LNC-車床系列

程程 式式 手手 冊冊

2009/8 版本:V04.00.002(4408110034)

Leading Numerical Controller

LNC Technology Co., Ltd.

�

�

車床系列

目 錄

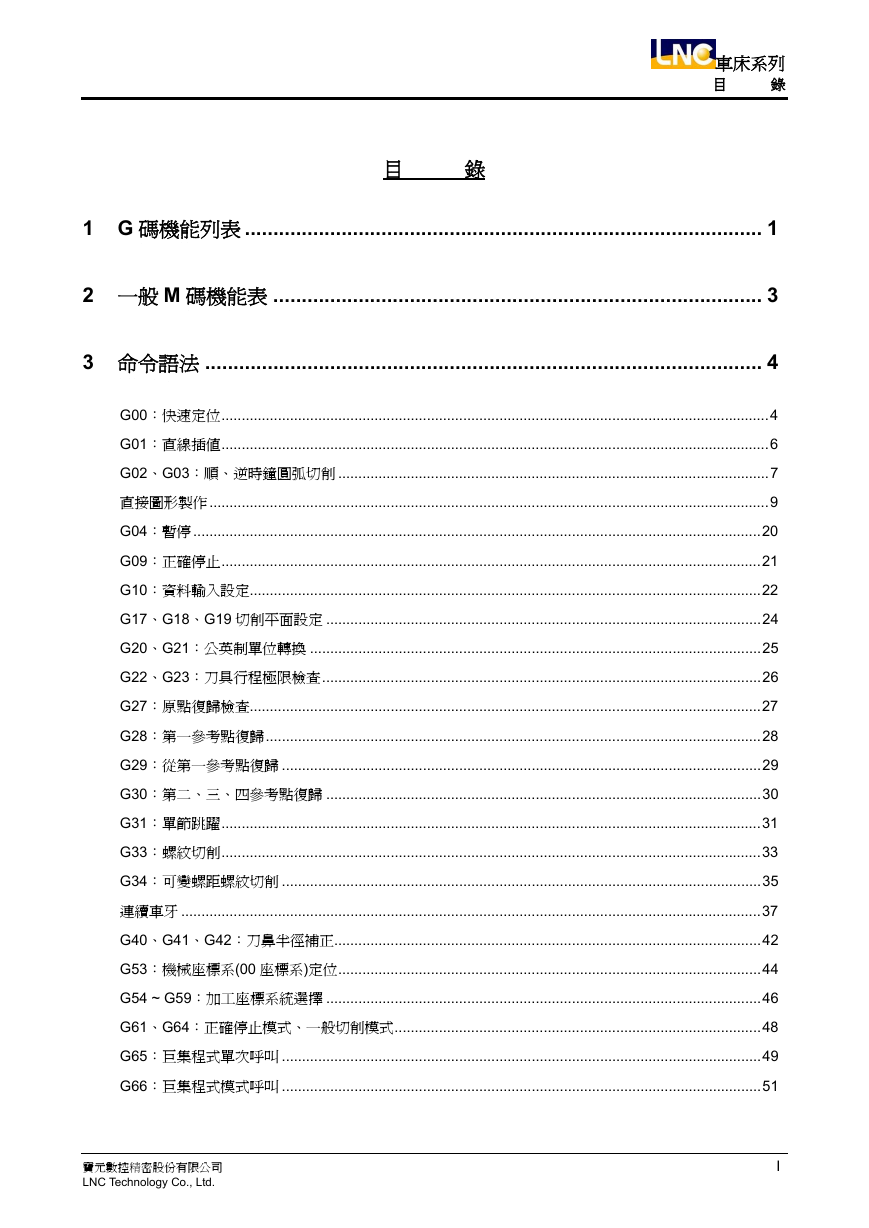

目 錄

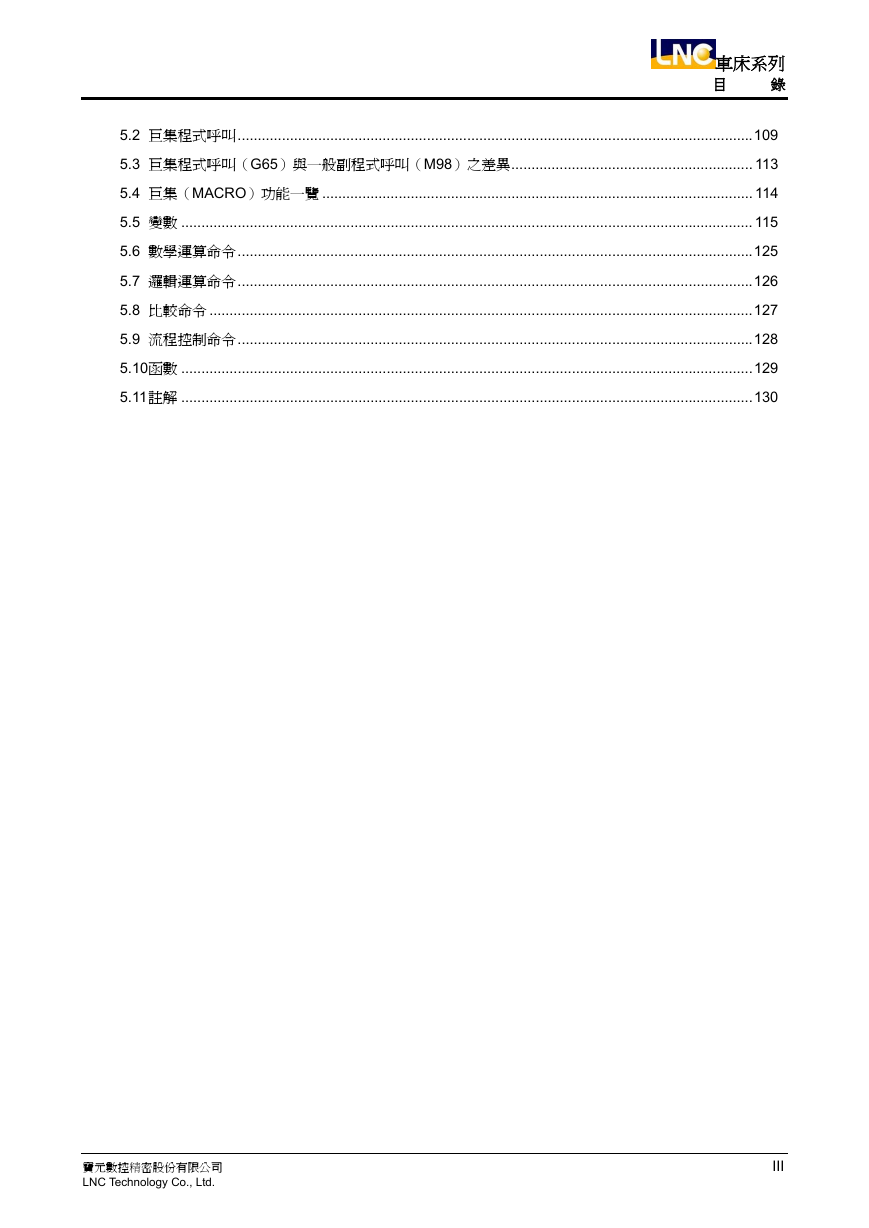

1 G 碼機能列表 ........................................................................................... 1

2 一般 M 碼機能表 ...................................................................................... 3

3 命令語法 .................................................................................................. 4

G00:快速定位........................................................................................................................................4

G01:直線插值........................................................................................................................................6

G02、G03:順、逆時鐘圓弧切削 ...........................................................................................................7

直接圖形製作...........................................................................................................................................9

G04:暫停.............................................................................................................................................20

G09:正確停止......................................................................................................................................21

G10:資料輸入設定...............................................................................................................................22

G17、G18、G19 切削平面設定 ............................................................................................................24

G20、G21:公英制單位轉換 ................................................................................................................25

G22、G23:刀具行程極限檢查.............................................................................................................26

G27:原點復歸檢查...............................................................................................................................27

G28:第一參考點復歸...........................................................................................................................28

G29:從第一參考點復歸 .......................................................................................................................29

G30:第二、三、四參考點復歸 ............................................................................................................30

G31:單節跳躍......................................................................................................................................31

G33:螺紋切削......................................................................................................................................33

G34:可變螺距螺紋切削 .......................................................................................................................35

連續車牙 ................................................................................................................................................37

G40、G41、G42:刀鼻半徑補正..........................................................................................................42

G53:機械座標系(00 座標系)定位.........................................................................................................44

G54 ~ G59:加工座標系統選擇 ............................................................................................................46

G61、G64:正確停止模式、一般切削模式...........................................................................................48

G65:巨集程式單次呼叫 .......................................................................................................................49

G66:巨集程式模式呼叫 .......................................................................................................................51

寶元數控精密股份有限公司

LNC Technology Co., Ltd.

I

�

車床系列

目 錄

G67:取消巨集程式模式呼叫 ................................................................................................................52

G68:致能 X 軸鏡像加工功能 ...............................................................................................................53

G69:取消 X 軸鏡像加工功能 ...............................................................................................................53

G70:複合型精車削循環 .......................................................................................................................55

G71:複合型橫向(外徑)粗切削循環..................................................................................................56

G72:複合型徑向(端面)粗切削循環..................................................................................................58

G73:複合型輪廓粗切削循環 ................................................................................................................60

G74:複合型端面啄式切削循環(Z 軸) ..............................................................................................62

G75:複合型橫向啄式切削循環(X 軸) ..............................................................................................63

G76:複合型螺紋切削循環....................................................................................................................64

G77:單一型徑向切削固定循環 ............................................................................................................65

G78:單一型螺紋切削固定循環 ............................................................................................................66

G79:單一型端面固定切削循環 ............................................................................................................71

G80:固定循環取消...............................................................................................................................72

G83:端面鑽孔固定循環 .......................................................................................................................73

G84:端面攻牙固定循環 .......................................................................................................................77

G85:端面搪孔固定循環 .......................................................................................................................79

G87:橫向鑽孔固定循環 .......................................................................................................................81

G88:橫向攻牙固定循環 .......................................................................................................................85

G89:橫向搪孔固定循環 .......................................................................................................................88

G187:橫向鑽孔固定循環 .....................................................................................................................90

G188:橫向攻牙固定循環 .....................................................................................................................94

G189:橫向搪孔固定循環 .....................................................................................................................96

G90、G91:絕對、增量模式 ................................................................................................................98

G92:座標系統設定...............................................................................................................................99

G94、G95:每分鐘進給量、每轉進給量設定 .....................................................................................100

G96、G97:表面切削速度一定設定/取消 ...........................................................................................101

G98、G99:復歸點設定......................................................................................................................102

4 輔助機能(M 碼)使用說明 ................................................................. 103

5 巨集程式(MACRO).......................................................................... 108

5.1 巨集程式簡介................................................................................................................................108

II

寶元數控精密股份有限公司

LNC Technology Co., Ltd.

�

車床系列

目 錄

5.2 巨集程式呼叫................................................................................................................................109

5.3 巨集程式呼叫(G65)與一般副程式呼叫(M98)之差異............................................................ 113

5.4 巨集(MACRO)功能一覽 ........................................................................................................... 114

5.5 變數 .............................................................................................................................................. 115

5.6 數學運算命令................................................................................................................................125

5.7 邏輯運算命令................................................................................................................................126

5.8 比較命令 .......................................................................................................................................127

5.9 流程控制命令................................................................................................................................128

5.10 函數 ..............................................................................................................................................129

5.11 註解 ..............................................................................................................................................130

寶元數控精密股份有限公司

LNC Technology Co., Ltd.

III

�

�

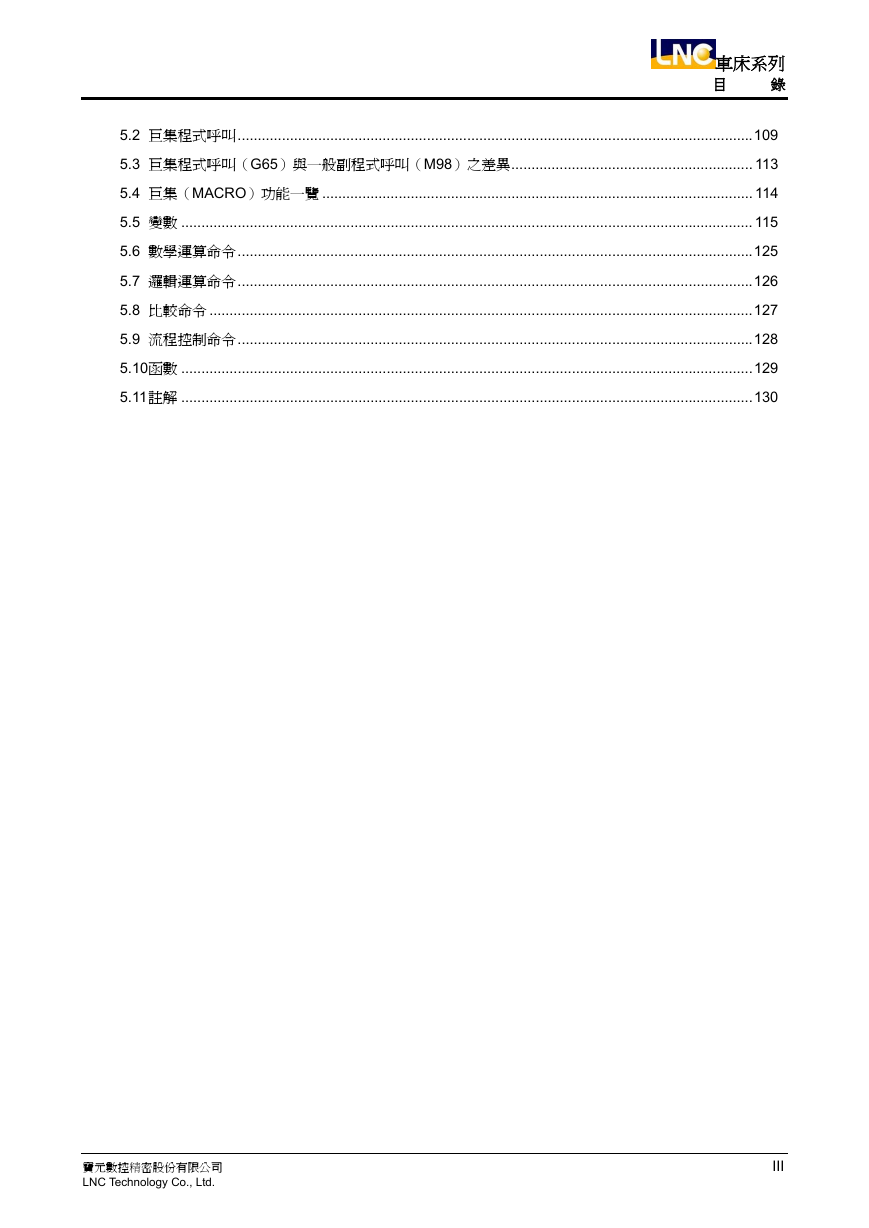

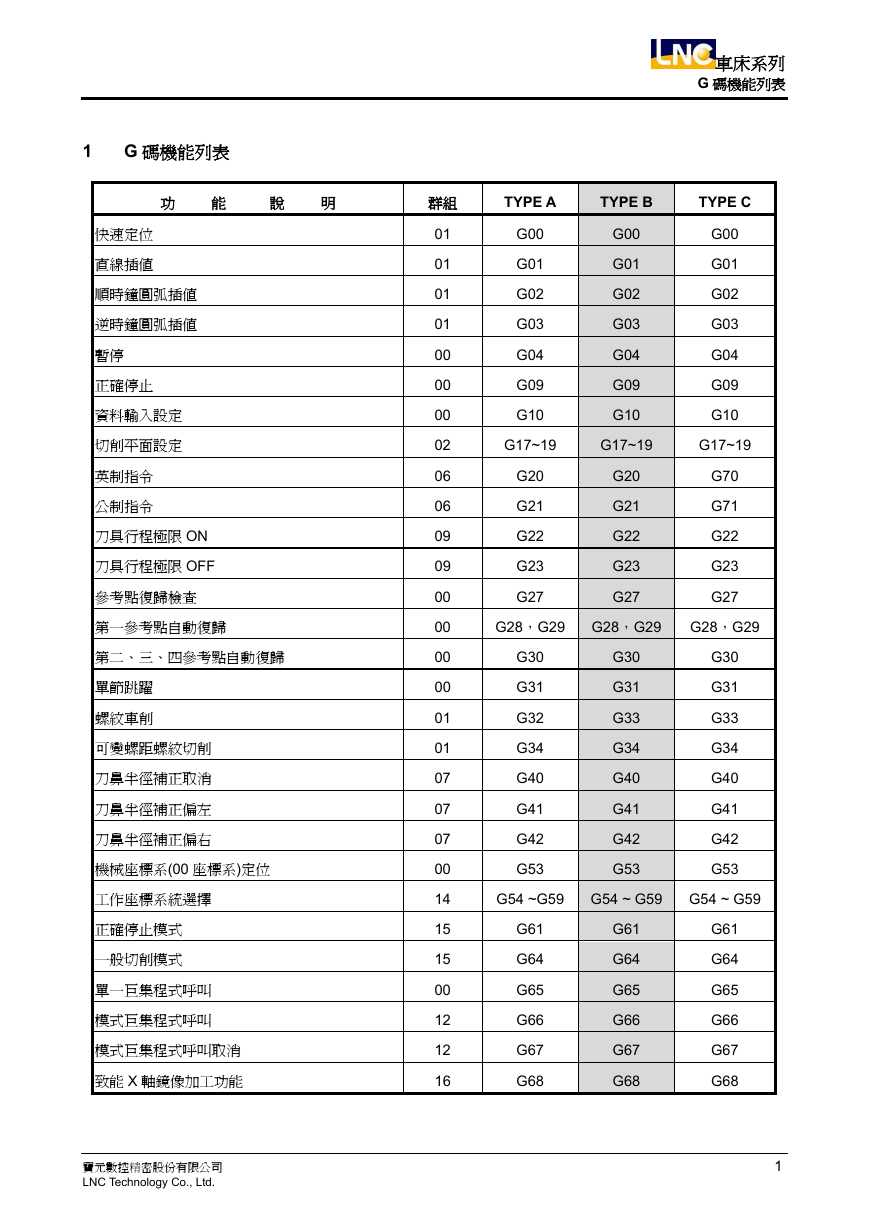

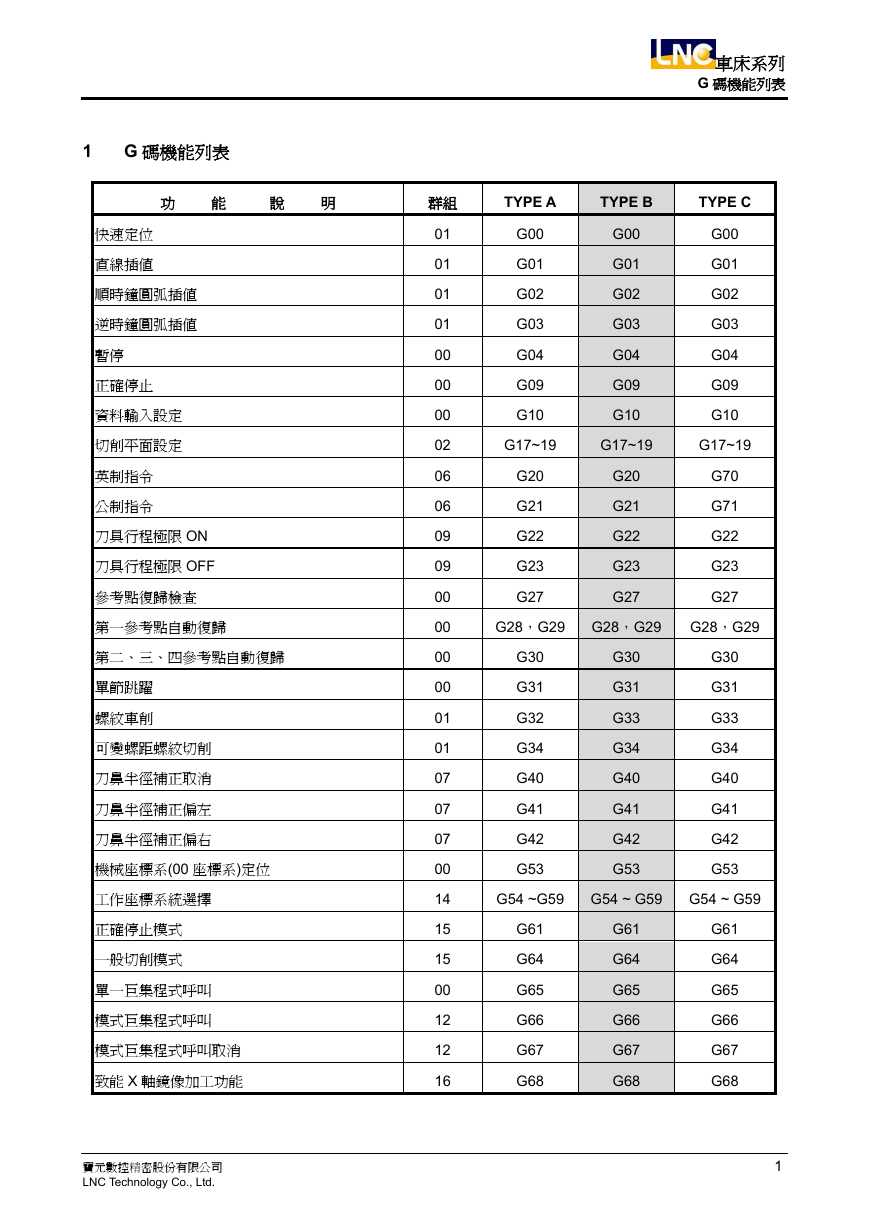

1 G 碼機能列表

功 能 說 明

群組

TYPE A

TYPE B

TYPE C

車床系列

G 碼機能列表

快速定位

直線插值

順時鐘圓弧插值

逆時鐘圓弧插值

暫停

正確停止

資料輸入設定

切削平面設定

英制指令

公制指令

刀具行程極限 ON

刀具行程極限 OFF

參考點復歸檢查

第一參考點自動復歸

第二、三、四參考點自動復歸

單節跳躍

螺紋車削

可變螺距螺紋切削

刀鼻半徑補正取消

刀鼻半徑補正偏左

刀鼻半徑補正偏右

機械座標系(00 座標系)定位

工作座標系統選擇

正確停止模式

一般切削模式

單一巨集程式呼叫

模式巨集程式呼叫

模式巨集程式呼叫取消

致能 X 軸鏡像加工功能

01

01

01

01

00

00

00

02

06

06

09

09

00

00

00

00

01

01

07

07

07

00

14

15

15

00

12

12

16

G00

G01

G02

G03

G04

G09

G10

G00

G01

G02

G03

G04

G09

G10

G00

G01

G02

G03

G04

G09

G10

G17~19

G17~19

G17~19

G20

G21

G22

G23

G27

G20

G21

G22

G23

G27

G70

G71

G22

G23

G27

G28,G29

G28,G29

G28,G29

G30

G31

G32

G34

G40

G41

G42

G53

G30

G31

G33

G34

G40

G41

G42

G53

G30

G31

G33

G34

G40

G41

G42

G53

G54 ~G59 G54 ~ G59 G54 ~ G59

G61

G64

G65

G66

G67

G68

G61

G64

G65

G66

G67

G68

G61

G64

G65

G66

G67

G68

寶元數控精密股份有限公司

LNC Technology Co., Ltd.

1

�

車床系列

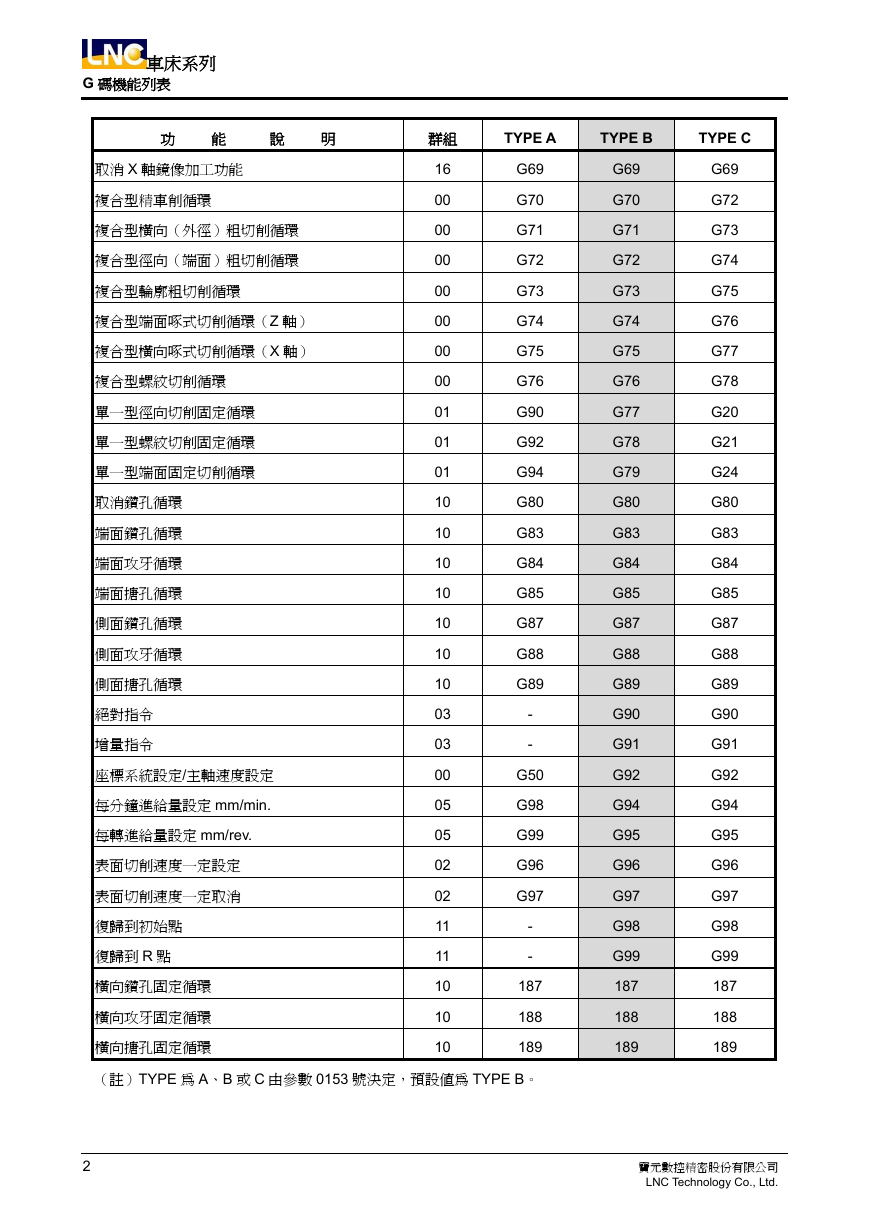

G 碼機能列表

功 能 說 明

群組

TYPE A

TYPE B

TYPE C

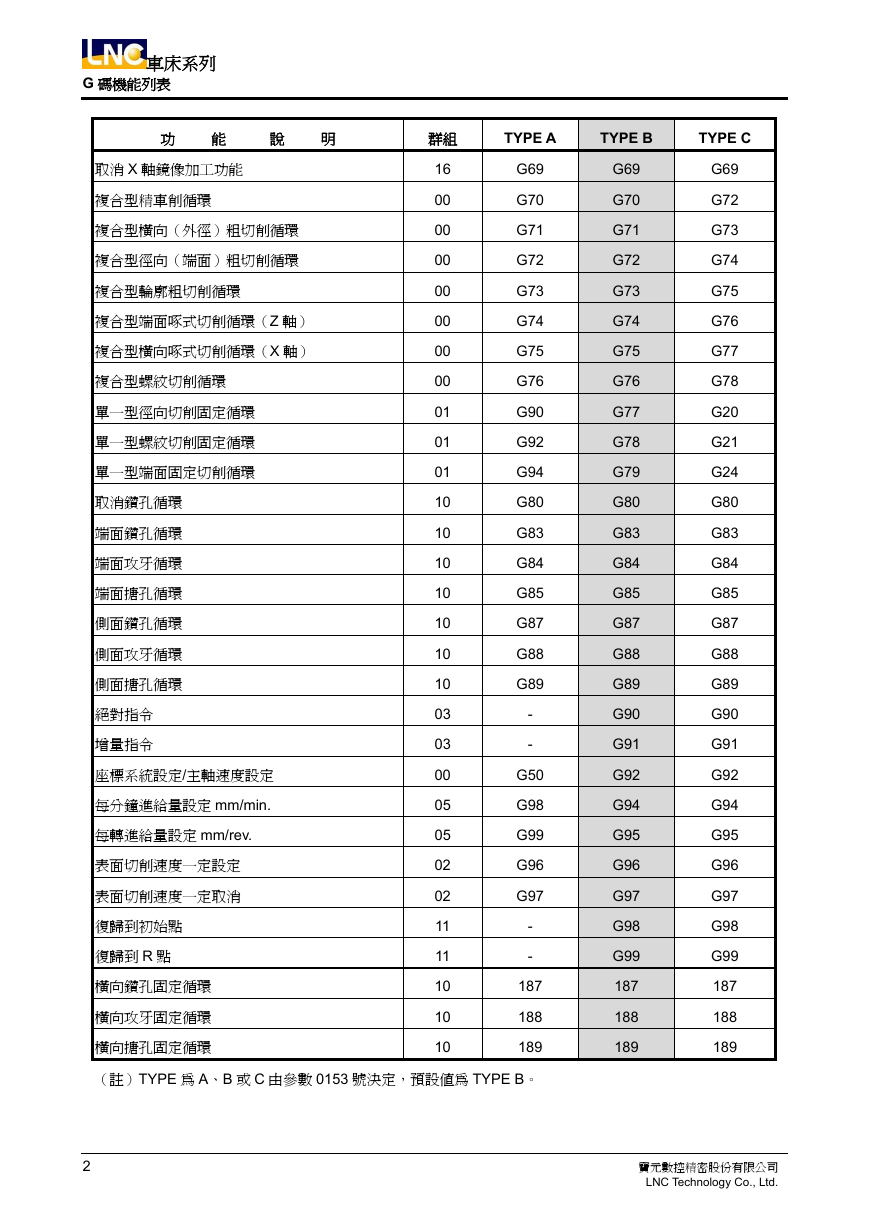

取消 X 軸鏡像加工功能

複合型精車削循環

複合型橫向(外徑)粗切削循環

複合型徑向(端面)粗切削循環

複合型輪廓粗切削循環

複合型端面啄式切削循環(Z 軸)

複合型橫向啄式切削循環(X 軸)

複合型螺紋切削循環

單一型徑向切削固定循環

單一型螺紋切削固定循環

單一型端面固定切削循環

取消鑽孔循環

端面鑽孔循環

端面攻牙循環

端面搪孔循環

側面鑽孔循環

側面攻牙循環

側面搪孔循環

絕對指令

增量指令

座標系統設定/主軸速度設定

每分鐘進給量設定 mm/min.

每轉進給量設定 mm/rev.

表面切削速度一定設定

表面切削速度一定取消

復歸到初始點

復歸到 R 點

橫向鑽孔固定循環

橫向攻牙固定循環

橫向搪孔固定循環

16

00

00

00

00

00

00

00

01

01

01

10

10

10

10

10

10

10

03

03

00

05

05

02

02

11

11

10

10

10

G69

G70

G71

G72

G73

G74

G75

G76

G90

G92

G94

G80

G83

G84

G85

G87

G88

G89

-

-

G50

G98

G99

G96

G97

-

-

187

188

189

G69

G70

G71

G72

G73

G74

G75

G76

G77

G78

G79

G80

G83

G84

G85

G87

G88

G89

G90

G91

G92

G94

G95

G96

G97

G98

G99

187

188

189

G69

G72

G73

G74

G75

G76

G77

G78

G20

G21

G24

G80

G83

G84

G85

G87

G88

G89

G90

G91

G92

G94

G95

G96

G97

G98

G99

187

188

189

(註)TYPE 為 A、B 或 C 由參數 0153 號決定,預設值為 TYPE B。

2

寶元數控精密股份有限公司

LNC Technology Co., Ltd.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc