letters to nature

20. Pavlov, V. V., Pisarev, R. V., Kirilyuk, A. & Rasing, T. Observation of a transversal nonlinear magneto-

optical effect in thin magnetic garnet films. Phys. Rev. Lett. 78, 2004–2007 (1997).

21. Novoselov, K. S., Geim, A. K., van der Berg, D., Dubonos, S. V. & Maan, J. C. Domain wall

propagation on nanometer scale: coercivity of a single pinning center. IEEE Trans. Magn. 38,

2583–2585 (2002).

22. Peeters, F. M. & Li, X. Q. Hall magnetometer in the ballistic regime. Appl. Phys. Lett. 72, 572–574

(1998).

23. Kent, A. D., von Molnar, S., Gider, S. & Awschalom, D. D. Properties and measurement of

scanning tunneling microscope fabricated ferromagnetic particle arrays. J. Appl. Phys. 76, 6656–6660

(1994).

24. Li, Y. Q. et al. Hall magnetometry on a single iron nanoparticle. Appl. Phys. Lett. 80, 4644–4646

(2002).

25. Hengstmann, T. M., Grundler, D., Heyn, C. & Heitmann, D. Stray-field investigation on permalloy

nanodisks. J. Appl. Phys. 90, 6542–6544 (2001).

26. Schuh, D., Biberger, J., Bauer, A., Breuer, W. & Weiss, D. Hall-magnetometry on ferromagnetic dots

and dot arrays. IEEE Trans. Magn. 37, 2091–2093 (2001).

27. Vergne, R., Cotillard, J. C. & Porteseil, J. L. Some statistical aspects of magnetization processes in

ferromagnetic bodies—motion of a single 180-degrees Bloch wall in an imperfect crystalline medium.

Rev. Phys. Appl. 16, 449–476 (1981).

28. Wunderlich, J. et al. Influence of geometry on domain wall propagation in a mesoscopic wire. IEEE

Trans. Magn. 37, 2104–2107 (2001).

29. Kim, D. H., Choe, S. B. & Shin, S. C. Direct observation of Barkhausen avalanche in Co thin films.

Phys. Rev. Lett. 90, 087203 (2003).

30. Magnus, K. Vibrations (Blackie & Son, London, 1965).

31. Acheson, D. From Calculus to Chaos (Oxford Univ. Press, Oxford, 1997).

Acknowledgements This research was supported by the EPSRC (UK). We thank S. Gillott and

M. Sellers for technical assistance and J. Steeds for advice on dislocation motion. S.V.D. also

acknowledges support from Russian Ministry of Science and Technology.

Competing interests statement The authors declare that they have no competing financial

interests.

Correspondence and requests for materials should be addressed to A.K.G. (geim@man.ac.uk).

..............................................................

Subwavelength-diameter silica wires

for low-loss optical wave guiding

Limin Tong1,2, Rafael R. Gattass1, Jonathan B. Ashcom1*, Sailing He2,

Jingyi Lou2, Mengyan Shen1,3, Iva Maxwell1 & Eric Mazur1

1Department of Physics and Division of Engineering and Applied Sciences,

Harvard University, Cambridge, Massachusetts 02138, USA

2Centre for Optical and Electromagnetic Research and Department of Physics,

Zhejiang University, Hangzhou 310027, China

3Department of Physics, Graduate School of Science, Tohoku University, Sendai,

Miyagi 9808578, Japan

* Present address: Lincoln Laboratory, Massachusetts Institute of Technology, Lexington, Massachusetts

02420, USA

.............................................................................................................................................................................

Silica waveguides with diameters larger than the wavelength of

transmitted light are widely used in optical communications,

sensors and other applications1–3. Minimizing the width of the

waveguides is desirable for photonic device applications, but the

fabrication of low-loss optical waveguides with subwavelength

diameters remains challenging because of strict requirements on

surface roughness and diameter uniformity4–7. Here we report

the fabrication of subwavelength-diameter silica ‘wires’ for use as

low-loss optical waveguides within the visible to near-infrared

spectral range. We use a two-step drawing process to fabricate

long free-standing silica wires with diameters down to 50 nm that

show surface smoothness at the atomic level together with

uniformity of diameter. Light can be launched into these wires

by optical evanescent coupling. The wires allow single-mode

operation, and have an optical loss of less than 0.1 dB mm21.

We believe that these wires provide promising building blocks for

future microphotonic devices with subwavelength-width

structures.

The fabrication of thin silica wires was first investigated in the

nineteenth century, when the mechanical properties of the wires

were studied, but their optical properties and applications remained

uninvestigated8,9. It was not until a century later that researchers

began to investigate the optical applications of silica wires made by

drawing high-purity glass fibres from a laser-heated melt10–14. With

a diameter of more than one micrometre, these silica wires allow

multimode waveguiding of visible and infrared light. Submicro-

metre wires allow single-mode operation, but both theoretical and

experimental results show that the laser power required for drawing

silica submicrometre- or nanometre-diameter wires (SMNWs) with

a uniform diameter is impractically large14,15. When drawing wires

from a flame-heated melt, turbulence and convection make it

difficult to control the temperature gradient in the drawing region,

and consequently size uniformity is difficult to maintain when the

wire diameter is reduced to less than one micrometre. Silica

nanowires with diameters ranging from ten to several hundred

nanometres have recently been obtained with other methods16–18,

but the diameter fluctuation and sidewall roughness of those wires

makes them unsuitable for low-loss optical wave guiding.

Here we introduce a two-step drawing process for fabricating

long uniform silica SMNWs by a flame-heated fibre drawing

method. First, we use a flame to draw a silica fibre to a micro-

metre-diameter wire. Second, to obtain a steady temperature

distribution in the drawing region while further reducing the wire

diameter, we use a tapered sapphire fibre with a tip diameter of

about 80 m m to absorb the thermal energy from the flame (Fig. 1).

The sapphire fibre taper, which is fabricated using laser-heating

growth method19, confines the heating to a small volume and helps

maintain a steady temperature distribution during the drawing.

One end of a micrometre-diameter silica wire is placed horizontally

on the sapphire tip, and the flame is adjusted until the temperature

of the tip is just above the drawing temperature (about 2,000 K). We

then rotate the sapphire tip around its axis of symmetry to wind the

silica wire around the tip. The wire coil is moved about 0.5 mm out

of the flame to prevent melting and the wire is then drawn

perpendicular to the axis of the sapphire tip in the horizontal

plane at a speed of 1–10 mm s21 to form a SMNW.

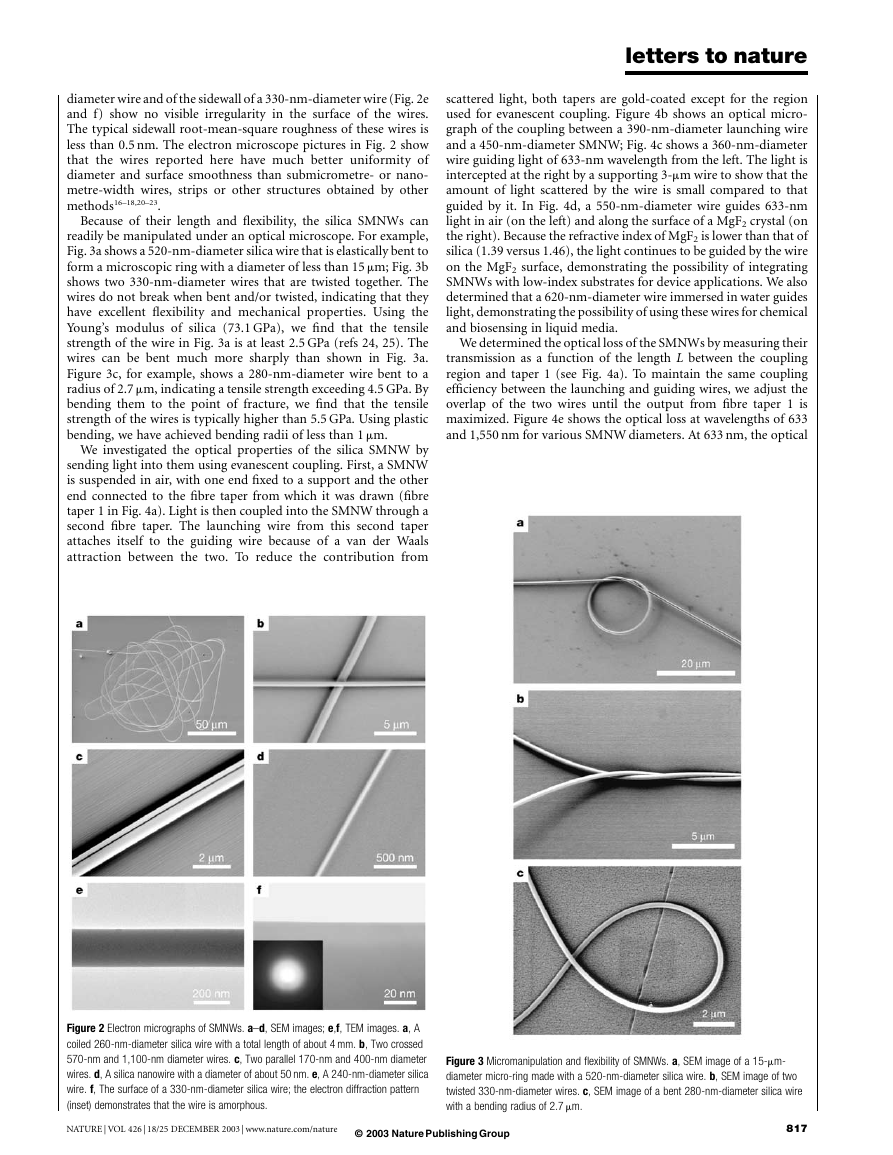

Using this technique, we obtained silica SMNWs with diameters

down to 50 nm and lengths up to tens of millimetres. Figure 2a

shows a scanning electron microscope (SEM) image of a 4-mm-long

wire with a diameter of 260 nm; the wire is roughly coiled up to

show its length. The maximum diameter variation DD is about 8 nm

over the 4-mm length L of the wire, giving DD/L ¼ 2 £ 1026. The

excellent uniformity of wires with diameters ranging from 50 to

1,100 nm can also be seen in Fig. 2b–d. Higher-magnification

transmission electron microscope (TEM) images of a 240-nm-

Figure 1 The second step in the fabrication process of silica submicrometre- and

nanometre wires (SMNWs). a, Schematic diagram of the drawing of the wire from a coil of

micrometre-diameter silica wire wound around the tip of a sapphire taper. The sapphire

taper is heated with a CH3OH torch with a nozzle diameter of about 6 mm. The wire is

drawn in a direction perpendicular to the sapphire taper. b, Magnified view of the drawing

process. The sapphire taper ensures that the temperature distribution in the drawing

region remains steady.

816

© 2003 Nature Publishing Group

NATURE | VOL 426 | 18/25 DECEMBER 2003 | www.nature.com/nature

�

letters to nature

scattered light, both tapers are gold-coated except for the region

used for evanescent coupling. Figure 4b shows an optical micro-

graph of the coupling between a 390-nm-diameter launching wire

and a 450-nm-diameter SMNW; Fig. 4c shows a 360-nm-diameter

wire guiding light of 633-nm wavelength from the left. The light is

intercepted at the right by a supporting 3-m m wire to show that the

amount of light scattered by the wire is small compared to that

guided by it. In Fig. 4d, a 550-nm-diameter wire guides 633-nm

light in air (on the left) and along the surface of a MgF2 crystal (on

the right). Because the refractive index of MgF2 is lower than that of

silica (1.39 versus 1.46), the light continues to be guided by the wire

on the MgF2 surface, demonstrating the possibility of integrating

SMNWs with low-index substrates for device applications. We also

determined that a 620-nm-diameter wire immersed in water guides

light, demonstrating the possibility of using these wires for chemical

and biosensing in liquid media.

We determined the optical loss of the SMNWs by measuring their

transmission as a function of the length L between the coupling

region and taper 1 (see Fig. 4a). To maintain the same coupling

efficiency between the launching and guiding wires, we adjust the

overlap of the two wires until the output from fibre taper 1 is

maximized. Figure 4e shows the optical loss at wavelengths of 633

and 1,550 nm for various SMNW diameters. At 633 nm, the optical

diameter wire and of the sidewall of a 330-nm-diameter wire (Fig. 2e

and f) show no visible irregularity in the surface of the wires.

The typical sidewall root-mean-square roughness of these wires is

less than 0.5 nm. The electron microscope pictures in Fig. 2 show

that the wires reported here have much better uniformity of

diameter and surface smoothness than submicrometre- or nano-

metre-width wires, strips or other structures obtained by other

methods16–18,20–23.

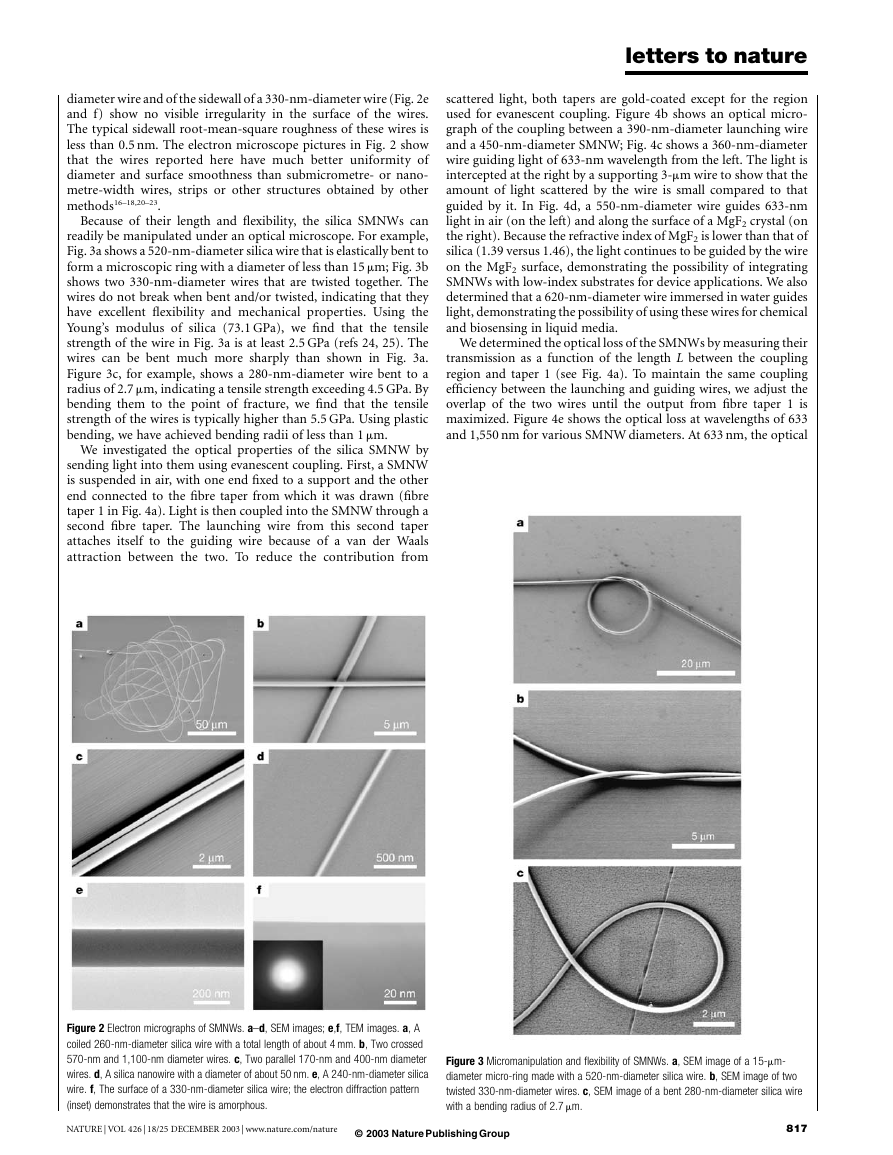

Because of their length and flexibility, the silica SMNWs can

readily be manipulated under an optical microscope. For example,

Fig. 3a shows a 520-nm-diameter silica wire that is elastically bent to

form a microscopic ring with a diameter of less than 15 m m; Fig. 3b

shows two 330-nm-diameter wires that are twisted together. The

wires do not break when bent and/or twisted, indicating that they

have excellent flexibility and mechanical properties. Using the

Young’s modulus of silica (73.1 GPa), we find that the tensile

strength of the wire in Fig. 3a is at least 2.5 GPa (refs 24, 25). The

wires can be bent much more sharply than shown in Fig. 3a.

Figure 3c, for example, shows a 280-nm-diameter wire bent to a

radius of 2.7 m m, indicating a tensile strength exceeding 4.5 GPa. By

bending them to the point of fracture, we find that the tensile

strength of the wires is typically higher than 5.5 GPa. Using plastic

bending, we have achieved bending radii of less than 1 m m.

We investigated the optical properties of the silica SMNW by

sending light into them using evanescent coupling. First, a SMNW

is suspended in air, with one end fixed to a support and the other

end connected to the fibre taper from which it was drawn (fibre

taper 1 in Fig. 4a). Light is then coupled into the SMNW through a

second fibre taper. The launching wire from this second taper

attaches itself to the guiding wire because of a van der Waals

attraction between the two. To reduce the contribution from

Figure 2 Electron micrographs of SMNWs. a–d, SEM images; e,f, TEM images. a, A

coiled 260-nm-diameter silica wire with a total length of about 4 mm. b, Two crossed

570-nm and 1,100-nm diameter wires. c, Two parallel 170-nm and 400-nm diameter

wires. d, A silica nanowire with a diameter of about 50 nm. e, A 240-nm-diameter silica

wire. f, The surface of a 330-nm-diameter silica wire; the electron diffraction pattern

(inset) demonstrates that the wire is amorphous.

Figure 3 Micromanipulation and flexibility of SMNWs. a, SEM image of a 15-m m-

diameter micro-ring made with a 520-nm-diameter silica wire. b, SEM image of two

twisted 330-nm-diameter wires. c, SEM image of a bent 280-nm-diameter silica wire

with a bending radius of 2.7 m m.

NATURE | VOL 426 | 18/25 DECEMBER 2003 | www.nature.com/nature

© 2003 Nature Publishing Group

817

�

letters to nature

loss of a 190-nm-diameter wire is about 1.7 dB mm21, which is

much lower than the optical loss of other subwavelength-structures

such as metallic plasmon waveguides26–28.

The increasing loss with decreasing wire diameter can be attrib-

uted to surface contamination: as the wire diameter is reduced

below the wavelength, more light is guided outside the wire as an

evanescent wave and becomes susceptible to scattering by surface

contamination. Calculations show that the critical diameter for

single-mode operation of a silica wire is about 450 nm at 633-nm

wavelength and 1,100 nm at 1,550-nm wavelength29, and that about

20% of the energy propagates outside the silica core under those

conditions. Figure 4e shows that wires with these diameters have an

optical loss below 0.1 dB mm21. For smaller diameters, more light

propagates outside the silica core as an evanescent wave. Evanescent

wave propagation is extremely useful for enhancing the perform-

ance of devices such as optical sensors.

Because of the large index contrast between silica and air, silica

SMNWs can be bent sharply without incurring large bending

losses. Using a three-dimensional finite-difference time domain

simulation30, we find a bending loss of less than 0.3 dB for a 908

turn with a bending radius of 5 m m in an air-clad 450-nm-diameter

silica wire (for light of 633-nm wavelength). These results indicate

that the silica SMNWs are also suitable for applications where tight

waveguide bends are desired. Using two probes from a scanning

tunnelling microscope for micromanipulation, we were able to

successfully guide 633-nm wavelength light through a bend with a

5.6-m m radius in a silica wire with a diameter of about 510 nm (see

Fig. 4f). As can be seen in the figure, the intensity of scattered light

after the bend is not greatly reduced, indicating that the bending loss

is low. The ability to guide light through sharp bends is especially

useful for miniaturization of photonic devices. Also, with low

bending loss, micro-rings made from these wires (such as the one

shown in Fig. 3a) can be incorporated into photonic devices such as

optical microresonators for optical communication or optical

sensing. For example, we used a 950-nm-diameter SMNW to

make a ring with a 75-m m radius similar to the one shown in

Fig. 3a; preliminary measurements show that the ring has Q factor

of about 1,500 at a wavelength of 1,550 nm.

Figure 4 Optical characterization of SMNWs. a, Schematic diagram for launching light

into a silica wire using evanescent coupling. b, Optical microscope image of a 390-nm-

diameter taper coupling light into a 450-nm-diameter silica wire. c, Long-time exposure

micrograph of 633-nm wavelength light guided by a 360-nm-diameter silica wire in air,

and intercepted by a 3-m m guiding wire on the right. d, Optical microscope image of

633-nm-wavelength light guided by a 550-nm-diameter silica wire with its left half

suspended in air and its right half placed on a MgF2 crystal. e, Measured optical loss of

silica wires at 633 nm (filled blue circles) and 1,550 nm (filled yellow circles). f, Optical

microscope image of 633-nm light travelling through a sharp bend with a radius of 5.6 m m

in a 510-nm-wide silica wire.

818

© 2003 Nature Publishing Group

NATURE | VOL 426 | 18/25 DECEMBER 2003 | www.nature.com/nature

�

The wires reported here are suitable for low-loss optical wave

guiding, and will be promising components in future micropho-

tonic devices for various applications, such as optical communi-

cations and optical sensing. Owing to their excellent uniformity,

large length, high flexibility, and strength, these wires can be

manipulated and assembled with high accuracy and used as

micro- or nanoscale tools in physical, chemical, biological, micro-

A

electronic and materials research.

Received 22 August; accepted 4 November 2003; doi:10.1038/nature02193.

1. Yamane, M. & Asahara, Y. Glasses for Photonics (Cambridge Univ. Press, Cambridge, UK, 2000).

2. Murata, H. Handbook of Optical Fibers and Cables 2nd edn (Marcel Dekker, New York, 1996).

3. Mynbaev, D. K. & Scheiner, L. L. Fiber-Optic Communications Technology (Prentice Hall, New York,

2001).

4. Marcuse, D. Mode conversion caused by surface imperfections of a dielectric slab waveguide. Bell Syst.

Tech. J. 48, 3187–3215 (1969).

5. Marcuse, D. & Derosier, R. M. Mode conversion caused by diameter changes of a round dielectric

waveguide. Bell Syst. Tech. J. 48, 3217–3232 (1969).

6. Ladouceur, F. Roughness, inhomogeneity, and integrated optics. J. Lightwave Technol. 15, 1020–1025

(1997).

7. Lee, K. K. et al. Effect of size and roughness on light transmission in a Si/SiO2 waveguide:

experiments and model. Appl. Phys. Lett. 77, 1617–1619 (2000). Erratum. Appl. Phys. Lett. 77, 2258

(2000).

8. Boys, C. V. On the production, properties, and some suggested uses of the finest threads. Phil. Mag. 23,

489–499 (1887).

9. Threlfall, R. On Laboratory Arts (Macmillan, London, 1898).

10. Knight, J. C., Cheung, G., Jacques, F. & Birks, T. A. Phase-matched excitation of whispering-gallery-

mode resonances by a fiber taper. Opt. Lett. 22, 1129–1131 (1997).

11. Birks, T. A., Wadsworth, W. J. & Russell, P. St. J. Supercontinuum generation in tapered fibers. Opt.

Lett. 25, 1415–1417 (2000).

12. Cai, M. & Vahala, K. Highly efficient hybrid fiber taper coupled microsphere laser. Opt. Lett. 26,

884–886 (2001).

13. Kakarantzas, G., Dimmick, T. E., Birks, T. A., Le Roux, R. & Russell, P. St. J. Miniature all-fiber devices

based on CO2 laser microstructuring of tapered fibers. Opt. Lett. 26, 1137–1139 (2001).

14. Dimmick, T. E., Kakarantzas, G., Birks, T. A. & Russell, P. St. J. Carbon dioxide laser fabrication of

fused-fiber couplers and tapers. Appl. Opt. 38, 6845–6848 (1999).

15. Grellier, A. J. C., Zayer, N. K. & Pannell, C. N. Heat transfer modeling in CO2 laser processing of

optical fibres. Opt. Commun. 152, 324–328 (1998).

16. Wang, Z. L., Gao, R. P. P., Gole, J. L. & Stout, J. D. Silica nanotubes and nanofiber arrays. Adv. Mater.

12, 1938–1940 (2000).

17. Pan, Z. W., Dai, Z. R., Ma, C. & Wang, Z. L. Molten gallium as a catalyst for the large-scale growth of

highly aligned silica nanowires. J. Am. Chem. Soc. 124, 1817–1822 (2002).

18. Hu, J. Q., Meng, X. M., Jiang, Y., Lee, C. S. & Lee, S. T. Fabrication of germanium-filled silica

nanotubes and aligned silica nanofibers. Adv. Mater. 15, 70–73 (2003).

19. Labelle, H. E. & Mlavsky, A. I. Growth of sapphire filaments from melt. Nature 216, 574–575

(1967).

20. Morales, A. M. & Lieber, C. M. A laser ablation method for the synthesis of crystalline semiconductor

nanowires. Science 279, 208–211 (1998).

21. Xia, Y., Rogers, J. A., Paul, K. E. & Whitesides, G. M. Unconventional methods for fabricating and

patterning nanostructures. Chem. Rev. 99, 1823–1848 (1999).

22. Ito, T. & Okazaki, S. Pushing the limits of lithography. Nature 406, 1027–1031 (2000).

23. Lee, K. K., Lim, D. R., Kimerling, L. C., Shin, J. & Cerrina, F. Fabrication of ultralow-loss Si/SiO2

waveguides by roughness reduction. Opt. Lett. 26, 1888–1890 (2001).

24. Matthewson, M. J., Kurkjian, C. R. & Gulati, S. T. Strength measurement of optical fibers by bending.

J. Am. Ceram. Soc. 69, 815–821 (1986).

25. Krause, J. T., Testardi, L. R. & Thurston, R. N. Deviations from linearity in the dependence of

elongation upon force for fibers of simple glass formers and of glass optical light guides. Phys. Chem.

Glasses 20, 135–139 (1979).

26. Takahara, J., Yamagishi, S., Taki, H., Morimoto, A. & Kobayashi, T. Guiding of a one-dimensional

optical beam with nanometer diameter. Opt. Lett. 22, 475–477 (1997).

27. Maier, S. A., Kik, P. G. & Atwater, H. A. Observation of coupled plasmon-polarization modes in Au

nanoparticle chain waveguides of different lengths: Estimation of waveguide loss. Appl. Phys. Lett. 81,

1714–1716 (2002).

28. Maier, S. A. et al. Local detection of electromagnetic energy transport below the diffraction limit in

metal nanoparticle plasmon waveguides. Nature Mater. 2, 229–232 (2003).

29. Snyder, A. W. & Love, J. D. Optical Waveguide Theory (Chapman and Hall, New York, 1983).

30. Taflove, A. Computational Electrodynamics: The Finite-difference Time-domain Method (Artech

House, Boston, 1995).

Acknowledgements We thank Y. Lu, Z. Han and B. Tull for assistance in SEM and TEM imaging,

and L. Liu and X. Chen for help with numerical simulations. This work was supported by the US

National Science Foundation and by the National Natural Science Foundation in China.

T.L. acknowledges support from the Centre for Imaging and Mesoscale Structures at Harvard

University.

Competing interests statement The authors declare that they have no competing financial

interests.

Correspondence and requests for materials should be addressed to E.M.

(mazur@deas.harvard.edu).

letters to nature

..............................................................

Synthesis of a Mo¨bius aromatic

hydrocarbon

D. Ajami1, O. Oeckler2, A. Simon2 & R. Herges1

1Institut fu¨r Organische Chemie, Universita¨t Kiel, Otto-Hahn-Platz 4, 24098 Kiel,

Germany

2Max-Planck-Institut fu¨r Festko¨rperforschung, Heisenbergstraße 1,

D-70569 Stuttgart, Germany

.............................................................................................................................................................................

The defining feature of aromatic hydrocarbon compounds is a

cyclic molecular structure stabilized by the delocalization of p

electrons that, according to the Hu¨ckel rule, need to total 4n 1 2

(n 5 1,2,…); cyclic compounds with 4n p electrons are antiaro-

matic and unstable. But in 1964, Heilbronner predicted1 on

purely theoretical grounds that cyclic molecules with the topol-

ogy of a Mo¨bius band—a ring constructed by joining the ends of a

rectangular strip after having given one end half a twist—should

be aromatic if they contain 4n, rather than 4n 1 2, p electrons.

The prediction stimulated attempts to synthesize Mo¨bius aro-

matic hydrocarbons, but twisted cyclic molecules are destabilized

by large ring strains, with the twist also suppressing overlap of

the p orbitals involved in electron delocalization and stabiliza-

tion. In larger cyclic molecules, ring strain is less pronounced but

the structures are very flexible and flip back to the less-strained

Hu¨ ckel topology2,3. Although transition-state species4, an

unstable intermediate5 and a non-conjugated cyclic molecule6,

all with a Mo¨bius topology, have been documented, a stable

aromatic Mo¨bius system has not yet been realized. Here we report

that combining a ‘normal’ aromatic structure (with p orbitals

orthogonal to the ring plane) and a ‘belt-like’ aromatic structure

(with p orbitals within the ring plane) yields a Mo¨bius compound

stabilized by its extended p system.

Numerous theoretical calculations have been performed to pre-

dict the properties of potential Mo¨bius aromatic systems7–12. The

twist in the p system is usually introduced by a suitable arrangement

of E and Z double bonds. Trans-benzene13 is the smallest conceivable

antiaromatic Mo¨bius annulene. It is only a very shallow minimum

on the energy hypersurface, with an energy as much as

107 kcal mol21 above benzene14. The next-higher Mo¨bius homo-

logue, trans-cyclooctatetraene, indeed comes energetically closer to

its Hu¨ckel (all-cis and global minimum) isomer14. Nevertheless,

with a relative energy of 21.3 kcal mol21, it is expected to be

extremely difficult to synthesize. Moreover, there is almost no

conjugation between the E and the neighbouring Z double bonds

Table 1 Relative stabilities

[16]annulene

Mo¨ bius stabilized [16]annulene

Topology

Sym.

Topology

0.0

2.0

5.1

7.6

15.8

51.4

Sym.

E ref

.............................................................................................................................................................................

C1

C2

C2

C1

C1

Cs

C1

.............................................................................................................................................................................

in kcal mol21) of the most stable isomers of the parent

Calculated relative stabilities (E ref

[16]annulene and of our modified [16]annulene at the B3LYP/6-31G* level of DFT.

Mo¨ bius

Mo¨ bius

Mo¨ bius

Mo¨ bius

Mo¨ bius

Hu¨ ckel

Mo¨ bius

Hu¨ ckel

Hu¨ ckel

Mo¨ bius

Mo¨ bius

Mo¨ bius

Mo¨ bius

E ref

0.0

0.3

2.8

2.8

6.7

7.0

8.3

S4

C1

C1

C2

C2

C2

NATURE | VOL 426 | 18/25 DECEMBER 2003 | www.nature.com/nature

© 2003 Nature Publishing Group

819

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc