Drive Objects

603Fh – Error Code

6040h – Controlword

6041h – Statusword

605Bh – Shutdown Option Code

605Ch – Disable Operation Option Code

605Dh – Halt Option Code

605Eh – Fault Reaction Option Code

6060h – Modes of Operation

6061h – Modes of Operation Display

6062h – Position Demand Value

6063h – Position Actual Internal Value

6064h – Position Actual Value

6065h – Following Error Window

6066h – Following Error Time Out

6067h – Position Window

6068h – Position Window Time

606Bh – Velocity Demand Value

606Ch – Velocity Actual Value

606Dh – Velocity Window

606Eh – Velocity Window Time

606Fh – Velocity Threshold

6070h – Velocity Threshold Time

6071h – Target Torque

6073h – Maximum Current

6074h – Torque Demand Value

6075h – Motor Rated Current

6076h – Motor Rated Torque

6077h – Torque Actual Value

6078h – Current Actual Value

6079h – DC Link Circuit Voltage

607Ah – Target Position

607Ch – Home Offset

607Dh – Software Position Limit

607Eh – Polarity

607Fh – Max Profile Velocity

6080h – Max Motor Speed

6081h – Profile Velocity in Profile Position Mode

6083h – Profile Acceleration

6084h – Profile Deceleration

6085h – Quick Stop Deceleration

6087h – Torque Slope

608Fh – Position Encoder Resolution

6091h – Gear Ratio

6092h – Feed Constant

6098h – Homing Mode

6099h – Homing Speeds

609Ah – Homing Acceleration

60B0h – Position Offset

60B1h – Velocity Offset

60B2h – Torque Offset

60B8h – Touch Probe Function

60B9h – Touch Probe Status

60BAh – Touch Probe 1 Position Positive Edge

60BBh – Touch Probe 1 Position Negative Edge

60BCh – Touch Probe 2 Position Positive Edge

60BDh – Touch Probe 2 Position Negative Edge

60C0h – Interpolation Submode

60C1h – Interpolation Data Record

60C2h – Interpolation Time Period

60C4h – Interpolation Data Configuration

60C5h – Max Acceleration

60C6h – Max Deceleration

60D5h – Touch Probe 1 Positive Edge Counter

60D6h – Touch Probe 1 Negative Edge Counter

60D7h – Touch Probe 2 Positive Edge Counter

60D8h – Touch Probe 2 Negative Edge Counter

60F2h – Positioning Option Code

60F4h – Following Error Actual Value

60FCh – Position Demand Internal Value

60FDh – Digital Inputs

60FEh – Digital Outputs

60FFh – Target Velocity

6502h – Supported Drive Modes

12 CANopen and EtherCAT Troubleshooting

12.1 Warning Codes

12.2 Error and Fault Codes

Service Request Error (Abort) Codes

Emergency Error (Fault) Codes

12.3 Common Communication Problems

b1 – PLL synchronization failed

C1 – CANopen cable disconnected, heartbeat lost

Fb1 – Fieldbus – Target position exceeds velocity limit

Fb3 – EtherCAT cable disconnected

Fb4 – Fieldbus target command lost

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc