Allen-Bradley I/O

Modules

1732, 1734, 1734D, 1738, 1746,

1747, 1756, 1761, 1762, 1764,

1769, 1771, 1790, 1791, 1791D,

1791P, 1791R, 1792D, 1794,

1797, 1798, 1799

Wiring Diagrams

�

Important User Information Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls (Publication SGI-1.1 available from your local

Rockwell Automation sales office or online at

http://www.literature.rockwellautomation.com) describes some important differences

between solid state equipment and hard-wired electromechanical devices. Because of

this difference, and also because of the wide variety of uses for solid state equipment,

all persons responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular

installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of

safety considerations.

WARNING

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

IMPORTANT

Identifies information that is critical for successful

application and understanding of the product.

ATTENTION

Identifies information about practices or circumstances that can

lead to personal injury or death, property damage, or economic

loss. Attentions help you identify a hazard, avoid a hazard and

recognize the consequences.

SHOCK HAZARD

Labels may be located on or inside the drive to alert

people that dangerous voltage may be present.

BURN HAZARD

Labels may be located on or inside the drive to alert

people that surfaces may be dangerous temperatures.

�

Introduction

Preface

The purpose for showing these connection diagrams here is to

illustrate the following attributes of each I/O module, I/O block, or

fixed I/O controller:

• the number of inputs and/or outputs

• whether there is a single common for all I/O, a common for a

set of I/O separate from other sets of I/O, or a signal return for

each I/O circuit so that each I/O circuit is isolated from all

others

• whether an output is a current source or a current sink

• whether an input is a source load or a sink load

To fit them into this concise format, these diagrams are intentionally

simplified to the point that they do not show the type of cables,

twisted pairs, cable shields or the grounding of cable shields. We

make an exception where the cable shield must be connected at an

I/O terminal.

For those input modules or blocks that can tolerate the leakage

current of proximity sensors, we usually show a proximity sensor at

one input and hard contacts at the others for ease of illustration.

IMPORTANT

Many of the catalog numbers included in this

publication have specific wiring guidelines and

recommendations that are listed in the products

technical documentation (e.g. installation instructions

or user manuals) but not here because the purpose

of this publication is to show connection diagrams

and basic information required to wire each I/O

module.

For a full description of how to use each of the

catalog numbers listed in this publication, see the

individual products technical documentation.

1

Publication CIG-WD001B-EN-P - May 2005

�

Preface 2

Abbreviations

In these diagrams we used the following abbreviations:

no

nc

n.c.

normally open (contact outputs)

normally closed (contact outputs)

no connection (do not connect to this terminal)

Symbols

In these diagrams we used the following symbols:

ac power source

ac/dc power source

dc power source

output load

current-signal analog sensor

voltage-signal analog sensor

RTD

thermocouple

3-wire proximity sensor

4-wire proximity sensor

hard-contact switching devices

TTL switching device

+

+

+

Prox

+or

TTL

Publication CIG-WD001B-EN-P - May 2005

�

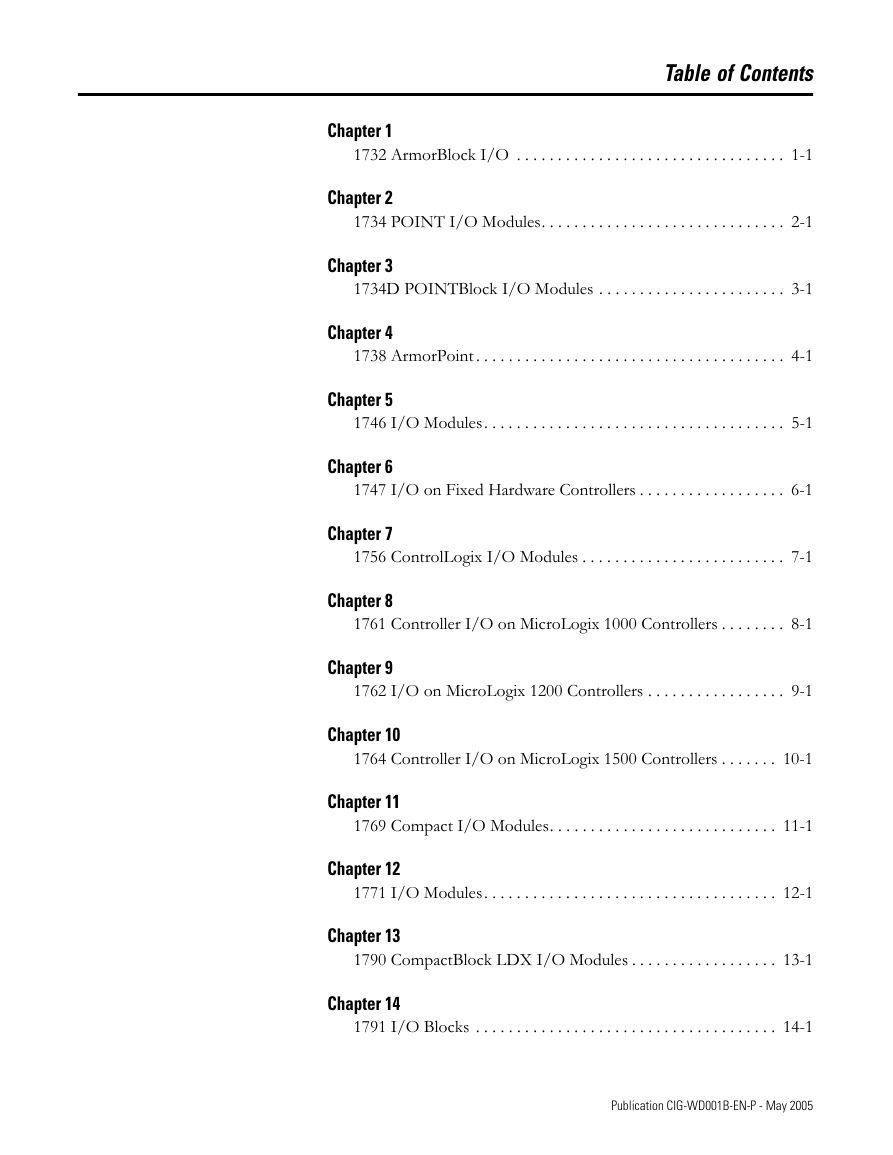

Table of Contents

Chapter 1

1732 ArmorBlock I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Chapter 2

1734 POINT I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Chapter 3

1734D POINTBlock I/O Modules . . . . . . . . . . . . . . . . . . . . . . . 3-1

Chapter 4

1738 ArmorPoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Chapter 5

1746 I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Chapter 6

1747 I/O on Fixed Hardware Controllers . . . . . . . . . . . . . . . . . . 6-1

Chapter 7

1756 ControlLogix I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Chapter 8

1761 Controller I/O on MicroLogix 1000 Controllers . . . . . . . . 8-1

Chapter 9

1762 I/O on MicroLogix 1200 Controllers . . . . . . . . . . . . . . . . . 9-1

Chapter 10

1764 Controller I/O on MicroLogix 1500 Controllers . . . . . . . 10-1

Chapter 11

1769 Compact I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Chapter 12

1771 I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Chapter 13

1790 CompactBlock LDX I/O Modules . . . . . . . . . . . . . . . . . . 13-1

Chapter 14

1791 I/O Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

1

Publication CIG-WD001B-EN-P - May 2005

�

Table of Contents 2

Chapter 15

1791D CompactBlock I/O Blocks . . . . . . . . . . . . . . . . . . . . . . . 15-1

Chapter 16

1791P CompactBlock I/O Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

Chapter 17

1791R CompactBlock I/O Blocks . . . . . . . . . . . . . . . . . . . . . . . 17-1

Chapter 18

1792D ArmorBlock MaXum I/O Blocks . . . . . . . . . . . . . . . . . 18-1

Chapter 19

1794 FLEX I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-1

Chapter 20

1797 FLEX Ex Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1

Chapter 21

1798 FLEX Armor I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . 21-1

Chapter 22

1799 Embedded I/O Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-1

Publication CIG-WD001B-EN-P - May 2005

�

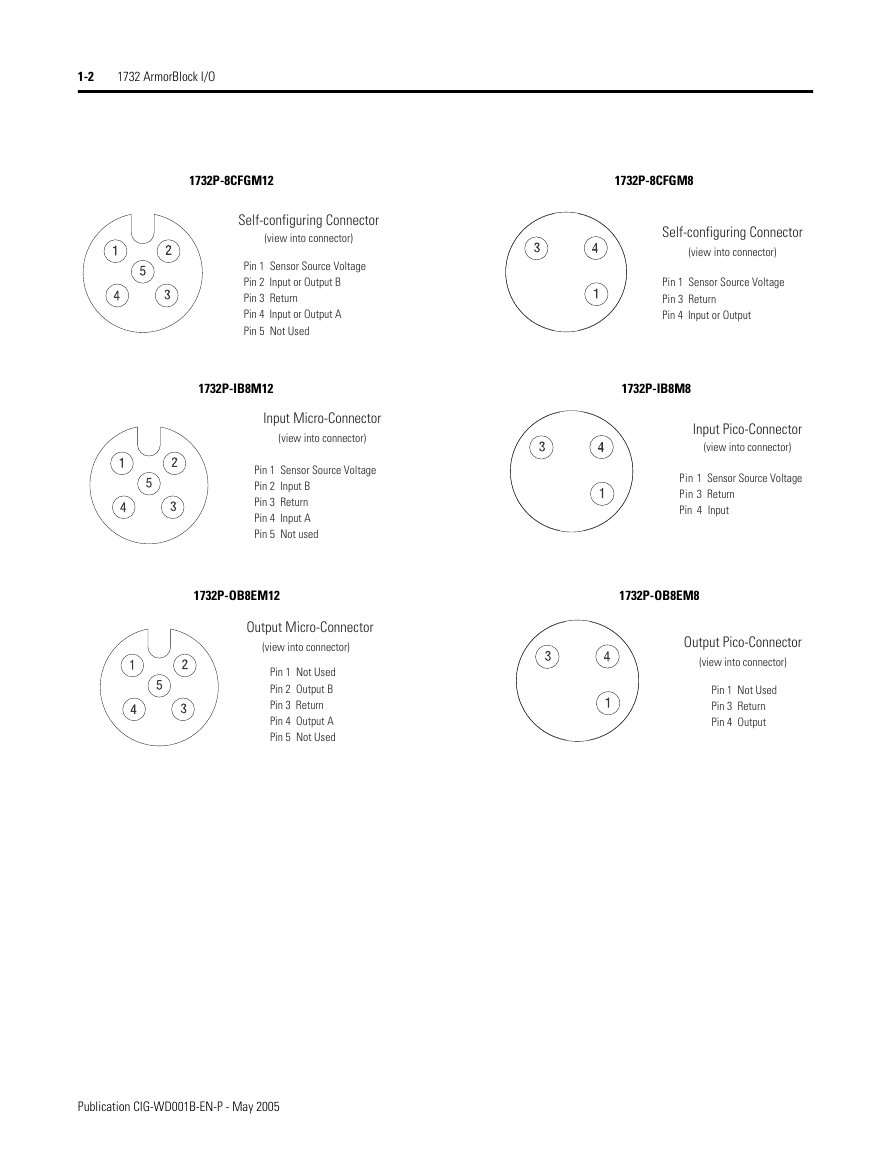

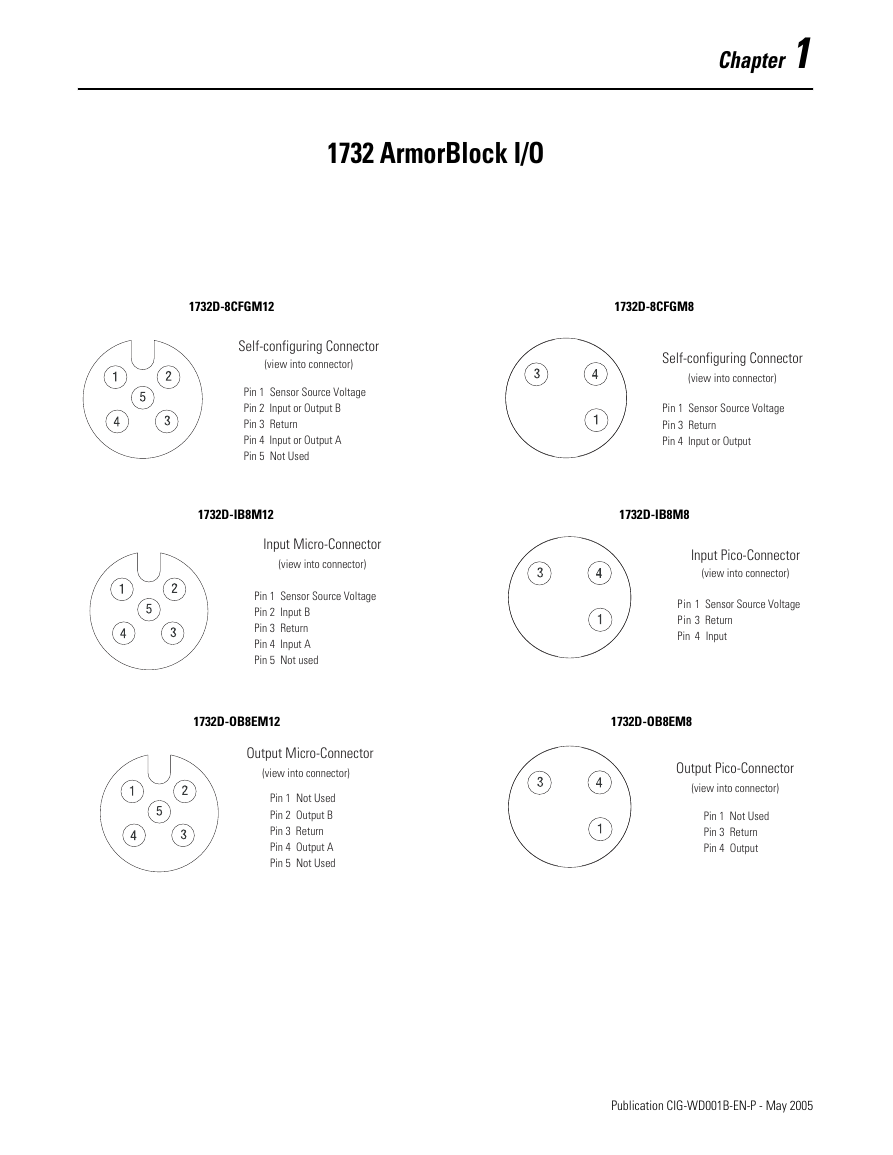

Chapter 1

1732 ArmorBlock I/O

1732D-8CFGM12

1732D-8CFGM8

Self-configuring Connector

(view into connector)

Pin 1 Sensor Source Voltage

Pin 2 Input or Output B

Pin 3 Return

Pin 4 Input or Output A

Pin 5 Not Used

Self-configuring Connector

(view into connector)

Pin 1 Sensor Source Voltage

Pin 3 Return

Pin 4 Input or Output

1732D-IB8M12

1732D-IB8M8

Input Micro-Connector

(view into connector)

Pin 1 Sensor Source Voltage

Pin 2 Input B

Pin 3 Return

Pin 4 Input A

Pin 5 Not used

Input Pico-Connector

(view into connector)

Pin 1 Sensor Source Voltage

Pin 3 Return

Pin 4 Input

1732D-OB8EM12

1732D-OB8EM8

Output Micro-Connector

(view into connector)

Pin 1 Not Used

Pin 2 Output B

Pin 3 Return

Pin 4 Output A

Pin 5 Not Used

Output Pico-Connector

(view into connector)

Pin 1 Not Used

Pin 3 Return

Pin 4 Output

1

Publication CIG-WD001B-EN-P - May 2005

�

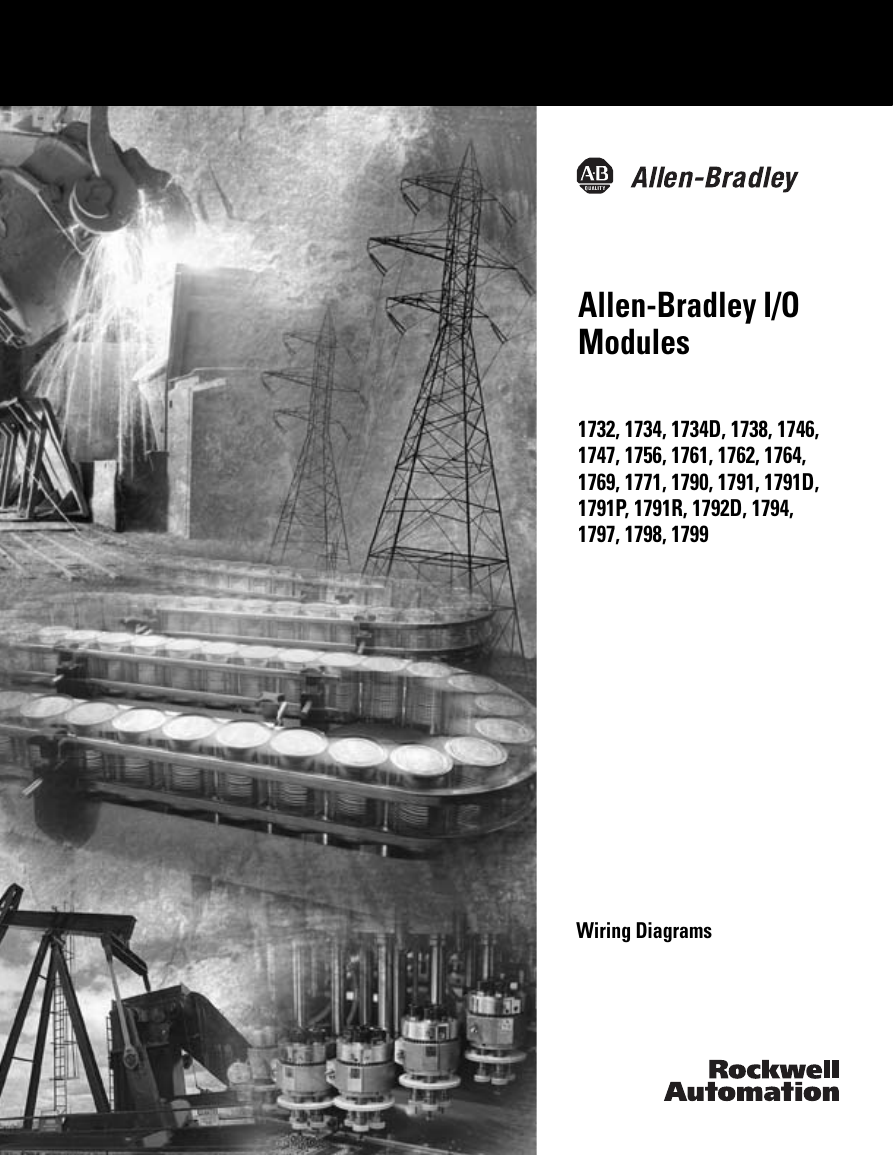

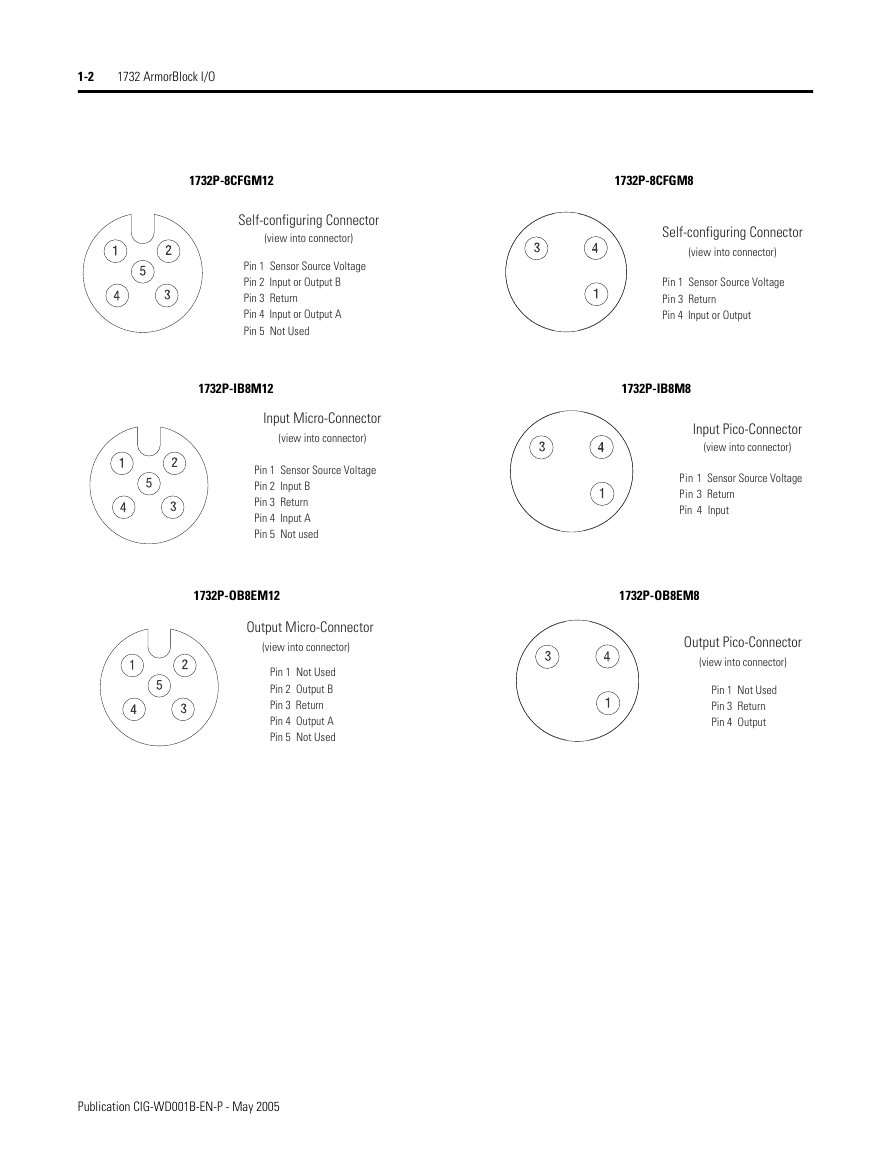

1-2 1732 ArmorBlock I/O

1732P-8CFGM12

1732P-8CFGM8

Self-configuring Connector

(view into connector)

Pin 1 Sensor Source Voltage

Pin 2 Input or Output B

Pin 3 Return

Pin 4 Input or Output A

Pin 5 Not Used

Self-configuring Connector

(view into connector)

Pin 1 Sensor Source Voltage

Pin 3 Return

Pin 4 Input or Output

1732P-IB8M12

1732P-IB8M8

Input Micro-Connector

(view into connector)

Pin 1 Sensor Source Voltage

Pin 2 Input B

Pin 3 Return

Pin 4 Input A

Pin 5 Not used

Input Pico-Connector

(view into connector)

Pin 1 Sensor Source Voltage

Pin 3 Return

Pin 4 Input

1732P-OB8EM12

1732P-OB8EM8

Output Micro-Connector

(view into connector)

Pin 1 Not Used

Pin 2 Output B

Pin 3 Return

Pin 4 Output A

Pin 5 Not Used

Output Pico-Connector

(view into connector)

Pin 1 Not Used

Pin 3 Return

Pin 4 Output

Publication CIG-WD001B-EN-P - May 2005

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc