U N D E R S E A R O B O T S

Ultragentle manipulation of delicate structures using

a soft robotic gripper

Nina R. Sinatra1*, Clark B. Teeple1, Daniel M. Vogt1, Kevin Kit Parker1,

David F. Gruber2,3, Robert J. Wood1

Copyright © 2019

The Authors, some

rights reserved;

exclusive licensee

American Association

for the Advancement

of Science. No claim

to original U.S.

Government Works

Here, we present ultragentle soft robotic actuators capable of grasping delicate specimens of gelatinous marine

life. Although state-of-the-art soft robotic manipulators have demonstrated gentle gripping of brittle animals

(e.g., corals) and echinoderms (e.g., sea cucumbers) in the deep sea, they are unable to nondestructively grasp

more fragile soft-bodied organisms, such as jellyfish. Through an exploration of design parameters and laboratory

testing of individual actuators, we confirmed that our nanofiber-reinforced soft actuators apply sufficiently low

contact pressure to ensure minimal harm to typical jellyfish species. We then built a gripping device using several

actuators and evaluated its underwater grasping performance in the laboratory. By assessing the gripper’s region

of acquisition and robustness to external forces, we gained insight into the necessary precision and speed with

which grasping maneuvers must be performed to achieve successful collection of samples. Last, we demonstrated

successful manipulation of three live jellyfish species in an aquarium setting using a hand-held prototype gripper.

Overall, our ultragentle gripper demonstrates an improvement in gentle sample collection compared with existing

deep-sea sampling devices. Extensions of this technology may improve a variety of in situ characterization techniques

used to study the ecological and genetic features of deep-sea organisms.

INTRODUCTION

The marine environment has long been a deep well of bioinspiration for

previously unexplored materials and structures (1–3), cutting-edge medical

treatments (4, 5), and biomimetic manipulators and locomotors (6–11).

However, it is less common for these inventions to have practical

applications toward the biology and ecology of the animals from which

they are inspired. Gelatinous macroplankton—including cnidarian

medusae, ctenophores, and pelagic tunicates—are becoming increasingly

recognized as key ecosystem consumers of energy and nutrients

(12, 13) and are estimated to constitute a global biomass of 38.3 Tg C

(14). For many years, gelatinous zooplankton were overlooked by

marine scientists, largely because of a lack of delicate equipment to

study them, and have been referred to as “forgotten fauna” (15).

Discoveries such as life cycle reversal (16) and green fluorescent

protein (17, 18) are two examples of findings from gelatinous

zooplankton that have cross-disciplinary impacts and demonstrate

the importance of learning more about these life-forms.

Despite this vast potential, collecting intact samples of gelatinous

organisms to study remains extremely challenging. For example,

jellyfish are composed of more than 95% water, and their mesogleal

tissue has an extremely low stiffness (Young’s modulus of 0.34 to

1.2 kPa) (19–22). Capturing these delicate creatures in the ocean

has been a challenge for the research community because existing

technologies (e.g., nets and vacuum devices) frequently damage

samples during the collection process (15, 23). The ideal grasping

device for delicate materials in dynamic domains must incorporate

a soft and flexible interface, compliant yet tough (able to absorb

energy and deform plastically before fracture) appendages, and a

radius of curvature compatible with the target size. This work focuses

1John A. Paulson School of Engineering and Applied Sciences and the Wyss Institute

for Biologically Inspired Engineering, Harvard University, 29 Oxford Street, Cambridge,

MA 02138, USA. 2Department of Natural Sciences, Baruch College, City University

of New York, 55 Lexington Ave., New York, NY 10010, USA. 3PhD Program in Biology,

Graduate Center, City University of New York, 365 5th Ave., New York, NY 10016, USA.

*Corresponding author. Email: sinatra.nina@gmail.com

on developing a soft gripper with such properties. The target

organisms for this device are three small (roughly 7 to 10 cm) jellyfish

species: Aurelia aurita, Catostylus mosaicus, and Mastigias papua.

Jellyfish present extreme challenges for delicate grasping and

manipulation, and lessons learned from this exploration may be

transferred to other tasks involving fragile or gelatinous objects.

Currently, state-of-the-art aquatic grippers can be classified into

five categories: (i) forked metal or plastic jaws (24, 25), (ii) soft

hydraulic actuators (26, 27), (iii) jamming grippers (28), (iv) suction

samplers (29), and (v) noncontact containers that close around a

swimming animal (30). Metal or plastic grippers are the most widespread

marine sampling method due to their use in oil and natural gas

industries, but their rigid surfaces can snag or compress gelatinous

animals, and a fixed radius of curvature is unable to conform

controllably to the shape of amorphous or soft-bodied animals (31).

Foam-coated hydraulic actuators have substantially improved non-

destructive sampling of delicate benthic and midwater animals (e.g.,

coral and sea stars) by decreasing grip force while increasing pressure

distribution (26). However, the contact pressure exerted by foam-covered

actuators (1 to 10 kPa) is too high to grasp gelatinous animals

without causing harm (fig. S4). Although particle jamming grippers

are capable of lifting sedentary objects, their operating mechanism

is not well suited for grasping floating organisms (28, 32). Suction

samplers use a pump to draw an untethered animal through an inlet

tube and into a storage container; however, delicate organisms can

be damaged as they move through the tubing (30, 33).

Last, noncontact tools such as the detritus sampler (“D-Sampler”)

or the RAD (rotary-actuated dodecahedron) sampler are open

containers that are positioned near floating specimens and then closed

around the organism. Use of the D-Sampler with remotely operated

vehicles (ROVs) is challenging because the container is typically

positioned by moving the entire vehicle (30, 34). Although the RAD

sampler (30) has successfully captured centimeter-scale squid and octopi,

misalignment of the container (an origami-inspired structure that

folds to form a sealed dodecahedron) as it closes can trap and cleave

1 of 11

l

D

o

w

n

o

a

d

e

d

f

r

o

m

h

t

t

p

:

/

/

r

o

b

o

i

t

i

c

s

.

s

c

e

n

c

e

m

a

g

.

o

r

g

/

a

t

i

U

n

v

e

r

s

i

t

y

o

f

i

C

h

n

e

s

e

A

c

a

d

e

m

y

o

f

i

S

c

e

n

c

e

s

o

n

S

e

p

e

m

b

e

r

t

3

0

,

2

0

2

0

Sinatra et al., Sci. Robot. 4, eaax5425 (2019) 28 August 2019SCIENCE ROBOTICS | RESEARCH ARTICLE�

the tentacles of fragile specimens. A flexible, compliant gripper is needed

to bridge this capability gap, thereby achieving nondestructive grasping

of gelatinous marine organisms. In this study, we report a multi-scale

approach for gentle grasping using nanofiber-reinforced soft actuators.

Previously, we developed flexible and robust microscale soft

actuators composed of an elastomer matrix reinforced with polymer

nanofibers (35). Nanofibers were selected as the strain-limiting layer

because of their ease of processing and high specific strength; the

actuators underwent large deformations without requiring stiffer

reinforcing materials, such as carbon or glass fibers. Furthermore,

the nanofabric’s high surface area facilitated bonding with elastomeric

materials during the fabrication processes and demonstrated no

delamination from the matrix after tensile testing of the actuator to

failure. Unlike our previous nanofiber-reinforced polydimethylsiloxane

microrobots (whose matrix has a Shore hardness of 43), the mesoscale

actuators presented here incorporate a lower durometer silicone matrix

(Shore 20A), which is better suited for interacting with fragile structures.

Here, we leverage the flexibility and durability of these materials to

engineer mesoscale soft hydraulic actuators.

Our grasping device is composed of six composite actuator “fingers”

connected to a three-dimensional (3D)–printed “palm” produced using

a PolyJet-based printer (Objet Connex500, Stratasys). Each actuator

contains an elastic yet tough silicone matrix and a strain-limiting

layer of flexible polymer nanofibers. The gripper is lightweight (123 g)

and can be actuated using very low hydraulic pressure (1 to 6 psi,

or 6.9 to 41.4 kPa, with respect to ambient).

Upon pressurization, a channel within each actuator inflates, and

the appendage bends in the direction of the stiffer fiber-reinforced

layer. Inflation of several actuators spaced around a marine organism

enables the animal to be gently cradled by the soft silicone digits.

The actuators overlap and contact one another, forming a soft

network that restricts the position of the target but does not fully

immobilize it (36); this caging grasp reduces the need to precisely

control individual finger placement and instead relies on collective

inflation of all actuators. The low contact pressure exerted by each

actuator (0.0455 ± 0.007 kPa) also facilitates nondestructive interaction.

To better understand the device’s performance space, we empirically

identified the region of acquisition using a synthetic target and

quantified the resistance to forces on the object during a grasp. The

soft gripper can be adapted both to deep-sea exploration using an

ROV (Fig. 1A) and to portable specimen collection in the shallower

waters of the photic zone. Last, we demonstrate the use of the portable

device setup to successfully grasp three jellyfish species (Fig. 1, B to D).

RESULTS

Design criteria for ultragentle gripper

The objective for this device is to perform nondestructive grasping

of gelatinous marine organisms in the marine environment. We

identified several performance requirements to ensure successful

function. First, because the gripper will be fully submerged in the

ocean during operation, it must be composed of materials that are

resistant to corrosion in salt water. To fulfill this aim, we selected a

silicone matrix, nylon and polyurethane reinforcing fiber, PolyJet

palm chassis, and stainless steel fasteners, each of which is undamaged

by seawater immersion during the operational life cycle of this

device (several weeks) (37–41). Second, the materials must withstand

use at typical ocean temperatures, which reach a minimum of 0° to

3°C in the deep sea (several thousand meters) and a surface average

of 17°C. The operational range of all the materials listed above is

within this window; for example, silicone rubbers are highly resistant

to low temperatures and have an embrittlement temperature between

−20° and −30°C (42). Because of the design of the hydraulic pump

used to inflate the soft fingers (26), pressure within the actuators is

equalized to that of the surrounding waters and is therefore not a

barrier to operation.

The following design criteria relate to the organisms that the

gripper will be required to interact with. The actuator length must

be determined by the average size of the intended object or species.

Although gelatinous animals exist in a variety of shapes and sizes,

we selected three of the most widely studied jellyfish species to serve

as models: A. aurita, C. mosaicus, and M. papua. The average bell

diameter for these species is 7 to 10 cm (43, 44). To fully enclose the

body of the selected jellyfish, the total length for our actuators must

exceed this amount and was set at 15 cm. However, actuator size

may be easily scaled to accommodate larger or smaller organisms.

Larger actuators may require thicker nanofiber sheets near the distal

tip to maintain uniform curvature throughout the length of the

actuator. During extended operation, a small amount of air can

become trapped in this area of the internal channel. The silicone

membrane will deform more around the enclosed air than around

water, leading to higher local curvature at the distal end (i.e., the

“finger tip” will bend more than the rest of the actuator). Last, to

execute a nondestructive grasp, the contact pressure exerted by each

actuator should be below 1 kPa, the current state of the art for soft

marine grippers (26). We have evaluated the pressure exerted by

our composite actuators in a subsequent section.

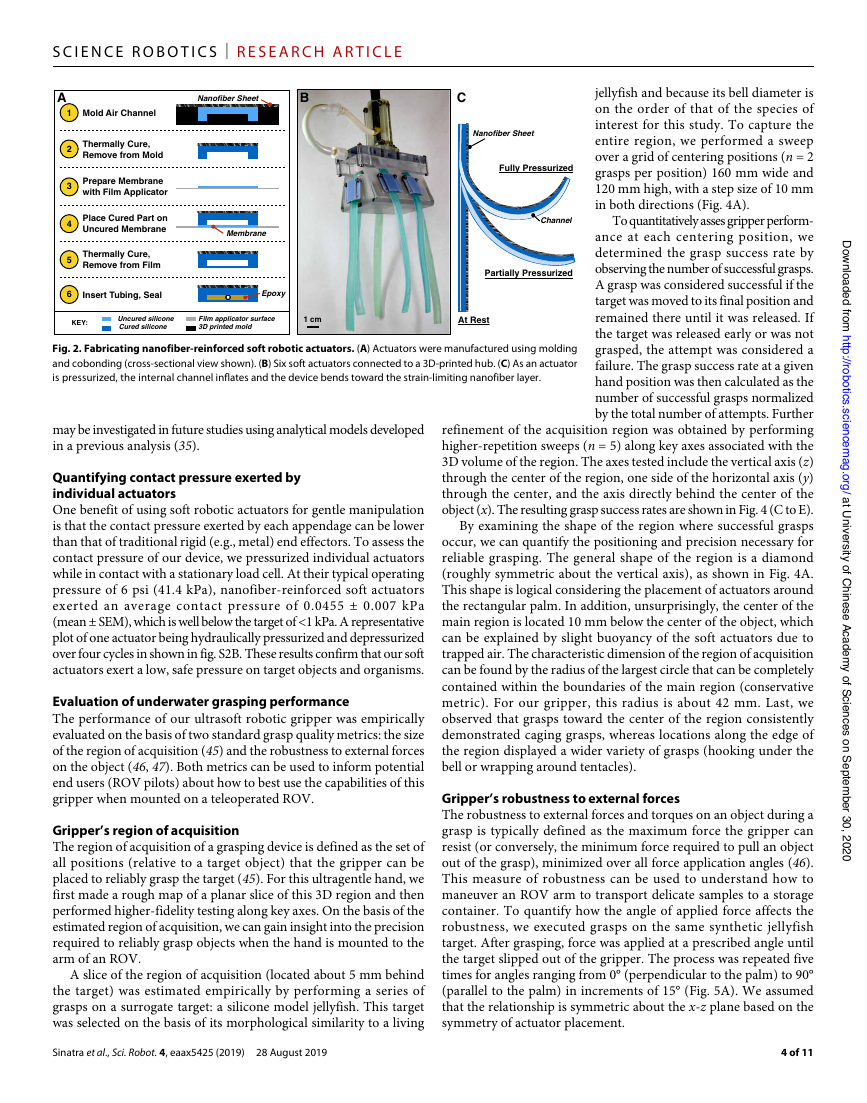

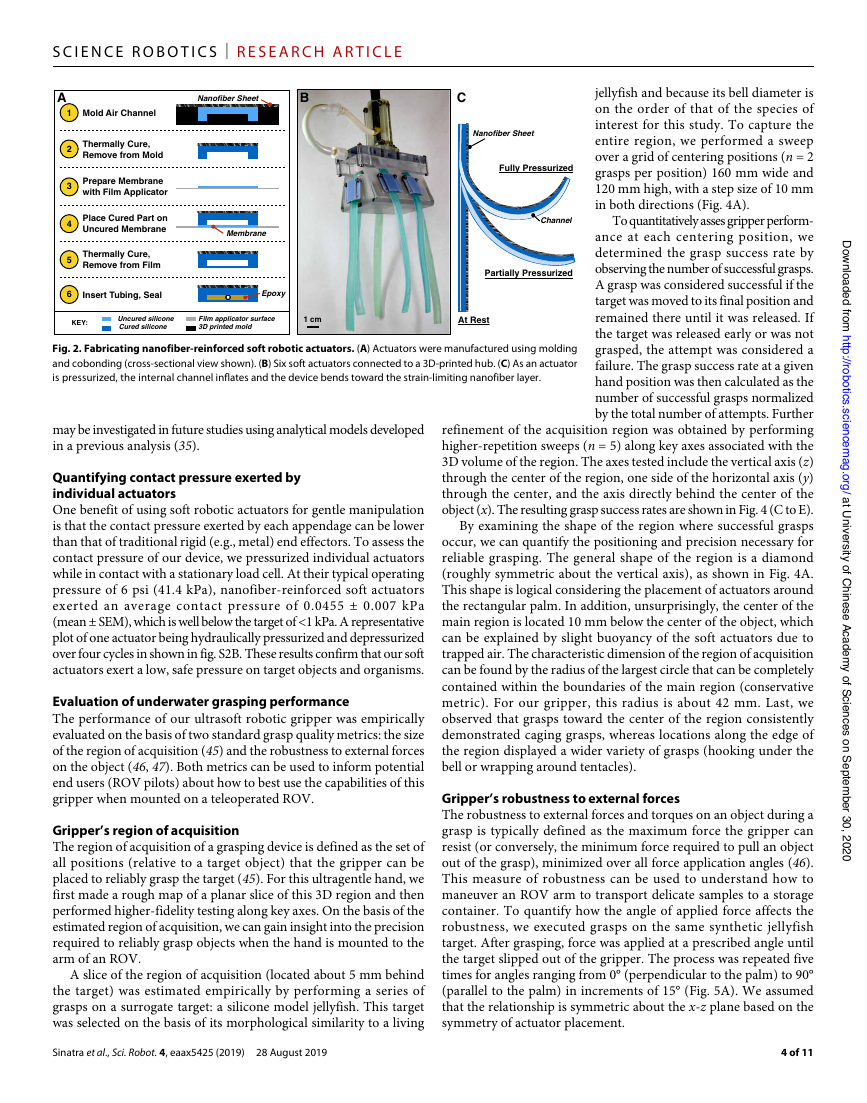

Robotic palm design

The soft robotic gripper includes six modular actuators attached to

a custom-designed, 3D-printed hub (Fig. 2B) composed of a transparent

photopolymer (RGD720, Stratasys). The appendages are individually

attached to the central palm and may be removed or exchanged in

the case of actuator failure or to experiment with different digit

configurations. The set of actuators are pressurized hydraulically

(Fig. 2C) using a single channel at the back of the hub, which can be

attached to a fluid source using quick-disconnect fittings. In the

present configuration, the actuators were evenly spaced, with two

on either side of a 78-mm rectangular palm and one on either end

of the opposite 45-mm edge. This layout was chosen because adhesion

and friction between actuators on either side of the hub resulted in

a strong caging grasp (fig. S7). The actuators placed at the top and

bottom of the palm prevent a target object from being released at

either end and contribute to a caging grasp by overlapping the center

actuators. Actuator position can be rapidly adjusted by modifying

the 3D-printed hub design. Additive manufacturing supports iterative

development of soft grippers with varying numbers and positions of

actuators (e.g., a hexagonal hub with six actuators or a circular palm

with 10 digits). This flexibility can enable further customization to

support organisms with specific shapes and symmetries (27).

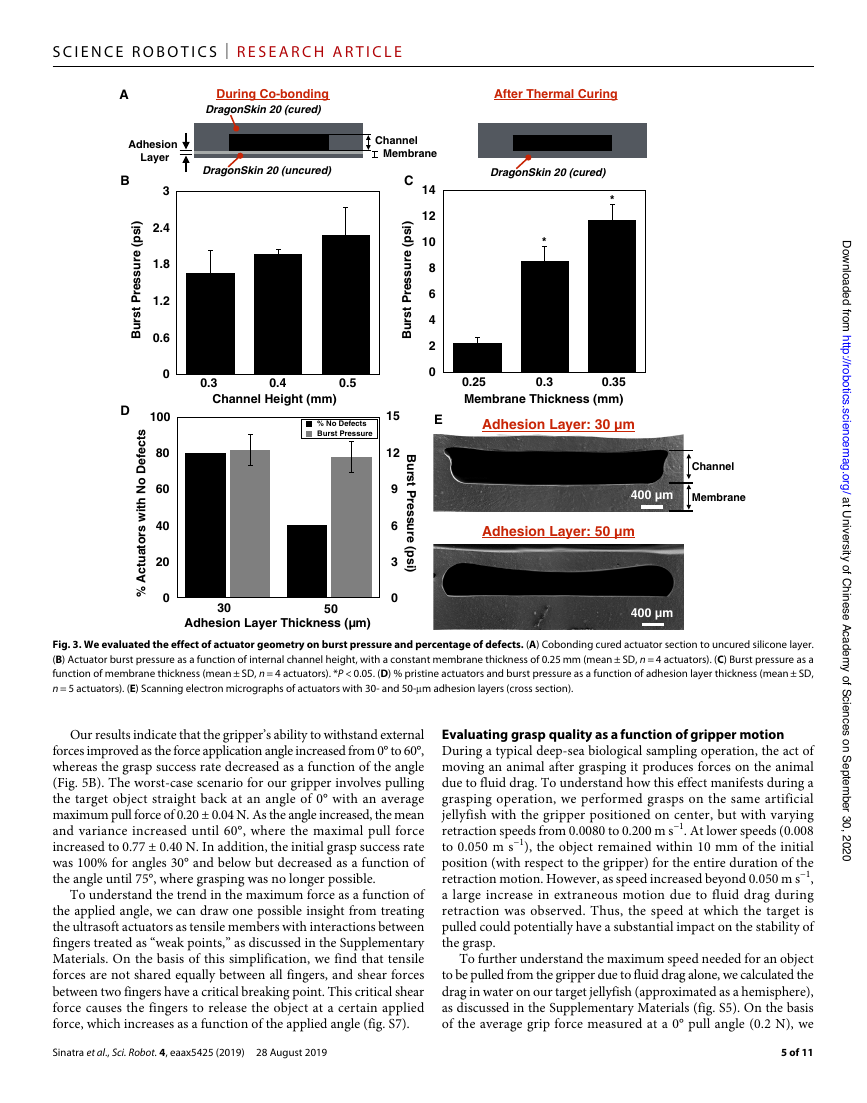

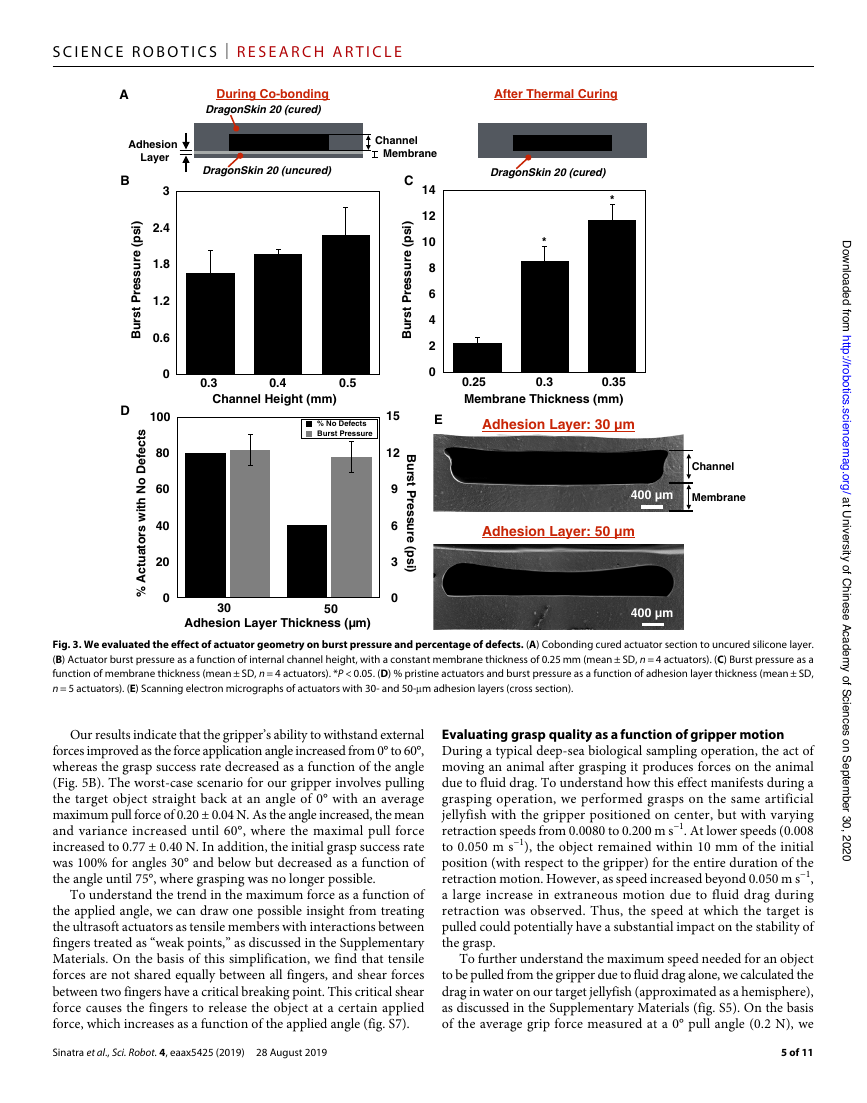

Actuator design

Understanding the impact of geometric and process variables during

actuator fabrication is crucial to regulating input pressure range

and reducing manufacturing defects. Three key design parameters

can be tuned toward achieving these goals: interior channel height,

thickness of the inflating membrane, and thickness of the adhesive

layer during the cobonding process (illustrated in Fig. 3A). Each of

2 of 11

l

D

o

w

n

o

a

d

e

d

f

r

o

m

h

t

t

p

:

/

/

r

o

b

o

i

t

i

c

s

.

s

c

e

n

c

e

m

a

g

.

o

r

g

/

a

t

i

U

n

v

e

r

s

i

t

y

o

f

i

C

h

n

e

s

e

A

c

a

d

e

m

y

o

f

i

S

c

e

n

c

e

s

o

n

S

e

p

e

m

b

e

r

t

3

0

,

2

0

2

0

Sinatra et al., Sci. Robot. 4, eaax5425 (2019) 28 August 2019SCIENCE ROBOTICS | RESEARCH ARTICLE�

A

Delicate Gripping

< 1 kPa

< 1 kPa

< 1 kPa

B

C

D

2 cm

2 cm

Fig. 1. Soft robotic actuators are a promising approach to grasping fragile marine organisms. (A) Illustration

demonstrating the envisioned application of soft robotic actuators (green) attached to an ROV. These actuators were

designed for ultragentle manipulation of delicate tissues, such as jellyfish and other gelatinous marine species. The

target species for our soft gripper are (B) A. aurita, (C) C. mosaicus (photo credit: Peter Campbell; www.greenlivingpedia.org/

Image:Blue_Blubber_Jellyfish_IMGP2102.JPG), and (D) M. papua.

these parameters was compared against two success metrics: the actuator

failure pressure and the number of defects observed during manu-

facturing. The defects formed during the process of cobonding the

concave portion of the interior channel (already cured) to a thin cast

film of uncured silicone (which forms the upper membrane enclosing

the channel). These irregularities were small cylindrical pillars spanning

the top and bottom of the channel, which formed after the cured part

was placed onto the film. We hypothesize that these pillars formed as a

result of surface tension drawing the uncured liquid toward the center

of the channel, forming a Gaussian- shaped mound that eventually

contacts the opposite side of the channel. For each batch of actuators,

the total number of actuators with “pillar” defects and the burst

pressure of each actuator under pneumatic actuation were measured.

We assumed that the relative difference between the burst pressure

of actuators with and without nanofiber reinforcement would be

similar when actuated hydraulically and pneumatically.

To begin our assessment of the impact of the three design

parameters on actuator burst pressure and defect percentage, we

varied the interior channel height. The

channel height can be tuned by modifying

the 3D-printed mold that was used to

form the thicker portion of each actuator.

Three molds were printed, with channel

heights of 0.3, 0.4, and 0.5 mm. For

fixed membrane (0.25 mm) and adhesion

layer (0.05 mm) thicknesses, a 0.5-mm

channel displayed the highest failure

pressure (Fig. 3B). Thus, we selected

this height for all subsequent actuators.

Next, channel membrane thickness was

varied from 0.25 to 0.35 mm in 0.5-mm

increments, using a constant channel

height (0.5 mm) and adhesion layer

thickness (0.05 mm). We observed an

increase in burst pressure with membrane

thickness; the 0.35-mm membrane

displayed significantly higher burst

pressure than the two thinner options

(Fig. 3C). This is a logical result, because

imposing a thicker barrier against applied

pressure will require a higher pressure

to induce a rupture. Although the failure

pressure of actuators with a 0.35-mm

membrane was acceptable on the basis

of current operational requirements

for ROV-mounted robots, a wider

range of membrane thicknesses may

be explored to accommodate higher

pressure requirements.

2 cm

Last, adhesion layer thickness was

varied (set to either 0.03 or 0.05 mm),

and burst pressure and defect percentage

were measured for actuators with a

constant channel height of 0.5 mm and

a 0.35-mm membrane. The 0.03-mm

adhesive layer yielded a significantly

higher percentage of pristine (lacking

fabrication defects) actuators for a

slightly (albeit not statistically sig-

nificantly) higher burst pressure, as compared with the thicker

adhesive layer (Fig. 3D). Scanning electron micrographs of actuator

cross sections revealed that the thinner adhesive layer yielded a

uniform membrane thickness across the width of the channel (Fig. 3E).

In contrast, capillary action resulted in a nonuniform membrane

when a 0.05-mm adhesive layer was used. Thus, we selected the

following parameters for all subsequent soft actuators: 0.5-mm

internal channel height, 0.35-mm channel membrane thickness, and

0.03-mm adhesion layer thickness.

We also noted that the failure pressure of pneumatically pressurized

nanofiber-reinforced actuators was significantly higher than that of

silicone-only actuators (both fabricated with the previously listed

parameters; fig. S6). In addition to decreasing the overall actuator

curvature, incorporating a fibrous reinforcement layer increased the

toughness and stiffness of the device while maintaining the extensibility

of an elastomer-only layup (35). Although tuning the nanofiber elastic

modulus can affect the overall curvature of the soft actuator, the impact

of other design parameters (e.g., fiber layer thickness and orientation)

3 of 11

l

D

o

w

n

o

a

d

e

d

f

r

o

m

h

t

t

p

:

/

/

r

o

b

o

i

t

i

c

s

.

s

c

e

n

c

e

m

a

g

.

o

r

g

/

a

t

i

U

n

v

e

r

s

i

t

y

o

f

i

C

h

n

e

s

e

A

c

a

d

e

m

y

o

f

i

S

c

e

n

c

e

s

o

n

S

e

p

e

m

b

e

r

t

3

0

,

2

0

2

0

Sinatra et al., Sci. Robot. 4, eaax5425 (2019) 28 August 2019SCIENCE ROBOTICS | RESEARCH ARTICLE�

A

1

Mold Air Channel

Nanofiber Sheet

B

C

2

3

4

5

6

Thermally Cure,

Remove from Mold

Prepare Membrane

with Film Applicator

Place Cured Part on

Uncured Membrane

Thermally Cure,

Remove from Film

Membrane

Insert Tubing, Seal

Epoxy

KEY:

Uncured silicone

Cured silicone

Film applicator surface

3D printed mold

1 cm

Fig. 2. Fabricating nanofiber-reinforced soft robotic actuators. (A) Actuators were manufactured using molding

and cobonding (cross-sectional view shown). (B) Six soft actuators connected to a 3D-printed hub. (C) As an actuator

is pressurized, the internal channel inflates and the device bends toward the strain-limiting nanofiber layer.

Nanofiber Sheet

Fully Pressurized

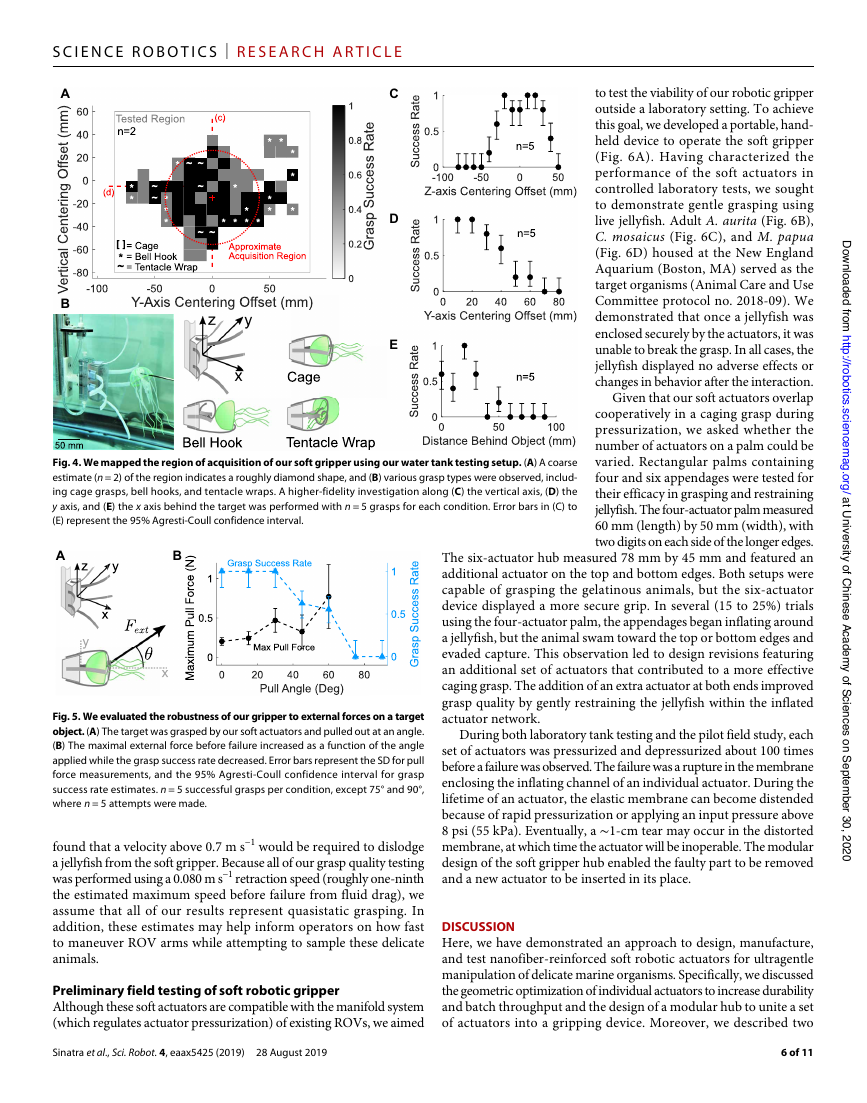

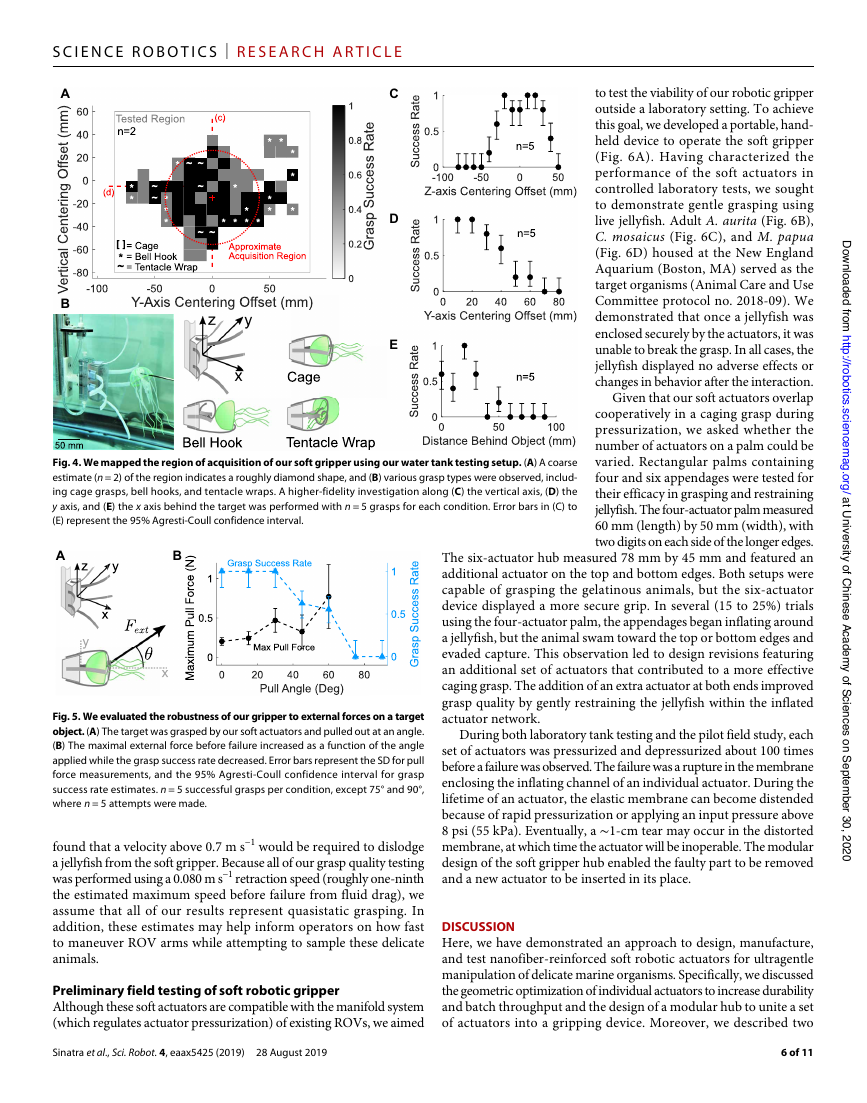

jellyfish and because its bell diameter is

on the order of that of the species of

interest for this study. To capture the

entire region, we performed a sweep

over a grid of centering positions (n = 2

grasps per position) 160 mm wide and

120 mm high, with a step size of 10 mm

in both directions (Fig. 4A).

l

D

o

w

n

o

a

d

e

d

f

r

o

m

h

t

t

p

:

/

/

r

o

b

o

i

t

i

c

s

.

s

c

e

n

c

e

m

a

g

.

o

r

g

/

a

t

i

U

n

v

e

r

s

i

t

y

o

f

i

C

h

n

e

s

e

A

c

a

d

e

m

y

o

f

i

S

c

e

n

c

e

s

o

n

S

e

p

e

m

b

e

r

t

3

0

,

2

0

2

0

Channel

At Rest

Partially Pressurized

To quantitatively asses gripper perform-

ance at each centering position, we

determined the grasp success rate by

observing the number of successful grasps.

A grasp was considered successful if the

target was moved to its final position and

remained there until it was released. If

the target was released early or was not

grasped, the attempt was considered a

failure. The grasp success rate at a given

hand position was then calculated as the

number of successful grasps normalized

by the total number of attempts. Further

refinement of the acquisition region was obtained by performing

higher-repetition sweeps (n = 5) along key axes associated with the

3D volume of the region. The axes tested include the vertical axis (z)

through the center of the region, one side of the horizontal axis (y)

through the center, and the axis directly behind the center of the

object (x). The resulting grasp success rates are shown in Fig. 4 (C to E).

By examining the shape of the region where successful grasps

occur, we can quantify the positioning and precision necessary for

reliable grasping. The general shape of the region is a diamond

(roughly symmetric about the vertical axis), as shown in Fig. 4A.

This shape is logical considering the placement of actuators around

the rectangular palm. In addition, unsurprisingly, the center of the

main region is located 10 mm below the center of the object, which

can be explained by slight buoyancy of the soft actuators due to

trapped air. The characteristic dimension of the region of acquisition

can be found by the radius of the largest circle that can be completely

contained within the boundaries of the main region (conservative

metric). For our gripper, this radius is about 42 mm. Last, we

observed that grasps toward the center of the region consistently

demonstrated caging grasps, whereas locations along the edge of

the region displayed a wider variety of grasps (hooking under the

bell or wrapping around tentacles).

Gripper’s robustness to external forces

The robustness to external forces and torques on an object during a

grasp is typically defined as the maximum force the gripper can

resist (or conversely, the minimum force required to pull an object

out of the grasp), minimized over all force application angles (46).

This measure of robustness can be used to understand how to

maneuver an ROV arm to transport delicate samples to a storage

container. To quantify how the angle of applied force affects the

robustness, we executed grasps on the same synthetic jellyfish

target. After grasping, force was applied at a prescribed angle until

the target slipped out of the gripper. The process was repeated five

times for angles ranging from 0° (perpendicular to the palm) to 90°

(parallel to the palm) in increments of 15° (Fig. 5A). We assumed

that the relationship is symmetric about the x-z plane based on the

symmetry of actuator placement.

4 of 11

may be investigated in future studies using analytical models developed

in a previous analysis (35).

Quantifying contact pressure exerted by

individual actuators

One benefit of using soft robotic actuators for gentle manipulation

is that the contact pressure exerted by each appendage can be lower

than that of traditional rigid (e.g., metal) end effectors. To assess the

contact pressure of our device, we pressurized individual actuators

while in contact with a stationary load cell. At their typical operating

pressure of 6 psi (41.4 kPa), nanofiber-reinforced soft actuators

exerted an average contact pressure of 0.0455 ± 0.007 kPa

(mean ± SEM), which is well below the target of <1 kPa. A representative

plot of one actuator being hydraulically pressurized and depressurized

over four cycles in shown in fig. S2B. These results confirm that our soft

actuators exert a low, safe pressure on target objects and organisms.

Evaluation of underwater grasping performance

The performance of our ultrasoft robotic gripper was empirically

evaluated on the basis of two standard grasp quality metrics: the size

of the region of acquisition (45) and the robustness to external forces

on the object (46, 47). Both metrics can be used to inform potential

end users (ROV pilots) about how to best use the capabilities of this

gripper when mounted on a teleoperated ROV.

Gripper’s region of acquisition

The region of acquisition of a grasping device is defined as the set of

all positions (relative to a target object) that the gripper can be

placed to reliably grasp the target (45). For this ultragentle hand, we

first made a rough map of a planar slice of this 3D region and then

performed higher-fidelity testing along key axes. On the basis of the

estimated region of acquisition, we can gain insight into the precision

required to reliably grasp objects when the hand is mounted to the

arm of an ROV.

A slice of the region of acquisition (located about 5 mm behind

the target) was estimated empirically by performing a series of

grasps on a surrogate target: a silicone model jellyfish. This target

was selected on the basis of its morphological similarity to a living

Sinatra et al., Sci. Robot. 4, eaax5425 (2019) 28 August 2019SCIENCE ROBOTICS | RESEARCH ARTICLE�

A

During Co-bonding

DragonSkin 20 (cured)

After Thermal Curing

Adhesion

Layer

B

)

i

s

p

(

e

r

u

s

s

e

r

P

t

s

r

u

B

3

2.4

1.8

1.2

0.6

0

D

100

s

t

c

e

f

e

D

o

N

h

t

i

w

s

r

o

t

a

u

t

c

A

%

DragonSkin 20 (uncured)

0.3

0.4

0.5

Channel Height (mm)

% No Defects

Burst Pressure

80

60

40

20

0

30

Adhesion Layer Thickness (µm)

50

Channel

Membrane

C

)

i

s

p

(

e

r

u

s

s

e

r

P

t

s

r

u

B

14

12

10

8

6

4

2

0

DragonSkin 20 (cured)

*

*

0.25

0.35

Membrane Thickness (mm)

0.3

E

Adhesion Layer: 30 µm

Channel

400 µm

Membrane

Adhesion Layer: 50 µm

15

12

9

6

3

0

B

u

r

s

t

P

r

e

s

s

u

r

e

(

p

s

i

)

400 µm

Fig. 3. We evaluated the effect of actuator geometry on burst pressure and percentage of defects. (A) Cobonding cured actuator section to uncured silicone layer.

(B) Actuator burst pressure as a function of internal channel height, with a constant membrane thickness of 0.25 mm (mean ± SD, n = 4 actuators). (C) Burst pressure as a

function of membrane thickness (mean ± SD, n = 4 actuators). *P < 0.05. (D) % pristine actuators and burst pressure as a function of adhesion layer thickness (mean ± SD,

n = 5 actuators). (E) Scanning electron micrographs of actuators with 30- and 50-m adhesion layers (cross section).

Our results indicate that the gripper’s ability to withstand external

forces improved as the force application angle increased from 0° to 60°,

whereas the grasp success rate decreased as a function of the angle

(Fig. 5B). The worst-case scenario for our gripper involves pulling

the target object straight back at an angle of 0° with an average

maximum pull force of 0.20 ± 0.04 N. As the angle increased, the mean

and variance increased until 60°, where the maximal pull force

increased to 0.77 ± 0.40 N. In addition, the initial grasp success rate

was 100% for angles 30° and below but decreased as a function of

the angle until 75°, where grasping was no longer possible.

To understand the trend in the maximum force as a function of

the applied angle, we can draw one possible insight from treating

the ultrasoft actuators as tensile members with interactions between

fingers treated as “weak points,” as discussed in the Supplementary

Materials. On the basis of this simplification, we find that tensile

forces are not shared equally between all fingers, and shear forces

between two fingers have a critical breaking point. This critical shear

force causes the fingers to release the object at a certain applied

force, which increases as a function of the applied angle (fig. S7).

Evaluating grasp quality as a function of gripper motion

During a typical deep-sea biological sampling operation, the act of

moving an animal after grasping it produces forces on the animal

due to fluid drag. To understand how this effect manifests during a

grasping operation, we performed grasps on the same artificial

jellyfish with the gripper positioned on center, but with varying

retraction speeds from 0.0080 to 0.200 m s−1. At lower speeds (0.008

to 0.050 m s−1), the object remained within 10 mm of the initial

position (with respect to the gripper) for the entire duration of the

retraction motion. However, as speed increased beyond 0.050 m s−1,

a large increase in extraneous motion due to fluid drag during

retraction was observed. Thus, the speed at which the target is

pulled could potentially have a substantial impact on the stability of

the grasp.

To further understand the maximum speed needed for an object

to be pulled from the gripper due to fluid drag alone, we calculated the

drag in water on our target jellyfish (approximated as a hemisphere),

as discussed in the Supplementary Materials (fig. S5). On the basis

of the average grip force measured at a 0° pull angle (0.2 N), we

5 of 11

l

D

o

w

n

o

a

d

e

d

f

r

o

m

h

t

t

p

:

/

/

r

o

b

o

i

t

i

c

s

.

s

c

e

n

c

e

m

a

g

.

o

r

g

/

a

t

i

U

n

v

e

r

s

i

t

y

o

f

i

C

h

n

e

s

e

A

c

a

d

e

m

y

o

f

i

S

c

e

n

c

e

s

o

n

S

e

p

e

m

b

e

r

t

3

0

,

2

0

2

0

Sinatra et al., Sci. Robot. 4, eaax5425 (2019) 28 August 2019SCIENCE ROBOTICS | RESEARCH ARTICLE�

Fig. 4. We mapped the region of acquisition of our soft gripper using our water tank testing setup. (A) A coarse

estimate (n = 2) of the region indicates a roughly diamond shape, and (B) various grasp types were observed, includ-

ing cage grasps, bell hooks, and tentacle wraps. A higher-fidelity investigation along (C) the vertical axis, (D) the

y axis, and (E) the x axis behind the target was performed with n = 5 grasps for each condition. Error bars in (C) to

(E) represent the 95% Agresti-Coull confidence interval.

A

B

C

D

E

A

B

Fig. 5. We evaluated the robustness of our gripper to external forces on a target

object. (A) The target was grasped by our soft actuators and pulled out at an angle.

(B) The maximal external force before failure increased as a function of the angle

applied while the grasp success rate decreased. Error bars represent the SD for pull

force measurements, and the 95% Agresti-Coull confidence interval for grasp

success rate estimates. n = 5 successful grasps per condition, except 75° and 90°,

where n = 5 attempts were made.

found that a velocity above 0.7 m s−1 would be required to dislodge

a jellyfish from the soft gripper. Because all of our grasp quality testing

was performed using a 0.080 m s−1 retraction speed (roughly one-ninth

the estimated maximum speed before failure from fluid drag), we

assume that all of our results represent quasistatic grasping. In

addition, these estimates may help inform operators on how fast

to maneuver ROV arms while attempting to sample these delicate

animals.

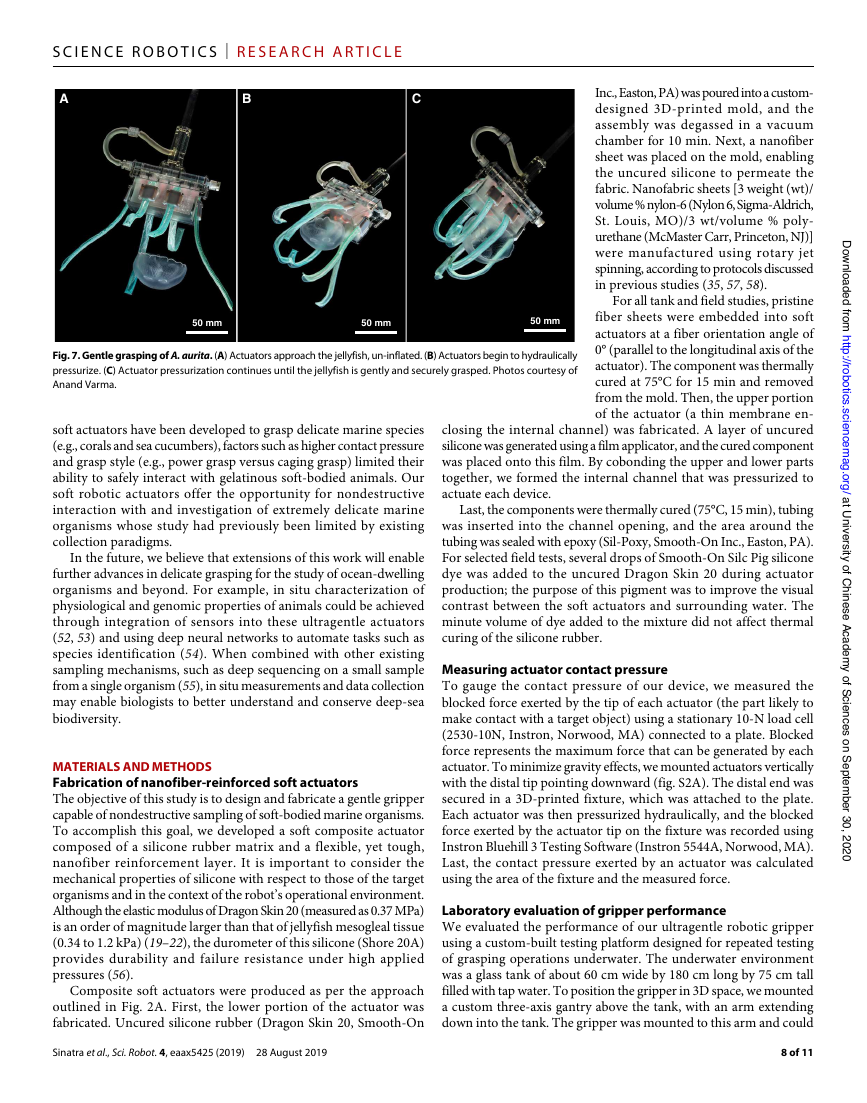

Preliminary field testing of soft robotic gripper

Although these soft actuators are compatible with the manifold system

(which regulates actuator pressurization) of existing ROVs, we aimed

to test the viability of our robotic gripper

outside a laboratory setting. To achieve

this goal, we developed a portable, hand-

held device to operate the soft gripper

(Fig. 6A). Having characterized the

performance of the soft actuators in

controlled laboratory tests, we sought

to demonstrate gentle grasping using

live jellyfish. Adult A. aurita (Fig. 6B),

C. mosaicus (Fig. 6C), and M. papua

(Fig. 6D) housed at the New England

Aquarium (Boston, MA) served as the

target organisms (Animal Care and Use

Committee protocol no. 2018-09). We

demonstrated that once a jellyfish was

enclosed securely by the actuators, it was

unable to break the grasp. In all cases, the

jellyfish displayed no adverse effects or

changes in behavior after the interaction.

Given that our soft actuators overlap

cooperatively in a caging grasp during

pressurization, we asked whether the

number of actuators on a palm could be

varied. Rectangular palms containing

four and six appendages were tested for

their efficacy in grasping and restraining

jellyfish. The four-actuator palm measured

60 mm (length) by 50 mm (width), with

two digits on each side of the longer edges.

The six-actuator hub measured 78 mm by 45 mm and featured an

additional actuator on the top and bottom edges. Both setups were

capable of grasping the gelatinous animals, but the six-actuator

device displayed a more secure grip. In several (15 to 25%) trials

using the four-actuator palm, the appendages began inflating around

a jellyfish, but the animal swam toward the top or bottom edges and

evaded capture. This observation led to design revisions featuring

an additional set of actuators that contributed to a more effective

caging grasp. The addition of an extra actuator at both ends improved

grasp quality by gently restraining the jellyfish within the inflated

actuator network.

During both laboratory tank testing and the pilot field study, each

set of actuators was pressurized and depressurized about 100 times

before a failure was observed. The failure was a rupture in the membrane

enclosing the inflating channel of an individual actuator. During the

lifetime of an actuator, the elastic membrane can become distended

because of rapid pressurization or applying an input pressure above

8 psi (55 kPa). Eventually, a ∼1-cm tear may occur in the distorted

membrane, at which time the actuator will be inoperable. The modular

design of the soft gripper hub enabled the faulty part to be removed

and a new actuator to be inserted in its place.

DISCUSSION

Here, we have demonstrated an approach to design, manufacture,

and test nanofiber-reinforced soft robotic actuators for ultragentle

manipulation of delicate marine organisms. Specifically, we discussed

the geometric optimization of individual actuators to increase durability

and batch throughput and the design of a modular hub to unite a set

of actuators into a gripping device. Moreover, we described two

6 of 11

l

D

o

w

n

o

a

d

e

d

f

r

o

m

h

t

t

p

:

/

/

r

o

b

o

i

t

i

c

s

.

s

c

e

n

c

e

m

a

g

.

o

r

g

/

a

t

i

U

n

v

e

r

s

i

t

y

o

f

i

C

h

n

e

s

e

A

c

a

d

e

m

y

o

f

i

S

c

e

n

c

e

s

o

n

S

e

p

e

m

b

e

r

t

3

0

,

2

0

2

0

Sinatra et al., Sci. Robot. 4, eaax5425 (2019) 28 August 2019SCIENCE ROBOTICS | RESEARCH ARTICLE�

3D-Printed Palm

A

Carbon

Fiber Rod

Actuators

B

2 cm

C

Inflate/Deflate

Switch

Peristaltic Pump

Waterproof Box

D

2 cm

2 cm

Fig. 6. A handheld grasping device was developed to test our soft actuators outside the laboratory. (A) Design

of soft robotic gripping device, shown with a four-actuator hub. Inset: Different hubs, including this six-actuator

palm, can be attached modularly. Soft fiber-reinforced actuators grasping (B) A. aurita, (C) C. mosaicus, and

(D) M. papua. (C and D) Photos courtesy of Anand Varma.

important grasp quality metrics: the region of acquisition of the

gripper in a rectangular configuration and the robustness of its

grasp to applied force. Next, we incorporated the device into a portable

tool that can be used to interact with biological specimens in a

laboratory or in shallow marine environments. Last, we demonstrated

the use of this hand-held soft gripper to successfully perform gentle

grasping of three canonical jellyfish species.

Generalizing laboratory grasping performance

The region of acquisition measured for our gripper provides insight

into the precision needed to reliably grasp objects. On the basis of

the circular region characterized with a 5-mm distance behind the

object, we can estimate that a lateral centering offset within 42 mm

of the target will result in at least a 50% chance of a successful grasp.

In addition, the gripper has better performance when translated

directly along the y or z axes (radii of 50 and 65 mm, respectively).

Moreover, the gripper was able to grasp objects up to 50 mm behind

the target (x axis), albeit with high variability in grasp success

(Fig. 4E).

Although we would expect consistently high grasp success near

0-mm centering offsets, the observed nonperfect performance in

Fig. 4 (C and E) likely stems from natural variation in the grasping

process. Together, this information can be used to inform ROV

operators of positioning requirements to most effectively use this

gripper.

In addition, passive adaptation of fingers enables the gripper to

robustly achieve grasps in a larger region. Most of the grasps within

the main region were cage grasps, indi-

cating that caging is a primary grasping

mode for this gripper. The success of

caging grasps generalizes to real organisms,

as shown in our preliminary field testing.

Conversely, grasps along the edges and

outside the main region included higher

occurrences of marginally stable grasps.

These grasps use the passive compliance

of soft actuators to hook around the bell

or curl around tentacles. Although less

reliable, these grasps represent a family

of edge cases where the fingers passively

adapt to grasp the target in positions

where caging would likely fail. However,

the success of these marginal grasps may

not generalize to the actual organisms

because they rely on the strength of the

bell and tentacles.

2 cm

Although the laboratory and pilot

studies presented here focused on grasping

either a stationary target or a live jellyfish

in an enclosed space, these results show

promise toward ROV-mounted actuator

operation in the ocean. Wild jellyfish

display a variety of movements and

swimming speeds, from the sedentary

Cassiopea to the complex swimming

behaviors of Cubozoa (box jellyfish)

(48, 49). Most jellyfish have a slight

negative buoyancy and must swim to

survive and feed in the water column.

For example, C. mosaicus swims at a rate of under 60 cm min−1 (50)

both against and along the background current. The average swim

speed of A. aurita depends on the direction of motion and ranges

from 176 to 233 cm min−1 (51).

Despite diversity in movement characteristics, an ROV-mounted

high-torque underwater pump and pressure regulator will make it

possible to grasp gelatinous organisms. When operating soft actuators

using an ROV, pressure regulation would ensure that the actuators

will not be overpressurized (excess pressure will reduce operating

life) and that sufficient flow will enable them to close in a sufficient

amount of time. We expect that the differences between positioning

the gripper on an ROV and using the portable device will depend on

the type of ROV robot arm that is used and the skill of the ROV

pilots. We see promise in the work of Teoh et al. (30), showing that

adept pilots could encase jellyfish at depth with an ROV-mounted

manipulator.

Last, our gripper’s robustness to external forces is large enough

to prevent organisms from being released after they are captured.

Even the worst-case pull force (0.20 ± 0.04 N at 0° pulling angle) is

two orders of magnitude greater than the theoretical thrust force of

0.002 to 0.004 N generated by A. aurita (derived in the Supplementary

Materials). Furthermore, when the gripper is en route to a sample

collection container, the worst-case estimate for the maximum

speed before drag from the water causes the fingers to release (0.7 m s−1)

is still very reasonable for typical ROV operation.

These results represent an unprecedented capability for delicate

manipulation of fragile tissue samples. Although other fiber-reinforced

7 of 11

l

D

o

w

n

o

a

d

e

d

f

r

o

m

h

t

t

p

:

/

/

r

o

b

o

i

t

i

c

s

.

s

c

e

n

c

e

m

a

g

.

o

r

g

/

a

t

i

U

n

v

e

r

s

i

t

y

o

f

i

C

h

n

e

s

e

A

c

a

d

e

m

y

o

f

i

S

c

e

n

c

e

s

o

n

S

e

p

e

m

b

e

r

t

3

0

,

2

0

2

0

Sinatra et al., Sci. Robot. 4, eaax5425 (2019) 28 August 2019SCIENCE ROBOTICS | RESEARCH ARTICLE�

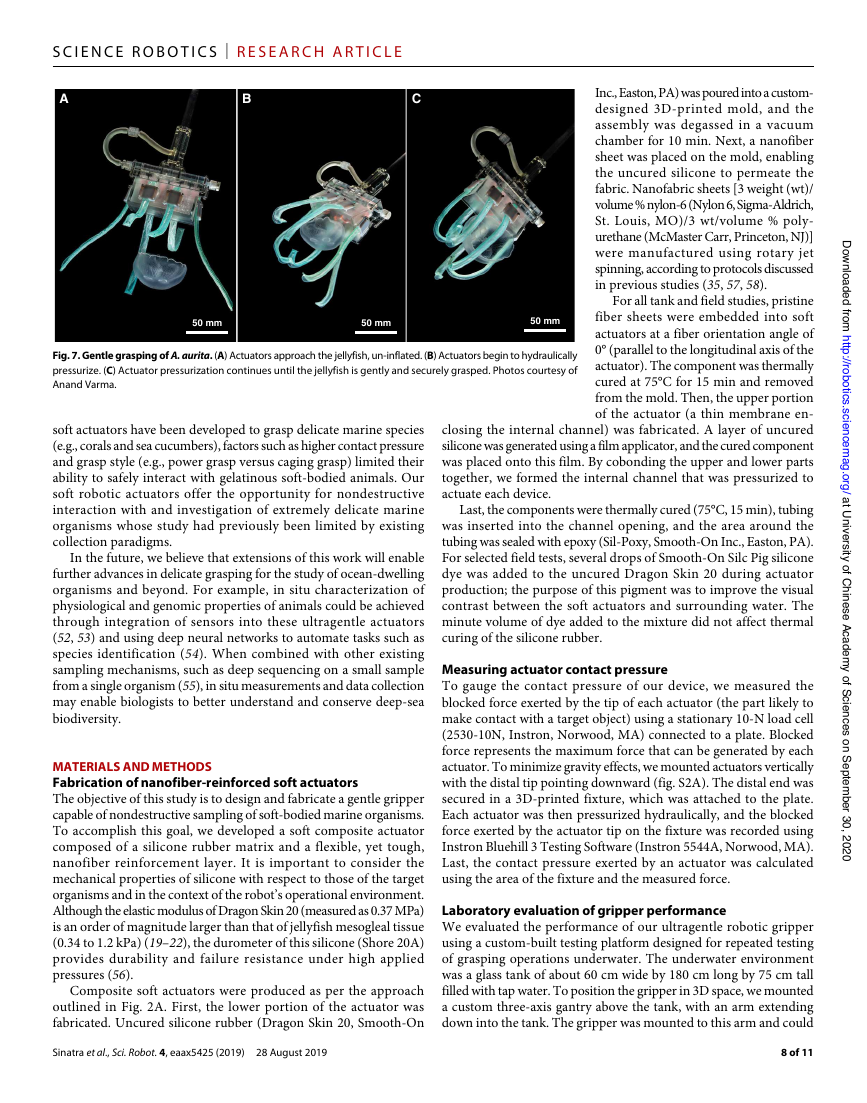

Fig. 7. Gentle grasping of A. aurita. (A) Actuators approach the jellyfish, un-inflated. (B) Actuators begin to hydraulically

pressurize. (C) Actuator pressurization continues until the jellyfish is gently and securely grasped. Photos courtesy of

Anand Varma.

A

B

C

50 mm

50 mm

soft actuators have been developed to grasp delicate marine species

(e.g., corals and sea cucumbers), factors such as higher contact pressure

and grasp style (e.g., power grasp versus caging grasp) limited their

ability to safely interact with gelatinous soft-bodied animals. Our

soft robotic actuators offer the opportunity for nondestructive

interaction with and investigation of extremely delicate marine

organisms whose study had previously been limited by existing

collection paradigms.

In the future, we believe that extensions of this work will enable

further advances in delicate grasping for the study of ocean-dwelling

organisms and beyond. For example, in situ characterization of

physiological and genomic properties of animals could be achieved

through integration of sensors into these ultragentle actuators

(52, 53) and using deep neural networks to automate tasks such as

species identification (54). When combined with other existing

sampling mechanisms, such as deep sequencing on a small sample

from a single organism (55), in situ measurements and data collection

may enable biologists to better understand and conserve deep-sea

biodiversity.

MATERIALS AND METHODS

Fabrication of nanofiber-reinforced soft actuators

The objective of this study is to design and fabricate a gentle gripper

capable of nondestructive sampling of soft-bodied marine organisms.

To accomplish this goal, we developed a soft composite actuator

composed of a silicone rubber matrix and a flexible, yet tough,

nanofiber reinforcement layer. It is important to consider the

mechanical properties of silicone with respect to those of the target

organisms and in the context of the robot’s operational environment.

Although the elastic modulus of Dragon Skin 20 (measured as 0.37 MPa)

is an order of magnitude larger than that of jellyfish mesogleal tissue

(0.34 to 1.2 kPa) (19–22), the durometer of this silicone (Shore 20A)

provides durability and failure resistance under high applied

pressures (56).

Composite soft actuators were produced as per the approach

outlined in Fig. 2A. First, the lower portion of the actuator was

fabricated. Uncured silicone rubber (Dragon Skin 20, Smooth-On

Inc., Easton, PA) was poured into a custom-

designed 3D-printed mold, and the

assembly was degassed in a vacuum

chamber for 10 min. Next, a nanofiber

sheet was placed on the mold, enabling

the uncured silicone to permeate the

fabric. Nanofabric sheets [3 weight (wt)/

volume % nylon-6 (Nylon 6, Sigma-Aldrich,

St. Louis, MO)/3 wt/volume % poly-

urethane (McMaster Carr, Princeton, NJ)]

were manufactured using rotary jet

spinning, according to protocols discussed

in previous studies (35, 57, 58).

50 mm

For all tank and field studies, pristine

fiber sheets were embedded into soft

actuators at a fiber orientation angle of

0° (parallel to the longitudinal axis of the

actuator). The component was thermally

cured at 75°C for 15 min and removed

from the mold. Then, the upper portion

of the actuator (a thin membrane en-

closing the internal channel) was fabricated. A layer of uncured

silicone was generated using a film applicator, and the cured component

was placed onto this film. By cobonding the upper and lower parts

together, we formed the internal channel that was pressurized to

actuate each device.

Last, the components were thermally cured (75°C, 15 min), tubing

was inserted into the channel opening, and the area around the

tubing was sealed with epoxy (Sil-Poxy, Smooth-On Inc., Easton, PA).

For selected field tests, several drops of Smooth-On Silc Pig silicone

dye was added to the uncured Dragon Skin 20 during actuator

production; the purpose of this pigment was to improve the visual

contrast between the soft actuators and surrounding water. The

minute volume of dye added to the mixture did not affect thermal

curing of the silicone rubber.

Measuring actuator contact pressure

To gauge the contact pressure of our device, we measured the

blocked force exerted by the tip of each actuator (the part likely to

make contact with a target object) using a stationary 10-N load cell

(2530-10N, Instron, Norwood, MA) connected to a plate. Blocked

force represents the maximum force that can be generated by each

actuator. To minimize gravity effects, we mounted actuators vertically

with the distal tip pointing downward (fig. S2A). The distal end was

secured in a 3D-printed fixture, which was attached to the plate.

Each actuator was then pressurized hydraulically, and the blocked

force exerted by the actuator tip on the fixture was recorded using

Instron Bluehill 3 Testing Software (Instron 5544A, Norwood, MA).

Last, the contact pressure exerted by an actuator was calculated

using the area of the fixture and the measured force.

Laboratory evaluation of gripper performance

We evaluated the performance of our ultragentle robotic gripper

using a custom-built testing platform designed for repeated testing

of grasping operations underwater. The underwater environment

was a glass tank of about 60 cm wide by 180 cm long by 75 cm tall

filled with tap water. To position the gripper in 3D space, we mounted

a custom three-axis gantry above the tank, with an arm extending

down into the tank. The gripper was mounted to this arm and could

8 of 11

l

D

o

w

n

o

a

d

e

d

f

r

o

m

h

t

t

p

:

/

/

r

o

b

o

i

t

i

c

s

.

s

c

e

n

c

e

m

a

g

.

o

r

g

/

a

t

i

U

n

v

e

r

s

i

t

y

o

f

i

C

h

n

e

s

e

A

c

a

d

e

m

y

o

f

i

S

c

e

n

c

e

s

o

n

S

e

p

e

m

b

e

r

t

3

0

,

2

0

2

0

Sinatra et al., Sci. Robot. 4, eaax5425 (2019) 28 August 2019SCIENCE ROBOTICS | RESEARCH ARTICLE�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc