Evaluation Board User Guide

UG-207

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel: 781.329.4700 • Fax: 781.461.3113 • www.analog.com

Evaluation Board for 1 GSPS DDS with 14-Bit DAC

FEATURES

Full-featured evaluation board for the AD9910

PC evaluation software for control and measurement of the

AD9910

USB interface

Graphic user interface (GUI) software with frequency sweep

capability for board control and data analysis

Factory tested and ready to use

PACKAGE CONTENTS

AD9910 evaluation board

AD9910/PCBZ installation software CD

USB cable

GENERAL DESCRIPTION

This user guide describes how to set up and use the AD9910

evaluation board. The AD9910 is a 1 GSPS DDS with a

14-bit DAC.

The evaluation board software provides a graphical user interface

(GUI) for easy communication with the device along with many

user-friendly features such as the mouse-over effect.

This user guide is intended for use in conjunction with the

AD9910 data sheet, which is available from Analog Devices,

Inc., at www.analog.com.

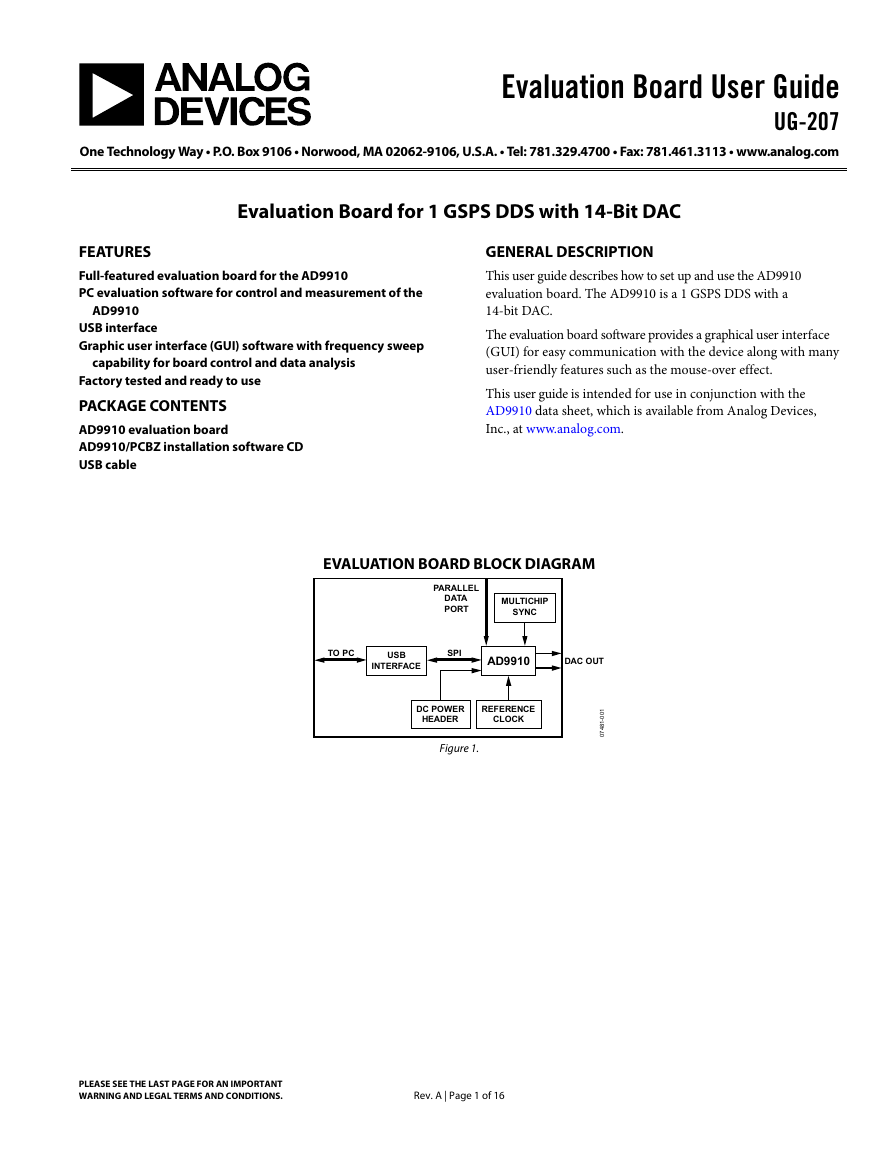

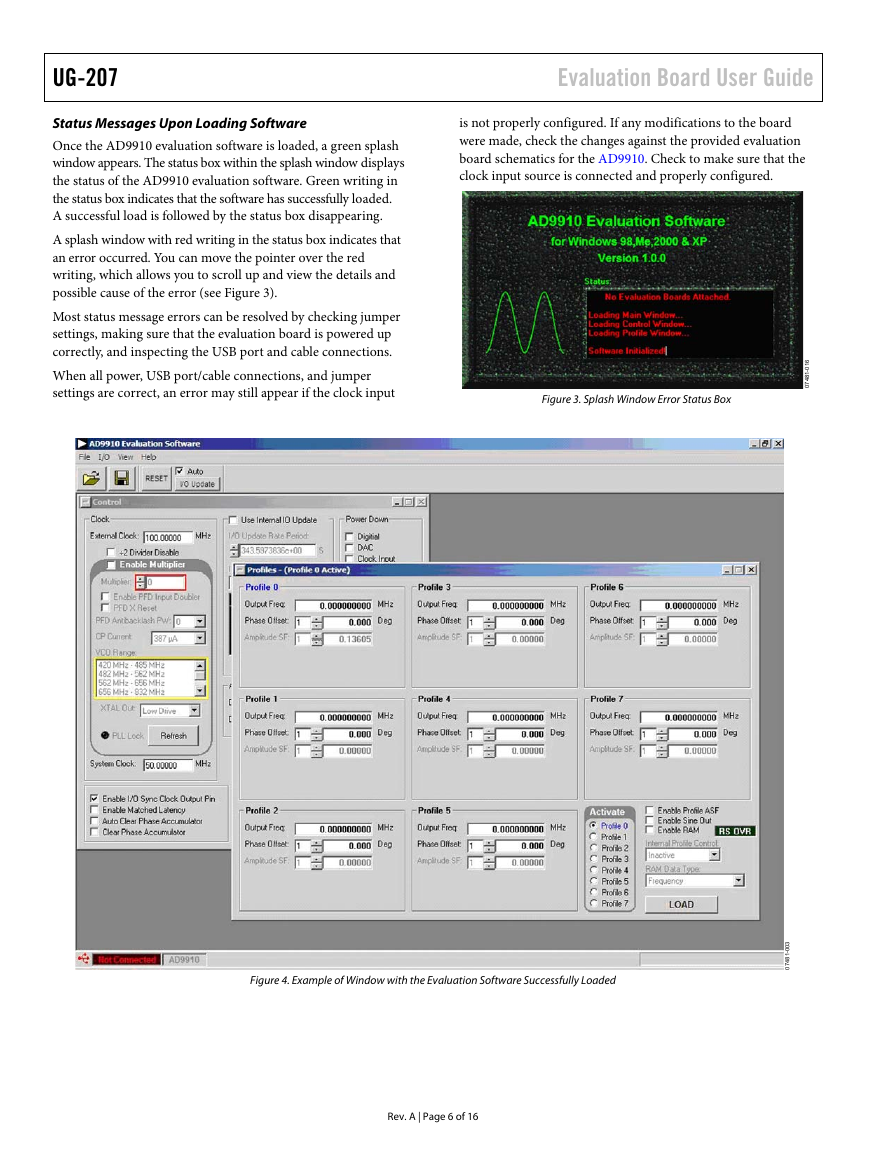

EVALUATION BOARD BLOCK DIAGRAM

PARALLEL

DATA

PORT

MULTICHIP

SYNC

TO PC

USB

INTERFACE

SPI

AD9910

DAC OUT

DC POWER

HEADER

REFERENCE

CLOCK

Figure 1.

1

0

0

-

1

8

4

7

0

PLEASE SEE THE LAST PAGE FOR AN IMPORTANT

WARNING AND LEGAL TERMS AND CONDITIONS.

Rev. A | Page 1 of 16

�

Evaluation Board User Guide

Installing the Software..................................................................5

Installing the Driver......................................................................5

Launching the Program................................................................5

Control Window............................................................................7

Profiles Window............................................................................9

Single-Tone Mode .........................................................................9

View Windows............................................................................ 11

OSK and Digital Ramp Control ............................................... 12

Multichip Sync Control ............................................................. 13

RAM Operation.......................................................................... 14

Debug........................................................................................... 15

Register Map (Software Buffer) Values ................................... 15

UG-207

TABLE OF CONTENTS

Features .............................................................................................. 1

Package Contents.............................................................................. 1

General Description......................................................................... 1

Evaluation Board Block Diagram................................................... 1

Revision History ............................................................................... 2

Evaluation Board Hardware............................................................ 3

Requirements ................................................................................ 3

Setting Up the Evaluation Board................................................ 3

Connectors .................................................................................... 3

Jumpers .......................................................................................... 3

Evaluation Board Layout ............................................................. 4

Evaluation Board Software.............................................................. 5

REVISION HISTORY

10/10—Rev. 0 to Rev. A

Document Title Changed from AD9910/PCBZ to

UG-207.................................................................................Universal

Updated Format..................................................................Universal

Changes to Device Clock Oscillator Options Section ................. 3

Changes to Power Down Digital, DAC, Clock Input, and Aux

DAC Section...................................................................................... 8

Change to DUT I/O Section ......................................................... 16

Deleted Ordering Information Section ....................................... 17

4/08—Revision 0: Initial Version

Rev. A | Page 2 of 16

�

Evaluation Board User Guide

EVALUATION BOARD HARDWARE

REQUIREMENTS

To successfully use the evaluation board and run the software,

the requirements listed in Table 1 must be met.

Requirement

Windows® 98/ME/2000/XP

Table 1. AD9910/PCBZ Requirements

Item

Operating

System

Processor

Memory

Ports

Clocking

Pentium® I or later

128 MB minimum

One USB port

Signal generator capable of generating

sinusoidal waves of at least 0 dBm, up to at

least 10 MHz

Power Supplies Capability to generate at least two

Measurement

Cables

independent dc voltages (1.8 V/3.3 V)

Appropriate measurement device, such as a

spectrum analyzer or a high bandwidth

oscilloscope

USB 1.1/2.0 cable, and SMA-to-X cables (X =

SMA or BNC, depending on the connector of

the device interfacing with the board)

SETTING UP THE EVALUATION BOARD

DC Power Supply

The AD9910 evaluation board has two power supply connectors

(four pins each): TB1 and TB2. TB1 powers the USB interface

circuitry, the digital I/O interface, and the digital core. TB2

powers the DAC and the clock input circuitry.

CONNECTORS

Table 2 shows the necessary connections and the appropriate

biasing voltage.

Table 2. Connections and Biasing Voltage

Connector

TB1

TB1

TB1

TB1

TB2

TB2

TB2

Label

VCC_USB

GND

DVDD_IO

DVDD

GND

DAC_VDD

CLK_VDD

Pin No.

1

2

3

4

1, 3

2

4

Voltage (V)

3.3

0

3.3

1.8

0

3.3

1.8

UG-207

Device Clock Oscillator Options

The AD9910 architecture provides the user with three options

when providing an input signal to the part. The first option allows

the user to provide a high frequency input signal, connected to J1.

The second option allows the user to connect using a lower input

reference frequency, enabling the clock multiplier, and connects

through J1. The third option allows the user to connect a crystal

resonator on the backside of the board.

Note that the AD9910 evaluation board does not populate the

PLL loop filter components. Therefore, to use the internal PLL of

the AD9910, the user must solder down these components, or

else the PLL is not stable. The AD9910 data sheet has helpful

formulas to calculate the appropriate values. In addition, an Excel

file to help choose the loop filter component values is available at

www.analog.com. Go to the AD9910 product page and click on

the Evaluation Boards and Development Kits tab.

To enable the crystal mode, switch the jumper, W7, to the XTAL

mode. Remove C51 and 52. Place 0 (zero) Ω resistors at R4 and

R11 on the backside of the board. The crystal oscillates at 25 MHz.

Refer to the AD9910 data sheet for details on the maximum input

speeds and input sensitivities of these two inputs.

Device Communication Requirements

Two interface options are available on the evaluation board.

• USB 1.1/2.0

• Header row (U5 and U9), which places the part under the

control of an external controller (such as a microprocessor,

FPGA, or DSP)

Analog Devices provides a GUI for the PC; it does not provide

control software for external controllers.

JUMPERS

Use the jumper settings listed in Table 3 to enable different

modes of communication.

Table 3. Jumper Settings for Communication Modes

Mode

PC Control,

USB Port

Settings

Set Jumper W1 and Jumper W2 to enable. Set

Jumper W4 to enable. Place a jumper on W5, W6,

and W3.

Set Jumper W1and Jumper W2 to disable. Set

Jumper W4 to disable. Remove the jumper on

W5, W6, and W3.

External

Control

Jumper W1, Jumper W2, and Jumper W4 enable the USB

circuitry to control the AD9910. Jumper W3 controls the

EEPROM, used in starting up the USB circuitry. Jumper W5

and Jumper W6 control Signal SDO and Signal SDIO to and

from the AD9910.

Rev. A | Page 3 of 16

�

UG-207

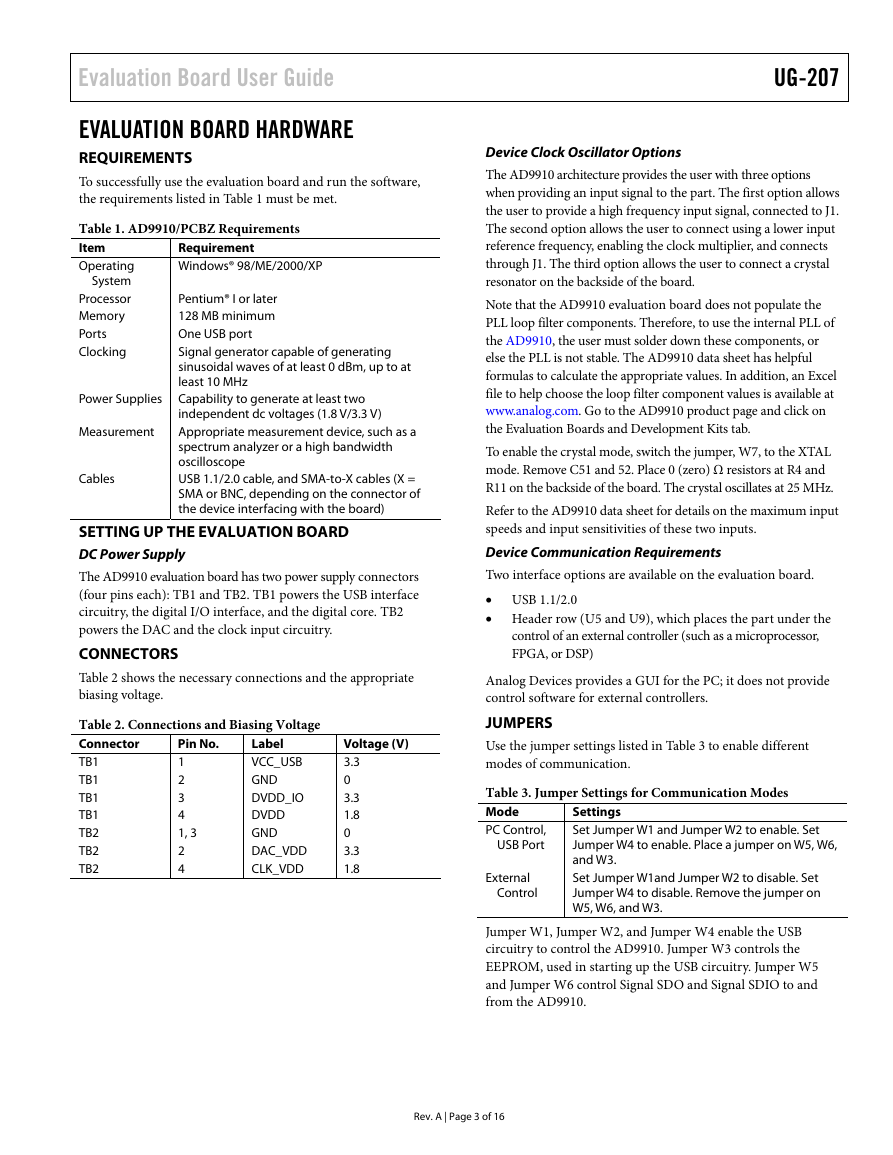

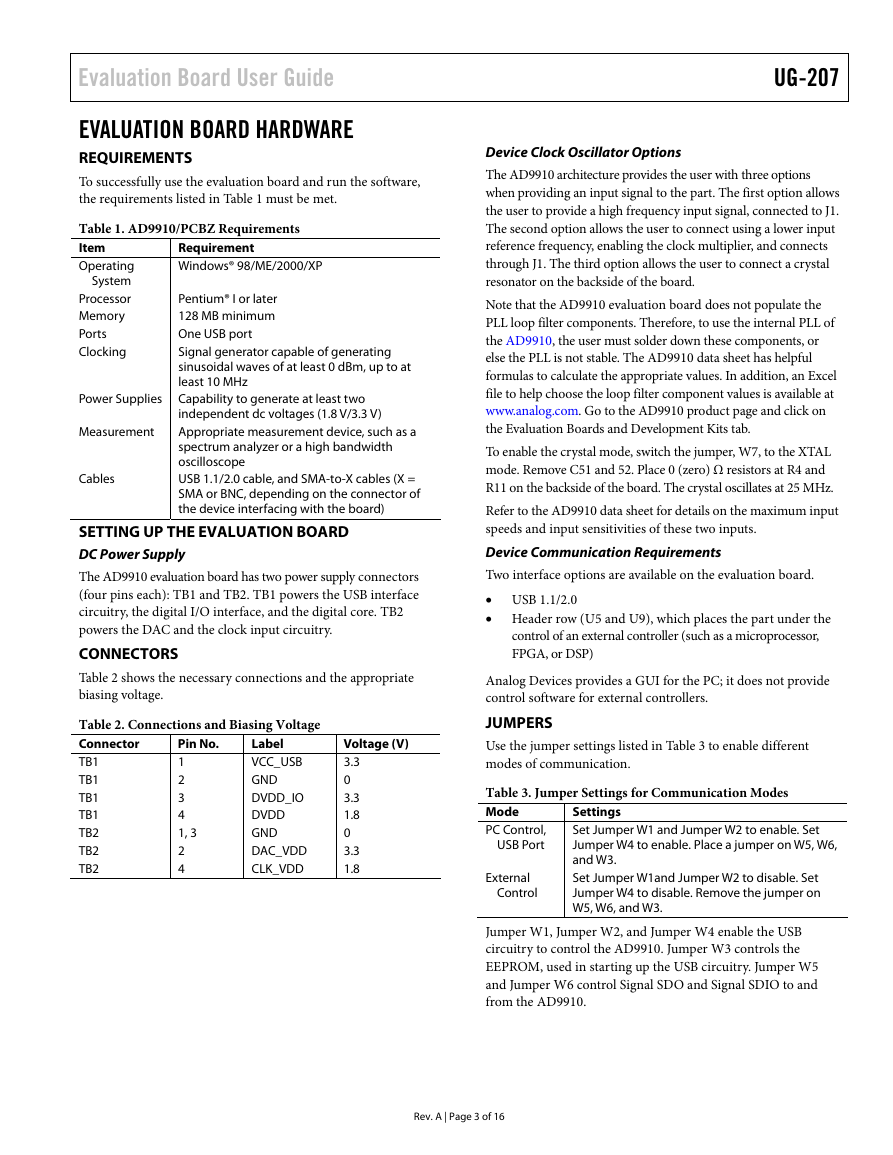

EVALUATION BOARD LAYOUT

Evaluation Board User Guide

STATUS PINS

MANUAL I/O

CONTROL HEADERS

MULTIDEVICE

SYCNHRONOUS CONTROL

CLOCK MODE

SELECT

REF

CLOCK

INPUT

DAC

OUTPUT

2

0

0

-

1

8

4

7

0

USB PORT

POWER SUPPLY

CONNECTIONS

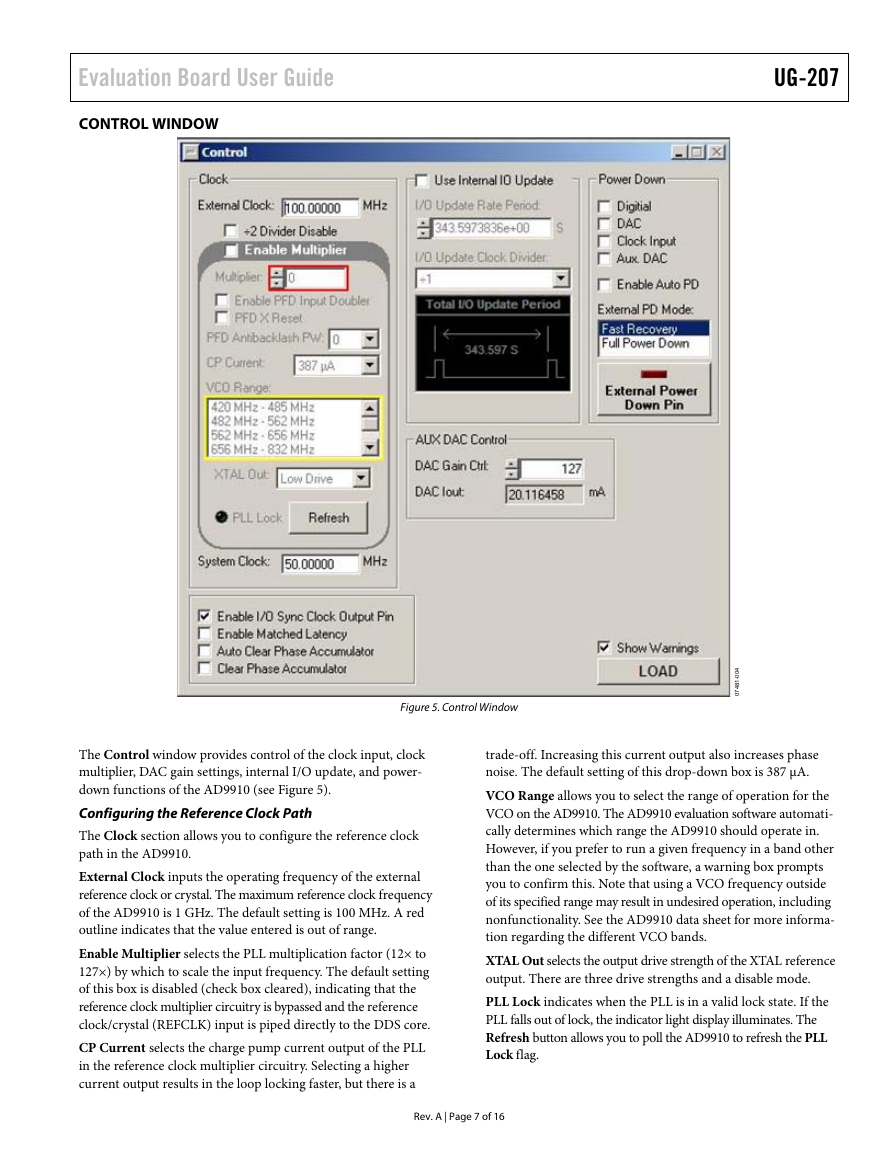

Figure 2. AD9910 PCB Evaluation Board

Manual I/O Control Headers

These pins provide the communication interface for the

AD9910 when the part is under the command of an external

controller (see Table 3 for correct jumper settings).

Multidevice Synchronous Control

These connections set up the AD9910 for multidevice

synchronous operation.

DAC Output

These connections represent the filtered or unfiltered (default)

output of the DAC.

Clock Mode Select

This connection controls whether the reference clock source is a

20 MHz to 30 MHz crystal, or is from an external signal generator.

A 25 MHz crystal is provided on the underside of the AD9910

evaluation board.

Ref Clock Input

This is the input for the external reference clock signal.

Power Supply Connections

These two connectors, TB1 and TB2, provide all necessary

supply voltages needed by the AD9910 and the evaluation board

(see Table 2).

USB Port

When the part is under PC control (default mode), the evaluation

board communicates with the AD9910 via this port.

Rev. A | Page 4 of 16

�

Evaluation Board User Guide

EVALUATION BOARD SOFTWARE

INSTALLING THE SOFTWARE

Follow these steps to install the AD9910 evaluation software:

1. Log into your PC system with administrative privileges.

2. Uninstall any previous versions of the AD9910 evaluation

3.

software from your PC system.

Insert the AD9910 evaluation software CD into your

CD-ROM drive. Do not connect the AD9910 evaluation

board to the computer until the AD9910 evaluation

software has been successfully installed. Refer to the

Readme.txt file located in the Software folder before

proceeding with the installation of the AD9910 evaluation

software.

4. Run the setup.exe file located in the Software folder and

follow the AD9910 evaluation software onscreen

installation instructions.

INSTALLING THE DRIVER

Once the software is successfully installed onto your PC, the

next step is to interface the AD9910 evaluation software to the

AD9910 evaluation board via the USB Port (see Figure 2).

In order for the evaluation board and software to communicate

properly, drivers must be loaded onto your PC system. The

following instructions explain how to install these drivers on

your PC system.

Windows 98/ME/2000 Users

1. Power up the AD9910 evaluation board (see Table 2).

2. Connect the evaluation board to the computer using a USB

cable via the USB port. Then, the VBUS LED (CR1 on the

AD9910 evaluation board) illuminates. When the USB

cable is connected, the Found New Hardware Wizard

window appears.

If you are using Windows 2000, click Finish in the Found

New Hardware Wizard.

3.

After the window has disappeared, the USB Status LED (CR2

on the AD9910 evaluation board) flashes, which indicates that

the evaluation board is connected properly.

UG-207

Windows XP Users

1. Power up the AD9910 evaluation board (see Table 2).

2. Connect the evaluation board to the computer via the USB

port using a USB cable. Then, the VBUS LED (CR1 on the

AD9910 evaluation board) illuminates.

3. When the USB cable is connected, the Found New

Hardware Wizard appears. Click Next to continue to the

AD9910 Firmware Loader.

4. Click Continue Anyway when the Hardware Installation

Warning window appears.

5. Click Finish in the Found New Hardware Wizard when

installation is complete.

6. Click Next when the next Found New Hardware Wizard

appears. This is for the EZSSP device.

7. Click Continue Anyway when the Hardware Installation

Warning window appears.

8. Click Finish in the Found New Hardware Wizard when

installation is complete.

Once the Found New Hardware Wizard window disappears,

the USB status LED (CR2 on the AD9910 evaluation board)

flashes, which indicates that the evaluation board is connected

properly. If the LED does not flash, verify that all power and USB

connections are properly connected.

LAUNCHING THE PROGRAM

Follow these three steps to load the AD9910 evaluation

software:

1. Before starting the software, make sure that the AD9910

evaluation board is powered up, connected to the computer,

and that the USB status LED is flashing.

2. Click the Start button, located at the bottom left-hand

corner of your screen.

3. Select Programs, then the AD9910 Eval Software folder,

and then AD9910 Eval Software to load the software.

One of several status messages appears. These messages are

discussed in further detail in the next section, Status Messages

Upon Loading Software.

Rev. A | Page 5 of 16

�

UG-207

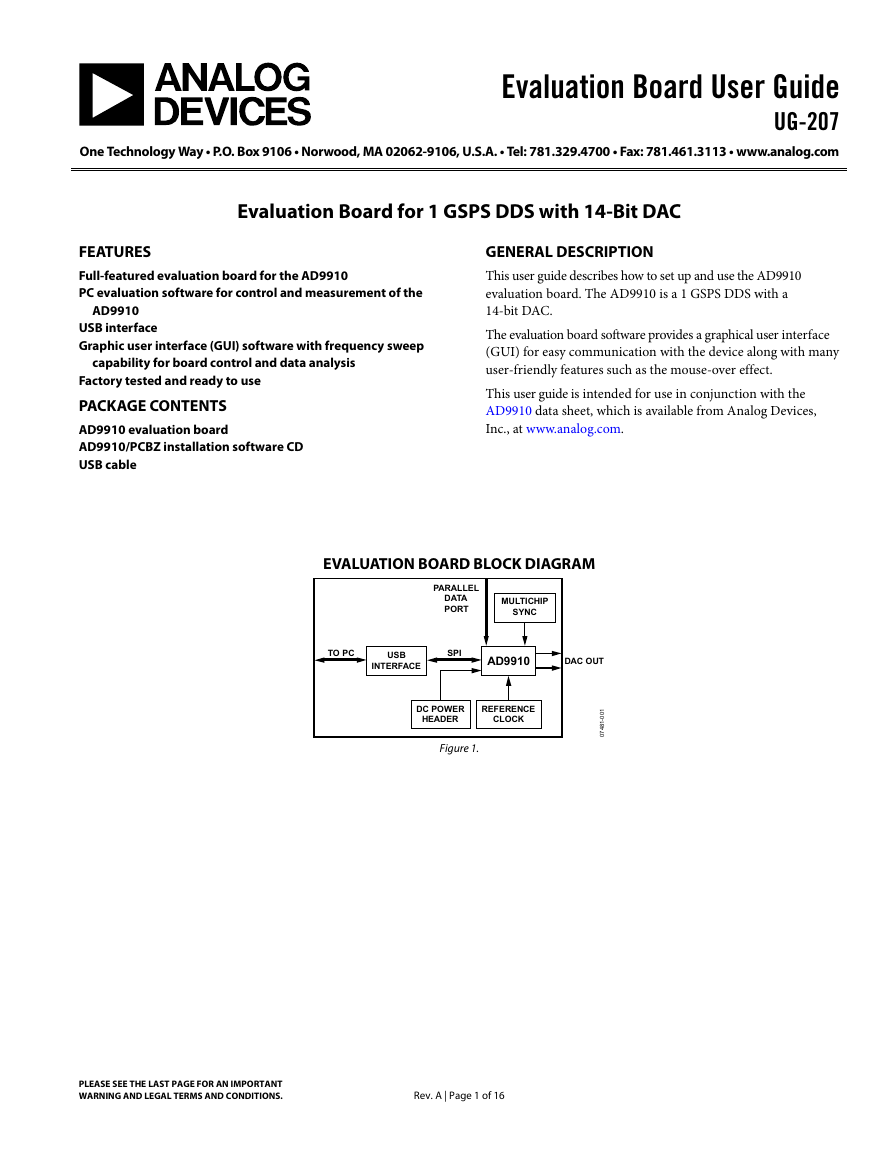

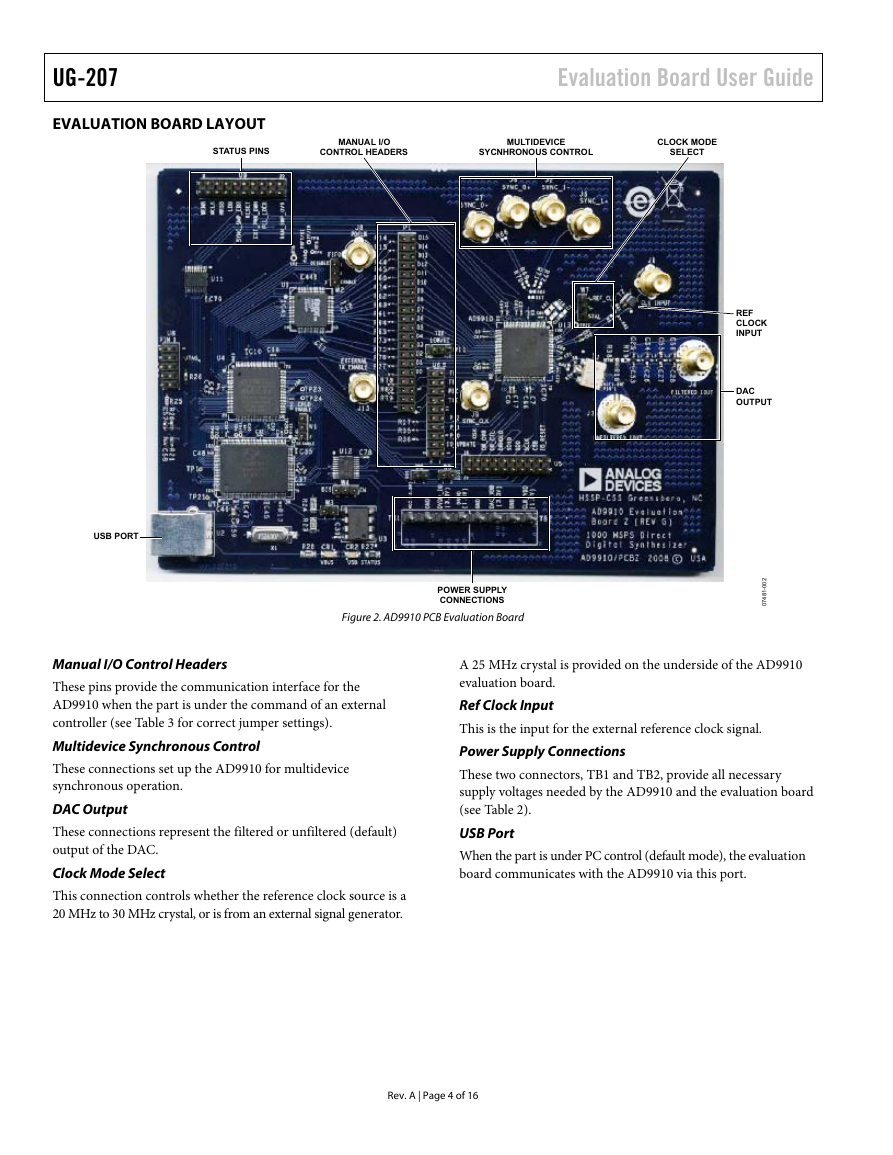

Status Messages Upon Loading Software

Once the AD9910 evaluation software is loaded, a green splash

window appears. The status box within the splash window displays

the status of the AD9910 evaluation software. Green writing in

the status box indicates that the software has successfully loaded.

A successful load is followed by the status box disappearing.

A splash window with red writing in the status box indicates that

an error occurred. You can move the pointer over the red

writing, which allows you to scroll up and view the details and

possible cause of the error (see Figure 3).

Most status message errors can be resolved by checking jumper

settings, making sure that the evaluation board is powered up

correctly, and inspecting the USB port and cable connections.

When all power, USB port/cable connections, and jumper

settings are correct, an error may still appear if the clock input

Evaluation Board User Guide

is not properly configured. If any modifications to the board

were made, check the changes against the provided evaluation

board schematics for the AD9910. Check to make sure that the

clock input source is connected and properly configured.

Figure 3. Splash Window Error Status Box

6

1

0

-

1

8

4

7

0

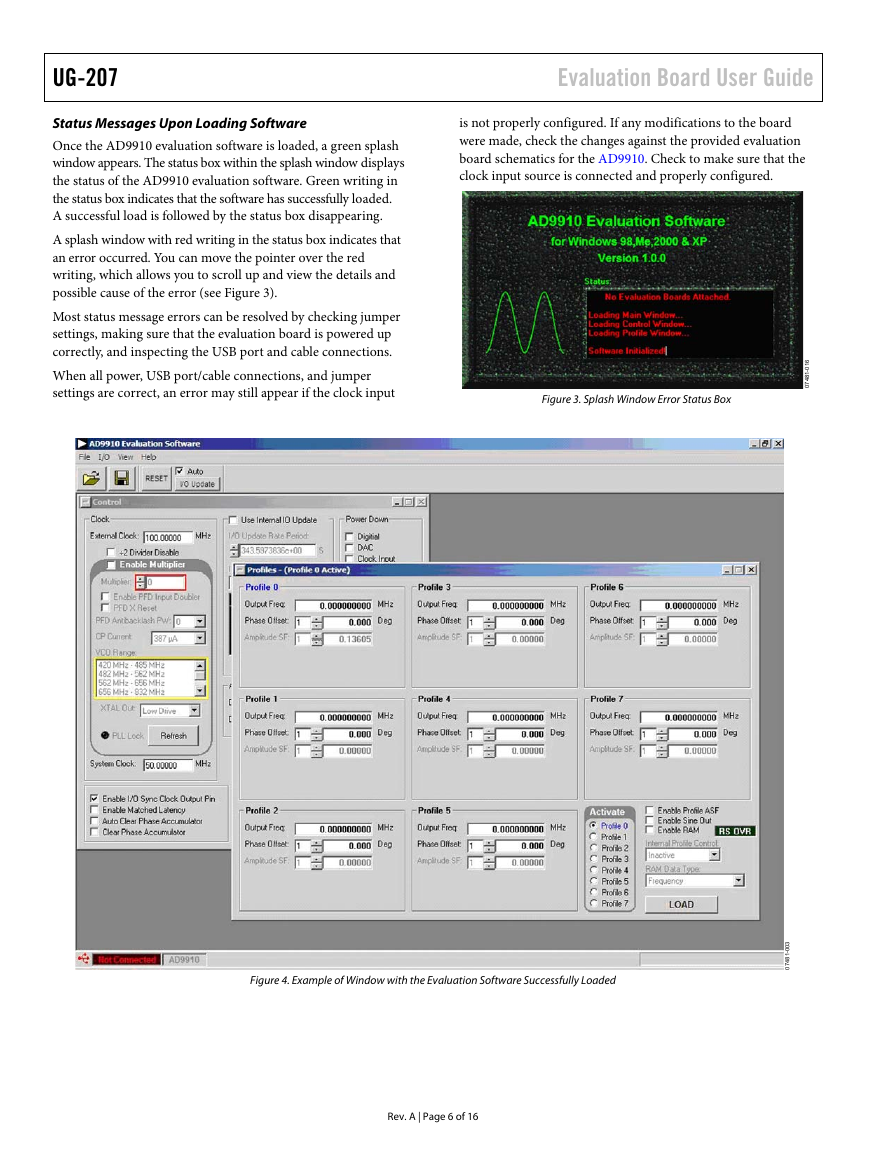

Figure 4. Example of Window with the Evaluation Software Successfully Loaded

3

0

0

-

1

8

4

7

0

Rev. A | Page 6 of 16

�

Evaluation Board User Guide

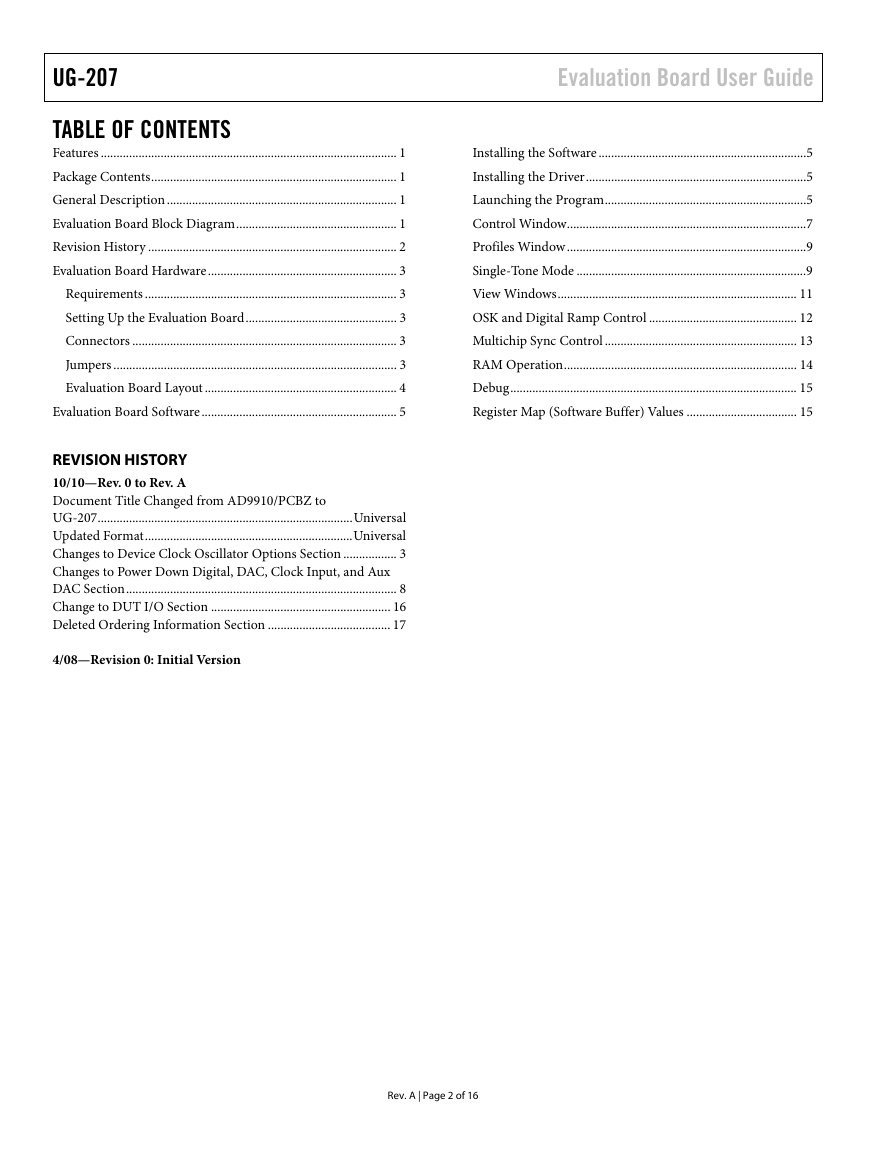

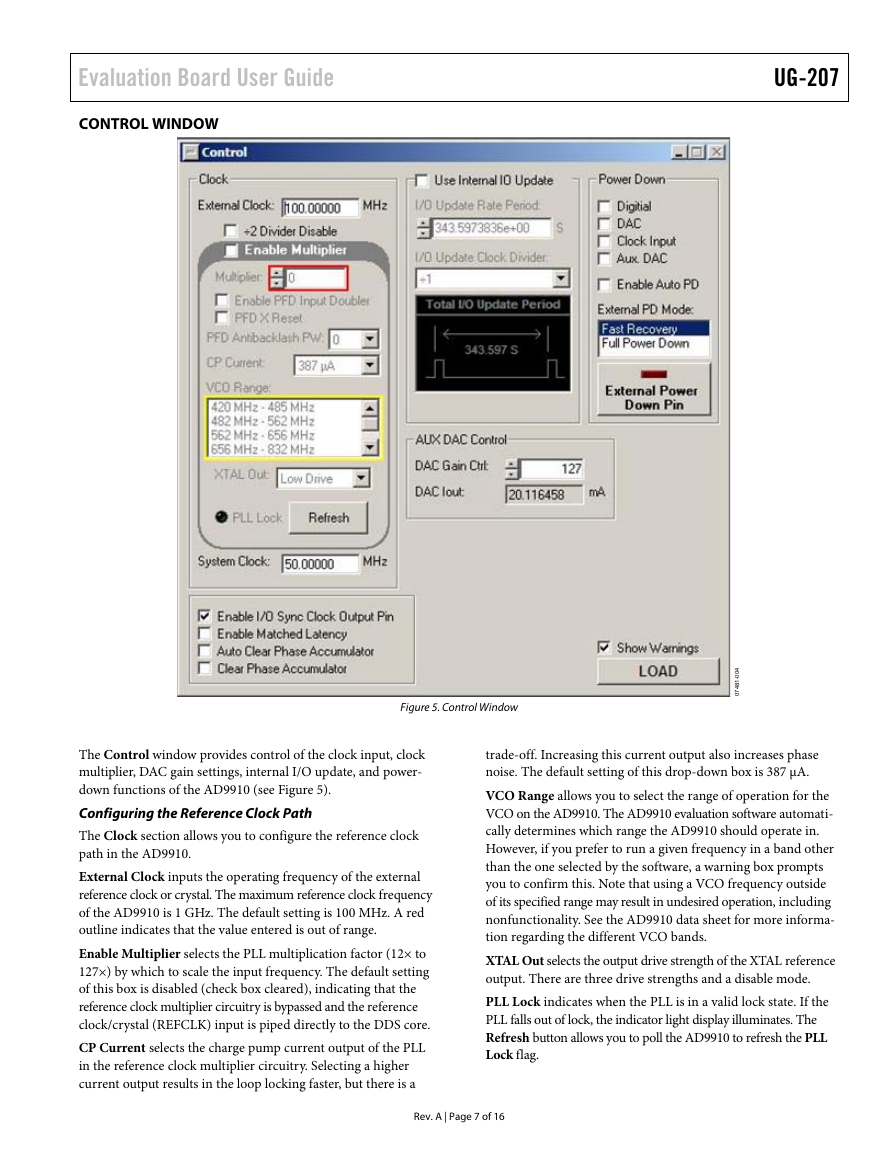

CONTROL WINDOW

UG-207

Figure 5. Control Window

4

0

0

-

1

8

4

7

0

The Control window provides control of the clock input, clock

multiplier, DAC gain settings, internal I/O update, and power-

down functions of the AD9910 (see Figure 5).

Configuring the Reference Clock Path

The Clock section allows you to configure the reference clock

path in the AD9910.

External Clock inputs the operating frequency of the external

reference clock or crystal. The maximum reference clock frequency

of the AD9910 is 1 GHz. The default setting is 100 MHz. A red

outline indicates that the value entered is out of range.

Enable Multiplier selects the PLL multiplication factor (12× to

127×) by which to scale the input frequency. The default setting

of this box is disabled (check box cleared), indicating that the

reference clock multiplier circuitry is bypassed and the reference

clock/crystal (REFCLK) input is piped directly to the DDS core.

CP Current selects the charge pump current output of the PLL

in the reference clock multiplier circuitry. Selecting a higher

current output results in the loop locking faster, but there is a

trade-off. Increasing this current output also increases phase

noise. The default setting of this drop-down box is 387 μA.

VCO Range allows you to select the range of operation for the

VCO on the AD9910. The AD9910 evaluation software automati-

cally determines which range the AD9910 should operate in.

However, if you prefer to run a given frequency in a band other

than the one selected by the software, a warning box prompts

you to confirm this. Note that using a VCO frequency outside

of its specified range may result in undesired operation, including

nonfunctionality. See the AD9910 data sheet for more informa-

tion regarding the different VCO bands.

XTAL Out selects the output drive strength of the XTAL reference

output. There are three drive strengths and a disable mode.

PLL Lock indicates when the PLL is in a valid lock state. If the

PLL falls out of lock, the indicator light display illuminates. The

Refresh button allows you to poll the AD9910 to refresh the PLL

Lock flag.

Rev. A | Page 7 of 16

�

UG-207

System Clock displays the operating frequency the DDS core

(system). The value shown is derived from the values entered in

the External Clock text box and the Multiplier spin box.

Refer to the AD9910 data sheet for more information regarding

clock modes and operation.

Setting the I/O Update Options

Use Internal IO Update sets the I/O update pin to an output.

This output generates an active high pulse when the internal

I/O update occurs. The rate of the internal I/O update can be

programmed through the serial port. Refer to the AD9910 data

sheet for more information.

Power Down Digital, DAC, Clock Input, and Aux DAC

These power-down controls allows you to power down each of

the specific circuit blocks individually.

External PD Mode allows you to control which power-down

mode is used in conjunction with the External Power Down

Pin button. The Fast Recovery mode sets the AD9910 into a

power-down state that keeps clocks running and bias circuits

active, but does not allow the part to output data. This mode

uses significantly more power than the Full Power Down

mode. The Full Power Down mode stops clocks and powers

down bias circuits. This mode takes significantly longer to

power back up from a power-down state.

The External Power Down Pin button allows you to control the

EXT_PWR_DWN (external power-down) pin without having

to alter the evaluation board. See the AD9910 data sheet for

more information about power down conditions.

AUX DAC Control

DAC Gain Ctrl controls the auxiliary DAC setting to select the

full-scale output current of the DAC. See the AD9910 data sheet

for more information about DAC gain setting.

DAC Iout displays the full-scale output current of the DAC.

This number is based on a DAC_RSET resistor value of 10 kΩ.

Evaluation Board User Guide

Setting Other Control Window Options

Enable I/O Sync Clock Output Pin allows you to enable or

disable the output driver for the I/O sync clock output.

Enable Matched Latency allows you to align the application of

the frequency tuning word, the phase offset word, and the

amplitude scale factor at the same time. If this bit is cleared,

then those words are not applied simultaneously.

Auto Clear Phase Accumulator sets the DDS phase accumulator

to a reset state when the I/O update pin is set high or when a

profile changes.

Clear Phase Accumulator holds the DDS phase accumulator in

a reset state as long as this bit (Bit 11) is set.

The Show Warnings check box can be cleared to have the

AD9910 evaluation board software suppress any warnings

about the operation of the AD9910. For example, a warning

appears if you try to program the VCO or PLL to a state that is

not recommended in the AD9910 data sheet.

Loading Data

The LOAD button is used to send data to the AD9910. All

LOAD buttons found in the evaluation software have the same

functionality.

When new data is detected, LOAD flashes orange, indicating

that you need to click LOAD to send the updates to the serial

I/O buffer where they are stored until an I/O update is issued.

The I/O update sends the contents of the serial I/O buffer to

active registers.

I/O updates can be sent manually or automatically. By default,

the AD9910 evaluation software is set to auto-I/O update, so

that when LOAD is clicked, an I/O update signal is automati-

cally sent to the device. If synchronization across channels is

desired, clear the Auto check box on the toolbar and click the

I/O Update button (see Figure 4) when you wish to send an

I/O update.

The Show Warnings check box, located above LOAD, can be

selected to display warnings when you have entered data that

exceeds the specifications of the AD9910.

Rev. A | Page 8 of 16

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc