IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 39, NO. 4, JULY/AUGUST 2003

1031

Sensorless Drive of Surface-Mounted

Permanent-Magnet Motor by High-Frequency

Signal Injection Based on Magnetic Saliency

Ji-Hoon Jang, Student Member, IEEE, Seung-Ki Sul, Fellow, IEEE, Jung-Ik Ha, Member, IEEE,

Kozo Ide, Member, IEEE, and Mitsujiro Sawamura

Abstract—This paper presents a new sensorless control scheme

of a surface-mounted permanent-magnet (SMPM) motor using

high-frequency voltage signal

injection method based on the

high-frequency impedance difference. In the SMPM motor, due

to the flux of the permanent magnet, the stator core around the

-axis winding is saturated. This makes the magnetic saliency in

the motor. This magnetic saliency has the information about the

rotor position. The high-frequency voltage signal is injected into

the motor in order to detect the magnetic saliency and estimate

the rotor position. In this paper, the relationship between the

high-frequency voltages and high-frequency currents is developed

using the voltage equations at the high frequency, and the high-fre-

quency impedance characteristics are analyzed experimentally

under various conditions. The proposed sensorless control scheme

makes it possible to drive the SMPM motor in the low-speed

region including zero speed, even under heavy load conditions.

The experimental results verify the performance of the proposed

sensorless algorithm.

Index Terms—High-frequency signal injection, sensorless drive,

surface-mounted permanent-magnet (SMPM) motor.

I. INTRODUCTION

R ECENTLY, with the advent of high-performance perma-

nent magnets with high coercivity and high residual flux,

it has been possible for the permanent-magnet (PM) motors to

be superior to general-purpose induction motors in power den-

sity, torque-to-inertia ratio, and efficiency. Therefore, the PM

motors are of more and more interest in many industrial appli-

cations as substitutes for induction motors. Besides the afore-

mentioned advantages, the vector control of PM motors is much

simpler than that of induction motors because there is no need

to consider the slip frequency as in induction motor drive. How-

ever, PM motor drives require position sensors or rotational

transducers to perform the vector control correctly because the

rotor flux is obtained from permanent magnets. These position

Paper IPCSD 03–023, presented at the 2002 IEEE Applied Power Electronics

Conference and Exposition, Dallas, TX, March 10–14, and approved for publi-

cation in the IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS by the Industrial

Drives Committee of the IEEE Industry Applications Society. Manuscript sub-

mitted for review June 1, 2002 and released for publication April 10, 2003.

J.-H. Jang and S.-K. Sul are with the School of Electrical Engineering and

Computer Science, Seoul National University, Seoul 151-744, Korea (e-mail:

bluemat@eepel.snu.ac.kr; sulsk@plaza.snu.ac.kr).

J.-I. Ha is with the Mechatronics Center, Samsung Electronics Company,

Suwon 442-742, Korea (e-mail: haji@ieee.org).

K. Ide and M. Sawamura are with the Mechatronics R&D Department, Cor-

porate R&D Center, Yaskawa Electric Company, Kitakyushu 803-8530, Japan

(e-mail: kozo@yaskawa.co.jp).

Digital Object Identifier 10.1109/TIA.2003.813734

sensors or rotational transducers not only increase cost, main-

tenance, and complexity, but also impair robustness and reli-

ability of the drive system. Therefore, many researchers have

been studying the sensorless drive of the PM motor in view of

the robustness, reliability, cost, and so on [1].

Conventional sensorless control schemes of the PM motor

can be classified into two types. The one is based on the back

electromotive force (EMF) voltage estimation [2]–[10]. In

this type, voltage model [2]–[4], state observer [5], [6], [10],

or Kalman filters [7]–[9] have been used. In voltage model

methods [2]–[4], the measured voltage and currents are used

to estimate the position of rotor flux linkage based on the

voltage equations of the PM motor. Parameter variations due

to temperature and saturation critically affect the performance

of the estimation of rotor position. In state observer and

Kalman filter methods [5]–[10], the parameter variation effect

is not as critical as in voltage model methods. However, the

common problem of the above-mentioned methods is that

the performance of the rotor position estimation is critically

dependent on the magnitude of back-EMF voltage which is

proportional to the rotor speed. In low-speed regions, where the

magnitude of back-EMF voltage is so small, the performance

is significantly degraded. In [10], a fluctuating high-frequency

current signal injection is used to solve this problem. The basic

idea of this method is to detect the small fluctuation of the

back-EMF voltage by injecting a high-frequency test current to

the machine at standstill. Using this method, maximum torque

starting capability can be obtained in the sensorless drive of

the PM motor. However, this method is valid only if the motor

is connected to the load by the flexible coupling. The other is

based on the magnetic saliency [11]–[14]. The basic idea of

these schemes is injecting some extra voltage or current signals

into the motor and using the corresponding signals to detect

the rotor position. Some algorithms inject voltage signals in a

sampling period to the motor [11]. Since the methods detect

the inductance of the motor using voltage signals in a short

time, they might be insignificant to the parameter variation

and measurement noise. Also, due to the injected signal in this

method being a periodic signal, a compensation scheme, such

as a Kalman filter, is required. Another algorithm injects the

rotating high-frequency voltage signals and uses a tracking

algorithm [12]. Since it utilizes the rotating high-frequency

signal, the dynamic characteristics are restricted in relation to

the frequency of the injected signal. The fluctuating high-fre-

quency voltage signal injection method [13], [14] shows good

0093-9994/03$17.00 © 2003 IEEE

�

1032

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 39, NO. 4, JULY/AUGUST 2003

performance in the low-speed region including zero speed

under loaded condition. However, it is used in the interior

PM (IPM) motor. The common problem of the conventional

sensorless control is that it cannot be applied to the sensorless

drive of a surface-mounted PM (SMPM) motor at low and zero

speed under heavy-load condition.

This paper presents a sensorless control scheme of an SMPM

motor using high-frequency fluctuating voltage signal injection

method based on the high-frequency impedance difference

due to the magnetic saliency. Since it uses the high-frequency

current signal corresponding to the high-frequency impedance

difference of the SMPM motor to estimate the rotor position,

the relationship between the rotor position estimation error

and high-frequency current signal has been investigated. Also,

the high-frequency impedance characteristics of the SMPM

motor have been tested and analyzed under various conditions.

In sensorless control, the high-frequency fluctuating voltage

axis in the estimated synchronous

signal is injected on the

reference frame, and the -axis component of high-frequency

current in the estimated synchronous reference frame is used

to estimate the rotor position. The proposed rotor position

estimation algorithm enables sensorless torque, speed, and

position control under loaded condition. Experimental results

verify the fast and accurate operation of the proposed sensorless

algorithm.

II. ANALYSIS OF HIGH-FREQUENCY IMPEDANCE OF

SMPM MOTOR

A. Relationship Between the High-Frequency Voltage and

Current Signals

The voltage equations of the SMPM motor in the syn-

chronous reference frame are represented as follows:

(1)

where

is the back-EMF constant in volt-seconds per radian.

If the injected high-frequency component of voltages and cur-

rents are only considered and the injection frequency is suffi-

ciently higher than the rotor speed of the SMPM motor in (1),

the SMPM motor can be considered as a simple R–L load and

the voltage equations can be represented as follows:

reference frame at the injected high frequency, respectively. Fur-

thermore, in the steady state, (2) can be expressed as (3)

(3)

and

are

where

ances, respectively, and

per second.

- and -axes high-frequency imped-

is injected high frequency in radians

If the rotor position estimation error is defined as (4), the

relationship between the high-frequency voltages and currents

in the estimated synchronous reference frame can be expressed

as follows based on the coordinate transform theory (see the

Appendix):

where

is the estimated rotor position

(4)

(5)

and

are - and -axes high-frequency compo-

where

nents of voltages in the estimated synchronous reference frame,

are - and -axes high-frequency components

and

of currents, respectively, in the estimated synchronous reference

frame.

and

If the average and difference of

- and -axes high-frequency

impedances is defined as (6), (5) can be rewritten as (7)

(6)

where

pedances, and

frequency impedances

is the average of

- and -axes high-frequency im-

is the difference between - and -axes high-

(7)

Therefore, if the fluctuating high-frequency voltage signal is

axis in the estimated synchronous refer-

injected only on the

ence frame as in (8), the resultant high-frequency currents can

be represented as (9)

(2)

and

In (2),

are - and -axes high-frequency com-

ponents of voltages in the actual synchronous reference frame,

- and -axes high-fre-

respectively. Also,

quency components of currents in the actual synchronous ref-

are - and

erence frame, respectively.

-axes resistances and inductances in the actual synchronous

and

,

and

are

,

(8)

(9)

�

JANG et al.: SENSORLESS DRIVE OF SMPM MOTOR BY HIGH-FREQUENCY SIGNAL INJECTION

1033

TABLE I

PARAMETERS OF TESTED SMPM MOTOR

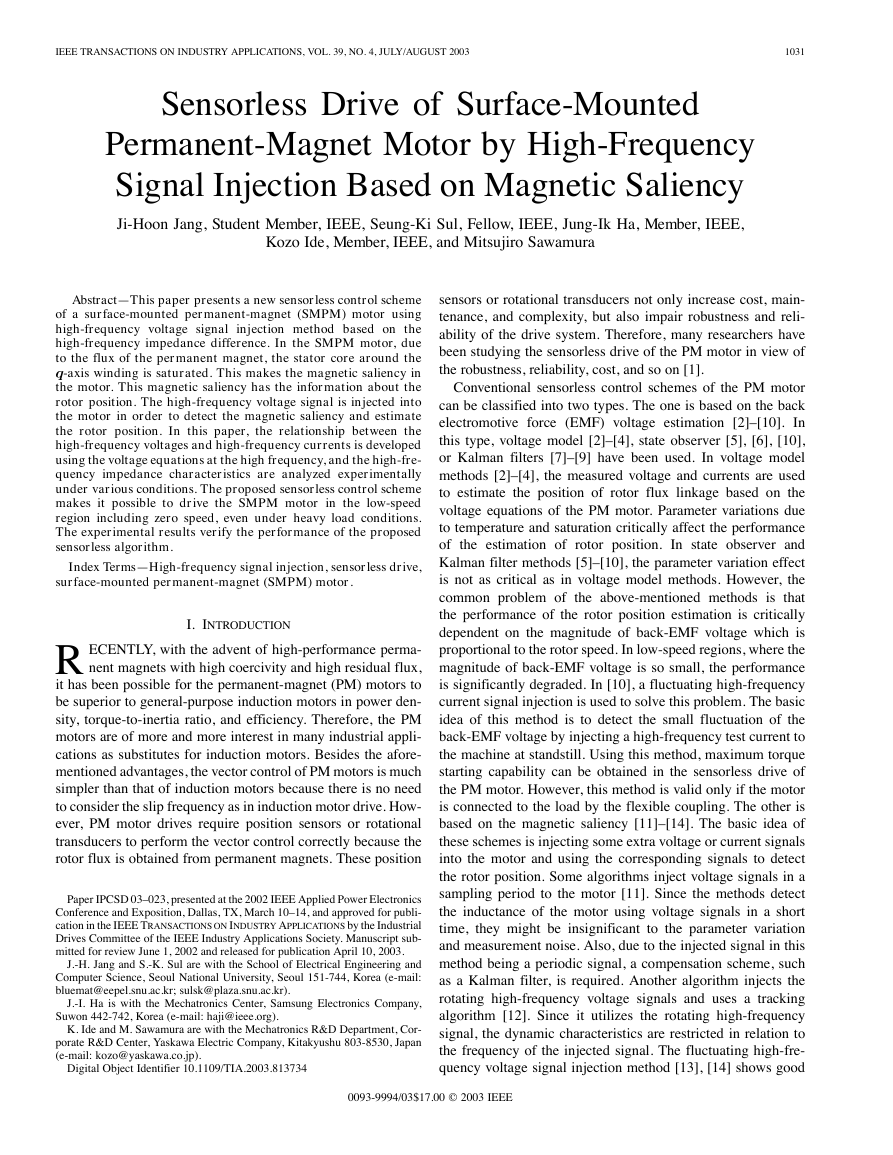

Fig. 2. Procedure of signal processing to measure the magnitude of

high-frequency variables.

negative in the sense of the rotor position estimation error in

(4) by its definition.

Fig. 2 shows the procedure of the signal processing to calcu-

late the magnitude of high-frequency variables. In Fig. 2,

is a coordinate transform operator which can be expressed as in

(10), and “ ” can be voltages or currents. If “ ” can be repre-

sented in (11), its magnitude can be obtained through the signal

means a

processing from (12)–(14). In (12) and (13),

low-pass filter

(10)

(11)

(12)

(13)

(14)

Therefore, the magnitude of high-frequency voltage and cur-

rent, and the high-frequency impedance on the measurement

axis, can be obtained as follows:

(15)

(16)

(17)

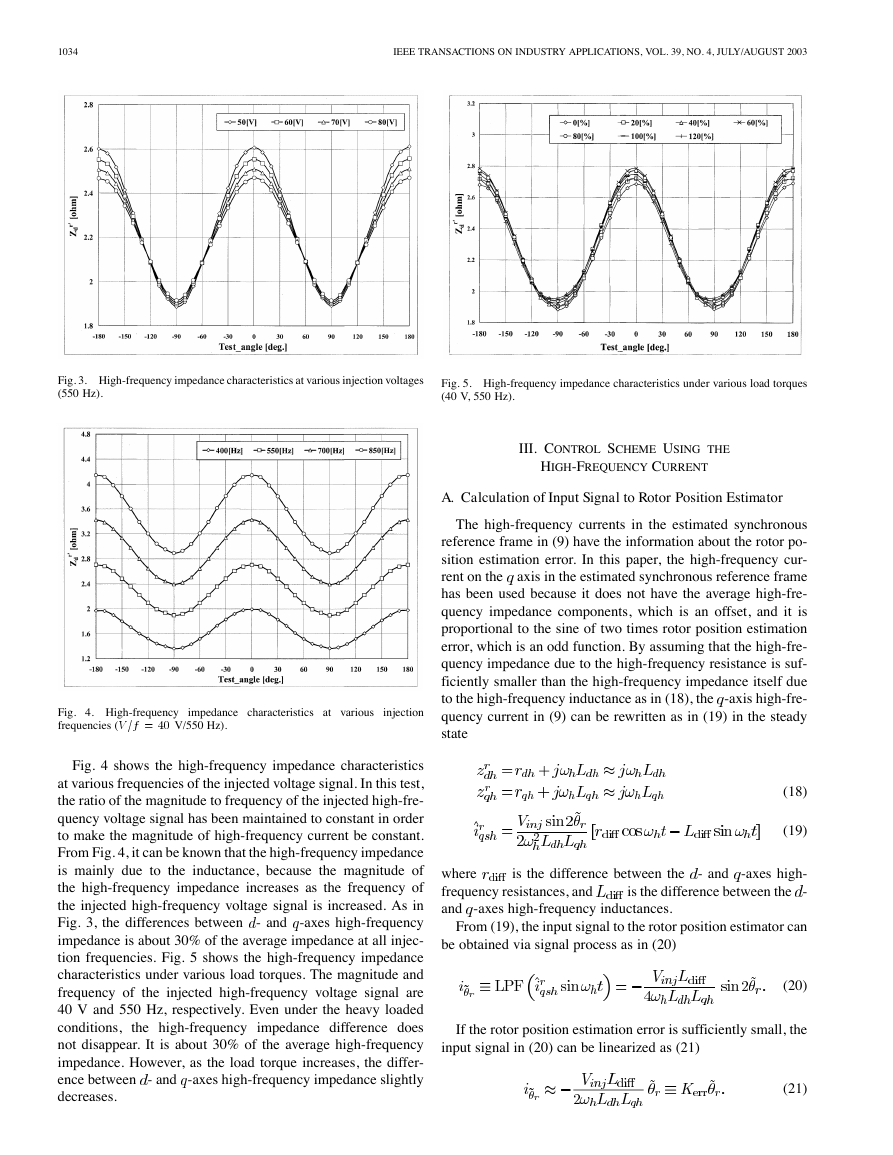

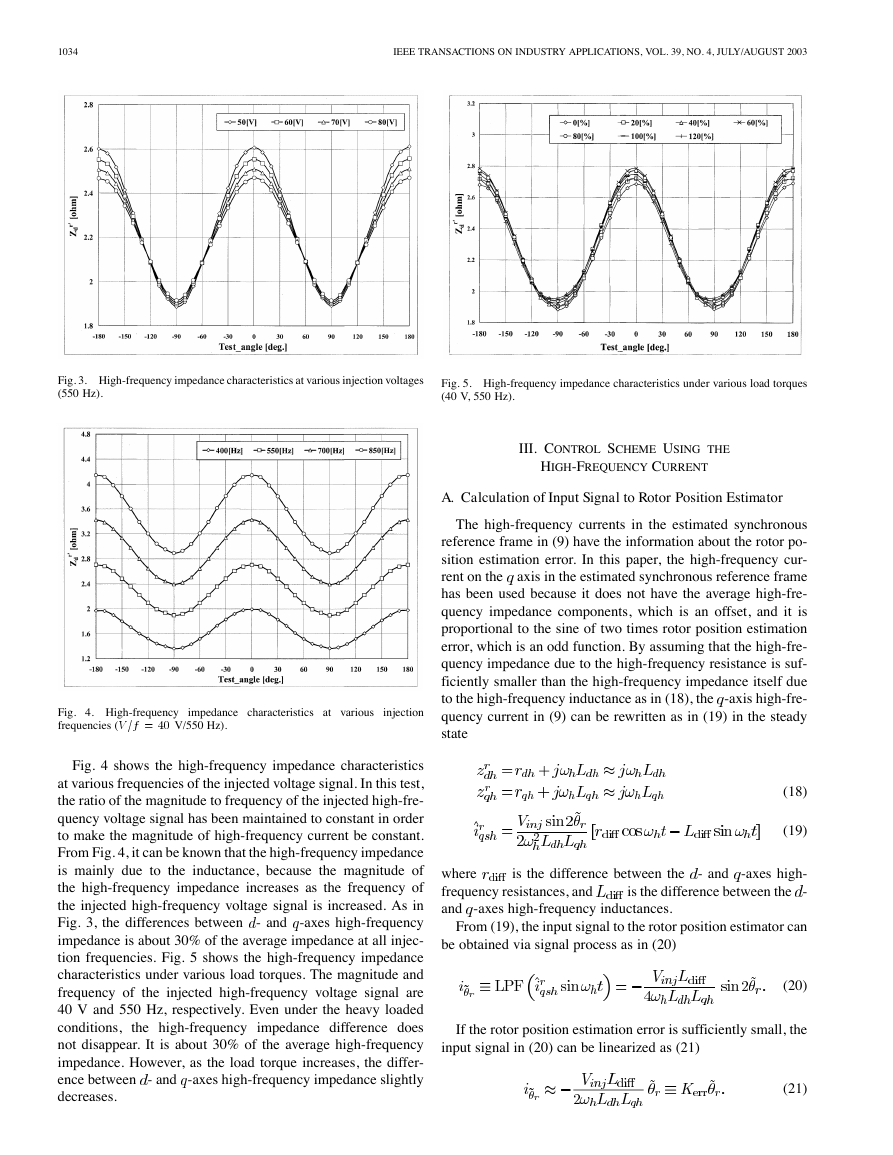

Figs. 3–5 show the measurement results of high-frequency

impedance of the tested SMPM motor at various operating

conditions. In the figures, “Test_angle” is the relative position

axis, and it means the

of measurement axis to the actual

” in Fig. 1. Therefore, when “Test_angle” is zero, the

“

axis. Fig. 3

high-frequency voltage signal is injected into the

shows the high-frequency impedance characteristics at various

magnitudes of the injected high-frequency voltage signal where

the injection frequency is 550 Hz. As can be seen in the figure,

the -axis high-frequency impedance is larger than that of the

axis. The high-frequency impedance differences (

) between

) at

all magnitudes of the injected high-frequency voltage signals.

-axis high-frequency

As the magnitude is increased,

impedance decreases, but the -axis high-frequency impedance

does not decrease. This is due to the fact that the stator core

-axis winding is already saturated. Therefore,

around the

increasing the magnitude of the injected voltage signal cannot

affect the -axis high-frequency impedance.

the

and

axes are about 30% of the average impedance (

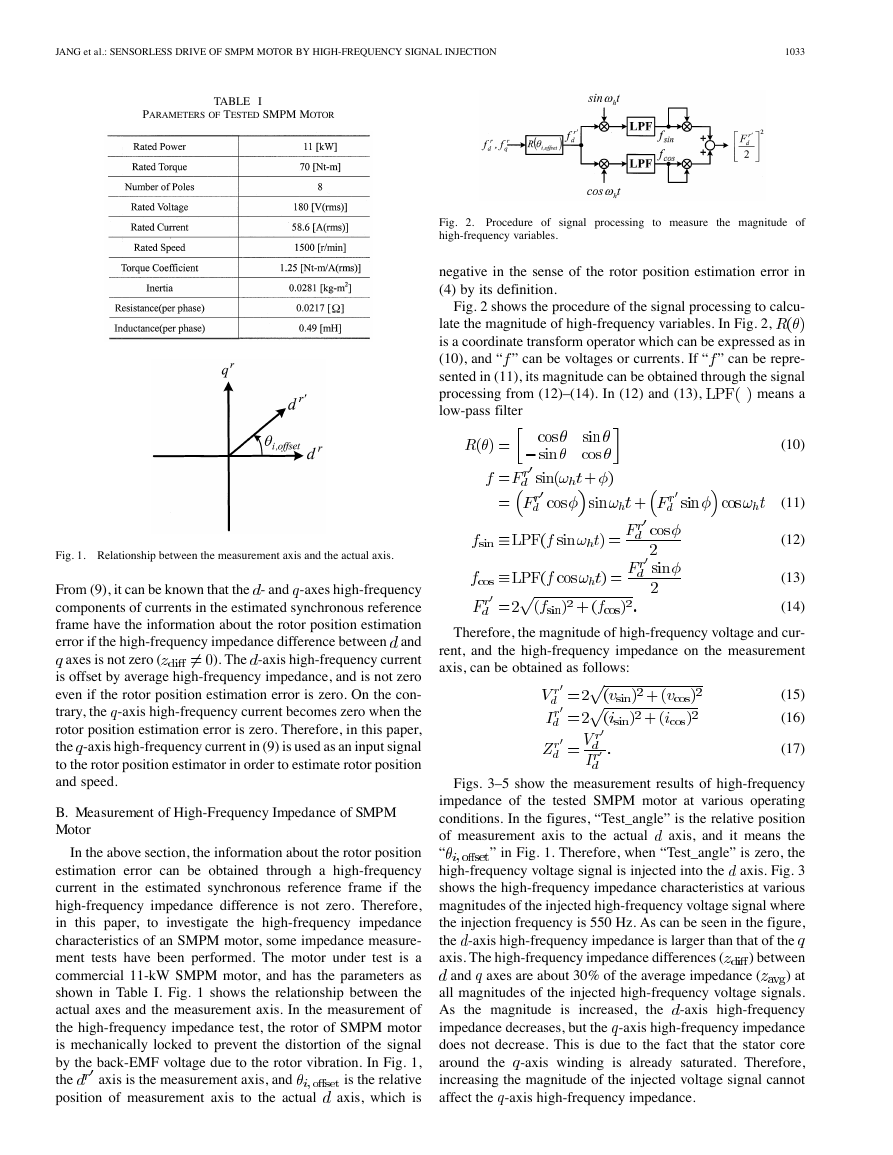

Fig. 1. Relationship between the measurement axis and the actual axis.

axes is not zero (

From (9), it can be known that the - and -axes high-frequency

components of currents in the estimated synchronous reference

frame have the information about the rotor position estimation

error if the high-frequency impedance difference between and

). The -axis high-frequency current

is offset by average high-frequency impedance, and is not zero

even if the rotor position estimation error is zero. On the con-

trary, the -axis high-frequency current becomes zero when the

rotor position estimation error is zero. Therefore, in this paper,

the -axis high-frequency current in (9) is used as an input signal

to the rotor position estimator in order to estimate rotor position

and speed.

B. Measurement of High-Frequency Impedance of SMPM

Motor

In the above section, the information about the rotor position

estimation error can be obtained through a high-frequency

current in the estimated synchronous reference frame if the

high-frequency impedance difference is not zero. Therefore,

in this paper, to investigate the high-frequency impedance

characteristics of an SMPM motor, some impedance measure-

ment tests have been performed. The motor under test is a

commercial 11-kW SMPM motor, and has the parameters as

shown in Table I. Fig. 1 shows the relationship between the

actual axes and the measurement axis. In the measurement of

the high-frequency impedance test, the rotor of SMPM motor

is mechanically locked to prevent the distortion of the signal

by the back-EMF voltage due to the rotor vibration. In Fig. 1,

is the relative

the

axis, which is

position of measurement axis to the actual

axis is the measurement axis, and

�

1034

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 39, NO. 4, JULY/AUGUST 2003

Fig. 3. High-frequency impedance characteristics at various injection voltages

(550 Hz).

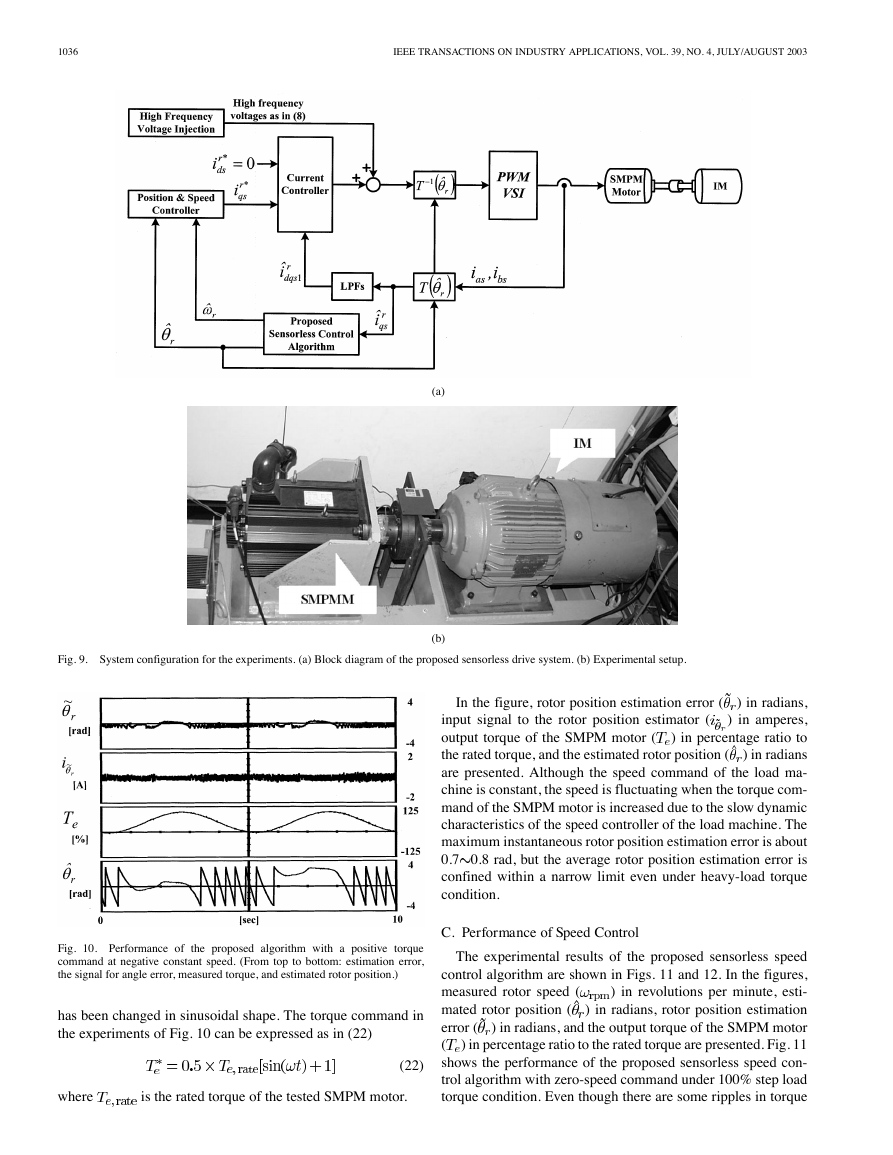

Fig. 5. High-frequency impedance characteristics under various load torques

(40 V, 550 Hz).

III. CONTROL SCHEME USING THE

HIGH-FREQUENCY CURRENT

A. Calculation of Input Signal to Rotor Position Estimator

The high-frequency currents in the estimated synchronous

reference frame in (9) have the information about the rotor po-

sition estimation error. In this paper, the high-frequency cur-

axis in the estimated synchronous reference frame

rent on the

has been used because it does not have the average high-fre-

quency impedance components, which is an offset, and it is

proportional to the sine of two times rotor position estimation

error, which is an odd function. By assuming that the high-fre-

quency impedance due to the high-frequency resistance is suf-

ficiently smaller than the high-frequency impedance itself due

to the high-frequency inductance as in (18), the -axis high-fre-

quency current in (9) can be rewritten as in (19) in the steady

state

(18)

(19)

where

frequency resistances, and

and -axes high-frequency inductances.

is the difference between the - and -axes high-

is the difference between the -

From (19), the input signal to the rotor position estimator can

be obtained via signal process as in (20)

(20)

If the rotor position estimation error is sufficiently small, the

input signal in (20) can be linearized as (21)

(21)

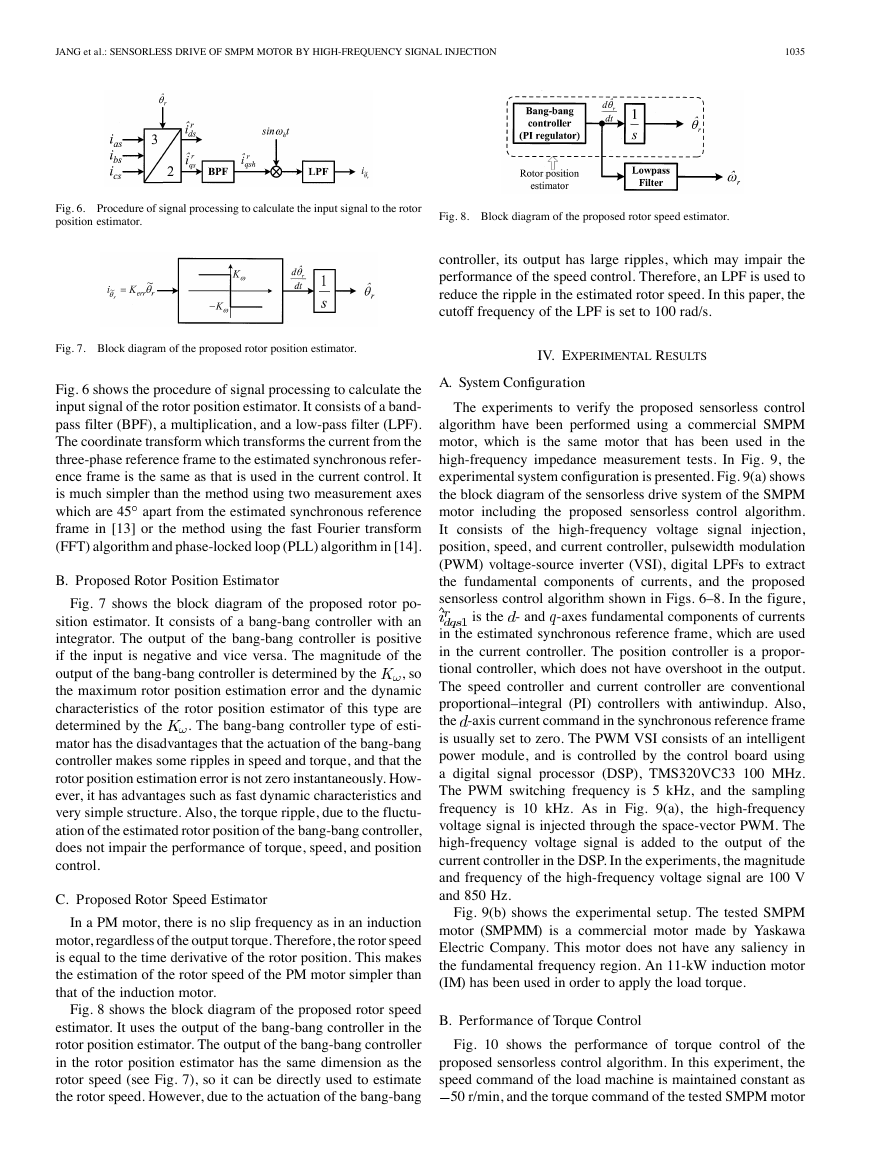

Fig. 4. High-frequency impedance characteristics at various injection

frequencies (V =f = 40 V/550 Hz).

Fig. 4 shows the high-frequency impedance characteristics

at various frequencies of the injected voltage signal. In this test,

the ratio of the magnitude to frequency of the injected high-fre-

quency voltage signal has been maintained to constant in order

to make the magnitude of high-frequency current be constant.

From Fig. 4, it can be known that the high-frequency impedance

is mainly due to the inductance, because the magnitude of

the high-frequency impedance increases as the frequency of

the injected high-frequency voltage signal is increased. As in

Fig. 3, the differences between - and -axes high-frequency

impedance is about 30% of the average impedance at all injec-

tion frequencies. Fig. 5 shows the high-frequency impedance

characteristics under various load torques. The magnitude and

frequency of the injected high-frequency voltage signal are

40 V and 550 Hz, respectively. Even under the heavy loaded

conditions,

the high-frequency impedance difference does

not disappear. It is about 30% of the average high-frequency

impedance. However, as the load torque increases, the differ-

ence between - and -axes high-frequency impedance slightly

decreases.

�

JANG et al.: SENSORLESS DRIVE OF SMPM MOTOR BY HIGH-FREQUENCY SIGNAL INJECTION

1035

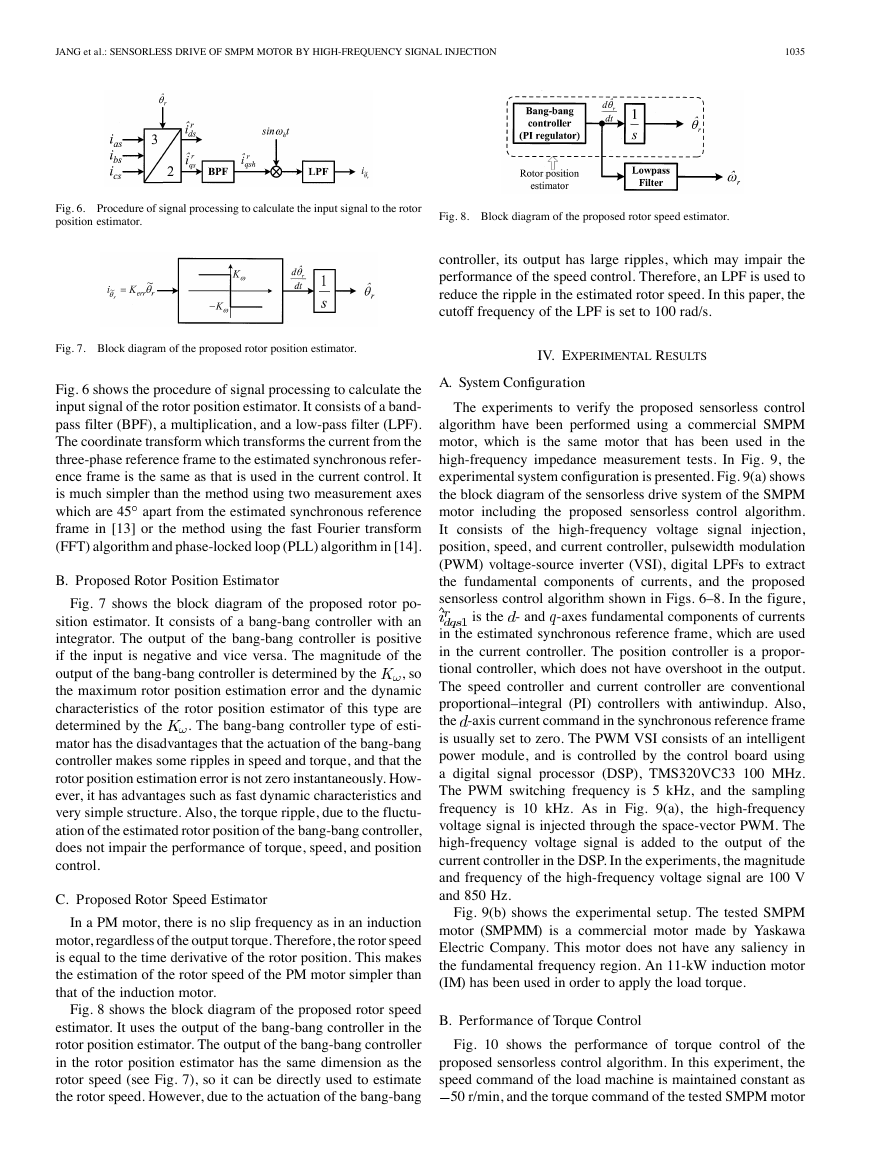

Fig. 6. Procedure of signal processing to calculate the input signal to the rotor

position estimator.

Fig. 8. Block diagram of the proposed rotor speed estimator.

Fig. 7. Block diagram of the proposed rotor position estimator.

Fig. 6 shows the procedure of signal processing to calculate the

input signal of the rotor position estimator. It consists of a band-

pass filter (BPF), a multiplication, and a low-pass filter (LPF).

The coordinate transform which transforms the current from the

three-phase reference frame to the estimated synchronous refer-

ence frame is the same as that is used in the current control. It

is much simpler than the method using two measurement axes

which are 45 apart from the estimated synchronous reference

frame in [13] or the method using the fast Fourier transform

(FFT) algorithm and phase-locked loop (PLL) algorithm in [14].

B. Proposed Rotor Position Estimator

Fig. 7 shows the block diagram of the proposed rotor po-

sition estimator. It consists of a bang-bang controller with an

integrator. The output of the bang-bang controller is positive

if the input is negative and vice versa. The magnitude of the

, so

output of the bang-bang controller is determined by the

the maximum rotor position estimation error and the dynamic

characteristics of the rotor position estimator of this type are

. The bang-bang controller type of esti-

determined by the

mator has the disadvantages that the actuation of the bang-bang

controller makes some ripples in speed and torque, and that the

rotor position estimation error is not zero instantaneously. How-

ever, it has advantages such as fast dynamic characteristics and

very simple structure. Also, the torque ripple, due to the fluctu-

ation of the estimated rotor position of the bang-bang controller,

does not impair the performance of torque, speed, and position

control.

C. Proposed Rotor Speed Estimator

In a PM motor, there is no slip frequency as in an induction

motor, regardless of the output torque. Therefore, the rotor speed

is equal to the time derivative of the rotor position. This makes

the estimation of the rotor speed of the PM motor simpler than

that of the induction motor.

Fig. 8 shows the block diagram of the proposed rotor speed

estimator. It uses the output of the bang-bang controller in the

rotor position estimator. The output of the bang-bang controller

in the rotor position estimator has the same dimension as the

rotor speed (see Fig. 7), so it can be directly used to estimate

the rotor speed. However, due to the actuation of the bang-bang

controller, its output has large ripples, which may impair the

performance of the speed control. Therefore, an LPF is used to

reduce the ripple in the estimated rotor speed. In this paper, the

cutoff frequency of the LPF is set to 100 rad/s.

IV. EXPERIMENTAL RESULTS

A. System Configuration

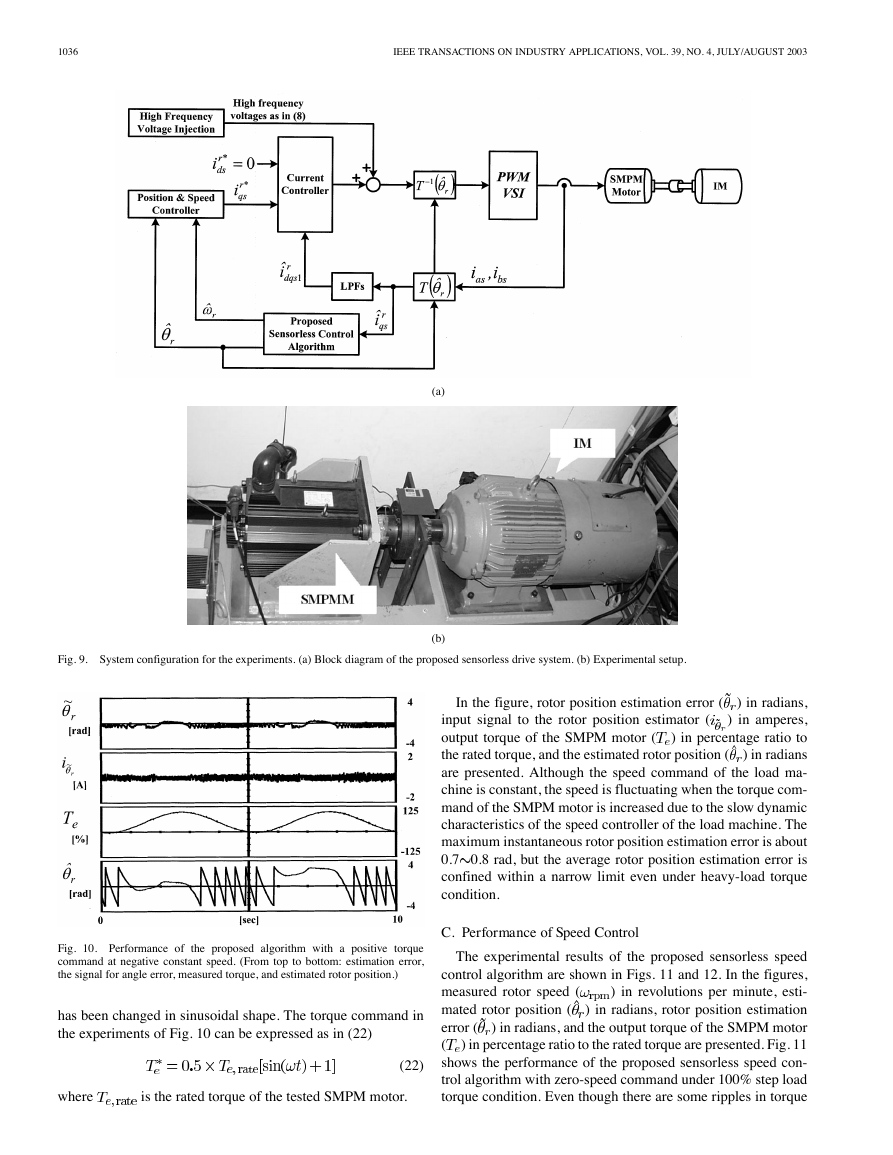

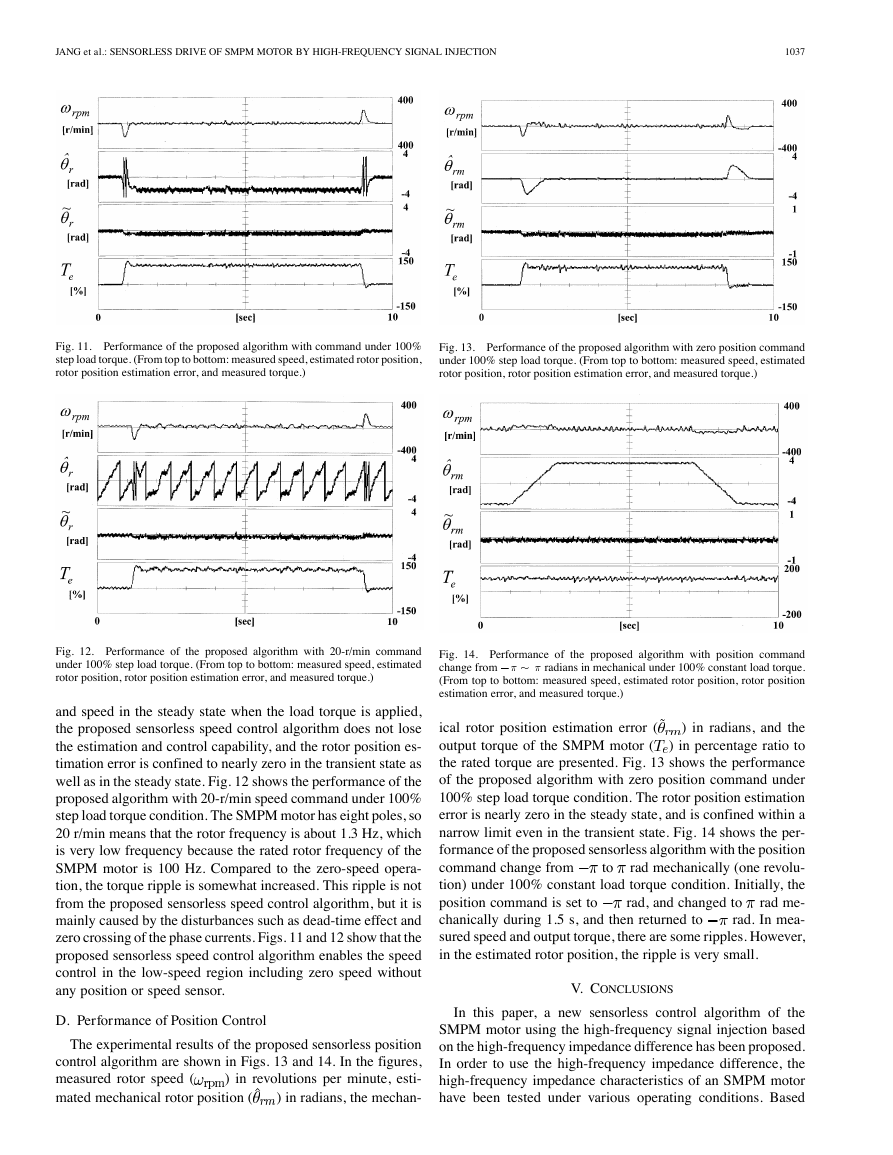

The experiments to verify the proposed sensorless control

algorithm have been performed using a commercial SMPM

motor, which is the same motor that has been used in the

high-frequency impedance measurement tests. In Fig. 9, the

experimental system configuration is presented. Fig. 9(a) shows

the block diagram of the sensorless drive system of the SMPM

motor including the proposed sensorless control algorithm.

It consists of the high-frequency voltage signal

injection,

position, speed, and current controller, pulsewidth modulation

(PWM) voltage-source inverter (VSI), digital LPFs to extract

the fundamental components of currents, and the proposed

sensorless control algorithm shown in Figs. 6–8. In the figure,

is the - and -axes fundamental components of currents

in the estimated synchronous reference frame, which are used

in the current controller. The position controller is a propor-

tional controller, which does not have overshoot in the output.

The speed controller and current controller are conventional

proportional–integral (PI) controllers with antiwindup. Also,

the -axis current command in the synchronous reference frame

is usually set to zero. The PWM VSI consists of an intelligent

power module, and is controlled by the control board using

a digital signal processor (DSP), TMS320VC33 100 MHz.

The PWM switching frequency is 5 kHz, and the sampling

frequency is 10 kHz. As in Fig. 9(a), the high-frequency

voltage signal is injected through the space-vector PWM. The

high-frequency voltage signal is added to the output of the

current controller in the DSP. In the experiments, the magnitude

and frequency of the high-frequency voltage signal are 100 V

and 850 Hz.

Fig. 9(b) shows the experimental setup. The tested SMPM

motor (SMPMM) is a commercial motor made by Yaskawa

Electric Company. This motor does not have any saliency in

the fundamental frequency region. An 11-kW induction motor

(IM) has been used in order to apply the load torque.

B. Performance of Torque Control

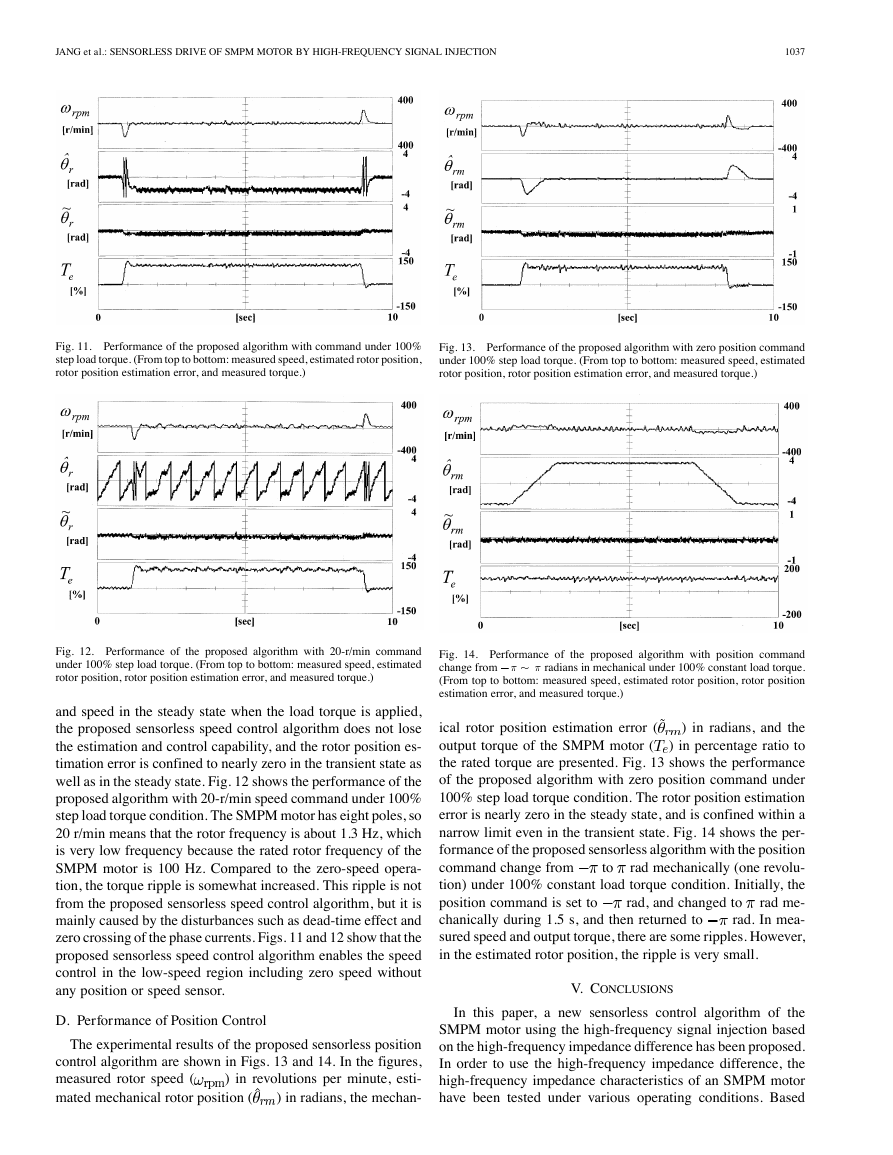

Fig. 10 shows the performance of torque control of the

proposed sensorless control algorithm. In this experiment, the

speed command of the load machine is maintained constant as

50 r/min, and the torque command of the tested SMPM motor

�

1036

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 39, NO. 4, JULY/AUGUST 2003

(a)

(b)

Fig. 9. System configuration for the experiments. (a) Block diagram of the proposed sensorless drive system. (b) Experimental setup.

In the figure, rotor position estimation error (

) in radians,

) in amperes,

input signal to the rotor position estimator (

) in percentage ratio to

output torque of the SMPM motor (

) in radians

the rated torque, and the estimated rotor position (

are presented. Although the speed command of the load ma-

chine is constant, the speed is fluctuating when the torque com-

mand of the SMPM motor is increased due to the slow dynamic

characteristics of the speed controller of the load machine. The

maximum instantaneous rotor position estimation error is about

0.7 0.8 rad, but the average rotor position estimation error is

confined within a narrow limit even under heavy-load torque

condition.

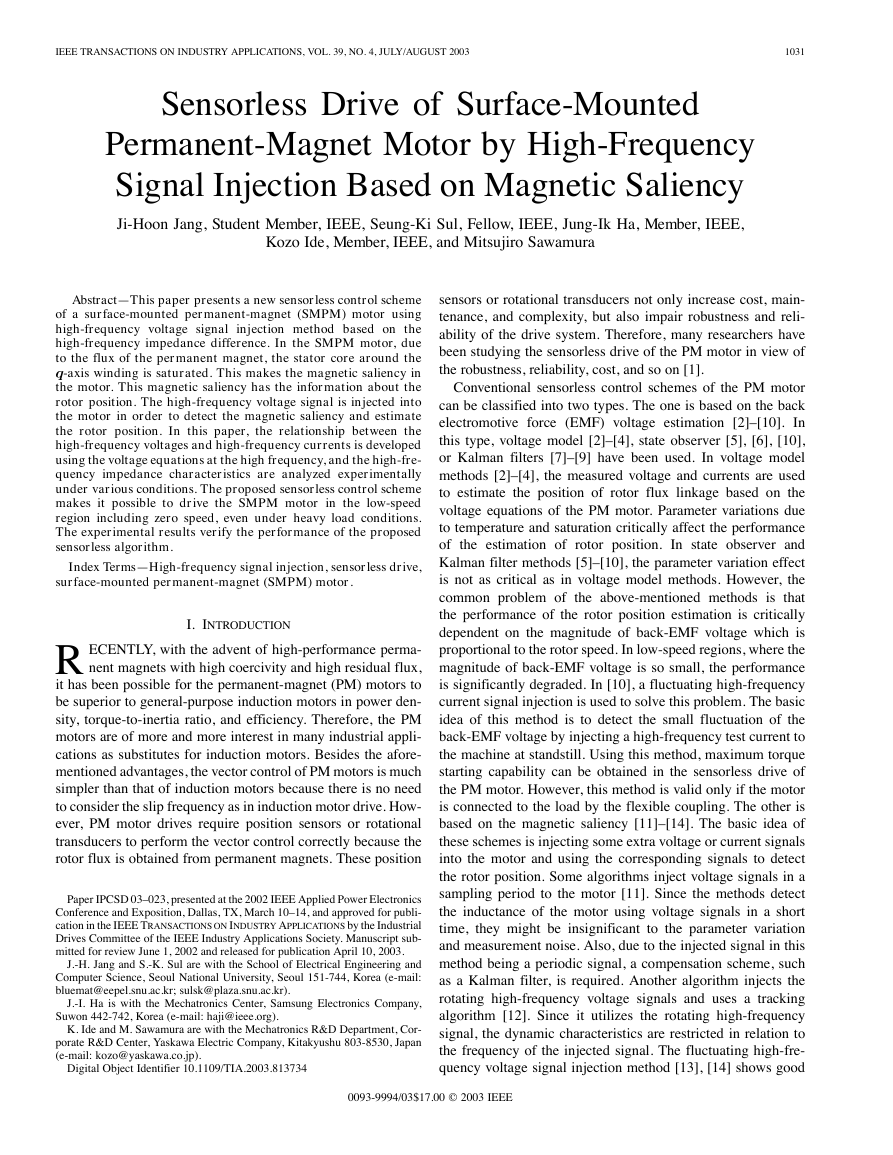

C. Performance of Speed Control

The experimental results of the proposed sensorless speed

control algorithm are shown in Figs. 11 and 12. In the figures,

) in revolutions per minute, esti-

measured rotor speed (

) in radians, rotor position estimation

mated rotor position (

) in radians, and the output torque of the SMPM motor

error (

) in percentage ratio to the rated torque are presented. Fig. 11

(

shows the performance of the proposed sensorless speed con-

trol algorithm with zero-speed command under 100% step load

torque condition. Even though there are some ripples in torque

Fig. 10. Performance of the proposed algorithm with a positive torque

command at negative constant speed. (From top to bottom: estimation error,

the signal for angle error, measured torque, and estimated rotor position.)

has been changed in sinusoidal shape. The torque command in

the experiments of Fig. 10 can be expressed as in (22)

(22)

where

is the rated torque of the tested SMPM motor.

�

JANG et al.: SENSORLESS DRIVE OF SMPM MOTOR BY HIGH-FREQUENCY SIGNAL INJECTION

1037

Fig. 11. Performance of the proposed algorithm with command under 100%

step load torque. (From top to bottom: measured speed, estimated rotor position,

rotor position estimation error, and measured torque.)

Fig. 13. Performance of the proposed algorithm with zero position command

under 100% step load torque. (From top to bottom: measured speed, estimated

rotor position, rotor position estimation error, and measured torque.)

Fig. 12. Performance of the proposed algorithm with 20-r/min command

under 100% step load torque. (From top to bottom: measured speed, estimated

rotor position, rotor position estimation error, and measured torque.)

and speed in the steady state when the load torque is applied,

the proposed sensorless speed control algorithm does not lose

the estimation and control capability, and the rotor position es-

timation error is confined to nearly zero in the transient state as

well as in the steady state. Fig. 12 shows the performance of the

proposed algorithm with 20-r/min speed command under 100%

step load torque condition. The SMPM motor has eight poles, so

20 r/min means that the rotor frequency is about 1.3 Hz, which

is very low frequency because the rated rotor frequency of the

SMPM motor is 100 Hz. Compared to the zero-speed opera-

tion, the torque ripple is somewhat increased. This ripple is not

from the proposed sensorless speed control algorithm, but it is

mainly caused by the disturbances such as dead-time effect and

zero crossing of the phase currents. Figs. 11 and 12 show that the

proposed sensorless speed control algorithm enables the speed

control in the low-speed region including zero speed without

any position or speed sensor.

Fig. 14. Performance of the proposed algorithm with position command

change from �� � � radians in mechanical under 100% constant load torque.

(From top to bottom: measured speed, estimated rotor position, rotor position

estimation error, and measured torque.)

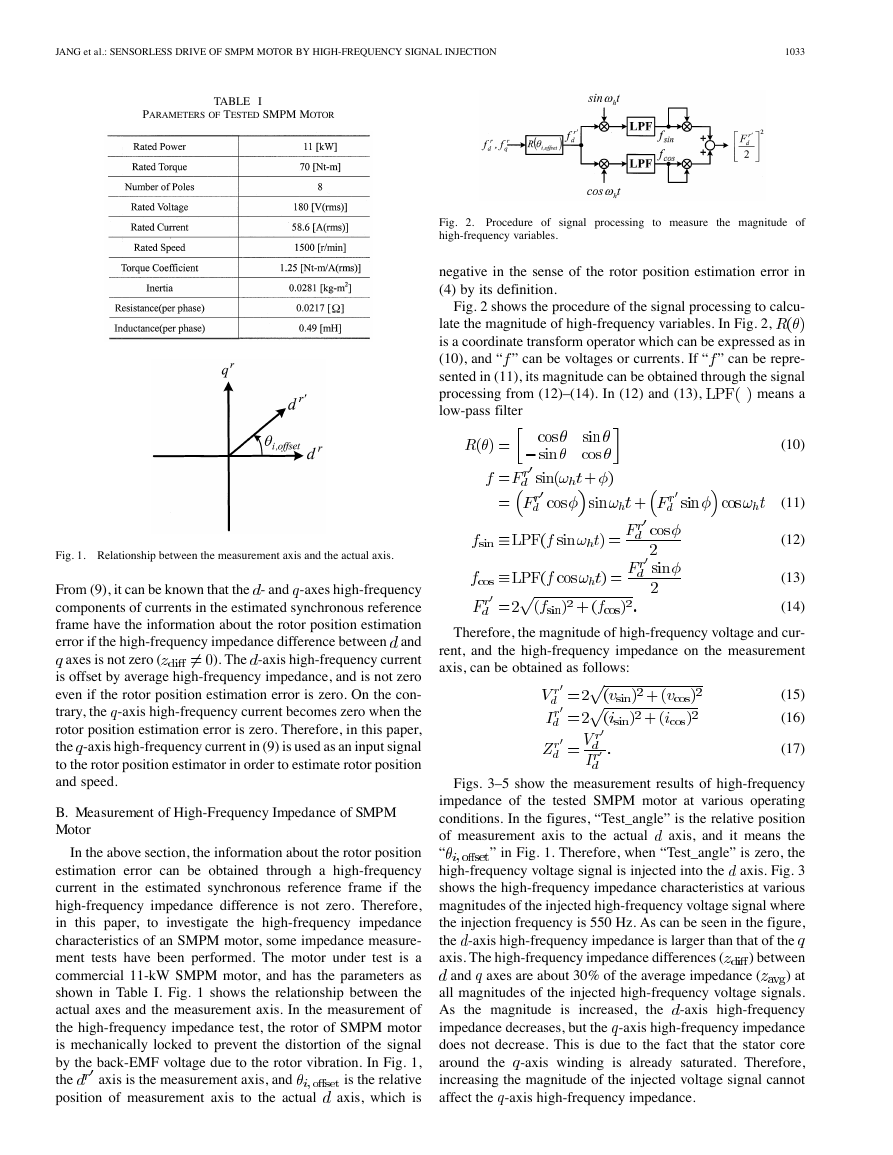

) in radians, and the

ical rotor position estimation error (

) in percentage ratio to

output torque of the SMPM motor (

the rated torque are presented. Fig. 13 shows the performance

of the proposed algorithm with zero position command under

100% step load torque condition. The rotor position estimation

error is nearly zero in the steady state, and is confined within a

narrow limit even in the transient state. Fig. 14 shows the per-

formance of the proposed sensorless algorithm with the position

rad mechanically (one revolu-

command change from

tion) under 100% constant load torque condition. Initially, the

rad me-

position command is set to

rad. In mea-

chanically during 1.5 s, and then returned to

sured speed and output torque, there are some ripples. However,

in the estimated rotor position, the ripple is very small.

rad, and changed to

to

V. CONCLUSIONS

D. Performance of Position Control

The experimental results of the proposed sensorless position

control algorithm are shown in Figs. 13 and 14. In the figures,

) in revolutions per minute, esti-

measured rotor speed (

) in radians, the mechan-

mated mechanical rotor position (

In this paper, a new sensorless control algorithm of the

SMPM motor using the high-frequency signal injection based

on the high-frequency impedance difference has been proposed.

In order to use the high-frequency impedance difference, the

high-frequency impedance characteristics of an SMPM motor

have been tested under various operating conditions. Based

�

1038

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 39, NO. 4, JULY/AUGUST 2003

on the characteristics, it is shown that the rotor position can

be estimated using high-frequency component of currents on

axis in the estimated synchronous reference frame if the

the

direct ( ) and quadrature ( ) axes high-frequency impedances,

mainly high-frequency inductances, are different. The proposed

sensorless control algorithm contains a high-frequency voltage

signal injection scheme, extraction of rotor position estimation

error information from the high-frequency component of

currents, rotor position estimator, and rotor speed estimator.

In order to verify the proposed sensorless algorithm, an exper-

imental system using a commercial SMPM motor has been set

up and tested. The experimental results clarify that the proposed

sensorless control algorithm using the high-frequency voltage

signal injection based on the high-frequency impedance differ-

ence enables torque, speed, and position control in the low-

speed region including zero speed without any speed or posi-

tion sensor under heavy-load condition.

APPENDIX

The high-frequency components of the voltage equations in

(3) can be written as in (A.1). Therefore, the high-frequency

components of currents can be expressed as in (A.2) through

the inversion of a matrix

(A.1)

(A.2)

The relationship between the variables in the actual syn-

chronous reference frame and variables in the estimated

synchronous reference frame can be written as in (A.3) and

(A.4)

(A.3)

(A.4)

Equation (A.2) can be expressed as in (A.5) using (A.3) and

(A.4)

Equation (A.5) shows the relationship between the high-fre-

quency components of currents and voltages in the estimated

synchronous reference frame.

(A.5)

REFERENCES

[1] P. Pillay and P. Freere, “Literature survey of permanent magnet AC

motors and drives,” in Conf. Rec. IEEE-IAS Annu. Meeting, 1991, pp.

74–84.

[2] R. Wu and G. R. Slemon, “A permanent magnet motor drive without

a shaft sensor,” IEEE Trans. Ind. Applicat., vol. 27, pp. 1005–1011,

Sept./Oct. 1991.

[3] M. Naidu and B. K. Bose, “Rotor position estimation scheme of a perma-

nent magnet synchronous machine for high performance variable speed

drive,” in Conf. Rec. IEEE-IAS Annu. Meeting, 1992, pp. 48–53.

[4] N. Ertugrul and P. Acarnley, “A new algorithm for sensorless operation

of permanent magnet motors,” IEEE Trans. Ind. Applicat., vol. 30, pp.

126–133, Jan./Feb. 1994.

[5] L. A. Jones and J. H. Lang, “A state observer for the permanent-magnet

synchronous motor,” IEEE Trans. Ind. Electron., vol. 36, pp. 374–382,

June 1989.

[6] R. B. Sepe and J. H. Lang, “Real-time observer-based (adaptive) con-

trol of a permanent-magnet synchronous motor without mechanical sen-

sores,” IEEE Trans. Ind. Applicat., vol. 28, pp. 1345–1352, Nov./Dec.

1992.

[7] R. Dhauoadi, N. Mohan, and L. Norum, “Design and implementation of

an extended Kalman filter for the state estimation of a permanent magnet

synchronous motor,” IEEE Trans. Power Electron., vol. 6, pp. 491–497,

May 1991.

[8] J. Hu, D. Zhu, and B. Wu, “Permanent magnet synchronous motor drive

without mechanical sensors,” in Conf. Rec. IEEE CCECE, 1996, pp.

603–606.

[9] S. Bolognani, R. Oboe, and M. Zigliotto, “Sensorless full-digital PMSM

drive with EKF estimation of speed and rotor position,” IEEE Trans. Ind.

Electron., vol. 46, pp. 184–191, Feb. 1999.

[10] J. S. Kim and S. K. Sul, “New approach for high performance PMSM

drives without rotational position sensors,” IEEE Trans. Power Elec-

tron., vol. 12, pp. 904–911, Sept. 1997.

[11] M. Schroedl, “Sensorless control of AC machines at low speed and

standstill based on the ‘INFORM’ method,” in Conf. Rec. IEEE-IAS

Annu. Meeting, 1996, pp. 270–277.

[12] P. L. Jansen and R. D. Lorenz, “Transducerless position and velocity

estimation in induction and salient AC machines,” IEEE Trans. Ind. Ap-

plicat., vol. 31, pp. 240–247, Mar./Apr. 1995.

[13] J. I. Ha, S. K. Sul, and M. H. Park, “Position controlled interior per-

manent magnet motor without any rotational transducer,” in Conf. Rec.

IEEE-2K, 2000, pp. 396–399.

[14] T. Aihara, A. Toba, T. Yanase, A. Mashimo, and K. Endo, “Sensorless

torque control of salient-pole synchronous motor at zero-speed opera-

tion,” IEEE Trans. Power Electron., vol. 14, pp. 202–208, Jan. 1999.

Ji-Hoon Jang (S’01) was born in Seoul, Korea,

in 1975. He received the B.S. and M.S. degrees in

electrical engineering in 1999 and 2001, respectively,

from Seoul National University, Seoul, Korea, where

he is currently working toward the Ph.D. degree.

His research interests are high-performance ac ma-

chine drives, sensorless drives of ac machines, and

electrical systems in vehicles.

Seung-Ki Sul (S’78–M’80–SM’98–F’00) was born

in Korea in 1958. He received the B.S., M.S., and

Ph.D. degrees in electrical engineering from Seoul

National University, Seoul, Korea, in 1980, 1983, and

1986, respectively.

From 1986 to 1988, he was an Associate Re-

searcher with the Department of Electrical and

Computer Engineering, University of Wisconsin,

Madison. From 1988 to 1990, he was a Principal

Research Engineer with Gold-Star

Industrial

Systems Company. Since 1991, he has been a

member of the faculty of the School of Electrical Engineering, Seoul National

University, where he is currently a Professor. His current research interests are

power-electronic control of electric machines, electric vehicle drives, custom

powers, and power-converter circuits.

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc