A4950

Full-Bridge DMOS PWM Motor Driver

Features and Benefits

• Low RDS(on) outputs

• Overcurrent protection (OCP)

▫ Motor short protection

▫ Motor lead short to ground protection

▫ Motor lead short to battery protection

• Low Power Standby mode

• Adjustable PWM current limit

• Synchronous rectification

• Internal undervoltage lockout (UVLO)

• Crossover-current protection

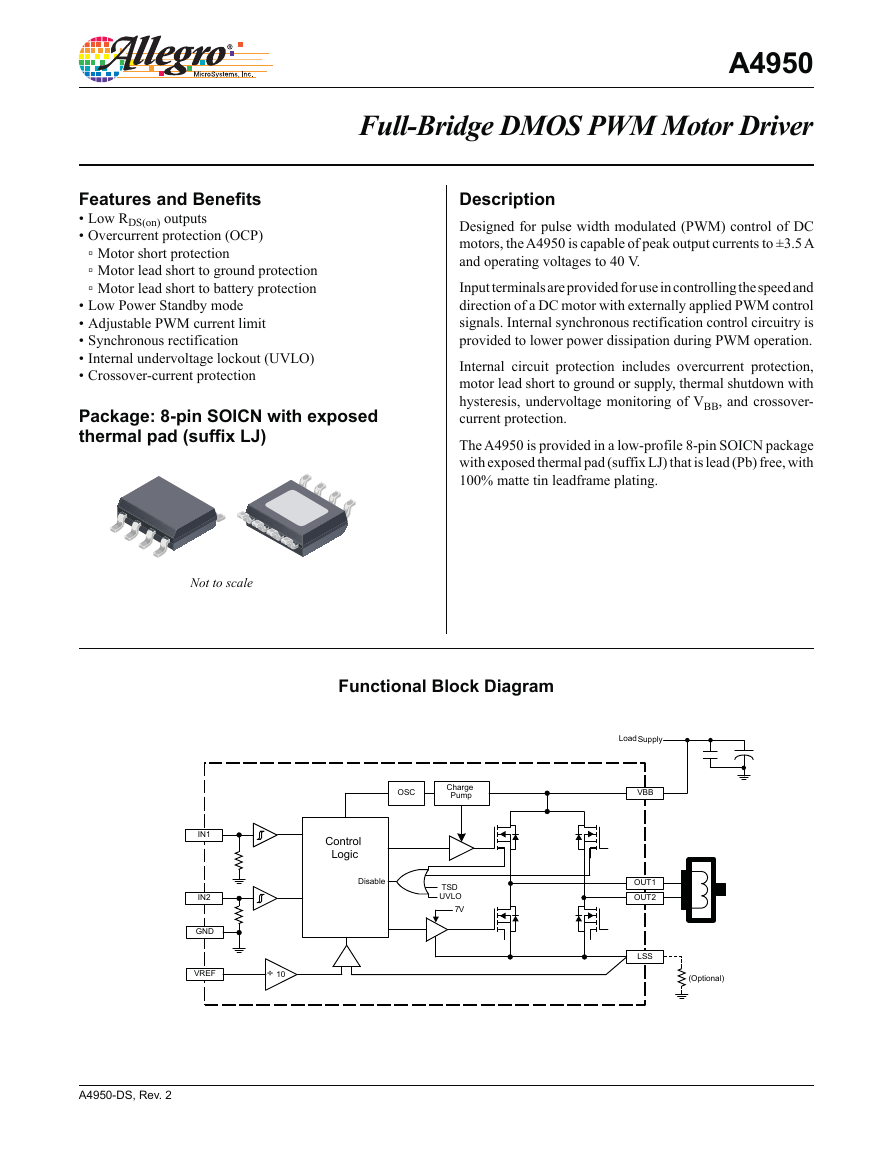

Package: 8-pin SOICN with exposed

thermal pad (suffix LJ)

Description

Designed for pulse width modulated (PWM) control of DC

motors, the A4950 is capable of peak output currents to ±3.5 A

and operating voltages to 40 V.

Input terminals are provided for use in controlling the speed and

direction of a DC motor with externally applied PWM control

signals. Internal synchronous rectification control circuitry is

provided to lower power dissipation during PWM operation.

Internal circuit protection includes overcurrent protection,

motor lead short to ground or supply, thermal shutdown with

hysteresis, undervoltage monitoring of VBB, and crossover-

current protection.

The A4950 is provided in a low-profile 8-pin SOICN package

with exposed thermal pad (suffix LJ) that is lead (Pb) free, with

100% matte tin leadframe plating.

Not to scale

IN1

IN2

GND

VREF

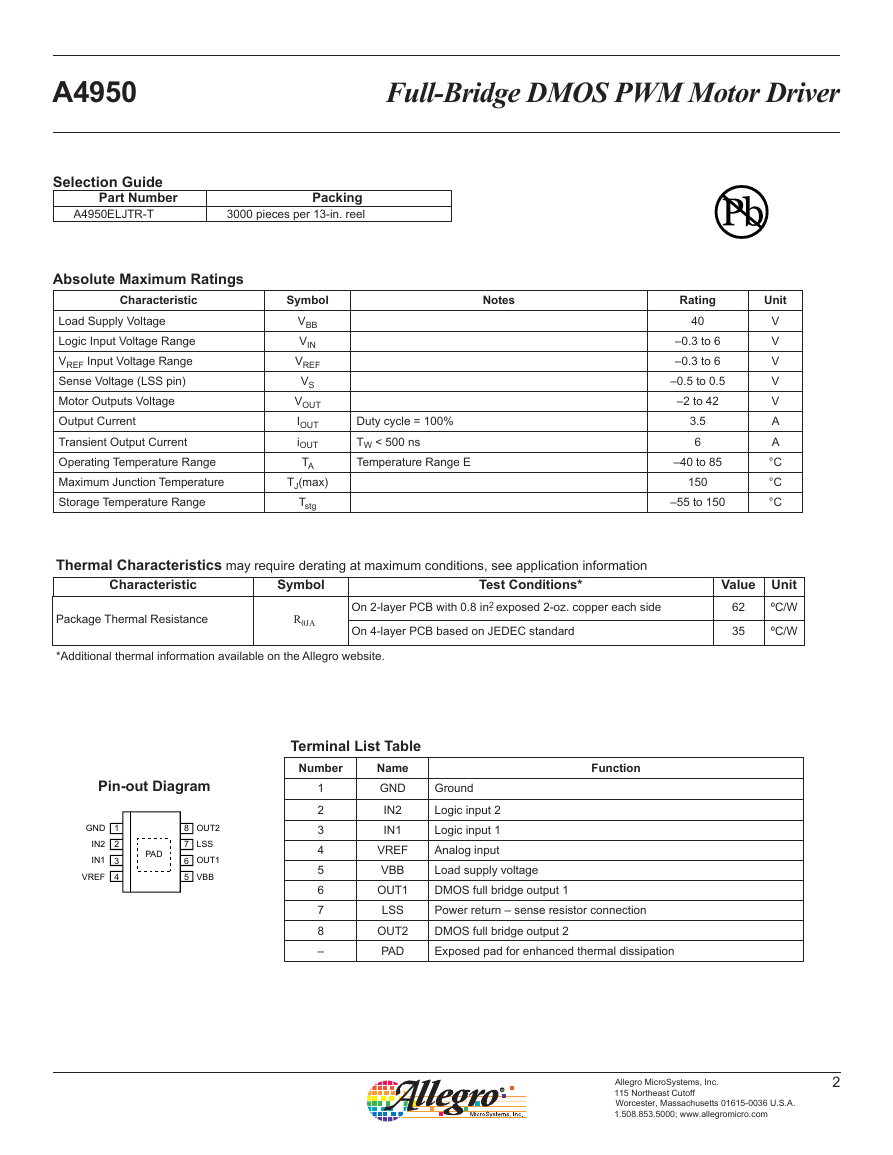

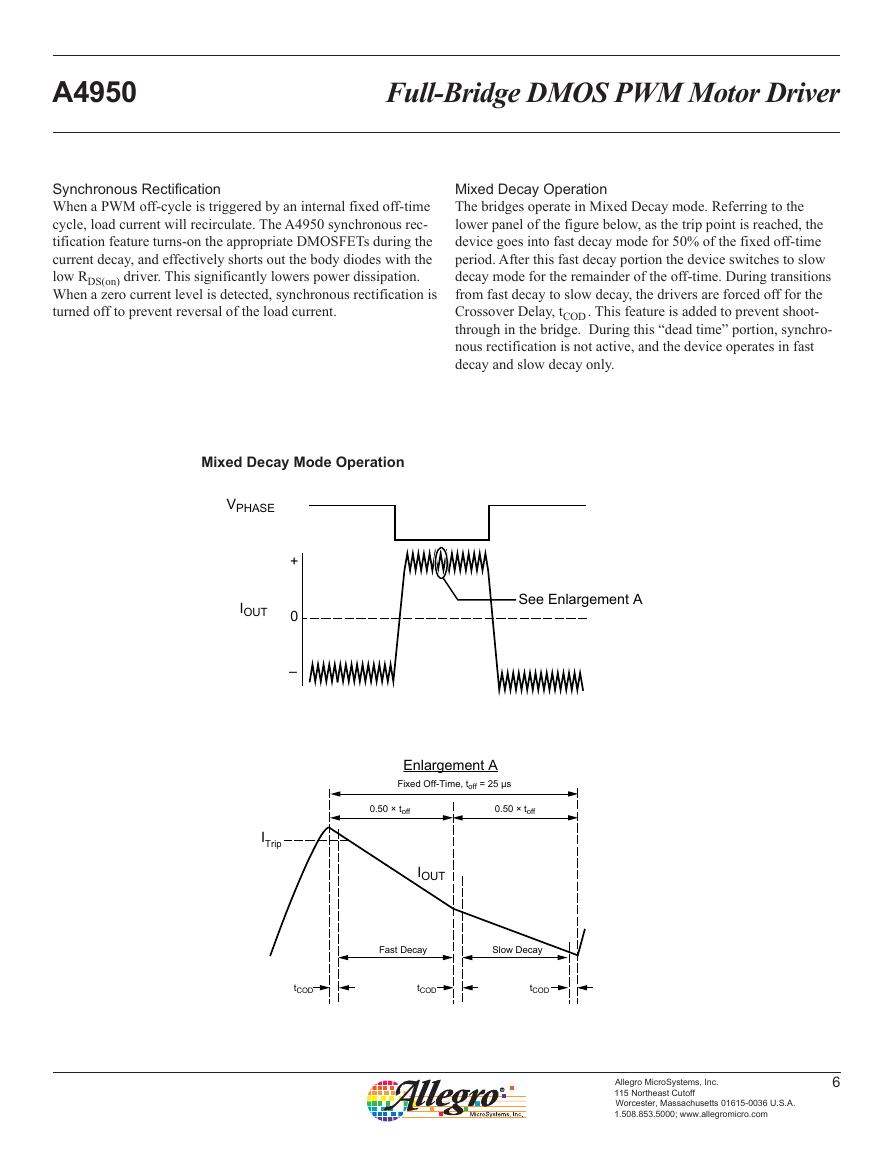

Functional Block Diagram

OSC

Charge

Pump

Control

Logic

Disable

TSD

UVLO

7V

Load Supply

VBB

OUT1

OUT2

LSS

÷

10

(Optional)

A4950-DS, Rev. 2

�

A4950

Full-Bridge DMOS PWM Motor Driver

Selection Guide

Part Number

A4950ELJTR-T

Packing

3000 pieces per 13-in. reel

Absolute Maximum Ratings

Characteristic

Symbol

Notes

Load Supply Voltage

Logic Input Voltage Range

VREF Input Voltage Range

Sense Voltage (LSS pin)

Motor Outputs Voltage

Output Current

Transient Output Current

Operating Temperature Range

Maximum Junction Temperature

Storage Temperature Range

VBB

VIN

VREF

VS

VOUT

IOUT

iOUT

TA

TJ(max)

Tstg

Duty cycle = 100%

TW < 500 ns

Temperature Range E

Rating

40

–0.3 to 6

–0.3 to 6

–0.5 to 0.5

–2 to 42

3.5

6

–40 to 85

150

–55 to 150

Unit

V

V

V

V

V

A

A

°C

°C

°C

Thermal Characteristics may require derating at maximum conditions, see application information

Characteristic

Package Thermal Resistance

Symbol

RθJA

Test Conditions*

On 2-layer PCB with 0.8 in2. exposed 2-oz. copper each side

On 4-layer PCB based on JEDEC standard

Value Unit

ºC/W

62

35

ºC/W

*Additional thermal information available on the Allegro website.

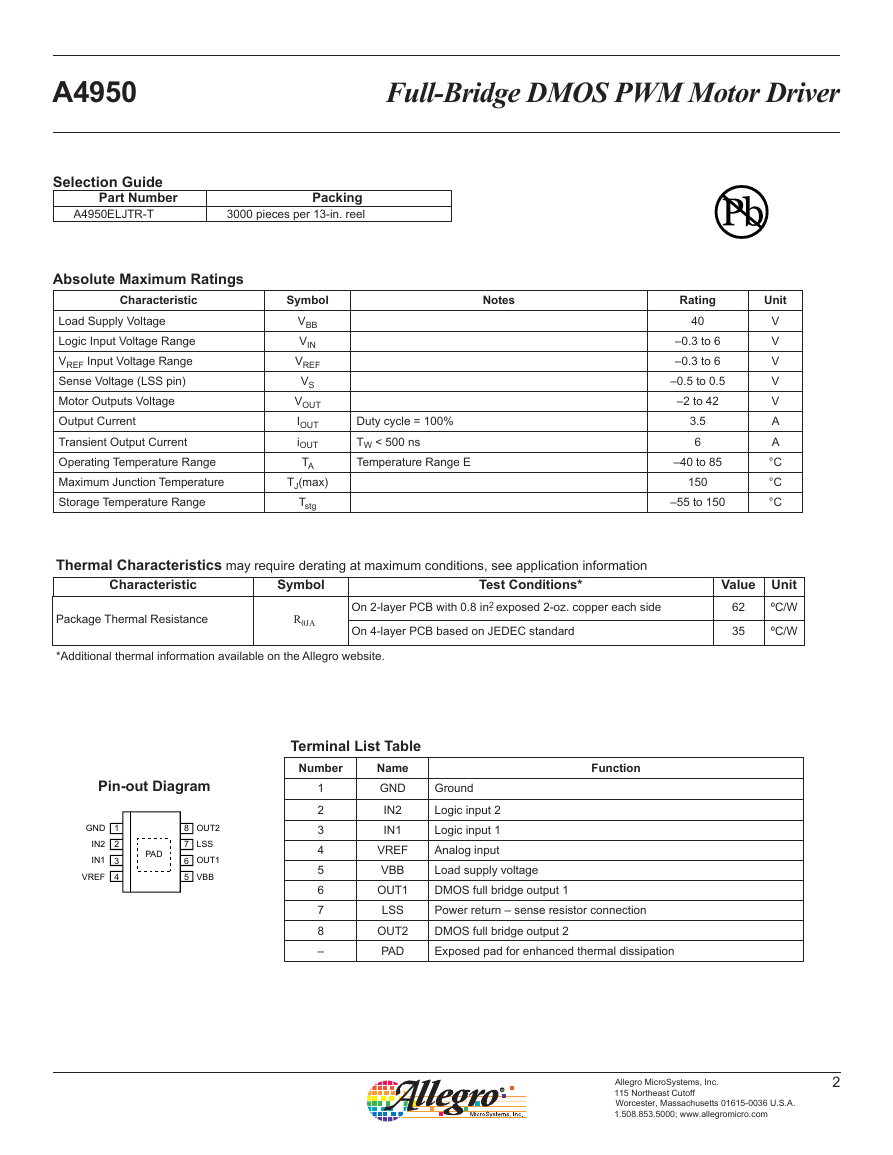

Pin-out Diagram

GND

IN2

IN1

VREF

1

2

3

4

PAD

8

7

6

5

OUT2

LSS

OUT1

VBB

Terminal List Table

Number

Name

GND

IN2

IN1

VREF

VBB

OUT1

LSS

OUT2

PAD

1

2

3

4

5

6

7

8

–

Function

Ground

Logic input 2

Logic input 1

Analog input

Load supply voltage

DMOS full bridge output 1

Power return – sense resistor connection

DMOS full bridge output 2

Exposed pad for enhanced thermal dissipation

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

2

�

A4950

Full-Bridge DMOS PWM Motor Driver

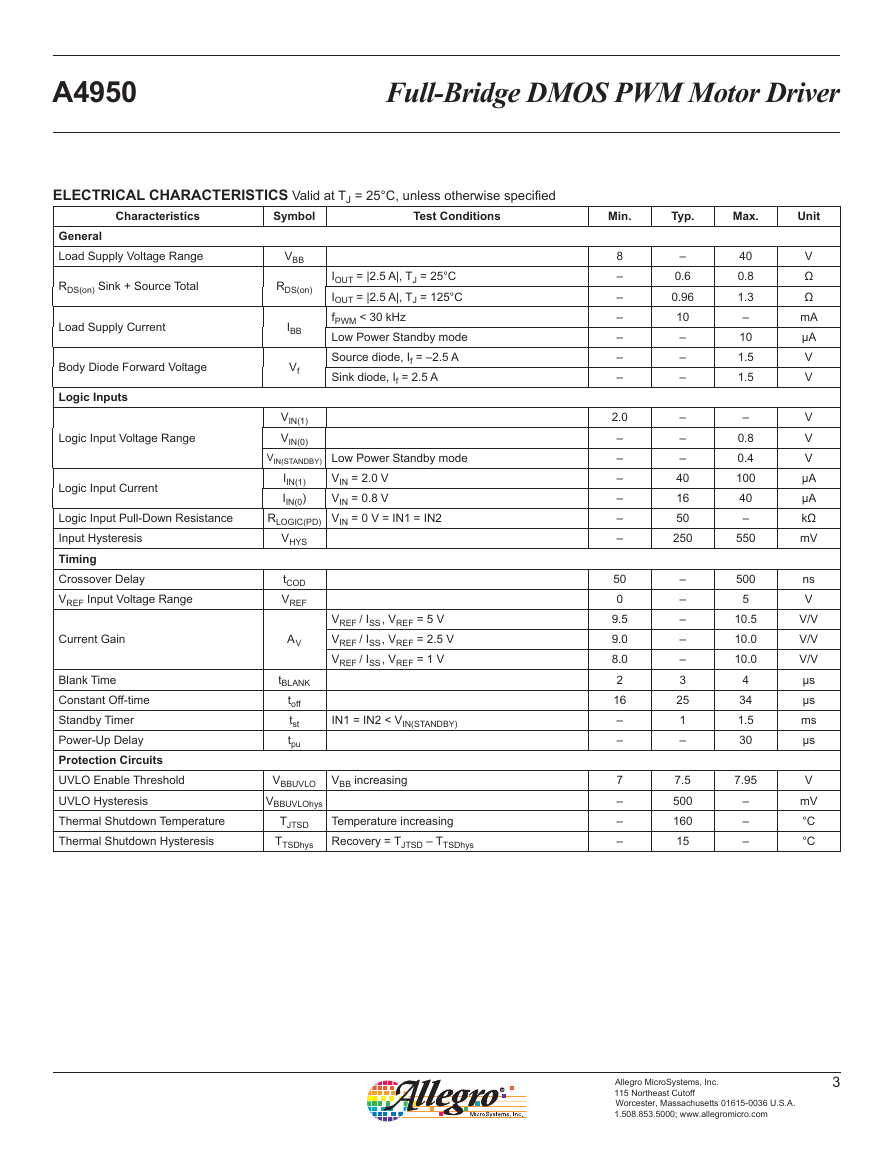

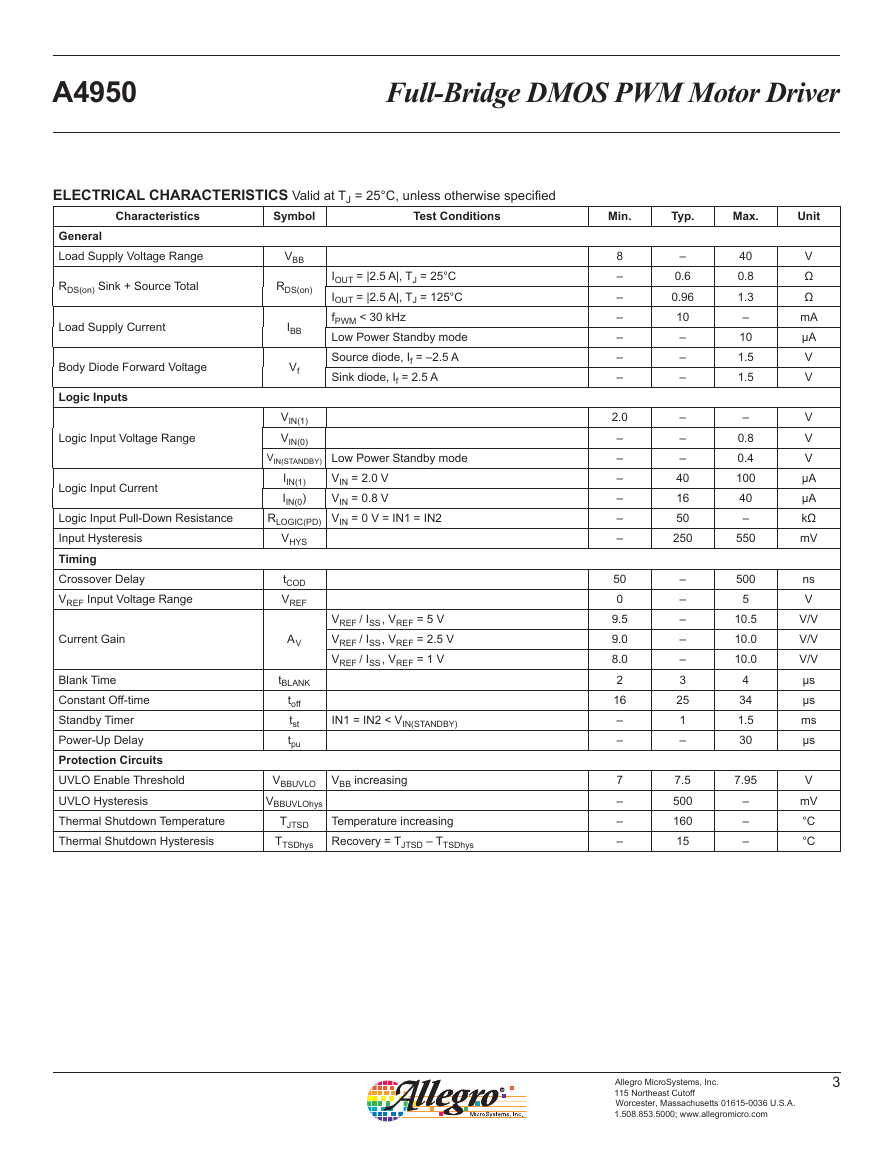

ELECTRICAL CHARACTERISTICS Valid at TJ = 25°C, unless otherwise specified

Characteristics

Symbol

Test Conditions

Min.

Typ.

Max.

Unit

General

Load Supply Voltage Range

RDS(on) Sink + Source Total

Load Supply Current

Body Diode Forward Voltage

Logic Inputs

Logic Input Voltage Range

Logic Input Current

Logic Input Pull-Down Resistance

Input Hysteresis

Timing

Crossover Delay

VREF Input Voltage Range

Current Gain

Blank Time

Constant Off-time

Standby Timer

Power-Up Delay

Protection Circuits

UVLO Enable Threshold

UVLO Hysteresis

Thermal Shutdown Temperature

Thermal Shutdown Hysteresis

IOUT = |2.5 A|, TJ = 25°C

IOUT = |2.5 A|, TJ = 125°C

fPWM < 30 kHz

Low Power Standby mode

Source diode, If = –2.5 A

Sink diode, If = 2.5 A

VBB

RDS(on)

IBB

Vf

VIN(1)

VIN(0)

VIN(STANDBY) Low Power Standby mode

IIN(1)

IIN(0)

VIN = 2.0 V

VIN = 0.8 V

RRRLOGIC(PD) VIN = 0 V = IN1 = IN2

VHYS

tCOD

VREF

A V

tBLANK

toff

tst

tpu

VREF / ISS , VREF = 5 V

VREF / ISS , VREF = 2.5 V

VREF / ISS , VREF = 1 V

IN1 = IN2 < VIN(STANDBY)

VBBUVLO

VBBUVLOhys

VBB increasing

TJTSD

TTSDhys

Temperature increasing

Recovery = TJTSD – TTSDhys

8

–

–

–

–

–

–

2.0

–

–

–

–

–

–

50

0

9.5

9.0

8.0

2

16

–

–

7

–

–

–

–

0.6

0.96

10

–

–

–

–

–

–

40

16

50

250

–

–

–

–

–

3

25

1

–

7.5

500

160

15

40

0.8

1.3

–

10

1.5

1.5

–

0.8

0.4

100

40

–

550

500

5

10.5

10.0

10.0

4

34

1.5

30

7.95

–

–

–

V

Ω

Ω

mA

μA

V

V

V

V

V

μA

μA

kΩ

mV

ns

V

V/V

V/V

V/V

μs

μs

ms

μs

V

mV

°C

°C

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

3

�

A4950

Full-Bridge DMOS PWM Motor Driver

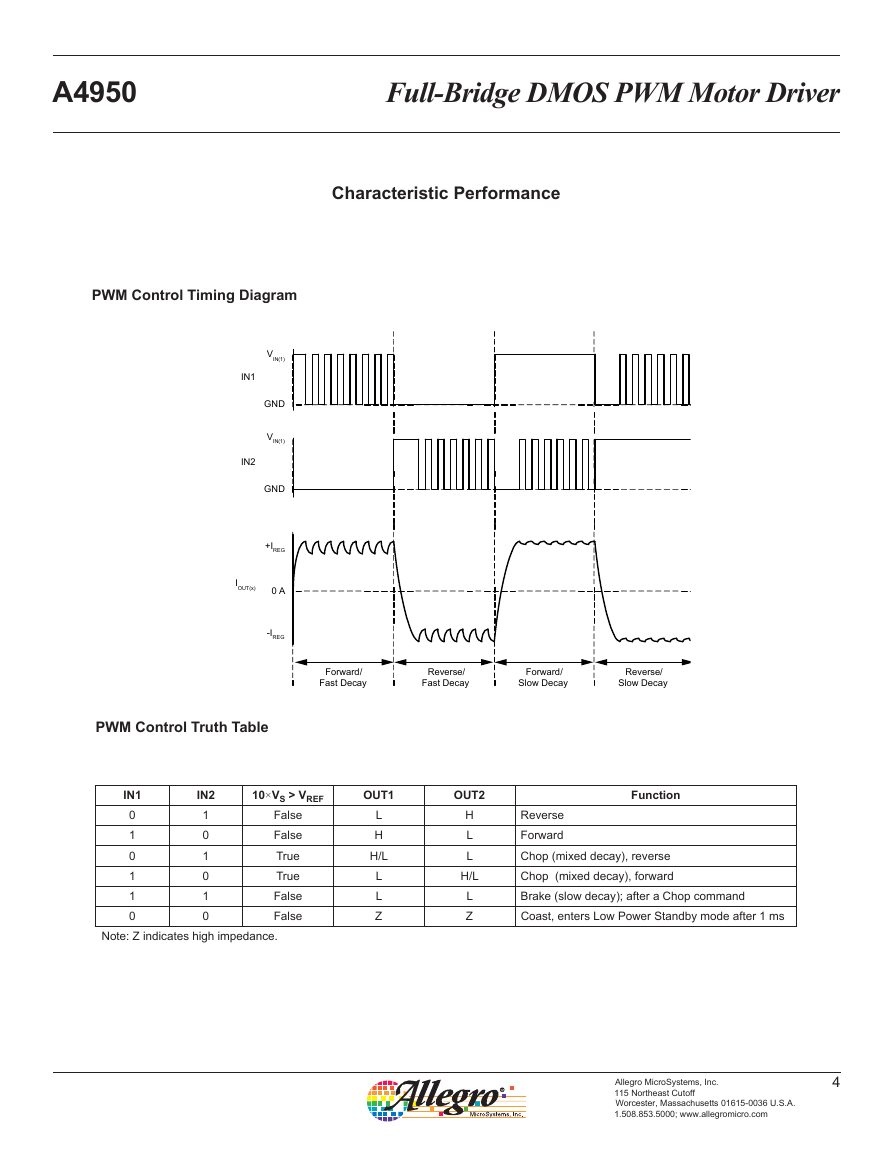

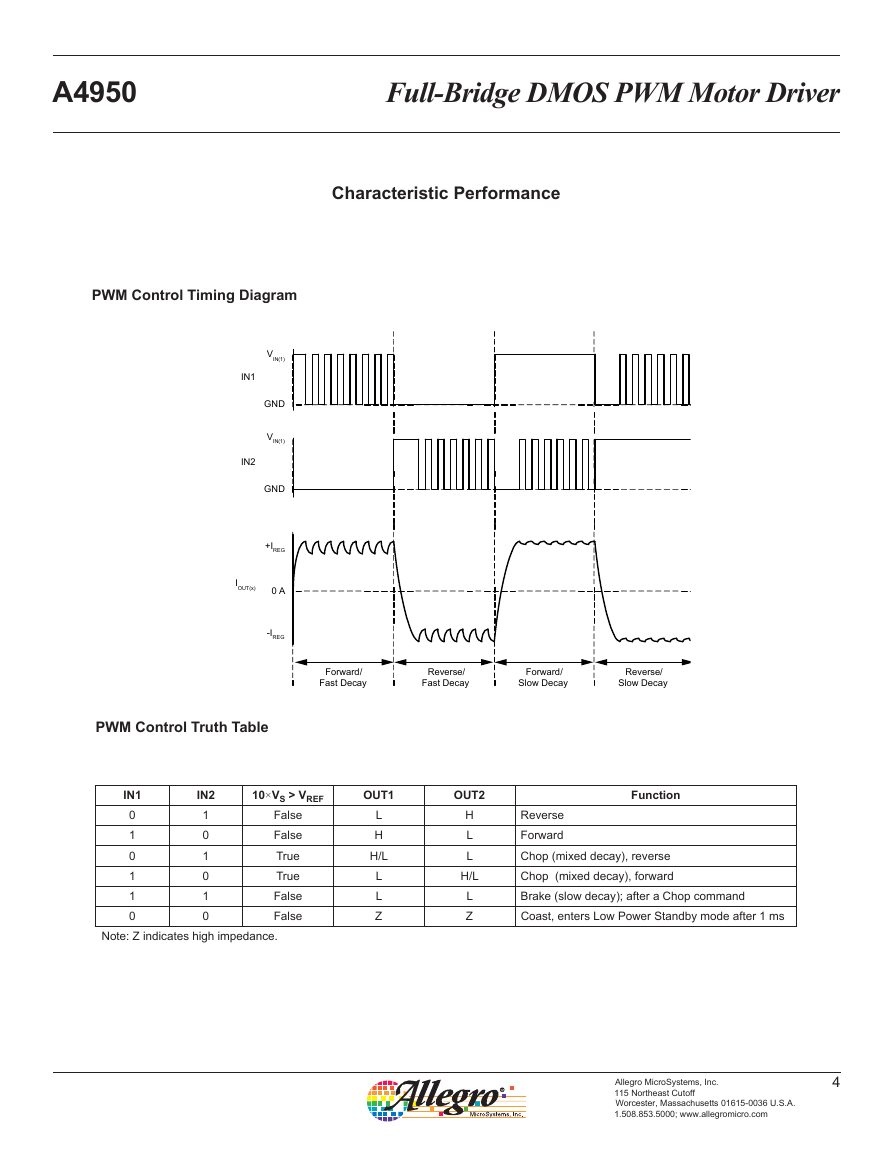

Characteristic Performance

PWM Control Timing Diagram

IN1

IN2

VIN(1)

GND

VIN(1)

GND

+IREG

IOUT(x)

0 A

-IREG

Forward/

Fast Decay

Reverse/

Fast Decay

Forward/

Slow Decay

Reverse/

Slow Decay

PWM Control Truth Table

IN1

0

1

0

1

1

0

IN2

1

0

1

0

1

0

10×VS > VREF

OUT1

OUT2

Function

False

False

True

True

False

False

L

H

H/L

L

L

Z

H

L

L

H/L

L

Z

Reverse

Forward

Chop (mixed decay), reverse

Chop (mixed decay), forward

Brake (slow decay); after a Chop command

Coast, enters Low Power Standby mode after 1 ms

Note: Z indicates high impedance.

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

4

�

A4950

Full-Bridge DMOS PWM Motor Driver

Functional Description

Device Operation

The A4950 is designed to operate DC motors. The output drivers

are all low-RDS(on) , N-channel DMOS drivers that feature inter-

nal synchronous rectification to reduce power dissipation. The

current in the output full bridge is regulated with fixed off-time

pulse width modulated (PWM) control circuitry. The IN1 and IN2

inputs allow two-wire control for the bridge.

Protection circuitry includes internal thermal shutdown, and pro-

tection against shorted loads, or against output shorts to ground

or supply. Undervoltage lockout prevents damage by keeping the

outputs off until the driver has enough voltage to operate nor-

mally.

Standby Mode

Low Power Standby mode is activated when both input (INx)

pins are low for longer than 1 ms. Low Power Standby mode

disables most of the internal circuitry, including the charge pump

and the regulator. When the A4950 is coming out of standby

mode, the charge pump should be allowed to reach its regulated

voltage (a maximum delay of 200 μs) before any PWM com-

mands are issued to the device.

Internal PWM Current Control

Initially, a diagonal pair of source and sink FET outputs are

enabled and current flows through the motor winding and the

optional external current sense resistor, RS . When the voltage

across RS equals the comparator trip value, then the current sense

comparator resets the PWM latch. The latch then turns off the

sink and source FETs (Mixed Decay mode).

VREF

The maximum value of current limiting is set by the selection of

RSx and the voltage at the VREF pin. The transconductance func-

tion is approximated by the maximum value of current limiting,

ITripMAX (A), which is set by:

VREF

ITripMAX = 10 RS

where VREF is the input voltage on the VREF pin (V) and RS is

the resistance of the sense resistor (Ω) on the LSS terminal.

Overcurrent Protection

A current monitor will protect the IC from damage due to output

shorts. If a short is detected, the IC will latch the fault and disable

the outputs. The fault latch can only be cleared by coming out of

Low Power Standby mode or by cycling the power to VBB. Dur-

ing OCP events, Absolute Maximum Ratings may be exceeded

for a short period of time before the device latches.

Shutdown

If the die temperature increases to approximately 160°C, the full

bridge outputs will be disabled until the internal temperature falls

below a hysteresis, TTSDhys , of 15°C. Internal UVLO is present

on VBB to prevent the output drivers from turning-on below the

UVLO threshold.

Braking

The braking function is implemented by driving the device in

Slow Decay mode, which is done by applying a logic high to both

inputs, after a bridge-enable Chop command (see PWM Control

Truth Table). Because it is possible to drive current in both direc-

tions through the DMOS switches, this configuration effectively

shorts-out the motor-generated BEMF, as long as the Chop com-

mand is asserted. The maximum current can be approximated by

VBEMF / RL . Care should be taken to ensure that the maximum

ratings of the device are not exceeded in worse case braking situ-

ations: high speed and high-inertia loads.

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

5

�

A4950

Full-Bridge DMOS PWM Motor Driver

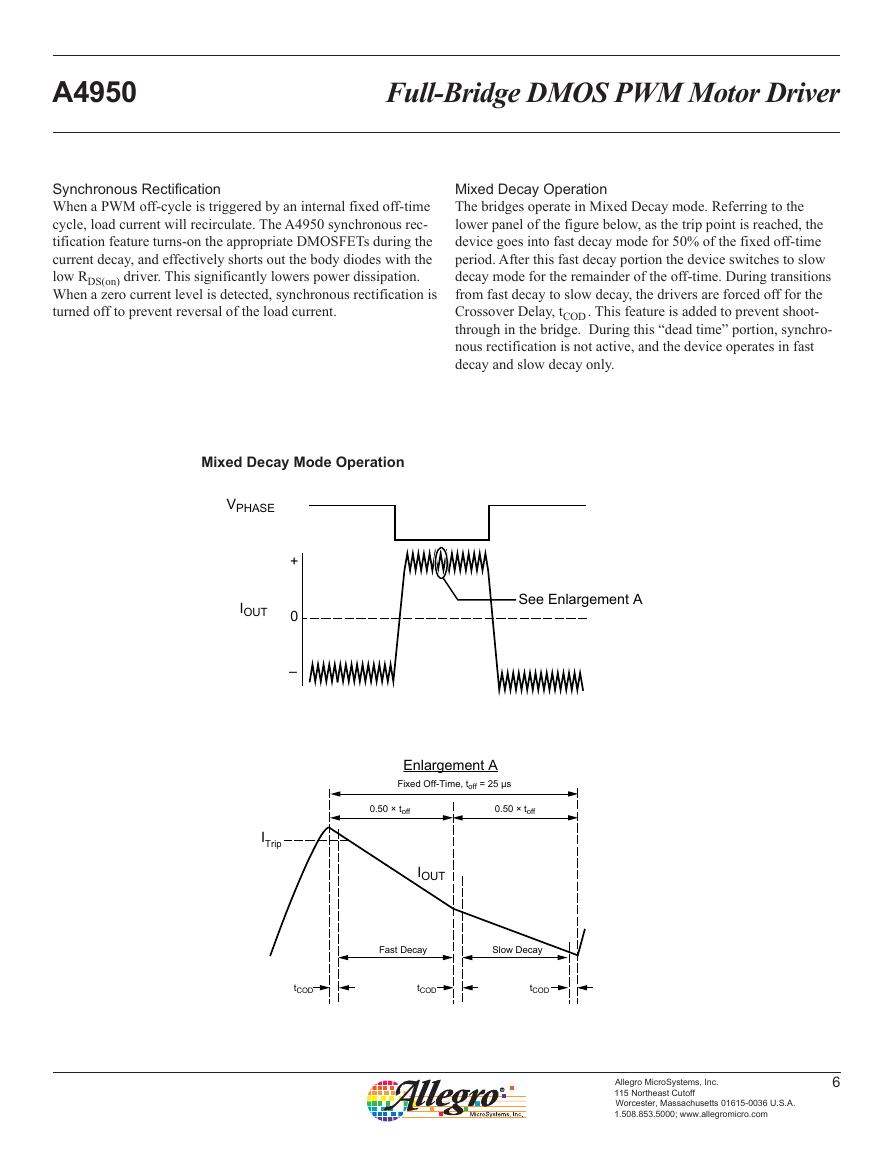

Synchronous Rectification

When a PWM off-cycle is triggered by an internal fixed off-time

cycle, load current will recirculate. The A4950 synchronous rec-

tification feature turns-on the appropriate DMOSFETs during the

current decay, and effectively shorts out the body diodes with the

low RDS(on) driver. This significantly lowers power dissipation.

When a zero current level is detected, synchronous rectification is

turned off to prevent reversal of the load current.

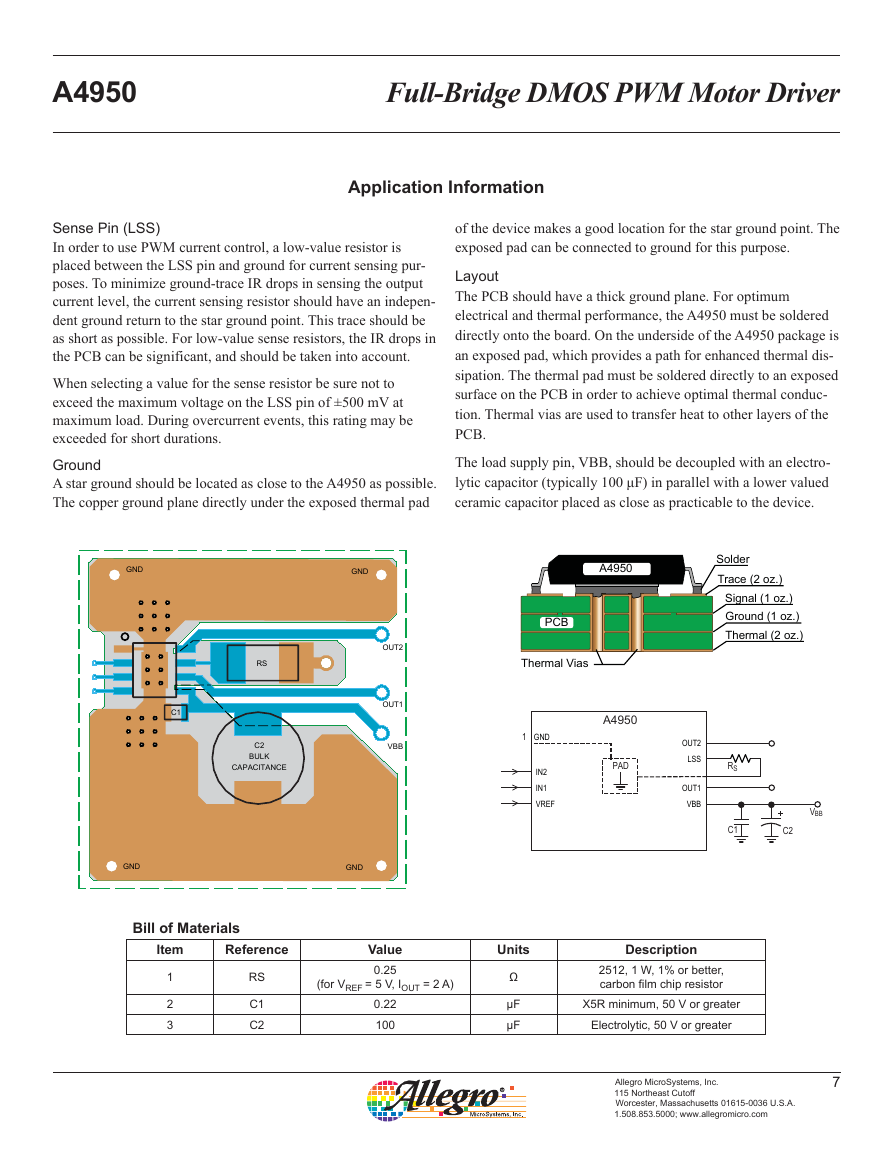

Mixed Decay Operation

The bridges operate in Mixed Decay mode. Referring to the

lower panel of the figure below, as the trip point is reached, the

device goes into fast decay mode for 50% of the fixed off-time

period. After this fast decay portion the device switches to slow

decay mode for the remainder of the off-time. During transitions

from fast decay to slow decay, the drivers are forced off for the

Crossover Delay, tCOD . This feature is added to prevent shoot-

through in the bridge. During this “dead time” portion, synchro-

nous rectification is not active, and the device operates in fast

decay and slow decay only.

Mixed Decay Mode Operation

VPHASE

IOUT

+

0

–

See Enlargement A

Enlargement A

Fixed Off-Time, toff = 25 μs

0.50 × toff

0.50 × toff

ITrip

IOUT

Fast Decay

Slow Decay

tCOD

tCOD

tCOD

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

6

�

A4950

Full-Bridge DMOS PWM Motor Driver

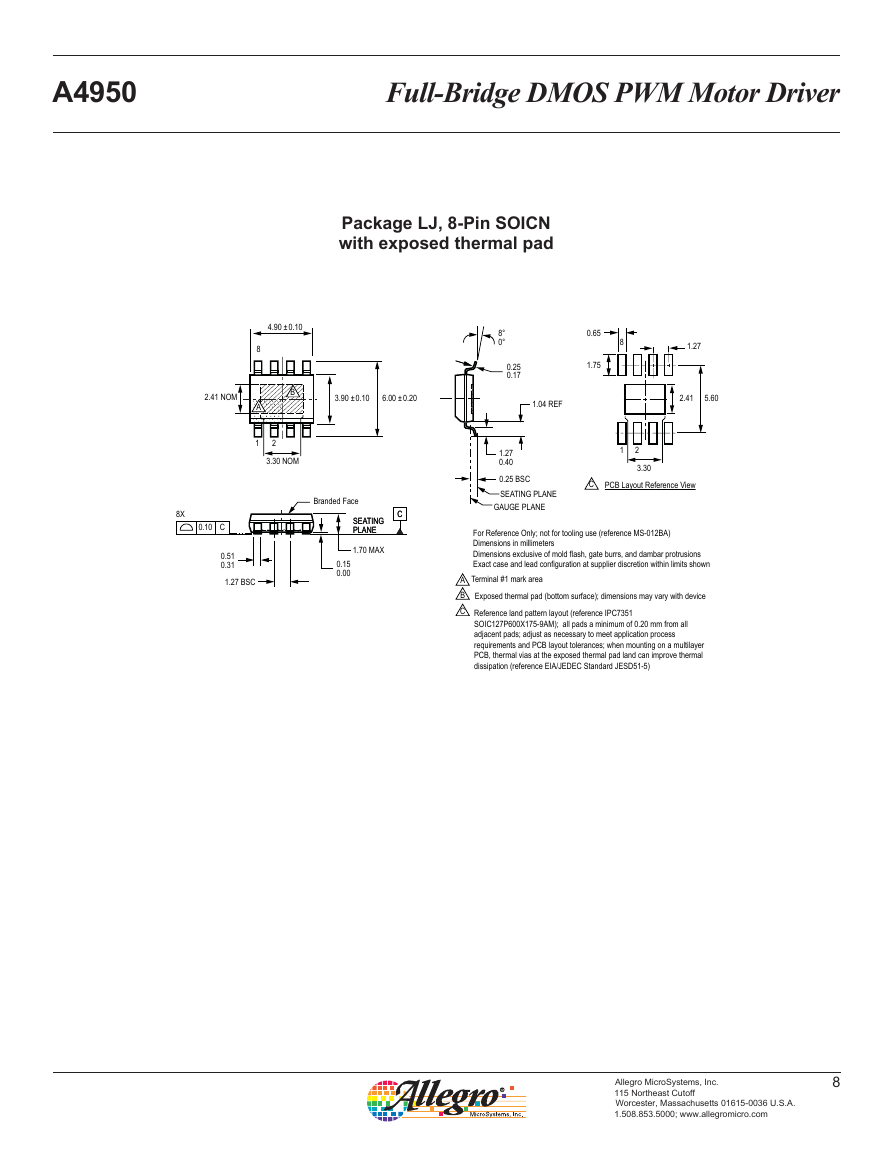

Application Information

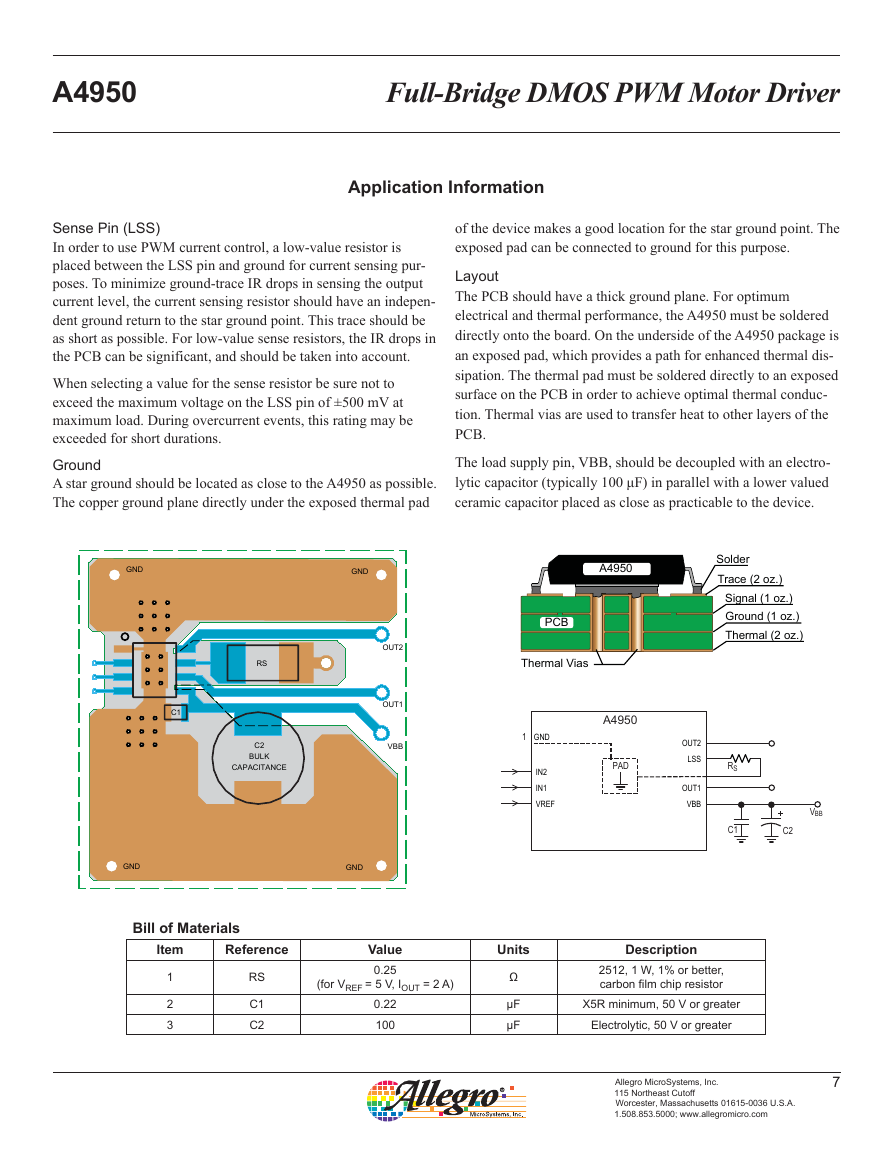

Sense Pin (LSS)

In order to use PWM current control, a low-value resistor is

placed between the LSS pin and ground for current sensing pur-

poses. To minimize ground-trace IR drops in sensing the output

current level, the current sensing resistor should have an indepen-

dent ground return to the star ground point. This trace should be

as short as possible. For low-value sense resistors, the IR drops in

the PCB can be significant, and should be taken into account.

When selecting a value for the sense resistor be sure not to

exceed the maximum voltage on the LSS pin of ±500 mV at

maximum load. During overcurrent events, this rating may be

exceeded for short durations.

Ground

A star ground should be located as close to the A4950 as possible.

The copper ground plane directly under the exposed thermal pad

of the device makes a good location for the star ground point. The

exposed pad can be connected to ground for this purpose.

Layout

The PCB should have a thick ground plane. For optimum

electrical and thermal performance, the A4950 must be soldered

directly onto the board. On the underside of the A4950 package is

an exposed pad, which provides a path for enhanced thermal dis-

sipation. The thermal pad must be soldered directly to an exposed

surface on the PCB in order to achieve optimal thermal conduc-

tion. Thermal vias are used to transfer heat to other layers of the

PCB.

The load supply pin, VBB, should be decoupled with an electro-

lytic capacitor (typically 100 μF) in parallel with a lower valued

ceramic capacitor placed as close as practicable to the device.

GND

GND

A4950

C1

RS

C2

BULK

CAPACITANCE

OUT2

OUT1

VBB

GND

GND

PCB

Thermal Vias

A4950

PAD

1

GND

IN2

IN1

VREF

Solder

Trace (2 oz.)

Signal (1 oz.)

Ground (1 oz.)

Thermal (2 oz.)

OUT2

LSS

OUT1

VBB

RS

C1

VBB

C2

Bill of Materials

Item

Reference

1

2

3

RS

C1

C2

Value

0.25

(for VREF = 5 V, IOUT = 2 A)

0.22

100

Units

Ω

μF

μF

Description

2512, 1 W, 1% or better,

carbon film chip resistor

X5R minimum, 50 V or greater

Electrolytic, 50 V or greater

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

7

�

A4950

Full-Bridge DMOS PWM Motor Driver

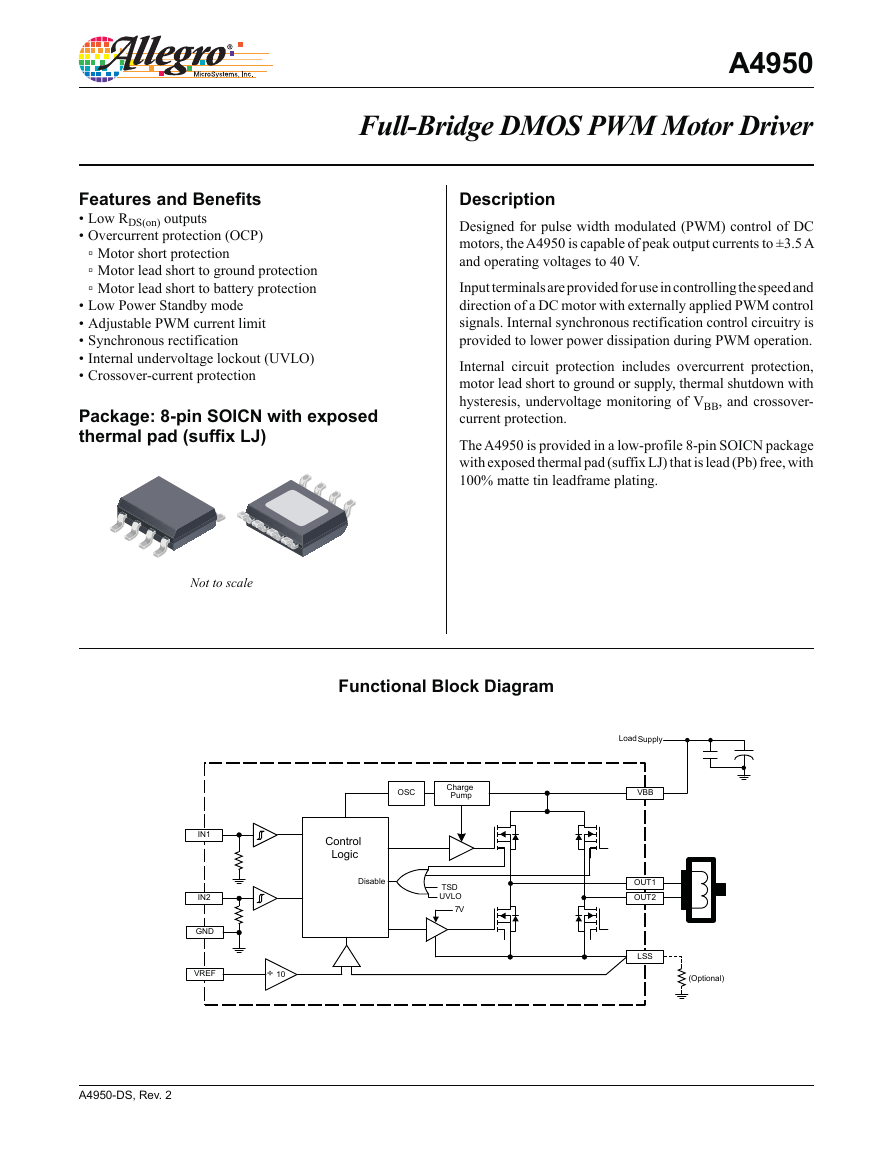

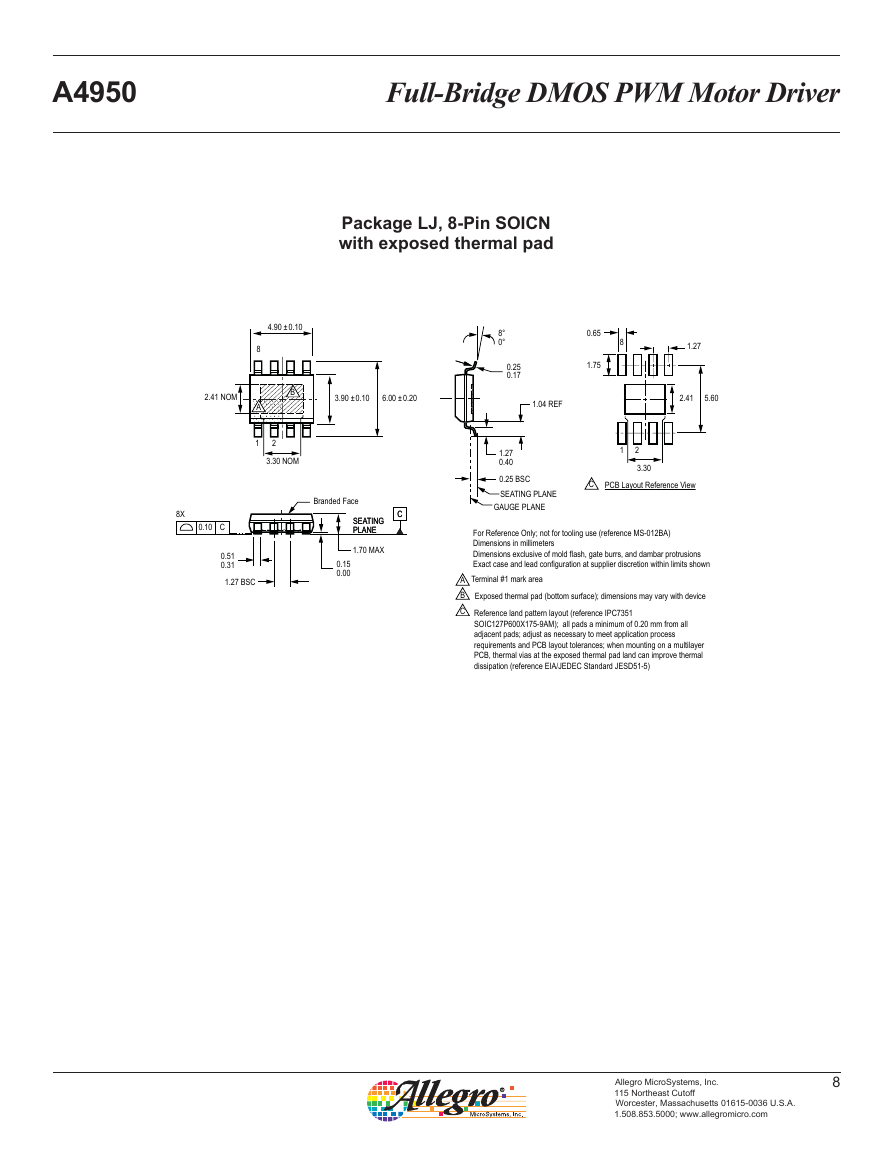

Package LJ, 8-Pin SOICN

with exposed thermal pad

4.90 ±0.10

8

A

2.41 NOM

B

3.90 ±0.10

6.00 ±0.20

1

2

3.30 NOM

8X

0.10

C

0.51

0.31

1.27 BSC

Branded Face

C

C

SEATING

SEATING

PLANE

PLANE

1.70 MAX

0.15

0.00

8°

0°

0.25

0.17

1.04 REF

1.27

0.40

0.25 BSC

SEATING PLANE

GAUGE PLANE

1.27

2.41

5.60

0.65

1.75

8

1

2

3.30

C

PCB Layout Reference View

For Reference Only; not for tooling use (reference MS-012BA)

Dimensions in millimeters

Dimensions exclusive of mold flash, gate burrs, and dambar protrusions

Exact case and lead configuration at supplier discretion within limits shown

A Terminal #1 mark area

B

C

Exposed thermal pad (bottom surface); dimensions may vary with device

Reference land pattern layout (reference IPC7351

SOIC127P600X175-9AM); all pads a minimum of 0.20 mm from all

adjacent pads; adjust as necessary to meet application process

requirements and PCB layout tolerances; when mounting on a multilayer

PCB, thermal vias at the exposed thermal pad land can improve thermal

dissipation (reference EIA/JEDEC Standard JESD51-5)

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

8

�

2023年江西萍乡中考道德与法治真题及答案.doc

2023年江西萍乡中考道德与法治真题及答案.doc 2012年重庆南川中考生物真题及答案.doc

2012年重庆南川中考生物真题及答案.doc 2013年江西师范大学地理学综合及文艺理论基础考研真题.doc

2013年江西师范大学地理学综合及文艺理论基础考研真题.doc 2020年四川甘孜小升初语文真题及答案I卷.doc

2020年四川甘孜小升初语文真题及答案I卷.doc 2020年注册岩土工程师专业基础考试真题及答案.doc

2020年注册岩土工程师专业基础考试真题及答案.doc 2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc

2023-2024学年福建省厦门市九年级上学期数学月考试题及答案.doc 2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc

2021-2022学年辽宁省沈阳市大东区九年级上学期语文期末试题及答案.doc 2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc

2022-2023学年北京东城区初三第一学期物理期末试卷及答案.doc 2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc

2018上半年江西教师资格初中地理学科知识与教学能力真题及答案.doc 2012年河北国家公务员申论考试真题及答案-省级.doc

2012年河北国家公务员申论考试真题及答案-省级.doc 2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc

2020-2021学年江苏省扬州市江都区邵樊片九年级上学期数学第一次质量检测试题及答案.doc 2022下半年黑龙江教师资格证中学综合素质真题及答案.doc

2022下半年黑龙江教师资格证中学综合素质真题及答案.doc