Autotuning of PID Controllers

�

Cheng-Ching Yu

Autotuning of

PID Controllers

A Relay Feedback Approach

2nd Edition

With 140 Figures

123

�

Cheng-Ching Yu, PhD

Department of Chemical Engineering

National Taiwan University

1 Roosevelt Road

Section 4

Taipei 106-17

Taiwan

British Library Cataloguing in Publication Data

Yu, Cheng-Ching, 1956-

Autotuning of PID controllers. - 2nd ed.

1. PID controllers

I. Title

629.8

ISBN-10: 1846280362

Library of Congress Control Number: 2005931920

e-ISBN 1-84628-037-0

Printed on acid-free paper

ISBN-10: 1-84628-036-2 2nd edition

ISBN-13: 978-1-84628-036-8 2nd edition

ISBN: 3-540-76250-7 1st edition

© Springer-Verlag London Limited 2006

First published 1999

Second edition 2006

MATLAB® is the registered trademark of The MathWorks, Inc., 3 Apple Hill Drive, Natick, MA 01760-

2098, U.S.A. http://www.mathworks.com

Apart from any fair dealing for the purposes of research or private study, or criticism or review, as

permitted under the Copyright, Designs and Patents Act 1988, this publication may only be reproduced,

stored or transmitted, in any form or by any means, with the prior permission in writing of the

publishers, or in the case of reprographic reproduction in accordance with the terms of licences issued

by the Copyright Licensing Agency. Enquiries concerning reproduction outside those terms should be

sent to the publishers.

The use of registered names, trademarks, etc. in this publication does not imply, even in the absence of

a specific statement, that such names are exempt from the relevant laws and regulations and therefore

free for general use.

The publisher makes no representation, express or implied, with regard to the accuracy of the infor-

mation contained in this book and cannot accept any legal responsibility or liability for any errors or

omissions that may be made.

Printed in Germany

9 8 7 6 5 4 3 2 1

Springer Science+Business Media

springeronline.com

�

To Patricia, Jessica, and Albert

–

�

Preface

This edition is a major revision to the first edition. The revision is motivated by

the new progress in relay feedback autotuning, as proposed by Bill Luyben, where

the shape of the relay response can be utilized to identify likely model structure.

Several new chapters have been added, notably the use of the shape-factor for

autotuning and controller monitoring, incorporating autotuning in a multiple-

model setup, dealing with an imperfect actuator. At the turn of the century, com-

petitiveness in the global economy remains the same and the need for rapid and

flexible manufacturing has become standard practice. This has given process con-

trol engineers an expanded role in process operation.

It has long been recognized that industrial control is one of the key technologies

to make existing processes economically competitive. In theory, sophisticated

control strategies–supervisory, adaptive, model predictive control–should be the

norm of industrial practice in modern plants. Unfortunately, a recent survey, by

Desborough and Miller has shown otherwise. This indicates that 97% of regula-

tory controllers are of the proportional–integral–derivative (PID) type and only

32% of the loops show “excellent” or “good” performance. Six years have passed

since the first edition was published, and the practice of industrial process control

is very much the same: PID controllers are widely used but poorly tuned.

This book is aimed at engineers and researchers who are looking for ways to

improve controller performance. It provides a simple and yet effective method of

tuning PID controllers automatically. Practical tools needed to handle various

process conditions, e.g. load disturbance, nonlinearity and noise, are also given.

The mathematics of the subject is kept to a minimum level and emphasis is

placed on experimental designs that give relevant process information for the in-

tended tuning rules. Numerous worked examples and case studies are used to il-

lustrate the autotuning procedure and closed-loop performance.

This book is an independent learning tool that has been designed to educate

people in technologies associated with controller tuning. Most aspects of autotun-

ing are covered, and you are encouraged to try them out on industrial control prac-

tice.

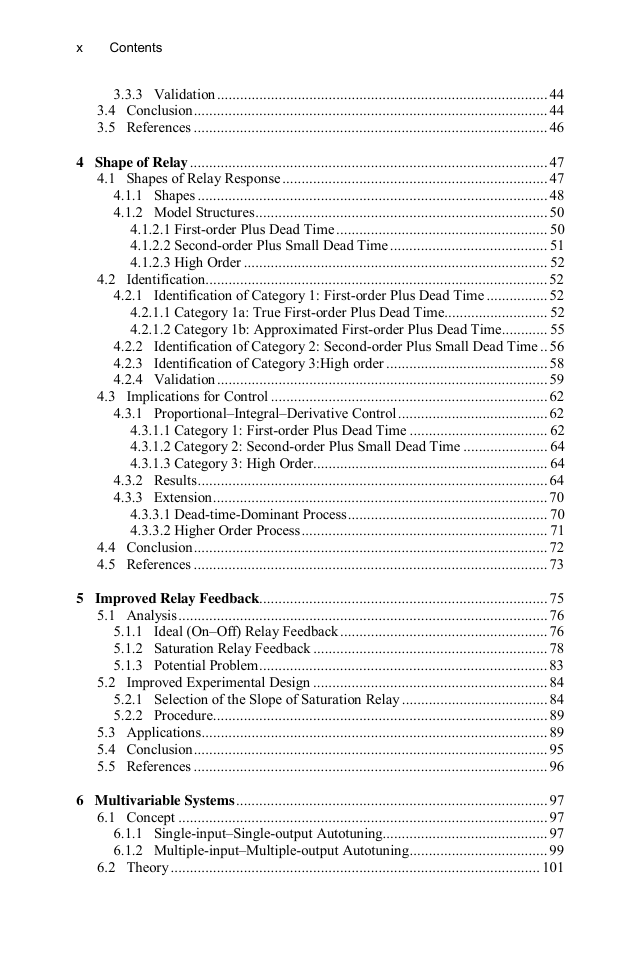

The book is divided into 12 chapters. In Chapter 1, perspectives on process

control and the need for automatic tuning of PID controllers are given. The PID

vii

�

viii Preface

controller is introduced in Chapter 2. Corresponding P, I, and D actions are ex-

plained and typical tuning rules are tabulated. Chapter 3 shows how and why the

relay feedback tests can be used as a means of autotuning, and an autotuning pro-

cedure is also given. A simple and an improved algorithm are explored and ana-

lytical expressions for relay feedback responses are also derived. The shape of re-

lay feedback is discussed in Chapter 4. This gives useful information on possible

model structure and ranges of model parameters. Once model structure is avail-

able, an appropriate tuning rule can be applied for improved control performance.

In Chapter 5, a ramp type of relay is proposed to provide better accuracy in identi-

fying process parameters. The improved experimental design is shown to work

well for both single-input–single-output (SISO) and multivariable systems. Chap-

ter 6 is devoted to a more common situation: multivariable systems. Experiments

are devised and procedures are given for the automatic tuning of multiloop SISO

controllers. Chapter 7 is devoted to a practical problem: autotuning under load dis-

turbance. A procedure is presented to find controller parameters under load

changes. The multiple-model approach is known to be effective in handling proc-

esses that are nonlinear, and Chapter 8 extends the relay feedback autotuning in a

multiple-model framework. In Chapter 9, the controller monitoring problem is ad-

dressed. Again, the shape of relay feedback response gives a useful indication on

the appropriateness of the tuning constant. Moreover, monitoring and retuning are

completed in a single-relay feedback test. The issue of an imperfect actuator is

dealt with in Chapter 10. For control valve with hyteresis, an autotuning procedure

is proposed to overcome the frequently encountered problem in practice. In Chap-

ter 11, the importance of control structure design is illustrated using a plantwide

control example. Procedures for the design of the control structure and the tuning

of the entire plant are given and the results clearly indicate that the combination of

better process understanding and improved tuning makes the recycle plant much

easier to operate. Chapter 12 summarizes the guidelines for autotuning procedures

and describes when and what type of relay feedback test should be employed.

The book is based on work my students and I have been engaged in for almost

20 years to improve PID controller performance. I wrote the book because I be-

lieve strongly in the benefits of improved control, and a well-tuned PID controller

is a fundamental step for improved process operation.

Acknowledgements

Thanks are due to K. J. Åström, T. Hägglund, W. L. Luyben, Q. G. Wang, I. B.

Lee, and my colleague H. P. Huang, who have contributed to the development of

relay feedback autotuning. Undergraduate and graduate students and postdoc fel-

lows of NTU and NTUST have contributed to this book by their questions and in-

terest in the subject. In particular, the continuous feedback from Walters Shen, K.

L. Wu, D. M. Chang, Y. C. Cheng, Y. H. Chen, T. Thyagarajan, and R. C. Panda

needs to be acknowledged. The superb editing work of Brenda Tsai and Vincent

Chang made this book possible. Finally, without the understanding and support of

my family, this book would not have been undertaken, or completed.

�

Contents

1 Introduction...................................................................................................1

1.1 Scope of Process Control.........................................................................1

1.2 Proportional–Integral–Derivative Control Performance............................2

1.3 Relay Feedback Identification .................................................................5

1.4 Conclusion..............................................................................................6

1.5 References ..............................................................................................7

2 Features of ProportionalIntegralDerivative Control................................9

2.1 Proportional–Integral–Derivative Controller ............................................9

2.1.1 Proportional Control ........................................................................9

2.1.2 Proportional–Integral Control.........................................................10

2.1.3 Proportional–Integral–Derivative Control.......................................12

2.2 Proportional–Integral–Derivative Implementation..................................13

2.2.1 Reset Windup ................................................................................13

2.2.2 Arrangement of Derivative Action..................................................15

2.3 Proportional–Integral–Derivative Tuning Rules .....................................17

2.3.1 Ziegler–Nichols Types of Tuning Rules..........................................17

2.3.2 Model-based Tuning ......................................................................19

2.4 Conclusion............................................................................................20

2.5 References ............................................................................................20

3 Relay Feedback ...........................................................................................23

3.1 Experimental Design.............................................................................24

3.2 Approximate Transfer Functions: Frequency-domain Modeling.............26

3.2.1 Simple Approach ...........................................................................27

3.2.2 Improved Algorithm ......................................................................30

3.2.3 Parameter Estimation .....................................................................32

3.2.4 Examples.......................................................................................32

3.3 Approximate Transfer Functions: Time-domain Modeling.....................36

3.3.1 Derivation for a Second-order Overdamped System........................39

3.3.2 Results...........................................................................................41

ix

�

x

Contents

3.3.3 Validation......................................................................................44

3.4 Conclusion............................................................................................44

3.5 References ............................................................................................46

4 Shape of Relay.............................................................................................47

4.1 Shapes of Relay Response.....................................................................47

4.1.1 Shapes ...........................................................................................48

4.1.2 Model Structures............................................................................50

4.1.2.1 First-order Plus Dead Time....................................................... 50

4.1.2.2 Second-order Plus Small Dead Time......................................... 51

4.1.2.3 High Order ............................................................................... 52

4.2 Identification.........................................................................................52

4.2.1 Identification of Category 1: First-order Plus Dead Time ................52

4.2.1.1 Category 1a: True First-order Plus Dead Time........................... 52

4.2.1.2 Category 1b: Approximated First-order Plus Dead Time............ 55

4.2.2 Identification of Category 2: Second-order Plus Small Dead Time ..56

4.2.3 Identification of Category 3:High order ..........................................58

4.2.4 Validation......................................................................................59

4.3 Implications for Control ........................................................................62

4.3.1 Proportional–Integral–Derivative Control.......................................62

4.3.1.1 Category 1: First-order Plus Dead Time .................................... 62

4.3.1.2 Category 2: Second-order Plus Small Dead Time ...................... 64

4.3.1.3 Category 3: High Order............................................................. 64

4.3.2 Results...........................................................................................64

4.3.3 Extension.......................................................................................70

4.3.3.1 Dead-time-Dominant Process.................................................... 70

4.3.3.2 Higher Order Process................................................................ 71

4.4 Conclusion............................................................................................72

4.5 References ............................................................................................73

5 Improved Relay Feedback...........................................................................75

5.1 Analysis................................................................................................76

5.1.1 Ideal (On–Off) Relay Feedback......................................................76

5.1.2 Saturation Relay Feedback .............................................................78

5.1.3 Potential Problem...........................................................................83

5.2 Improved Experimental Design .............................................................84

5.2.1 Selection of the Slope of Saturation Relay ......................................84

5.2.2 Procedure.......................................................................................89

5.3 Applications..........................................................................................89

5.4 Conclusion............................................................................................95

5.5 References ............................................................................................96

6 Multivariable Systems.................................................................................97

6.1 Concept ................................................................................................97

6.1.1 Single-input–Single-output Autotuning...........................................97

6.1.2 Multiple-input–Multiple-output Autotuning....................................99

6.2 Theory................................................................................................ 101

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc