1 About this document

1.1 Function of this document

1.2 Target group

1.3 Depth of information

1.4 Symbology used

2 For your safety

2.1 Authorised personnel

2.2 Correct use

2.3 General safety notes and protective measures

2.3.1 Electrical installation work

2.3.2 Laser radiation from the laser measurement system

2.4 Quick stop and Quick restart

2.4.1 Switching off the LMS

2.4.2 Switching back on the LMS

2.5 Environmental protection

2.5.1 Power consumption

2.5.2 Disposal after final de-commissioning

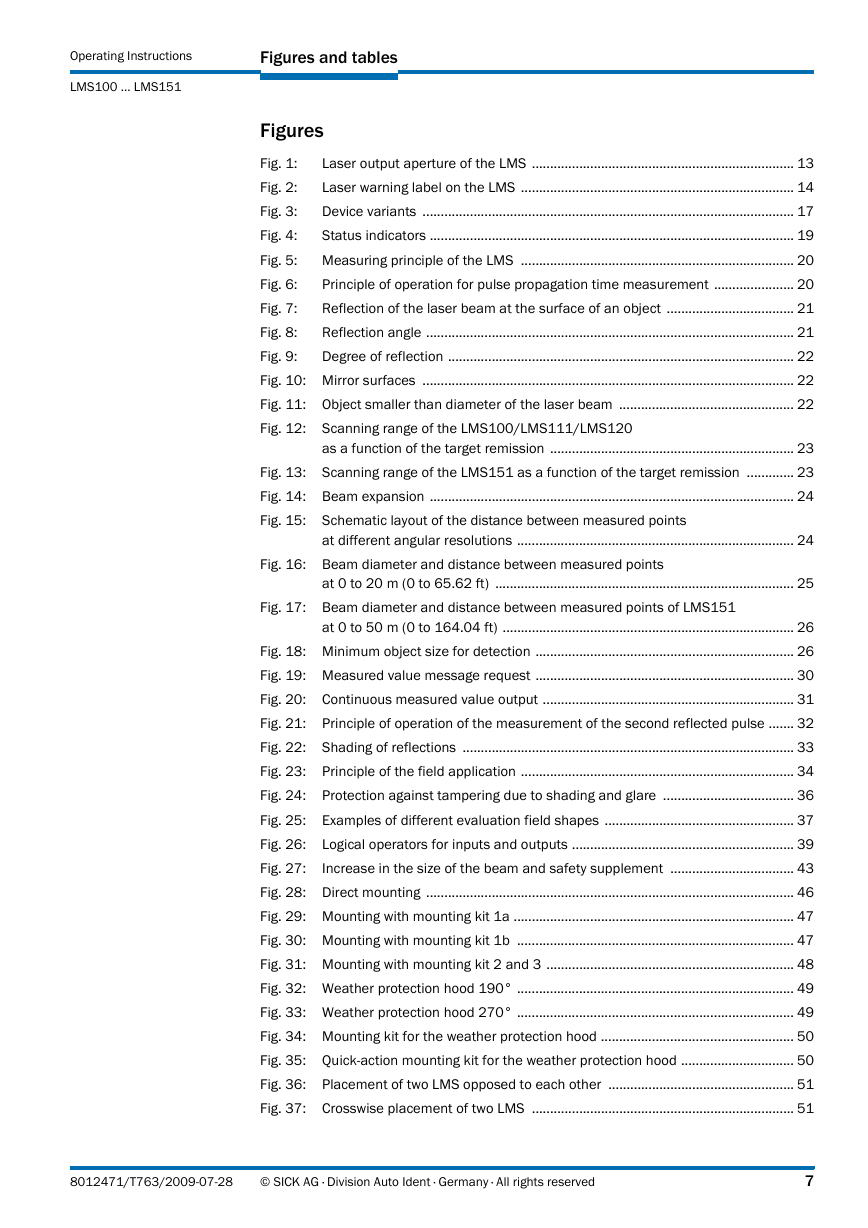

3 Product description

3.1 Delivery

3.1.1 Contents of the CD-ROM

3.2 Device variants

3.3 Special features of the LMS

3.4 Controls and status indicators

3.4.1 User interface

3.4.2 Status indicators

3.5 Operating principle of the LMS

3.5.1 Scanning range of the LMS

3.5.2 Beam diameter and distance between measured points

3.5.3 Minimum object size

3.5.4 Contamination measurement

3.6 Applications

3.7 Measurement of objects

3.7.1 Basic parameters

3.7.2 Filter

3.7.3 Measured value output

3.7.4 Measured value output for a second reflected pulse

3.8 Field application

3.8.1 Evaluation cases

3.8.2 Evaluation fields

3.8.3 Operator for the evaluation cases on the output

3.9 Inputs and outputs

3.9.1 Digital switching inputs

3.9.2 Encoder inputs

3.9.3 Digital switching outputs

3.9.4 External switching outputs

3.9.5 Logical operators for inputs and outputs

3.9.6 Sabotage outputs

3.10 Data interfaces

3.10.1 Ethernet interface

3.10.2 CAN

3.10.3 Serial host interface

3.10.4 Serial auxiliary interface

3.11 Data communication using messages

3.11.1 Frame and coding for the messages

3.12 Planning

3.12.1 LMS system requirements

3.12.2 Mounting requirements

3.12.3 Distance between LMS and the object/surface to be monitored

4 Mounting

4.1 Overview of the mounting steps

4.2 Preparations for mounting

4.2.1 Components to be mounted

4.2.2 Material and accessories necessary

4.2.3 Necessary tools

4.2.4 Select mounting location

4.3 Mounting steps

4.3.1 Direct mounting

4.3.2 Mounting with mounting kit 1a or 1b

4.3.3 Mounting with mounting kit 2 and 3

4.3.4 Mounting the LMS111/LMS151 with weather protection hood

4.3.5 Using multiple LMS laser measurement systems

4.4 Dismanteling the system

5 Electrical installation

5.1 Overview of the installation steps

5.2 Connections of the LMS

5.2.1 Connections of the LMS100

5.2.2 Connections of the LMS120

5.2.3 Connections of the LMS111/LMS151

5.3 Preparing the electrical installation

5.3.1 Supply voltage

5.3.2 Wire cross-sections

5.3.3 General conditions for the data interfaces

5.4 Perform electrical installation on the LMS

5.4.1 Equipment

5.4.2 Connection on the auxiliary interface and the Ethernet interface of the LMS100�…�LMS151

5.4.3 Connecting the system plug on the LMS100 and LMS120

5.4.4 Connecting the round M12 plug connector on the LMS111/LMS151

5.4.5 Wiring of inputs and outputs on the LMS

6 Commissioning and configuration

6.1 Overview of the commissioning steps

6.2 SOPAS ET configuration software

6.2.1 System requirements for SOPAS ET

6.2.2 Installation of SOPAS ET

6.2.3 SOPAS ET default setting

6.3 Establish communication with the LMS

6.3.1 Connect the data interfaces

6.3.2 Starting SOPAS ET and opening the scan assistant

6.3.3 Configuring the serial connection

6.3.4 Configuring the Ethernet connection

6.3.5 Performing scan

6.4 Initial commissioning

6.4.1 Configuring the LMS

6.5 Connection and test measurement

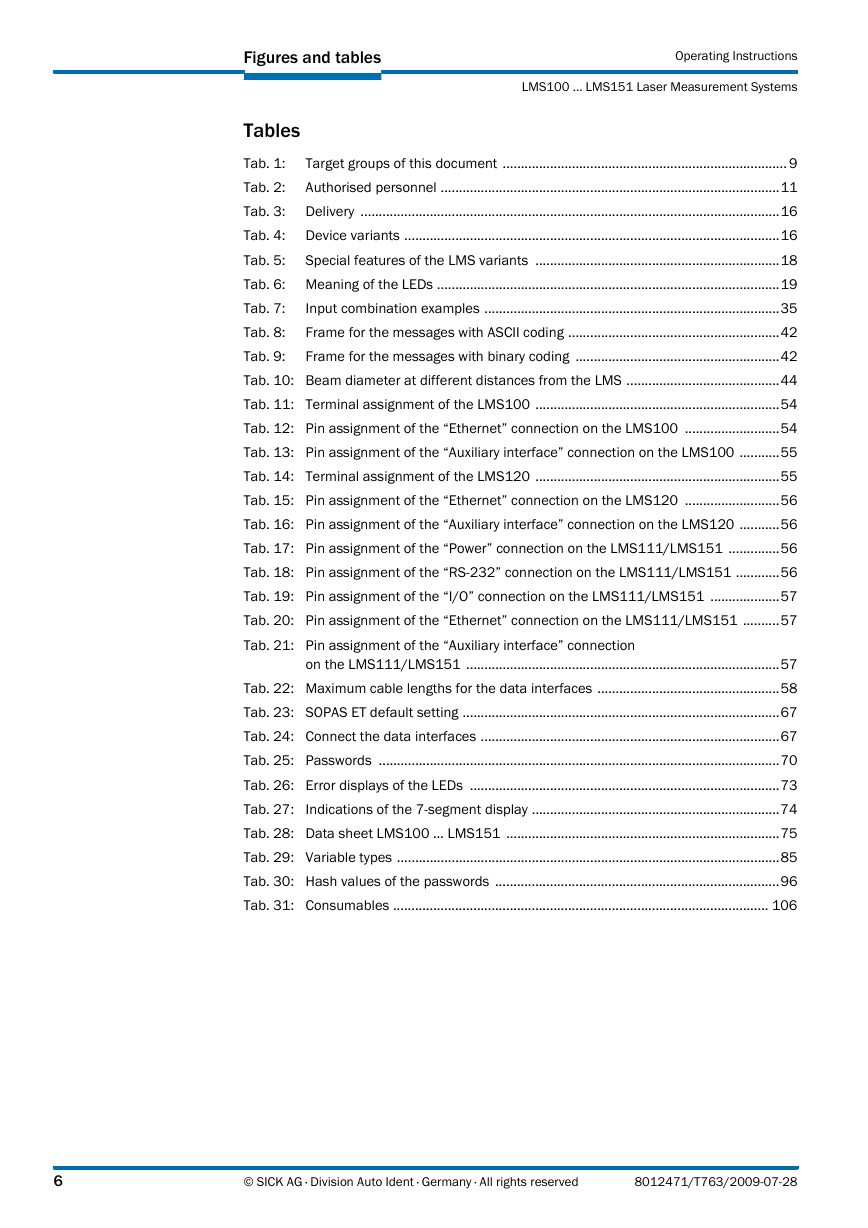

7 Maintenance

7.1 Maintenance during operation

7.1.1 Cleaning the optics cover

7.2 Exchanging an LMS

8 Troubleshooting

8.1 In the event of faults or errors

8.2 Error displays of the LEDs

8.3 Indications of the 7-segment display

8.4 Detailed error analysis

8.4.1 Field evaluation monitor

8.4.2 Field evaluation logging

9 Technical specifications

9.1 Data sheet LMS laser measurement system

9.2 Dimensional drawings

9.2.1 Dimensional drawing LMS100/LMS120

9.2.2 Dimensional drawing LMS111/LMS151

9.2.3 Dimensional drawings, mounting kits

9.2.4 Dimensional drawings, weather protection hoods

10 Annex

10.1 Overview of the annexes

10.2 Messages

10.3 Ordering information

10.3.1 Consumables

10.4 Glossary

10.5 EC Declaration of Conformity

SICK

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc