FPGA Realization of a High-performance

Servo Controller for PMSM

Zhaoyong Zhou and Tiecai Li

Department of Electrical Engineering

Harbin Institute of Technology

Harbin, China

E-mail: zhouzy@hit.edu.cn

Abstract—This paper proposes a fully digitized hardware design

scheme of a vector-controlled servo controller, which is verified

and implemented on one-chip field programmable gate arrays

(FPGA), for high-performance servo drives of the permanent

magnet synchronous motor (PMSM). This scheme integrates the

vector control strategy, the M/T speed measurement algorithm,

the PI regulating technique and the SVPWM principle as well as

the EDA design methodology, and it will be a good substitute for

traditional PMSM drives practice. The realized control IC also

contains a standard host communication interface, which enables

the on-line configuration for all kinds of control parameters. The

actual sample frequencies of the torque loop and the speed loop

are limited by the selected FPGA; with respect to the Altera

FPGA prototype mentioned in this paper, the two loops can

respectively obtain a sample frequency of 40kHz and 20kHz as

well as a bandwidth of 5kHz and 400Hz. Experimental results

indicate that the controller can provide a controllable speed

range from 0.2 RPM to 10,000 RPM with satisfactory dynamic

and static performances.

Keywords-vector control; servo; FPGA; PMSM

I.

INTRODUCTION

High performance AC servo drive depends on the well

control of the currents; however, the strong coupling and

nonlinear natures of the AC motors make it impossible to

directly control the stator currents to obtain the desired

performances as the behavior of DC motors. Hence, a specific

algorithm must be introduced to realize the decoupling of

relevant variables. Fortunately this problem has been resolved

by the vector control technology. The principle of vector

control, often referred to as field-oriented-control, was first

proposed by F. Blaschke of Siemens in the early 1970s for

controlling induction motors, and after several years of efforts

this method had been developed into a complete theory system

[1], [2]. In the latest twenty years, the vector control

technology has been used wider and wider in high performance

AC drives due to the rapid progress in power electronics,

computer and microelectronics.

In engineering practice, because of the complexity of

servo control algorithm, it is basically implemented with

software based on DSP [3]; this approach can provide a

flexible skill, but suffers from a long period of development

and exhausts many resources of the CPU. In some cases, dual

DSPs have to be adopted to achieve superior performances [4].

Toshio Takahashi and Eddy Ho

Digital Control IC Design Center

International Rectifier

California, USA

E-mail: ttakaha1@irf.com

technology

implementation

In recent years, a novel design methodology has arisen, that is

FPGA-based hardware

[5].

Compared with ASIC, FPGA is only a collection of standard

cells, which have none of specific functions, but owing to its

field programmable characteristics and reuse of the IP cores,

user can design his own ASIC according to their schemes with

professional placement and routing tools in a shortest time,

instead of participation of the semiconductor manufacturers. In

addition, since FPGA can carry out parallel processing by

means of hardware mode, which occupies nothing of the CPU,

the system can get a very high speed level as well as an

exciting precision. This new design methodology has been

used in high performance motion control field, such as [6]-[8],

which realize different current controller. In [6], the designed

digital current controller integrates both nonlinear ∆ modulator

and linear PI regulator and can obtain a very high bandwidth.

Literature [7] provides a co-processor scheme based on the

indirect vector control with current feed forward, and literature

[8] proposes a digital hardware implementation where it can

operate under different instructions. All these digital current

controllers have achieved very high performances, however, it

is obvious that these schemes have a common property that the

current is considered as a co-processor and the speed or

position control is implemented by DSP. As known to all,

position control is very flexible and difficult to generalize, but

the speed control is universal just as the current control, and

high performance speed control can be impossible without the

current control. Thus, it is necessary to integrate the speed and

the current into a single chip, which can be separately used as a

speed controller or a current controller; furthermore, the two

controllers can also be incorporated into a position control

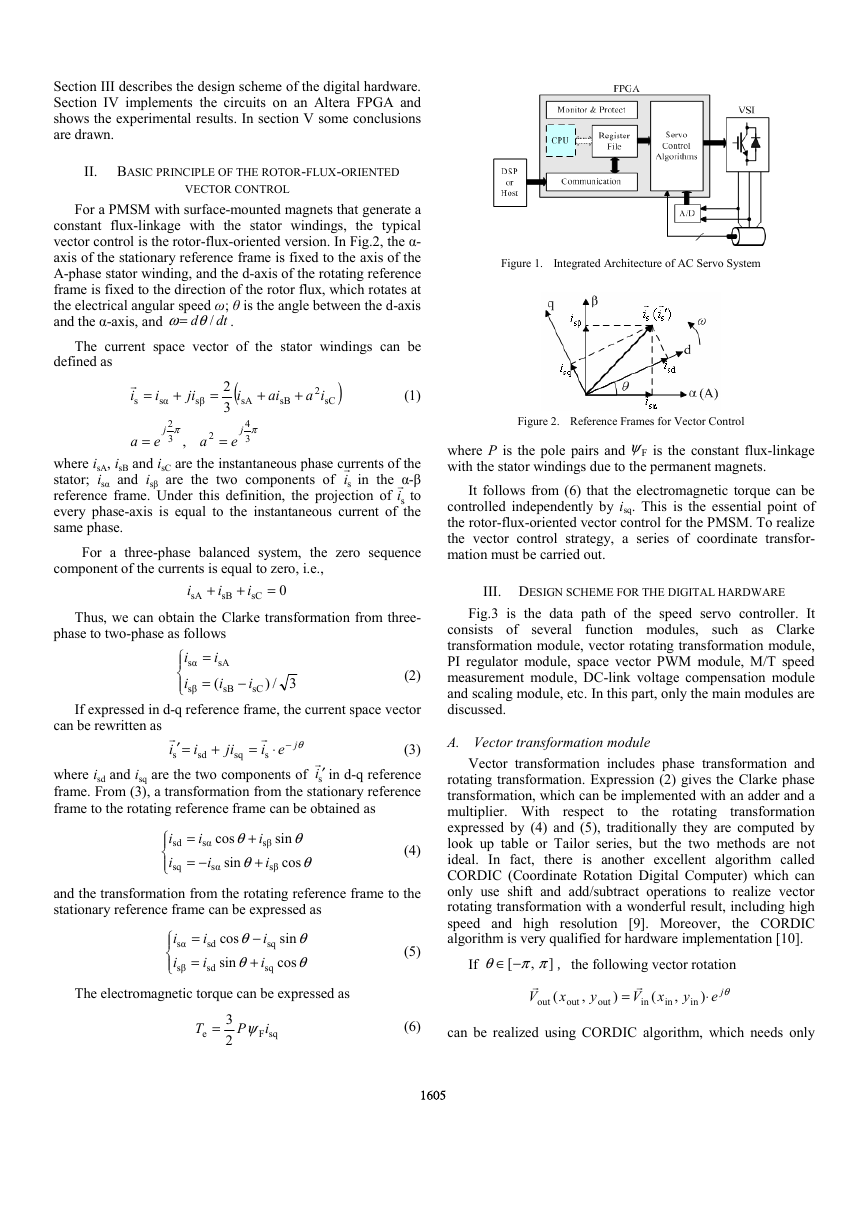

system, as shown in Fig.1. If the FPGA has integrated CPU,

the position, speed and current control can be all implemented

with only one single chip, which will lead to a real SOC

(system on a chip), the important trend of high performance

motion control integration design.

This paper studies

the current vector control, PI

regulation, feed back speed measurement and space vector

PWM, and presents their digital structures. These algorithms

are designed in International Rectifier iMOTION products such

as the IRMCK201/IRMCK202 digital control ICs, and being

applied to the real industry application. In detail, it is organized

as follows. In section II, vector control principle of the PMSM

is briefly reviewed and the relevant expressions are derived.

0-7803-8269-2/04/$17.00 (C) 2004 IEEE.

1604

�

Section III describes the design scheme of the digital hardware.

Section IV implements the circuits on an Altera FPGA and

shows the experimental results. In section V some conclusions

are drawn.

II. BASIC PRINCIPLE OF THE ROTOR-FLUX-ORIENTED

VECTOR CONTROL

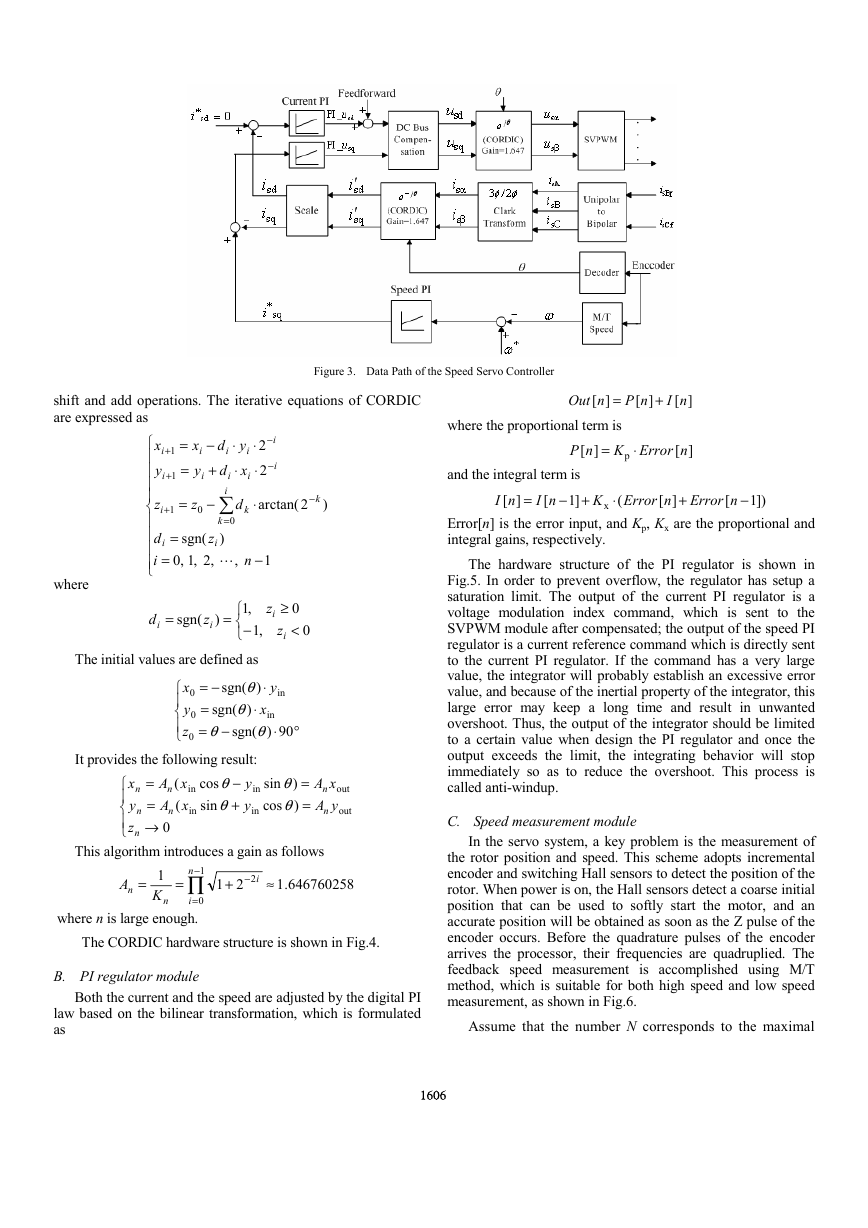

For a PMSM with surface-mounted magnets that generate a

constant flux-linkage with the stator windings, the typical

vector control is the rotor-flux-oriented version. In Fig.2, the α-

axis of the stationary reference frame is fixed to the axis of the

A-phase stator winding, and the d-axis of the rotating reference

frame is fixed to the direction of the rotor flux, which rotates at

the electrical angular speed ω; θ is the angle between the d-axis

and the α-axis, and .

d /θω=

dt

The current space vector of the stator windings can be

defined as

=r

i

s

i

sα

+

ji

sβ

=

+

ai

sB

+

2

ia

sC

sA

)

(

i

2

3

(1)

j

2

3

π

,

a

=

e

π

j

4

3

2

a

=

e

where isA, isB and isC are the instantaneous phase currents of the

stator; isα and isβ are the two components of in the α-β

reference frame. Under this definition, the projection of to

every phase-axis is equal to the instantaneous current of the

same phase.

sir

sir

For a three-phase balanced system, the zero sequence

component of the currents is equal to zero, i.e.,

Thus, we can obtain the Clarke transformation from three-

i

sA

+

i

sB

+

i

sC

=

0

phase to two-phase as follows

i

sα

i

sβ

=

=

i

sA

i

(

sB

−

i

sC

3/)

(2)

If expressed in d-q reference frame, the current space vector

can be rewritten as

+

r

=′

i

s

ji

i

sd

(3)

where isd and isq are the two components of in d-q reference

frame. From (3), a transformation from the stationary reference

frame to the rotating reference frame can be obtained as

si ′r

sq

−⋅=

r

θjei

s

i

sd

i

sq

=

i

sα

−=

i

sα

θ

+

i

cos

sβ

θ

+

i

sin

sβ

θ

sin

(4)

θ

cos

and the transformation from the rotating reference frame to the

stationary reference frame can be expressed as

i

sα

i

sβ

=

=

i

sd

i

sd

cos

sin

θ

−

i

sq

θ

+

i

sq

sin

cos

θ

(5)

θ

The electromagnetic torque can be expressed as

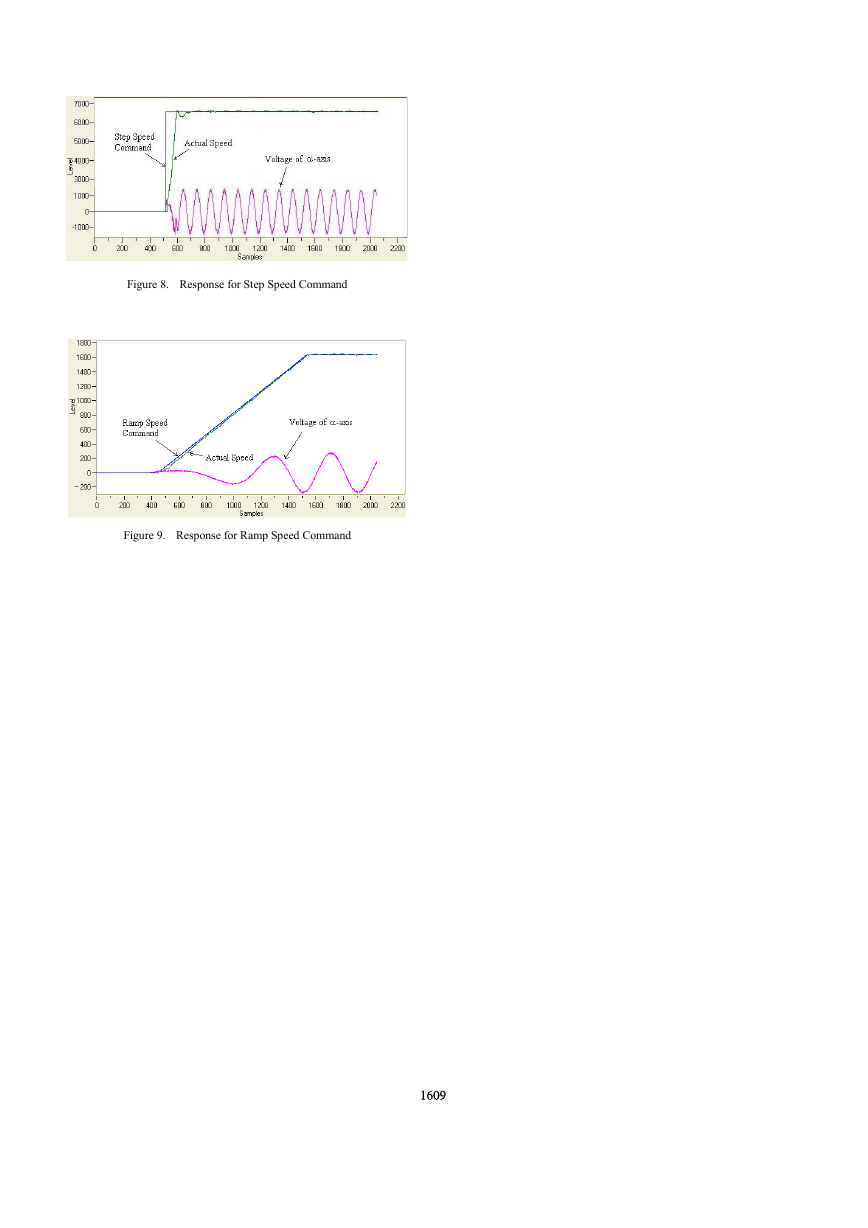

Figure 1. Integrated Architecture of AC Servo System

Figure 2. Reference Frames for Vector Control

where P is the pole pairs and is the constant flux-linkage

with the stator windings due to the permanent magnets.

Fψ

It follows from (6) that the electromagnetic torque can be

controlled independently by isq. This is the essential point of

the rotor-flux-oriented vector control for the PMSM. To realize

the vector control strategy, a series of coordinate transfor-

mation must be carried out.

III. DESIGN SCHEME FOR THE DIGITAL HARDWARE

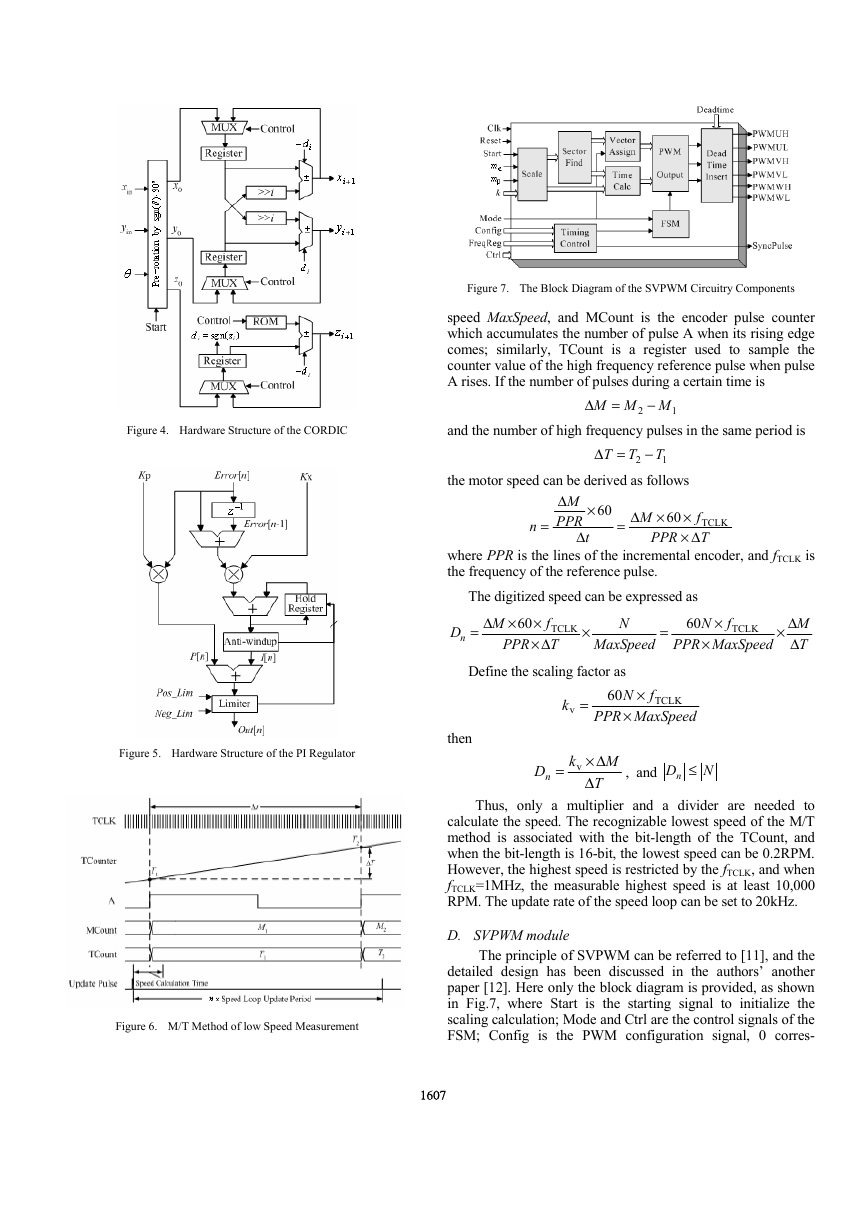

Fig.3 is the data path of the speed servo controller. It

consists of several function modules, such as Clarke

transformation module, vector rotating transformation module,

PI regulator module, space vector PWM module, M/T speed

measurement module, DC-link voltage compensation module

and scaling module, etc. In this part, only the main modules are

discussed.

A. Vector transformation module

to

the rotating

Vector transformation includes phase transformation and

rotating transformation. Expression (2) gives the Clarke phase

transformation, which can be implemented with an adder and a

multiplier. With respect

transformation

expressed by (4) and (5), traditionally they are computed by

look up table or Tailor series, but the two methods are not

ideal. In fact, there is another excellent algorithm called

CORDIC (Coordinate Rotation Digital Computer) which can

only use shift and add/subtract operations to realize vector

rotating transformation with a wonderful result, including high

speed and high resolution [9]. Moreover, the CORDIC

algorithm is very qualified for hardware implementation [10].

,

[ ππθ −∈

]

If ,the following vector rotation

θje

=

r

xV

(

in

r

V

out

out

out

y

y

⋅

)

(

x

in

,

in

)

,

T

e

ψ=

P

i

sqF

3

2

(6)

can be realized using CORDIC algorithm, which needs only

1605

�

Figure 3. Data Path of the Speed Servo Controller

+

nI

][

nP

][

⋅

Error

n

][

nOut

][

=

where the proportional term is

K

nP

][

and the integral term is

+−

]1

nI

][

nI

[

K

=

=

p

−

+

1

=

=

x

i

y

x

i

y

−

+

shift and add operations. The iterative equations of CORDIC

are expressed as

d

i

⋅

d

y

i

i

⋅

xd

i

i

∑

d

=

k

0

)

,

+

1

=

z

sgn(

,2,1,0

arctan(

−

k

)2

2

2

i

=

L

⋅

⋅

+

1

−

−

=

n

1

z

z

−

⋅

0

k

i

i

i

i

i

i

i

where

=

d

i

sgn(

z

)

i

=

z

i

≥

z

i

0

<

0

,1

,1

−

in

y

x

0

y

z

−=

=

sgn(

θ

−=

The initial values are defined as

θ

⋅

sgn(

)

θ

⋅

x

)

in

θ

⋅

90)

sgn(

It provides the following result:

y

y

sin

cos

cos

sin

in

0

0

in

x

n

y

z

n

n

=

=

→

xA

(

n

in

xA

(

n

0

in

−

θ

+

θ

°

θ

)

θ

)

=

=

xA

n

yA

n

out

out

This algorithm introduces a gain as follows

n

∏−

=

0

where n is large enough.

1

=

A

n K

=

n

i

1

+

21

−

2 ≈

i

.1

646760258

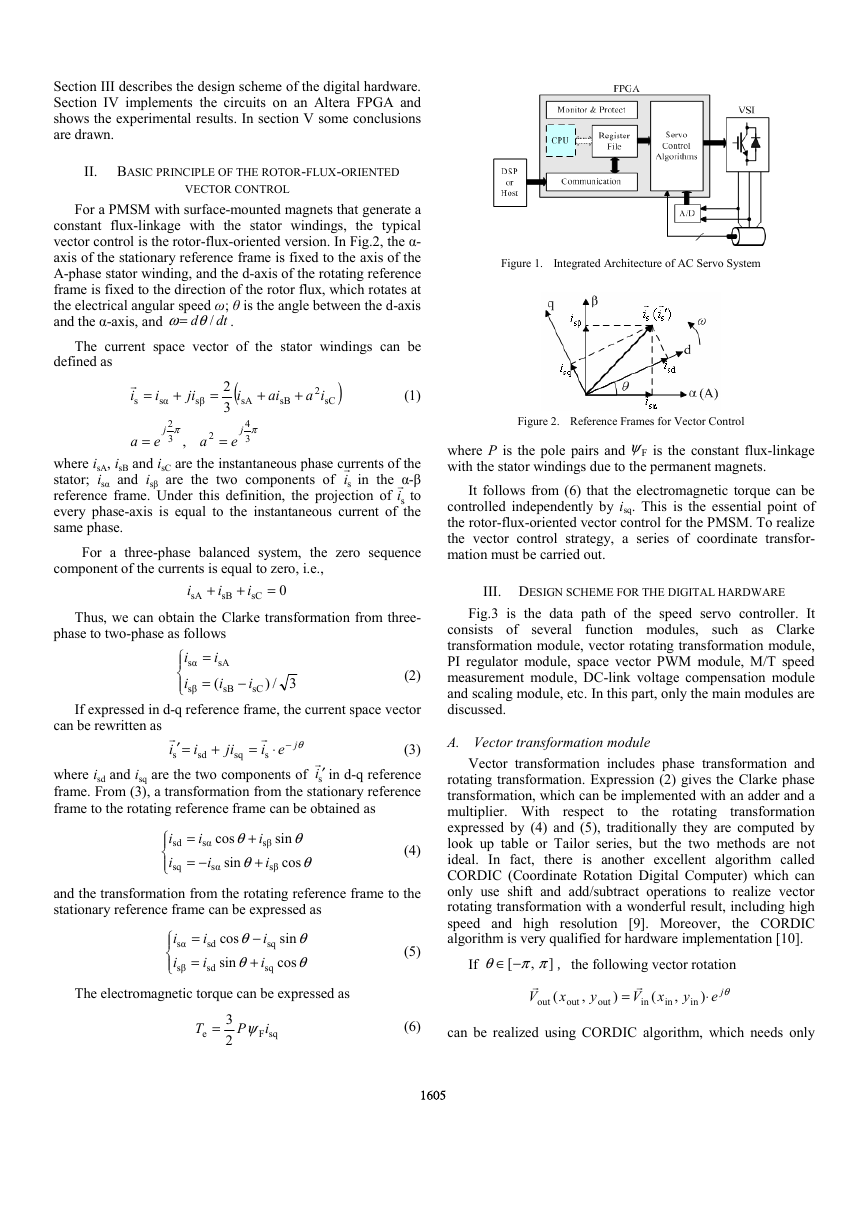

The CORDIC hardware structure is shown in Fig.4.

B. PI regulator module

Both the current and the speed are adjusted by the digital PI

law based on the bilinear transformation, which is formulated

as

1606

⋅

x

(

Error

n

][

+

Error

[

n

−

])1

Error[n] is the error input, and Kp, Kx are the proportional and

integral gains, respectively.

The hardware structure of the PI regulator is shown in

Fig.5. In order to prevent overflow, the regulator has setup a

saturation limit. The output of the current PI regulator is a

voltage modulation index command, which is sent to the

SVPWM module after compensated; the output of the speed PI

regulator is a current reference command which is directly sent

to the current PI regulator. If the command has a very large

value, the integrator will probably establish an excessive error

value, and because of the inertial property of the integrator, this

large error may keep a long time and result in unwanted

overshoot. Thus, the output of the integrator should be limited

to a certain value when design the PI regulator and once the

output exceeds the limit, the integrating behavior will stop

immediately so as to reduce the overshoot. This process is

called anti-windup.

C. Speed measurement module

In the servo system, a key problem is the measurement of

the rotor position and speed. This scheme adopts incremental

encoder and switching Hall sensors to detect the position of the

rotor. When power is on, the Hall sensors detect a coarse initial

position that can be used to softly start the motor, and an

accurate position will be obtained as soon as the Z pulse of the

encoder occurs. Before the quadrature pulses of the encoder

arrives the processor, their frequencies are quadruplied. The

feedback speed measurement is accomplished using M/T

method, which is suitable for both high speed and low speed

measurement, as shown in Fig.6.

Assume that the number N corresponds to the maximal

�

Figure 7. The Block Diagram of the SVPWM Circuitry Components

speed MaxSpeed, and MCount is the encoder pulse counter

which accumulates the number of pulse A when its rising edge

comes; similarly, TCount is a register used to sample the

counter value of the high frequency reference pulse when pulse

A rises. If the number of pulses during a certain time is

and the number of high frequency pulses in the same period is

the motor speed can be derived as follows

2 MMM

−

2 T

T

1

=∆

T

∆

−

=

1

=

n

∆

M

PPR

∆

t

×

60

×∆=

M

60

PPR

×

f

TCLK

∆×

T

Figure 4. Hardware Structure of the CORDIC

where PPR is the lines of the incremental encoder, and fTCLK is

the frequency of the reference pulse.

The digitized speed can be expressed as

×∆=

M

60

60

PPR

PPR

×

f

TCLK

∆×

T

MaxSpeed

N

=

×

×

fN

×

MaxSpeed

TCLK

Dn

∆×

M

∆

T

Define the scaling factor as

60

PPR

=

k

v

×

fN

×

MaxSpeed

TCLK

Figure 5. Hardware Structure of the PI Regulator

then

k

= v

Dn

M

∆×

∆

T

, and

Dn ≤

N

Thus, only a multiplier and a divider are needed to

calculate the speed. The recognizable lowest speed of the M/T

method is associated with the bit-length of the TCount, and

when the bit-length is 16-bit, the lowest speed can be 0.2RPM.

However, the highest speed is restricted by the fTCLK, and when

fTCLK=1MHz, the measurable highest speed is at least 10,000

RPM. The update rate of the speed loop can be set to 20kHz.

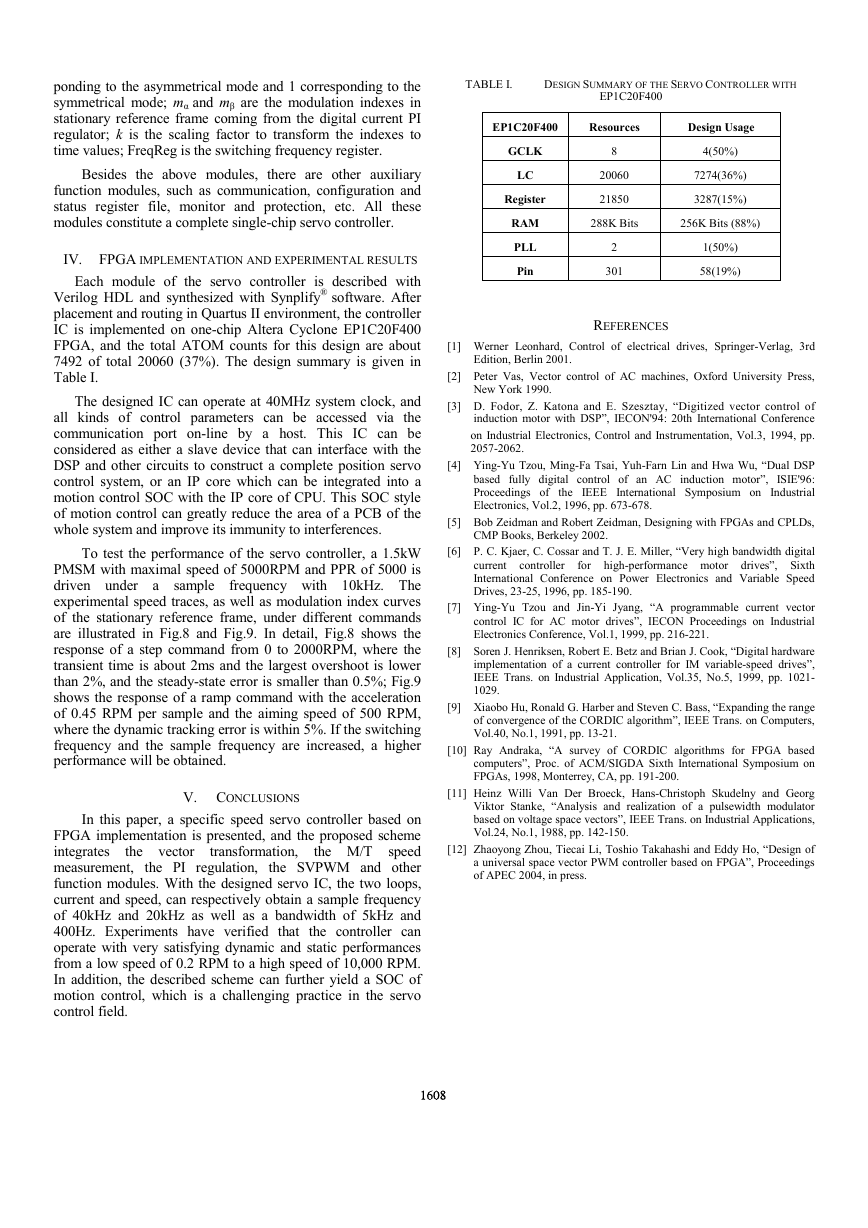

D. SVPWM module

The principle of SVPWM can be referred to [11], and the

detailed design has been discussed in the authors’ another

paper [12]. Here only the block diagram is provided, as shown

in Fig.7, where Start is the starting signal to initialize the

scaling calculation; Mode and Ctrl are the control signals of the

FSM; Config is the PWM configuration signal, 0 corres-

Figure 6. M/T Method of low Speed Measurement

1607

�

ponding to the asymmetrical mode and 1 corresponding to the

symmetrical mode; mα and mβ are the modulation indexes in

stationary reference frame coming from the digital current PI

regulator; k is the scaling factor to transform the indexes to

time values; FreqReg is the switching frequency register.

Besides the above modules, there are other auxiliary

function modules, such as communication, configuration and

status register file, monitor and protection, etc. All these

modules constitute a complete single-chip servo controller.

IV. FPGA IMPLEMENTATION AND EXPERIMENTAL RESULTS

Each module of the servo controller is described with

Verilog HDL and synthesized with Synplify® software. After

placement and routing in Quartus II environment, the controller

IC is implemented on one-chip Altera Cyclone EP1C20F400

FPGA, and the total ATOM counts for this design are about

7492 of total 20060 (37%). The design summary is given in

Table I.

The designed IC can operate at 40MHz system clock, and

all kinds of control parameters can be accessed via the

communication port on-line by a host. This IC can be

considered as either a slave device that can interface with the

DSP and other circuits to construct a complete position servo

control system, or an IP core which can be integrated into a

motion control SOC with the IP core of CPU. This SOC style

of motion control can greatly reduce the area of a PCB of the

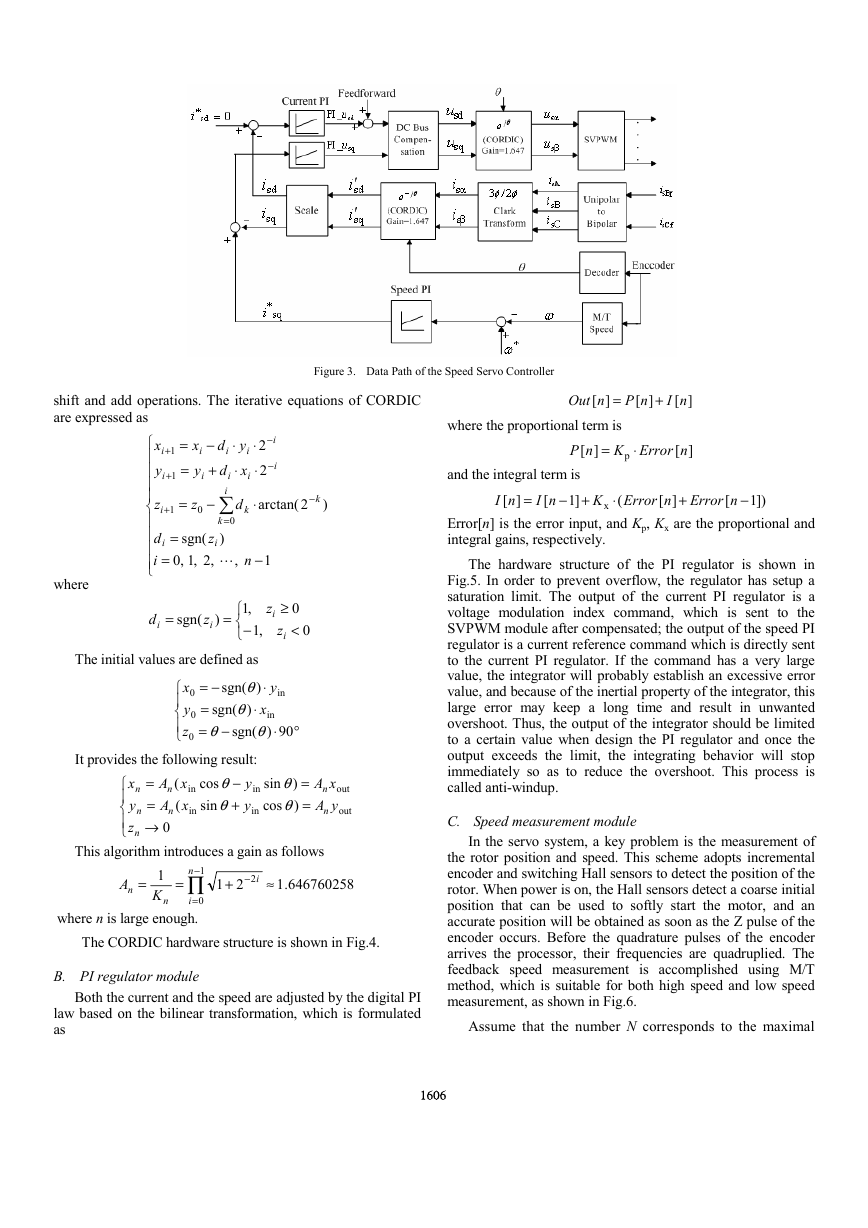

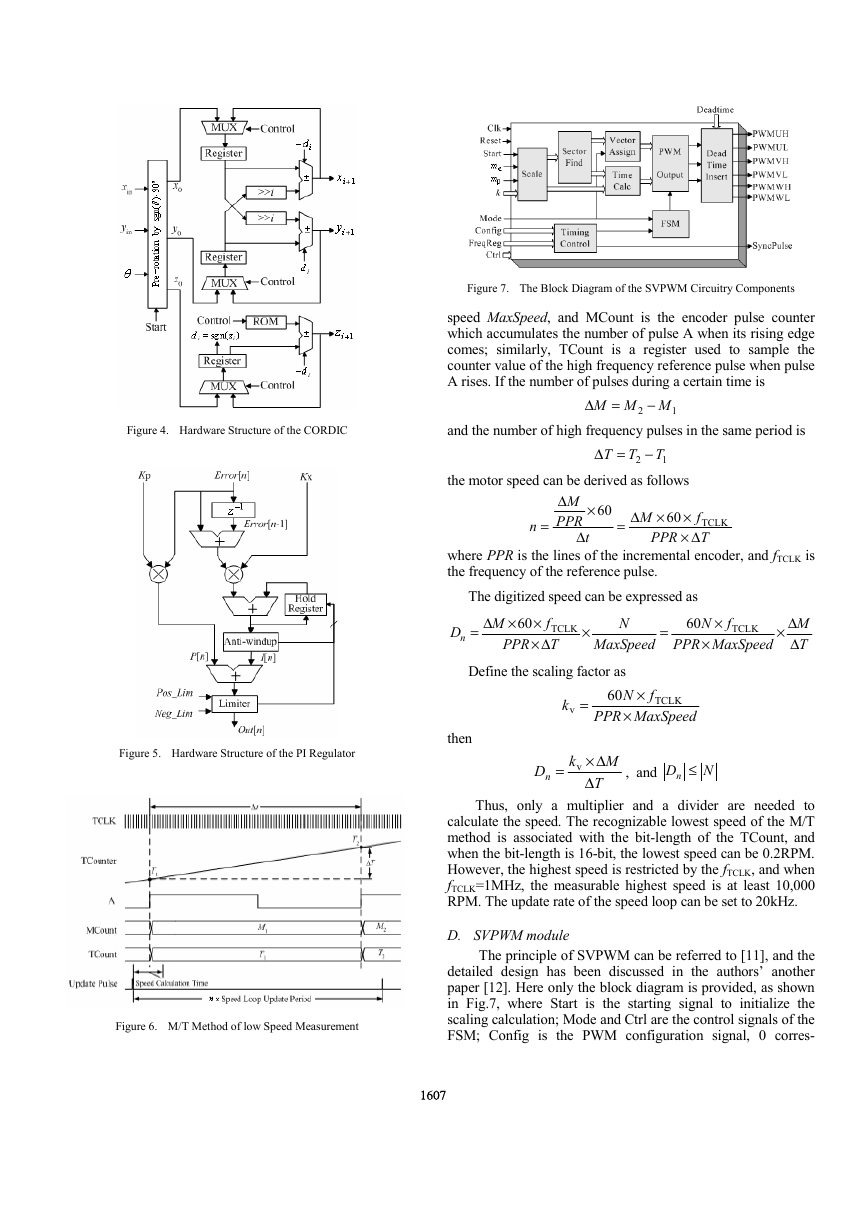

whole system and improve its immunity to interferences.

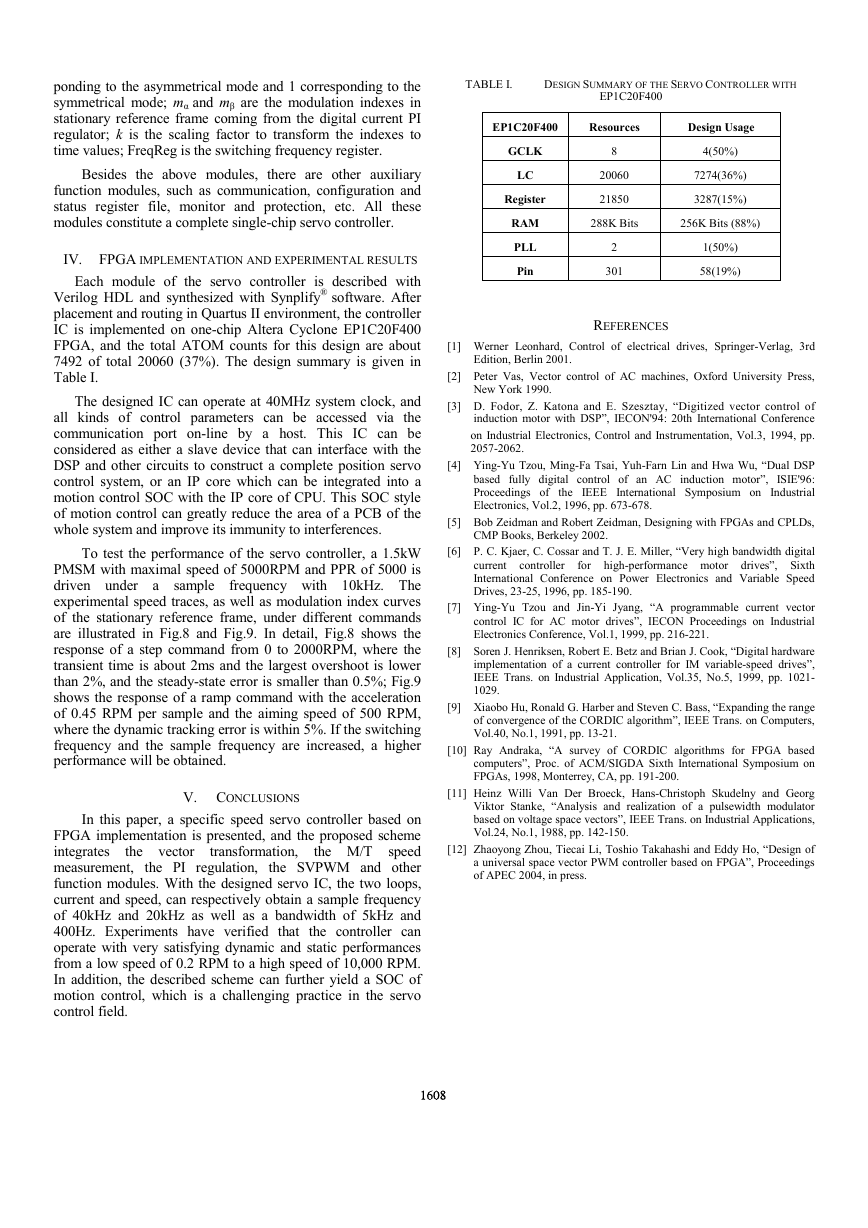

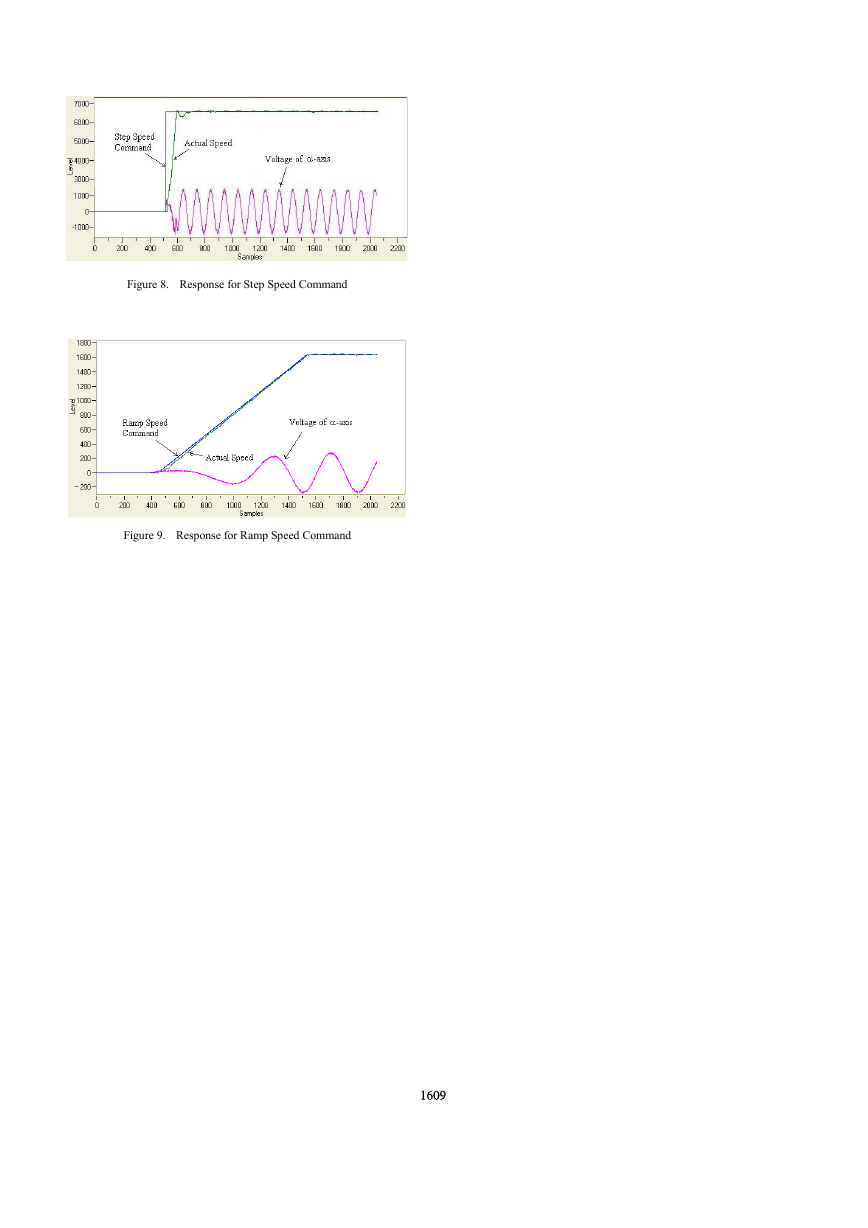

To test the performance of the servo controller, a 1.5kW

PMSM with maximal speed of 5000RPM and PPR of 5000 is

driven under a sample

frequency with 10kHz. The

experimental speed traces, as well as modulation index curves

of the stationary reference frame, under different commands

are illustrated in Fig.8 and Fig.9. In detail, Fig.8 shows the

response of a step command from 0 to 2000RPM, where the

transient time is about 2ms and the largest overshoot is lower

than 2%, and the steady-state error is smaller than 0.5%; Fig.9

shows the response of a ramp command with the acceleration

of 0.45 RPM per sample and the aiming speed of 500 RPM,

where the dynamic tracking error is within 5%. If the switching

frequency and the sample frequency are increased, a higher

performance will be obtained.

V. CONCLUSIONS

the M/T

the vector

transformation,

In this paper, a specific speed servo controller based on

FPGA implementation is presented, and the proposed scheme

integrates

speed

measurement, the PI regulation, the SVPWM and other

function modules. With the designed servo IC, the two loops,

current and speed, can respectively obtain a sample frequency

of 40kHz and 20kHz as well as a bandwidth of 5kHz and

400Hz. Experiments have verified that the controller can

operate with very satisfying dynamic and static performances

from a low speed of 0.2 RPM to a high speed of 10,000 RPM.

In addition, the described scheme can further yield a SOC of

motion control, which is a challenging practice in the servo

control field.

1608

TABLE I.

DESIGN SUMMARY OF THE SERVO CONTROLLER WITH

EP1C20F400

EP1C20F400

Resources

Design Usage

GCLK

LC

Register

RAM

PLL

Pin

8

20060

21850

4(50%)

7274(36%)

3287(15%)

288K Bits

256K Bits (88%)

2

301

1(50%)

58(19%)

REFERENCES

[1] Werner Leonhard, Control of electrical drives, Springer-Verlag, 3rd

Edition, Berlin 2001.

[2] Peter Vas, Vector control of AC machines, Oxford University Press,

New York 1990.

[3] D. Fodor, Z. Katona and E. Szesztay, “Digitized vector control of

induction motor with DSP”, IECON'94: 20th International Conference

on Industrial Electronics, Control and Instrumentation, Vol.3, 1994, pp.

2057-2062.

[4] Ying-Yu Tzou, Ming-Fa Tsai, Yuh-Farn Lin and Hwa Wu, “Dual DSP

based fully digital control of an AC induction motor”, ISIE'96:

Proceedings of the IEEE International Symposium on Industrial

Electronics, Vol.2, 1996, pp. 673-678.

[5] Bob Zeidman and Robert Zeidman, Designing with FPGAs and CPLDs,

CMP Books, Berkeley 2002.

[6] P. C. Kjaer, C. Cossar and T. J. E. Miller, “Very high bandwidth digital

current controller

for high-performance motor drives”, Sixth

International Conference on Power Electronics and Variable Speed

Drives, 23-25, 1996, pp. 185-190.

[7] Ying-Yu Tzou and Jin-Yi Jyang, “A programmable current vector

control IC for AC motor drives”, IECON Proceedings on Industrial

Electronics Conference, Vol.1, 1999, pp. 216-221.

[8] Soren J. Henriksen, Robert E. Betz and Brian J. Cook, “Digital hardware

implementation of a current controller for IM variable-speed drives”,

IEEE Trans. on Industrial Application, Vol.35, No.5, 1999, pp. 1021-

1029.

[9] Xiaobo Hu, Ronald G. Harber and Steven C. Bass, “Expanding the range

of convergence of the CORDIC algorithm”, IEEE Trans. on Computers,

Vol.40, No.1, 1991, pp. 13-21.

[10] Ray Andraka, “A survey of CORDIC algorithms for FPGA based

computers”, Proc. of ACM/SIGDA Sixth International Symposium on

FPGAs, 1998, Monterrey, CA, pp. 191-200.

[11] Heinz Willi Van Der Broeck, Hans-Christoph Skudelny and Georg

Viktor Stanke, “Analysis and realization of a pulsewidth modulator

based on voltage space vectors”, IEEE Trans. on Industrial Applications,

Vol.24, No.1, 1988, pp. 142-150.

[12] Zhaoyong Zhou, Tiecai Li, Toshio Takahashi and Eddy Ho, “Design of

a universal space vector PWM controller based on FPGA”, Proceedings

of APEC 2004, in press.

�

Figure 8. Response for Step Speed Command

Figure 9. Response for Ramp Speed Command

1609

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc