Authorized licensed use limited to: UNIVERSITY OF WINDSOR. Downloaded on July 22, 2009 at 15:02 from IEEE Xplore. Restrictions apply.

�

.

InverteriMotor

Controller

InverteriMotor

Control

Braking Control

Motor Torque

Motor

Torque

Delivered

Traction Motor

>ommand I

-----+I

I Motorhverter

Motor Nonlinearities 1-q

I

I

Efficiency

Energy Recovered

Inverter Load

Current

Vehicle Velocity

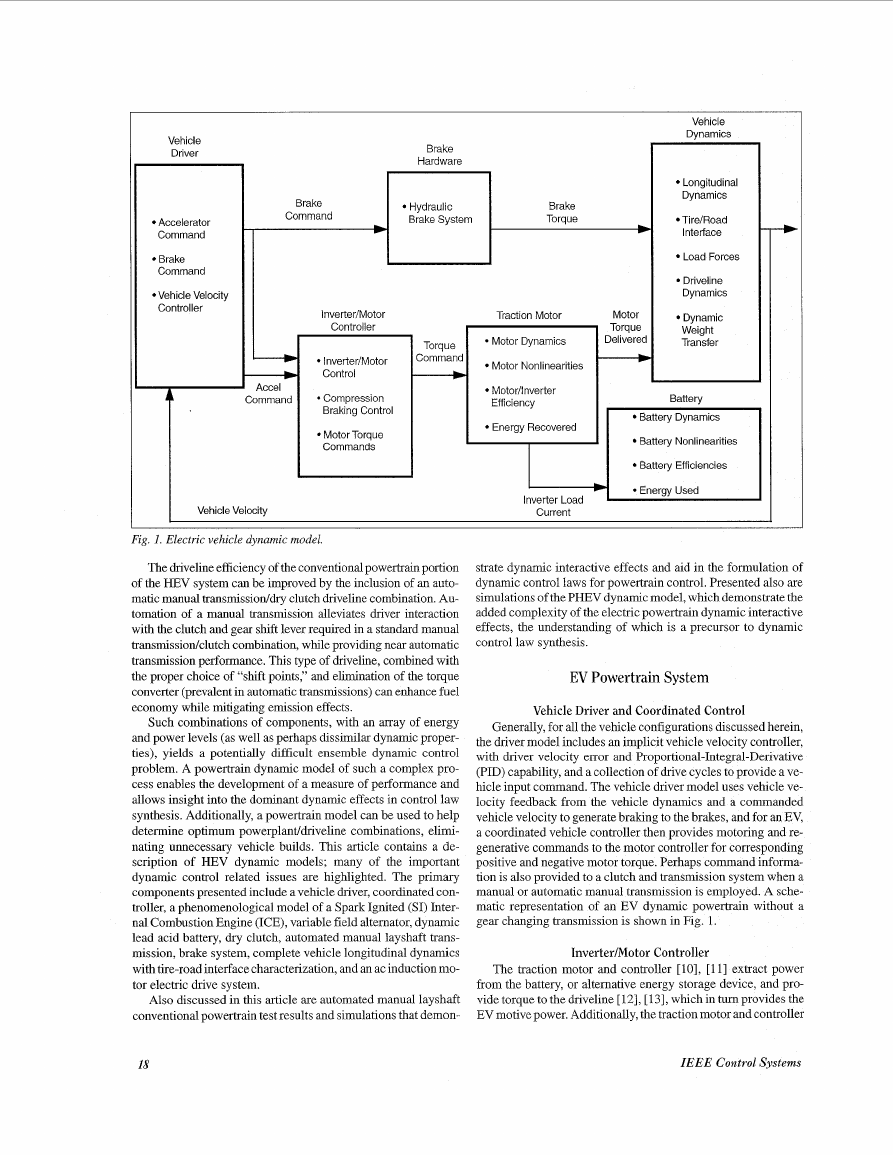

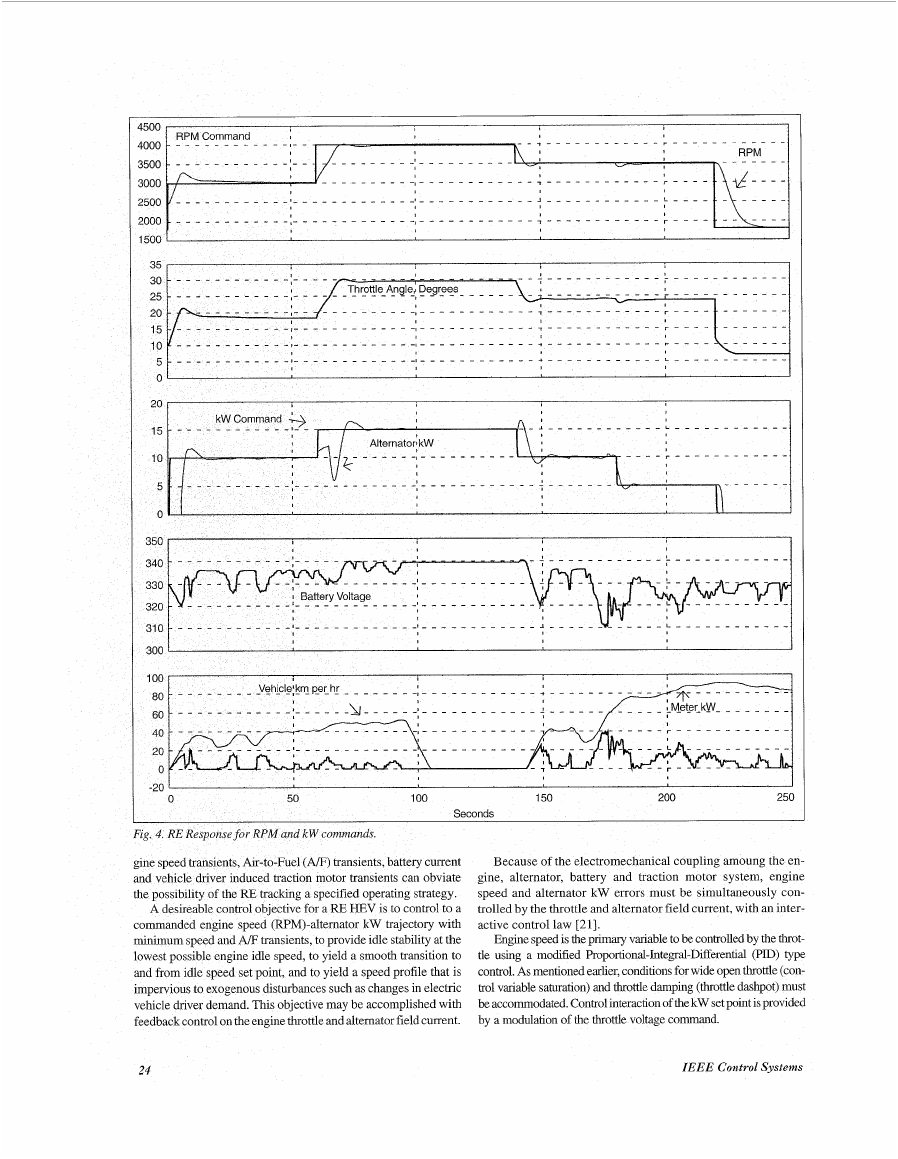

Fig. I . Electric vehicle dynamic model.

The driveline efficiency of the conventional powertrain portion

of the HEV system can be improved by the inclusion of an auto-

matic manual transmissioddry clutch driveline combination. Au-

tomation of a manual transmission alleviates driver interaction

with the clutch and gear shift lever required in a standard manual

bansmissiodclutch combination, while providing near automatic

transmission performance. This type of driveline, combined with

the proper choice of “shift points,” and elimination of the torque

converter (prevalent in automatic transmissions) can enhance fuel

economy while mitigating emission effects.

Such combinations of components, with an array of energy

and power levels (as well as perhaps dissimilar dynamic proper-

ties), yields a potentially difficult ensemble dynamic control

problem. A powertrain dynamic model of such a complex pro-

cess enables the development of a measure of performance and

allows insight into the dominant dynamic effects in control law

synthesis. Additionally, a powertrain model can be used to help

determine optimum powerplantldriveline combinations, elimi-

nating unnecessary vehicle builds. This article contains a de-

scription of HEV dynamic models; many of the important

dynamic control related issues are highlighted. The primary

components presented include a vehicle driver, coordinated con-

troller, a phenomenological model of a Spark Ignited (SI) Inter-

nal Combustion Engine (ICE), variable field altemator, dynamic

lead acid battery, dry clutch, automated manual layshaft trans-

mission, brake system, complete vehicle longitudinal dynamics

with tire-road interface characterization, and an ac induction mo-

tor electric drive system.

Also discussed in this article are automated manual layshaft

conventional powertrain test results and simulations that demon-

strate dynamic interactive effects and aid in the formulation of

dynamic control laws for powertrain control. Presented also are

simulations of the PHEV dynamic model, which demonstrate the

added complexity of the electric powertrain dynamic interactive

effects, the understanding of which is a precursor to dynamic

control law synthesis.

EV Powertrain System

Vehicle Driver and Coordinated Control

Generally, for all the vehicle configurations discussed herein,

the driver model includes an implicit vehicle velocity controller,

with driver velocity error and Propohonal-Integral-Denvatrve

(PID) capability, and a collection of drive cycles to provide a ve-

hicle input command. The vehicle driver model uses vehicle ve-

locity feedback from the vehicle dynamics and a commanded

vehicle velocity to generate braking to the brakes, and for an EV,

a coordinated vehicle controller then provides motoring and re-

generative commands to the motor controller for corresponding

positive and negative motor torque. Perhaps command informa-

tion is also provided to a clutch and transmission system when a

manual or automatic manual transmssion is employed. A sche-

matic representation of an EV dynamic powertrain without a

gear changing transmission is shown in Fig. 1.

Inverter/Motor Controller

The traction motor and controller [lo], [11] extract power

from the battery, or alternative energy storage device, and pro-

vide torque to the driveline [ 121, [ 131, which in turn provides the

EV motive power. Additionally, the traction motor and controller

18

IEEE Control Systems

Brake

Hardware

Brake

Command

Hydraulic

Brake System

Brake

Brake

Torque

Torque

Vehicle

Driver

Accelerator

Command

Brake

Command

Vehicle Velocity

Controller

1

-

I

4

I

Vehicle

Dynamics

Longitudinal

Longitudinal

Dynamics

Dynamics

Tire/Road

Tire/Road

Interface

Interface

Load Forces

Load Forces

Driveline

Dynamics

Dynamic

Weight

Transfer

Battery

Battery Dynamics

Battery Nonlinearities

Battery Efficiencies

�

may be operated as a starter/alternator combination [14] or as a

generator used to recover the vehicle kinetic energy dissipated

during braking [ 1.51, [ 161. The traction motor and controller then

provide power to the battery or altemative power source, and

negative torque to the driveline, which in turn brakes the vehicle.

The coordination of electric and hydraulic blending, during

braking, is performed by the traction motor controller to meet the

driver brake torque command. Compression braking torque,

electric braking torque used to emulate the feel of engine drag

present on an IC engine vehicle, is also determined by the trac-

tion motor controller. All negative motor torque is reduced lin-

early at low vehicle speeds where no energy can be recovered.

Clompression braking torque allows braking to occur while re-

covering the maximum energy, due to all braking being per-

folrmed electrically.

Traction Motor Dynamics

The traction motor dynamic model [lo] represents the dy-

namics of a specific field oriented controlled ac induction motor

as described by the following equations:

h,, = L, .iqs + L, .iqr

h,, = L,T .id + L, .id,

A,, =Lm.iqa +L;iq,

h, = L, . i, + L, ' i,

wlherei,,, iqr are d,q axis rotor current respectively, A; ids,iqs are

d , q axis primary current respectively, A; L, are mutual induc-

tance, H ; Lr, LJ are resolved rotor, stator inductance respec-

tively, H; P is poles; Rr, Rs are resolved rotor, stator resistance

reispectively, ohms; V,, Vqs are d, q axis primary voltage respec-

tively, V; h,,,h qr are d, q axis rotor equivalent flux respectively,

V-sec; h,, h , are d,q axis stator equivalent flux respectively,

V-sec;

o, is synchronous frequency, rps; or is rotor frequency, rps; &,is

rotor acceleration, rps*; T,is electric motor torque, Nm.

The traction motor torque delivered is modeled as a function

of the motor dynamics, motor nonlinearities, and losses in both

the motor and inverter as a function of motor speed. The traction

motor torque limit is characterized by functions of the form:

The inverter load current is a function of traction motor speed,

torque delivered, and terminal voltage of the battery during mo-

toring and during regeneration as:

where elb is battery terminal voltage, V; Tmposdel

is positive motor

torque delivered during motoring, Nm.; q is motor and inverter

combined efficiency.

Battery

The battery model is a lumped parameter dynamic character-

ization of a lead acid battery [8], [14]. The open circuit voltage is

a function of traction battery state of charge and empirical pa-

rameters for lead acid batteries. The dynamic relationships be-

tween battery voltage and current are modeled, including the

polarization capacitive effect, incipient capacitance of the bat-

tery, internal battery resistance, and terminal ohmic resistance.

For example,

V,, = 338.8.[0.94246 + 0.0.05754.( SOC)]

+ elb = zCh - R~ . ilh ,

R~ .

.

dt

where C, is capacitive impedance, F; C, is polarization capaci-

tance, F; Zlbis voltage drop due to_polarization capacitance, V; ilb

is battery discharge current, A; R is battery intemal resistance,

ohms; Rb is battery terminal resistance, ohms; SOC is battery

state of charge, percent; V,, is battery open circuit voltage, V.

Brake Controller

The dissipation of kinetic energy during braking, by an electric

or hybrid vehicle, can be recovered advantageously by controlling

power electronics such that the electric traction motor behaves as a

generator [ 121. The energy recovered during this process can be

returned to the energy storage device for future use.

A parallel braking system applies regenerative braking torque

(to the driven wheels), in addition to hydraulic braking torque

provided by the foundation braking system. Hydraulic brake

torque is determined in the brake controller, based on HEV coor-

dinated control commands [ 1.51, [ 161. Regenerative brake com-

mands are predetermined as a function of master cylinder

pressure in the traction motor controller and are based on PHEV

coordinated control commands. In a series braking system, not

illustrated here, integrated control exists between the brake con-

troller and the traction motor controller [16], [17].

T, = Tared

a,

box input. In addition, the vehicle drivetrain receives hydraulic

brakmg torque or other driveline loads, and vehicle velocity is

determined via integration of the longitudinal equations of mo-

tion. Rotational dynamics for each wheel, and halfshafts, and a

representation of the forces acting on the vehicle, are modeled.

Rotational wheel dynamics include wheel slip (skid), tireiroad

surface adhesion coefficient, wheel tractive force as a function of

dynamic weight transfer, road load torque for each wheel, and

rotational wheel speed.

Wheel slip (skid) is used to determine the tireiroad surface ad-

hesion coefficient with a nonlinear analytic tireiroad surface inter-

face model [l], [3], [17]. The tire model used for this study

assumed a high road surface adhesion coefficient for dry pave-

ment, because these are conventional driving conditions. The

wheel tractive force as a function of dynamic weight transfer is

the product of the road surface adhesion coefficient and the nor-

mal force acting on the wheel:

In calculating the normal forces acting on each wheel, the dy-

namic weight transfer is modeled for each of both front and rear

wheels in terms of the vehicle pitch and lever arms (wheel base)

to the vehicle center of mass. The road load torque for each wheel

is then determined from the wheel diameter and tractive force:

The torques acting on the wheels include the halfshaft torque, Ts,

road load torque, Tb, bearing friction torque, and the braking

torque. Rotational wheel acceleration is obtained by the sum of

the torque acting on the wheel divided by the wheel inertia.

Wheel speed is obtained by integrating rotational wheel acceler-

ation:

The halfshaft model accounts for the torsional compliance be-

tween the differential and wheel. The resulting halfshaft torque is

applied to the wheel. The relations for shaft torque, and shaft com-

pliance in terms of physical parameters are shown below:

The four wheel tractive forces, aerodynamic drag, grade

forces, and rolling resistance, describe the forces acting on the

vehicle and are depicted below:

Ft”, = Ft,, + Elr f Ft$ + Fdf - Fa,, - Fry - Fgrada .

The aerodynamic drag on the vehicle is a function of vehicle

velocity squared, air density, vehicle frontal area, and coefficient

of drag, where the vehicle velocity is determined by solving €or

vehicle acceleration and integrating over time:

The rolling resistance force is a function of vehicle weight, roll-

ing resistance coefficient, and vehicle speed:

F,, = f, . W, .1.3558(1+ k, . V + k, . V’)

The grade forces acting on the vehicle are a function of vehi-

cle weight and grade angle:

FgrOd, = W, .1.3558 sin0 .

plied by the vehicle acceleration.

The total forces on the vehicle equal the vehicle mass multi-

In these equations, 4 is frontal area of vehicle,m2;Cd is aero-

dynamic drag coefficient; Fa,, is aerodynamic drag force on ve-

hicle, N; Fgrad, is grade force on vehicle, N; Frr is rolling

resistance force on vehicle, N; f , is rolling resistance coefficient;

ev is tractive force on left front wheel, N; c,r is tractive force on

left rear wheel, N; e,, is total forces acting on vehicle, N; F,$ is

tractive force on right front wheel, N; Jdq is differential inertia,

kg.m2 ; Jfd-dg is final drive inertia on differential side, k g , m 2 ;

J , is wheel inertia, kg .m2 K , is halfshaft stiffness, “/rad; K , is

empirical constant; K2 is empirical constant; R,, is loss in shaft

bearings, k g . m 2 i sec.rad ; R, is wheel radius, ft; Tb is brake

torque, Nm; T

is final drive output torque, Nm; TIoad is road

torque, Nm; Tsis halfshaft torque, Nm; V is vehicle velocity,

fd.

m i sec2 ; W,is vehicle weight, lbf; y is air density, kg i m ; 8 is

grade angle, rad; 0, is halfshaft displacement, rad; p(7r,lr,rf,y)

is

coefficient of friction on right rear, left rear, right front, and left

front wheels respectively; 03 is wheel speed, radfsec; cofd is final

drive speed on differential side, radfsec; ol, is left wheel speed,

radisec; w, is right wheel speed, radisec.

Series HEV Powertrain System

Vehicle Driver and Coordinated Control

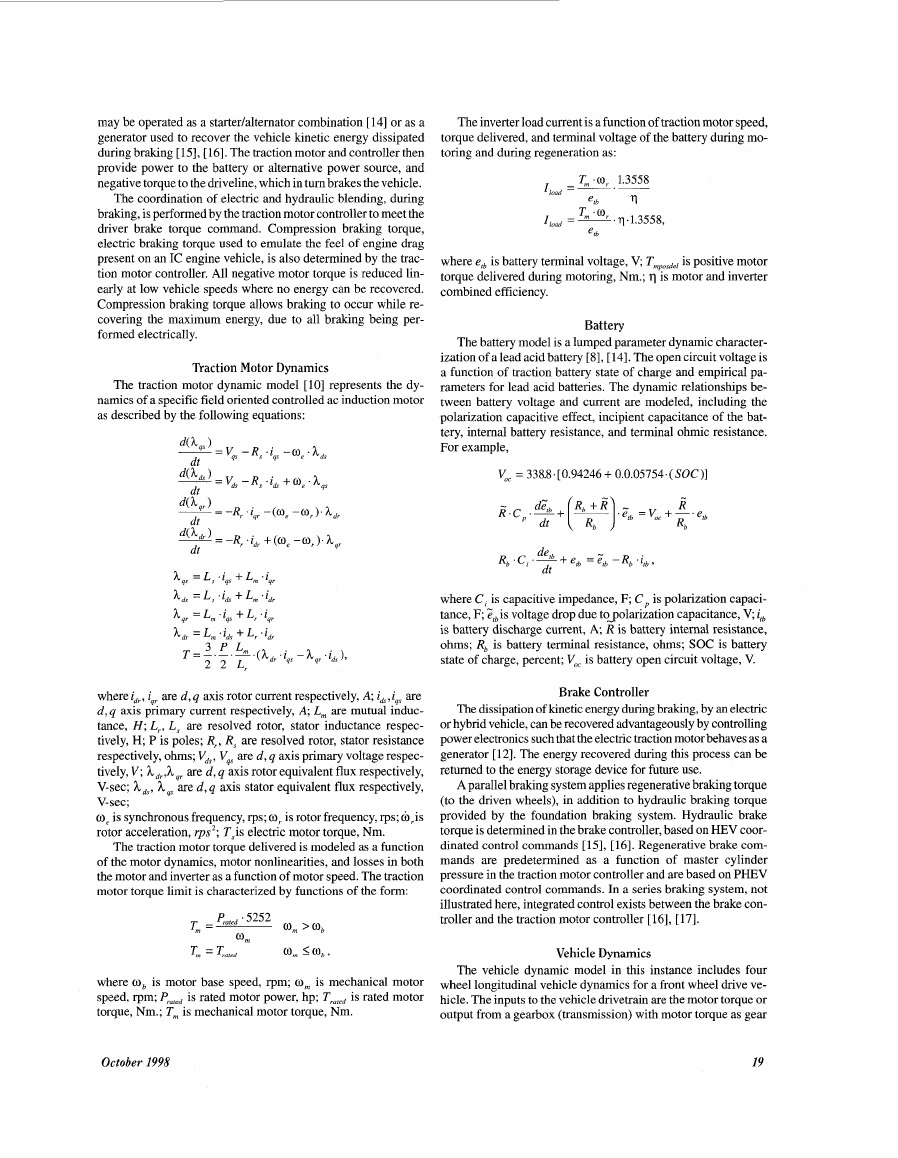

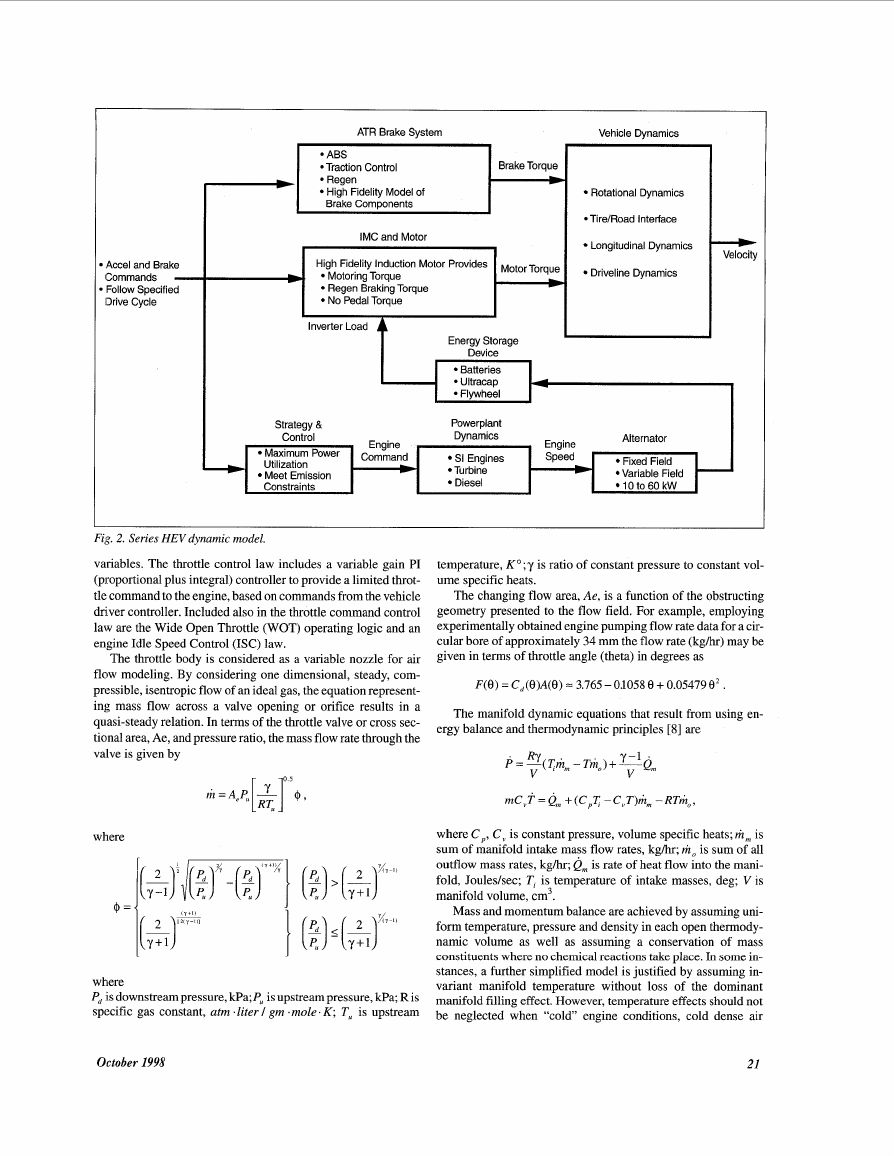

A Series HEV (SHEV) powertrain may be achieved with the

addition of an auxiliary power plant to the electric vehicle in

power series connection with the traction battery and traction

motor. In a “senes” configuration, the power unit interacts with

the vehicle system controller and the rest of the vehicle electrical

system, which includes the vehicle traction motor and other an-

cillary loads such as power steering or air conditioning. The ve-

hicle system controller provides a desired power command and a

desired engine speed command to the SHEV system. Two or

more control variables may be used to attempt to achieve the de-

sired altemator power at a desired engine speed. In addition, the

coordinated vehicle controller provides motoring and regenera-

tive commands to the motor controller. A schmatic representa-

tion of a series HEV is given in Fig. 2.

Engine Dynamic Model

The key exogenous control variable to the SI ICE engine sys-

tem [9] is the throttle angle (or mechanical equivalent). For a die-

sel engine it might be the fuel control system command. Control

variables such as spark advance, Exhaust Gas Recirculation

(EGR), and Air-to-Fuel ratio (AF), and variable geometry

turbocharger on a supercharged power plant, are for this current

representation considered to be precalibrated emission control

20

IEEE Control Systems

�

ATR Brake System

Vehicle Dynamics

Brake Torque

I

Rotational Dynamics

*Tire/Road lntetface

Longitudinal Dynamics

Driveline Dynamics

ICommands -

Accel and Brake

Follow Specified

13rive Cycle

High Fidelity Model of

Brake Components

IMC and Motor

High Fidelity Induction Motor Provides

Motoring Torque

Regen Braking Torque

No Pedal Torque

t

Inverter Load

-

-

Strateav &

Maximum Power

Maximum Power

Utilization

Utilization

Meet Emission

Meet Emission

Constraints

Constraints

Command

Command

b

b

Energy Storage

Device

Batteries

Powerplant

SI Engines

SI Engines

Turbine

Turbine

Diesel

Diesel

Speed

Speed

I

*Variable Field -

Fixed Field

Fixed Field

Variable Field

10 to 60 kW

10 to 60 kW

temperature, KO; y is ratio of constant pressure to constant vol-

ume specific heats.

The changing flow area, Ae, is a function of the obstructing

geometry presented to the flow field. For example, employing

experimentally obtained engine pumping flow rate data for a cir-

cular bore of approximately 34 mm the flow rate (kghr) may be

given in terms of throttle angle (theta) in degrees as

F ( e ) = c,(e)A(e) = 3.765 - 0.1058 e + 0.05479 e* .

The manifold dynamic equations that result from using en-

ergy balance and thermodynamic principles [8] are

P . = -(Th,,,

RY

V

-Tho)+ -Qm y-1 ‘

V

where C,, C , is constant pressure, volume specific heats; m,,, is

sum of manifold intake mass flow rates, kghr; riz, is sum of all

outflow mass rates, kghr; Q, is rate of heat flow into the mani-

fold, Jouleslsec; Tt is temperature of intake masses, deg; V is

manifold volume, cm3.

Mass and momentum balance are achieved by assuming uni-

form temperature, pressure and density in each open thermody-

namic volume as well as assuming a conservation of mass

constituents where no chemical reactions take place. In some in-

stances, a further simplified model is justified by assuming in-

variant manifold temperature without loss of the dominant

manifold filling effect. However, temperature effects should not

be neglected when “cold” engine conditions, cold dense air

Fig. 2. Series HEV dynamic model.

variables. The throttle control law includes a variable gain PI

(proportional plus integral) controller to provide a limited throt-

tle command to the engine, based on commands from the vehicle

driver controller. Included also in the throttle command control

law are the Wide Open Throttle (WOT) operating logic and an

engine Idle Speed Control (ISC) law.

The throttle body is considered as a variable nozzle for air

flow modeling. By considering one dimensional, steady, com-

pressible, isentropic flow of an ideal gas, the equation represent-

ing mass flow across a valve opening or orifice results in a

quasi-steady relation. In terms of the throttle valve or cross sec-

tional area, Ae, and pressure ratio, the mass flow rate through the

valve is given by

where

where

P, is downstream pressure, kPa; P, is upstream pressure, kPa; R is

specific gas constant, atm .liter I gm .mole. K ; Tu is upstream

October 1998

21

�

charge, or evaporating and condensing fuel are important dy-

namic issues.

An estimation of mass flow rates out of the manifold is given

approximately by a product of the engine speed, engine displace-

ment, and volumetric efficiency, which in turn is resolved in

terms of engine speed, intake temperature, manifold pressure,

and exhaust gas pressure. Manifold mass flow rate egress is

given in terms of manifold pressure and engine speed by an ap-

proximate polynomial functional form

.

M = ---(OS22

N

1000

+ O.OS553(-))(0.17P+

N

1000

0.00098P2),

where M is speed density mass flow rate, kg/hr and N is engine

speed, rpm.

The engine torque developed at any time is a function of the

mass rates (mass charge) or ratios of rates (mass constituents)

that were sampled one engine induction event earlier. This

breathing event is a crank angle synchronized relationship that is

primarily dependent 011 engine speed. For a zero order extrapola-

tion, the minimum delay in torque generation that results from

ingestion of the manifold constituents is 180 crankangle degrees.

For a four cylinder engine with a speed of N RPM, this is repre-

sented by a propagation lag relationship with idealized delay T is

30/N seconds.

A similar lag exists for the mixed A/F from the end of com-

bustion to exhaust valve closure. In addition, a nonspeed depend-

ent propagation lag, and some gaseous diffusion, is assumed to

persist in the exhaust pipe before the A/F sensor location [18].

Representation of the A/F delays in an SI ICE is extremely im-

portant as the torque response is highly sensitive to A/F tran-

sients, including throttle input and fuel control system transients.

The nonlinear structure for the A/F (Air/Fuel) system con-

sists of an EGO (exhaust gas oxygen) A/F sensor in the exhaust

pipe, with a time constant of the order of 70 ms, followed by a

nonlinear (Nernst) rich/lean Signum function and a PI fuel com-

mand control law [18]. An intake runner port fuel injector is as-

sumed with a fuel rate output, and with fuel condensation and

evaporation dynamics [ 191. The resulting system equations are

.

dm

T -‘=rp~~-m~,

” dt m, = (1 - Tl)rifi + mi,

,

m is manifold fuel flow rate, kglhr; m t~ is injector fuel rate com-

mand, kg/hr;nifL is injected fuel flow rate, kglhr;m is fuel evapo-

ration rate, kghr; q is fuel accumulation parameter, = 0.25 sec; T~

is injector time constant, = 50 ms; 7, is condensation and evapo-

ration time, = 0.5 sec.

The fuel mass flow rate is combined with the throttle mass air

flow rate to form the manifold A/F. This A/F is delayed by the in-

duction breathing lag, preparatory to combustion torque genera-

tion, followed by a combustion torque delay, a power-stroke to

exhaust delay, and a plug stroke exhaust system delay that is de-

pendent on the location of the EGO sensor.

Torque generated from the combustion process is dependent

on the ignition of a cylinder charge o f air, fuel, and residual gas,

as well as other variables and parameters that influence combus-

tion efficiency. Assuming a spark advance, EGR (exhaust gas

recirculation), and fuel emission calibrated 1.8 liter engine, an

approximate brake torque relationship is of the form

T = q ( A l F , ( A / F ) 2 , M , M 2 , N ,..., N4, EGR).

The rotational motion of the engine crankshaft is given in

terms of the engine polar moment of inertia, angular accelera-

tion, and the difference between the net torque generated by the

engine and the load torque on the driveshaft. Thus,

J,N = (30 / E)( T, -

where the load torque may be the starter-alternator (S/A) load,

clutch torque, air conditioning, power steering, or any driveshaft

load and J , is engine flywheel inertia, kg . m ’.

StartedAlternator

The alternator model is empirically derived from data taken at

several voltage, field current, and speed operating points. Using

voltage, field current, and speed as inputs, the alternator current

output is determined by functional relationships. This model rep-

resents a three phase synchronous machine generating full wave

rectified DC current [ 161. The starter portion of the StartedAlter-

nator (S/A) is also empirically derived from data and dynamic

simulation results [7]. It is depicted by a 1.4 kW ac motor directly

connected to the voltage bus and geared to the ICE crank. The

S/A system is controlled via on/off logic and field current com-

mands to control the S/A torque input (or output) of the device.

For an HEV application, the alternator may be assumet to out-

put 70 amps over a voltage operating range from 200 to 380

Volts. The alternator output current can be represented as a func-

tion of field current, speed, voltage and temperature where the al-

ternator field current is a separate dynamic control component.

The alternator output current approximation at a certain speed

and varying output voltage is

The field current can be represented as follows:

The inductance and resistance vary with speed, load and interior

alternator temperature.

Here, I,,l is alternator output current, A; I , is alternator field

current, A; Lfld is alternator field inductance, H; R, is alternator

is alternator field voltage, V; V,,, is al-

filed resistance, ohms; V,,

ternator output voltage, V mail is alternator rotational speed, krpm.

Series HEV Control

A large ICE powerplant (approximately 60kW or more),

could be employed to directly supply the demand power while

using a scaled down battery for partial load leveling or as a direct

power source during high power demand. In such a power source

tradeoff the nature of the performance requirements, limitations

on sensor and control mechanisms, and dynamic control law

structure will likely change. The control objectives with a more

powerful ICE/alternator and reduced traction battery system

22

IEEE Control Systems

�

340

338

336

334

332

330

328

326

324

1000 \

500 1

0

0

1

I

I

15

5

10

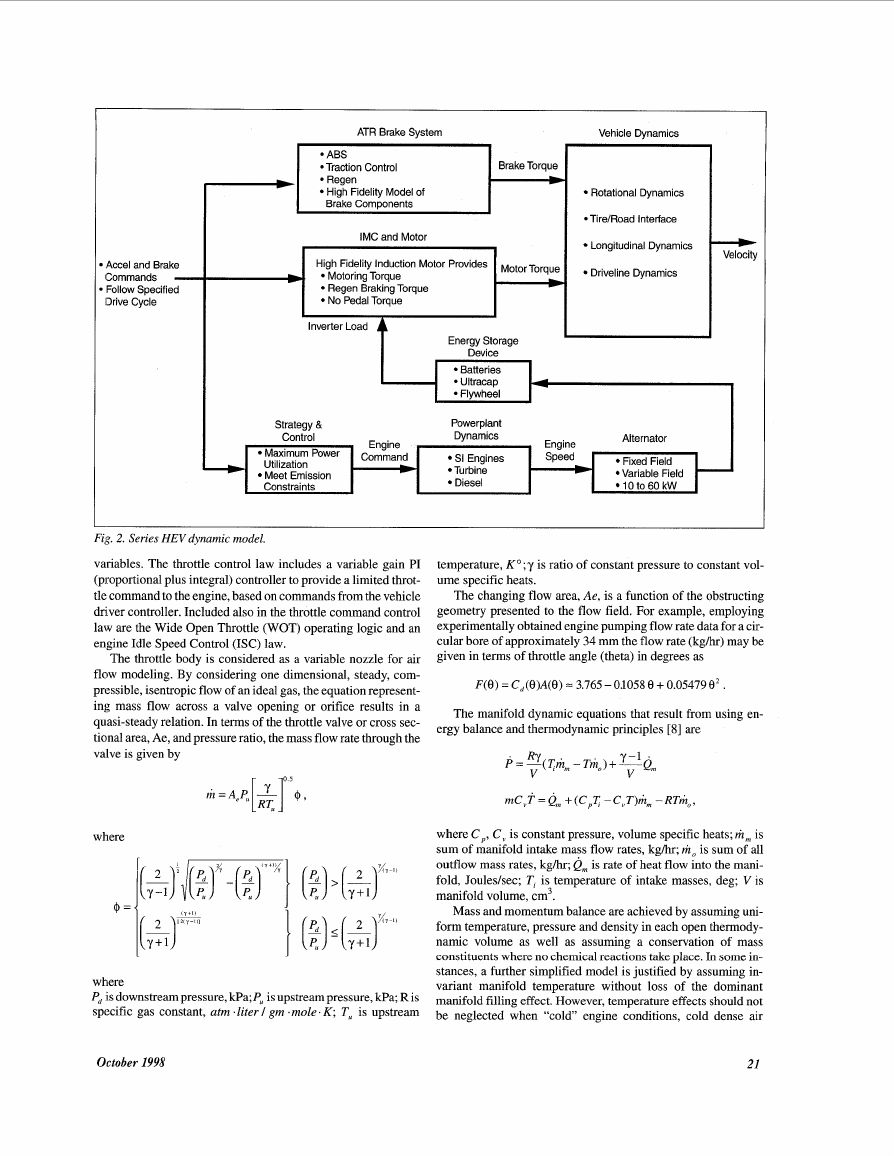

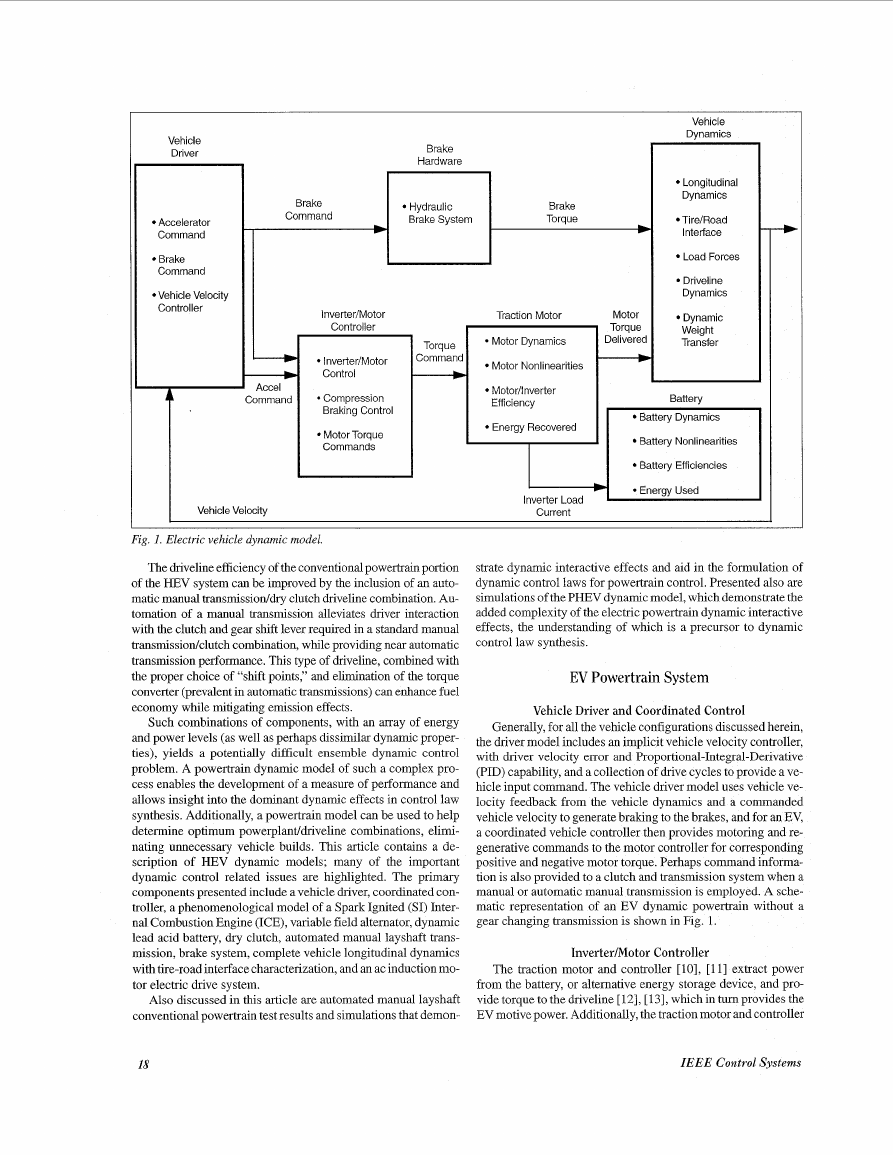

Fig. 3. Series power unit control.

might yield a load leveling or load following strategy [20]. In this

instance, the combined powerplanthattery system would be the

prime vehicle power source used to follow the desired vehicle pro-

file while the battery power supply would be used to mitigate the

traction motor transient demands to the ICE/altemator system.

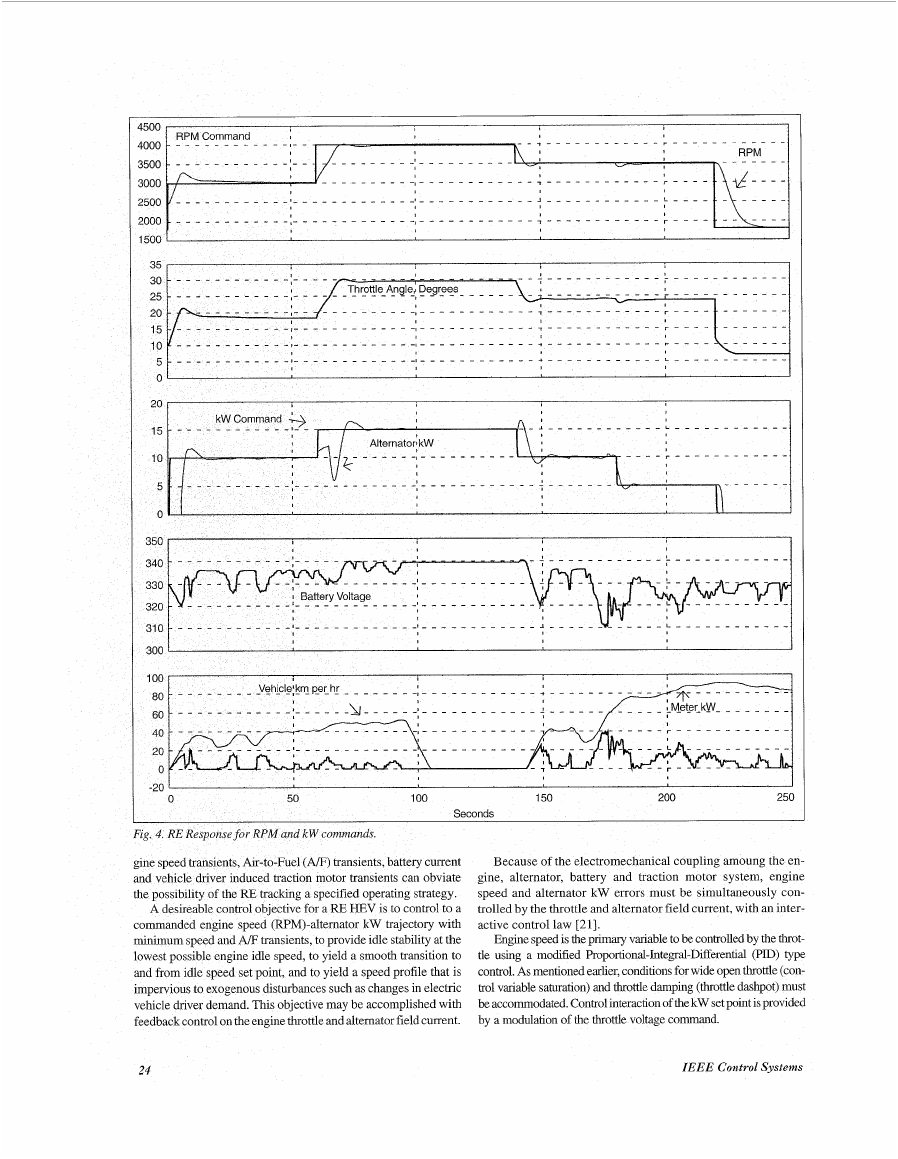

Simulation results for such a combination are shown in Fig. 3.

In this simulation, the vehicle driver would like to follow the

the first few active (non-idle) seconds of the Federal Urban

Driving Cycle (FUDS). In the transient behavior depicted in

Fig. 3, the driver’s input goes directly to the Induction Motor

Control (IMC) of the traction motor and simultaneously to the

thirottle command of the ICE. Until the ICE/alternator can

achieve alternator “cut-in’’ (i.e., that speed at which there is a

power output from the alternator), the traction motor draws

power from the energy storage device which in this case is a low

storage (small) battery pack. The combination of components

thus illustrated would require a smaller battery pack and re-

duced ICE by proper sizing and proration of power between the

ICE and energy storage device.

Simulations that include engine, alternator, battery, and trac-

tion motor/driveline sizing and dynamic interactions, could be

used to examine energy tradeoffs and transient tradeoffs by vary-

ing control and sizing (kW output) between an alternator and bat-

tery system as series power sources. For instance, for a small

ICE-alternator-battery power source (about 25 kW), a system

operating strategy could be such that the “Range Extender” (RE)

is to be activated during estimated low battery State-of-Charge

(SOC) and simply operates until a desired SOC [8], [20] has been

achieved. There exists dynamic interaction among the ICE, alter-

nator, battery and vehicle traction motor (drivetrain) such that en-

Olctober 1998

23

�

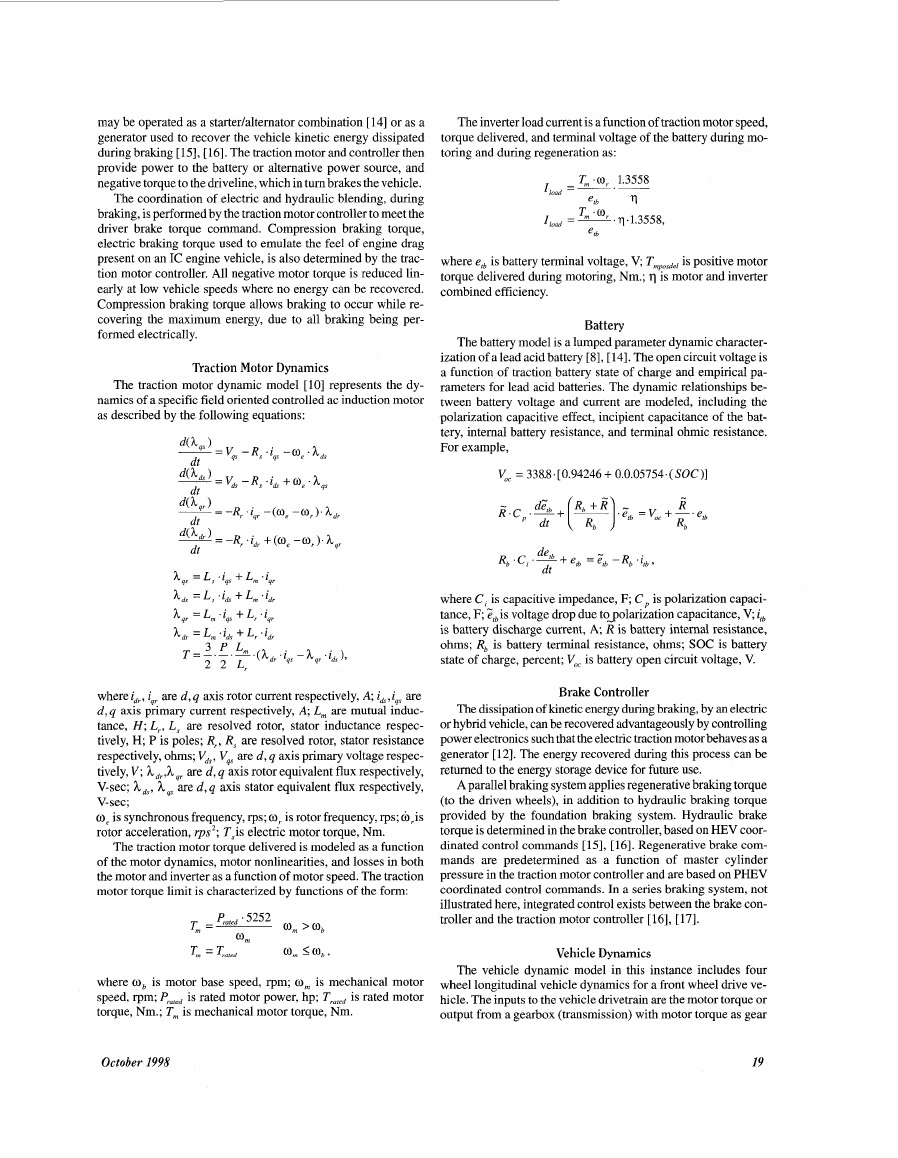

ified operating strategy.

A desireable control objective for a RE HEV is to control to a

commanded engine speed (RPM)-alternator kW trajectory with

minimum speed and A/F transients, to provide idle stability at the

lowest possible engine idle speed, to yield a smooth transition to

and from idle speed set point, and to yield a speed profile that is

impervious to exogenous disturbances such as changes in electric

vehicle driver demand. This objective may be accomplished with

feedback control on the engine throttle and alternator field current.

speed and alternator kW errors must be simultaneously con-

trolled by the throttle and alternator field current, with an inter-

active control law [21].

Engine speed is the pnmaq variable to be controlled by the throt-

tle using a modified Proportional-Integral-Differentd (PID) type

control. As mentioned earlier, conditions for wide open throttle (con-

trol variable saturation) and throttle damping (throttle dashpot) must

be accommodated. Control interaction of the kW set point is provided

by a modulation of the throttle voltage command.

24

IEEE Control Systems

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc