Abaqus Training Seminar

for Machining Simulation

Mohamed Elkhateeb

Date: Sept. 29. 2017

PPPUUURRRDDDUUUEEE ––– CCCLLLAAAMMM

http://engineering.purdue.edu/CLM/

Purdue University : Center for Laser-based Manufacturing

PPPUUURRRDDDUUUEEE ––– CCCLLLAAAMMM

�

Content

1. Machining simulation Methodology

2. Abaqus Workbench

3. 2D Machining Simulation of AISI 4140

Steel

4. 3D Machining Simulation of Ti6Al4V

Interaction

5. Conclusion

6. ALE

Purdue University : Center for Laser-based Manufacturing

PPPUUURRRDDDUUUEEE ––– CCCLLLAAAMMM

�

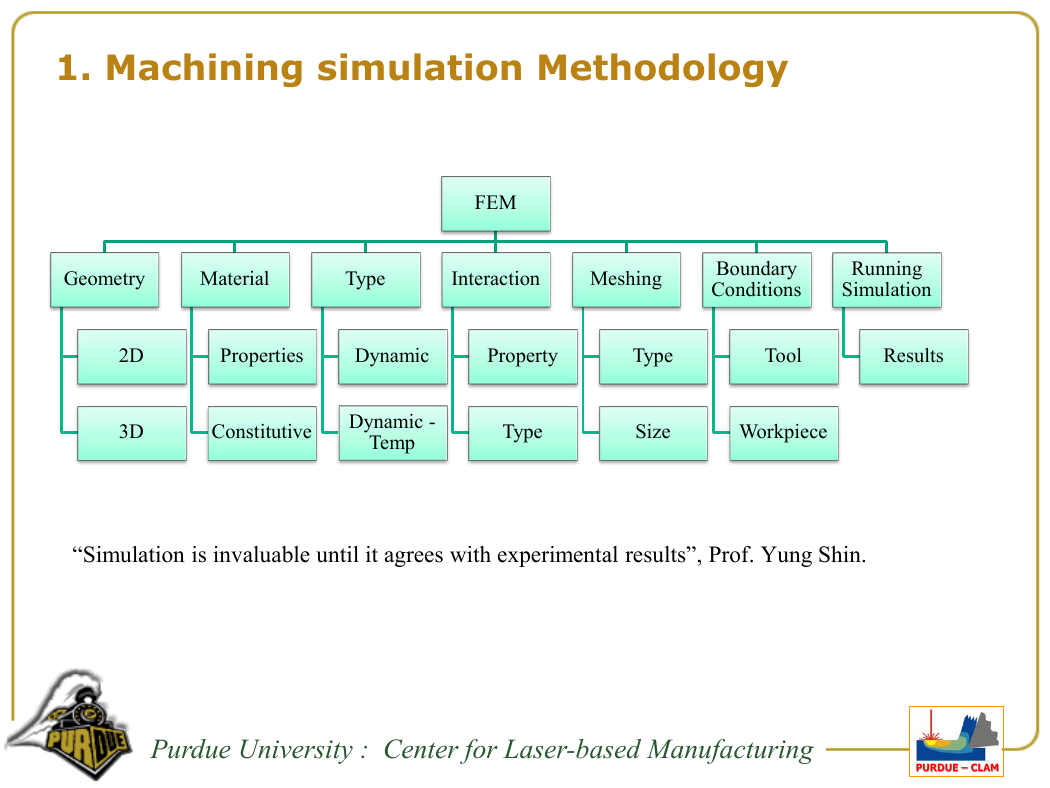

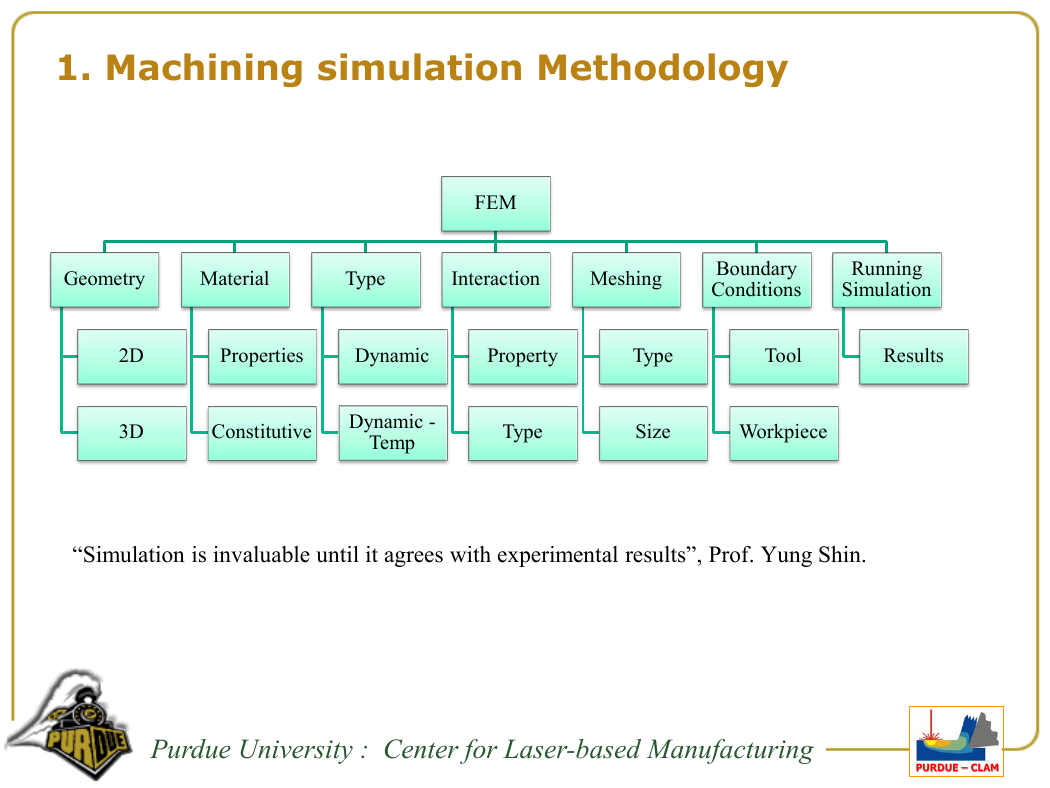

1. Machining simulation Methodology

FEM

Geometry

Material

Type

Interaction

Meshing

Boundary

Conditions

Running

Simulation

2D

3D

Properties

Dynamic

Property

Type

Tool

Results

Constitutive

Dynamic -

Temp

Type

Size

Workpiece

“Simulation is invaluable until it agrees with experimental results”, Prof. Yung Shin.

Purdue University : Center for Laser-based Manufacturing

PPPUUURRRDDDUUUEEE ––– CCCLLLAAAMMM

�

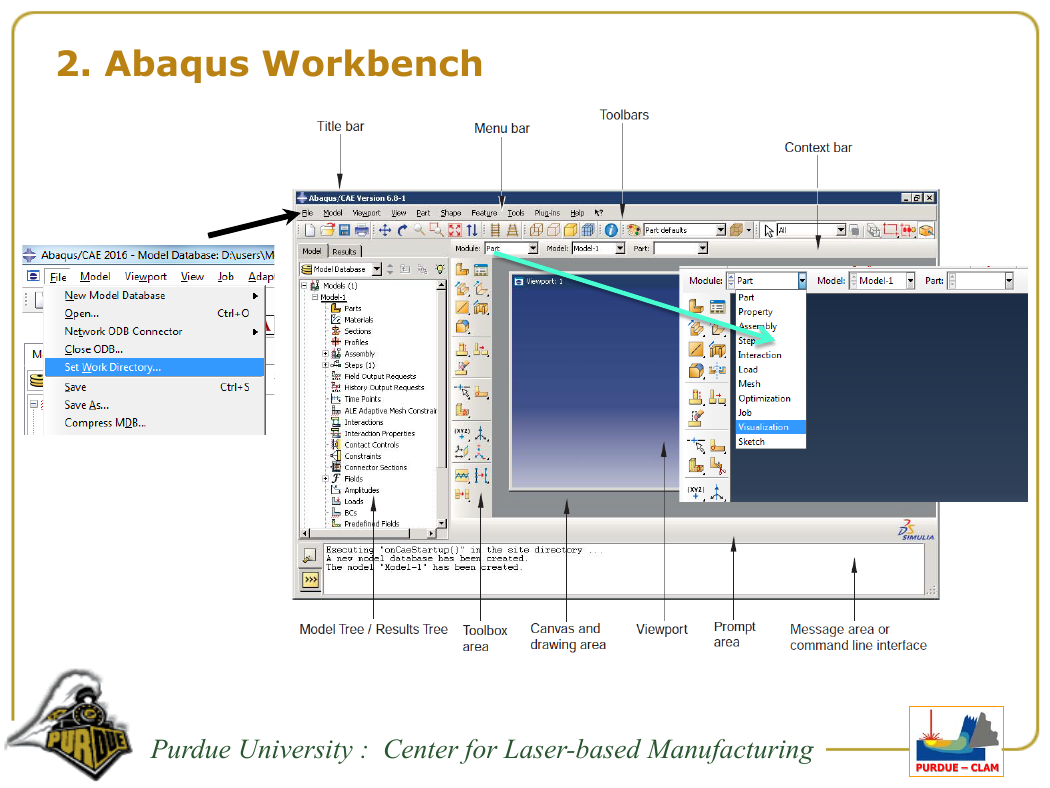

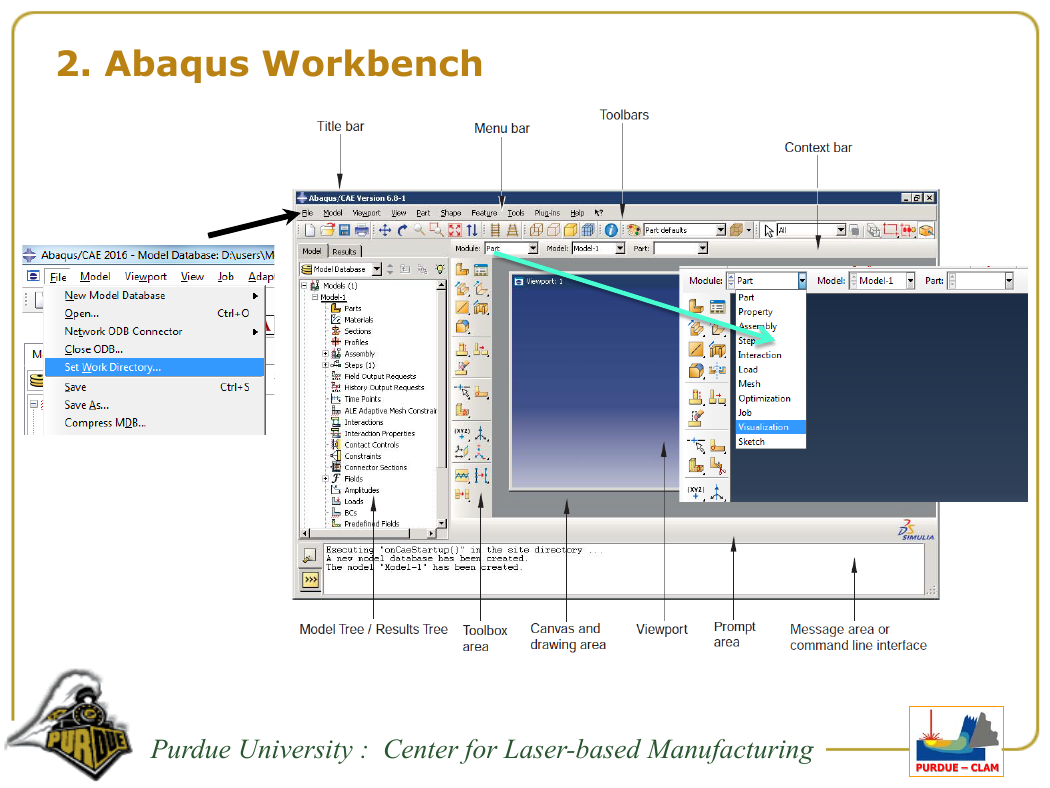

2. Abaqus Workbench

Purdue University : Center for Laser-based Manufacturing

PPPUUURRRDDDUUUEEE ––– CCCLLLAAAMMM

�

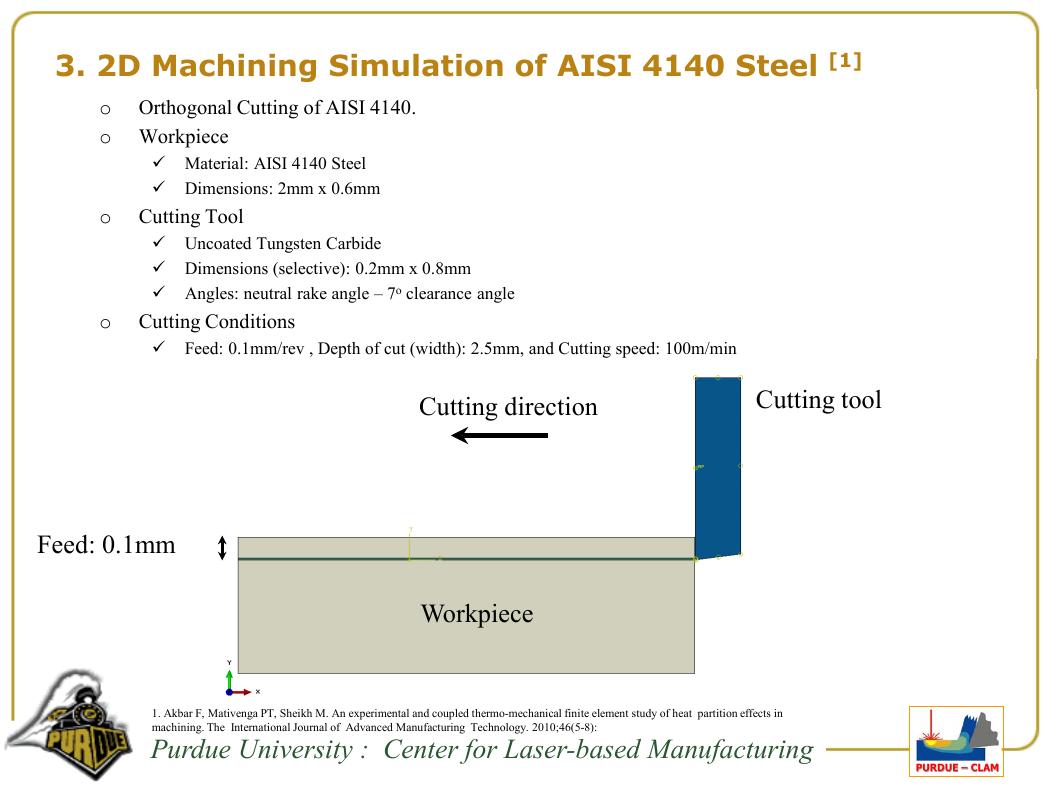

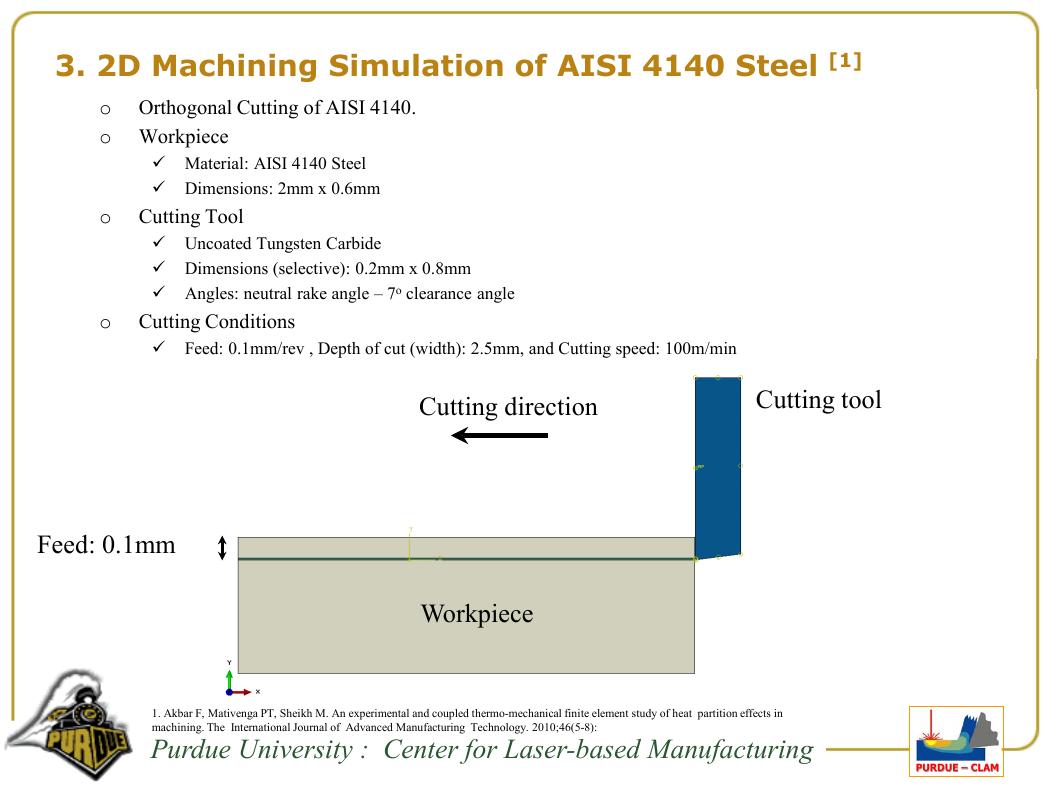

3. 2D Machining Simulation of AISI 4140 Steel [1]

o Orthogonal Cutting of AISI 4140.

o Workpiece

Material: AISI 4140 Steel

Dimensions: 2mm x 0.6mm

o Cutting Tool

Uncoated Tungsten Carbide

Dimensions (selective): 0.2mm x 0.8mm

Angles: neutral rake angle – 7o clearance angle

o Cutting Conditions

Feed: 0.1mm/rev , Depth of cut (width): 2.5mm, and Cutting speed: 100m/min

Cutting direction

Cutting tool

Workpiece

1. Akbar F, Mativenga PT, Sheikh M. An experimental and coupled thermo-mechanical finite element study of heat partition effects in

machining. The International Journal of Advanced Manufacturing Technology. 2010;46(5-8):

Purdue University : Center for Laser-based Manufacturing

PPPUUURRRDDDUUUEEE ––– CCCLLLAAAMMM

Feed: 0.1mm

�

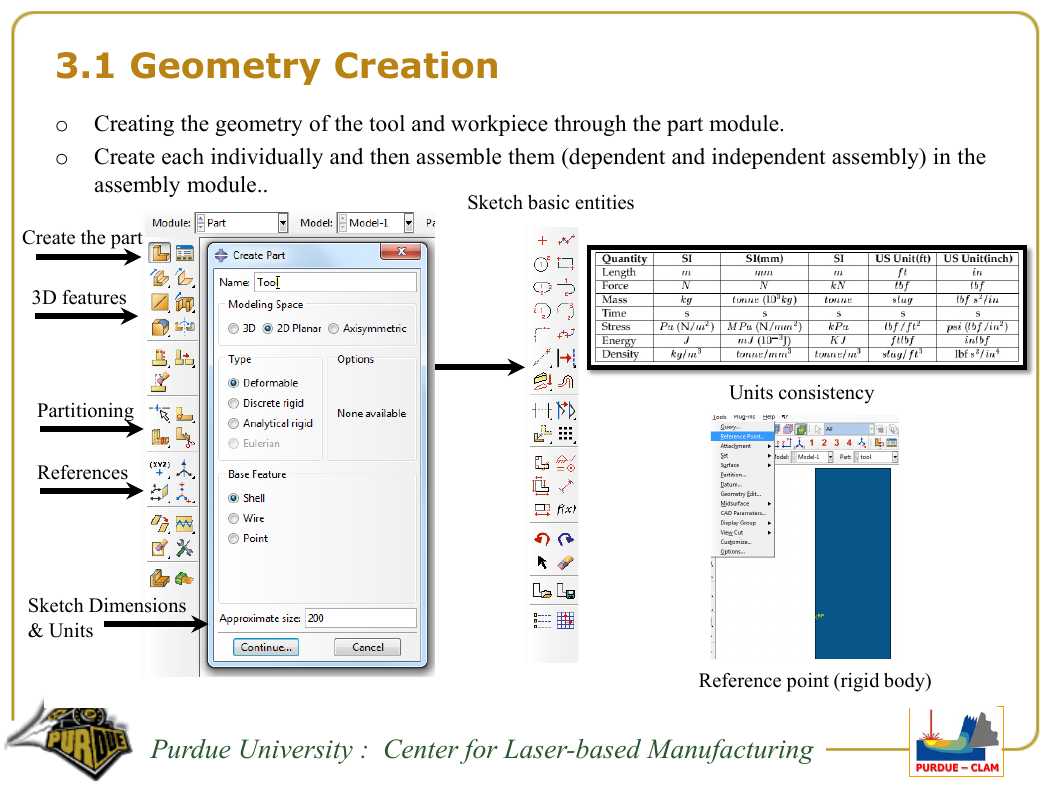

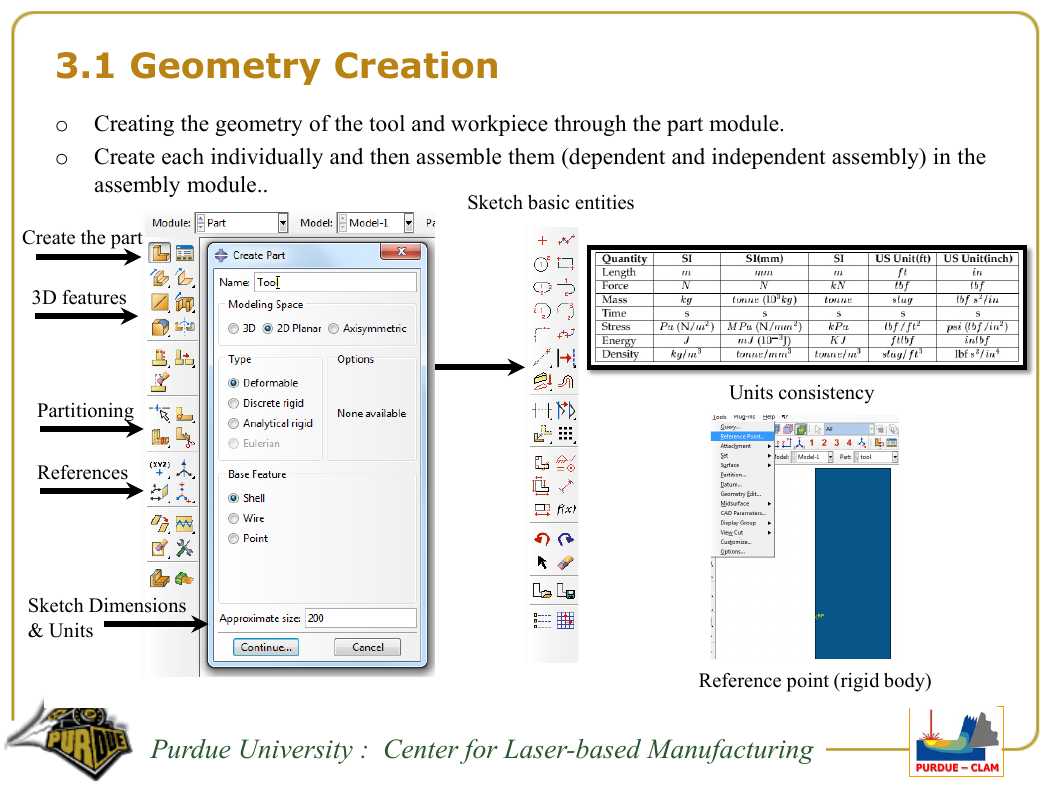

3.1 Geometry Creation

o Creating the geometry of the tool and workpiece through the part module.

o Create each individually and then assemble them (dependent and independent assembly) in the

assembly module..

Create the part

3D features

Partitioning

References

Sketch Dimensions

& Units

Sketch basic entities

Units consistency

Reference point (rigid body)

Purdue University : Center for Laser-based Manufacturing

PPPUUURRRDDDUUUEEE ––– CCCLLLAAAMMM

�

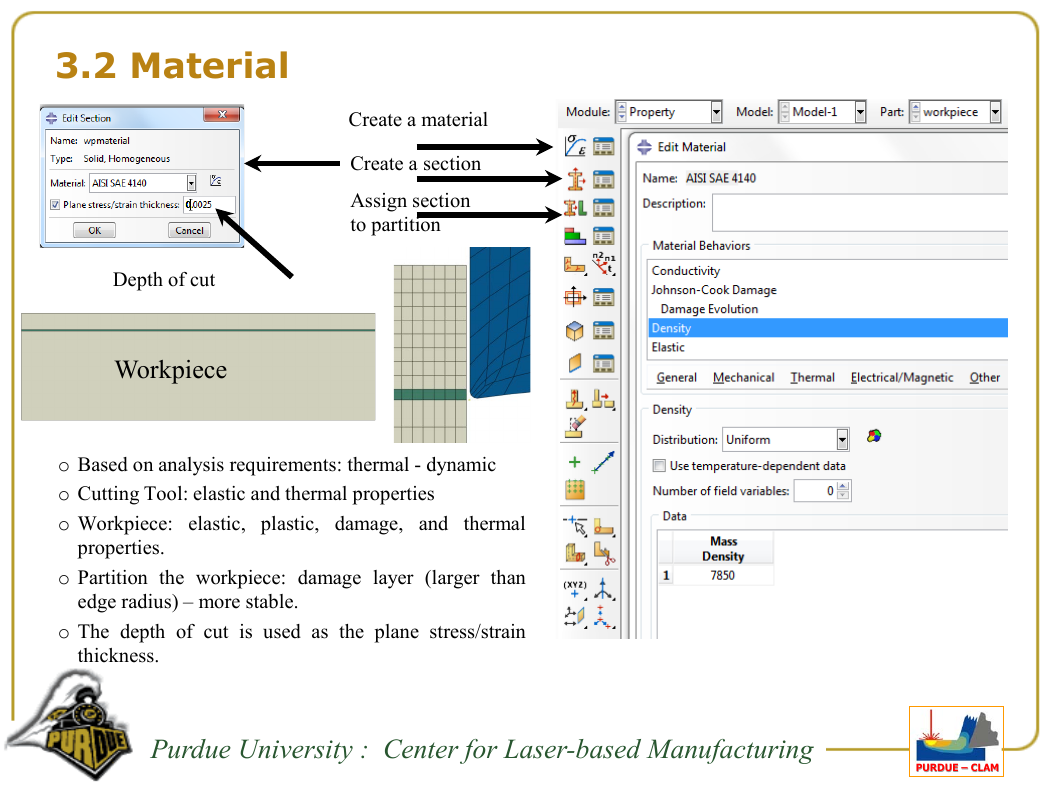

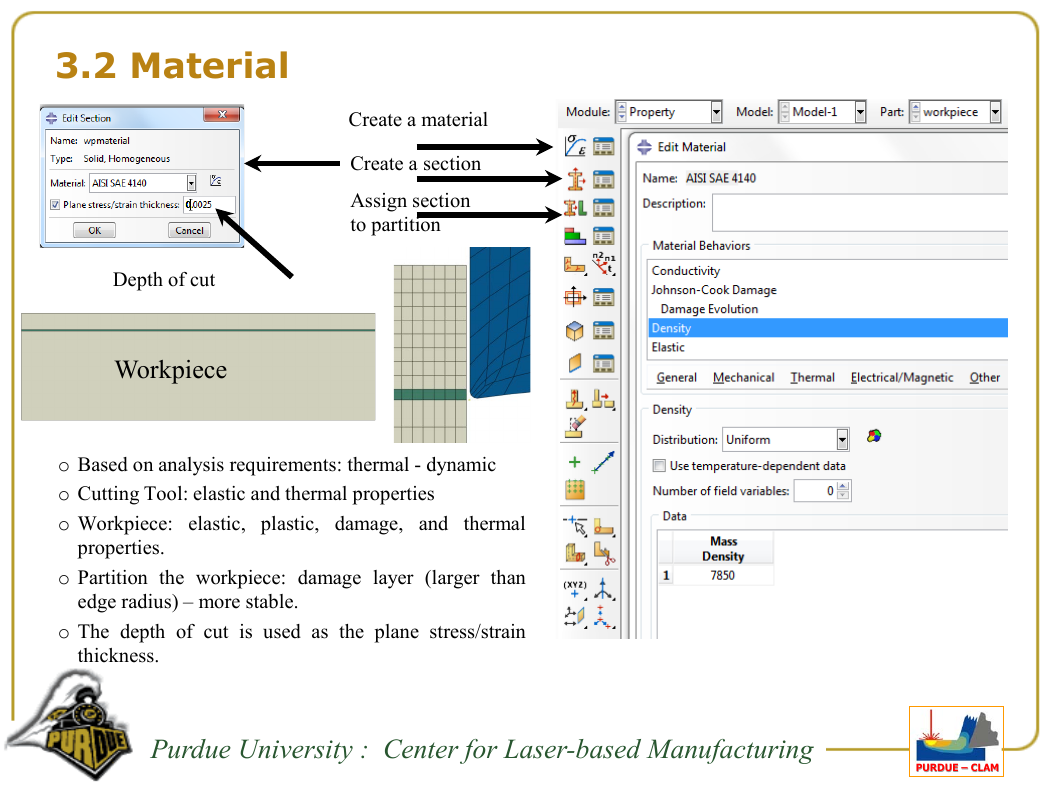

3.2 Material

Depth of cut

Workpiece

Create a material

Create a section

Assign section

to partition

o Based on analysis requirements: thermal - dynamic

o Cutting Tool: elastic and thermal properties

o Workpiece: elastic, plastic, damage, and thermal

properties.

o Partition the workpiece: damage layer (larger than

edge radius) – more stable.

o The depth of cut is used as the plane stress/strain

thickness.

Purdue University : Center for Laser-based Manufacturing

PPPUUURRRDDDUUUEEE ––– CCCLLLAAAMMM

�

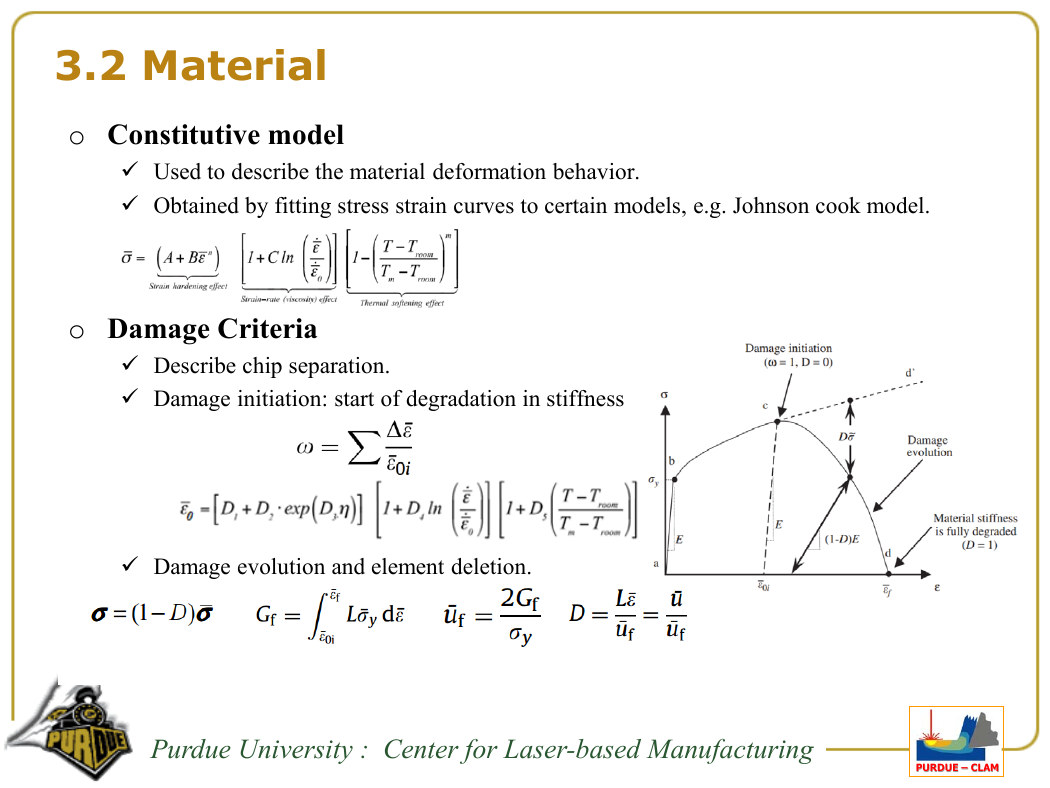

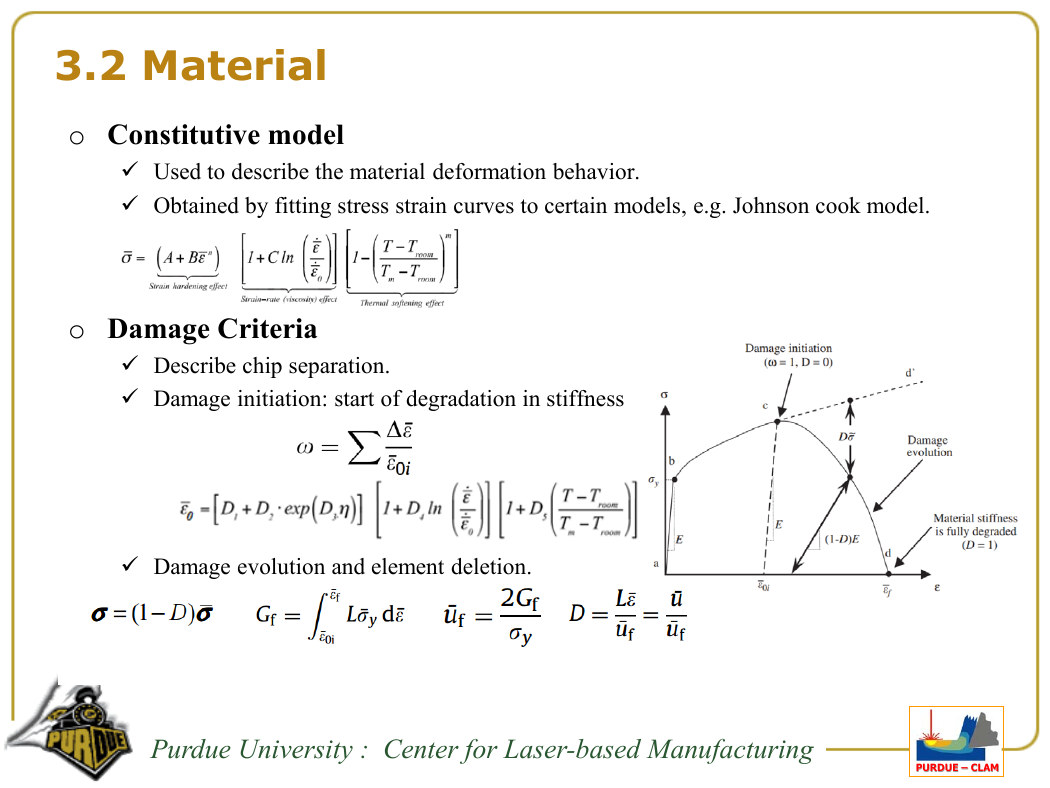

3.2 Material

o Constitutive model

Used to describe the material deformation behavior.

Obtained by fitting stress strain curves to certain models, e.g. Johnson cook model.

o Damage Criteria

Describe chip separation.

Damage initiation: start of degradation in stiffness

Damage evolution and element deletion.

Purdue University : Center for Laser-based Manufacturing

PPPUUURRRDDDUUUEEE ––– CCCLLLAAAMMM

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc